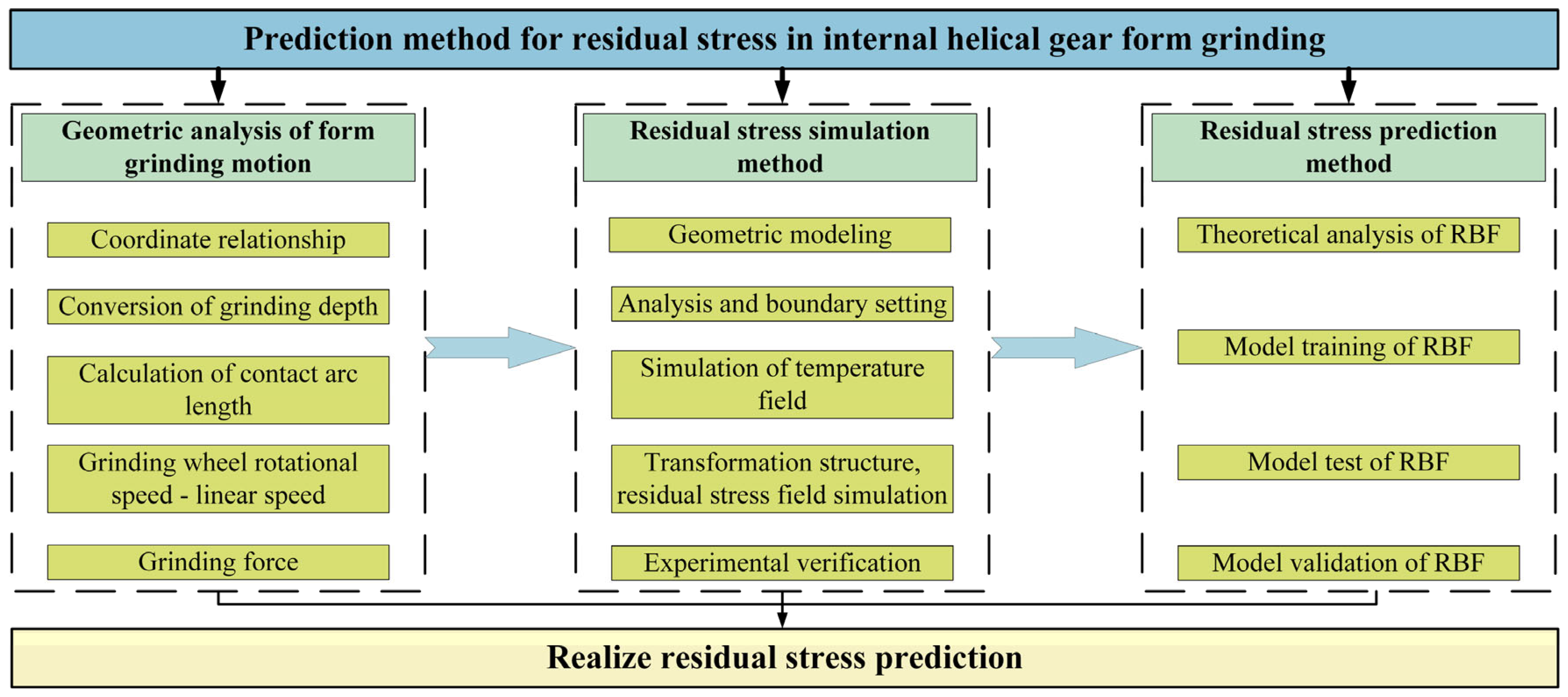

1. Introduction

Due to the advantages of low volume, high output power density, high transmission accuracy, and low noise, the internal helical gears are widely used in aero-engine, high-grade machine tools, new energy vehicles, and other fields. Profile grinding is the only precision manufacturing means of internal helical gears. The residual stress created during internal helical gear profile grinding is liable to lead to micro-cracks, deformation on the tooth surface, reduction in fatigue strength, the loading capacity, and service life of the transmission system, and consequently decrease the reliability and durability of the internal helical gear [

1,

2]. In addition, the severe heat generated during the grinding process can easily lead to grinding burns. Grinding burn and residual stress are also key surface integrity problems caused by grinding thermal–mechanical coupling, which are closely related. Excessive grinding temperature will lead to phase transformation of the surface material, which is often accompanied by tensile stress that is not conducive to fatigue performance [

3,

4]. Therefore, it is significant to predict the residual stress and optimize the grinding parameters to enhance the grinded gear surface quality.

Many scholars have used different methods to predict the residual stress caused by different machining methods for different machining objects. For example, Cheng et al. [

5] measured the residual stresses perpendicular to the feed direction using an X-350A X-ray residual stress meter. The residual stresses under different geometric features and cutting parameters were studied. A new method for predicting residual stresses based on Gaussian process regression was proposed. The performance of the proposed method was verified by other machine learning algorithms. Shan et al. [

6] put forward a prediction model of residual stress in cutting based on an analytical method considering mechanical stress and thermal stress. Through orthogonal cutting experiment of the Ti6Al4V tube verifies that the predicted values using this method are in good agreement with the experimental values. Yi et al. [

7] obtained residual stress distribution of the workpiece at different depths layer by layer by electrolytic polishing and X-ray diffraction. Based on experimental data, a prediction model of milling residual stress was proposed by using a genetic algorithm and a BP neural network. Zhang et al. [

8] proposed a new analytical model based on the equivalent stress method to predict cutting residual stress, taking into account the nonlinear flow characteristics and thermal–mechanical coupling effects of workpiece material at the tool–workpiece contact surface. Rissaki et al. [

9] established two types of artificial neural network models to predict the axial and circumferential residual stress distribution of the weld centerline. The performance of the model was evaluated by a test set and a sensitivity study, and the output trend of the model was revealed. Yeong et al. [

10] created a database of maximum residual stresses in shot peened Inconel 718 specimens based on Rayleigh wave dispersion data and utilized convolutional neural networks for residual stress prediction. Sembiring et al. [

11] proposed a concept based on an artificial neural network to predict residual stresses in various nickel-based alloys treated by ultrasonic nanocrystalline surface modification (UNSM) by obtaining a large amount of residual stress data from experiments on Alloy600. Wu et al. [

12] measured residual stresses in experimental samples using a PROTO LXRD stress apparatus. An artificial neural network was trained with experimental data of laser energy 5J and 7J, and the training results were tested with experimental data of 6J to predict the residual stress of laser shock-treated superalloy.

For the sake of figuring out the generating mechanism of residual stress during gear profile grinding, Yi et al. [

13] calculated the residual stress caused by grinding based on thermal–structural coupling finite element method, analyzed the distribution characteristics of residual stress field, and the influence of the size of tooth root transition arc on the residual stress distribution at tooth root. Wen et al. [

14] put forward a thermal–mechanical coupling calculation model considering the difference of tooth surfaces on both sides of the same gear. Grinding simulation was carried out on both tooth surfaces successively, and it was found that there was a difference in residual stress on both tooth surfaces. Su et al. [

15] established the thermal–mechanical coupling model of cycloidal grinding by the moving heat source method and the load step loading method. By calculating Mises equivalent stress in the three-dimensional grinding area, the magnitude and force direction of the first, second, and third principal stresses were solved, and the influence of grinding process parameters on residual stress distribution was further discussed. Xiao et al. [

16] put forward a gear grinding model to analyze the residual stress distribution of the gear tooth surface, considering the change in chip geometry. Wang et al. [

17] established the mathematical model of grinding face gear with disc wheel, the calculation model of grinding force and grinding heat, further studied the three processes of elastic loading, plastic deformation, and stress release of face gear grinding, and established the mathematical model of residual stress of end grinding teeth. According to previous studies, the RBF neural network has been successfully used to predict photovoltaic power generation rate [

18], reactor temperature [

19], highway traffic situation [

20], stock price trend [

21], and many other fields.

