1. Motivation

The concept of a Digital Twin (DT), a virtual representation of the properties of physical assets, is not new. It dates back to 2002, when it was originally defined for the application domain of product lifecycle management (PLM) as a “conceptual ideal for PLM”, initially adopted for mainly engineering and simulation tasks in the astronautics and aerospace fields [

1]. Although an ideal representation was already envisioned, the main goal was to provide technical insights as well as visualization and virtual or augmented reality tools with suitable data. However, from an architectural point of view, these tools were isolated. Their integration with other lifecycle phases or IT systems, e.g., in operational industrial plants, required an immense effort [

2].

With the advent of the (Industrial) Internet of Things (IIoT) and Industry 4.0, the technologies for networked machines, and especially the ubiquitous availability of sensors in industrial plants and their environments, the situation is about to change. The effort to obtain data and then process them for useful information to feed digital twins is decreasing [

3,

4]. Interconnected scalable edge/cloud environments make these data available all over the globe across company boundaries. However, new interlinked challenges appear with respect to distributed data management in such environments:

In order to avoid selective, use case-driven, proprietary solutions and/or the market dominance of major IT players, the concept of “dataspaces” was created [

5]. Dataspaces may be understood as a kind of “data middleware” that organizes the controlled sharing and usage of data between partners in a federation based upon the principles of data sovereignty [

6,

7]. A more detailed discussion will follow below.

Consequently, the evolution and the potential of the concept of digital twins must be considered in parallel to those of dataspaces. This was our motivation to write this paper and classify it as a perspective paper with the following objectives:

To provide a uniform but also future-oriented description of the two concepts—“Digital Twin” and “Dataspaces”—with a focus on the application domain of industrial production.

To present and propose a reference model for digital twin systems that embraces both concepts.

To describe the focal thematic aspects to be considered and derive an essential thesis.

To highlight how digital twins may benefit today and tomorrow from the emergence and availability of dataspaces.

For all these aspects, a ten-year perspective is taken.

In

Section 2 and

Section 3, we provide an overview of the various term definitions, conceptual approaches and standards, and major initiatives for digital twins and dataspaces. In

Section 4, we summarize the high-level requirements when merging the concepts of digital twins and dataspaces. As a major result of this paper, we propose a Reference Model for Digital Twin Systems (DTS-RM) in

Section 5, based upon the original idea that a digital twin is a comprehensive, nearly ideal representation of the properties of a physical asset or a process. In

Section 6, aspects of digital twin development are discussed delineated as three focal aspects structured according to the DTS-RM virtual world spaces, i.e., the digital twin, the Dataspace, and the Application Space. After a short presentation of two validation projects in

Section 7, the paper finishes in

Section 8 with conclusions, statements, and recommendations concerning the idea that both digital twins and dataspaces shall be considered as kernel components of entire digital ecosystems.

2. Digital Twin–Term Definitions and Concepts

Originally, the term digital twin was introduced for the astronautics and aerospace domain. Nowadays, it is applied in multiple application domains, from smart cities, energy, and health to logistics and industrial production. There are survey publications on digital twin’s definitions and uses (e.g., [

4]); however, up to now, there is no common definition and conceptual approach to digital twins that is jointly accepted and applied across different domains and industries. Even in the application domain of the industrial production, which is the focus of this paper, the term and concepts of digital twins are not used in a unified manner.

2.1. Michael Grieves, Florida Institute of Technology

The term digital twin has evolved since its first appearance in 2002 in the work of Michael Grieves, at the Florida Institute of Technology, in his course on product lifecycle management [

8]. According to Grieves, the digital twin represents a digital entity of a physical system that exists on its own. This entity includes all the information of the physical system, which is connected to the physical system throughout the product’s lifecycle. Furthermore, he proposed that the elements of the conceptual digital twin approach comprise “a real space, a virtual space, the link for data flow from real space to virtual space, the link for information flow from virtual space to real space and virtual sub-spaces”.

Although the technology necessary to develop and implement digital twin systems was not available when Michael Grieves coined the term (and is still lacking in some areas today, almost two decades later), his description was already very mature. The main caveat is that Grieves’ focus on digital twins was for products, as his backgrounds lies in product lifecycle management, but as discussed later, a digital twin can be used in an even broader domain. In 2012, the National Aeronautics and Space Administration (NASA) defined a digital twin as “a multi-physics, multiscale, probabilistic, ultra-fidelity simulation that reflects, in a timely manner, the state of a corresponding twin based on the historical data, real-time sensor data, and physical model” [

1].

Over time, the concept of digital twins has been taken up by several companies and researchers, but the recent literature reviews show no single definition that has been broadly agreed upon [

9,

10,

11]. It turned out that with the emergence of the Internet of Things (IoT) and (more recently) dataspaces, digital twins may be used for more than just simulation purposes; rather, they tend to become essential conceptual and architectural elements in distributed environments to respond to the requirements of multiple use cases. This is reflected in the IIC’s definition of digital twins, as discussed in the following section.

2.2. Industry IoT Consortium (IIC)

The Industry IoT Consortium (IIC (formerly called the Industrial Internet Consortium (IIC))) whitepaper ‘Digital Twins for Industrial Applications’ [

12], defines a digital twin to be ‘a formal digital representation of some asset, process or system that captures attributes and behaviors of that entity suitable for communication, storage, interpretation or processing within a certain context’. Note that this definition is more expressive than the definition in the IIC Vocabulary Version 2.3-2020-10-05 (

https://www.iiconsortium.org/pdf/Vocabulary-Report-2.3.pdf accessed on 19 July 2022):

‘A digital twin is a digital representation sufficient to meet the requirements of a set of use cases, whereby the entity in the definition of digital representation is typically an asset, process or system’.

The reason for this deviation is that the IIC working group “vocabulary” takes a generic, foundational view whereby the whitepapers try to focus on the usage of terms in a given context. Digital Twins may be deconstructed into a composite digital twin and a set of composite digital twins may form a system of composite digital twins. For example, a production cell is a composite digital twin that consists of the digital twins of the devices of the cell, whereas an entire plant is a system of composite digital twins.

The composition may be hierarchical (e.g., corresponding to an equipment hierarchy), associational (e.g., to express the relationship of digital twins to the same production line), or peer-to-peer (to group digital twins of the same or similar types; for example, the digital twins of a group of real-world assets of the same type) [

13].

