Optimizing the Powertrain of a Fuel Cell Electric Bus: A Sizing and Hybridization Analysis

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

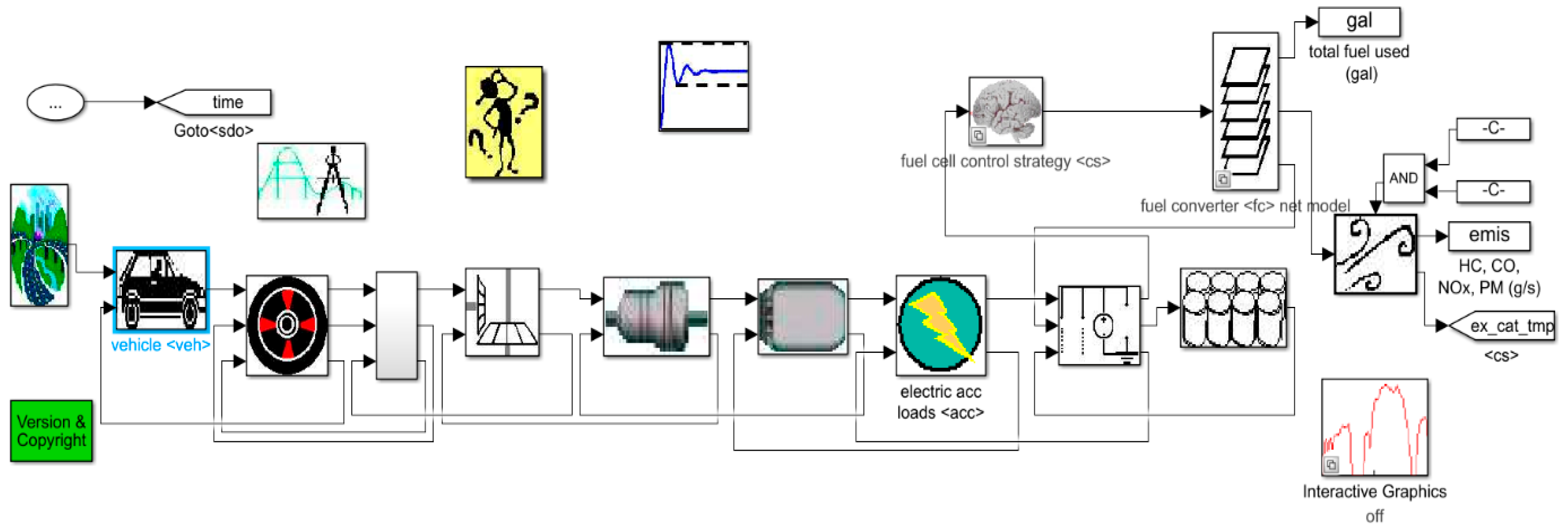

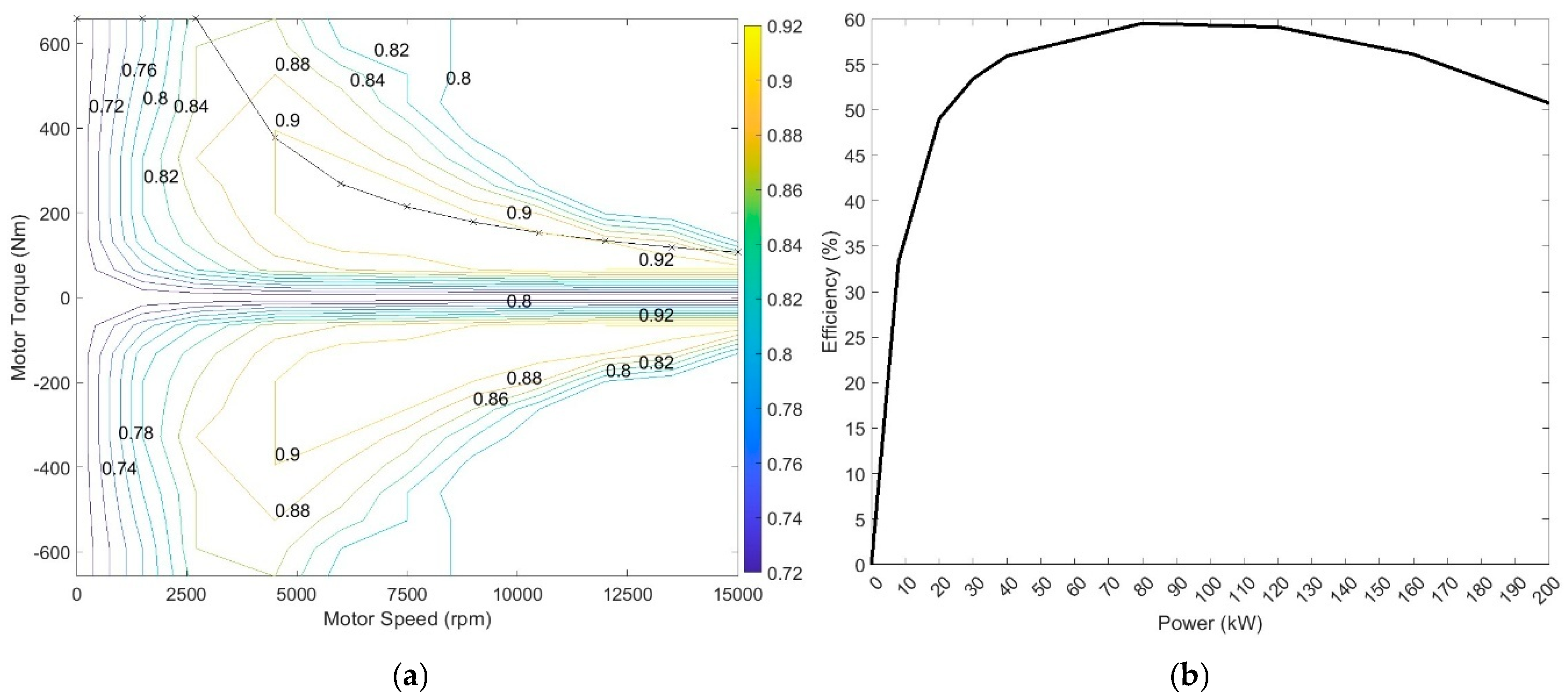

3.1. Fuel Cell Electric Bus Model Development in ADVISOR

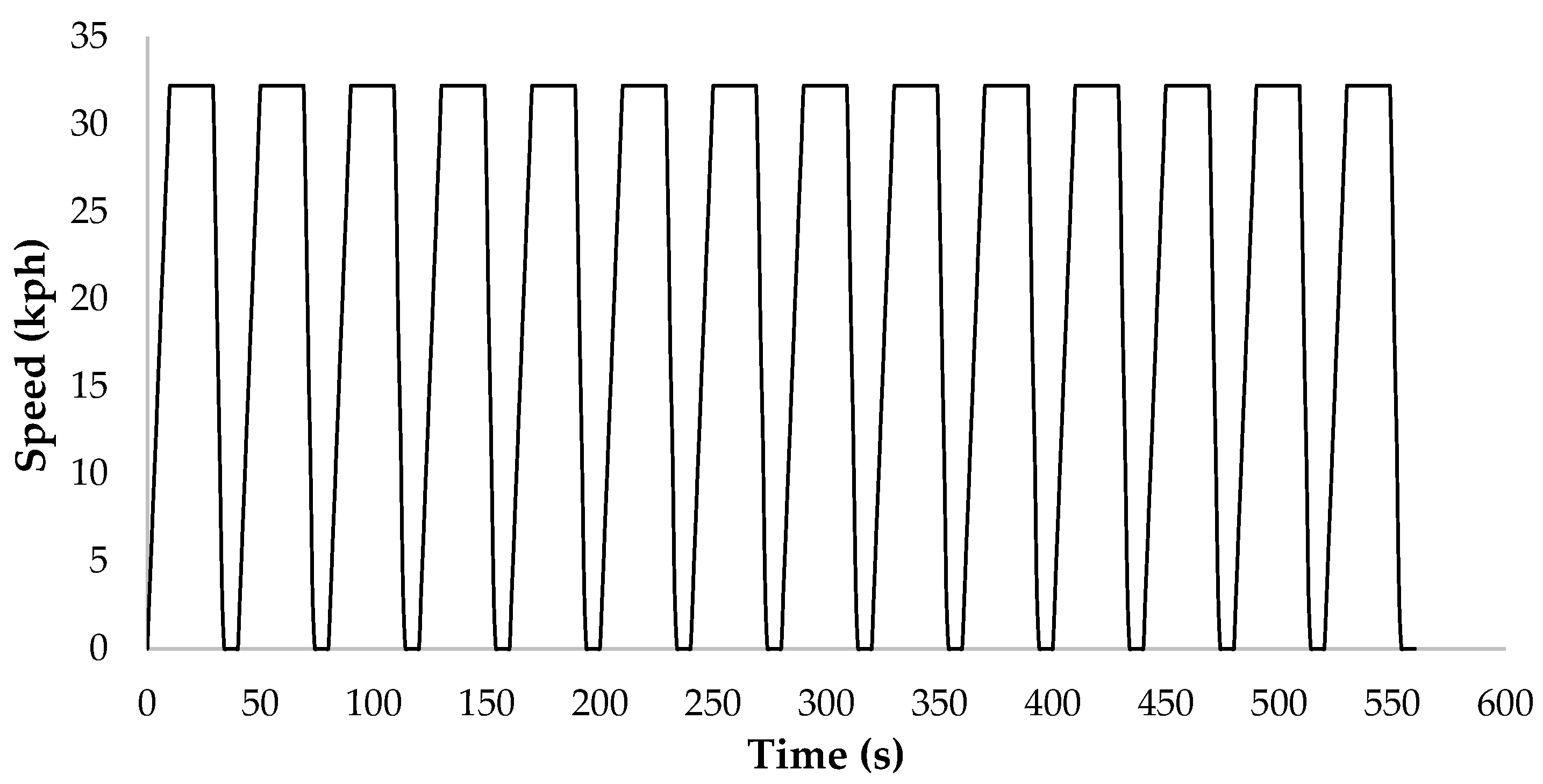

3.2. Simulation Procedure and Evaluation Metrics

3.3. Parametric Analysis and Sizing Strategy

4. Results

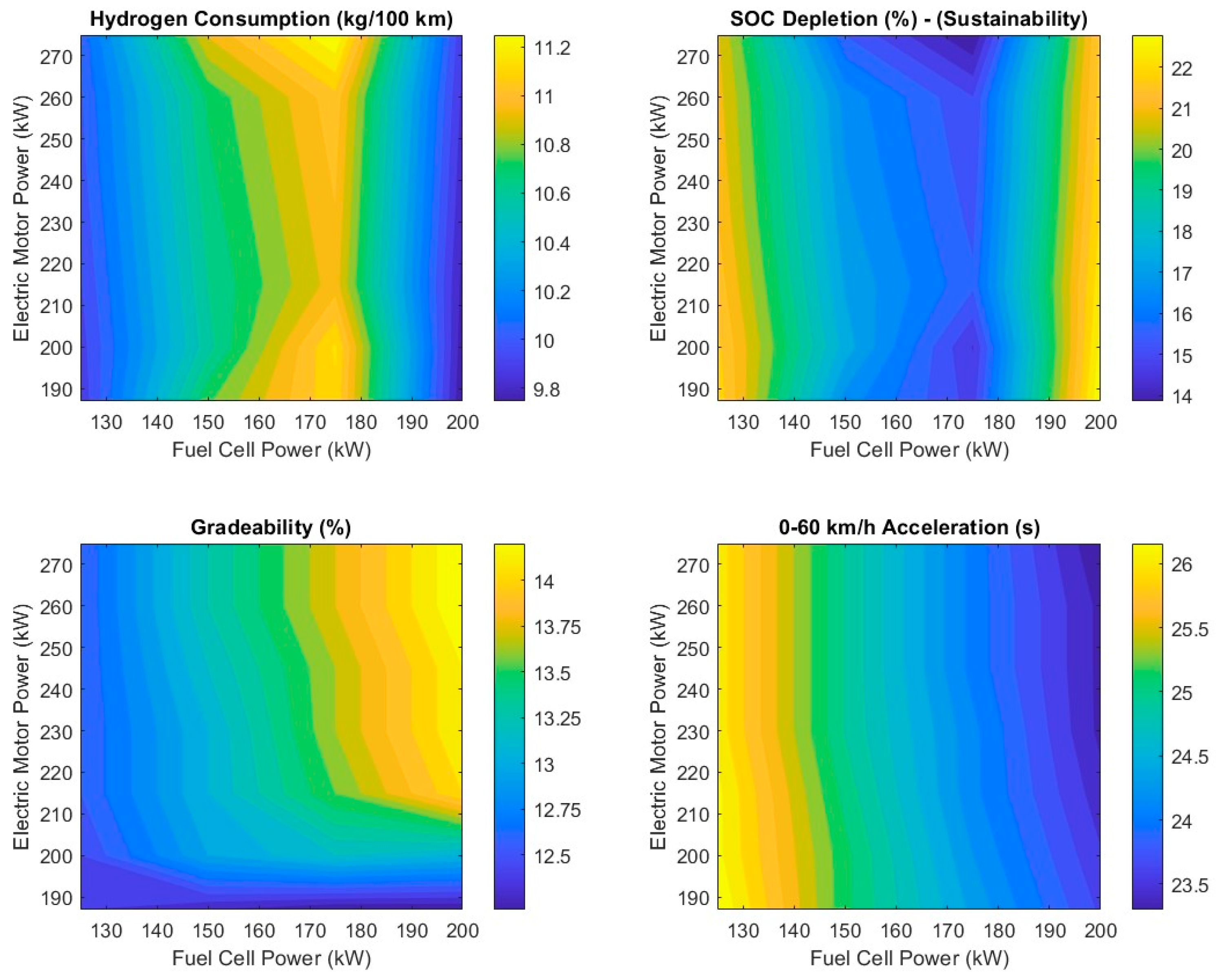

4.1. The Effect of Fuel Cell and Electric Motor Sizing

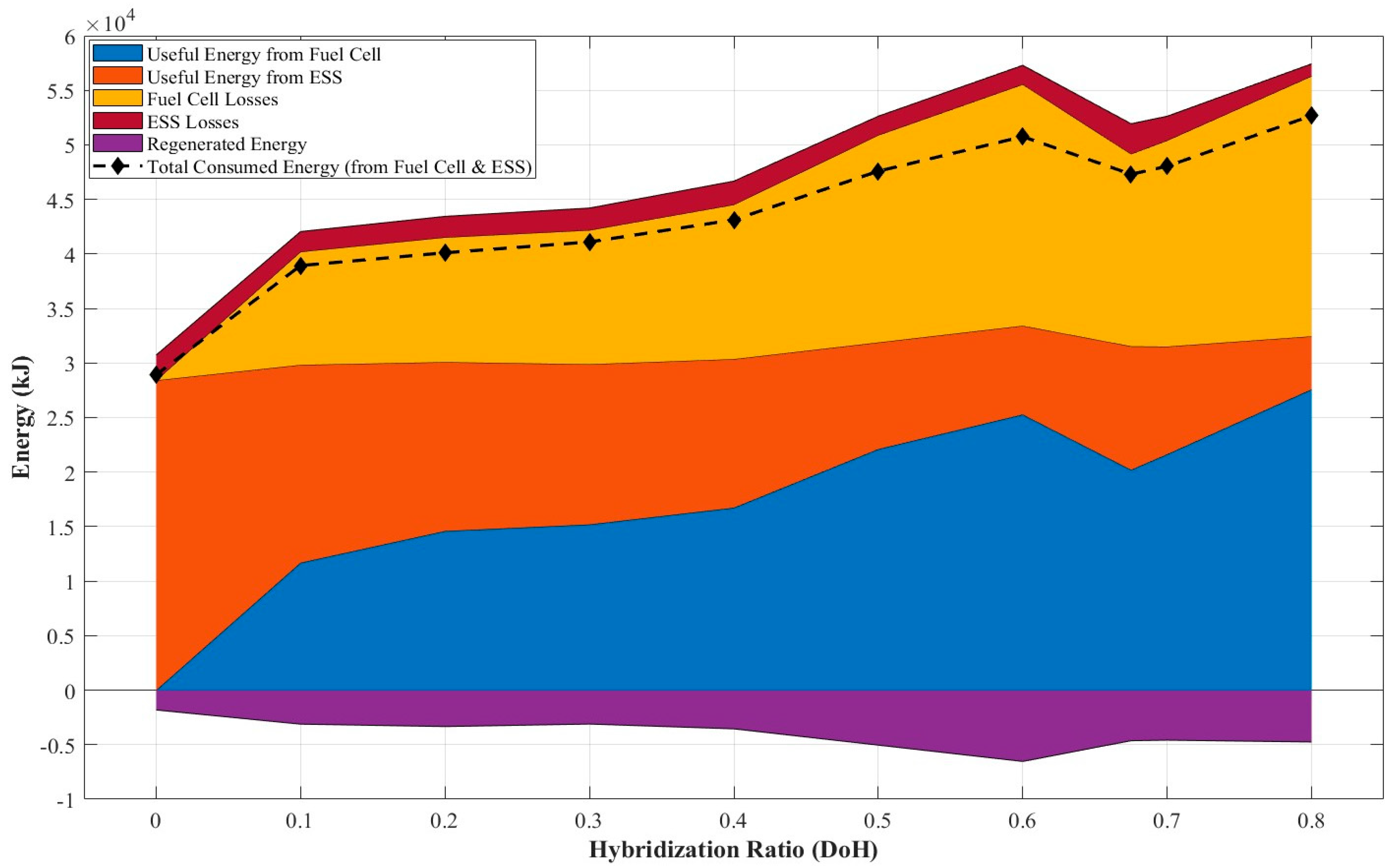

4.2. The Effect of the Hybridization Ratio on Efficiency and Sustainability

5. Conclusions

