Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP)

Abstract

1. Introduction

2. Literature Review

3. Experimental Methodology

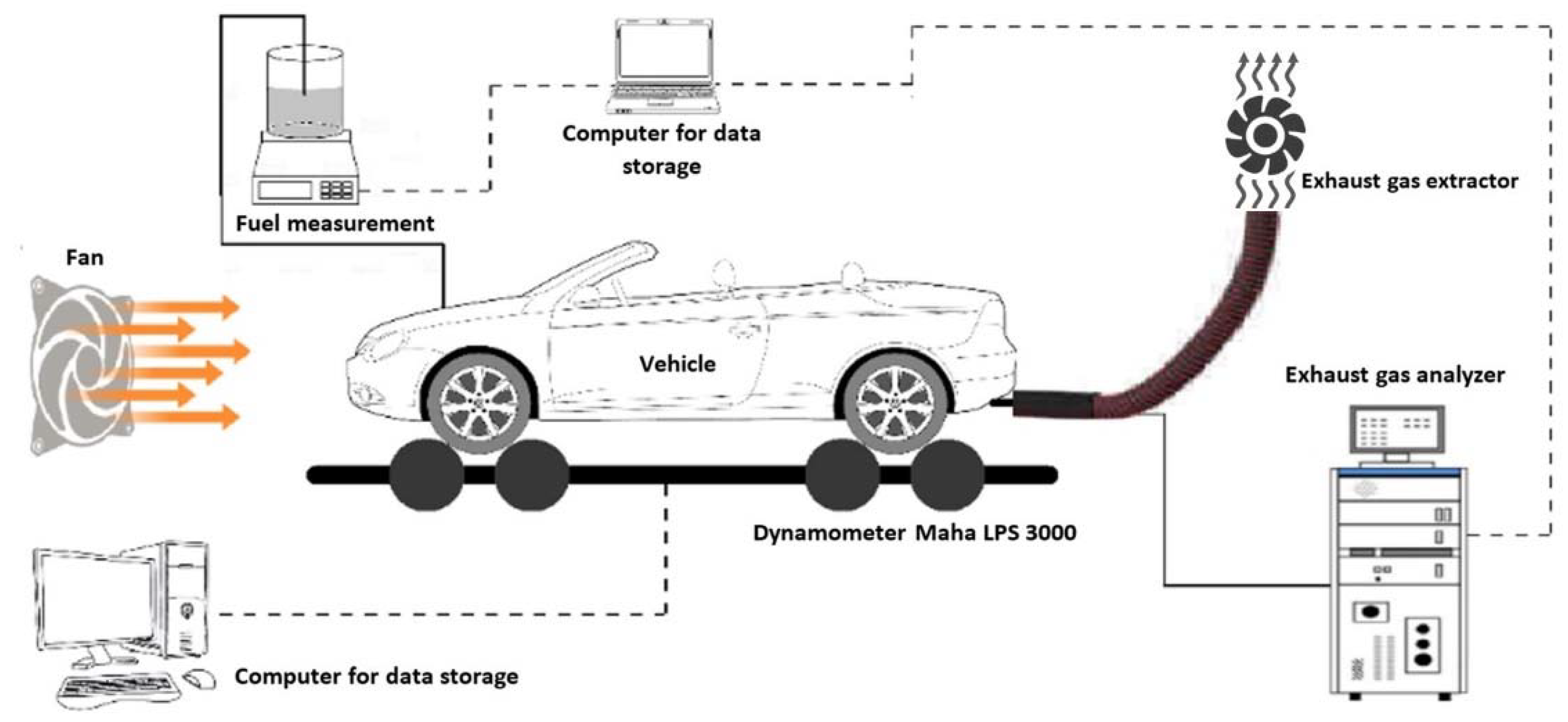

3.1. Laboratory Procedure and Resources

- ○

- The vehicle is located on the chassis dynamometer that measures the engine’s performance (power and torque) and wheel speed.

- ○

- The atmospheric conditions inside the laboratory were controlled and acquired to assure similar conditions. By means of a fan, a continuous airflow was maintained, simulating a speed of 90 km/h; this speed does not coincide with the vehicle speed, but it is the same in all tests and allows an effective engine cooling.

- ○

- The fuel that was consumed by the vehicle comes from a vessel positioned on a digital gravimetric weight scale, which continuously measures the mass of the fuel.

- ○

- Emissions from the exhaust pipe were measured through a sample that was picked and driven to the exhaust gas analyzer.

3.2. Vehicle

- -

- The piezo injectors (very precise) assume a vertical and centered position relative to the cylinder, in order to spray in the center of the piston. Furthermore, the injection moment and the injection pressure are parameters controlled according to the engine load and rotation, and the pressure can reach 1800 bar, which greatly favors the air–fuel mixture and there are pre-injections and post-injections, in addition to the main injection.

- -

- The system is equipped with two EGR valves associated with different circuits: high pressure and low pressure. The high-pressure circuit directs part of the gases released by the engine directly to the intake, having its line of action at low loads and engine speeds. The low-pressure circuit guides part of the exhaust gases to the particulate filter outlet for the intake of the turbocharger.

- -

- The exhaust system of the vehicle used in the tests has a catalytic oxidation converter and a particulate filter. The particle filter is located very close to the engine, immediately after the oxidation catalyst. As a result, the temperature may be increased, which aids in the system’s optimal working. Thus, in addition to helping ensure effective regeneration, the amount of fuel inherent to post-injections to increase the temperature is reduced. It is important to note that the oxidation catalytic converter is accountable for transforming hydrocarbons (HC) and carbon monoxide (CO) (polluting gases) into water and carbon dioxide (CO2) and, the particulate filter enables the conversion of soot to CO2.