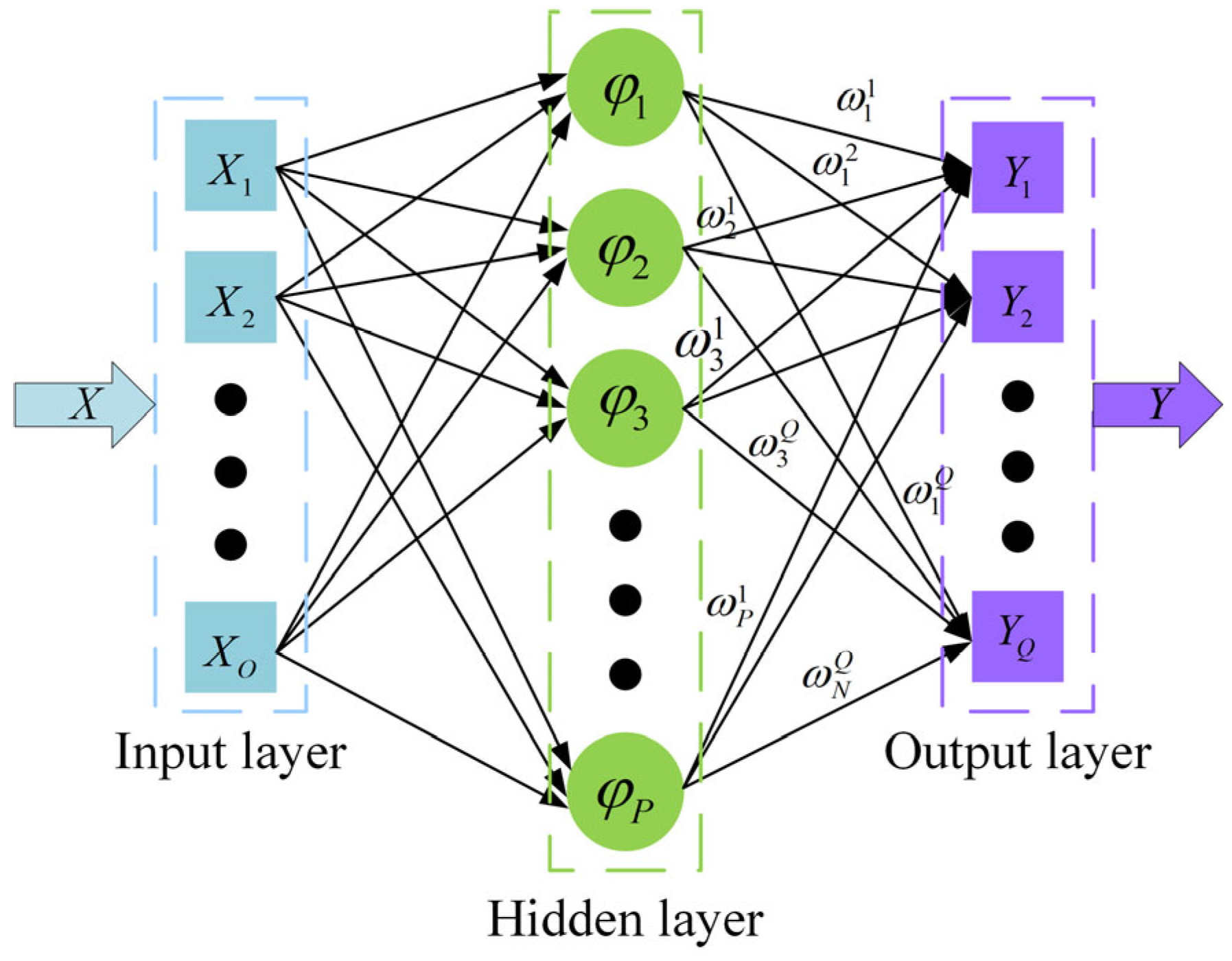

In summary, numerous scholars have extensively investigated the prediction of residual stress resulting from various factors, simulated such stress in different gear types, and utilized RBF neural networks to forecast residual stress across diverse fields. However, limited research has been conducted on residual stress in internal helical gear profile grinding. Existing studies predominantly rely on conventional experimental approaches to gather residual stress data, necessitating significant resources in terms of labor, materials, and time. Consequently, this study proposes employing numerical simulation and neural network optimization techniques to predict residual stress in internal helical gear profile grinding. The study involves simulating residual stress in internal helical gear profile grinding by manipulating grinding process parameters (ap, vw, vs) as variables, followed by utilizing RBF neural networks to predict residual stress during the profile grinding process.

2. Establishment and Verification of Residual Stress Simulation Model

The formation of residual stress in profile grinding of internal helical gear results in the profile grinding force–thermal coupling effect: mechanical stress results from Hertzian stress field induced by abrasive particles contacting workpiece, and thermal stress results from thermal elastoplastic deformation induced by grinding temperature. Controlling the residual stress generated by thermal–mechanical coupling can help reduce fatigue cracks and surface roughness on ground surfaces [

22]. Therefore, numerical simulation of residual stress in profile grinding has important engineering significance for improving the service reliability of the gear as a key component.

2.1. Kinematic Analysis of Grinding Motion of Internal Helical Gear

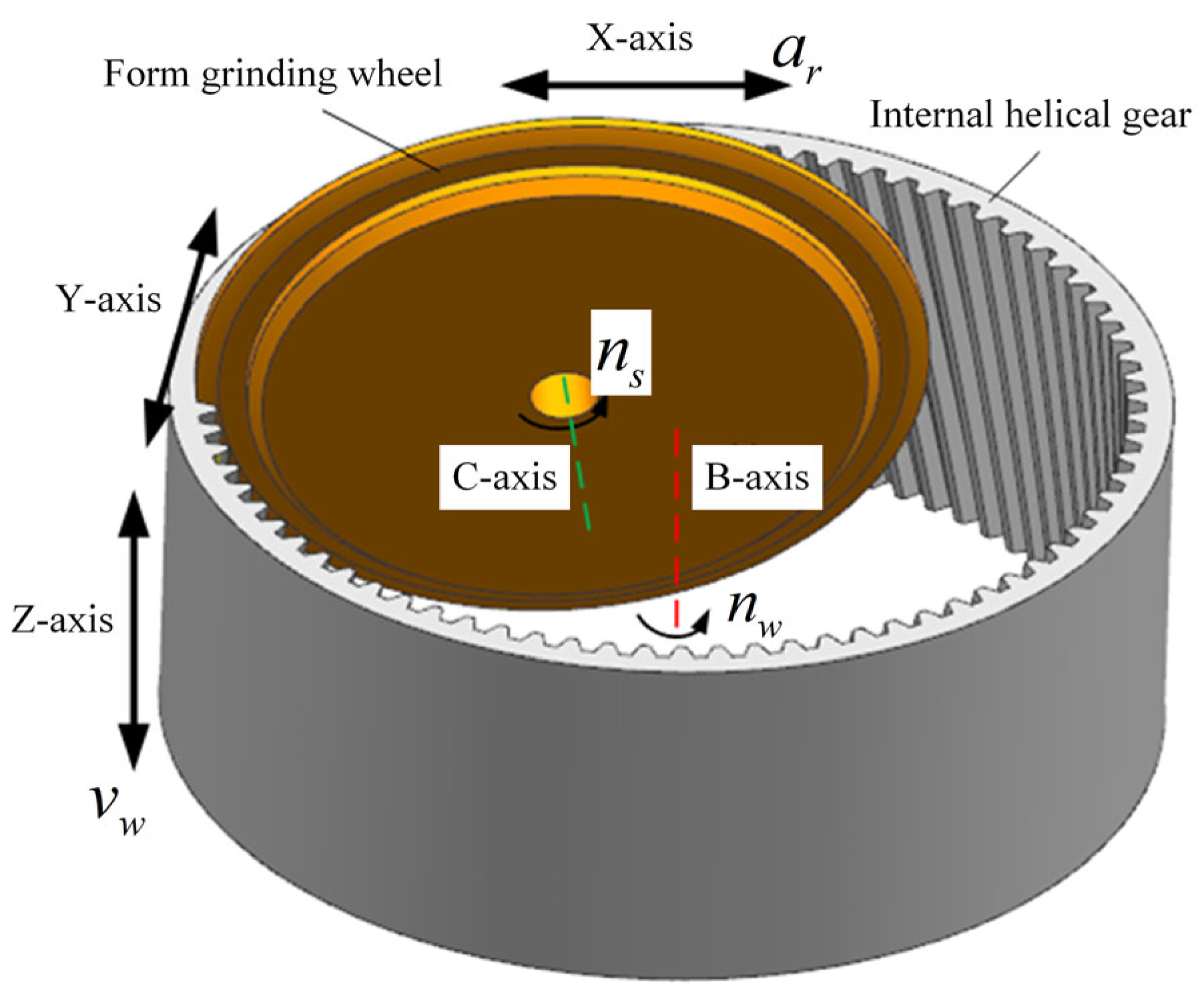

In the profile grinding wheel and gear movement relationship as shown in

Figure 1, because the helical gear tooth surface is helical, so in the gear feed there needs to be an additional rotation along the B-axis, and along the Z-axis movement to form a helical movement to finally complete the grinding. The grinding wheel movement along the Z-axis is the feed speed

vw, the grinding wheel movement along the C-axis is the grinding wheel speed

ns, and the grinding wheel movement along the X-axis is the radial grinding depth

ar.

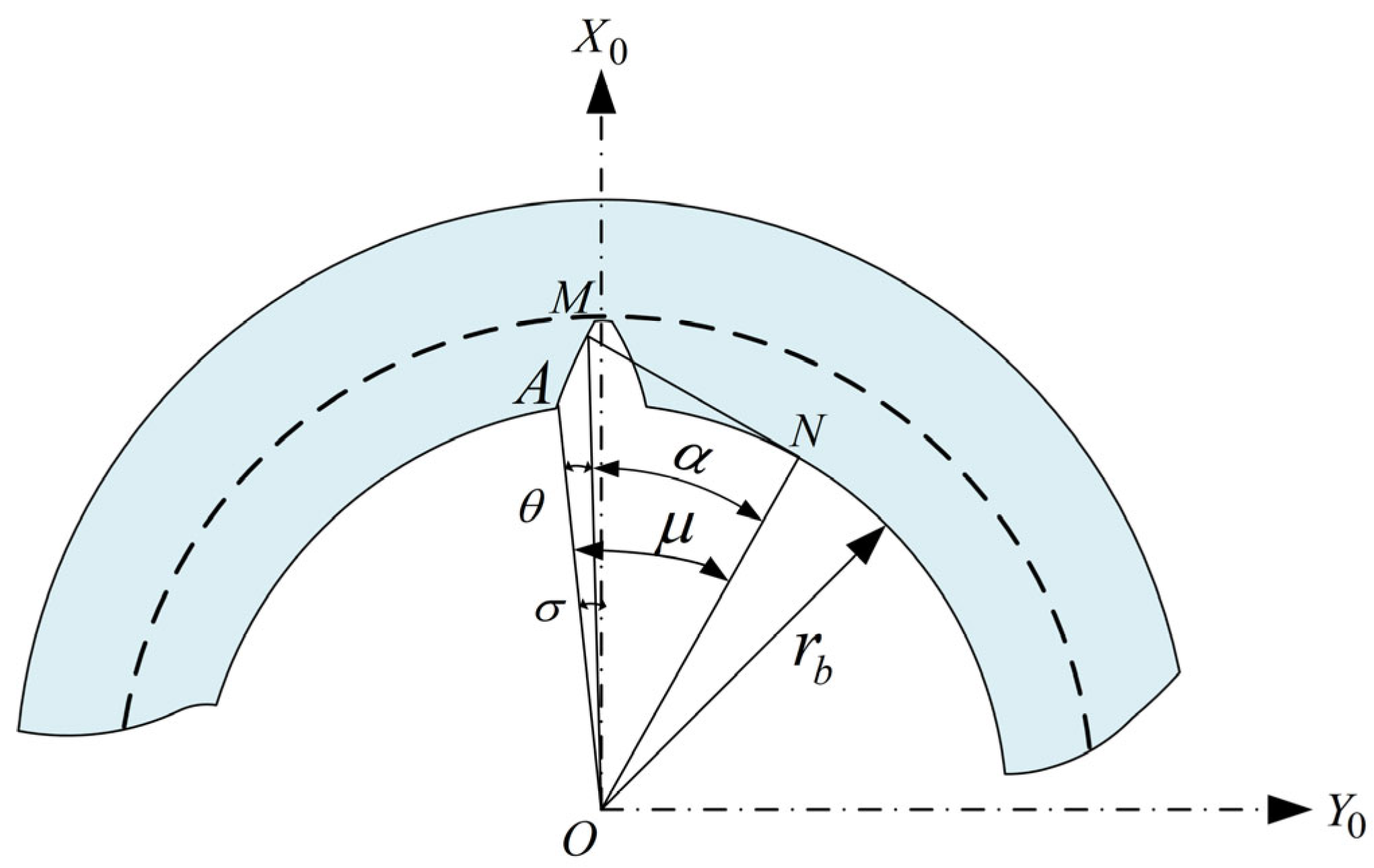

The tooth surface generation of an internal helical gear is a three-dimensional geometric construction process based on the involute principle and spiral motion, so the profile curve of the standard helical tooth surface at the end of arbitrary tooth width is involute. As shown in

Figure 2, the involute tooth profile at the end section of the internal helical gear is established. The tooth surface coordinate system

S0 is established at the center of the gear. The tooth surface profile is symmetrical about the

X0 axis. Any point

M on the involute of the tooth profile corresponds to the pressure angle

α, the spread angle

θ,

μ is the sum of the spread angle and pressure angle,

rb is the radius of the base circle, and

σ is the half angle of the base circle tooth slot.

