Applied Intelligent Grey Wolf Optimizer (IGWO) to Improve the Performance of CI Engine Running on Emulsion Diesel Fuel Blends

Abstract

:1. Introduction

1.1. Literature Review on Emulsion Diesel Fuel

1.2. Literature Review on Optimization Methods for Diesel Engine Behavior

1.3. Research Gap, Objectives, and Novelty

2. Experimental Methodology

3. Modeling and Optimization

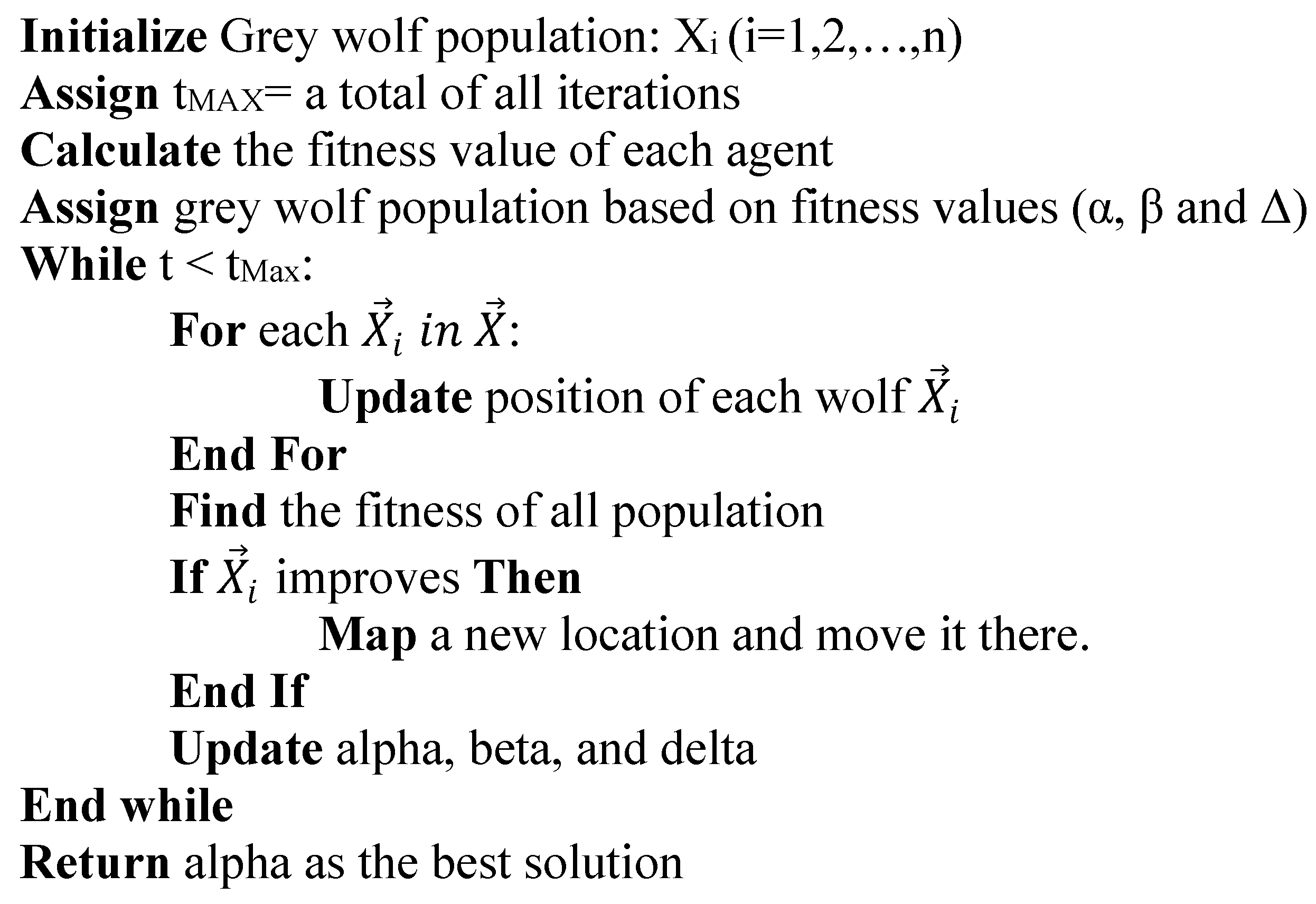

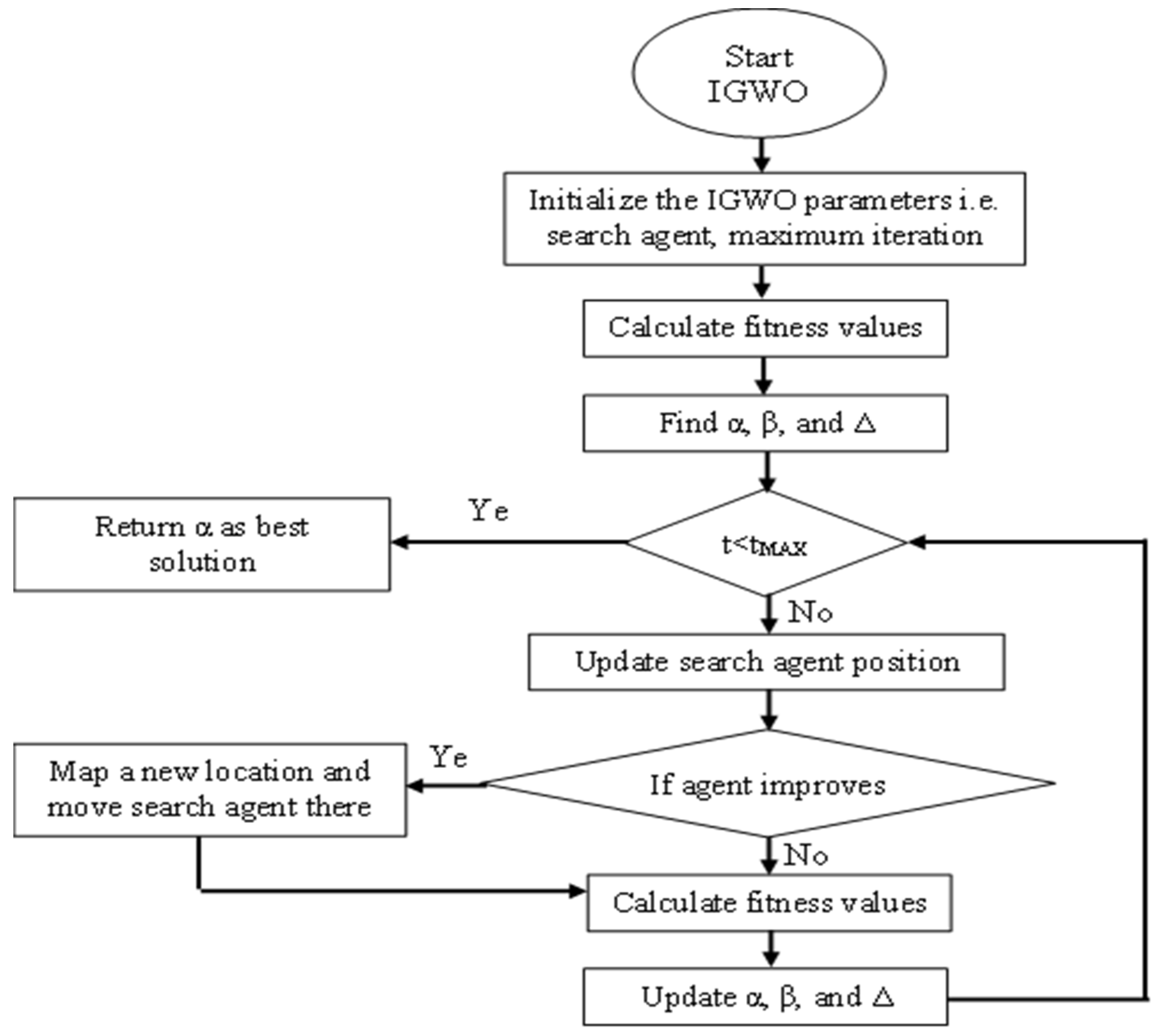

3.1. Grey Wolf Optimization (GWO)

3.2. Intelligent Gray Wolf Optimizer (IGWO)

4. Results and Discussion

4.1. Experimental Analysis

4.2. Regression Model and Optimization Process

4.2.1. Fitting Regression Models

4.2.2. IGWO Optimization

5. Limitations, Recommendations, and Future Works

- For the preparation of emulsified fuel, it is desirable to have higher stability of emulsified fuel with minimum expenditure of chemicals and power so that the emulsified fuel can be used for a more extended period. In order to solve this problem, it is necessary to optimize all the factors affecting the W/D emulsion fuel, including the blending speed, stirring duration, surfactant type and concentration, oil–water ratio, temperature, pH, and hydrophilic–lipophilic balance (HLB).

- In addition to other performance factors, the optimal water content should be determined by considering the full map of environmental behavior, which includes acoustic and exhaust emissions such as noise, carbon monoxide (CO), carbon dioxide (CO2), unburned hydrocarbon (UHC), particulate matter (PM) and soot, smoke opacity, and nitrogen oxides (NOx).

- The impact of W/D emulsion fuel on fuel attributes such as flash point and cetane number, besides Fourier-transform infrared spectroscopy (FTIR). In addition, combustion parameters such as combustion gas pressure profile, P.P. increase rate, heat release rate, IDT, combustion duration, and energy and exergy analyses of the CI engine’s behavior will be addressed in the forthcoming investigation.