Motivation of the Approach

The goal of the IIC is to push the technologies of the Industrial Internet across multiple domains and mirror them with the demands of the market. As of today, the IIC is not a standardization organization and has no ambition to turn the IIC results into de jure standards at the ISO or IEC level. However, the IIC aims to investigate interoperable solutions on a practical level, which means they endorse testbed implementations that rely on international standards and demonstrate success stories regarding interoperability. Consequently, the digital twin definition from the IIC remains at the conceptual level and must be broad enough to encompass all possible use cases of multiple Industrial Internet domains such as energy, health, logistics, and production. This also helps to position it within the Industrial Internet Reference Architecture (IIRA) (

https://www.iiconsortium.org/IIRA.htm accessed on 19 July 2022).

Consequently, the added value of the IIC definition is that it works well at a marketing and communication level, as well as in joint undertakings with other consortia.

2.3. Digital Twin Consortium (DTC)

However, the DTC provides a much broader view of digital twins and their supporting IT infrastructure. This is also the topic of this paper, as described in

Section 5. According to the DTC glossary, “a digital twin system is a system of systems that implements a digital twin.” It includes an IT/OT platform that provides a set of information technology and operation technology services for computing, networking, and data storage. In addition, there are integration service interfaces that allow applications to access to the stored representations. Of great importance are also the synchronization methods that ensure that the stored representations reflect the observations from the real world. Further definitions, such as those for the DT platform, DT applications, or DT services, can be taken directly from the DTC glossary.

Motivation of the Approach

The Digital Twin Consortium (DTC) formed by the Object Management Group (OMG) (

https://www.arcweb.com/blog/digital-twin-consortium-formed-object-management-group accessed on 19 July 2022) has the goal of promoting the development and acceptance of digital twins where interoperability and security are of particular interest. The DTC is particularly concerned with design and architecture issues. It proposes the developed models to standardization organizations for their implementation in standards. The members of the DTC come from industry, research, and administration.

Consequently, the added value of the DTC definition is that it is comprehensive and encompasses all the aspects required to be considered for a submission to standardization organizations.

2.4. Industrial Digital Twin Association (IDTA)

The Industrial Digital Twin Association (IDTA), established in early 2021, aims to become the “one-stop shop for the Digital Twin—An alliance of active creators working together to make the Digital Twin practical for industry through open technologies”.

Having this in mind, the IDTA defines an Industrial Digital Twin that “serves as a link between physical industrial products and the digital world and thus as a core technology of Industry 4.0.” The IDTA argues that the Industry 4.0 “Asset Administration Shell (AAS) is the technical realization of the digital twin for Industry 4.0. It creates cross-vendor interoperability and is available for all assets” (Plattform Industrie 4.0 2020a).

The IDTA aims at generating an open-source community for this endeavor. Existing open source technologies may be those of the German BMBF BaSys project [

14] or the Fraunhofer Advanced Asset Administration Shell Tools for Digital Twins (FA

3ST) [

15,

16].

Motivation of the Approach

The main and primary objective of the IDTA is to consolidate and promote the concepts and models resulting from the Platform Industry 4.0, especially the Asset Administration Shell (AAS), its meta-model, and API specifications. The term digital twin is understood as a synonym for an AAS in the sense that the AAS is the digital twin for industrial applications; although, in this case, a digital twin instance is per se interoperable with other digital twin instances if they follow the series of AAS specifications. However, up to now, the IDTA does not follow a systemic approach apart from the statement that there is a need for a “platform” to support interactions between AAS/digital twin instances, especially in an operational phase. Some requirements on platforms, especially on security, are given. However, as of today, the IDTA does not specify the characteristics and the services of such a platform. Apart from offerings of AAS instances in repositories, as of today, the IDTA remains at the API and AAS model level and within their structures (e.g., definition of AAS partial models for asset types). The discussion paper “Functional View of the AAS in an Industry 4.0 System Environment” [

17], which takes a systemic view, may be used in the future as a conceptual basis to guide the refinement and mapping of the underlying data sharing infrastructures such as GAIA-X.

Consequently, the added value of the IDTA definition is that the AAS is increasingly accepted and implemented in industry and subjected to standardization, whereby it currently misses the perspective towards comprehensive digital twins, comprising elements with possibly several distinct representation formats, and the usage of the digital twins in dataspaces.

2.5. ISO 23247

The ISO 23247 is a series of standards that provides a framework for digital twins in the manufacturing domain. Part two of the series (ISO 23247-2 2020) presents a reference architecture that can be used as a framework for the development of digital twins [

18].