3.3. Fuels

4. Results and Discussion

4.1. Fuel Consumption and Gaseous Emissions

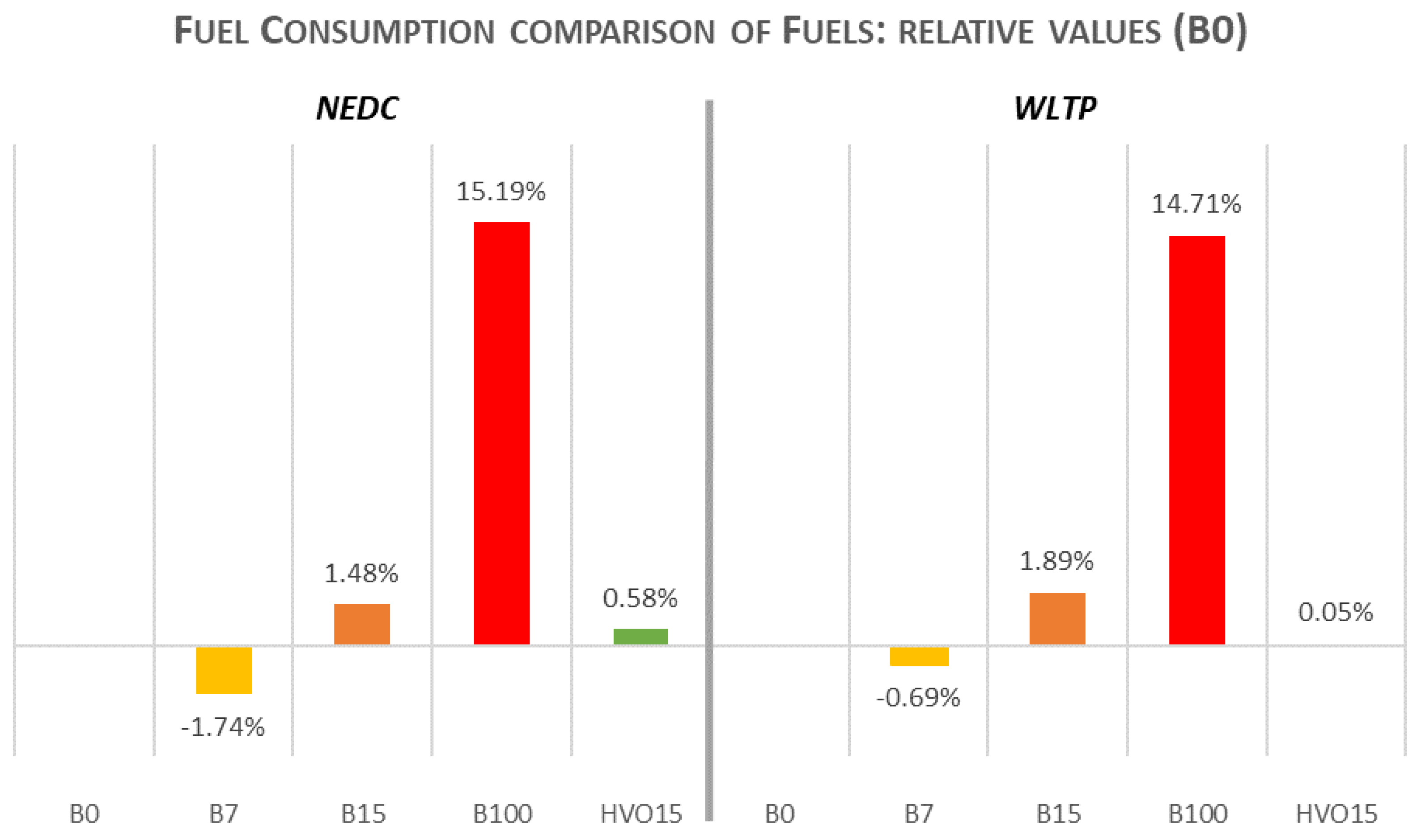

4.1.1. Mass of Fuel Consumed

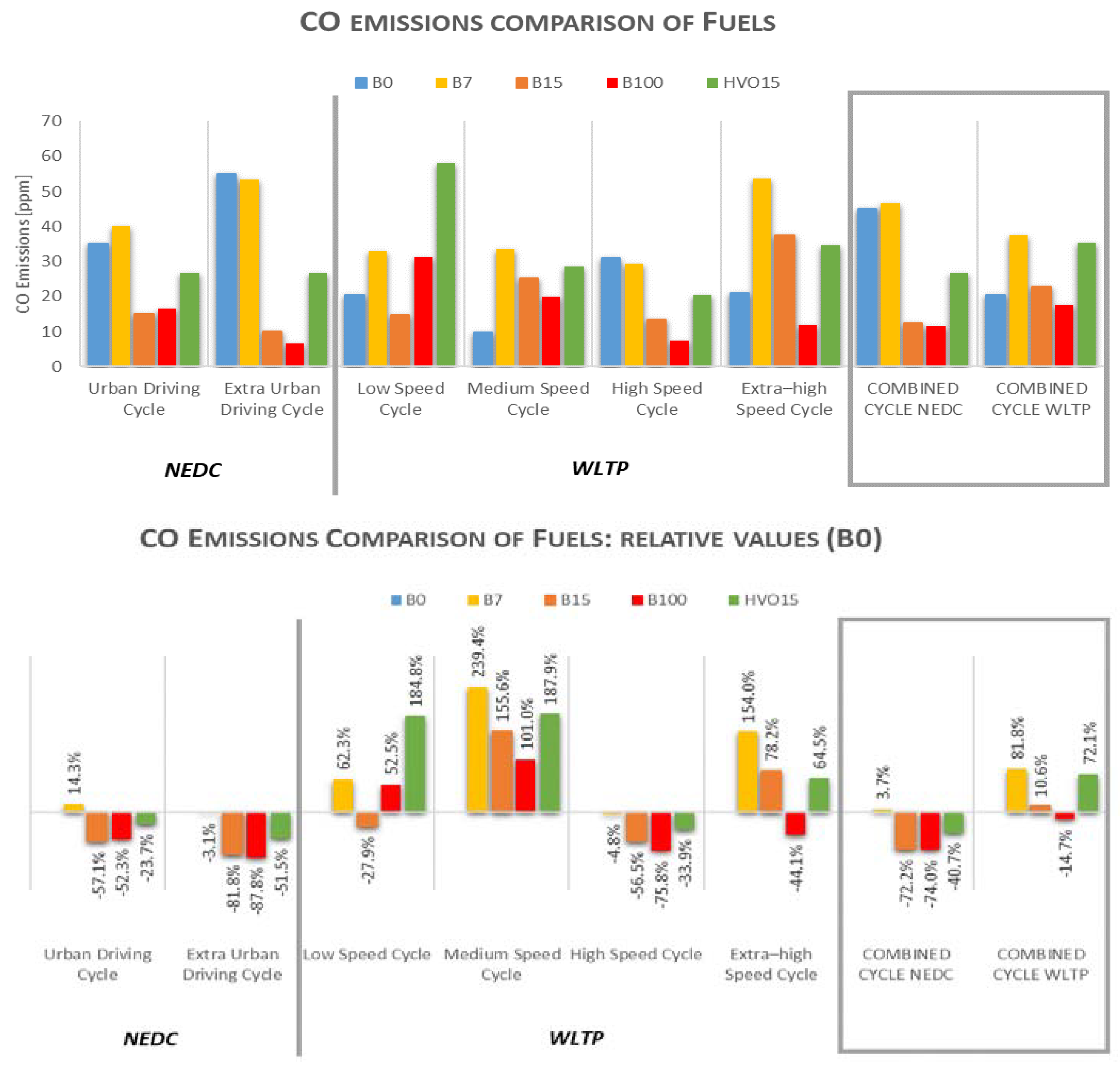

4.1.2. Carbon Oxide (CO)

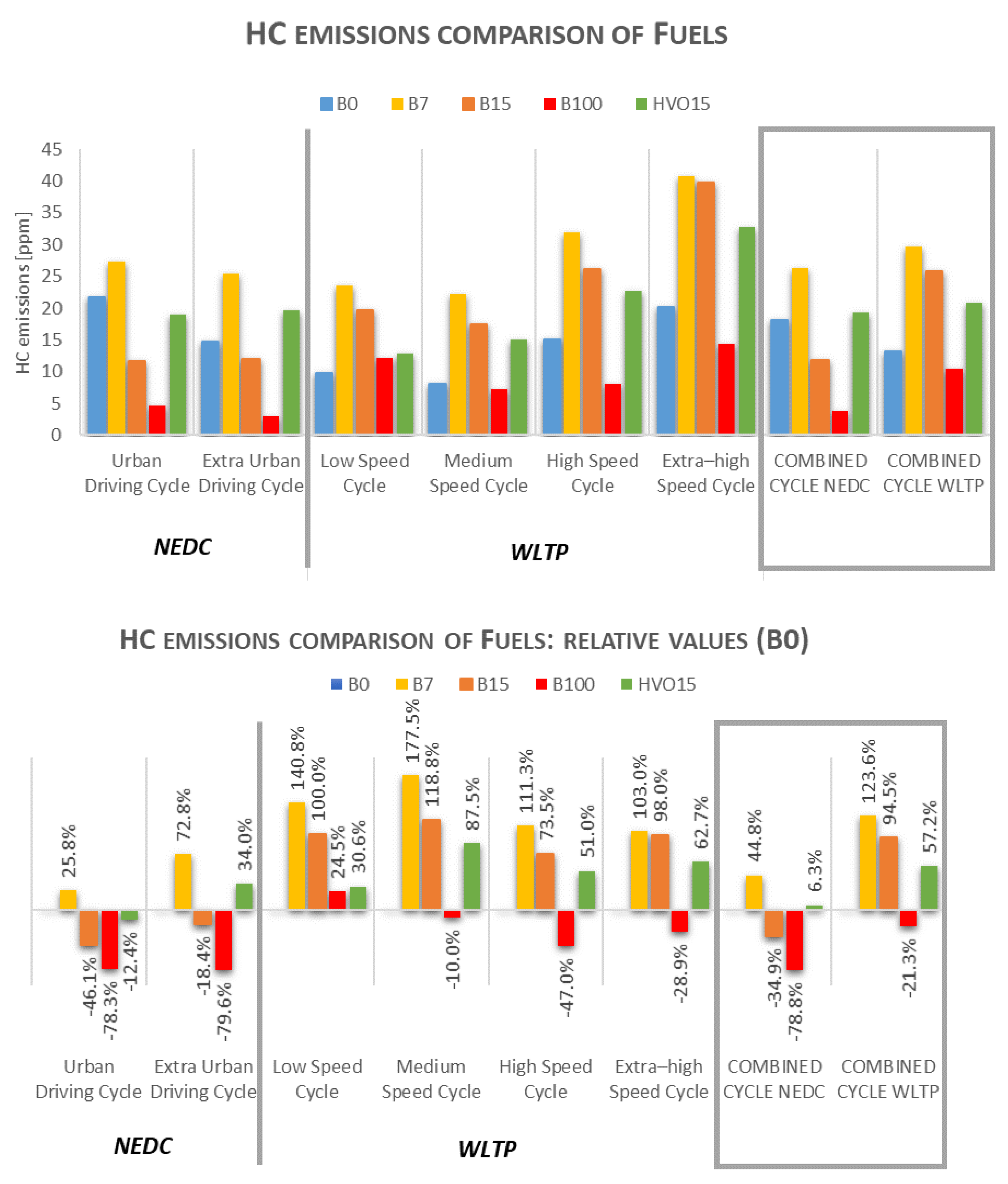

4.1.3. Hydrocarbons (HC)

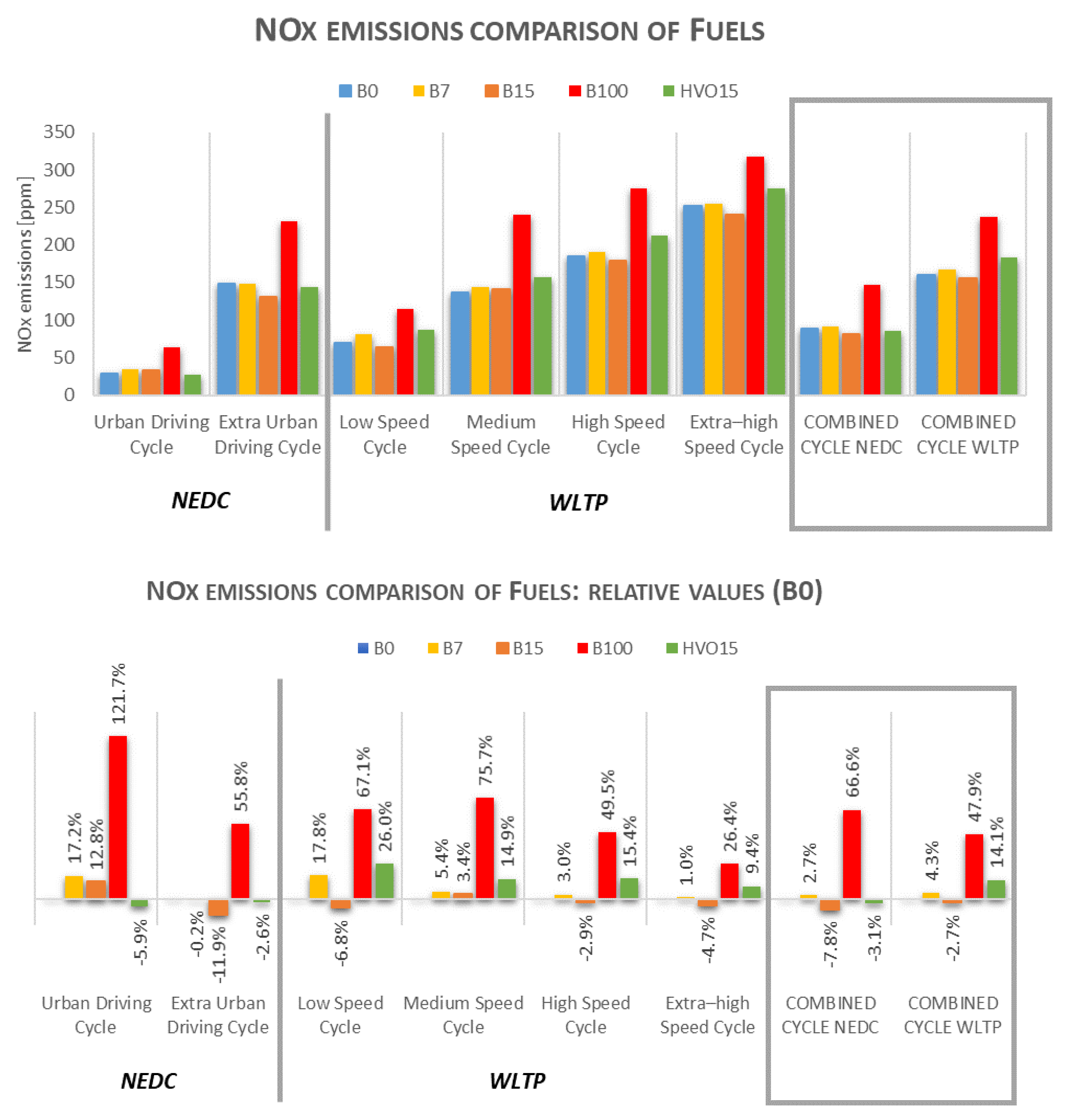

4.1.4. Nitrogen Oxides (NOx)

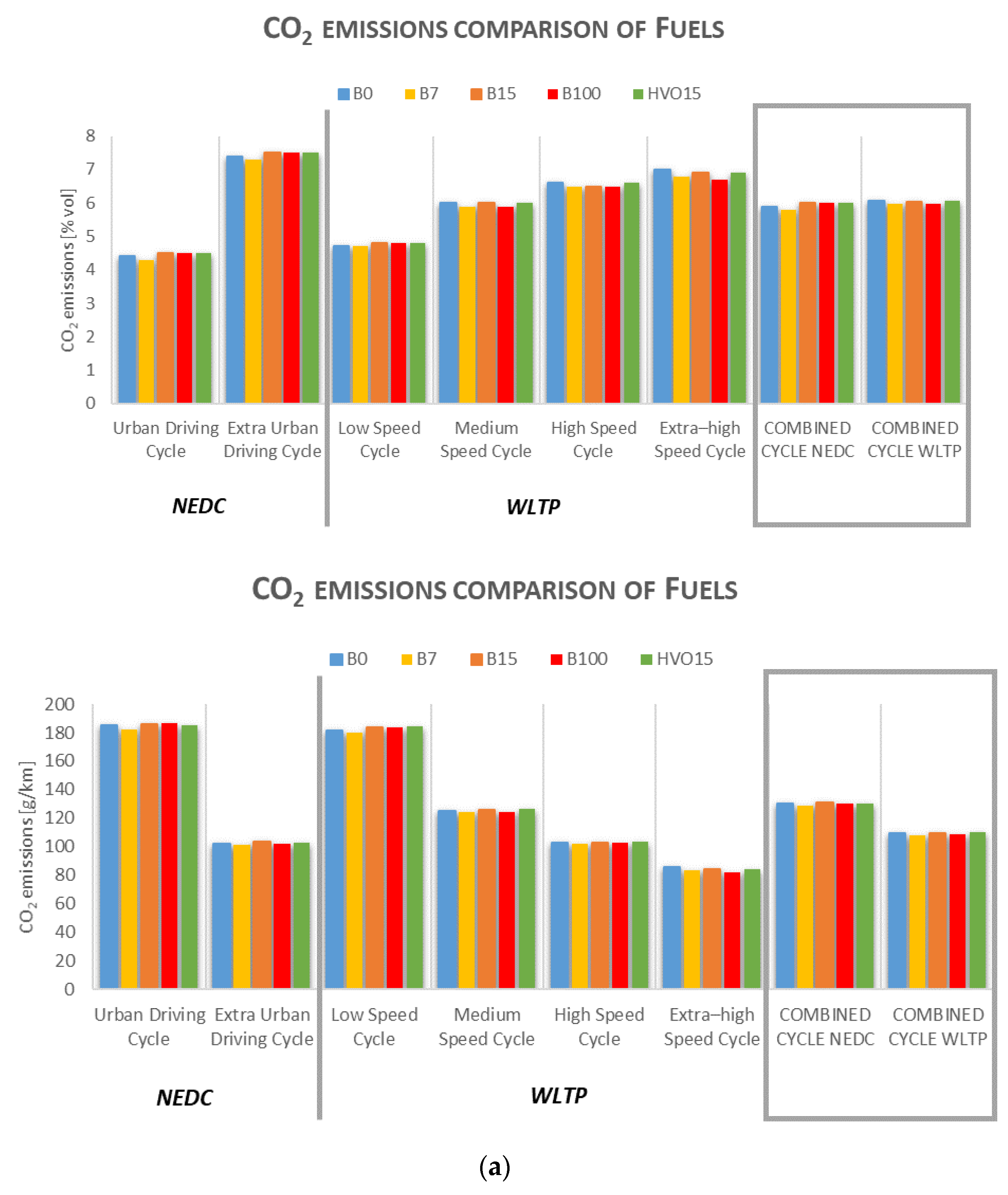

4.1.5. Carbon Dioxide (CO2)

4.2. Performance Test

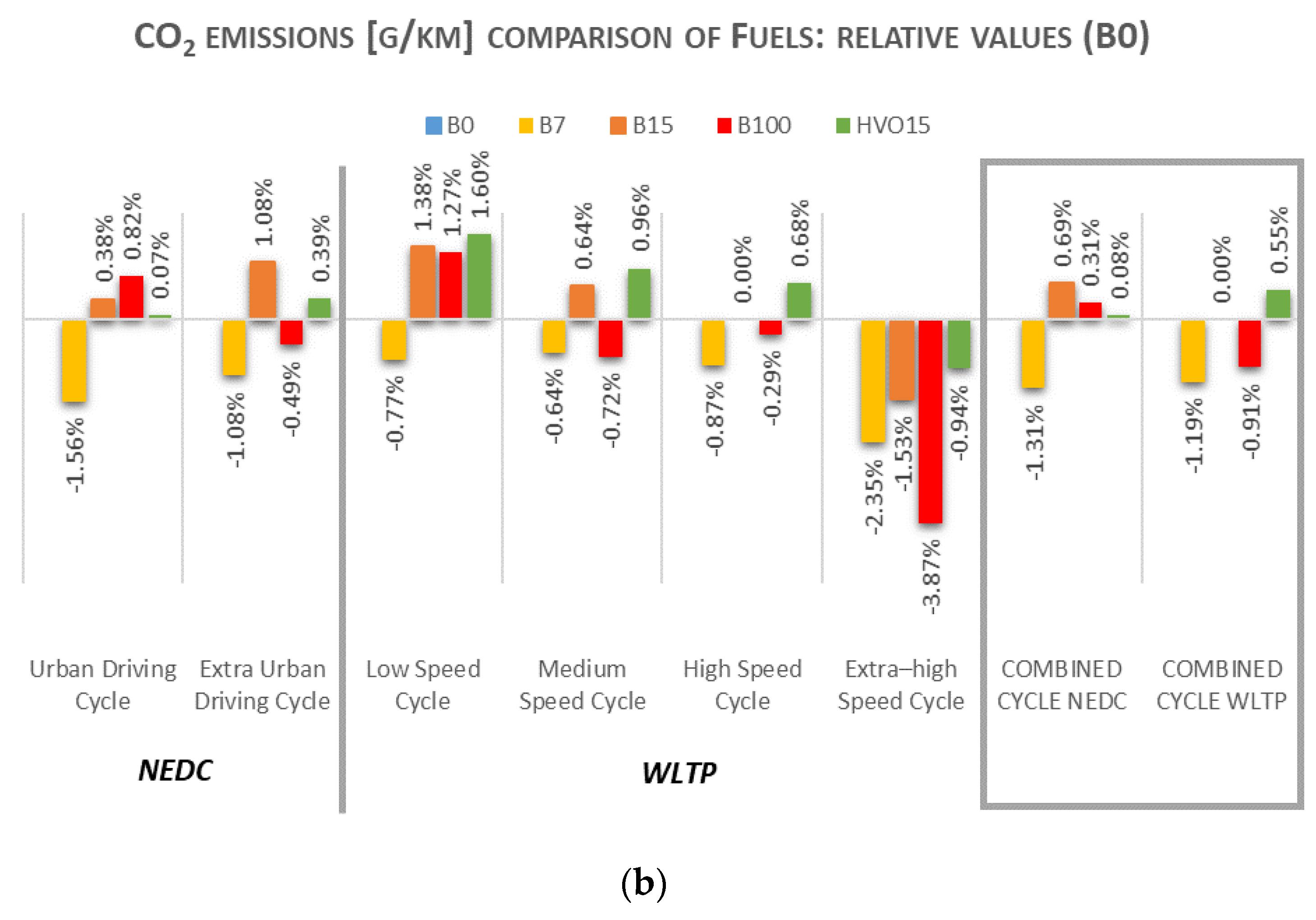

4.2.1. Engine Performance (Power and Torque)