- The effects of nanoparticle additives in W/D emulsion fuel on engine performance, exhaust emissions, and combustion behavior of a CI engine will be thoroughly examined.

- The present work suggests the following points:

- In order to avoid long-term stratification of the W/D emulsion fuel, a pump may be required to place in the bottom of a fuel tank to circulate the combination and avoid water.

- It is necessary to make adjustments to both the fuel filter and the fuel tank.

6. Conclusions

- The BP generated by a CI engine for various (W/D) emulsion diesel fuel ratios is highest when 5% water is added, with a 3% improvement and a slight reduction of -0.9% when 10% is added, compared to pure diesel. Because W/D emulsion fuel has a lower C.V. than pure diesel fuel, it releases less heat during combustion, which is responsible for the little drop in BP when less than 10% of water is introduced. However, a slight decrease in BP can be accepted when weighed against the enormous reduction in emissions achieved by utilizing W/D.

- The BSFC was lowest at 2000 rpm and 5% water addition. The average reduction in BSFC was −6.34% and −3.55% when utilizing 5% and 10%, respectively, compared to pure diesel. At high speed, the BSFC increased as the amount of water added to the fuel increased. However, at lower speeds, there was no substantial change in the BSFC with the quantity of additional water within the examined range.

- The maximum BTE for a CI engine was obtained with a W/D emulsion fuel ratio of 5%. The average BTE improvement was 7.94%, 5.6%, and 2.81% when water was added at levels of 5%, 10%, and 15%, respectively. Beyond this, the BTE was lower than pure diesel within the studied range as the amount of water in the emulsion increased. The improvement in BTE was due to the increased BP. Furthermore, the amount of water in the emulsion is responsible for the considerable delay in the ignition and produces latent heat during the process of vaporization. Therefore, when the ignition is delayed, which creates micro-explosions, the combustion efficiency improves dramatically.

- The CI engine generated much less NOx when the W/D emulsion fuel was utilized. The drop varied between 3.22 and 67.14%, according to the water content. This is related to the emulsion’s finely distributed water droplets causing a phenomenon known as a heat sink, which reduces the temperature of an adiabatic flame.

- The viscosity of the W/D emulsion increases with the addition of water until a value of 43 centipoises at 15% water and subsequently drops. However, boosting the viscosity of W/D emulsions leads to an advanced injection time in particular injection systems.

- The MPR model and IGWO algorithms agreed well with actual experimental findings. IGWO offered optimized parameters, enhanced exploration capabilities, and a desirable computational time.

- According to the IGWO algorithm, the fuel blend with 9% water addition has the highest BTE of 33.3%, the highest BP of 11.2 kW, the lowest BSFC of 0.259 kg/kW·h, and the lowest reduction in NOx exhaust emission to 419 ppm at 1998 rpm engine speed. While according to the GWO algorithm, the fuel blend with 12% water addition has the highest BTE of 32.8%, the highest BP of 10.7 kW, the lowest BSFC of 0.274 kg/kW·h, and the lowest reduction in NOx exhaust emission to 402 ppm.

- Regarding the optimizer, the IGWO shows better results than GWO in finding the best water addition engine speed. This is because, in the early stages of searching, IGWO has strong exploration capabilities. In the later stages of searching, it has strong exploitation capabilities. Additionally, the wolf update mechanism in IGWO can lessen the likelihood of encountering the local optimum.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| List of Abbreviations | |

| ABC | artificial bee colony |

| ANN | artificial neural network |

| ANOVA | analysis of variance |

| BP | brake power |

| BSFC | Brake-specific fuel consumption |

| BT | brake torque |

| BTE | brake thermal efficiency |

| CI | compression ignition |

| C.C. | combustion chamber |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CR | compression ratio |

