Advancements in Active Journal Bearings: A Critical Review of Performance, Control, and Emerging Prospects

Abstract

1. Introduction

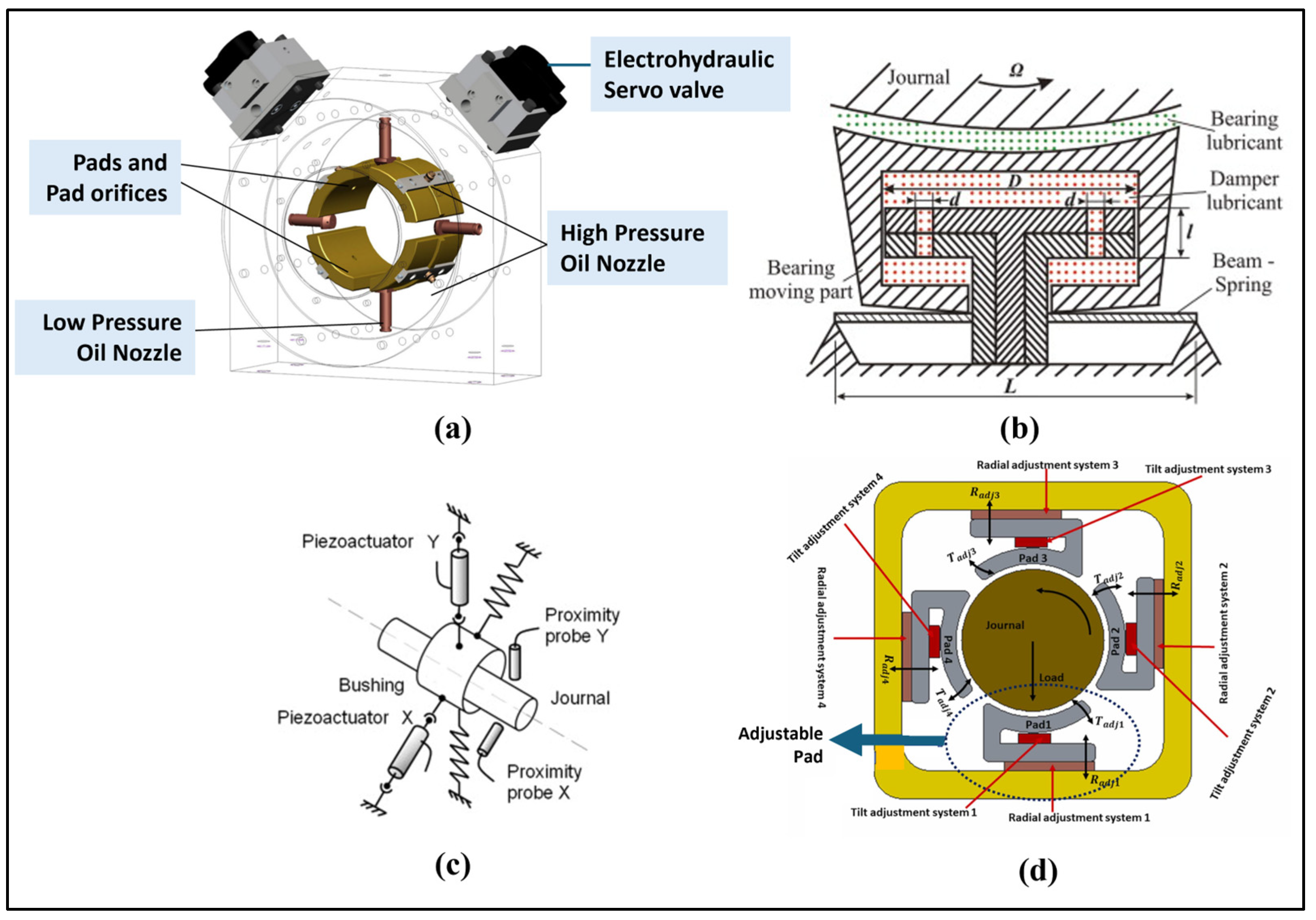

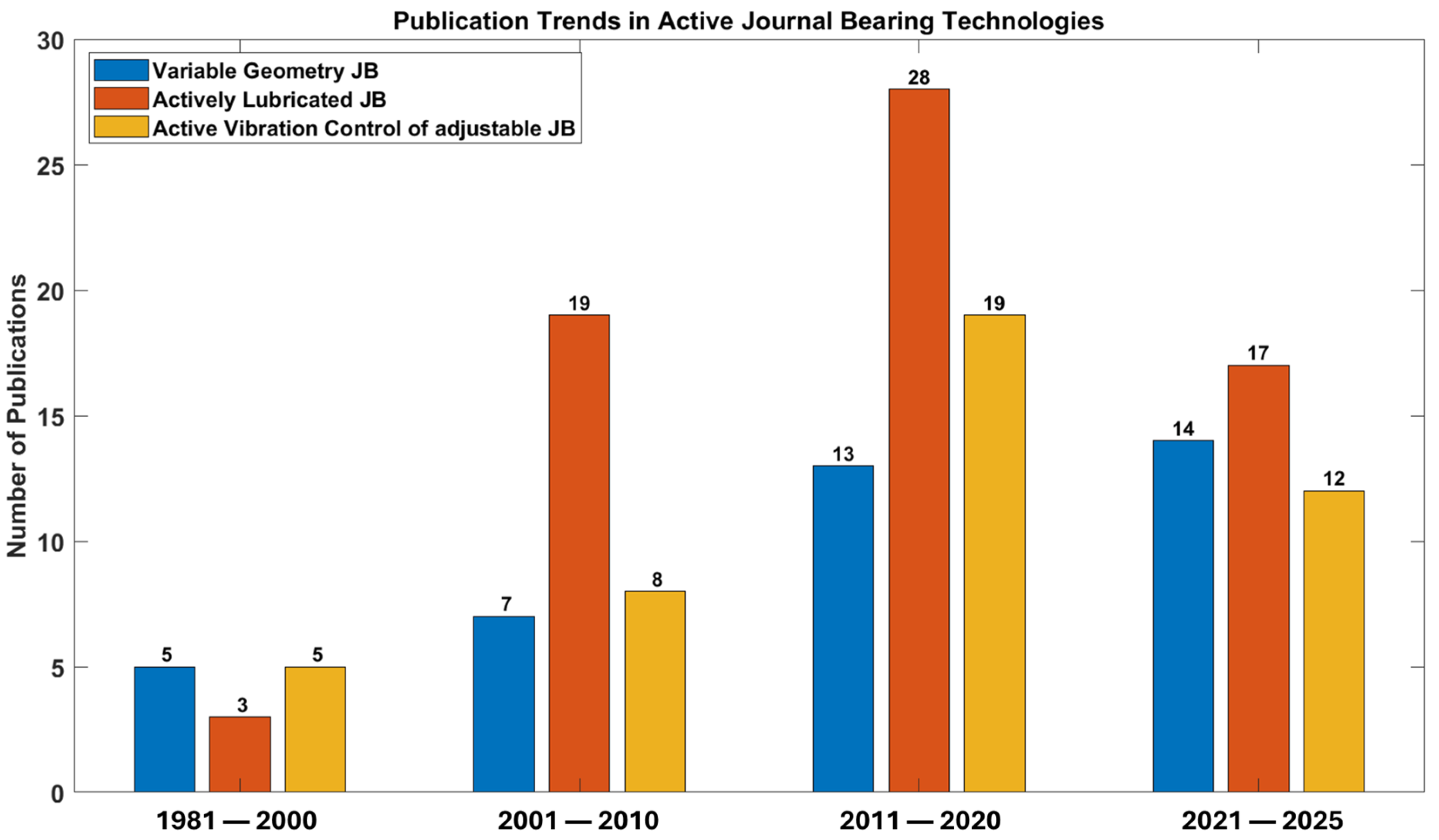

2. Design and Testing of Active/Adjustable Journal Bearings

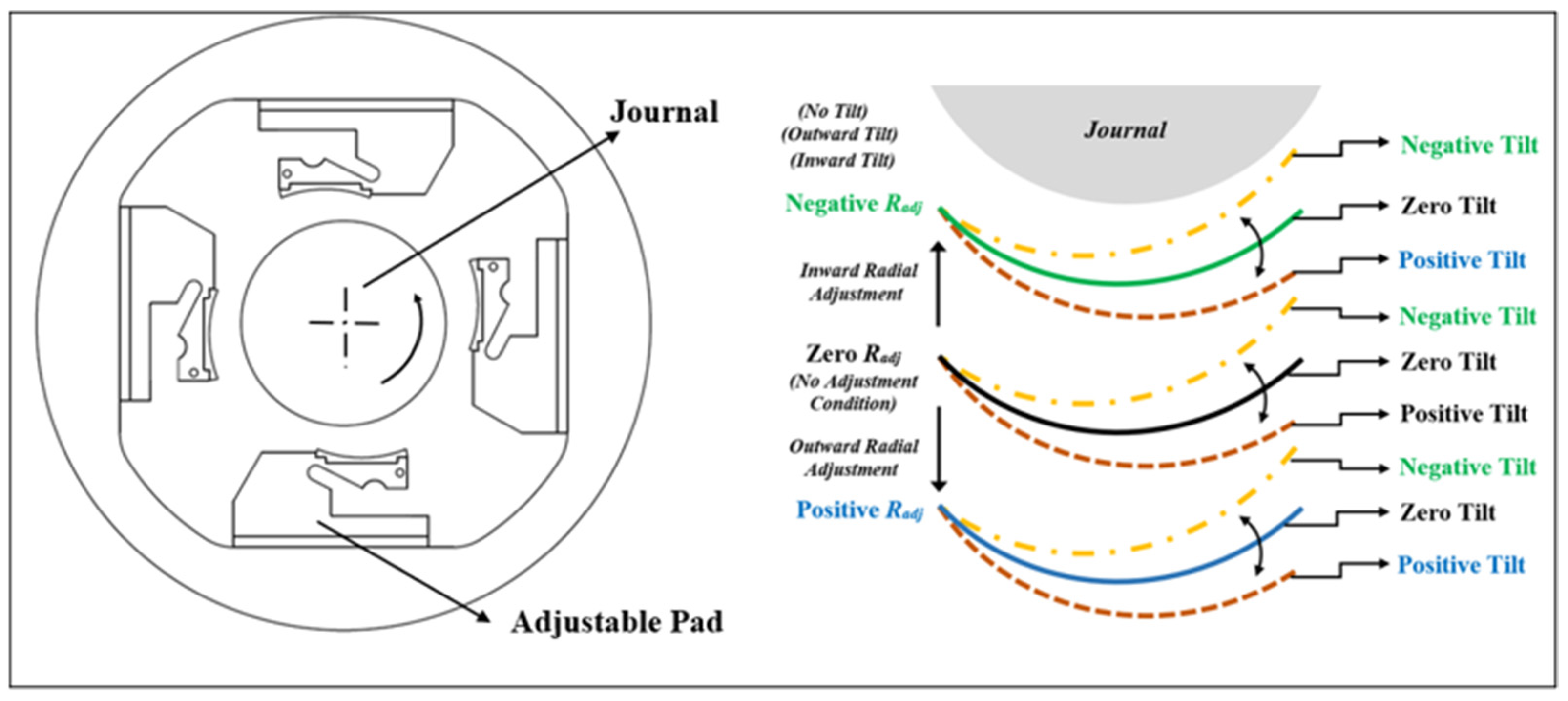

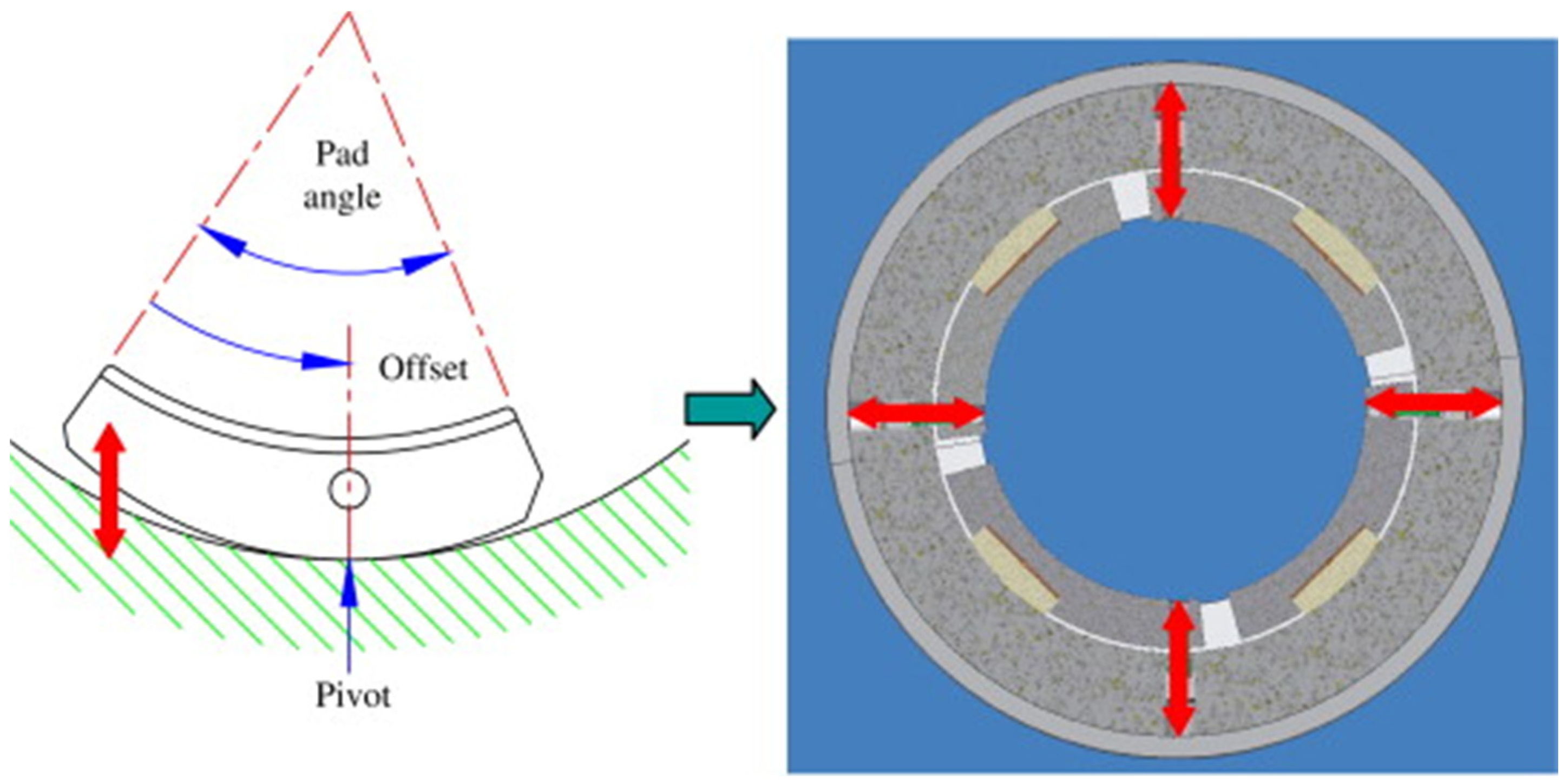

2.1. Variable Geometry Journal Bearings

| Authors | Year | Type of Study | Type of Adjustable Feature | Principle of Operation | Findings |

|---|---|---|---|---|---|

| Martin [8,39] | 2001, 2004 | Experimental | Flexible pad geometry and deformable shaft segments | Rotor dynamics tested using magnetic loading and adjustable fluid film bearings on a fixed shaft. | Displacement data confirmed that adjustable bearings increased stiffness via higher direct coefficients allowing precise repositioning, repeatable resets under 1.9 kN loads |

| Martin [28] | 2011 | Experimental | Shaft segment variation through external adjustments using Pins | Adjustable tilting-pad bearings allow active control of rotor position and film shape | Adjustable bearings achieved over 50% orbit suppression, lower oil temperatures, upto 20% torque reduction, and energy savings of 14–23 GJ/day |

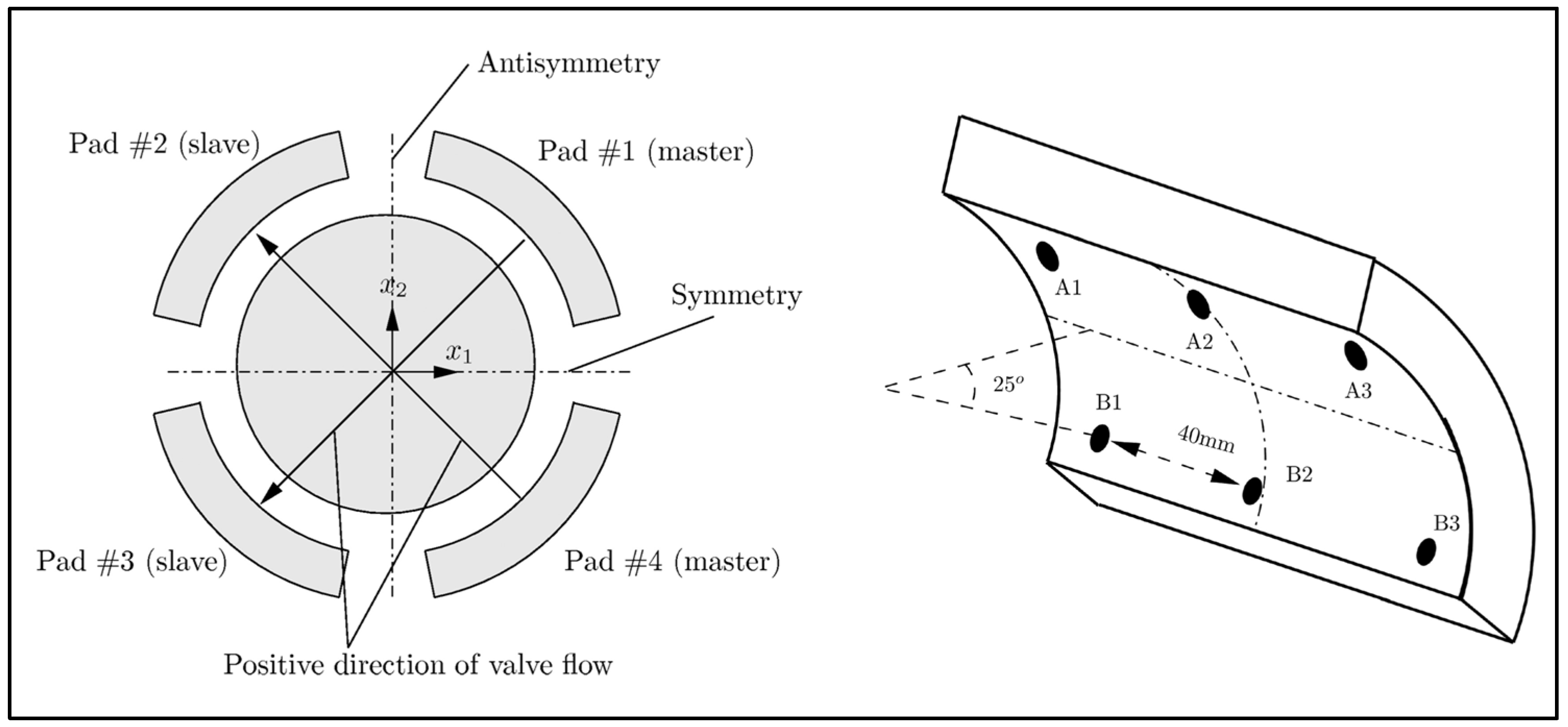

| Shenoy and Pai [40,54] | 2011, 2008 | Numerical | Radial and tilt adjustable single pad geometry using external means | Single pad adjustable bearing ūnder radial and tilt motion | Negative pad adjustments improved bearing performance by increasing stiffness and damping coefficients, raising stability margins, and suppressing half-frequency whirl |