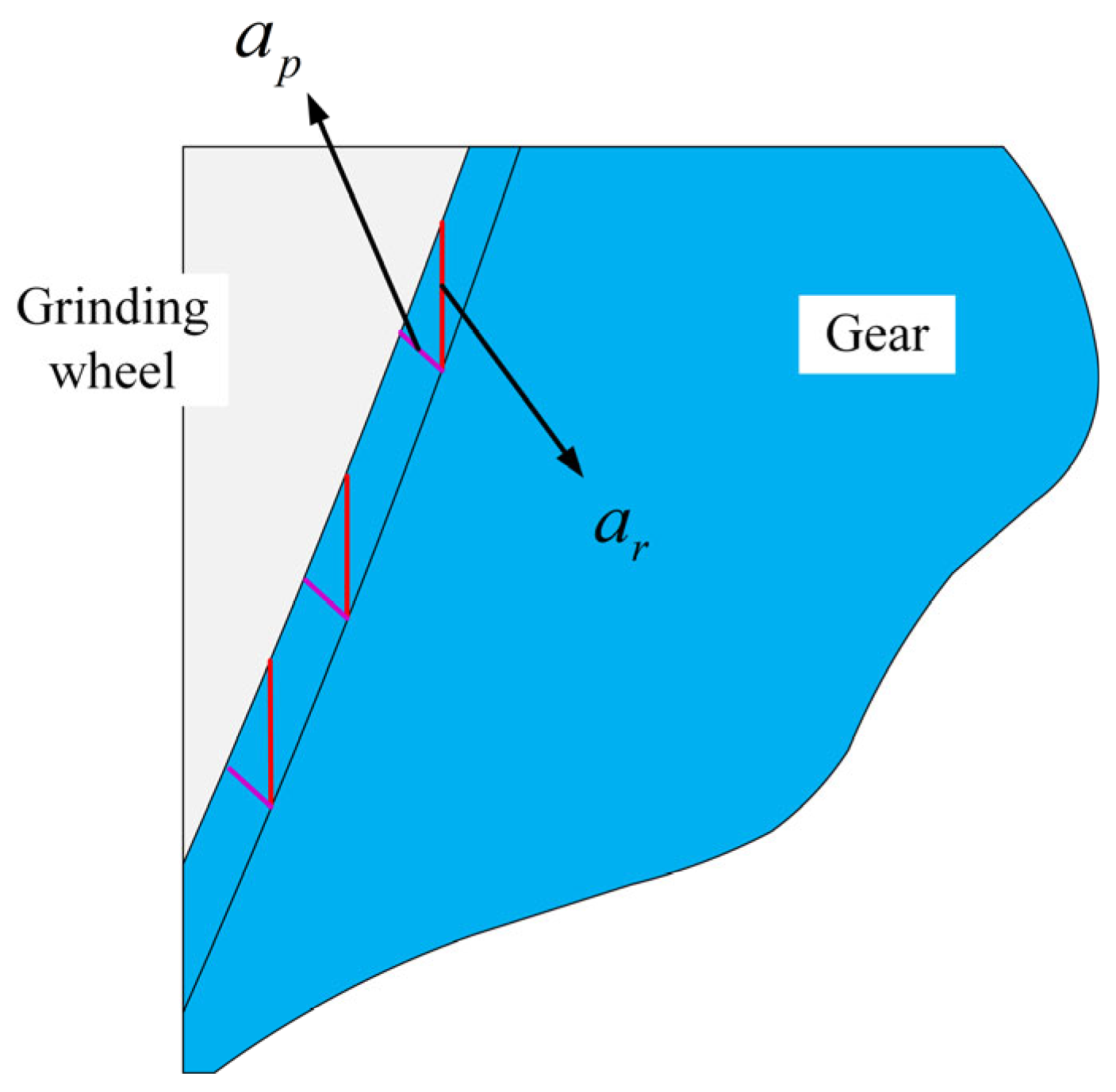

In the profile grinding of internal helical gears, as shown in

Figure 3, the depth along the direction of the connection between the center of the grinding wheel and the center of the gear is the radial grinding depth. The direction of any point on the tooth surface perpendicular to the tooth surface is called the normal direction, and the grinding depth in this direction and pointing to the inside of the gear is the normal grinding depth. This parameter is one of the important parameters describing the gear profile grinding process. As shown in

Figure 3,

ar is the radial grinding depth and

ap is the normal grinding depth. The relationship between the two is as follows:

During grinding the instantaneous grinding arc length

lc involved in grinding is as follows:

In Formula (2), Rd represents the equivalent grinding wheel diameter on the tooth surface. Because the grinding wheel needs to be trimmed to an ideal curved surface for grinding during the profile grinding process, the diameter of the grinding wheel at different points on the tooth surface is also different. Therefore, it is necessary to convert the actual diameter of the grinding wheel into the equivalent diameter. Where Rl represents the distance from any point on the tooth surface of the internal helical gear and the meshing surface of the grinding wheel to the axis of the grinding wheel, R and rf represent the original radius of the grinding wheel and the radius of the tooth root circle.

The wheel speed

ns is converted into linear speed

vs as follows:

2.2. Temperature Field Model of Internal Helical Gear Profile Grinding

During the grinding process of a helical gear tooth slot, the grinding wheel exhibits a characteristic movement pattern of grinding inward from one end of the slot and outward from the other end. Consequently, the heat produced by the grinding wheel at various positions during grinding can be conceptualized as a mobile heat source model. Moving heat sources mainly include rectangular heat sources and triangular heat sources. The results show that the triangular heat source not only has the advantage of simple calculation in mathematical treatment, but also can reflect the heat flux distribution characteristics in the actual grinding process more accurately [

23]. Then, the triangular moving heat source model is adopted for the following thermodynamic analysis and calculation. Suppose a triangular heat source moves along the Z-axis. The expression is as follows:

The overall heat flux resulting from internal helical gear profile grinding is determined by the grinding force

Ft. This force comprises axial, normal, and tangential components, with the axial force being negligible and thus disregarded. The primary force responsible for material removal and deformation is the tangential force. Therefore, the heat flux calculation is based solely on the tangential force, grinding wheel linear velocity

vs, grinding contact arc length

lc, and grinding width be, as expressed in the following formula [

24]:

The total heat flux includes four parts: entering gear, grinding wheel, grinding debris, and grinding fluid, so it is necessary to introduce the heat distribution ratio, and focus on analyzing the heat entering the grinding wheel and the internal helical gear. According to the heat distribution model proposed by ROWE [

25], the heat distribution ratio of the incoming workpiece is obtained as follows:

In the above Formula (6),

λg is the thermal conductivity of abrasive grains of grinding wheel,

Bw is the thermal contact coefficient of workpiece,

r0 is the effective contact radius of abrasive grains,

ta is the average thickness of deformed cutting,

is the shear strain of chip forming zone,

Kw,

ρw, and

cw are the thermal conductivity, density, and specific heat capacity of internal helical gear wheel material, respectively, and the gear material is selected as 20CrMnTi. The specific thermal performance parameters are shown in

Table 1 below.

From the above analysis, the heat flux density into the tooth surface can be calculated as follows:

During the grinding, in order to ensure the ideal surface processing quality, it is necessary to effectively cool the grinding zone with sufficient grinding fluid. Grinding fluid cools the grinding heat in the form of convection heat transfer during helical gear profile grinding. Convective heat transfer coefficients can be calculated based on the following model:

In Equation (8),

u = (

vs +

vw)/2,

ρf is the density of the grinding fluid,

cf is the specific heat capacity of the grinding fluid,

λf is the thermal conductivity of the grinding fluid, and

μf is the dynamic viscosity of the grinding fluid. The grinding fluid used in this study is an oil-based grinding fluid, and its specific parameters are shown in

Table 2.

2.3. Grinding Force Model

The grinding force in the grinding process can be divided into tangential, normal, and axial grinding forces. The axial force in the forming grinding process of the internal helical gear is small and can be ignored. The tangential grinding force is the premise of calculating the total grinding heat flux, and the grinding heat is the dominant mechanism leading to residual stress. Although the normal force has a certain influence on the residual stress through mechanical deformation, its contribution is secondary to the grinding heat.