| CS | constant engine speed |

| C.V. | calorific value |

| DC | direct current |

| EGR | exhaust gas recirculation |

| FL | Full load |

| GA | genetic algorithm |

| GWO | grey wolf optimizer |

| IGWO | intelligent grey wolf optimizer |

| IDT | ignition delay time |

| LL | lower limit |

| MAE | mean absolute error |

| MPR | multivariate polynomial regression |

| NOx | nitrogen oxides |

| OBL | opposition-based learning |

| PM | particulate matter |

| P.P. | peak pressure |

| PSO | particle swarm optimization |

| RME | rapeseed methyl ester |

| SFC | specific fuel consumption |

| SI | spark ignition |

| TDC | top dead center |

| UHC | unburn hydrocarbon |

| UL | upper limit |

| VCR | variable compression ratio |

| VL | variable load |

| VS | variable engine speed |

| W/D | water-in-diesel |

| WOA | whale optimization algorithm |

| List of symbols | |

| A, C | vectors |

| d | search space dimension |

| Dα, Dβ, and Dδ | updated location |

| n | polynomial degree |

| r1, r2 | random vectors |

| R2 | correlation coefficient |

| t | current iteration |

| x | a variable |

| X (t) | location of a wolf |

| x, x1, x2 | independent variables |

| XP(t) | updated position |

| y | dependent variable |

| Greek symbols | |

| regulate the movement of the wolf | |

| uncertainty error | |

| β | wolf, regression coefficient |

| ω | realistic error, omega wolves |

| wolf, intercept | |

| δ | wolf |

References

- Alahmer, A.; Aladayleh, W. Effect two grades of octane numbers on the performance, exhaust and acoustic emissions of spark ignition engine. Fuel 2016, 180, 80–89. [Google Scholar] [CrossRef]

- Zacharczuk, W.; Andruszkiewicz, A.; Tatarek, A.; Alahmer, A.; Alsaqoor, S. Effect of Ca-based additives on the capture of SO2 during combustion of pulverized lignite. Energy 2021, 231, 120988. [Google Scholar] [CrossRef]

- Alsaqoor, S.; Alahmer, A.; Aljabarin, N.; Gougazeh, M.; Czajczynska, D.; Krzyzynska, R. Effects of utilization of solid and semi-solid organic waste using pyrolysis techniques. In Proceedings of the 2017 8th International Renewable Energy Congress (IREC), Amman, Jordan, 21–23 March 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Khalife, E.; Tabatabaei, M.; Najafi, B.; Mirsalim, S.M.; Gharehghani, A.; Mohammadi, P.; Aghbashlo, M.; Ghaffari, A.; Khounani, Z.; Shojaei, T.R. A Novel Emulsion Fuel Containing Aqueous Nano Cerium Oxide Additive in Diesel–Biodiesel Blends to Improve Diesel Engines Performance and Reduce Exhaust Emissions: Part I—Experimental Analysis. Fuel 2017, 207, 741–750. [Google Scholar] [CrossRef]

- Vellaiyan, S.; Amirthagadeswaran, K.S. Emission characteristics of water-emulsified diesel fuel at optimized engine operation condition. Pet. Sci. Technol. 2017, 35, 1355–1363. [Google Scholar] [CrossRef]

- Alahmer, A. Influence of using emulsified diesel fuel on the performance and pollutants emitted from diesel engine. Energy Convers. Manag. 2013, 73, 361–369. [Google Scholar] [CrossRef]

- Scarpete, D. Diesel-Water Emulsion, an Alternative Fuel to Reduce Diesel Engine Emissions. A Review. Mach. Technol. Mater. 2013, 7, 13–16. [Google Scholar]

- Syafiq, Z.; Fahmi, O.; Awad, I.O.; Adam, A. The study of stability, combustion characteristics and performance of water in diesel emulsion fuel. MATEC Web Conf. 2016, 90, 1022. [Google Scholar] [CrossRef] [Green Version]

- Tan, Y.H.; Abdullah, M.O.; Nolasco-Hipolito, C.; Zauzi, N.S.A.; Abdullah, G.W. Engine performance and emissions characteristics of a diesel engine fueled with diesel-biodiesel-bioethanol emulsions. Energy Convers. Manag. 2016, 132, 54–64. [Google Scholar] [CrossRef]

- Ghojel, J.I.; Tran, X.-T. Ignition Characteristics of Diesel–Water Emulsion Sprays in a Constant-Volume Vessel: Effect of Injection Pressure and Water Content. Energy Fuels 2010, 24, 3860–3866. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, N.; Vibhanshu, V.; Deep, A. Emission Studies on a VCR Engine Using Stable Diesel Water Emulsion; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Seifi, M.R.; Hassan-Beygi, S.R.; Ghobadian, B.; Desideri, U.; Antonelli, M. Experimental Investigation of a Diesel Engine Power, Torque and Noise Emission Using Water–Diesel Emulsions. Fuel 2016, 166, 392–399. [Google Scholar] [CrossRef]

- Azimi, M.; Mirjavadi, S.S.; Davari, E.; Seifi, M.R. The effect of water-diesel emulsion usage on a tractor engine performance and emission. Russ. Agric. Sci. 2016, 42, 488–492. [Google Scholar] [CrossRef]

- Kumar, N.; Sharma, A.; Vibhanshu, V. Performance Analyses of Diesel Engine at Different Injection Angles Using Water Diesel Emulsion; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Syu, J.-Y.; Chang, Y.-Y.; Tseng, C.-H.; Yan, Y.-L.; Chang, Y.-M.; Chen, C.-C.; Lin, W.-Y. Effects of water-emulsified fuel on a diesel engine generator’s thermal efficiency and exhaust. J. Air Waste Manag. Assoc. 2014, 64, 970–978. [Google Scholar] [CrossRef] [Green Version]