| Hariharan and Pai [55,56,57] | 2021, 2022 | Numerical | Radial and tilt adjustable multiple pad geometries under symmetrical adjustments | Multi-pad adjustable geometry with symmetrical adjustments to control film profile under normala nd misaligned conditions | Negative pad adjustments increased peak pressures (2.16 times), lowered attitude angles, enhanced load capacity, and improved the four-pad geometry’s misalignment tolerance |

| Ganesha et al. [46,47] | 2021 | Numerical | Radial and tilt adjustable multiple pad geometries under asymmetrical adjustments | Adjustable bearings modify film thickness in real-time via flexible elements for precise journal control. | ANOVA results showed that radial adjustment had highest influence on attitude angle (62.8%), followed by eccentricity ratio (16.8%), while tilt adjustment contributed only 3.8%. |

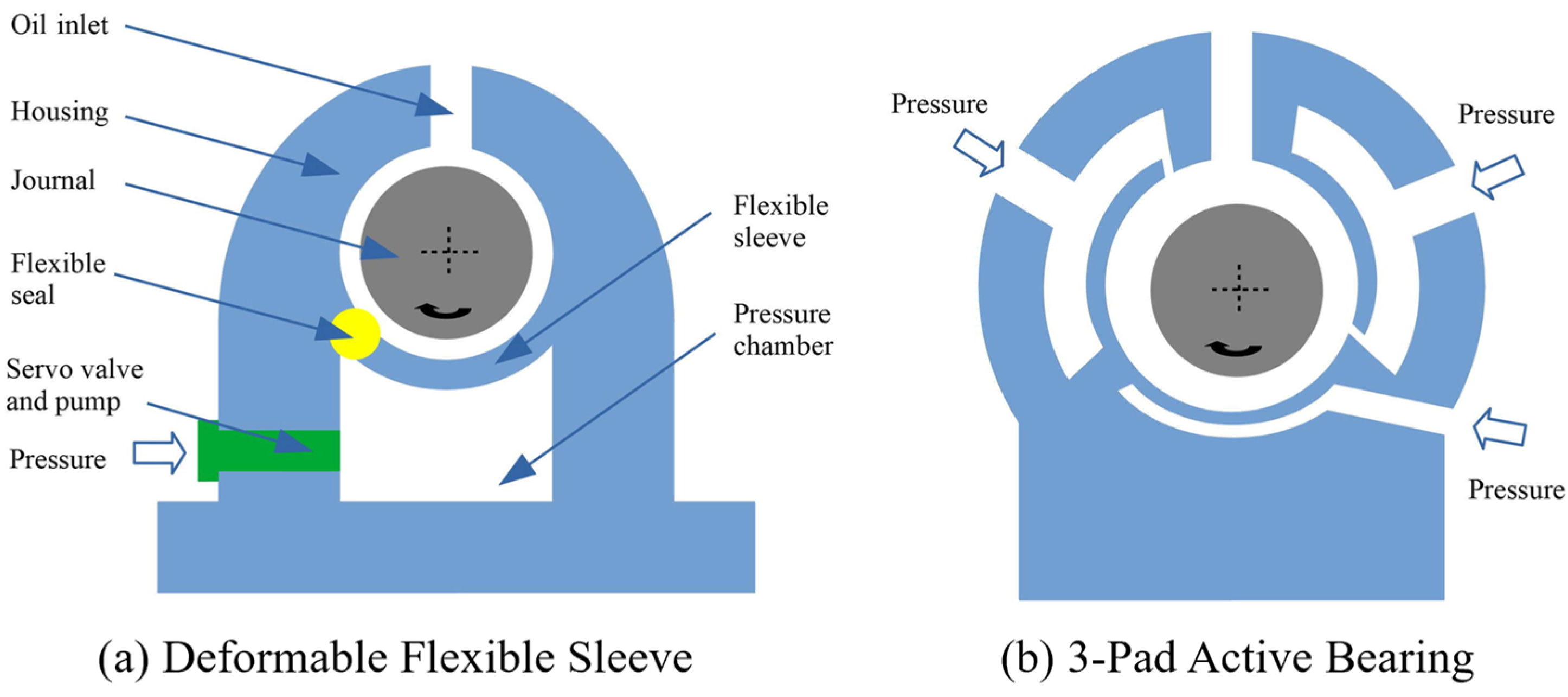

| Krodkiewski and Sun [50,58] | 2000, 1998 | Numerical and Experimental | Flexible sleeve modification by chamber pressure variation | A pressure-controlled sleeve adjusts film shape to actively influence rotor dynamics. | Increasing bulk modulus from 106 to 108 Pa reduced journal and sleeve vibrations, while chamber pressure adjustment enhanced rotor stability and dynamic response |