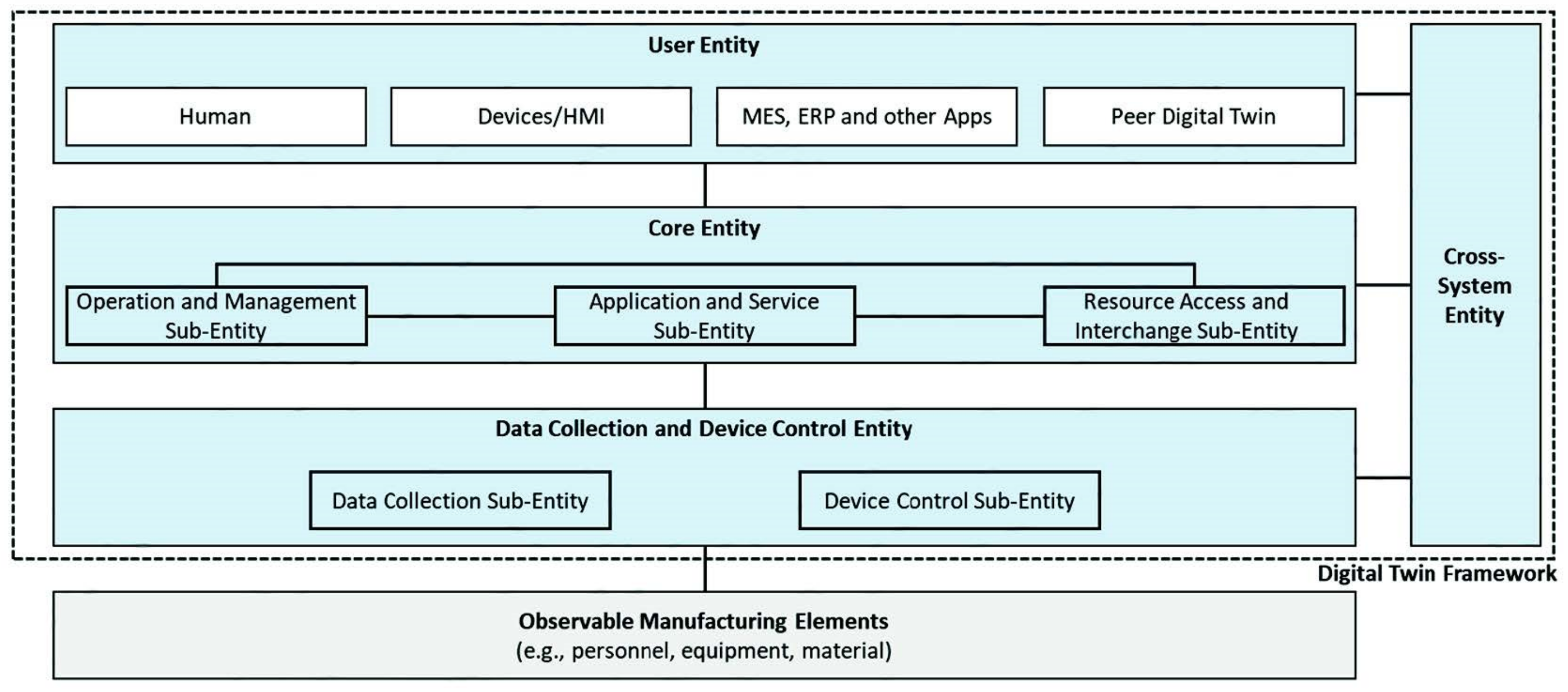

The reference architecture defines the key building blocks and how they interact (see

Figure 1). The real objects of a manufacturing operation, such as machinery and equipment, materials, personnel, etc., are at the bottom, referred to here as observable manufacturing elements. These should be represented by digital twins and are permanently aligned with the observable elements. For this purpose, the data collection and device control entity handles the collection and pre-processing of the data from the manufacturing elements as well as any control or actuation required towards them (i.e., providing connectors to different data source types complying to agreed standards).

The Core Entity with its Sub-Entity Operation and Management “manages and operates” the digital twin, including its provisioning, monitoring, and optimization. It is also used to visualize the information and synchronize it with the observable elements. In addition, the Application and Service Sub-Entity provides further services around the observable elements, such as simulation functions or operational analyses for predictive maintenance. These services materialize the value of the digital twin and enhance its capabilities with cognitive attributes. The Sub-Entity Resource Access and Interchange is responsible for the intercommunication of the digital twins among themselves but also with other applications that access the information or the services of a DT. It incorporates functional entities that enable interoperability with other digital twins and systems and resource access control.

At the top of the reference model in

Figure 1, the user is mapped. This User Entity includes human users as well as HMI and external applications similar to ERP that interact with the DTs. This layer enables user applications to utilize digital twins and their inherent tools based on APIs as requested by the specific pilot environments. This layer enables interaction with users (via dashboards and other appropriate interfaces) and enterprise and manufacturing systems (ERP, MES, etc.).

Finally, the functions shared by different entities are combined in the Cross-System Entity on the right side of the reference model. For example, security or translation services are classified here.

Motivation of the Approach

ISO 23247 has been published quite recently in October 2021 and is one of the few standards in the context of digital twins. The main topic of ISO 23247 is to define a whole framework for the management of digital twins for observable manufacturing elements such as machines, material, etc. Parts of this standard have different topics such as the reference architecture, the digital representation of manufacturing elements, and the requirements for the information exchange of digital twins. The standard shows the general use cases and benefits of digital twins with respect to manufacturing. Additionally, it provides aid for the construction and usage of digital twins and offers the first reference model for a digital twin framework for production.

2.6. Summary of the Terminological Discussion on Digital Twins

Considering the long history of the discussion of the digital twin concept and the different interests of the organizations involved, it seems obvious that up to now there is no unified definition of the concept of a digital twin and no unified understanding of its assigned concepts—this is likely to be the case in the future as well. The main distinctions relate to the following questions:

Is a digital twin understood as a pure meta-modelling concept for physical assets, or does it consider the interface to the physical asset, too?

Which levels of granularity, accuracy, and synchronicity with respect to the properties of the physical asset should it have?

Can we abstract from the interface between the digital twin and its physical counterpart to guarantee the specified level of accuracy and synchronicity?

Is a digital twin understood as an essential architectural element in an overall distributed architecture such as the (Industrial) Internet of Things?

Is the infrastructure that is required to support the interactions between digital twin instances within or outside the scope?

In this paper, we consider digital twins in their relationship to dataspaces. Hence, a broader scope that includes a systemic viewpoint and the supporting infrastructure is required. Furthermore, it is the use of digital twins that provides the benefit. In this sense, we are using the term “Digital Twin” close to the original idea that is a comprehensive, nearly ideal digital representation of a physical asset or process.

Note: In this paper, we concentrate on physical assets and exclude virtual assets. Thus, the assets are of a physical nature and are considered across their whole lifetime, i.e., they are also considered in the design and engineering phase when instances of the entity do not yet exist physically, and only entity types are represented.

3. European Data Strategy and Dataspaces

A similar terminological uncertainty exists in the conceptual world of dataspaces. On the one hand, there are concrete architectures and technologies, such as the International Data Spaces (IDS), on the other hand, the term is used as an umbrella term for all approaches that support the sharing of data in collaborative environments according to the European data strategy. Some clarification is needed for this concept, too.

In the following sections, the European strategy in this context as well as the concepts of dataspaces and GAIA-X are highlighted.

3.1. European Data Strategy

In times of increasing digitalization, data represent an important resource worth protecting. For this reason, the European Data Strategy (

http://www.dataeconomy.eu/eu-data-strategy-2020/, accessed on 13 June 2022) has evolved with the aim of offering a single marketplace for data in the European area that is subject to European legal and security guidelines. It is important to maintain the competitiveness of the European countries and at the same time to guarantee the highest level of data sovereignty for the data producers and consumers.

The increasing use of data opens up completely new perspectives both for individuals and for global economic development, because in the future it will enable better decision-making capabilities in many use cases. The following goals are being pursued by the European Data Strategy [

19]:

Data should be able to be transferred within the EU and across industries;

European values and rights, in particular the General Data Protection Regulation (GDPR) (in German: Datenschutzgrundverordnung (DSGVO)), are to be fully upheld;

The rules for the use of data should be fair, practicable, and unambiguous.

To this end, dataspaces should enable the access to and privacy-compliant use of data by creating suitable ecosystems. An ecosystem infrastructure should facilitate data integration from multiple data sources and should support data federation, data analytics, and machine learning in compliance with data protection requirements. Partners who feed in data should be given access to larger volumes of data, and if necessary, should also be able to profit from the analysis results of others. This idea enables new business models based on data.

Since the agility and speed varies greatly in different domains, the EU proposes to develop sector-specific dataspaces especially for the following strategic areas: manufacturing, agriculture, health, mobility, energy, finance, and others.