- Ithnin, A.M.; Ahmad, M.A.; Abu Bakar, M.A.; Rajoo, S.; Yahya, W.J. Combustion performance and emission analysis of diesel engine fuelled with water-in-diesel emulsion fuel made from low-grade diesel fuel. Energy Convers. Manag. 2015, 90, 375–382. [Google Scholar] [CrossRef]

- Attia, A.M.; Kulchitskiy, A. Influence of the structure of water-in-fuel emulsion on diesel engine performance. Fuel 2014, 116, 703–708. [Google Scholar] [CrossRef]

- Pamminger, M.; Wang, B.; Hall, C.M.; Vojtech, R.; Wallner, T. The impact of water injection and exhaust gas recirculation on combustion and emissions in a heavy-duty compression ignition engine operated on diesel and gasoline. Int. J. Engine Res. 2019, 21, 1555–1573. [Google Scholar] [CrossRef]

- Korakianitis, T.; Namasivayam, A.; Crookes, R. Hydrogen dual-fuelling of compression ignition engines with emulsified biodiesel as pilot fuel. Int. J. Hydrogen Energy 2010, 35, 13329–13344. [Google Scholar] [CrossRef]

- Alahmer, H.; Alahmer, A.; Alkhazaleh, R.; Alrbai, M. Exhaust Emission Reduction of a SI Engine Using Acetone–Gasoline Fuel Blends: Modeling, Prediction, and Whale Optimization Algorithm. Energy Rep. 2023, 9, 77–86. [Google Scholar] [CrossRef]

- Kumar, N.; Raheman, H.; Machavaram, R. Performance of a diesel engine with water emulsified diesel prepared with optimized process parameters. Int. J. Green Energy 2019, 16, 687–701. [Google Scholar] [CrossRef]

- Khanjani, A.; Sobati, M.A. Performance and emission of a diesel engine using different water/waste fish oil (WFO) biodiesel/diesel emulsion fuels: Optimization of fuel formulation via response surface methodology (RSM). Fuel 2021, 288, 119662. [Google Scholar] [CrossRef]

- Alahmer, A.; Rezk, H.; Aladayleh, W.; Mostafa, A.O.; Abu-Zaid, M.; Alahmer, H.; Gomaa, M.R.; Alhussan, A.A.; Ghoniem, R.M. Modeling and Optimization of a Compression Ignition Engine Fueled with Biodiesel Blends for Performance Improvement. Mathematics 2022, 10, 420. [Google Scholar] [CrossRef]

- Alahmer, A.; Alahmer, H.; Handam, A.; Rezk, H. Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization. Sustainability 2022, 14, 1367. [Google Scholar] [CrossRef]

- Vellaiyan, S.; Amirthagadeswaran, K.S. Taguchi-Grey relational-based multi-response optimization of the water-in-diesel emulsification process. J. Mech. Sci. Technol. 2016, 30, 1399–1404. [Google Scholar] [CrossRef]

- Lin, H.-C.; Su, C.-T.; Wang, C.-C.; Chang, B.-H.; Juang, R.-C. Parameter optimization of continuous sputtering process based on Taguchi methods, neural networks, desirability function, and genetic algorithms. Expert Syst. Appl. 2012, 39, 12918–12925. [Google Scholar] [CrossRef]

- Ahmad, N.; Janahiraman, T.V. A Comparison on Optimization of Surface Roughness in Machining AISI 1045 Steel Using Taguchi Method, Genetic Algorithm and Particle Swarm Optimization. In Proceedings of the 2015 IEEE Conference on Systems, Process and Control (ICSPC), Bandar Sunway, Malaysia, 18–20 December 2015; pp. 129–133. [Google Scholar]

- Alahmer, A.; Ajib, S. Solar cooling technologies: State of art and perspectives. Energy Convers. Manag. 2020, 214, 112896. [Google Scholar] [CrossRef]

- Patil, H.; Gadhave, A.; Mane, S.; Waghmare, J. Analyzing the Stability of the Water-in-Diesel Fuel Emulsion. J. Dispers. Sci. Technol. 2014, 36, 1221–1227. [Google Scholar] [CrossRef]

- Alahmer, A. Reduction a Particulate Matter of Diesel Emission by the Use of Several Oxygenated Diesel Blend Fuels. Int. J. Therm. Environ. Eng. 2014, 7, 45–50. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Saxena, A.; Soni, B.P.; Kumar, R.; Gupta, V. Intelligent Grey Wolf Optimizer—Development and application for strategic bidding in uniform price spot energy market. Appl. Soft Comput. 2018, 69, 1–13. [Google Scholar] [CrossRef]

- Mahdavi, S.; Rahnamayan, S.; Deb, K. Opposition based learning: A literature review. Swarm Evol. Comput. 2018, 39, 1–23. [Google Scholar] [CrossRef]