| Chasalevris and Dohnal [14,59] | 2016 | Numerical and Experimental | Radially movable partial arc pads to alter film thickness | Adjustable partial-arc bearings enable real-time control of rotor position | Optimized external stiffness and damping enhanced rotor stability, suppressed resonance, and reduced vibration response by up to 80% compared to plain bearings. |

| Chasalevris and Guignier [60] | 2019 | Numerical | Quasi-statically displaceable bearing pads in partial-arc bearings | Bearing pads are shifted to adjust the journal center and bore profile, enhancing rotor-stator alignment, and stability. | Effectively reduced rotor–stator eccentricity and whirling, improved bearing loading, and suppressed oil-whirl/whip in 50 MW and 200 MW turbines |

| Zhang et al. [61,62] | 2022, 2025 | Numerical and Experimental | Adjustable single pad through Mechanical transmission mechanism | Radial clearance is actively adjusted to modulate oil film pressure and stabilize rotor dynamics. | Reducing clearance from 90% to 30% cut vibration amplitudes by upto 64% (horizontal) and ~61% (vertical) at 3600 rpm, while increasing clearance from 30% to 70% at 12,000 rpm eliminated oil whip and restored stable orbits |

| Shutin [63] | 2023 | Physics-based Modeling, Machine Learning, and Experimental | Adjustable bearing geometry using mechanical Adjustments | Combines physics-based wear modeling and machine learning to predict Remaining Useful Life (RUL) under active thermal control. | Ambient lubricant stabilization extended service life by only 3%, whereas sub-ambient cooling markedly improved viscosity and life |

| Zhang et al. [64,65] | 2019, 2020 | Numerical and Experimental | Elliptical ratio adjustment by varying tip clearance actively | Adjusting the elliptical ratio alters oil film stiffness and pressure to control rotor vibrations. | Suppresses forced, resonance, and self-excited vibrations, with suppression rates up to 60% depending on load and rotor type. |

| Jin et al. [66] | 2019 | Numerical | Passive Mechanical Adjustment in tilting pad bearing (TPB) via elastic pivot | Elastic pivot enables self-adaptive preload that adjusts film thickness and vibration response under varying conditions. | Elastic pivot TPB provided 18.7% and 27.0% higher minimum film thickness under static and unbalance conditions, but with 9–11 times greater vibration amplitudes than the rigid pivot TPB. |

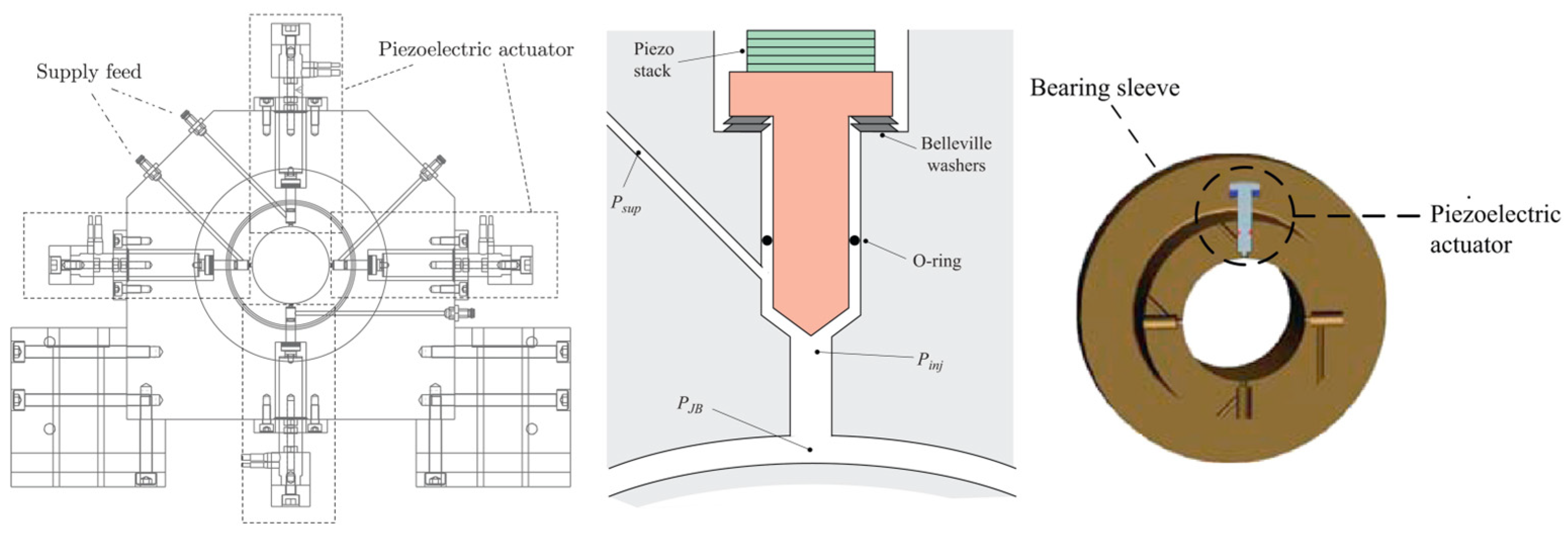

2.2. Actively Lubricated Journal Bearings

| Authors | Year | Type of Study | Type of Actuation | Principle of Operation | Findings |

|---|---|---|---|---|---|

| Nicoletti and Santos [11,70,86] | 2003, 2005, 2001 | Numerical and Experimental | Pressurized oil injection—Pad orifices | Pressurized oil is injected via pad orifices to actively counteract rotor vibrations using control algorithms. | Active lubrication reduced vibration amplitudes by up to 30%, suppressed whirl, and shifted resonance peaks associated with the first rigid mode, thereby enhancing rotor stability. |

| Santos and Watanabe [87] | 2004 | Theoretical | Hydraulic pressure modulation | Active lubrication adjusts hydrostatic pressure to influence bearing dynamics. | Active lubrication with proportional–derivative (PD) controllers increases direct stiffness through proportional control and enhances direct damping through derivative control. |

| Hashimoto and Ochiai [88,89] | 2009, 2010 | Experimental and Theoretical | Passive supply control (via starved lubrication) | Reduced oil supply and orientation adjustment enhance stability by minimizing destabilizing forces. | Starved lubrication with optimized orientation ensured stability up to 4500 rpm, while controlled transition to flooded lubrication maintained stability at 5500–6500 rpm. |

| Salazar and Santos [90,91] | 2015, 2017 | Experimental | Radial oil injection via servo-valves | Integral controller adjusts journal position through controlled oil injection to influence bearing dynamics. | Experiments demonstrated that with injection pressures up to 12 bar, the I-controller repositioned the journal within 24–27% of clearance and minimized tracking oscillations. |

| Uretta et al. [92,93] | 2010, 2019 | Experimental and Numerical | Magnetorheological (MR) fluid-based actuation | MR fluid viscosity is varied by magnetic field to modulate pressure and stiffness in a hybrid journal bearing. | 50% gain in load and stiffness; effective at low frequencies, but too slow for high-speed response. |

| Bompos and Nikolakopoulos [94,95,96,97] | 2011, 2014, 2016 | Numerical and experimental | Magnetorheological actuation via a steady magnetic field applied to the lubricant | Magnetic particles in the MR fluid and nano MR fluid increases lubricant’s viscosity and actively regulate the bearing’s steady state and dynamic properties. | Under magnetic field, the MR fluid increased the attitude angle by 0.7–37.4%, raised friction coefficients by 0.2–28%, and reduced fluid flow by 0.16–5.5%. |

| Estupinan and Santos [98,99] | 2012 | Numerical simulation | Piezoelectric and mechanical oil injectors | Active lubrication combines hydrodynamic film with controllable radial oil injection to adapt fluid film pressure and thickness. | Controlled oil injection enhanced minimum film thickness by up to 90%, limited maximum film pressure to the injection pressure, and reduced both vibration amplitudes and cyclic power losses. |

| Wang et al. [100,101] | 2017 | Experimental | Electromagnetic actuation via external magnetic field | MR fluid lubricated smart bearings control stiffness and damping by varying fluid viscosity under a magnetic field. | Under 2.4 A magnetic field, the floating ring bearing outer stiffness, damping, and added-mass rose up to 283%, 1220%, and 463%, while inner coefficients stayed mostly constant |

| Zhan et al. [102] | 2021 | Experimental and Modeling | Active lubrication with hydrostatic pressure control | Segmented linear models simplify multiple-input multiple-output dynamics for small shaft motions in hydrostatic rotor bearing model. | Identified model accurately captures position-dependent dynamics, with validation fits of 91.35% (horizontal) and 87.44% (vertical), and impulse-response fits of 84.13% and 78.41%. |

| Li et al. [103] | 2022 | Experimental | Piezoelectric microjet | Piezoelectric actuator ejects microdroplets of lubricant on demand via rectangular wave excitation. | Enables long-term, precise, low-power active lubrication for space bearings with 0.012 μL/pulse accuracy and >20-year service life. |

| Kazakov et al. [82] | 2022 | Simulation | Control of supply pressures | Friction torque minimized by regulating axial shaft displacement via pressure control using PI, adaptive PI, and DQN agents. | DQN agent reduces friction torque by up to 25% and shortens adjustment times (0.3–0.48 s), outperforming PI and adaptive PI controllers in torque minimization |

| Jensen and Santos [104,105] | 2022, 2023 | Theoretical and Experimental | Radial oil injection | Model-based control using a digital twin of rotor-bearing-foundation system to attenuate vibrations | Up to 75% vibration reduction achieved at bending mode; strong integral action causes low-frequency amplification. |

| Li et al. [106] | 2022 | Theoretical and Experimental | Servovalve-based hydrostatic pressure control | Servovalves adjust supply pressure to control journal position and minimize disturbances via active hydrostatic forces. | Machine Learning (ML)-based Model Predictive Controller (MPC) outperforms cut steady-state friction torque by ~10% and stabilize rotor displacements under 20 N impulses at 1500 rpm, outperforming PID and LQG controllers in tracking, disturbance rejection |

| van der Meer et al. [107] | 2023 | Experimental and Numerical | Magnetorheological (MR) fluid with localized magnetic field | Locally magnetized, low-viscosity MR fluid regulates bearing stiffness, damping, and load. | MR-lubricated bearings showed ~30% lower friction at 500 rpm and ~25% reduced transition speed using locally magnetized, low-particle MR fluid |

| Shutin and Kazakov [108] and Shutin [109] | 2023, 2024 | Numerical and Experimental | Hydraulic (active lubrication via servo valves) | Actively adjusts shaft position and pressure distribution to reduce shear stress in the lubricant film | Significant friction reduction (up to 6×) and 50% decrease in flow rate; 4-lobe geometry proved most effective. |

| Tomar et al. [110,111] and Sahu et al. [112,113] | 2023, 2024 | Numerical | MR and Electro-rheological (ER) fluid with textured surfaces | Bearing stiffness and stability are improved through the combined effects of smart fluid behavior and surface texturing. | Combined textured surfaces and MR fluid increase minimum film thickness by ~3.5%, stiffness by ~25.6%, and stability threshold speed by ~7% |