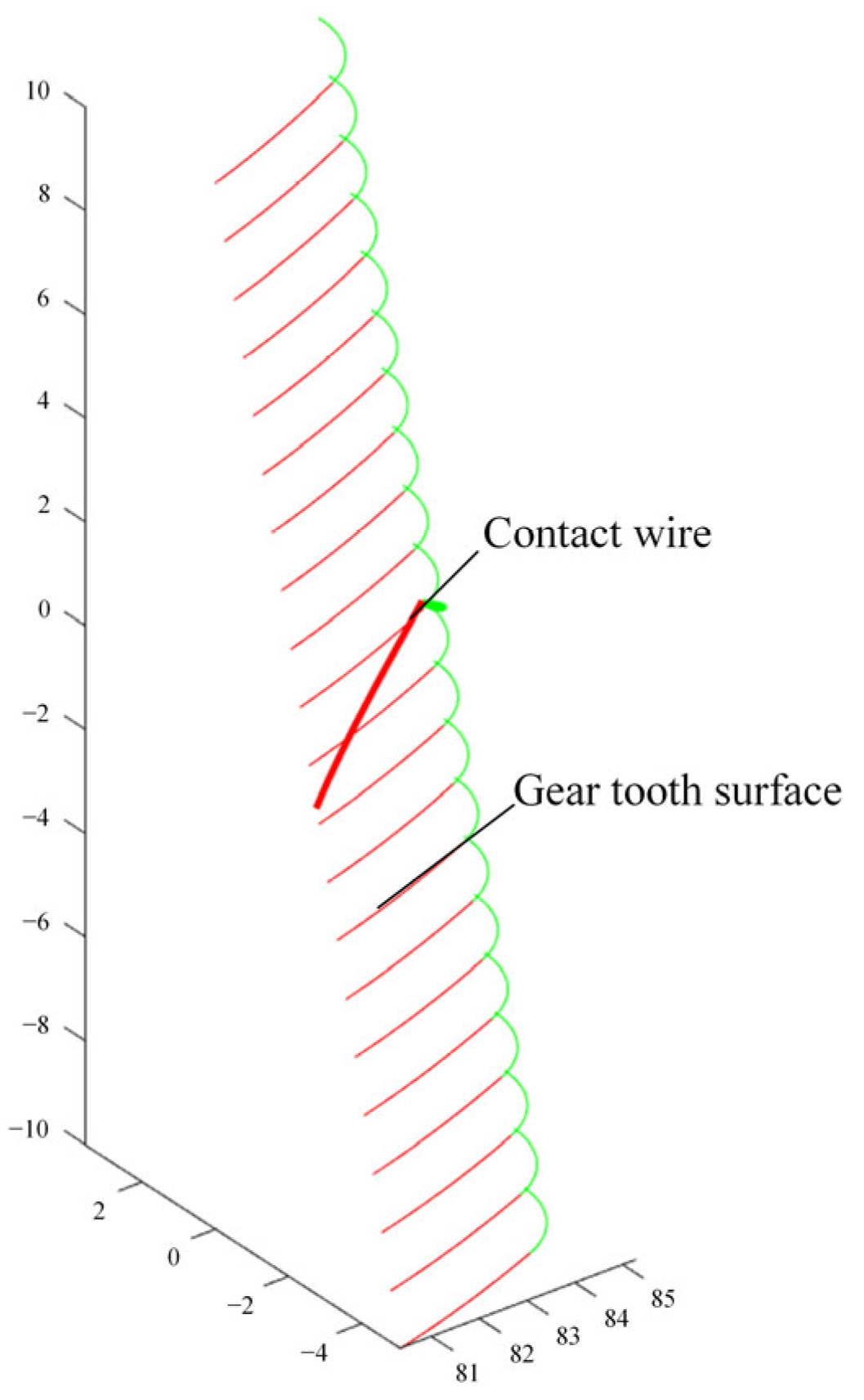

During the internal helical gear profile grinding, the instantaneous contact line between the grinding wheel and gear tooth surface is a complex space curve. According to the principle of gear meshing, MATLAB R2020a is used to calculate this space curve. The result is shown in

Figure 4.

Fitting and analyzing the instantaneous contact line yielded the following parametric equation:

In the above formula, R2 is the coefficient of determination of the fitting equation. When the coefficient of determination is close to 1, it means that the reliability of the fitting equation is high.

According to the principle of profile grinding, the grinding force acts on the contact line, so it is necessary to solve the grinding force along the contact line. According to the fitting equation, the arc length

l of any point on the contact line can be obtained as follows:

Combined with the plane grinding force formula, integrating on any involute rolling angle 0 −

μ, the internal helical gear profile grinding force formula can be obtained as follows:

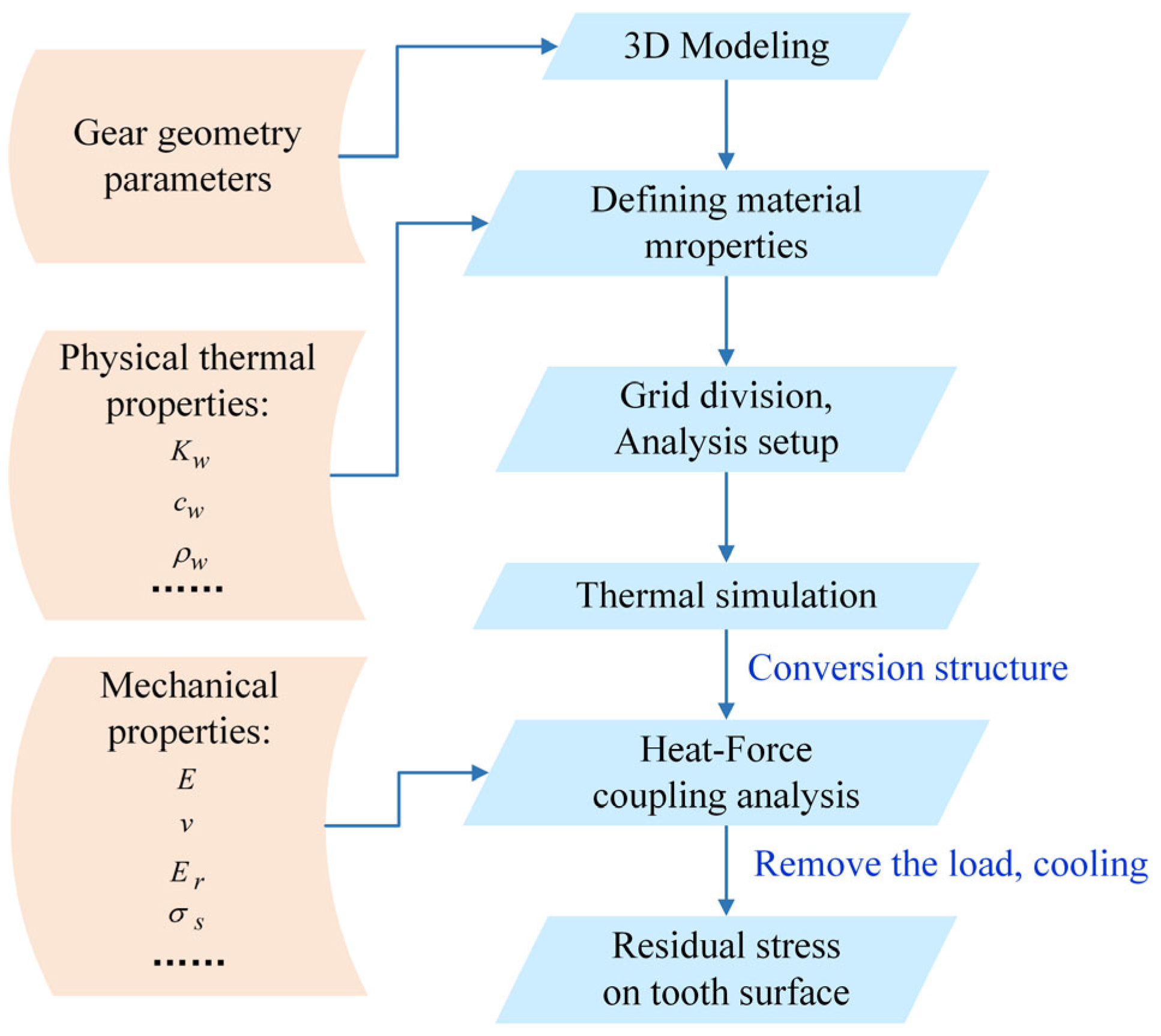

2.4. Simulation of Residual Stress in Profile Grinding

In the actual process of internal helical gear profile grinding, the grinding method is adopted one by one until all the teeth are machined, so as to realize the grinding of the whole gear. When grinding a tooth slot, the left and right tooth surfaces are ground simultaneously, and the grinding process and process parameters of each tooth slot are consistent. In order to simplify the simulation process and reduce the calculation time cost, the gear model is reasonably simplified, and the simplified model is shown in

Figure 5.

It is very important to characterize the thermal–mechanical behavior of the material accurately in the numerical simulation of residual stress on the tooth surface of an internal helical gear. Including Poisson’s ratio

, elastic modulus

E, coefficient of linear expansion

α′, and so on. Due to the significant temperature gradient changes at the tooth surface nodes of gears during heat treatment or service, the physical and mechanical properties of the material exhibit a strong temperature dependence. Therefore, when establishing a reliable residual stress prediction model, it is necessary to fully consider and input the functional relationship between the key physical parameters of materials and temperature. Ignoring the temperature dependence of these parameters will lead to deviation of simulation results from the actual physical state, which will significantly affect the accuracy of residual stress distribution prediction. Specifically, the key physical parameter data of the 20CrMnTi material at different temperatures on which this study is based are listed in

Table 3.

The residual stress simulation method based on thermal–force coupling can be divided into two types: (1) Direct coupling and sequential coupling. Although direct coupling can reflect the interaction of the thermal–force field in real time, the calculation is complicated and time-consuming. (2) Sequential coupling decouples the one-way influence of the temperature field on the stress field. A transient thermal analysis is conducted first. The temperature field results are introduced into the structural stress field as loads. For the problems with low nonlinear coupling degree, the sequential coupling method has higher computational efficiency and flexibility while ensuring accuracy, especially suitable for transient analysis with multiple time nodes. Based on the above advantages, this research chooses the sequential coupling method to carry out the simulation; the specific flow is shown in

Figure 6.

And the ultimate objective of the simulation is the final residual stress state that remains locked within the gear tooth after the entire process is complete, i.e., after the grinding heat source has moved away, the external mechanical loads are removed, and the workpiece has cooled down to room temperature.