- The initial parametric analysis revealed that the fuel cell power rating is the most significant factor influencing overall hydrogen consumption, whereas the impact of the electric motor size is comparatively minor.

- Furthermore, the primary performance metrics are governed by different components: acceleration performance was found to be predominantly dictated by the fuel cell’s power, while gradeability is critically dependent on the electric motor’s power, but only after the motor exceeds a power threshold of approximately 215 kW.

- The analysis demonstrates a clear degradation in dynamic performance as the powertrain shifts towards a fuel-cell-dominant architecture. While the pure-electric configuration ( = 0) and the mid-hybrid configuration ( = 0.4) both maintain high performance with acceleration times of 16.3 s and 17.3 s, respectively, the high-hybrid configuration (≈ 0.8) suffers a severe performance collapse, with acceleration time deteriorating to 38.9 s.

- Conversely, energy consumption rises significantly with increased . The total energy required to complete the CBD cycle increases from 28,916 kJ at = 0 to 43,128 kJ at = 0.4 and reaches 52,678 kJ at the ≈ 0.8 configuration.

- Gradeability remains high for both the = 0 (12.4%) and = 0.4 (12.2%) configurations but collapses to 8.4% at ≈ 0.8. In terms of sustainability, the SOC depletion is high for both the = 0 (23.0%) and = 0.4 (16.2%) cases, whereas the ≈ 0.8 case is the most charge-sustaining of the three, with a drop of only 5.0%.

- The energy recovered through regenerative braking was not constant but instead showed a general increasing trend as the hybridization ratio increased, rising from 1819 kJ in the pure-electric mode to a peak of 6537 kJ at a of approximately 0.6.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA—International Energy Agency. Global Energy Review 2025; International Energy Agency: Paris, France, 2025. [Google Scholar]

- Organization of the Petroleum Exporting Countries. World Oil Outlook 2050; Organization of the Petroleum Exporting Countries: Vienna, Austria, 2024. [Google Scholar]

- Perera, F. Pollution from Fossil-Fuel Combustion Is the Leading Environmental Threat to Global Pediatric Health and Equity: Solutions Exist. Int. J. Environ. Res. Public Health 2018, 15, 16. [Google Scholar] [CrossRef]

- De Wolf, D.; Smeers, Y. Comparison of Battery Electric Vehicles and Fuel Cell Vehicles. World Electr. Veh. J. 2023, 14, 262. [Google Scholar] [CrossRef]

- Xia, X.; Li, P. A Review of the Life Cycle Assessment of Electric Vehicles: Considering the Influence of Batteries. Sci. Total Environ. 2022, 814, 152870. [Google Scholar] [CrossRef] [PubMed]