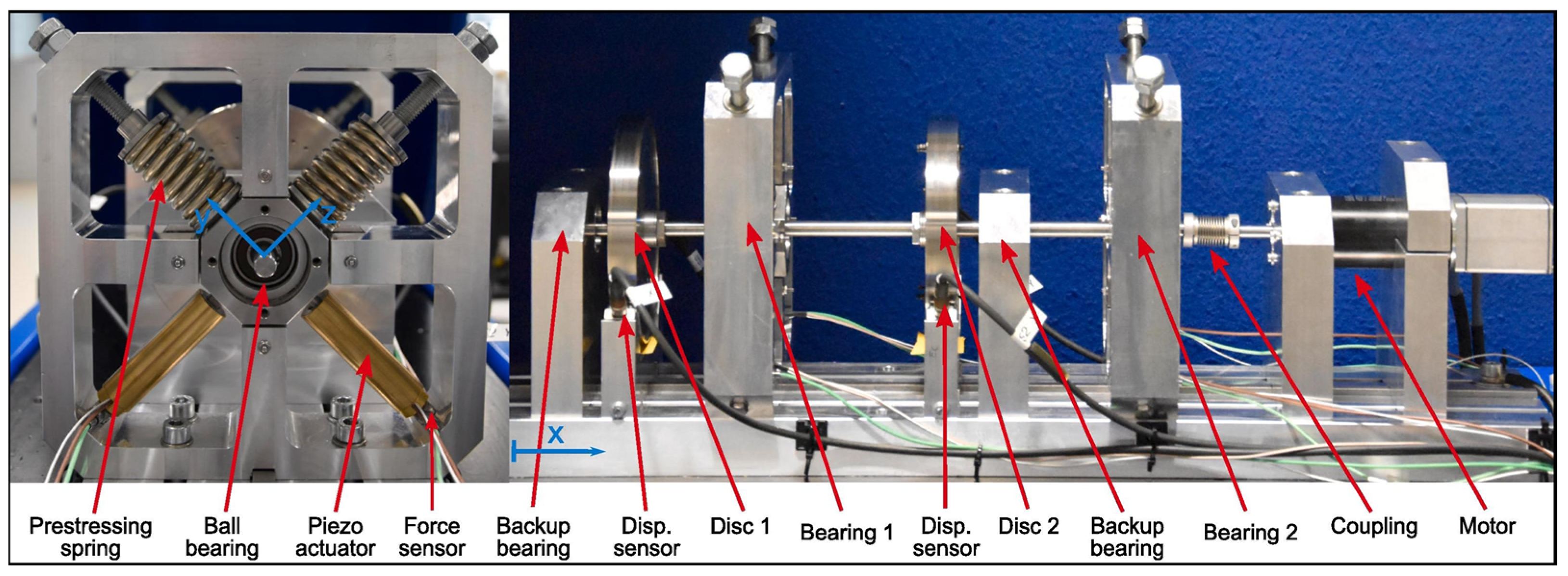

2.3. Active Vibration Control of Adjustable Journal Bearings

| Authors | Year | Type of Study | Type of Actuation | Principle of Operation | Findings |

|---|---|---|---|---|---|

| Stanway and Burrows [135] | 1981 | Theoretical modeling | Active control applied at critical rotor locations | Stabilization achieved through control inputs at strategic rotor points, analyzed under system constraints. | Study reveals trade-offs in actuator placement, sensing, and system identification, exposing conflicting control requirements. |

| Burrows et al. [136] | 1989 | Experimental and theoretical | Magnetic actuator | Uses a single magnetic actuator to estimate system response and apply optimal force to reduce synchronous vibration | Effectively reduced first critical speed vibrations by 80–90% using a single electromagnetic bearing and sparse measurements, while enabling on-line parameter estimation. |

| Yu et al. [137] and Shao et al. [138] | 1998, 2021 | Experimental and theoretical | Active magnetic bearing (electromagnetic actuator) | Applies optimized electromagnetic force using feedforward self-optimizing control for fast vibration suppression. | Attains ≥ 70% vibration reduction within 1 s and sustains performance under speed variations without relying on complex models. |

| Przybylowicz [139,140] | 2000, 2004 | Numerical | Piezoelectric (PZT) actuation to movable shell | Piezo actuators adjust the bearing shell based on journal motion, tuning the oil gap and damping. | Piezoelectric jacks dynamically adjusting the bearing shell doubled the system’s critical speed, greatly extending its stable operating range. |

| Carmignani [129] | 2001 | Experimental and Numerical | Piezoelectric actuators | Harmonic motion from piezo-actuated housing generates corrective forces to counter shaft unbalance. | Demonstrated effective vibration suppression via adaptive bearing actuation, with corrective moments validated by strong experimental–numerical agreement. |

| Cai et al. [119] | 2003, 2004 | Simulation-based modeling | Linear actuators translating tilting pads. | Adaptive control uses actuators to reposition pads, stabilizing the rotor despite uncertainties in fluid film behavior | The adaptive controller reduced rotor displacement by over 95% compared to passive operation, while maintaining control forces within ±2000 N |

| Alizadeh et al. [141] | 2003 | Experimental with control design and simulation | Piezoelectric ssactuators at bearings | Actuators apply corrective forces based on integral force feedback or robust control to suppress rotor vibrations. | Piezo-actuator damping reduced rotor orbit amplitudes by >80%, maintained ~90% stiffness, while both control strategies proved effective, with robust µ-synthesis offering superior handling of system uncertainties. |

| Wu and Queiroz [21] and Wu et al. [117] | 2007, 2010 | Theoretical modeling and Experimental | Linear and rotary actuators | Pad positions or tilt angles are adjusted in real-time via feedback control to regulate rotor motion and enhance stability. | Nonlinear tilt-angle control kept the journal centered without limit cycles, needing only sub-milliradian resolution and a few N·m torque, outperforming PID in efficiency. |

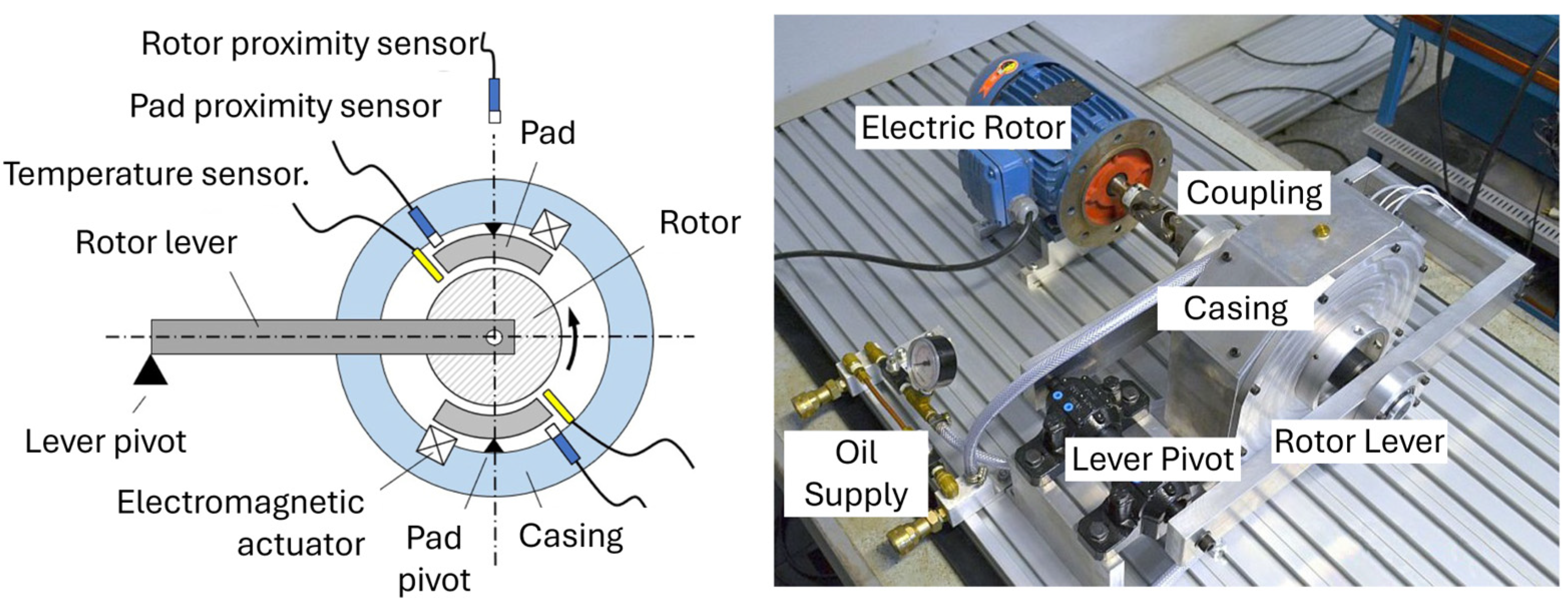

| Tuma et al. [15,116] | 2011 | Experimental and Numerical | Active—Piezoelectric Actuators | Journal vibrations detected by proximity probes are countered by piezoactuators adjusting a movable bushing. | Active control delays instability, extending stable speed to 23,000 rpm with just one actuated bushing. |

| Lau et al. [142] | 2012 | Experimental | GMM based actuators | GMM actuators control journal bearing position via self-tuning P control under a PID algorithm. | GMM actuators reduced shaft orbit size by over 35% across all tested speeds, with fluctuations limited to ~2 mm from a 20 mm uncontrolled orbit confirming feasibility for vibration suppression and positioning. |

| Viveros and Nicoletti [126] | 2014 | Numerical and experimental | Electromagnetic actuators | PD-controlled electromagnetic actuators reduce rotor vibrations using hydrodynamic support. | Achieved up to 18% vibration reduction; system shows competitive control capacity with smaller actuators. |

| Fang et al. [143] | 2015 | Theoretical and experimental | Active Magnetic Bearing (AMB) | Feedforward control with phase correction aligns rotor axis, minimizing vibrations. | AVC strategy reduced rotor vibration forces and torques by over 99% and halved displacement amplitudes, demonstrating high effectiveness for AMB-based devices |

| Pierart and Santos [144] | 2016 | Theoretical and Experimental | Piezoelectrically controlled radial oil jet | Proportional control of radial oil injection improves damping by adjusting gas film pressure. | Proportional controller enhanced the rotor–bearing damping factor up to 6×, with natural frequency errors under 5% and damping deviations within 50% between theory and experiment. |

| Ambur and Rinderknecht [145] | 2018 | Experimental and simulation | Piezoelectric actuators | Self-sensing piezo actuators detect bearing deflection, enabling unbalance estimation via frequency-domain parameter estimation | Robust fault detection was achieved using Weighted Least Squares, with all fault parameters identified in stationary tests, as outliers reduced accuracy by ~45% in magnitude and ~33° in phase |

| Hu et al. [146] | 2018 | Experimental and Simulation | Piezoelectric actuators | Piezo actuators regulate preload or clearance via pressure/position control using closed-loop PI control. | Variable position preload achieved up to ~90% higher axial stiffness and ~28% higher first-order natural frequencythan variable pressure preload under the same conditions |

| Preto et al. [147] | 2023 | Experimental | SMA thermal actuation | SMA wires at bearings adjust stiffness via Joule heating to alter system dynamics. | SMA rotor system reduced bearing and disc horizontal displacements by 20–30% compared to the elastic setup, while also increasing stiffness and raising the critical frequency. |

| Xu et al. [148,149] | 2023, 2025 | Experimental and numerical | Hydrostatic gas supply with PID and fuzzy PID control | External gas supply boosts film stiffness in air foil bearings, enabling active vibration control through pressure tuning. | Increasing the gas supply to 0.50 MPa cut rotor vibration by ~6.8 µm, suppressed low-frequency oscillations, and increased critical speed to 6200 r/min. |

| Li et al. [150] | 2023 | Theoretical and Experimental | Active Hybrid Bearings (AHBs) with PI and nonlinear controllers | Uses PI and adaptive nonlinear control to manage rotor vibration and viscous friction in AHB systems. | Active hybrid bearings cut rotor oscillations by several times and lower viscous friction losses by up to 19% via optimized rotor position control. |