- Dryer, F. Water addition to practical combustion systems—Concepts and applications. Symp. (Int.) Combust. 1977, 16, 279–295. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Sobati, M.A. Performance and emission characteristics of a diesel engine operating on different water in diesel emulsion fuels: Optimization using response surface methodology (RSM). Front. Energy 2019, 13, 636–657. [Google Scholar] [CrossRef]

- Alam Fahd, M.E.; Wenming, Y.; Lee, P.; Chou, S.; Yap, C.R. Experimental investigation of the performance and emission characteristics of direct injection diesel engine by water emulsion diesel under varying engine load condition. Appl. Energy 2013, 102, 1042–1049. [Google Scholar] [CrossRef]

- Okumuş, F.; Kaya, C.; Kökkülünk, G. NOX Based Comparative Analysis of a CI Engine Fueled with Water in Diesel Emulsion. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–20. [Google Scholar] [CrossRef]

- Nadeem, M.; Rangkuti, C.; Anuar, K.; Haq, M.; Tan, I.; Shah, S. Diesel engine performance and emission evaluation using emulsified fuels stabilized by conventional and gemini surfactants. Fuel 2006, 85, 2111–2119. [Google Scholar] [CrossRef]

- Selim, M.Y.E.; Ghannam, M.T. Combustion Study of Stabilized Water-in-Diesel Fuel Emulsion. Energy Sources Part A: Recover. Util. Environ. Eff. 2009, 32, 256–274. [Google Scholar] [CrossRef]

- Yang, W.; An, H.; Chou, S.; Chua, K.; Mohan, B.; Sivasankaralingam, V.; Raman, V.; Maghbouli, A.; Li, J. Impact of emulsion fuel with nano-organic additives on the performance of diesel engine. Appl. Energy 2013, 112, 1206–1212. [Google Scholar] [CrossRef]

- Ithnin, A.M.; Noge, H.; Kadir, H.A.; Jazair, W. An overview of utilizing water-in-diesel emulsion fuel in diesel engine and its potential research study. J. Energy Inst. 2014, 87, 273–288. [Google Scholar] [CrossRef]

- Alahmer, A.; Yamin, J.; Sakhrieh, A.; Hamdan, M. Engine performance using emulsified diesel fuel. Energy Convers. Manag. 2010, 51, 1708–1713. [Google Scholar] [CrossRef]

- Abu-Zaid, M. Performance of single cylinder, direct injection Diesel engine using water fuel emulsions. Energy Convers. Manag. 2004, 45, 697–705. [Google Scholar] [CrossRef]

- Vellaiyan, S.; Amirthagadeswaran, K.S. Influence of Water-in-Diesel Emulsion Fuel and Compression Ratio on Combustion, Performance and Emission Characteristics of Diesel Engine. J. Sustain. Energy Eng. 2016, 3, 238–253. [Google Scholar] [CrossRef]

- Ghojel, J.; Honnery, D.; Al-Khaleefi, K. Performance, emissions and heat release characteristics of direct injection diesel engine operating on diesel oil emulsion. Appl. Therm. Eng. 2006, 26, 2132–2141. [Google Scholar] [CrossRef]

- Wang, C.-H.; Chen, J.-T. An experimental investigation of the burning characteristics of water-oil emulsions. Int. Commun. Heat Mass Transf. 1996, 23, 823–834. [Google Scholar] [CrossRef]

- Khan, M.Y.; Karim, Z.A.A.; Hagos, F.Y.; Aziz, A.R.A.; Tan, I.M. Current Trends in Water-in-Diesel Emulsion as a Fuel. Sci. World J. 2014, 2014, 527472. [Google Scholar] [CrossRef] [Green Version]

- Subramanian, K. A comparison of water–diesel emulsion and timed injection of water into the intake manifold of a diesel engine for simultaneous control of NO and smoke emissions. Energy Convers. Manag. 2011, 52, 849–857. [Google Scholar] [CrossRef]

- Basha, J.S.; Anand, R.B. An Experimental Study in a CI Engine Using Nanoadditive Blended Water–Diesel Emulsion Fuel. Int. J. Green Energy 2011, 8, 332–348. [Google Scholar] [CrossRef]

- Jazair, W.; Kubo, S.; Takayasu, M.; Yatsufusa, T.; Kidoguchi, Y. Performance and Emission Characteristics of a Diesel Engine Fueled by Rapeseed Oil Bio-Fuel. J. Mek. 2011, 33, 32–39. [Google Scholar]

- Selim, M.Y.E.; Elfeky, S.M.S. Effects of Diesel/Water Emulsion on Heat Flow and Thermal Loading in a Precombustion Chamber Diesel Engine. Appl. Therm. Eng. 2001, 21, 1565–1582. [Google Scholar] [CrossRef]