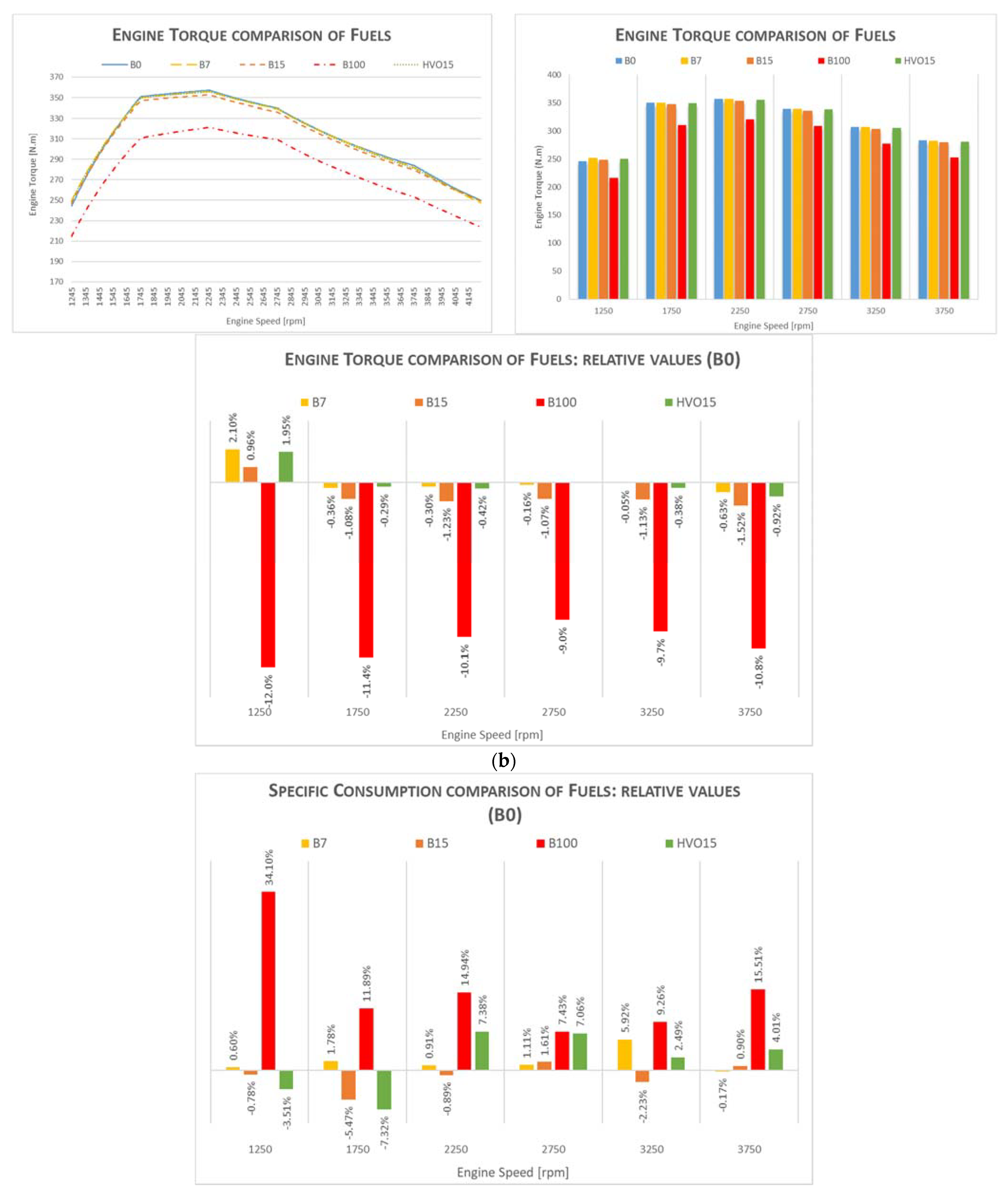

4.2.2. Specific Fuel Consumption

5. Conclusions

- -

- The use of B7 reveals a decrease in fuel consumption, which is detected with both NEDC and WLTP cycles.

- -

- The use of B15 can contribute to a small reduction of NOx emissions (at 8%). The use of HVO15 in the NEDC cycle reveals a small decrease (−3%) in NOx emissions but for WLTP an increase (14%) was measured.

- -

- The variations in CO2 emissions are small and inside the uncertainty of the method, so the only