- Mekhilef, S.; Saidur, R.; Safari, A. Comparative Study of Different Fuel Cell Technologies. Renew. Sustain. Energy Rev. 2012, 16, 981–989. [Google Scholar] [CrossRef]

- The Technology Collaboration Programme on Advanced Fuel Cells (AFC TCP). Annual Report 2024; International Energy Agency: Paris, France, 2024. [Google Scholar]

- Xu, L.; Mueller, C.D.; Li, J.; Ouyang, M.; Hu, Z. Multi-Objective Component Sizing Based on Optimal Energy Management Strategy of Fuel Cell Electric Vehicles. Appl. Energy 2015, 157, 664–674. [Google Scholar] [CrossRef]

- Madadi, M.H.; Chitsaz, I. Improving Fuel Efficiency and Durability in Fuel Cell Vehicles through Component Sizing and Power Distribution Management. Int. J. Hydrogen Energy 2024, 71, 661–673. [Google Scholar] [CrossRef]

- Venkata KoteswaraRao, K.; Naga Srinivasulu, G.; Ramesh Rahul, J.; Velisala, V. Optimal Component Sizing and Performance of Fuel Cell—Battery Powered Vehicle over World Harmonized and New European Driving Cycles. Energy Convers. Manag. 2024, 300, 117992. [Google Scholar] [CrossRef]

- Abdeldjalil, D.; Negrou, B.; Youssef, T.; Samy, M.M. Incorporating the Best Sizing and a New Energy Management Approach into the Fuel Cell Hybrid Electric Vehicle Design. Energy Environ. 2023, 36, 616–637. [Google Scholar] [CrossRef]

- Graber, G.; Calderaro, V.; Galdi, V. Two-Stage Optimization Method for Sizing Stack and Battery Modules of a Fuel Cell Vehicle Based on a Power Split Control. Electronics 2022, 11, 361. [Google Scholar] [CrossRef]

- Mounica, V.; Obulesu, Y.P. Hybrid Power Management Strategy with Fuel Cell, Battery, and Supercapacitor for Fuel Economy in Hybrid Electric Vehicle Application. Energies 2022, 15, 4185. [Google Scholar] [CrossRef]

- Molina, S.; Novella, R.; Pla, B.; Lopez-Juarez, M. Optimization and Sizing of a Fuel Cell Range Extender Vehicle for Passenger Car Applications in Driving Cycle Conditions. Appl. Energy 2021, 285, 116469. [Google Scholar] [CrossRef]

- Anbarasu, A.; Dinh, T.Q.; Sengupta, S. Novel Enhancement of Energy Management in Fuel Cell Hybrid Electric Vehicle by an Advanced Dynamic Model Predictive Control. Energy Convers. Manag. 2022, 267, 115883. [Google Scholar] [CrossRef]

- Xu, L.; Ouyang, M.; Li, J.; Yang, F.; Lu, L.; Hua, J. Optimal Sizing of Plug-in Fuel Cell Electric Vehicles Using Models of Vehicle Performance and System Cost. Appl. Energy 2013, 103, 477–487. [Google Scholar] [CrossRef]

- Broatch, A.; Olmeda, P.; Margot, X.; Aceros, S. Different Strategies in an Integrated Thermal Management System of a Fuel Cell Electric Bus under Real Driving Cycles in Winter. Energy Convers. Manag. 2023, 288, 117137. [Google Scholar] [CrossRef]

- Ahmadi, P.; Raeesi, M.; Changizian, S.; Teimouri, A.; Khoshnevisan, A. Lifecycle Assessment of Diesel, Diesel-Electric and Hydrogen Fuel Cell Transit Buses with Fuel Cell Degradation and Battery Aging Using Machine Learning Techniques. Energy 2022, 259, 125003. [Google Scholar] [CrossRef]

- Kim, H.; Hartmann, N.; Zeller, M.; Luise, R.; Soylu, T. Comparative Tco Analysis of Battery Electric and Hydrogen Fuel Cell Buses for Public Transport System in Small to Midsize Cities. Energies 2021, 14, 4384. [Google Scholar] [CrossRef]

- Jia, C.; Zhou, J.; He, H.; Li, J.; Wei, Z.; Li, K.; Shi, M. A Novel Energy Management Strategy for Hybrid Electric Bus with Fuel Cell Health and Battery Thermal- and Health-Constrained Awareness. Energy 2023, 271, 127105. [Google Scholar] [CrossRef]