3.2. International Data Spaces (IDS)

The International Data Spaces (IDS) (

https://internationaldataspaces.org/, accessed on 19 July 2022) offer technologies and concepts for dataspaces for different application domains, which enable the standardized exchange and linkage of data in a trusted environment. The International Data Spaces Association (IDSA) is a nonprofit organization with the goal of establishing the IDS architecture as an international standard in different domains such as mobility, value chains, health care, etc. Some of these domains are organized in dedicated IDS communities, e.g., the IDS-Industrial that focusses on the requirements and architectural patterns for industrial production (

https://internationaldataspaces.org/make/communities/, accessed on 19 July 2022).

Data sovereignty is generally understood to mean the self-determined handling of one’s data. Thus, a data owner can decide on the use of their own data; specifically, the data owner decides who may use their data, what may be done with it, and for how long. To achieve data sovereignty, the IDS represent a decentralized network that protects data and its use through policies. These policies specify the rules of data usage.

Thereby, the IDS are free from specific use cases or domains. A user or member of the IDS only need an IDS Connector, as a gateway, to participate. The principal IDS ecosystem [

20] is visualized at

Figure 2. The connector is used at the data provider’s and the data consumer’s side of the communication. Connectors are responsible for the safe administration and exchange of data. Connectors must be registered at a broker. The broker manages the available data sources and provides an opportunity to search for data sources. In addition, data can be processed by apps, which an IDS App Store provides. For example, the IDS App Store offers frequently used apps for the anonymization or aggregation of data.

The connector represents the central component of the IDS. The connector uses a message-oriented middleware (Apache Camel) to process data, to define routes, and to process messages at the individual endpoints. Data usage control is also implemented in this way. There are some implementations of IDS connectors where different protocols and data formats are realized. Other IDS components are still under development.

According to the IDSA, there are different connector types. While a basic connector provides an entry point to the IDS but does not implement usage control, this function is fully implemented by the so-called trusted connectors. Detailed information on this can be found in the IDS reference architecture [

20]. The implementations mostly use standardized protocols and security mechanisms such as X.509 certificates and TLS encryption.

3.3. GAIA-X

GAIA-X (

https://www.gaia-x.eu/, accessed on 19 July 2022) is an initiative to enable the development of European solutions for trusted data exchange between partners in a federation. GAIA-X is not a European cloud solution in response to the major cloud providers; rather, it provides an architectural standard to connect the various cloud service providers while complying with European data protection guidelines. The GAIA-X initiative is in line with the European Data Strategy and promotes innovation across different industries and sectors.

The GAIA-X architecture [

21] is roughly composed of a data ecosystem and an infrastructure ecosystem (see

Figure 3). The infrastructure ecosystem consists of service providers and service consumers. This ecosystem is made up of nodes, which ultimately provide a computing resource. A node can represent a cloud data center, an edge data center, and other hardware and operation services such as virtual machines or containers. The data ecosystem provides the actual data. It is composed of the accumulated dataspaces, which are industry-specific and accordingly also offer specific services. The entire ecosystem is based on common policies and standards.

In

Figure 3, the green parallelograms show several so-called federation services. The federation services provide a toolkit that enables interoperability between providers and consumers while ensuring data sovereignty. These are services are grouped into four areas:

Identity & Trust—authentication, authorization, identity management, and credential management;

Federated Catalogue—to search and select service offerings;

Sovereign Data Exchange—enables the sovereign data exchange of participants;

Compliance—mechanisms to ensure the Policy Rules, security, privacy, transparency.

Further details on the GAIA-X architecture can be found in [

21,

22]. It is important to note that the GAIA-X initiative itself will not provide an operational infrastructure but rather a set of open specifications and reference implementations that enable “federations” to set-up and operate GAIA-X infrastructures.

3.4. Summary on European Data Strategy and Dataspaces

The European Data Strategy aims to support the creation of an ecosystem for data exchange between providers and consumers. This is because data will soon more than ever represent a “raw material” that is particularly worthy of protection.

The International Data Spaces (IDS) are distributed networks (peer to peer) of data endpoints. The data endpoints are implemented by the so-called IDS Connector. The IDS Connector enables secure data exchange and guarantees data sovereignty.

IDS development provides an important cornerstone for enabling data exchange without central storage in a cloud environment in a secure and data-sovereign manner. The Gaia-X initiative uses the IDS development and supplements it with an ecosystem that realizes the infrastructure for the storage of data and its use through suitable services in a data-sovereign manner, even in heterogeneous cloud environments.

All these dataspace initiatives aim at providing a technological and regulatory infrastructure for fulfilling data sharing needs in the virtual world. However, they lack concepts of how to acquire the data from physical assets and contextualize them with the physical environment. This is the anchor that motivated the symbiotic view of the concept of the digital twin with dataspaces.

4. Combining Digital Twins with Dataspaces

It is to be expected that in the medium term, depending on the specific requirements, cooperative solutions with central data storage in one or more clouds and highly distributed data storage with efficient data processing in the edge will become established [

23]. As a result, GAIA-X and IDS are becoming very important. Central cloud environments as well as company clouds and local assets can be networked in a data-sovereign manner via IDS connectors. Overall, these developments are highly relevant for digital twins and can be seen as an important building block for the widespread use of digital twins aside from the context of value networks and the life cycle of assets. An initial application example for this is detailed in [

24]. Here, the concept of shared digital twins is introduced, which is based on adding an IDS connector that ensures the aspects of data sovereignty are upheld in a DT based on the AAS specifications of the Platform I4.0.

We argue that it is the combination of the concept of dataspaces and digital twins that enables one to realize the original idea of a digital twin as a comprehensive virtual representation of a physical asset, as discussed in

Section 2.

Depending on the specific use case, a subset of digital twin properties can be exchanged between companies. The exchange of complete digital twins is sensible for product digital twins, e.g., when the product is transferred from the manufacturer to the user. However, access to partial models within a digital twin or individual data points depending on authorizations is also conceivable. For example, relevant information about plant components shall be provided and shared between component manufacturers and plant operators in order to enable collaborative condition monitoring [

25]. Alternatively, between partners in a supply chain, only expected delivery dates are offered. However, information about the production route, the machines used, and their capacity for utilization is not provided. Regardless of the type of digital twin data that are exchanged, this must be done in a trustworthy and data protection-compliant manner. To make this possible, dataspaces and infrastructures such as GAIA-X are required.

GAIA-X is very important because it provides services that seek to significantly accelerate the development of dataspaces based on digital twins. For example, there is no single digital twin that is suitable for every business requirement or application that may occur. In practice, complex systems such as industrial plants, which usually consist of several thousand devices, contain more than one digital twin and very often a separate digital twin for each device. The GAIA-X federated catalogue service may be used to track all available DTs and find the most appropriate digital twin for a specific use case. Furthermore, it may also be used to find the “most similar” digital twins based on the comparison of the GAIA-X self-descriptions of the digital twins when there is no explicit match. Hence, to support the FAIR principles (Findability, Accessibility, Interoperability, and Reuse; for an example, see

https://library.cumc.columbia.edu/insight/what-are-fair-data-principles, accessed on 19 July 2022) that are required for each dataspace, it is necessary to combine digital twins with GAIA-X. While the standardized digital twins ensure accessibility by using the digital twin API and interoperability through the use of the digital twin standards, GAIA-X’s services are required to ensure the findability and reuse of digital twins.