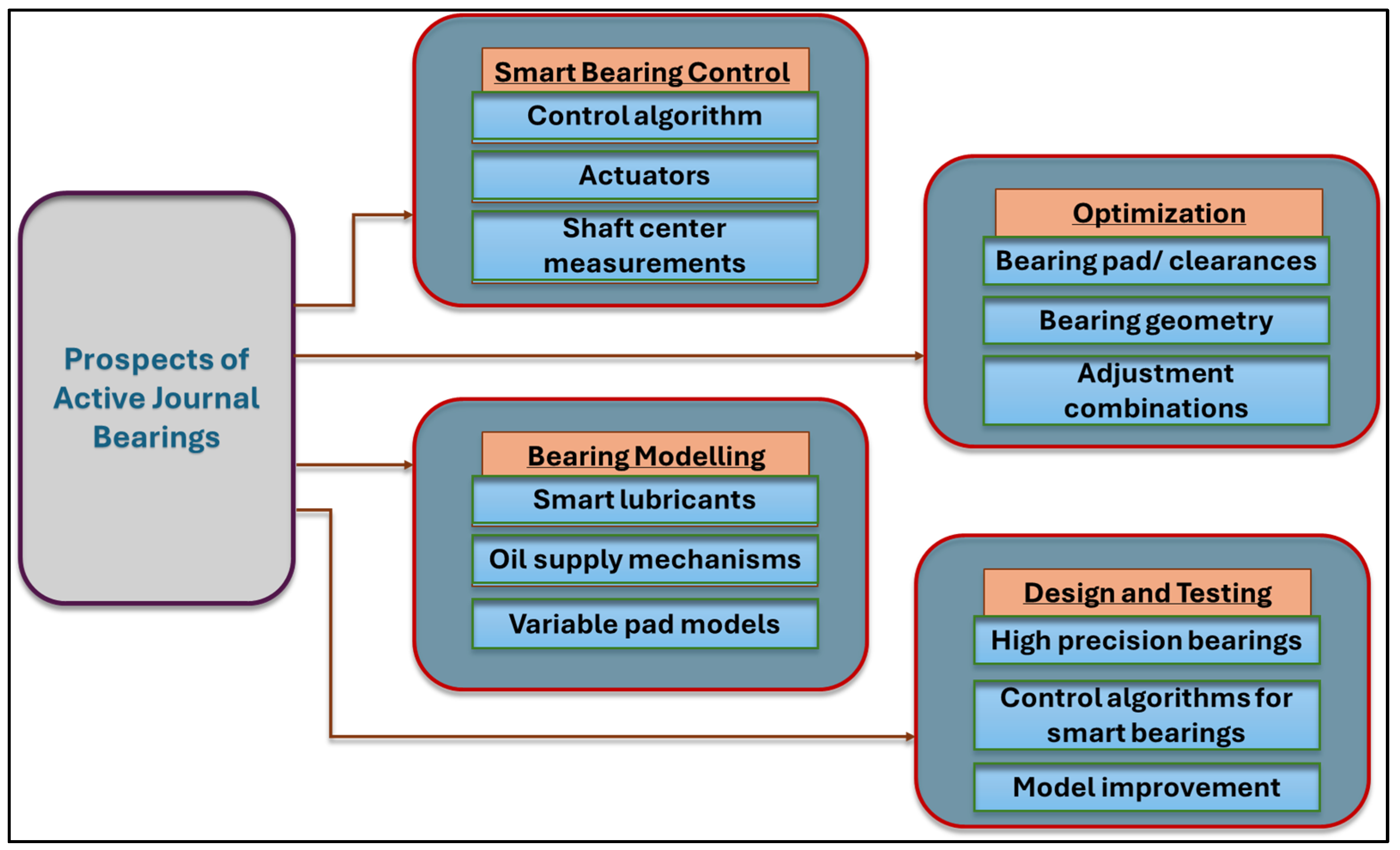

3. Applications and Future Prospects of Active Bearing Technologies

- Smart bearing control focuses on enhancing the adaptability and responsiveness of active journal bearings. This involves the development of advanced control algorithms, the integration of precise actuators, and the use of real-time shaft center measurements to enable adaptive operation. Both classical controllers, such as PI, PD, and PID, and advanced methods like artificial neural networks, fuzzy logic, and adaptive/self-tuning techniques are employed to maintain optimal bearing performance under varying operating conditions.

- Optimization in active journal bearings aims to enhance dynamic performance, efficiency, and stability by fine-tuning both the bearing design and its operating parameters. This involves adjusting bearing pads, clearances, and overall geometry, as well as optimizing pad-clearance combinations and pressure distribution. Component-level improvements, such as refining lubrication gaps, supply systems, and miniaturizing sensors and actuators, contribute to more compact, efficient, and reliable bearing systems.

- Bearing modelling focuses on accurately representing the behavior of active journal bearings under diverse operating conditions to improve performance and reliability. This includes incorporating smart lubricants and advanced oil supply mechanisms, as well as developing variable pad models that can simulate the bearing’s dynamic response. Continuous refinement of these simulation models ensures that the bearings perform optimally and reliably across different loads and operating environments.

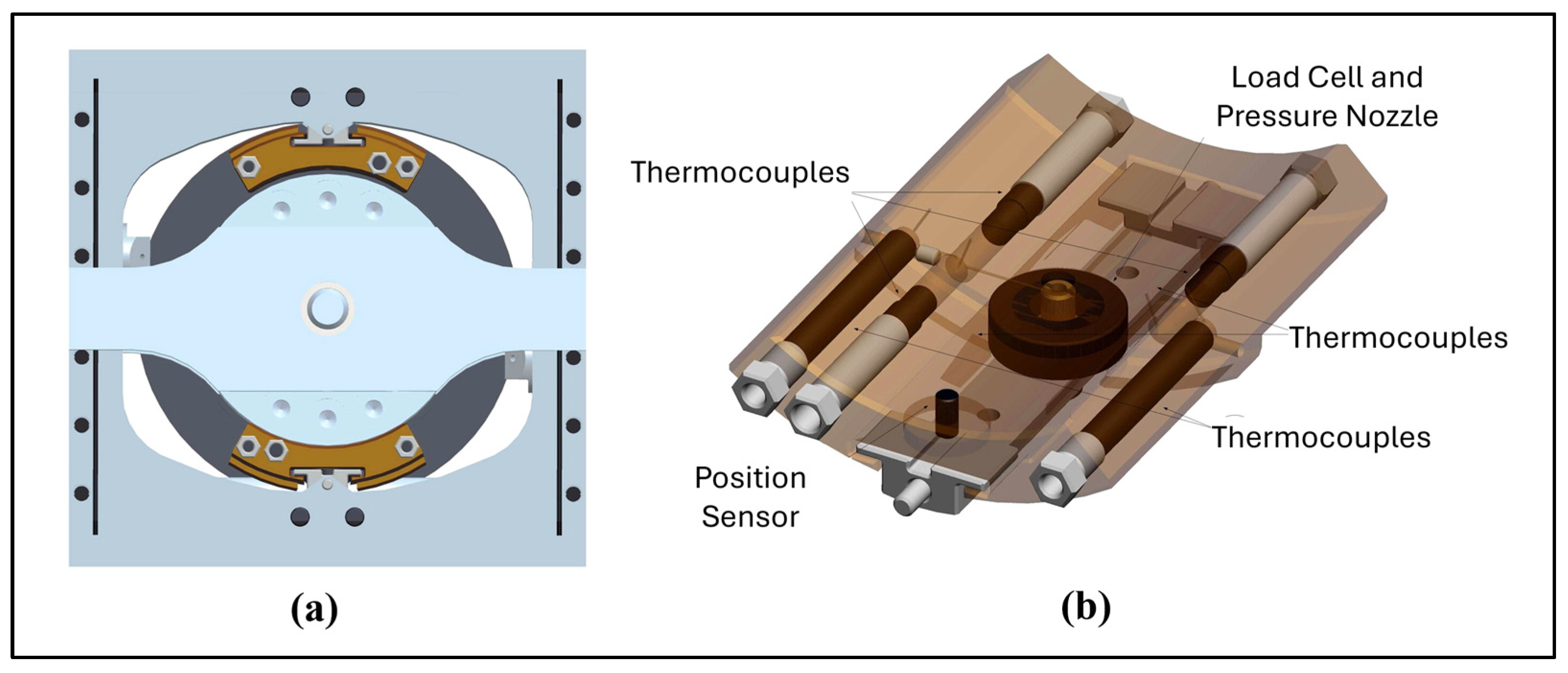

- Design and testing of active journal bearings focus on translating advanced models and control strategies into high-performance, reliable hardware. This involves manufacturing high-precision bearings specifically tailored for active operation, developing and validating control algorithms for smart bearings, and conducting continuous testing and refinement to ensure optimal performance, reliability, and safety under real operating conditions.

4. Conclusions

- Active or adjustable bearing systems have evolved from theoretical concepts to practical engineering solutions, significantly enhancing rotor dynamics and vibration control. Early studies focused on hydraulic dampers, variable sleeves, and controllable fluid film bearings, while modern developments extend these concepts to high-speed and multi-rotor systems with precise real-time control.

- Modern active bearings incorporate magnetic and piezoelectric actuators, flexible sleeves, deformable bushes, and advanced fluid supply systems, enabling real-time adjustment of film thickness, pressure distribution, and stiffness. Studies show they can reduce vibration amplitudes by 60–70%, increase damping up to sixfold, and raise critical speeds, greatly enhancing the stable operating range.

- Active control frameworks integrating proximity probes, adaptive algorithms, and actuator-driven adjustments allow rotor position correction, dynamic compensation, and mitigation of cavitation, wear, and other adverse phenomena. Adjustable clearances, optimized lubrication, and adaptive materials provide self-regulating capabilities, ensuring enhanced stability, reliable vibration suppression, and improved dynamic performance.

- Despite substantial advancements, challenges remain in managing system complexity, reducing energy consumption, achieving compact integration, and ensuring long-term industrial reliability. Ongoing research focuses on hybrid bearing systems, AI-driven adaptive control, miniaturized sensors and actuators, and advanced materials to enhance load capacity, thermal stability, and overall operational performance.

- Emerging trends in active bearing development focus on enhancing adaptability, dynamic performance, and reliability through advanced control algorithms, real-time monitoring, optimized geometries, and component-level improvements. Additionally, accurate bearing modelling, smart lubrication, high-precision manufacturing, and rigorous testing ensure that active bearings deliver stable, efficient, and robust performance across diverse operating conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fillon, M.; Bouyer, J. Thermohydrodynamic Analysis of a Worn Plain Journal Bearing. Tribol. Int. 2004, 37, 129–136. [Google Scholar] [CrossRef]

- Chaudhary, S.; Verma, R. A Comprehensive Review of Journal Bearing Models: Comparative Analysis of Thermal, Elastic, and Hydrodynamic Approaches Considering Misalignment, Surface Texture, Turbulence, and Cavitation. J. Tribol. 2025, 147, 110802. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, R.; Ji, F.; Yuan, X. Theoretical and Experimental Dynamics Analysis of Rotor-Bearing System Supported by Elliptical Bearings. Ind. Lubr. Tribol. 2021, 73, 145–152. [Google Scholar] [CrossRef]

- Chauhan, A.; Sehgal, R.; Sharma, R.K. A Study of Thermal Effects in an Offset-halves Journal Bearing Profile Using Different Grade Oils. Lubr. Sci. 2011, 23, 233–248. [Google Scholar] [CrossRef]

- Dimond, T.; Younan, A.; Allaire, P. A Review of Tilting Pad Bearing Theory. Int. J. Rotating Mach. 2011, 2011, 908469. [Google Scholar] [CrossRef]

- Rahmatabadi, A.D.; Sefid, M.; Rashidi Meybodi, R.; Nekoeimehr, M. Effects of Bearing Orientation on the Static Performance of Micropolar Lubricated Lobe Bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 3–13. [Google Scholar] [CrossRef]

- Rahmatabadi, A.D.; Rashidi Meybodi, R.; Nekoeimehr, M. Preload Effects on the Static Performance of Multi-Lobe Fixed Profile Journal Bearings with Micropolar Fluids. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 718–730. [Google Scholar] [CrossRef]

- Martin, J.K.; Parkins, D.W. Testing of a Large Adjustable Hydrodynamic Journal Bearing. Tribol. Trans. 2001, 44, 559–566. [Google Scholar] [CrossRef]

- Cai, Z.; de Queiroz, M.S.; Khonsari, M.M. Adaptive Control of Active Tilting-Pad Bearings. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; Volume 4, pp. 2907–2912. [Google Scholar] [CrossRef]

- Santos, I.F. On the Future of Controllable Fluid Film Bearings. Mech. Ind. 2011, 12, 275–281. [Google Scholar] [CrossRef]

- Nicoletti, R.; Santos, I.F. Linear and Non-Linear Control Techniques Applied to Actively Lubricated Journal Bearings. J. Sound Vib. 2003, 260, 927–947. [Google Scholar] [CrossRef]

- Salazar, J.G.; Santos, I.F. Active Tilting-Pad Journal Bearings Supporting Flexible Rotors: Part II–The Model-Based Feedback-Controlled Lubrication. Tribol. Int. 2017, 107, 106–115. [Google Scholar] [CrossRef]

- Chasalevris, A.; Dohnal, F. A Journal Bearing with Variable Geometry for the Suppression of Vibrations in Rotating Shafts: Simulation, Design, Construction and Experiment. Mech. Syst. Signal Process. 2015, 52, 506–528. [Google Scholar] [CrossRef]