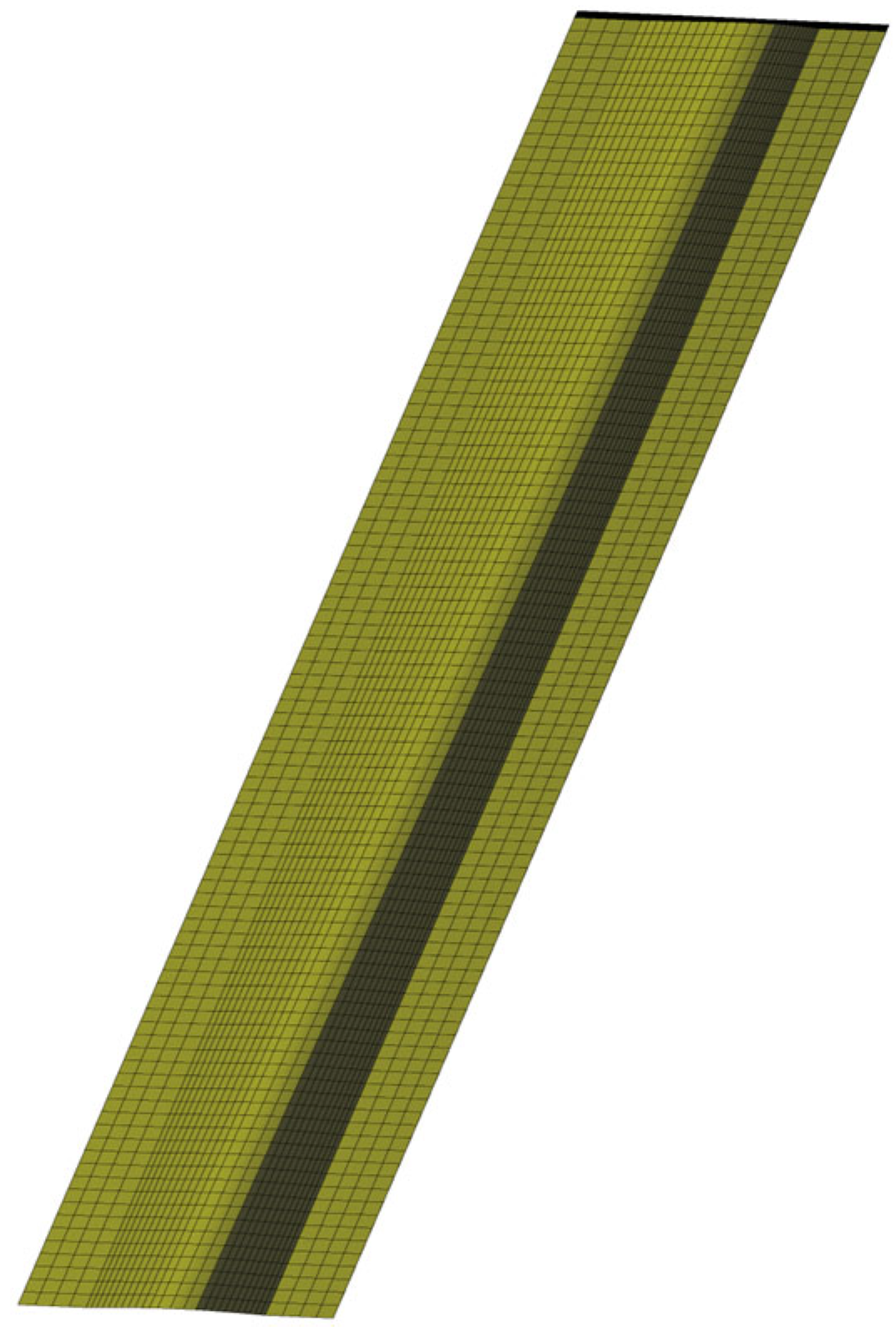

This paper’s finite element simulation relies on modeling key geometric parameters of the internal helical gear. These parameters are provided in

Table 4. These include core design elements: module, number of teeth, pressure angle, and helix angle. To accurately simulate the gear structure response and take into account the calculation efficiency, the geometric model is appropriately simplified, and high-precision hexahedral elements are used for spatial discretization. The finally generated finite element mesh model is shown in

Figure 7. And to ensure the accuracy of the critical region solution, the global cell size is strictly controlled at 0.3 mm.

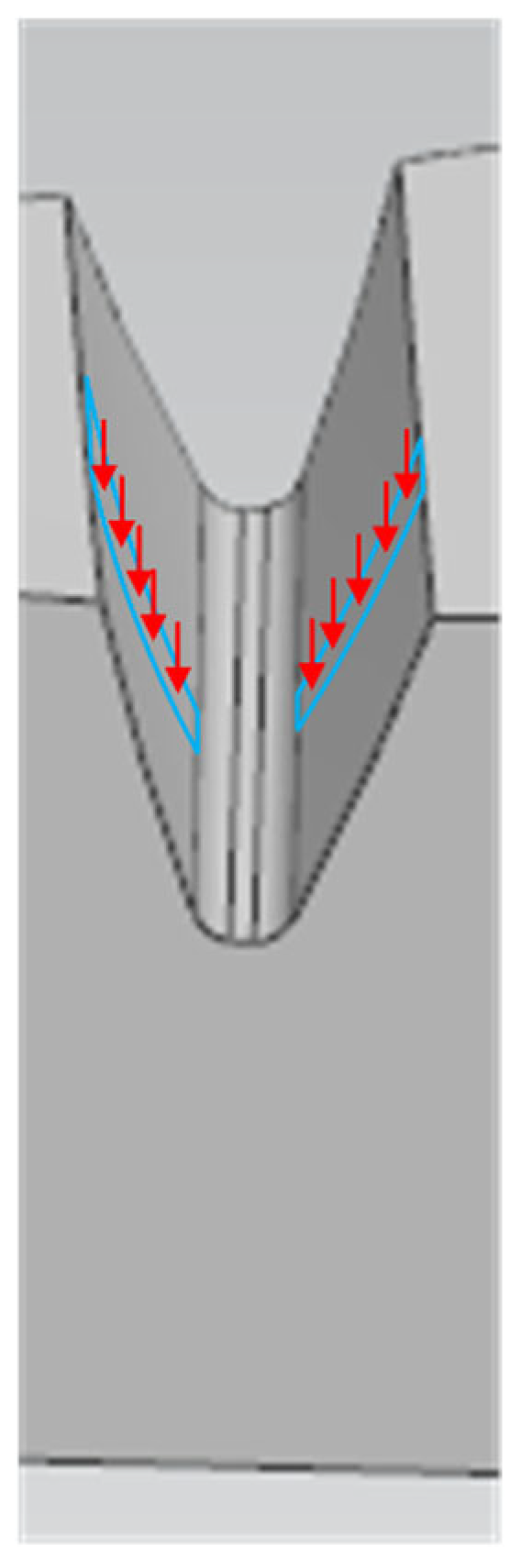

In the thermal–force coupling simulation, the grinding heat load is applied based on the actual process. The heat flux density representing grinding heat input is applied as a moving heat source within the grinding arc area (blue box in

Figure 8). This load moves dynamically along the set grinding speed direction, which is tangential to the tooth surface. Meanwhile, to reflect the actual cooling effect during grinding, equivalent convective heat transfer coefficient boundary conditions are applied to the entire tooth surface outside the grinding arc area. This region is the non-abrasive zone. These conditions simulate the continuous cooling effect of the grinding fluid on the tooth surface during machining.

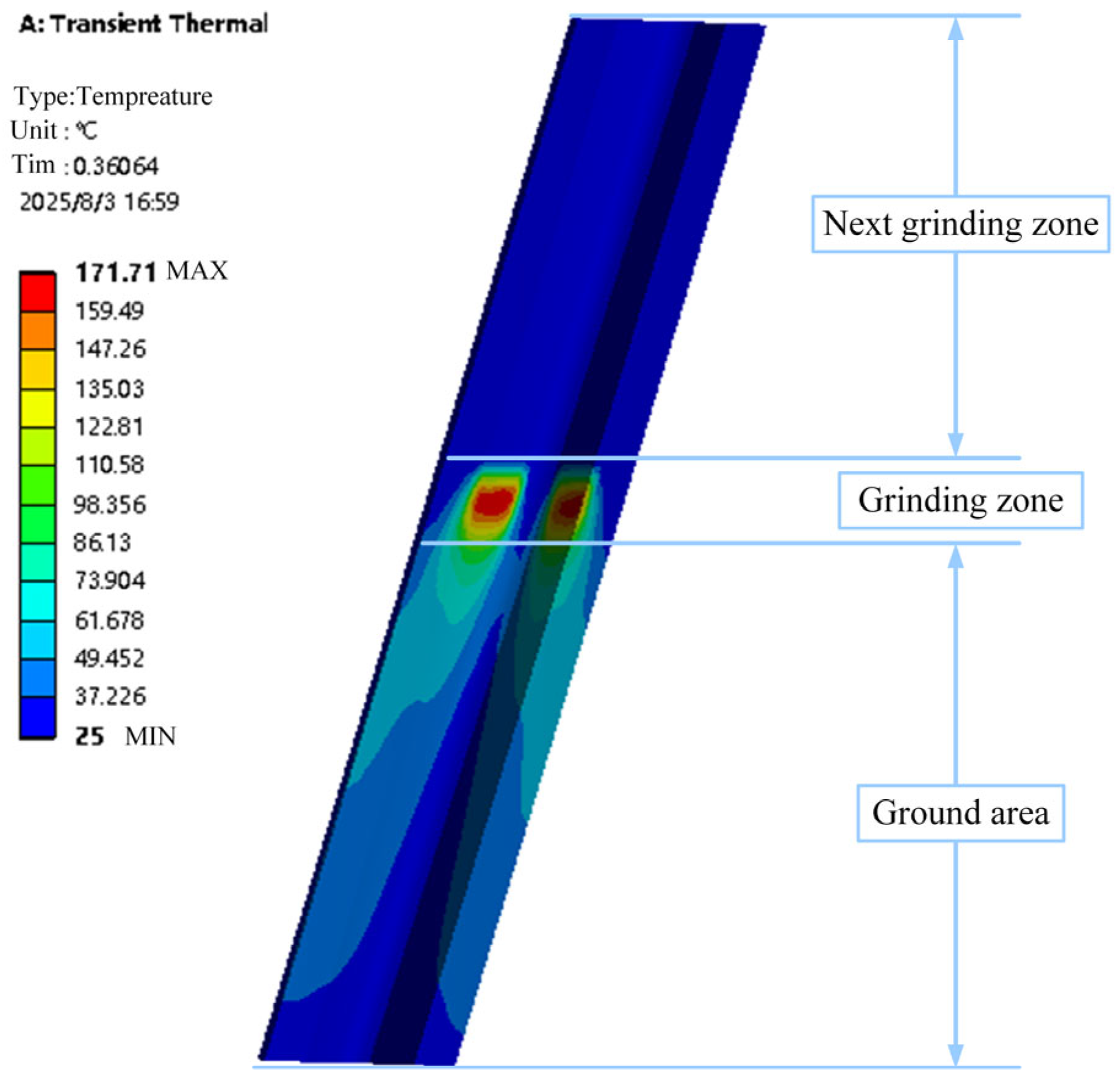

Figure 9 shows the temperature field cloud map at 0.36 s of grinding, when the grinding parameters are set to

vs = 38.5 m/s,

vw = 4 m/min, and

ap = 0.03 mm. It can be seen from the figure that the temperature near the bottom of the tooth groove in the grinding zone reaches the highest value of 171.7 °C. Due to the cooling effect of the grinding fluid, there is a significant temperature gradient between the grinding zone and the non-grinding zone.