- Kleinbaum, D.G.; Kupper, L.L.; Nizam, A.; Rosenberg, E.S. Applied Regression Analysis and Other Multivariable Methods; Cengage Learning: Boston, MA, USA, 2013; ISBN 128596375X. [Google Scholar]

- Kannan, K.; Udayakumar, M. NOx and HC Emission Control Using Water Emulsified Diesel in Single Cylinder Diesel Engine. ARPN J. Eng. Appl. Sci. 2009, 4, 59–62. [Google Scholar]

- Senthur, N.; BalaMurugan, S.; RamGanesh, H.; Divakara, S. Experimental analysis on the performance, emission, and combustion characteristics of diesel, and diesel-water emulsions in low heat rejection engine. Mater. Today Proc. 2021, 39, 1351–1355. [Google Scholar] [CrossRef]

- Hassan, Z.U.; Usman, M.; Asim, M.; Kazim, A.H.; Farooq, M.; Umair, M.; Imtiaz, M.U.; Asim, S.S. Use of diesel and emulsified diesel in CI engine: A comparative analysis of engine characteristics. Sci. Prog. 2021, 104. [Google Scholar] [CrossRef]

- Khatri, D.; Goyal, R.; Jain, A.; Johnson, A.T. Modeling and optimization of stability aspects for water diesel emulsified fuel using response surface methodology. Energy Sources Part A: Recover. Util. Environ. Eff. 2021, 44, 3055–3078. [Google Scholar] [CrossRef]

| Parameter | Diesel Engine Specifications |

|---|---|

| Type | Automotive 30 test bed |

| Bore × Stroke | 72.25 × 88.18 mm |

| Number of cylinders | Four cylinders |

| Engine operation | Four strokes |

| Type of injection | Direct injection |

| Air intake process | Naturally aspirated |

| Type of cooling | Water cooled |

| Swept volume | 1450 cc |

| Compression ratio | 21.5:1 |

| Intake and exhaust valve diameter | 34.51 × 28.49 mm |

| Connected rod length | 155.8 mm |

| Dynamometer | 400 V (nominal) DC machine |

| Indicator | Water Addition | |||||

|---|---|---|---|---|---|---|

| 5% | 10% | 15% | 20% | 25% | 30% | |

| BP | 3.00% | −0.90% | −7.90% | −17.64% | −26.43% | −34.61% |

| BSFC | −6.34% | −3.55% | 6.34% | 19.50% | 27.82% | 44.30% |

| BTE | 7.94% | 5.60% | 2.81% | −5.06% | −3.65% | −8.35% |

| NOx | −3.22% | −9.60% | −20.42% | −53.40% | −64.38% | −67.14% |

| Experiment | MAE | R2 |

|---|---|---|

| BP | 0.0188 | 0.994 |

| BTE | 0.0398 | 0.977 |

| BSFC | 0.0219 | 0.983 |

| NOx | 0.0208 | 0.986 |

| Parameter | Multivariate Polynomial Regression |

|---|---|

| BP (Equation (17)) | BP = −4.29312 + 14.5003X2 + 0.00983599X1 − 0.00754671X1X2 − 9.93347 × 10−7X12 − 43.6933X22 |

| BTE (Equation (18)) | BTE = −33.20698 + 122.5826X2 − 427.2943X22 + 0.07284862X1 − 0.06358392X1X2 + 0.00511619X1X22 − 2.618367 × 10−5X12 + 1.171184 × 10−5X12X2 + 2.798286 × 10−9X13 + 780.7556X23 |

| BSFC (Equation (19)) | BSFC = 1.2528 − 1.2505X2 + 6.6962X22 − 0.0011662X1 + 0.00036386X1X2 + 8.4762 × 10−5X1X22 + 4.4791 × 10−7X12 − 3.2857 × 10−8X12X2 + −5.4 × 10−11X13 − 9.8667X23 |

| NOx (Equation (19)) | NOx = 963.507143 − 158.968254X2 − 18793.3333X22 − 0.738604762X1 + 1.02732653X1X2 − 1.26X1X22 + 0.0003585X12 − 0.00013122449X12X2 − 5.35238095 × 10−8X13 + 43777.7778X23 |

| Response | Df | f-Value | p-Value |

|---|---|---|---|

| BP | 2 | 45.45034 | 0.0028 |

| BTE | 3 | 22.04998 | 0.0019 |

| BSFC | 4 | 5.2616 | 0.0026 |

| NOx | 3 | 1.1334 | 0.0069 |

| Optimizer | Engine Speed (rpm) | Water Addition % | BP (kW) | BTE (%) | BSFC (kg/kW·h) | NOx (ppm) |