conclusion is that the use of biofuels does not penalize the CO2 emissions in the combustion process. All the reduction of CO2 obtained in a well-to-tank assessment determines the contribution of biodiesel to global warming mitigation.

- -

- The use of low biofuel blends does not penalize the performance of the engine and at low speeds, where the engine is more frequently used, a small increase (2%) in power was achieved for B7. In this low engine speed operation (1250 to 2250 rpm), a decrease in specific fuel consumption was also detected for B15 (0.8 to 5.5%).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martins, J.; Brito, F.P. Alternative Fuels for Internal Combustion Engines. Energies 2020, 13, 4086. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Seljak, T.; Vihar, R.; Baškovič, U.Ž.; Dimaratos, A.; Bezergianni, S.; Samaras, Z.; Katrašnik, T. Improving PM-NOx trade-off with paraffinic fuels: A study towards diesel engine optimization with HVO. Fuel 2020, 265, 116921. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; Grosso, A. A review on biofuels for light-duty vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Ahmed, O.O. w3A review of global current scenario of biodiesel adoption and combustion in vehicular diesel engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar]

- Tamburini, E.; Gaglio, M.; Fano, G.C. Is Bioenergy Truly Sustainable WhenLand-Use-Change (LUC) Emissions Are Accounted for? The Case-Study of Biogas from Agricultural Biomass in Emilia-Romagna Region, Italy. Sustainability 2020, 12, 3260. [Google Scholar] [CrossRef]

