Three-Dimensional Modelling for Interfacial Behavior of a Thin Penny-Shaped Piezo-Thermo-Diffusive Actuator

Abstract

1. Introduction

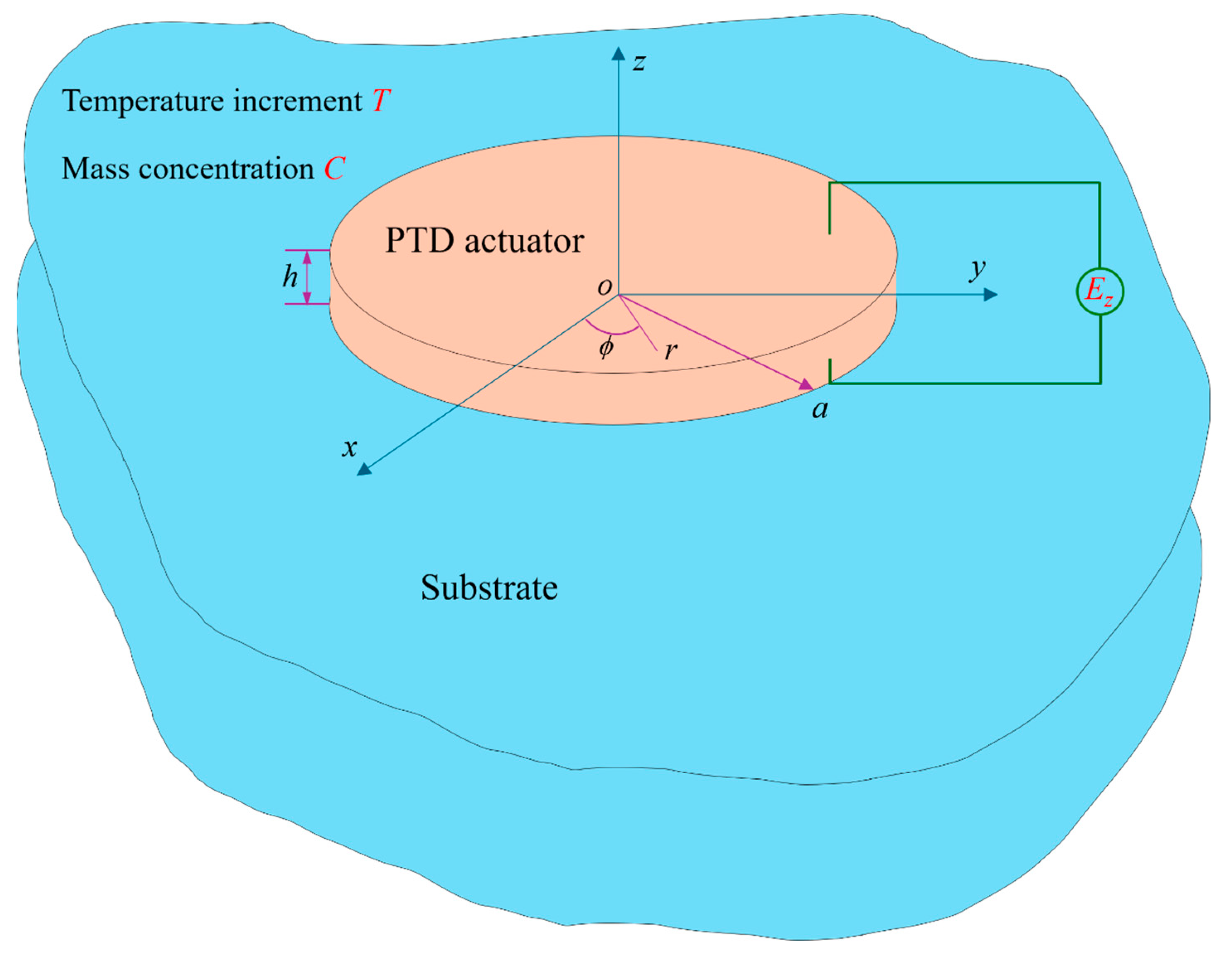

2. Problem Statement

2.1. Analysis of an Axisymmetric PTD Actuator

2.2. Analysis of an Isotropic