In addition, there are many application scenarios wherein collaboration and coordination between digital twins are required. For example, a digital twin of a product going through a production line is filled with the production data originating from the production digital twin as it is being produced. In this case, GAIA-X could optimize the communication between digital twins as it offers a new type of data processing, the so-called IoT-edge-cloud continuum. The optimization could be performed by considering various aspects such as data bandwidth or even CO

2 emissions based on energy consumption [

26]. Consequently, by leveraging GAIA-X, both the efficiency and effectiveness of digital twin applications can be improved.

Finally, GAIA-X conformance services could be used for the conformance checking of digital twins. This could include the checking of conformance to digital twin standards by considering not only the syntax of the digital twin APIs but also the semantics of the methods. More importantly, GAIA-X conformance could also be used to check domain-specific rules, which are particularly important for digital twins in value chain use cases where collaboration between partners (and their digital twins) within and across sectors is required. For example, in order to address the aspects of the circular economy, it is expected that the future dataspaces will cover different types of domains (in the manufacturing sector, this could be design, production, use, etc.) [

27].

5. Digital Twin System Reference Model (DTS-RM)

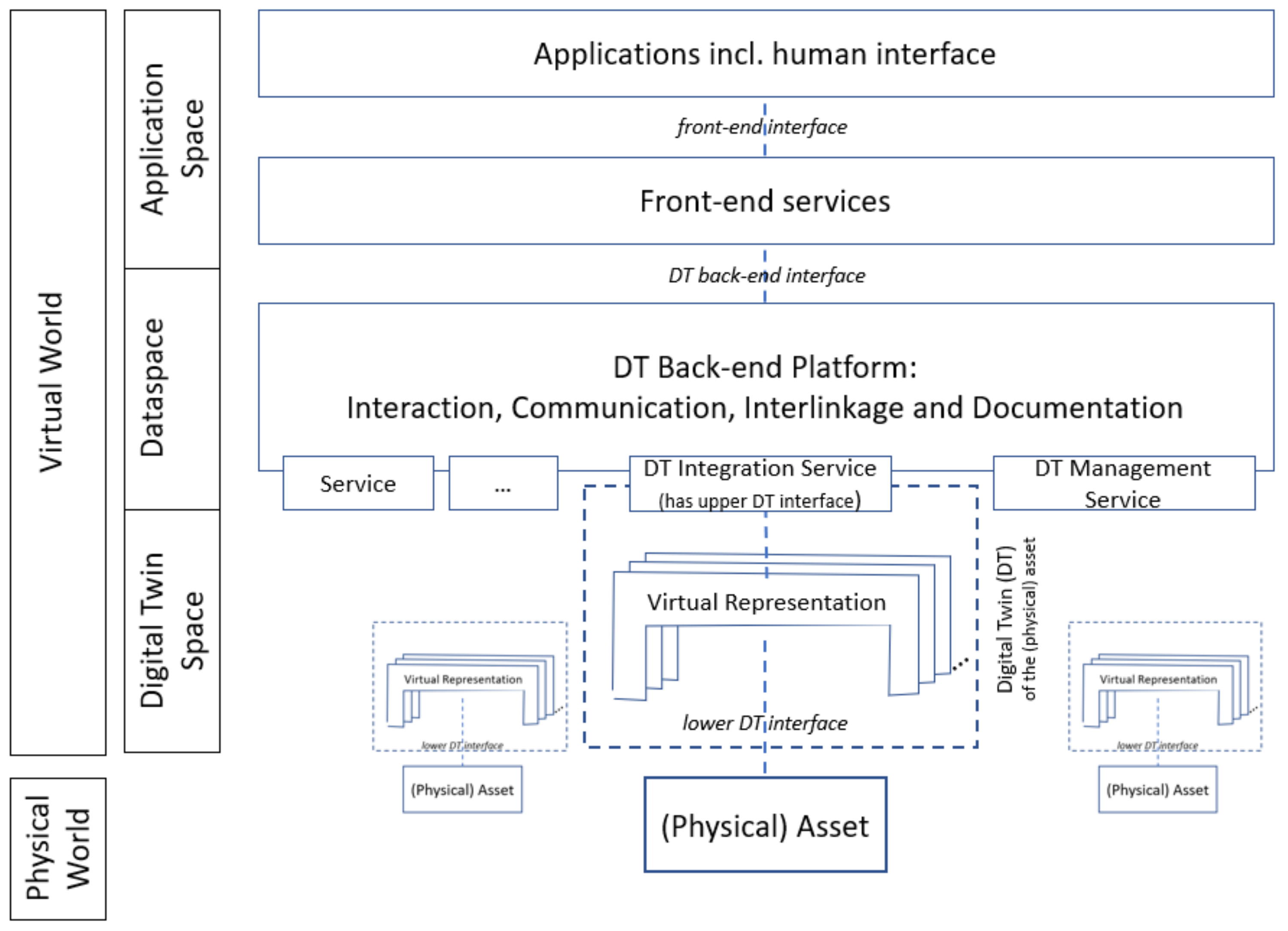

To position digital twins within emerging dataspaces, we propose a reference model for whole digital twin Systems instead of just considering digital twins as conceptual elements. The reference model is called the Digital Twin System Reference Model (DTS-RM) and is illustrated as a whole in

Figure 4. Two term definitions are adopted for the DTS-RM:

The DTS-RM divides the virtual world into:

A Digital Twin Space, providing the digital twin instances;

A Dataspace, providing the DTS-RM back-end platform comprising, among others, management services for the digital twin instances and their interactions;

An Application Space, providing the use-case specific instantiations and the applications including the human interface.

Their elements and characteristics are described in the following sub-sections. Note that for the further discussion in this paper, we adopt the service meta-model of [

17] that states that a service offers its functionality through interfaces as reusable units whereas an interface is specified by the means of operations.

5.1. DTS-RM Digital Twin Space

The core idea in the DTS-RM Digital Twin Space is to consider a digital twin as a logical concept that comprises a comprehensive (i.e., ideally 100% complete) virtual representation of all the static and dynamic aspects of the physical asset described by a set of asset properties. In practice, this is never possible. Only a subset of the data is accessible, retrievable, or observable. Since this is not possible in practice, an instance of a digital twin is composed of a set of digital twin elements (DT elements) that varies over the time of use of the digital twin by adding (or deleting) DT elements. This idea is illustrated in

Figure 5.