- Chasalevris, A.; Dohnal, F. Improving Stability and Operation of Turbine Rotors Using Adjustable Journal Bearings. Tribol. Int. 2016, 104, 369–382. [Google Scholar] [CrossRef]

- Tůma, J.; Šimek, J.; Škuta, J.; Los, J. Active Vibrations Control of Journal Bearings with the Use of Piezoactuators. Mech. Syst. Signal Process. 2013, 36, 618–629. [Google Scholar] [CrossRef]

- Santos, I.F. Trends in Controllable Oil Film Bearings. In IUTAM Symposium on Emerging Trends in Rotor Dynamics; Gupta, K., Ed.; Springer: Dordrecht, The Netherlands, 2011; pp. 185–199. [Google Scholar]

- Santos, I.F. Controllable Sliding Bearings and Controllable Lubrication Principles—An Overview. Lubricants 2018, 6, 16. [Google Scholar] [CrossRef]

- Ganesha, A.; Girish, H.; Pai, R.; Khader, S.M.A. A Data-Driven Exploration of Multi Pad Bidirectional Adjustable Bearings and Deep Learning Model-Based Optimization. Tribol. Int. 2024, 194, 109570. [Google Scholar] [CrossRef]

- Hariharan, G.; Pai, R.; Pham, D. Mathematical Formulation of a Modified Film Thickness Equation for Multipad Externally Adjustable Fluid Film Bearing. Cogent Eng. 2018, 5, 1493672. [Google Scholar] [CrossRef]

- Palazzolo, A.B.; Lin, R.R.; Alexander, R.M.; Kascak, A.F.; Montague, J. Test and Theory for Piezoelectric Actuator-Active Vibration Control of Rotating Machinery. J. Vib. Acoust. 1991, 113, 167–175. [Google Scholar] [CrossRef]

- Wu, A.; Cai, Z.; de Queiroz, M.S. Model-Based Control of Active Tilting-Pad Bearings. IEEE/ASME Trans. Mechatron. 2007, 12, 689–695. [Google Scholar] [CrossRef]

- Deckler, D.C.; Veillette, R.J.; Braun, M.J.; Choy, F.K. Simulation and Control of an Active Tilting-Pad Journal Bearing. Tribol. Trans. 2004, 47, 440–458. [Google Scholar] [CrossRef]

- Santos, I.F. On the Adjusting of the Dynamic Coefficients of Tilting-Pad Journal Bearings. Tribol. Trans. 1995, 38, 700–706. [Google Scholar] [CrossRef]

- Cerda Varela, A.; Bjerregaard Nielsen, B.; Santos, I.F. Steady State Characteristics of a Tilting Pad Journal Bearing with Controllable Lubrication: Comparison between Theoretical and Experimental Results. Tribol. Int. 2013, 58, 85–97. [Google Scholar] [CrossRef]

- Varela, A.C.; Santos, I.F. Performance Improvement of Tilting-Pad Journal Bearings by Means of Controllable Lubrication. Mech. Ind. 2012, 13, 17–32. [Google Scholar] [CrossRef]

- Estupiñan, E.A.; Santos, I.F. Linking Rigid Multibody Systems via Controllable Thin Fluid Films. Tribol. Int. 2009, 42, 1478–1486. [Google Scholar] [CrossRef]

- Santos, I.F.; Nicoletti, R. THD Analysis in Tilting-Pad Journal Bearings Using Multiple Orifice Hybrid Lubrication. J. Tribol. 1999, 121, 892–900. [Google Scholar] [CrossRef]

- Martin, J.K. Improved Performance of Hydrodynamic Bearings by Proactive Adjustment. Méc. Ind. 2011, 12, 17–24. [Google Scholar] [CrossRef]

- Shenoy, B.S.; Pai, R. Performance Evaluation of a Single-Pad, Externally-Adjustable Fluid Film Bearing. Aust. J. Mech. Eng. 2009, 7, 125–135. [Google Scholar] [CrossRef]

- Sun, L.; Krodkiewski, J.M.; Cen, Y. Self-Tuning Adaptive Control of Forced Vibration in Rotor Systems Using an Active Journal Bearing. J. Sound Vib. 1998, 213, 1–14. [Google Scholar] [CrossRef]

- Sun, L.; Krodkiewski, J.M.M. Experimental Investigation of Dynamic Properties of an Active Journal Bearing. J. Sound Vib. 2000, 230, 1103–1117. [Google Scholar] [CrossRef]

- Santos, I.F.; Russo, F.H. Tilting-Pad Journal Bearings With Electronic Radial Oil Injection. J. Tribol. 1998, 120, 583–594. [Google Scholar] [CrossRef]

- Silva, H.A.P.; Nicoletti, R. Rotor Vibration Control Using Tilting-Pad Journal Bearing with Active Pads—Numerical and Experimental Results. J. Sound Vib. 2023, 546, 117441. [Google Scholar] [CrossRef]

- Guimarães Oliveira, A.; Almeida Silva, A.; Jose de Araújo, C.; Senko, R.; Pierre Batista Dos Reis, R. Design and Experimental Analysis of a Smart Bearing Using Shape Memory Alloy Springs. J. Intell. Mater. Syst. Struct. 2020, 31, 1390–1402. [Google Scholar] [CrossRef]

- Borges, J.M.; Silva, A.A.; de Araújo, C.J.; Pimentel, R.L.; de Aquino, A.S.; Senko, R.; dos Reis, R.P.B. On the Active Control of a Rotor-Bearing System Using Shape Memory Alloy Actuators: An Experimental Analysis. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 269. [Google Scholar] [CrossRef]

- Wang, W.; Cai, S.Z.; Wu, C.; Wong, P.L. Vibration Suppression Evaluation of Smart Journal Bearing Using Giant Magnetostrictive Actuators. Key Eng. Mater. 2015, 642, 323–327. [Google Scholar] [CrossRef]

- Martin, J.K.; Parkins, D.W. Theoretical Studies of a Continuously Adjustable Hydrodynamic Fluid Film Bearing. J. Tribol. 2002, 124, 203–211. [Google Scholar] [CrossRef]

- Martin, J.K. Measured Stiffness and Displacement Coefficients of a Stationary Rotor Hydrostatic Bearing. Tribol. Int. 2004, 37, 809–816. [Google Scholar] [CrossRef]

- Martin, J.K. Measuring the Performance of a Novel Fluid Film Bearing Supporting a Rotor on a Stationary Shaft, by Non-Contacting Means. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2004, 218, 143–151. [Google Scholar] [CrossRef]

- Shenoy, S.; Pai, R. Dynamic Characteristics of a Single Pad Externally Adjustable Fluid Film Bearing. Ind. Lubr. Tribol. 2011, 63, 146–151. [Google Scholar] [CrossRef]

- Shenoy, B.S.; Pai, R. Effect of Turbulence on the Static Performance of a Misaligned Externally Adjustable Fluid Film Bearing Lubricated with Couple Stress Fluids. Tribol. Int. 2011, 44, 1774–1781. [Google Scholar] [CrossRef]

- Binu, K.G.; Shenoy, B.S.; Rao, D.S.; Pai, R. Static Characteristics of a Fluid Film Bearing with TiO2 Based Nanolubricant Using the Modified Krieger–Dougherty Viscosity Model and Couple Stress Model. Tribol. Int. 2014, 75, 69–79. [Google Scholar] [CrossRef]

- Hariharan, G.; Pai, R. Analysis on the Steady State Performance of a Multi Pad Externally Adjustable Fluid Film Bearing. Ind. Lubr. Tribol. 2019, 71, 803–809. [Google Scholar] [CrossRef]

- Hariharan, G.; Pai, R. Computational Analysis of the Steady State Performance of an Adjustable/Controllable Multi-Pad Bearing Profile under LBP Orientations. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 3365–3376. [Google Scholar] [CrossRef]

- Girish, H.; Pai, R. Stability Performance of an Adjustable Multi-Pad Fluid Film Bearing Profile under Load-between-Pad Orientations. Int. J. Dyn. Control 2022, 10, 349–361. [Google Scholar] [CrossRef]

- Ganesha, A.; Pai, R.; Rao, S.; Khader, S.A. Multi-Objective Optimization and Significant Analysis of Bearing Element Adjustments on the Static Performance of an Innovative Adjustable Bearing through Design of Experiment. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1820–1833. [Google Scholar] [CrossRef]

- Ganesha, A.; Pai, R.; Abdul Khader, S.M. Mathematical Formulation of the Film Thickness in a Multi-Pad Externally Adjustable Hydrodynamic Bearing Using the Transformation Technique. J. Comput. Methods Sci. Eng. 2021, 21, 525–534. [Google Scholar] [CrossRef]

- Pai, R.; Parkins, D.W. Performance Characteristics of an Innovative Journal Bearing With Adjustable Bearing Elements. J. Tribol. 2018, 140, 041705. [Google Scholar] [CrossRef]

- Krodkiewski, J.M.; Cen, Y.; Sun, L. Improvement of Stability of Rotor System by Introducing a Hydraulic Damper into an Active Journal Bearing. Int. J. Rotating Mach. 1997, 3, 45–52. [Google Scholar] [CrossRef]

- Krodkiewski, J.M.; Sun, L. Modelling of Multi-Bearing Rotor Systems Incorporating an Active Journal Bearing. J. Sound Vib. 1998, 210, 215–229. [Google Scholar] [CrossRef]

- Breńkacz, Ł.; Witanowski, Ł.; Drosińska-Komor, M.; Szewczuk-Krypa, N. Research and Applications of Active Bearings: A State-of-the-Art Review. Mech. Syst. Signal Process. 2021, 151, 107423. [Google Scholar] [CrossRef]

- Chasalevris, A.; Dohnal, F. A Journal Bearing With Variable Geometry for the Reduction of the Maximum Amplitude During Passage Through Resonance. J. Vib. Acoust. 2012, 134, 061005. [Google Scholar] [CrossRef]

- Chasalevris, A.; Dohnal, F. Vibration Quenching in a Large Scale Rotor-Bearing System Using Journal Bearings with Variable Geometry. J. Sound Vib. 2014, 333, 2087–2099. [Google Scholar] [CrossRef]

- Shenoy, S.B. Performance Evaluation of a Single Pad Externally Adjustable Fluid Film Bearing. Ph.D. Thesis, Manipal University, Manipal, India, 2008. [Google Scholar]

- Hariharan, G.; Srikanth Rao, D.; Pai, R. Studies on the Load Carrying Capacity of a Multi-Pad Adjustable Bearing Under Misaligned Conditions. In Advances in Fluid Dynamics: Selected Proceedings of ICAFD 2018; Springer: Singapore, 2021; pp. 277–288. [Google Scholar] [CrossRef]

- Girish, H.; Pai, R. Theoretical Investigation of the Effect of Offset Loads on the Static Characteristics of a Multi-Pad Adjustable Bearing Geometry. Aust. J. Mech. Eng. 2022, 20, 866–874. [Google Scholar] [CrossRef]

- Girish, H.; Pai, R. Effect of Journal Misalignment on the Static Characteristics of an Innovative Journal Bearing with Adjustable Elements in Load-on-Pad and Load-between-Pad Configurations. Eng. Comput. 2021, 38, 1513–1531. [Google Scholar] [CrossRef]

- Krodkiewski, J.M.; Sun, L. Modelling of Multi-Bearing Rotor Systems for Vibration Analysis and Control Law Synthesis. In Active Control in Mechanical Engineering; CRC Press: Boca Raton, FL, USA, 2021; pp. 221–232. [Google Scholar] [CrossRef]

- Chasalevris, A.; Dohnal, F. Modal Interaction and Vibration Suppression in Industrial Turbines Using Adjustable Journal Bearings. J. Phys. Conf. Ser. 2016, 744, 012156. [Google Scholar] [CrossRef]

- Chasalevris, A.; Guignier, G. Alignment and Rotordynamic Optimization of Turbine Shaft Trains Using Adjustable Bearings in Real-Time Operation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 2379–2399. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X.; Xu, H. Restoring the Stability of the Rotor System by Adjusting the Radial Clearance of the Bearing. J. Brazilian Soc. Mech. Sci. Eng. 2022, 44, 256. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X.; Xu, H. Theoretical and Experimental Study on the Effect of Adjustable Journal Bearings on the Vibration Response of Rigid and Slender Rotor Systems. Mech. Syst. Signal Process. 2025, 224, 111951. [Google Scholar] [CrossRef]