- Gad, M.S.; Hashish, A. Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds. Process. Saf. Environ. Prot. 2021, 147, 518–526. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Rajkumar, N.N. A comprehensive review on performance, combustion and emission characteristics of biodiesel fuelled diesel engines. Renew. Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Sharma, P.V. Performance and Emission Characteristics of Biodiesel Fueled Diesel Engines. Int. J. Renew. Energy Res. 2015, 5, 183–188. [Google Scholar]

- Kroyan, Y.; Wojcieszyk, M.; Kaario, O.; Zenger, M.L. Modeling the end-use performance of alternative fuels in light-duty vehicles. Energy 2020, 205, 117854. [Google Scholar] [CrossRef]

- An, H.; Yang, W.M.; Chua, S. Combustion and emissions characteristics of diesel engine fueled by biodiesel at partial load conditions. Appl. Energy 2012, 99, 363–371. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Chiba, M.; Shimizu, K.; Takahashi, H.; Sugiura, Y.; Harano, E.S.M. Diesel Engine Performance and Emissions When Using Biodiesel Fuel. Jpn. Agric. Res. Q. JARQ 2014, 48, 133–137. [Google Scholar] [CrossRef][Green Version]

- Islam, M.S.; Ahmed, A.S.; Islam, A.; Aziz, S.A.; Mridha, L. Study on Emission and Performance of Diesel Engine Using Castor Biodiesel. J. Chem. 2014, 2014, 451526. [Google Scholar] [CrossRef]

- Muralidharan, K.; Sheeba, D.V. Performance, emission and combustion characteristics of biodiesel fuelled variable compression ratio engine. Energy 2011, 36, 5385–5393. [Google Scholar] [CrossRef]

- Lease Plan. Estudo Leaseplan Sobre Impacto Do WLTP. Fleet Magazine. 2018. Available online: https://www.leaseplan.com/pt-pt/wltp/ (accessed on 18 December 2020).

- Pavlovic, J.; Ciuffo, B.; Fontaras, G.; Marotta, V.V. How much difference in type-approval CO2 emissions from passenger cars in Europe can be expected from changing to the new test procedure (NEDC vs. WLTP)? Transp. Res. Part A Policy Pract. 2018, 111, 136–147. [Google Scholar] [CrossRef]

- VDA. Exhaust Emissions. Available online: https://www.vda.de/en/topics/environment-and-climate/exhaust-emissions/exhaust-emissions-legislation-in-europe.html (accessed on 6 December 2020).

- WLTPfacts.eu. From NEDC to WLTP: What will Change? Available online: https://wltpfacts.eu/from-nedc-to-wltp-change/ (accessed on 8 December 2020).

- WLTPfacts.eu. What are the Benefits of WLTP? Available online: https://wltpfacts.eu/wltp-benefits/ (accessed on 10 December 2020).

- WLTPfacts. What is the Purpose of Lab Tests Like WLTP? Available online: https://www.wltpfacts.eu/purpose-lab-tests-wltp/ (accessed on 12 December 2020).

- Tsiakmakis, S.; Fontaras, G.; Samaras, B.C. A simulation-based methodology for quantifying European passenger car fleet CO2 emissions. Appl. Energy 2017, 199, 447–465. [Google Scholar] [CrossRef]

- Tsiakmakis, S.; Fontaras, G.; Cubito, C.; Pavlovic, J.; Ciuffo, K. From NEDC to WLTP: Effect on the Type-Approval CO2 Emissions of Light-Duty Vehicles; Publications Office of the European Union: Bruxelles, Belgium, 2017. [Google Scholar]

- Pavlovic, J.; Ciuffo, A.M. CO2 emissions and energy demands of vehicles tested under the NEDC and the new WLTP type approval test procedures. Appl. Energy 2016, 177, 661–670. [Google Scholar] [CrossRef]

- Bortel, J.V. Effect of HVO fuel mixtures on emissions and performance of a passenger car size diesel engine. Renew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- Blasio, G. Hydrotreated vegetable oil as enabler for high-efficient and ultra-low emission vehicles in the view of 2030 targets. Fuel 2022, 310, 122206. [Google Scholar] [CrossRef]

- Omari, A.; Pischinger, S.; Bhardwaj, O.; Holderbaum, B. Improving Engine Efficiency and Emission Reduction Potential of HVO by Fuel-Specific Engine Calibration in Modern Passenger Car Diesel Applications. SAE Int. J. Fuels Lubr 2017, 10. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Stravinskas, S.; Rapalis, P.; Matijošius, J.; Bereczky, Á. Research on the Combustion, Energy and Emission Parameters of Various Concentration Blends of Hydrotreated Vegetable Oil Biofuel and Diesel Fuel in a Compression-Ignition Engine. Energies 2019, 12, 2978. [Google Scholar] [CrossRef]

- Cheng, Q.; Tuomo, H.; Kaario, O.T.; Martti, L. Spray dynamics of HVO and EN590 diesel fuels. Fuel 2019, 245, 198–211. [Google Scholar] [CrossRef]

- Kotek, M.; Marík, J.; Zeman, P.; Hartová, V.; Hart, J.; Hönig, V. The Impact of Selected Biofuels on the Skoda Roomster 1.4TDI Engine’s Operational Parameters. Energies 2019, 12, 1388. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimäki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO blends on modern diesel passenger cars emissions during real world operation. Fuel 2019, 235, 1427–1435. [Google Scholar] [CrossRef]

- Volkswagen of America. 2.0 Liter TDI Common Rail BIN5 ULEV Engine; Volkswagen of America, Inc.: Herndon, VA, USA, 2008. [Google Scholar]

- Oil Neste. Hydrotreated Vegetable Oil (HVO); Neste: Espo, Finland, 2014. [Google Scholar]

- Guru, M.; Koca, A.; Can, O.; Sahin, C.Ç. Biodiesel production from waste chicken fat based sources and evaluation with Mg based additive in a diesel engine. Renew. Energy 2009, 35, 637–643. [Google Scholar] [CrossRef]

- Ministério da Educação Superintendência De Comunicação Social Coordenadoria de Comunicação Social Universidade Federal Do Piau. Boletim De Ensaio No 145/LBB/V.2/2019; Ministério da Educação Superintendência de Comunicação Social Coordenadoria de Comunicação Social Universidade Federal Do Piau: Piau, Brasil, 2019.