By this approach, digital twins are considered to be independent of their use cases and essentially constrained by the properties defined in the DT Elements. Use case-specific views are defined in the application space by means of front-end services (see below).

A DT-Element represents a physical asset, i.e., it comprises a set of properties of the physical asset with the following characteristics:

Properties may be data elements with read and/or write access, functional elements (operations) that may be called and can deliver a result, and events that may be observed in an asynchronous way and processed. Of course, properties can also refer to computational models, and thereby provide the basis for describing computational models.

There may be one, many, or practically an unlimited number of DT-Elements, i.e., multiple abstractions of the properties of the assets.

- ○

Note 1: From a conceptual point of view, these virtual representations may but need not be modelled by means of the Industry 4.0 AAS meta-model. This is a question of interoperability. Theoretically, it would even be possible to use different modelling languages or use different meta-models with the assumption that these DT-Elements are accessible through the same digital twin upper interface (see below), and technologies for semantic annotation could be used in order to enable semantic relationships between the DT-Elements.

- ○

Note 2: This approach enables an overlap of properties across different DT-Elements, as the same physical property (e.g., a temperature value) may be modelled by different property values if there are multiple methods to measure the temperature. Thematic and semantic conflicts can be mitigated by providing adequate context information, e.g., information about the observation methods used (see ISO 19156:2011 [

29]).

The interface between a DT-Element and the physical asset is called the “lower DT interface”. In industrial automation, this interface is typically realized by means of the IEC 62541 standard OPC UA.

The interface between the DT-Elements and the services of the digital twin back-end platform (see below) is called the “upper DT-Interface”. The Plattform Industry 4.0 and the IDTA (see

Section 2) propose to use the AAS interface to realize this upper DT-interface.

5.2. DTS-RM Dataspace

The DTS-RM Dataspace provides the DT-back-end platform for communication and interaction support between digital twin instances. The functionality of the DT-back-end platform is offered by means of services, among which are the following examples:

DT-Integration Services that support the access and the manipulation of the properties provided by the digital twin instances by means of their upper DT-Interfaces.

DT-Management services that support the whole lifecycle of digital twin instances, e.g., to create and register digital twin instances in a digital twin registry, to offer digital twin instances in a digital twin catalogue, or to support digital twin instance versioning.

DT-Element Discovery Services that provide missing information about the status or behavior of physical aspects that are requested by front-end services in the application space (see below) to fulfill requirements for given use cases. In practice, to close this information gap, it may be necessary to deploy an additional sensor to observe the requested property of the physical asset. A result of the performance of these services may be the creation of a further DT-Element for a given digital twin instance; however, this will be hidden to the application.

Any type of services that perform data analytics, including machine learning, that may also use properties of different digital twin instances and generate additional properties of other digital twin instances. In ISO 23247 these services are referred to as “interfaces to other sources that enrich the content of a digital twin”.

Services for policy management for data access and usage control.

Services to support the service organization, e.g., to mediate between front-end and back-end services, to provide data to the user interface.

Execution services of physically-based models, i.e., “virtual twins” as these are called in [

30].

A digital twin back-end platform may be implemented on top of an IIoT platform combining technologies of edge or cloud environments with dataspaces, e.g., an integrated GAIA-X/IDS environment.

5.3. DTS-RM Application Space

The purpose of the DTS-RM application space is to provide the applications that realize the defined use cases. Applications may but need not have human interfaces.

The core idea is that the application will abstract from the management of DT-instances. Furthermore, the applications typically only need a view of the physical assets represented by the corresponding DT instances. These views are provided by so-called DT-front-end services. Hence, the DT-front-end services provide interfaces that are tailored to the needs of both the applications and humans. They use the DT-back-end interface that comprises the sum of all operations provided by the DT-back-end platform.

There is the client role of an orchestrator (see also the discussion on digital ecosystems, in the conclusion in

Section 8), that mediates between the front-end services and the back-end platforms, e.g., it transforms the information demand about the status and/or perspective of physical assets as formulated by humans and/or applications into data retrieval requests on their corresponding digital twins to be fulfilled by the DT-Back-end platform.

6. Digital Twin Development

Digital Twin Space—the role of the (Industrial) Internet of Things, the synchronization of the virtual and the physical world, and the life cycle of assets;

Dataspace—interoperability and data analytics/machine learning;

Application Space—human–machine interface and value networks.

The logic in each section is as follows: first, the focal aspects are described; second, the kernel statements are extracted in the form of theses for future development with a time horizon of around ten years.

6.1. Digital Twin Space

6.1.1. Focal Aspects

The vast amount of IIoT sensor data and device metadata necessitates the organization and management of all that information in an efficient way. Assets in IIoT, e.g., sensors or whole IT systems such as Manufacturing Execution Systems (MES), enable the collection and communication of real-world data, while digital twins organize the virtual representation of these assets and manage their information.

Finally, the IIoT will interconnect smart devices such as objects with integrated sensors or intelligent components via the Internet. Smart devices typically communicate among each other by means of machine-to-machine (M2M) protocols [

31], e.g., via radio protocols such as Bluetooth, WiFi, NFC, or mobile communications.

As information about the physical asset will be collected and stored in the digital twin as properties of the DT-Elements, there is a need for interaction and synchronization with the physical asset over the whole life cycle of an asset, starting with the engineering of the asset over its operation phase up to its disposal. In all phases, technically, this information acquisition is carried out via the lower DT interface as described in the DTS-RM in

Section 5. Depending on the use case, information acquisition does not necessarily have to take place in real time. Data can also be stored temporarily and loaded into the digital twin from time to time or depending on network availability.

The flow of information in the reverse direction, i.e., from the digital twin to the real asset, may be relevant in the operation phase, e.g., for the reinitialization of a machine after a malfunction or for synchronization with other assets to grant usage permission to a certain user. Another important synchronization task is to track changes and modifications to the real asset, e.g., changes in the cabling, spatial arrangement, optimizations, etc. These can be used to adapt the design plans for future assets.

As outlined in

Section 2.1, the digital twin idea originated from the holistic approach to managing the lifecycle data of products. It enables a better interconnection of development, sourcing, production, distribution, and after sales services. Thereby, information from the development process is not lost after production and can be used seamlessly in later lifecycle stages, e.g., for maintenance or recycling. A digital twin of products along the whole lifecycle enables new business models associated with such product-service-systems.

6.1.2. Theses

The following theses express our perspectives on the future development of the DTS-RM digital twin space:

A digital twin will provide a comprehensive virtual representation across the entire product lifecycle of an asset from conception and engineering to operation and finally disposal, by fulfilling the demands of all the stakeholders involved.