- Shutin, D.; Bondarenko, M.; Polyakov, R.; Stebakov, I.; Savin, L. Method for On-Line Remaining Useful Life and Wear Prediction for Adjustable Journal Bearings Utilizing a Combination of Physics-Based and Data-Driven Models: A Numerical Investigation. Lubricants 2023, 11, 33. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, H.; Zhang, L.; Xing, Y.; Guo, Y. Vibration Suppression Mechanism Research of Adjustable Elliptical Journal Bearing under Synchronous Unbalance Load. Tribol. Int. 2019, 132, 185–198. [Google Scholar] [CrossRef]

- Zhang, S.; Xing, Y.; Xu, H.; Pei, S.; Zhang, L. An Experimental Study on Vibration Suppression of Adjustable Elliptical Journal Bearing-Rotor System in Various Vibration States. Mech. Syst. Signal Process. 2020, 141, 106477. [Google Scholar] [CrossRef]

- Jin, Y.; Chen, F.; Zhang, F.; Yuan, X. Nonlinear Dynamic Performance of Tilting-Pad Journal Bearing with Adjustable Elastic Pivot Design. Tribol. Int. 2019, 136, 533–547. [Google Scholar] [CrossRef]

- Nicoletti, R.; Santos, I.F. Control System Design for Flexible Rotors Supported by Actively Lubricated Bearings. J. Vib. Control 2008, 14, 347–374. [Google Scholar] [CrossRef]

- Santos, I.F.; Nicoletti, R.; Scalabrin, A. Feasibility of Applying Active Lubrication to Reduce Vibration in Industrial Compressors. J. Eng. Gas Turbines Power 2004, 126, 848–854. [Google Scholar] [CrossRef]

- Santos, I.F.; Scalabrin, A. Control System Design for Active Lubrication With Theoretical and Experimental Examples. J. Eng. Gas Turbines Power 2003, 125, 75–80. [Google Scholar] [CrossRef]

- Nicoletti, R.; Santos, I.F. Frequency Response Analysis of an Actively Lubricated Rotor/Tilting-Pad Bearing System. J. Eng. Gas Turbines Power 2005, 127, 638–645. [Google Scholar] [CrossRef]

- Haugaard, A.M.; Santos, I.F. Elastohydrodynamics Applied to Active Tilting-Pad Journal Bearings. J. Tribol. 2010, 132, 021702. [Google Scholar] [CrossRef]

- Haugaard, A.M.; Santos, I.F. Multi-Orifice Active Tilting-Pad Journal Bearings—Harnessing of Synergetic Coupling Effects. Tribol. Int. 2010, 43, 1374–1391. [Google Scholar] [CrossRef]

- Varela, A.C.; Santos, I.F. Tilting-Pad Journal Bearings With Active Lubrication Applied as Calibrated Shakers: Theory and Experiment. J. Vib. Acoust. 2014, 136, 061010. [Google Scholar] [CrossRef]

- Cerda Varela, A.; Ferreira Santos, I. Dynamic Coefficients of a Tilting Pad With Active Lubrication: Comparison Between Theoretical and Experimental Results. J. Tribol. 2015, 137, 31704. [Google Scholar] [CrossRef]

- Varela, A.C.; García, A.B.; Santos, I.F. Modelling of LEG Tilting Pad Journal Bearings with Active Lubrication. Tribol. Int. 2017, 107, 250–263. [Google Scholar] [CrossRef]

- Salazar, J.G.; Santos, I.F. Feedback-Controlled Lubrication for Reducing the Lateral Vibration of Flexible Rotors Supported by Tilting-Pad Journal Bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 1264–1275. [Google Scholar] [CrossRef]

- Salazar, J.G.; Santos, I.F. Experimental Identification of Dynamic Coefficients of Lightly Loaded Tilting-Pad Bearings under Several Lubrication Regimes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1423–1438. [Google Scholar] [CrossRef]

- Salazar, J.G.; Santos, I.F. Active Tilting-Pad Journal Bearings Supporting Flexible Rotors: Part I—The Hybrid Lubrication. Tribol. Int. 2017, 107, 94–105. [Google Scholar] [CrossRef]

- Gong, X.; Cao, D. Active Control of an Unsymmetrical Rotor System with Tilting Pad Journal Bearings. J. Vib. Control 2011, 17, 1582–1590. [Google Scholar] [CrossRef]

- Rehman, W.U.; Jiang, G.; Luo, Y.; Wang, Y.; Khan, W.; Rehman, S.U.; Iqbal, N. Control of Active Lubrication for Hydrostatic Journal Bearing by Monitoring Bearing Clearance. Adv. Mech. Eng. 2018, 10, 168781401876814. [Google Scholar] [CrossRef]

- Gong, X.-C.; Qin, Y.-L. Vibration Control of Unsymmetrical Rotating Machinery with an Active Tilting Pad Journal Bearing. In Proceedings of the 2021 IEEE International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Weihai, China, 13–15 August 2021; pp. 260–269. [Google Scholar] [CrossRef]

- Kazakov, Y.N.; Kornaev, A.V.; Shutin, D.V.; Li, S.; Savin, L.A. Active Fluid-Film Bearing With Deep Q-Network Agent-Based Control System. J. Tribol. 2022, 144, 081803. [Google Scholar] [CrossRef]

- Rahmatabadi, A.D.; Nekoeimehr, M.; Rashidi, R. Micropolar Lubricant Effects on the Performance of Noncircular Lobed Bearings. Tribol. Int. 2010, 43, 404–413. [Google Scholar] [CrossRef]

- Rashidi Meybodi, R.; Zare Mehrjardi, M.; Rahmatabadi, A.D. Tilt Angle Effects on the Performance of Micropolar Lubricated Noncircular Journal Bearings. Ind. Lubr. Tribol. 2017, 69, 536–549. [Google Scholar] [CrossRef]

- Mehrjardi, M.Z.; Rahmatabadi, A.D. Control of Self-Excited Rotor Disturbances in Three-Lobe Journal Bearing Space Using a Couple Stress Lubricant. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 759–776. [Google Scholar] [CrossRef]

- Nicoletti, R.; Santos, I.F. Vibration Control of Rotating Machinery Using Active Tilting-Pad Bearings. In Proceedings of the 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Proceedings (Cat. No.01TH8556), Como, Italy, 8–12 July 2001; Volume 1, pp. 589–594. [Google Scholar] [CrossRef]

- Santos, I.F.; Watanabe, F.Y. Compensation of Cross-Coupling Stiffness and Increase of Direct Damping in Multirecess Journal Bearings Using Active Hybrid Lubrication: Part I—Theory. J. Tribol. 2004, 126, 146–155. [Google Scholar] [CrossRef]

- Hashimoto, H.; Ochiai, M. Experimental Study on the Stabilization of Small-Bore Journal Bearings by Controlling Starved Lubrication and Bearing Orientation Angle. J. Tribol. 2009, 131, 011705. [Google Scholar] [CrossRef]

- Hashimoto, H.; Ochiai, M. Stabilization Method for Small-Bore Journal Bearings Utilizing Starved Lubrication. J. Tribol. 2010, 132, 011703. [Google Scholar] [CrossRef]

- Salazar, J.G.; Santos, I.F. Exploring Integral Controllers in Actively-Lubricated Tilting-Pad Journal Bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 835–848. [Google Scholar] [CrossRef]

- Salazar, J.G.; Santos, I.F. On the Controllability and Observability of Actively Lubricated Journal Bearings With Pads Featuring Different Nozzle-Pivot Configurations. J. Tribol. 2017, 139, 031702. [Google Scholar] [CrossRef]

- Urreta, H.; Leicht, Z.; Sanchez, A.; Agirre, A.; Kuzhir, P.; Magnac, G. Hydrodynamic Bearing Lubricated with Magnetic Fluids. J. Intell. Mater. Syst. Struct. 2010, 21, 1491–1499. [Google Scholar] [CrossRef]

- Urreta, H.; Aguirre, G.; Kuzhir, P.; Lopez de Lacalle, L.N. Actively Lubricated Hybrid Journal Bearings Based on Magnetic Fluids for High-Precision Spindles of Machine Tools. J. Intell. Mater. Syst. Struct. 2019, 30, 2257–2271. [Google Scholar] [CrossRef]

- Bompos, D.A.; Nikolakopoulos, P.G. CFD Simulation of Magnetorheological Fluid Journal Bearings. Simul. Model. Pract. Theory 2011, 19, 1035–1060. [Google Scholar] [CrossRef]

- Bompos, D.A.; Nikolakopoulos, P.G. Journal Bearing Stiffness and Damping Coefficients Using Nanomagnetorheological Fluids and Stability Analysis. J. Tribol. 2014, 136, 041704. [Google Scholar] [CrossRef]

- Bompos, D.A.; Nikolakopoulos, P.G. Experimental and Analytical Investigations of Dynamic Characteristics of Magnetorheological and Nanomagnetorheological Fluid Film Journal Bearing. J. Vib. Acoust. 2016, 138, 031012. [Google Scholar] [CrossRef]

- Bompos, D.A.; Nikolakopoulos, P.G. Rotordynamic Analysis of a Shaft Using Magnetorheological and Nanomagnetorheological Fluid Journal Bearings. Tribol. Trans. 2016, 59, 108–118. [Google Scholar] [CrossRef]

- Estupiñan, E.; Santos, I. Radial Oil Injection Applied to Main Engine Bearings: Evaluation of Injection Control Rules. J. Vib. Control 2012, 18, 587–595. [Google Scholar] [CrossRef]

- Estupinan, E.; Santos, I. Controllable Lubrication for Main Engine Bearings Using Mechanical and Piezoelectric Actuators. IEEE/ASME Trans. Mechatron. 2012, 17, 279–287. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Lu, W.; Meng, G. Stiffness and Damping Properties of (Semi) Floating Ring Bearing Using Magnetorheological Fluids as Lubricant. J. Tribol. 2017, 139, 051701. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Meng, G. Rotordynamic Coefficients of a Controllable Magnetorheological Fluid Lubricated Floating Ring Bearing. Tribol. Int. 2017, 114, 1–14. [Google Scholar] [CrossRef]

- Zhan, S.; Pan, W.; Zhang, Y.; Lu, C. Modeling and Parameter Identification for Active Lubricated Hydrostatic Bearing-Rotor System. In Mechanical Engineering and Materials: Proceedings of ICMEM 2020; Xu, J., Pandey, K.M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 197–207. [Google Scholar] [CrossRef]

- Li, K.; Liu, Y.; Liu, J.; Chen, W. Study on the Performance of a Designed Annular Piezoelectric Microjet for Active Lubrication of Space Bearing. IEEE Trans. Ind. Electron. 2022, 69, 2728–2736. [Google Scholar] [CrossRef]

- Jensen, K.M.; Santos, I.F. Design of Actively-Controlled Oil Lubrication to Reduce Rotor-Bearing-Foundation Coupled Vibrations—Theory & Experiment. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1493–1510. [Google Scholar] [CrossRef]

- Jensen, K.M.; Santos, I.F. Advances in Active Bearings in Rotating Machinery; Chasalevris, A., Proppe, C., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Li, S.; Babin, A.; Shutin, D.; Kazakov, Y.; Liu, Y.; Chen, Z.; Savin, L. Active Hybrid Journal Bearings with Lubrication Control: Towards Machine Learning. Tribol. Int. 2022, 175, 107805. [Google Scholar] [CrossRef]

- van der Meer, G.H.G.; Quinci, F.; Litwin, W.; Wodtke, M.; van Ostayen, R.A.J. Experimental Comparison of the Transition Speed of a Hydrodynamic Journal Bearing Lubricated with Oil and Magnetorheological Fluid. Tribol. Int. 2023, 189, 108976. [Google Scholar] [CrossRef]

- Shutin, D.; Kazakov, Y. Theoretical and Numerical Investigation of Reduction of Viscous Friction in Circular and Non-Circular Journal Bearings Using Active Lubrication. Lubricants 2023, 11, 218. [Google Scholar] [CrossRef]

- Shutin, D. Static Reduction of Viscous Friction and Stability of Rotor Motion in Actively Lubricated Fluid Film Bearings. AIP Conf. Proc. 2024, 3102, 020004. [Google Scholar] [CrossRef]