- Kaya, A.F.; Puglia, M.; Morselli, N.; Allesina, G.; Pedrazzi, S. Fuel Consumption of Diesel, Natural Gas, Hybrid, Full Electric and Hydrogen Fuel Cells Based Buses: A Simulated Comparison Using Standard Road Cycles and Gradeability Tests. Fuel 2025, 401, 135938. [Google Scholar] [CrossRef]

- O’Keefe, M.P.; Vertin, K. An Analysis of Hybrid Electric Propulsion Systems for Transit Buses; Technical Report; National Renewable Energy Laboratory: Golden, CO, USA, 2002. [Google Scholar]

- Zhang, G.; Chen, W.; Li, Q. Modeling, Optimization and Control of a FC/Battery Hybrid Locomotive Based on ADVISOR. Int. J. Hydrogen Energy 2017, 42, 18568–18583. [Google Scholar] [CrossRef]

- Brown, J.C.; Eichenberg, D.J.; Thompson, W.K. Baseline Testing of the Hybrid Electric Transit Bus; NASA Lewis Research Center: Cleveland, OH, USA, 1999. [Google Scholar]

- Gao, Y.; Rahman, K.M.; Ehsani, M. Parametric Design of the Drive Train of an Electrically Peaking Hybrid (ELPH) Vehicle. J. Passeng. CARS Part 1 1997, 106, 498–503. [Google Scholar]

- Dispenza, G.; Sergi, F.; Napoli, G.; Randazzo, N.; Di Novo, S.; Micari, S.; Antonucci, V.; Andaloro, L. Development of a Solar Powered Hydrogen Fueling Station in Smart Cities Applications. Int. J. Hydrogen Energy 2017, 42, 27884–27893. [Google Scholar] [CrossRef]

- Ni, M. An Overview of Hydrogen Storage Technologies. Energy Explor. Exploit. 2006, 24, 197–209. [Google Scholar] [CrossRef]

- Šimunović, J.; Pivac, I.; Barbir, F. Techno-Economic Assessment of Hydrogen Refueling Station: A Case Study in Croatia. Int. J. Hydrogen Energy 2022, 47, 24155–24168. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Xie, T. A Solution to Renewable Hydrogen Economy for Fuel Cell Buses—A Case Study for Zhangjiakou in North China. Int. J. Hydrogen Energy 2020, 45, 14603–14613. [Google Scholar] [CrossRef]