Digital Twins will provide a modular modelling approach and stakeholder views to ideally support different use cases tailored to different lifecycle phases.

When offering products and services in an integrated package, digital twins will enable new use cases and business models around product-service systems.

There is always a delta between the status of the real asset and its digital twin counterpart in terms of temporal perception or value accuracy. It will be essential to quantify this delta by means of digital twin meta-data about time and value uncertainty.

Regarding real-time communication and bidirectional interaction between a digital twin and its physical asset, a digital twin may act as a “real” deputy of the physical asset. Via the digital twin, users will be able to see what is happening on the factory floor in near real time.

6.2. Dataspace

6.2.1. Focal Aspects

The central task in the data and service space is to enable interoperability between all connected services such as data analytics or machine learning.

More generally, interoperability enables different systems, technologies, or organizations to work together. In principle, the use of digital twins is also about combining isolated data sets in a suitable way [

16]. This is intended to give a user, e.g., a human or a software system, a uniform view of the wealth of information in an integrated form.

Interoperability opens up the possibility of efficiently accessing data of digital twin instances within the digital twin back-end platform. In this sense, a digital twin backend system connects relevant systems with each other and simplifies the data access for users and systems. Integration services represent the technical implementation of accessing other systems, but also represent digital twins or parts of digital twins in the form of digital twin elements. Integration services are designed to enable the end-to-end networking of data across the various data sources. This creates the prerequisite for new business models since many services can only be offered based on integrated data. One example of this is the forecasting of delivery dates across the supply chain right through to the end product.

A large component of data analytics is the extraction and comprehension of relevant information and knowledge from the data. In the context of digital twins, this entails tracking and interpreting the data to map comprehensive and basic correlations of digitally twinned systems. Furthermore, by means of machine learning methods, digital twins can perform predictive analyses (e.g., for predictive maintenance) based on real life data, but can also carry out realistic model-based (twin based) simulations in order to derive efficient policies (e.g., by means of reinforcement learning) for quality assurance along the entire connected value chain.

It will become increasingly important for digital twins to be firmly anchored in the business processes for data provision and data use. In the medium term, this can lead to the digital twin of a product becoming more important for a company’s value creation than the physical product itself.

6.2.2. Theses

The following theses express our perspectives for the future development of the DTS-RM Dataspace:

Interoperability usually requires compliance with common standards, both at the syntactic and semantic levels. The semantic component will be critical for interoperability across the life phases of an (physical) asset.

Interoperability will be considered between all components of a digital twin system, i.e., between digital twin elements, between digital twin services, and between digital twin elements and digital twin services, as well as between the digital twin back-end platform and the digital twin front-end services.

Digital twins synchronized with physical assets facilitate and structure the path from data to knowledge by means of data analytics and machine learning methods in a bidirectional way. Data and simulation-driven digital twins create new opportunities for monitoring assets and optimizing them.

Data-driven machine learning methods provide digital twins with the means to become autonomous systems.

A digital twin will communicate its status, it may learn from other digital twins, and optimize its behavior in combination with other digital twins, thus enabling a collective accelerated learning.

6.3. Application Space

6.3.1. Focal Aspects

Digital Twins are essential to implement modern technical systems such as production planning and control systems as well as their orchestration along the entire value network. They provide new possibilities for higher efficiency, reliability, and quality through the automated documentation of the production steps.

A digital twin represents an asset and enables a representation of its state at any point in the lifecycle. Therefore, the digital twin allows human users to monitor the current state, simulate future scenarios, and manipulate (control) the asset from the virtual environment as well as the system to integrate with other systems for a cooperative operation without being accessible to the human user.

Whenever humans use a digital twin, interfaces are needed for their interaction. In the DTS-RM, these interfaces are provided by DT-front-end services. As some digital twin systems are created to support humans, suitable Human Machine Interfaces (HMI) are very important. However, some digital twins’ instances will be integrated directly into other systems and do not need to be directly accessible to humans. Therefore, dedicated DT-front-end services are created to best support the specific use-cases. Ideally, the HMI enables a bidirectional link between the physical asset and the human user, mediated by the corresponding DT instance, even without requiring the human to be in the same physical space as the asset. This leads to a decoupling between the humans and the physical assets, wherein DT Front-end services support the dedicated views and interaction with humans whereby the digital twin instances enable the interaction with and the manipulation of the real product.

Very often, today’s value chains span multiple plants in different continents and several different companies. Furthermore, stakeholders with various backgrounds and from various departments are involved in the value creation process. In this complex business environment, “Digital Twins have the potential to build bridges within and between different value chains” [

32]. These interconnections break up formerly rigid value chains and create value networks that support the lifecycles of entire product ranges.

6.3.2. Theses

The following theses express our perspectives for the future development of the DTS-RM Application space:

Digital Twins will provide the data and information to the human via individual views as well as to other systems by means of the digital twin front-end services to form a cooperative system of systems approach.

Digital Twins will be the container with which to share all the necessary data and information among the individual actors in the necessary fidelity.

No single actor in the value network will own all the data necessary for their task; rather, the potentially missing data may be retrieved through the digital twin back-end platform from other actors of the value network.

The application of the principles of DevOps (

https://en.wikipedia.org/wiki/DevOps, accessed on 19 July 2022), i.e., the combination of practices of software development (Dev) and IT operations (Ops), to digital twins and their supporting infrastructure will guarantee the continuous maintenance of the digital twin in an economic way.

The great potential of digital twins lies in their usability for humans. Therefore, the digital twins will be co-designed in accordance with human needs to achieve their optimal capabilities as socio-technical systems.

7. Validation Projects

The motivation and the idea for the DTS-RM as well as the perspective theses of the DTS-RM spaces result from our experience in several research projects and cooperative initiatives. Hence, the DTS-RM embraces the expectations of how the concepts and technologies of the digital twin and dataspaces will merge. Two of the projects, for which the relevant aspects of the DTS-RM are currently in progress, are briefly described in the following sub-sections.

7.1. COGNITWIN

COGNITWIN [

33] is a collaborative research project in the Horizon 2020 program of the European Commission that aims to provide cognitive solutions to the process industry (

https://www.sintef.no/projectweb/cognitwin/, accessed on 19 July 2022). Its overarching goal is to establish the fully digitalized concept of self-learning and proactive next-generation digital twins that can (i) detect, predict, and communicate less optimal process behaviors before they occur, and (ii) adapt themselves to continuously keep the process close to or at the optimum level. To address all these aspects, the concept of DTs is applied in a graduated way.