As shown in

Figure 10, the maximum grinding temperature in the grinding zone of the tooth surface changes with time. It can be seen that the temperature increases rapidly when the grinding wheel enters the grinding zone during the grinding, and the temperature change rate increases significantly. With the heat source moving at the set grinding feed speed, the temperature variation trend in the grinding zone gradually tends to be gentle. However, when the grinding wheel is about to leave the gear surface, the temperature suddenly rises again and then drops rapidly. This peak phenomenon is mainly due to the grinding fluid not effectively spraying the gear surface in the grinding exit stage, and is accompanied by a heat accumulation phenomenon. This phenomenon matches actual machining observations. Grinding thermal damage easily occurs as the grinding wheel is about to exit the tooth surface. Thereafter, the temperature drops rapidly until it approaches room temperature.

The simulation of grinding residual stress in helical gear forming mainly involves two steps. First, after simulating the grinding temperature field, the analysis module is switched. The temperature results are loaded as input, and the grinding force is applied using the same process parameters to obtain the stress field. Second, all loads are removed. After a set time, the grinding residual stress is obtained once the temperature cools to room temperature.

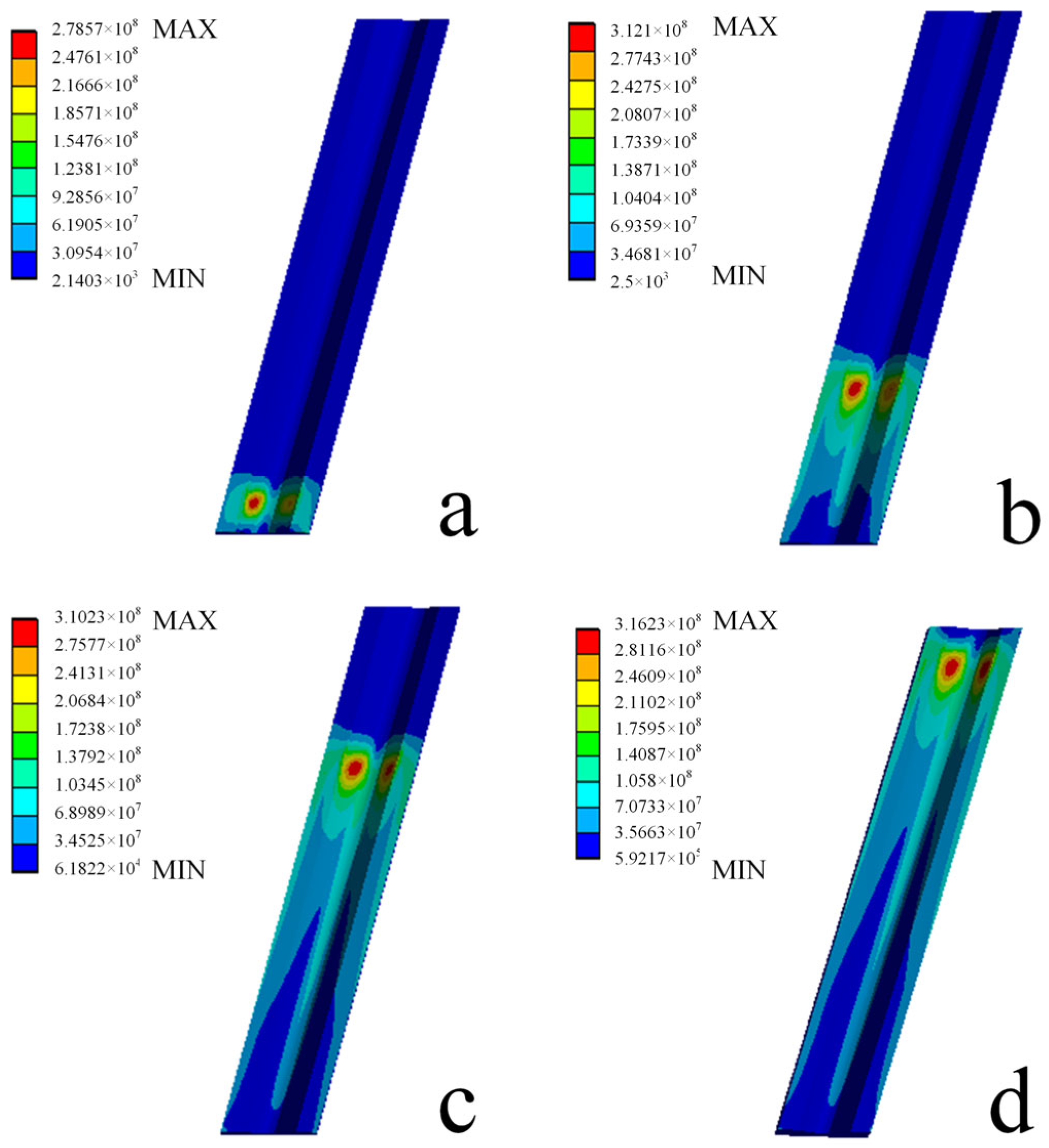

Figure 11 shows the typical process of grinding stress evolution at different stages in the process of internal helical gear profile grinding. The analysis results show that the grinding stress field and temperature field show a highly coupled variation trend, which is mainly due to the grinding heat being the dominant factor inducing grinding stress. Specifically, grinding stress increases sharply with the rapid accumulation of grinding heat in the tooth contact area at the initial stage of the grinding process. After that, when the grinding heat input and heat dissipation by conduction and convection reach a dynamic equilibrium, the grinding stress enters a relatively stable plateau. In the middle and late stages of grinding, the grinding stress increases slowly and fluctuates slightly on the basis of the steady stage due to the softening effect of the local material caused by continuous heat action. The three-stage characteristic of “sharp increase-steady-slow rise” reflects the complex mechanism of interaction between the dynamic load of the grinding heat source and the thermal response of the material.

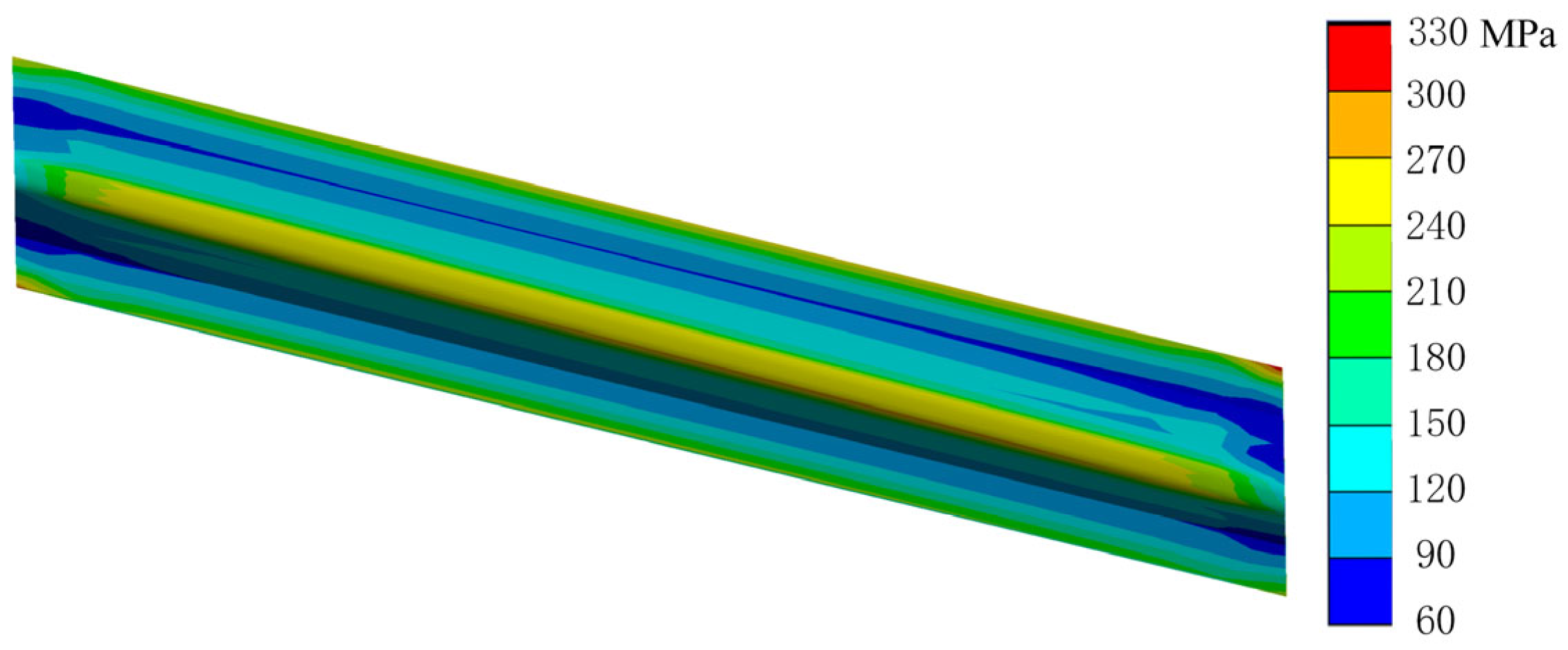

Figure 12 shows the final distribution nephogram of residual stress on the tooth surface of the internal helical gear after profile grinding. The results show that the residual stress decreases along the groove bottom to the tooth top. This phenomenon stems from the non-uniform thermal–mechanical coupling effect during grinding. Geometric constraints limit heat conduction, causing significantly higher grinding temperatures near the tooth root than at the top. This leads to greater thermal stress and thermal elastoplastic deformation. During cooling, stress release in this area is affected by geometric concentration, promoting localized residual stress in the root transition region. Based on the distribution law above, the maximum residual stress nephogram is selected as the key evaluation index for the subsequent process parameter optimization and fatigue performance evaluation.