- Tomar, A.K.; Sahu, K.; Sharma, S.C.; Marian, M. Combined Effect of Surface Irregularities and Applied Voltage on the Behavior of Hole-Entry Spherical Hybrid Journal Bearings Lubricated with an Electro-Rheological Fluid. J. Tribol. 2024, 146, 114101. [Google Scholar] [CrossRef]

- Tomar, A.K.; Sharma, S.C.; Sahu, K. Performance Analysis of Textured Spherical Hybrid Journal Bearings Operated with Magnetorheological Fluid. J. Tribol. 2024, 146, 014602. [Google Scholar] [CrossRef]

- Sahu, K.; Sharma, S.C.; Tomar, A.K. Analysis of MR Fluid Lubricated Slot Entry Hybrid Conical Journal Bearing with Texturing Arrangements. Tribol. Int. 2023, 188, 108788. [Google Scholar] [CrossRef]

- Sahu, K.; Tomar, A.K.; Sharma, S.C. Effect of Textured Shapes on Slot Entry Hybrid Conical Journal Bearing with ER Lubricant Behavior. Tribol. Trans. 2024, 67, 615–642. [Google Scholar] [CrossRef]

- Glavatskih, S.; Höglund, E. Tribotronics—Towards Active Tribology. Tribol. Int. 2008, 41, 934–939. [Google Scholar] [CrossRef]

- Brahem, M.; Chouchane, M.; Amamou, A. Active Vibration Control of a Rotor Bearing System Using Flexible Piezoelectric Patch Actuators. J. Intell. Mater. Syst. Struct. 2020, 31, 1284–1297. [Google Scholar] [CrossRef]

- Tůma, J.; Šimek, J.; Škuta, J.; Los, J.; Zavadil, J. Active Vibration Control of Hydrodynamic Journal Bearings. In Vibration Problems ICOVP 2011: The 10th International Conference on Vibration Problems; Springer: Dordrecht, The Netherlands, 2011; pp. 425–431. [Google Scholar] [CrossRef]

- Wu, A.; De Queiroz, M. A New Active Tilting-Pad Bearing: Nonlinear Modeling and Feedback Control. Tribol. Trans. 2010, 53, 755–763. [Google Scholar] [CrossRef]

- Kalligeros, C.; Chantoumakos, G.; Tsolakis, E.; Spiridakos, P.; Spitas, V. Advances in Active Bearings in Rotating Machinery; Chasalevris, A., Proppe, C., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Cai, Z.; de Queiroz, M.S.; Khonsari, M.M. On the Active Stabilization of Tilting-Pad Journal Bearings. J. Sound Vib. 2004, 273, 421–428. [Google Scholar] [CrossRef]

- Silva, H.A.P.; Nicoletti, R. Tilting-Pad Journal Bearing with Active Pads: A Way of Attenuating Rotor Lateral Vibrations. In Workshop on Active Bearings in Rotating Machinery; Springer International Publishing: Cham, Switzerland, 2022; pp. 44–54. [Google Scholar] [CrossRef]

- Tůma, J.; Šimek, J.; Mahdal, M.; Pawlenka, M.; Wagnerova, R. Piezoelectric Actuators in the Active Vibration Control System of Journal Bearings. J. Phys. Conf. Ser. 2017, 870, 012017. [Google Scholar] [CrossRef]

- Borges, J.M.; Silva, A.A.; de Araujo, C.J.; Fernandes, E.M.; Pimentel, R.L.; Santiago, A.A. Rotor-Bearing Vibration Control System Based on Fuzzy Controller and Smart Actuators. Int. J. Multiphys. 2013, 7, 197–210. [Google Scholar] [CrossRef]

- Jungblut, J.; Haas, J.; Rinderknecht, S. A New Active Balancing Device Utilizing Rotating Piezo Actuators. Mech. Syst. Signal Process. 2022, 181, 109521. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, H.; Zhang, S.; Pei, S. A Radial Clearance Adjustable Bearing Reduces the Vibration Response of the Rotor System during Acceleration. Tribol. Int. 2020, 144, 106112. [Google Scholar] [CrossRef]

- Marcinkevičius, A.H. Automatic Regulation of Clearance in a Tilting Pad Journal Bearing. Mechanika 2012, 18, 192–195. [Google Scholar] [CrossRef]

- Pizarro Viveros, H.; Nicoletti, R. Lateral Vibration Attenuation of Shafts Supported by Tilting-Pad Journal Bearing With Embedded Electromagnetic Actuators. J. Eng. Gas Turbines Power 2014, 136, 042503. [Google Scholar] [CrossRef]

- Silva, H.A.; Nicoletti, R. Rotor Frequency Response Self-Identification Using an Active Tilting-Pad Bearing. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 478. [Google Scholar] [CrossRef]

- Simões, R.C.; Steffen, V.; Der Hagopian, J.; Mahfoud, J. Modal Active Vibration Control of a Rotor Using Piezoelectric Stack Actuators. J. Vib. Control 2007, 13, 45–64. [Google Scholar] [CrossRef]

- Carmignani, C.; Forte, P.; Rustighi, E. Active Control of Rotor Vibrations by Means of Piezoelectric Actuators. In Proceedings of the ASME 2001 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Pittsburgh, PA, USA, 9–12 September 2001; American Society of Mechanical Engineers: Pittsburgh, PA, USA, 2001; Volume 6A, pp. 757–764. [Google Scholar] [CrossRef]

- Jungblut, J.; Haas, J.; Rinderknecht, S. Active Vibration Control of an Elastic Rotor by Using Its Deformation as Controlled Variable. Mech. Syst. Signal Process. 2022, 165, 108371. [Google Scholar] [CrossRef]

- Pinte, G.; Devos, S.; Stallaert, B.; Symens, W.; Swevers, J.; Sas, P. A Piezo-Based Bearing for the Active Structural Acoustic Control of Rotating Machinery. J. Sound Vib. 2010, 329, 1235–1253. [Google Scholar] [CrossRef]

- Morosi, S.; Santos, I.F. Active Lubrication Applied to Radial Gas Journal Bearings. Part 1: Modeling. Tribol. Int. 2011, 44, 1949–1958. [Google Scholar] [CrossRef]

- Morosi, S.; Santos, I.F. Experimental Investigations of Active Air Bearings. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; American Society of Mechanical Engineers: Pittsburgh, PA, USA, 2012; Volume 7: Structures and Dynamics, Parts A and B, pp. 901–910. [Google Scholar] [CrossRef]

- Qiu, J.; Tani, J.; Kwon, T. Control of Self-Excited Vibration of a Rotor System With Active Gas Bearings. J. Vib. Acoust. 2003, 125, 328–334. [Google Scholar] [CrossRef]

- Stanway, R.; Burrows, C.R. Active Vibration Control of a Flexible Rotor on Flexibly-Mounted Journal Bearings. J. Dyn. Syst. Meas. Control 1981, 103, 383–388. [Google Scholar] [CrossRef]

- Burrows, C.R.; Sahinkaya, M.N.; Clements, S. Active Vibration Control of Flexible Rotors: An Experimental and Theoretical Study. Proc. R. Soc. Lond. A Math. Phys. Sci. 1989, 422, 123–146. [Google Scholar] [CrossRef]

- Yu, Z.; Meng, L.T.; King, L.M. Electromagnetic Bearing Actuator for Active Vibration Control of a Flexible Rotor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1998, 212, 705–716. [Google Scholar] [CrossRef]

- Shao, X.; Wang, W.; Li, W.; Li, Q. Active Fast Vibration Control of Rotating Machinery via a Novel Electromagnetic Actuator. Struct. Control Health Monit. 2021, 28, e2707. [Google Scholar] [CrossRef]

- Przyblowiczm, P. Stability of a Rotor Supported on Journal Bearings with Piezoelectric Elements. ZAMM J. Appl. Math. Mech./Z. Für Angew. Math. Und Mech. 2000, 80, 329–330. [Google Scholar] [CrossRef]

- Przybylowicz, P.M. Active Stabilisation of a Rigid Rotor by Piezoelectrically Controlled Mobile Journal Bearing System. Aust. J. Mech. Eng. 2004, 1, 123–128. [Google Scholar] [CrossRef]

- Alizadeh, A.; Ehmann, C.; Schönhoff, U.; Nordmann, R. Active Bearing of Rotors Utilizing Robust Controlled Piezo Actuators. In Proceedings of the ASME 2003 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, IL, USA, 2–6 September 2003; Volume 5: 19th Biennial Conference on Mechanical Vibration and Noise, Parts A, B, and C, pp. 2669–2677. [Google Scholar] [CrossRef]

- Lau, H.Y.; Liu, K.P.; Wong, P.L.; Wang, W. A New Design of Smart Journal Bearing Based on GMM Actuators. Ind. Lubr. Tribol. 2012, 64, 147–151. [Google Scholar] [CrossRef]

- Fang, J.; Xu, X.; Xie, J. Active Vibration Control of Rotor Imbalance in Active Magnetic Bearing Systems. J. Vib. Control 2015, 21, 684–700. [Google Scholar] [CrossRef]

- Pierart, F.G.; Santos, I.F. Active Lubrication Applied to Radial Gas Journal Bearings. Part 2: Modelling Improvement and Experimental Validation. Tribol. Int. 2016, 96, 237–246. [Google Scholar] [CrossRef]

- Ambur, R.; Rinderknecht, S. Unbalance Detection in Rotor Systems with Active Bearings Using Self-Sensing Piezoelectric Actuators. Mech. Syst. Signal Process. 2018, 102, 72–86. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, D.; Gao, W.; Chen, Y.; Liu, T.; Tian, Y. Study on Variable Pressure/Position Preload Spindle-Bearing System by Using Piezoelectric Actuators under Close-Loop Control. Int. J. Mach. Tools Manuf. 2018, 125, 68–88. [Google Scholar] [CrossRef]

- Preto, E.; de Abreu, G.L.C.M.; Gonçalves, A.C.; Chavarette, F.R.; Savi, M.A. Experimental Investigation of Vibration Control of Flexible Rotors Using Shape Memory Alloys. Smart Mater. Struct. 2023, 32, 095001. [Google Scholar] [CrossRef]

- Xu, F.; Dong, Z.; Zhang, H.; Xie, Z. Vibration Characteristics Control of Hybrid Radial Gas Foil Bearing-Rotor System: Simulation and Experiment. Mech. Syst. Signal Process. 2023, 198, 110402. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, H.; Li, X.; Luan, W.; Wang, H.; Wang, Y.; Xie, Z. Vibration Characteristics of Hybrid Gas Foil Bearing-Rotor System in Space Microgravity. Mech. Syst. Signal Process. 2025, 225, 112311. [Google Scholar] [CrossRef]

- Li, S.; Zhou, C.; Savin, L.; Shutin, D.; Kornaev, A.; Polyakov, R.; Chen, Z. Theoretical and Experimental Study of Motion Suppression and Friction Reduction of Rotor Systems with Active Hybrid Fluid-Film Bearings. Mech. Syst. Signal Process. 2023, 182, 109548. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vernekar, N.K.; Pai, R.; Aroor, G.; Kumar, N.; Hariharan, G. Advancements in Active Journal Bearings: A Critical Review of Performance, Control, and Emerging Prospects. Modelling 2025, 6, 97. https://doi.org/10.3390/modelling6030097

Vernekar NK, Pai R, Aroor G, Kumar N, Hariharan G. Advancements in Active Journal Bearings: A Critical Review of Performance, Control, and Emerging Prospects. Modelling. 2025; 6(3):97. https://doi.org/10.3390/modelling6030097

Chicago/Turabian StyleVernekar, Navaneeth Krishna, Raghuvir Pai, Ganesha Aroor, Nitesh Kumar, and Girish Hariharan. 2025. "Advancements in Active Journal Bearings: A Critical Review of Performance, Control, and Emerging Prospects" Modelling 6, no. 3: 97. https://doi.org/10.3390/modelling6030097

APA StyleVernekar, N. K., Pai, R., Aroor, G., Kumar, N., & Hariharan, G. (2025). Advancements in Active Journal Bearings: A Critical Review of Performance, Control, and Emerging Prospects. Modelling, 6(3), 97. https://doi.org/10.3390/modelling6030097