For digital twins, COGNITWIN follows the IIC definition of digital twins as introduced in

Section 2.2. While the digital twin’s attributes are modeled by data properties, the behavior could be represented by a variety of models (e.g., physical, data-driven, etc.). Each model represents only a certain aspect of the asset and typically does not “cooperate” with the other models. COGNITWIN has introduced the notion of hybrid digital twins. A hybrid digital twin extends the “classic” DT by intertwining different models to achieve higher predictive capabilities. A typical scenario would be to use a simulation model to create virtual sensors to “measure” the missing data needed for ML models. In terms of the DTS-RM, the individual models correspond to the DT elements that all together provide the DT.

Moreover, human intervention is still required to respond to rare, sudden, and unknown events. To address this, COGNITWIN has introduced the so-called cognitive digital twins as an extension of the hybrid digital twins by combining expert knowledge with the power of hybrid analytics. The synergy with expert knowledge enables solutions to be found for previously unforeseen situations. Depending on the use cases to be supported and the degree of the reusability of the expert knowledge, the cognitive digital twin may be considered to be part of the DTS-RM Dataspace as a further DT element (with a well-defined DT upper interface accessible through the DT back-end platform) or positioned in the DTS-RM Application Space; hence, it may be inaccessible via the DT back-end platform. This is an architectural design decision.

7.2. Catena-X Automotive Network

As one of its offers, Catena-X creates a central, uniform, and consistent solution for the provision of or the exchange of data within the Catena-X network. For this purpose, Catena-X provides various methods, tools, and standards to ensure semantic interoperability. Digital Twins have established themselves here as a central element for structuring and accessing data. They act as an enabler of the Catena-X network. Catena-X has chosen the AAS as the basic meta-model for the DT as described in

Section 2.4. Hence, according to the DTS-RM, the AAS application programming interface acts as the upper DT interface, whereby the Catena-X network realizes the DT back-end platform. With the help of the defined semantics of the DT properties, both data provision and app development are simplified and encouraged.

As one of the Catena-X use cases, manufacturing as a service (MaaS) was chosen as a response to the sustainability and resilience demands in automotive supply chains. One of the MaaS scenarios requires a method to calculate the carbon footprint of any car components across the whole supply chain. In terms of the DTS-RM, this requires a DT back-end platform in the DTS-RM dataspace that supports a trustworthy and usage-controlled exchange of DT element data on CO2 emissions of all the constituting sub-components without revealing the structural details of the supply chain.

8. Conclusions

The results of this paper are summarized by five concluding statements that comprise theses and recommendations to be considered for future developments.

Digital Twins integrate all life cycle phases, models, and data that are created by one or more participants, within a company or across companies, and make them available in (DT) applications. Thus, they are conceptually closely linked to dataspaces, which pay particular attention to information integration, data sovereignty aspects, and relationships between trusted partners. When conceiving of a digital twin as a comprehensive double of all the properties of a physical entity required by a given application, DT data management plays a key role. This includes the questions of data ownership, data access control, data usage control, and data provenance tracking. These major aspects of data sovereignty must be considered in the design and implementation of dataspaces, as well as in the creation of digital twins, whenever information is shared between various stakeholders in value chains.

- 2.

A system approach is required to link the concepts of digital twins and dataspaces.

The development of distributed networks (peer to peer) is highly relevant for digital twins, their creation in a PLM environment, and their usage by several partners in the supply chain supported by a suitable IT landscape. The relation of the digital twin to its physical asset, which produces additional data during usage or operation, is a further linkage of digital twins and dataspaces.

- 3.

The design of a digital twin system architecture requires a reference model.

A reference model will guide an open architectural approach on a conceptual level. To avoid dedicated approaches for individual use cases and application domains leading to interoperability problems and poor development efficiency, a reference model for digital twin system architectures is required. Communities and organizations must strategically decide which proposals to follow and/or influence. A proposal of a reference model that combines both digital twins and dataspaces as a framework for this paper is given in

Section 5, entitled digital twin System-Reference Model (DTS-RM).

An important element of such a refence model is its semantic interoperability. Digital twins cross-link different content and often have an aggregated structure. Semantic interoperability makes this interconnection useful and provides a common frame of reference. It is important to consider that this aspect is already in a very early stage of development and has an interdisciplinary group of domain experts to assure its successful implementation. A further aspect is the connection and synchronization to the physical twin. A bi-directional communication will be required to enable (semi-) autonomous decision making and optimization in real-time.

- 4.

Digital Twins offer user- and application-specific views.

Front-end (applications related views on models) and back-end (pool of models) of digital twins must be considered separately. By definition, a digital twin includes all the information that comprises an asset, but as mentioned earlier, this ideal is generally impossible to achieve. Working on this huge data set is impractical; therefore, it might be beneficial to reduce the backend content of an individual digital twin system to only fit to the needs of the use cases and applications. However, the DT’s back-end platform is seamlessly extensible, i.e., it provides the means to efficiently adapt to the needs of the applications. The front-end needs to be designed independently of the back-end content in accordance with the needs of the user. It is quite likely that different views for different types of users would be beneficial.

- 5.

Digital Twins enable new business models.

The usage and exchange of digital twins along partners and value chains offer new business opportunities. An engineering product can no longer be viewed by itself. Product-Service-Systems provide more benefit to the customer and allow the provider to shape a new approach to upselling. In the economy of the future, businesses that extend their product range with a set of fitting or even individualized services have a competitive advantage. Manufacturing as a Service (MaaS) is an example of such a new approach as discussed, designed, and implemented in the Catena-X Automotive Network (

https://catena-x.net, accessed on 19 July 2022).

To realize an ecosystem of digital twins, we pursue the vision of a powerful infrastructure based upon open, international standards. Their development and application are highly important; however, even from a ten-year perspective, the provision, acceptance, joint use, and common interpretation of such standards is a big challenge. Concurrent developments, conflicts of interest, and legacy systems hinder the major progress towards this vision in the foreseeable future.

- 6.

Digital twin systems are kernel enablers of digital ecosystems.

In the digital age, a value chain can only counter the continuously increasing international competitive pressure and the ever-shorter innovation cycles through a high degree of flexibility and the responsible use of existing natural, technological, and human resources. One characteristic of a digital ecosystem is the complementary composition of the partnership and the multi-lateral role-change model of the partners: a company can be both a provider and a user in various individual projects. Digital ecosystems are built iteratively and collaboratively. The value creation structure is set up in such a way that the added value for all participants becomes visible as directly as possible and within a short time horizon.

The digital twin system and the assigned reference model presented in this paper comprise an approach that combines the development of digital twins and dataspaces. This synergetic combination enables the realization of powerful digital twin applications based on and integrated in dataspaces that enable data sovereignty at the level required by users and customers.