Elastic Substrate

3. The Governing Integral Equation

4. Other Quantities of Interest

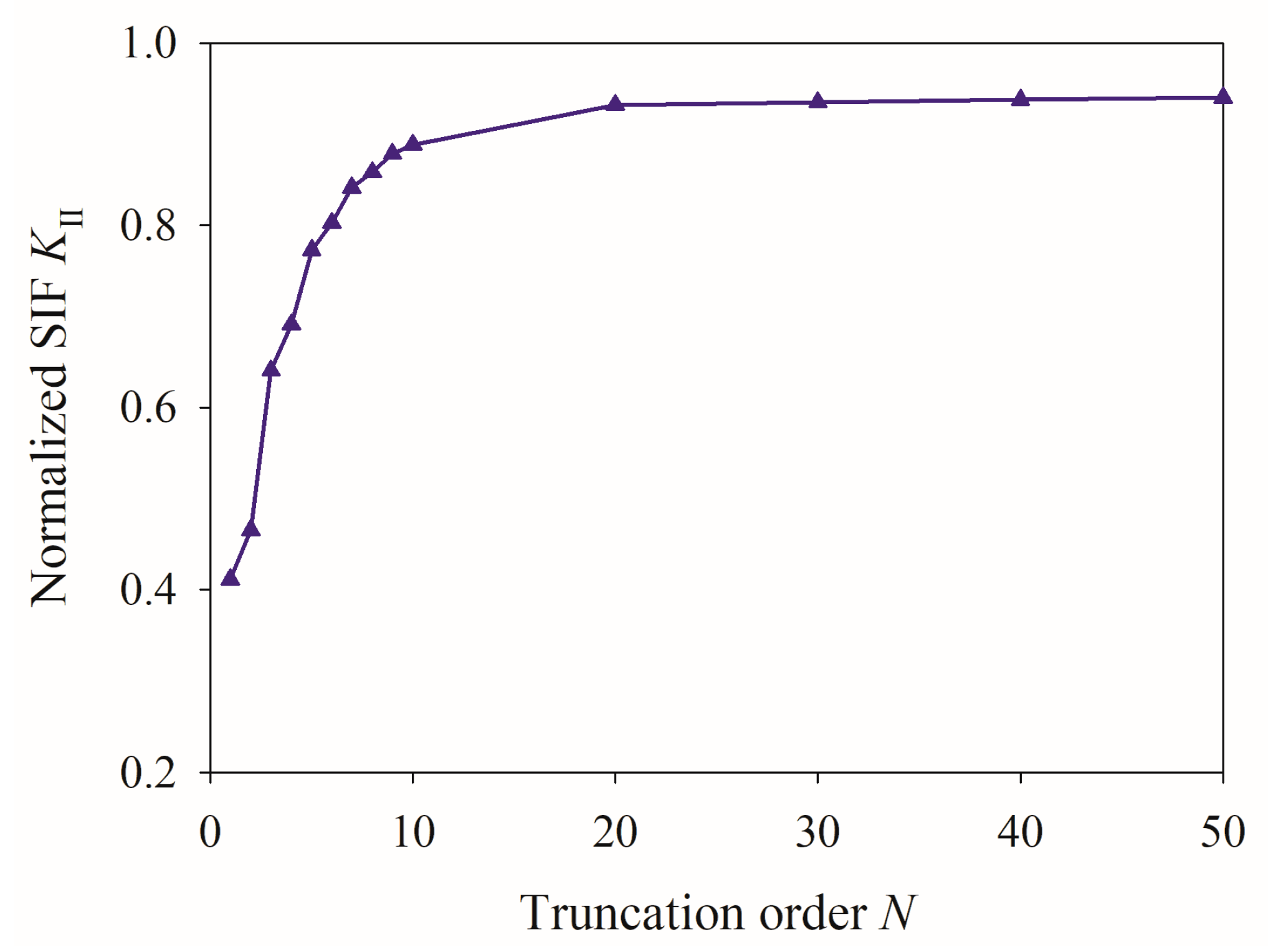