- Kaya, T.; Taskiran, O. Evaluation of the Effects of Biodiesel on Emissions and Performance by Comparing the Result of the New European Drive Cycle and Worldwide Harmonized Light Vehicles Test Cycle. Energies 2018, 11, 2814. [Google Scholar] [CrossRef]

- Secretaria Regional da Saúde. Intoxicação por Monóxido de Carbono (CO). 2011. Available online: http://iasaude.pt/attachments/article/1887/Intoxicacao_CO.pdf (accessed on 8 September 2020).

- Serrano, L.M.V. Análise Comparativa do Desempenho de Motores de Combustão Interna Quando Utilizam Biocombustíveis. Ph.D. Thesis, Faculdade de Ciências e Tecnologia, Universidade de Coimbra, Coimbra, Portugal, 2012. [Google Scholar]

- eCycle. Óxidos de Nitrogénio: O que são os NOx e Quais os Seus Impactos. May 2019. Available online: https://www.ecycle.com.br/3052-oxidos-de-nitrogenio (accessed on 8 September 2020).

- Viva, Ciência, Ozono. May 2019. Available online: http://www.cienciaviva.pt/divulgacao/eventos/diasemcarros/ozono.asp (accessed on 8 September 2020).

- Governo dos Açores. Fontes e Efeitos dos Poluentes Atmosféricos. May 2019. Available online: http://www.azores.gov.pt/Portal/pt/entidades/sreat-dra/livres/fontes+e+efeitos+dos+poluentes+atmosfericos.htm (accessed on 8 September 2020).

- Lopes, M.; Serrano, L.; Ribeiro, I.; Cascão, P.; Pires, N.; Rafael, S.; Tarelho, L.; Monteiro, A.; Nunes, T.; Evtyugina, M.; et al. Emissions characterization from EURO 5 diesel/biodiesel passenger car operating under the new European driving cycle. Atmos. Environ. 2014, 84, 339–348. [Google Scholar] [CrossRef]

- Serrano, L.; Lopes, M.; Pires, N.; Ribeiro, I.; Cascão, P.; Tarelho, L.; Monteiro, A.; Nielsen, O.; da Silva, M.G.; Borrego, C. Evaluation on effects of using low biodiesel blends in a EURO 5 passenger vehicle equipped with a common-rail diesel engine. Appl. Energy 2015, 146, 230–238. [Google Scholar] [CrossRef]

| Equipment | Parameter/Range | Resolution |

|---|---|---|

| Dynamometer Maha LPS 3000 | Speed [0.0–260.0 km/h] | 0.1 km/h |

| Force [0.0–6000.0 N] | 0.1 N | |

| Fuel Measurement Mettler Toledo PS7001-F | Mass [0.0–7000.0 g] | 0.1 g |

| Exhaust Gas Analyzer Bosch BEA 250 | CO [0.00–10.00] % vol | 0.001% vol |

| CO2 [0.00–18.00] % vol | 0.01% vol | |

| HC [0–9999] ppm vol | 1 ppm vol | |

| NOx [0–5000] ppm vol | <1 ppm vol |

| Engine type: | 4-cylinder with 16 valves |

| Engine code: | CBAB |

| Year of manufacture: | 2008–2012 |

| Turbocharger: | Variable geometry turbocharger (TDI) |

| Engine capacity (cm3): | 1986 (2.0) |

| Bore (mm): | 81 |

| Stroke (mm): | 95.5 |

| Compression Ratio: | 16.5 |

| Power Max (kW/rpm): | 103/4200 |

| Torque Max (Nm/rpm): | 320/1750–2500 |

| Fuel Injection System: | Common-rail piezoelectric injectors |

| Injection Sequence: | 1-3-4-2 |

| Injection Pressure (bar): | 230–1800 bar |

| Idle Speed (rpm): | 830 ± 100 |

| Units | Diesel | FAME | HVO | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test Method | B0 | Test Method | B7 | B15 | B100 | Test Method | HVO15 * | HVO100 | ||

| Cetane number | ASTMD6890 | 52.0 * | IP 617 | 52.1 [32] | 52.2 * | 53.7 [33] | ASTMD6890 | 55.5 | 79.5 [30] | |

| Density at 15 °C | kg/m3 | EN ISO 3675 EN ISO 2185 | 833.3 * | EN ISO 12185 | 837.6 [32] | 840.6 * | 882.3 [33] | EN ISO 3675 EN ISO 12185 | 834.6 | 780.6 [30] |

| Viscosity at 40 °C | mm2/s | - | 2.7 * | EN ISO 3104 | 2.8 [32] | 3.0 * | 4.7 [33] | EN ISO 3104 | 2.7 | 2.9 [30] |

| Lower Heating Value (LHV) | MJ/kg | ASTM D240 | 43.0 [34] | ASTM D240 | 42.6 [34] | 41.9 [34] | 37.2 [34] | - | 43.2 | 44.1 [32] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrano, L.; Santana, B.; Pires, N.; Correia, C. Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP). Fuels 2021, 2, 448-470. https://doi.org/10.3390/fuels2040026

Serrano L, Santana B, Pires N, Correia C. Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP). Fuels. 2021; 2(4):448-470. https://doi.org/10.3390/fuels2040026

Chicago/Turabian StyleSerrano, Luis, Barbara Santana, Nuno Pires, and Cristina Correia. 2021. "Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP)" Fuels 2, no. 4: 448-470. https://doi.org/10.3390/fuels2040026

APA StyleSerrano, L., Santana, B., Pires, N., & Correia, C. (2021). Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP). Fuels, 2(4), 448-470. https://doi.org/10.3390/fuels2040026