|---|---|---|---|---|---|---|

| GWO | 1999 | 12% | 10.7 | 32.8 | 0.274 | 402 |

| IGWO | 1998 | 9% | 11.2 | 33.3 | 0.259 | 419 |

| Ref. | CI Engine | Experimental Conditions | Water Addition | Engine Performance | Exhaust Emission | Optimal Blend |

|---|---|---|---|---|---|---|

| Current Study | 4 Stroke, 4 Cylinder, DI, Water-cooled | FL, VS (1000–3000) rpm | 0–30% Vol., 5% increment | BP ↑ until 5% BSFC ↓ until 10% BTE until 15% | NOx ↓ | 9% (according MPR-IGWO) 12% (according MPR-GWO) |

| Sharma et al., 2013 [11] | 4 strokes, VCR, 661 cc, water-cooled | VL and VCR | 0–25% Vol., 5% increment | BSFC ↓ and BTE ↑ | CO ↓, UHC ↓, smoke ↓ and NOx ↓ | 10% low CR, 25% high CR |

| Azimi et al., 2016 [13] | 4 strokes, four-cylinder, water-cooled | VS (1600–1900) rpm | 0, 2, 5, 8, and 10% Vol. | PB ↓ and BT ↑ | CO ↑, UHC ↓, and NOx ↓ | 2% |

| Hoseini and Sobati, 2019 [35] | 4 stroke, Single cylinder, 510 CC | CS (1800 rpm), FL | 0–20% Vol., 5% increment | PB ↓, BT ↓, BTE ↑, and BSFC ↑ | CO ↑, UHC ↑, CO2 ↑, and NOx ↓ | 5% |

| Okumş et al., 2020 [37] | 4 stroke, Single cylinder, 510 CC | VS and FL | 0–15% Vol., 5% increment | PB ↓, BT ↓, and BSFC ↑ | NOx ↓ | 10% |

| Selim and Ghannam, 2009 [39] | 4 stroke, Single cylinder, | VS, VL, VCR, and variable injection time | 0–30% Vol., 5% increment | PB ↓ and BSFC ↑ | - | 20% |

| Abu Zaid, 2004 [43] | 4 stroke, Single cylinder, 659 CC | FL, VS (1200–3300) rpm | 0–20% Vol., 5% increment | BT ↑, PB ↑, BTE ↑, and BSFC ↓ | - | 20% |

| Kannan and Udayakumar, 2009 [53] | 4 stroke, Single cylinder | CS, pressure fuel injection 200 bars | 0–20% Vol., 10% increment | BSFC ↓ and BTE ↑ | CO ↓, and NOx ↓ | 20% |

| Senthur et al., 2021 [54] | 4 stroke, Single cylinder, 661 CC | VL | 0–15% Vol., 5% increment | BTE ↑, and SFC ↑ Except 15% water addition | CO ↓, UHC ↓, smoke ↓, and NOx ↓ | 15% |

| Hassan et al., 2021 [55] | 4 stroke, Single cylinder, | VL | 0–10% Vol., 2% increment | BSFC ↑ and BTE ↓ | CO ↑, UHC ↑, smoke ↓, and NOx ↓ | 10% |

| Khatri et al., 2021 [56] | 4 stroke, Single cylinder, VCR | CS (1500 rpm) | 0 and 5% Vol. | BSFC ↑ and BTE ↓ | CO ↓, UHC ↓, smoke ↓, and NOx ↓ | 5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alahmer, H.; Alahmer, A.; Alkhazaleh, R.; Alrbai, M.; Alamayreh, M.I. Applied Intelligent Grey Wolf Optimizer (IGWO) to Improve the Performance of CI Engine Running on Emulsion Diesel Fuel Blends. Fuels 2023, 4, 35-57. https://doi.org/10.3390/fuels4010004

Alahmer H, Alahmer A, Alkhazaleh R, Alrbai M, Alamayreh MI. Applied Intelligent Grey Wolf Optimizer (IGWO) to Improve the Performance of CI Engine Running on Emulsion Diesel Fuel Blends. Fuels. 2023; 4(1):35-57. https://doi.org/10.3390/fuels4010004

Chicago/Turabian StyleAlahmer, Hussein, Ali Alahmer, Razan Alkhazaleh, Mohammad Alrbai, and Malik I. Alamayreh. 2023. "Applied Intelligent Grey Wolf Optimizer (IGWO) to Improve the Performance of CI Engine Running on Emulsion Diesel Fuel Blends" Fuels 4, no. 1: 35-57. https://doi.org/10.3390/fuels4010004

APA StyleAlahmer, H., Alahmer, A., Alkhazaleh, R., Alrbai, M., & Alamayreh, M. I. (2023). Applied Intelligent Grey Wolf Optimizer (IGWO) to Improve the Performance of CI Engine Running on Emulsion Diesel Fuel Blends. Fuels, 4(1), 35-57. https://doi.org/10.3390/fuels4010004