3. Validity Verification of Simulation Model

To verify the correctness of the numerical simulation method for residual stress, grinding was carried out on the independently developed YK7350N CNC gear grinding machine, as shown in

Figure 13a, and the machined internal helical gear was divided into single-tooth samples, as shown in

Figure 13b.

The specific operation process can include the following: (1) workpiece positioning, clamping, and installation of tools; (2) gear processing parameter input; (3) grinding wheel dressing; (4) adjusting tool; (5) input grinding process parameters; (6) grinding.

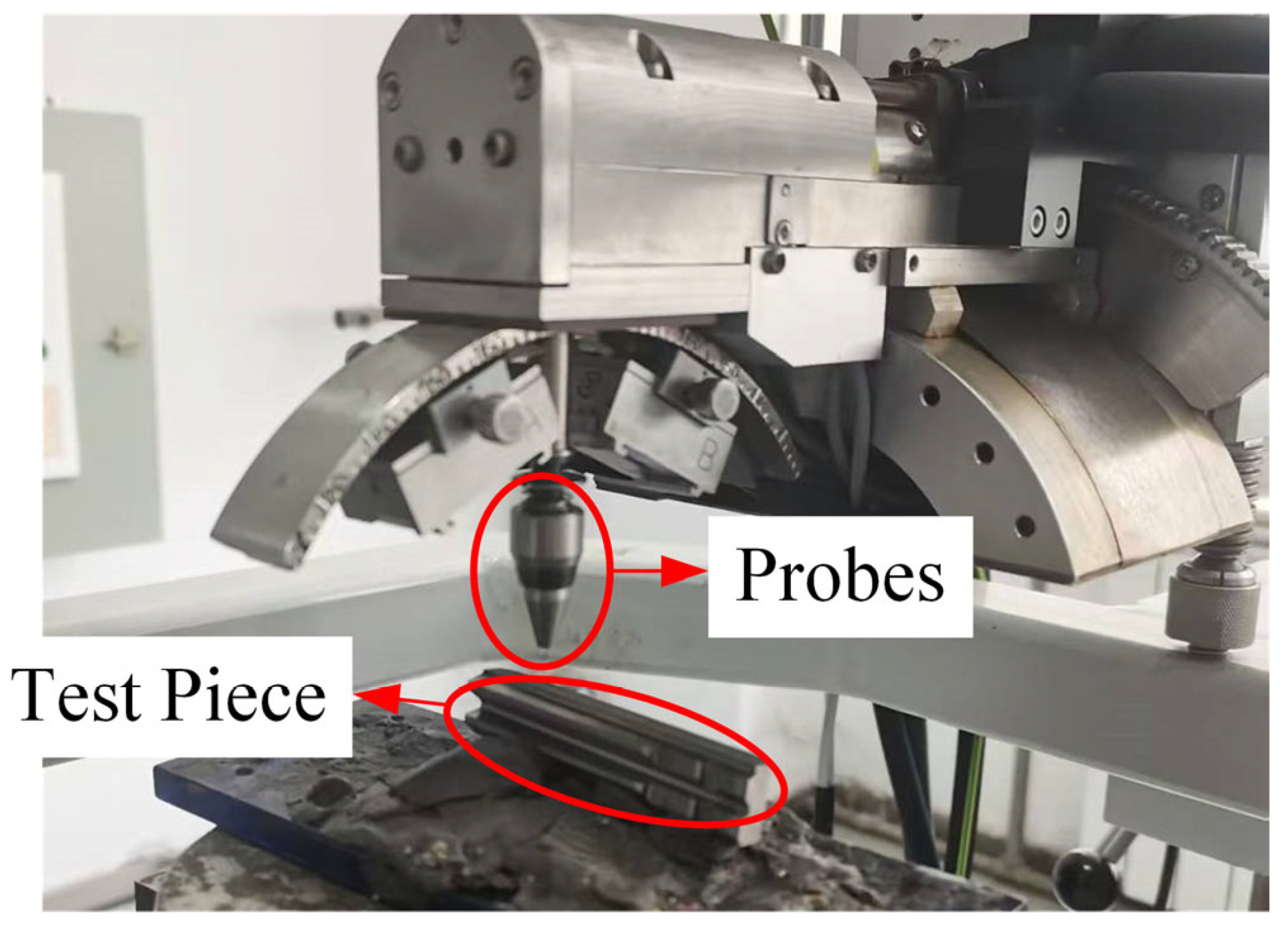

Profile grinding residual stress measurements were performed on the specimens using an XTRESS3000 stress analyzer, as shown in

Figure 14. The specimen was placed on the workpiece table, and the X-ray head was positioned perpendicular to the flank of the tooth being measured. The working flow is as follows: X-ray tube generates X-ray with a specific wavelength, and forms a parallel beam through the collimator; the detector captures the diffraction peak and records the intensity distribution under different

ψ angles; the central system and computer software automatically fit the diffraction peak position, calculate lattice strain, convert it into stress value, and obtain residual stress. It is noteworthy that the X-ray diffraction technique employed here primarily measures the macroscopic residual stress within the irradiated volume.