| Category | Parameter | Value |

|---|---|---|

| Vehicle Dynamics | Bus Model | ORION VI |

| Gross Vehicle Weight | 15,879 kg | |

| Wheelbase | 6.86 m | |

| Aerodynamic Drag Coefficient | 0.79 | |

| Frontal Area | 6.52 m2 | |

| Wheel Radius | 0.5 m | |

| Propulsion System | Electric Motor Type | 3-Phase AC Induction |

| Continuous Power | 187 kW | |

| Primary Power Source (APU) | 200 kW Fuel Cell Stack | |

| Energy Storage System (ESS) | NiMH Battery Pack | |

| ESS Module Capacity | 28 Ah | |

| ESS Module Voltage | 6 V | |

| ESS Module Count | 60 |

| No | (kW) | (kW) | (%) | (sec) | (Le/100 km) | (kg/100 km) | (%) |

|---|---|---|---|---|---|---|---|

| 1 | 125 | 187 | 12.4 | 26.3 | 37.3 | 9.9 | 22.21 |

| 2 | 125 | 200 | 12.5 | 26.2 | 37.4 | 9.94 | 22 |

| 3 | 125 | 215 | 12.6 | 26.2 | 37.5 | 9.97 | 21.72 |

| 4 | 125 | 230 | 12.6 | 26.1 | 37.6 | 9.99 | 21.47 |

| 5 | 125 | 245 | 12.6 | 26.1 | 37.7 | 10.02 | 21.32 |

| 6 | 125 | 260 | 12.6 | 26.1 | 37.7 | 10.04 | 21.2 |

| 7 | 125 | 275 | 12.6 | 26.1 | 37.9 | 10.06 | 21.08 |

| 8 | 150 | 187 | 12.3 | 25.2 | 40.6 | 10.78 | 16.78 |

| 9 | 150 | 200 | 13 | 25.2 | 39.9 | 10.62 | 17.67 |

| 10 | 150 | 215 | 13.1 | 25.1 | 40.1 | 10.65 | 17.38 |

| 11 | 150 | 230 | 13.1 | 25 | 40.2 | 10.68 | 17.15 |

| 12 | 150 | 245 | 13.2 | 25 | 40.3 | 10.71 | 16.97 |

| 13 | 150 | 260 | 13.3 | 25 | 40.4 | 10.74 | 16.82 |

| 14 | 150 | 275 | 13.3 | 25 | 41.2 | 10.96 | 15.63 |

| 15 | 175 | 187 | 12.2 | 24.4 | 42 | 11.16 | 15 |

| 16 | 175 | 200 | 13.2 | 24.3 | 42.1 | 11.18 | 14.72 |

| 17 | 175 | 215 | 13.6 | 24.2 | 41.3 | 10.99 | 15.74 |

| 18 | 175 | 230 | 13.7 | 24.2 | 41.4 | 11.02 | 15.53 |

| 19 | 175 | 245 | 13.7 | 24.1 | 41.5 | 11.04 | 15.36 |

| 20 | 175 | 260 | 13.8 | 24.1 | 41.6 | 11.07 | 15.22 |

| 21 | 175 | 275 | 13.8 | 24.1 | 42.6 | 11.32 | 13.86 |

| 22 [21] | 200 | 187 | 12.2 | 23.7 | 36.7 | 9.75 | 23.23 |

| 23 | 200 | 200 | 13.1 | 23.6 | 36.7 | 9.77 | 22.97 |

| 24 | 200 | 215 | 14.1 | 23.5 | 36.8 | 9.79 | 22.67 |

| 25 | 200 | 230 | 14.2 | 23.4 | 36.9 | 9.82 | 22.43 |

| 26 | 200 | 245 | 14.2 | 23.4 | 37 | 9.85 | 22.24 |

| 27 | 200 | 260 | 14.3 | 23.4 | 37.1 | 9.88 | 22.1 |

| 28 | 200 | 275 | 14.3 | 23.3 | 37.2 | 9.90 | 22.02 |

| No | (kw) | , kw | Number of Battery Modules | |

|---|---|---|---|---|

| 1 | 0 | 0 | 296 | 185 |

| 2 | 0.1 | 30.4 | 265.6 | 166 |

| 3 | 0.2 | 59.2 | 236.8 | 148 |

| 4 | 0.3 | 88 | 208 | 130 |

| 5 | 0.4 | 118.4 | 177.6 | 111 |

| 6 | 0.5 | 148.8 | 147.2 | 92 |

| 7 | 0.6 | 177.6 | 118.4 | 74 |

| 8 | 0.675 | 200 | 96 | 60 |

| 9 | 0.7 | 208 | 88 | 55 |

| 10 | 0.8 | 236.8 | 59.2 | 37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaya, A.F.; Puglia, M.; Morselli, N.; Allesina, G.; Pedrazzi, S. Optimizing the Powertrain of a Fuel Cell Electric Bus: A Sizing and Hybridization Analysis. Fuels 2025, 6, 78. https://doi.org/10.3390/fuels6040078

Kaya AF, Puglia M, Morselli N, Allesina G, Pedrazzi S. Optimizing the Powertrain of a Fuel Cell Electric Bus: A Sizing and Hybridization Analysis. Fuels. 2025; 6(4):78. https://doi.org/10.3390/fuels6040078

Chicago/Turabian StyleKaya, Ahmet Fatih, Marco Puglia, Nicolò Morselli, Giulio Allesina, and Simone Pedrazzi. 2025. "Optimizing the Powertrain of a Fuel Cell Electric Bus: A Sizing and Hybridization Analysis" Fuels 6, no. 4: 78. https://doi.org/10.3390/fuels6040078

APA StyleKaya, A. F., Puglia, M., Morselli, N., Allesina, G., & Pedrazzi, S. (2025). Optimizing the Powertrain of a Fuel Cell Electric Bus: A Sizing and Hybridization Analysis. Fuels, 6(4), 78. https://doi.org/10.3390/fuels6040078