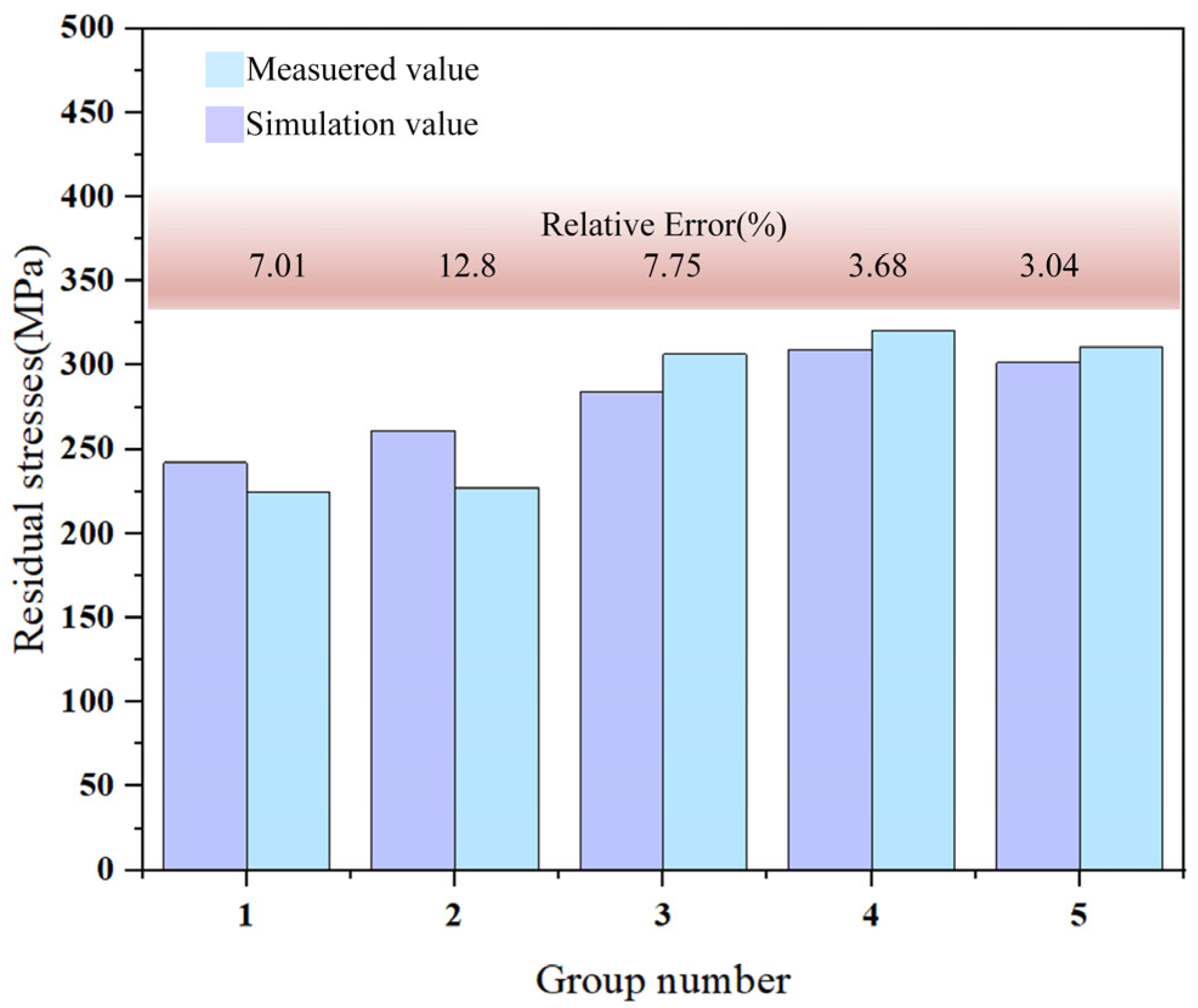

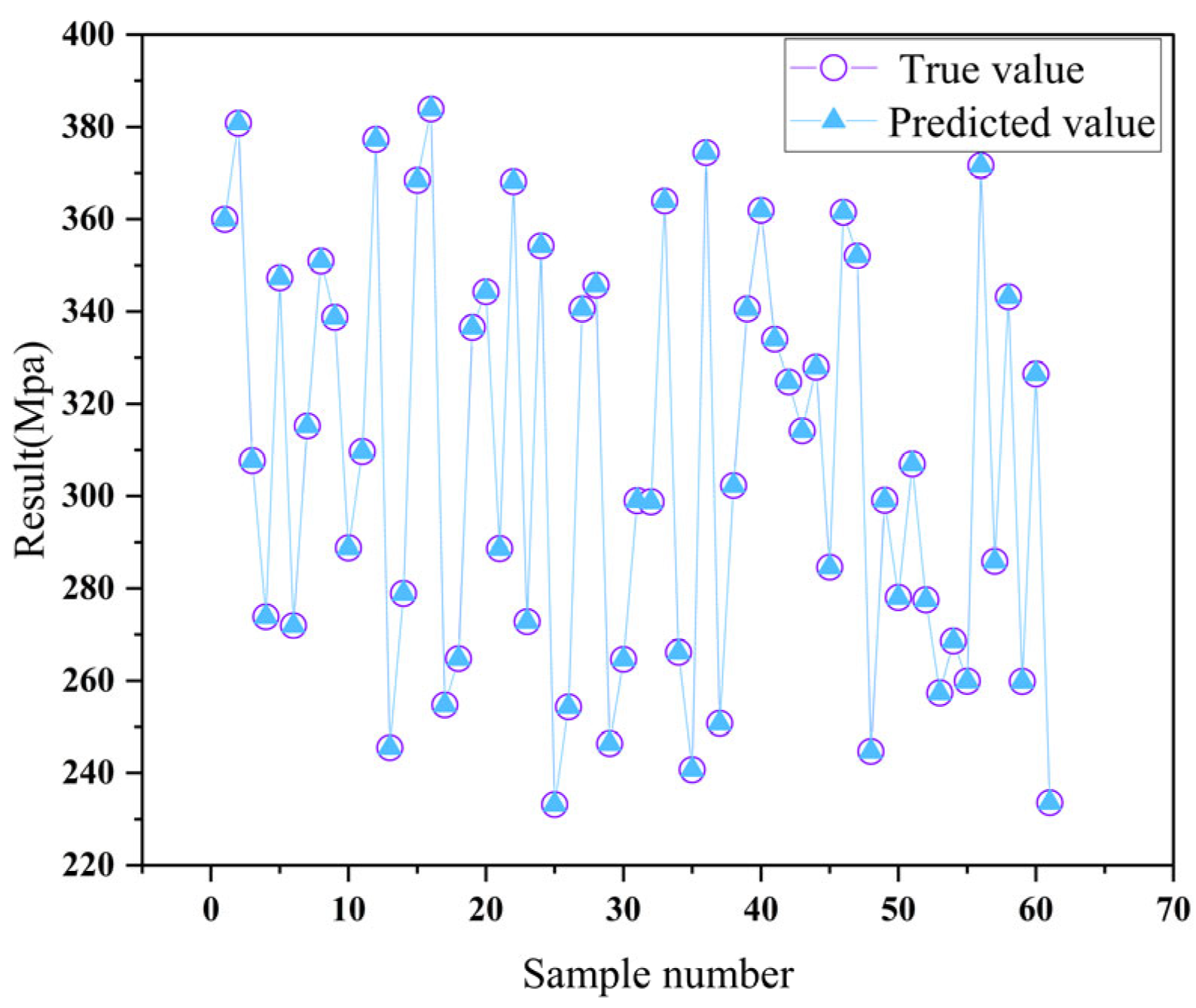

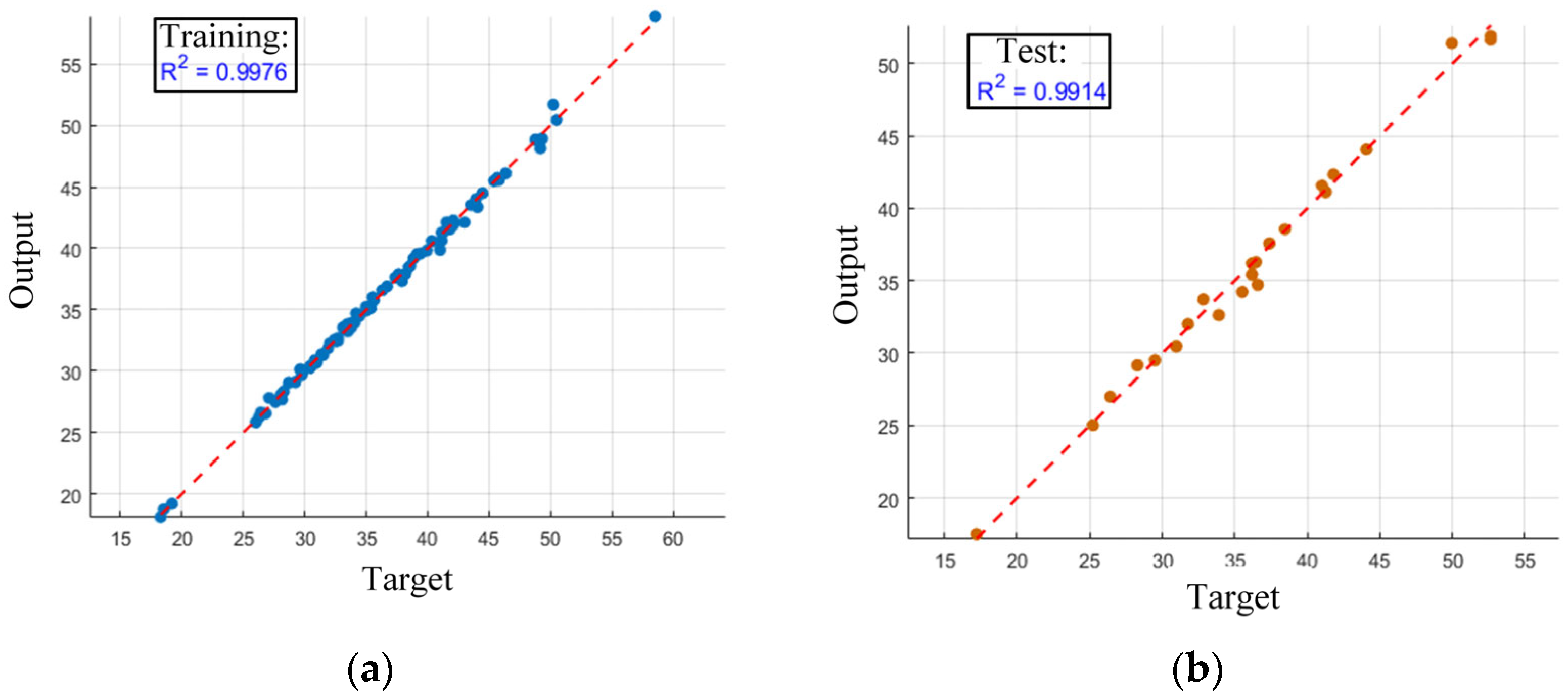

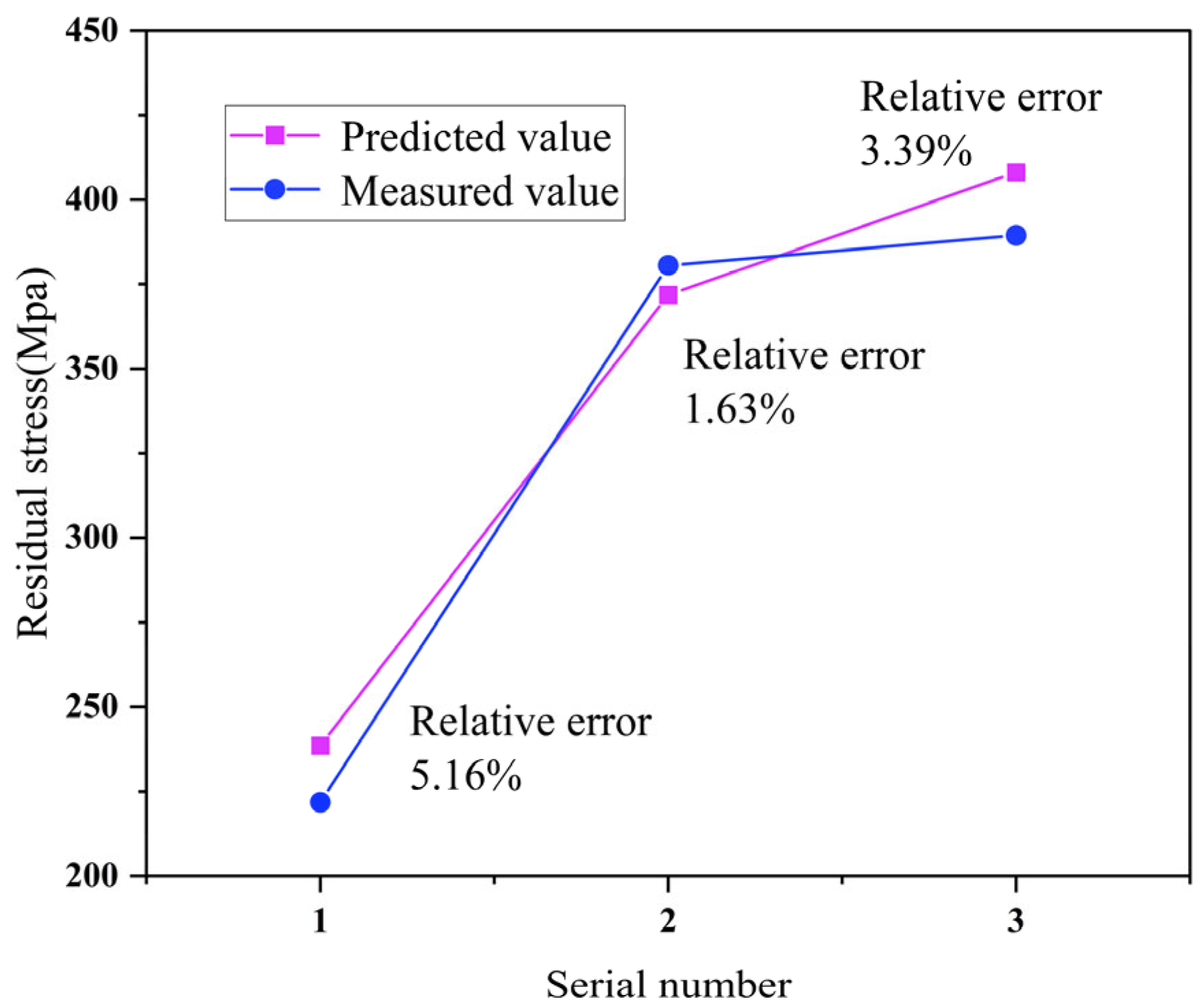

As shown in

Figure 15, after five groups of different grinding process parameters in

Table 5 are selected for simulation, grinding processing is carried out on the above gear grinding machine with the same process parameters. From the results measured on the stress analyzer and the simulation results, it can be seen that the maximum relative error is 12.8%. This is because the simulation analysis is carried out in an absolutely ideal environment, and the processing on the gear grinding machine will be affected by some external factors. Therefore, the simulation model of residual stress in helical gear profile grinding established in this study is reliable and can provide data support for follow-up research.