5. Results and Discussion

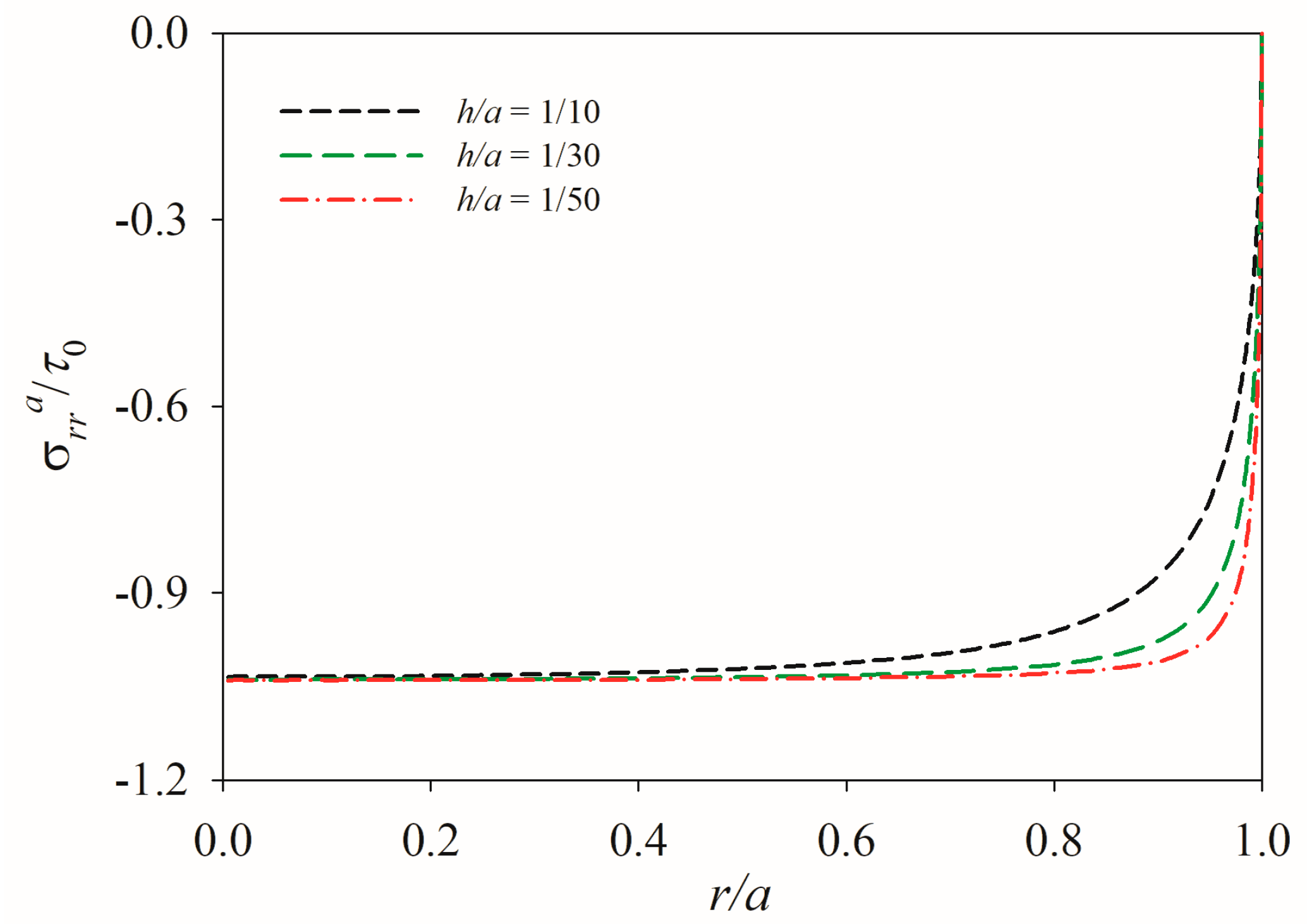

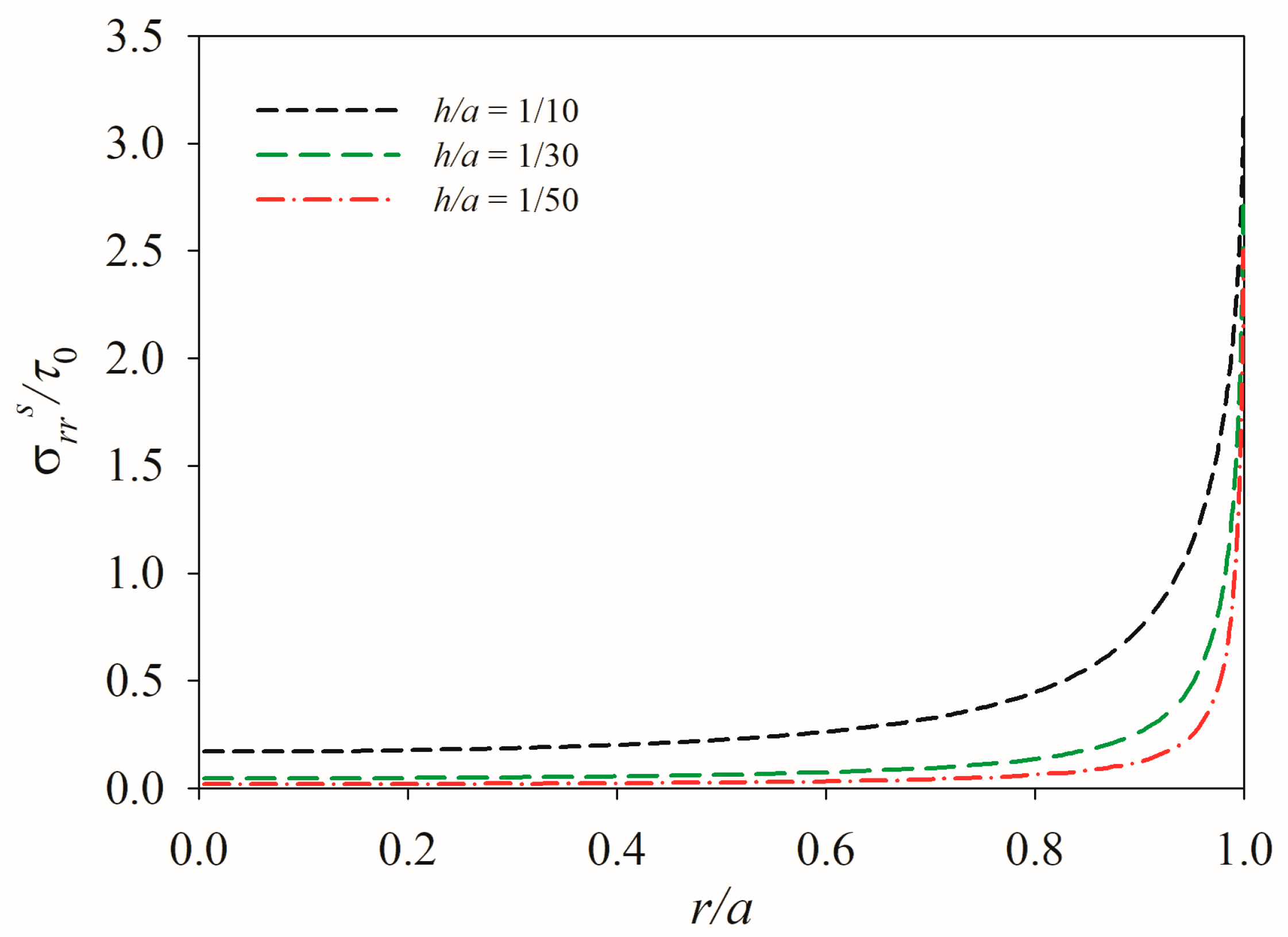

5.1. Influence of Aspect Ratio

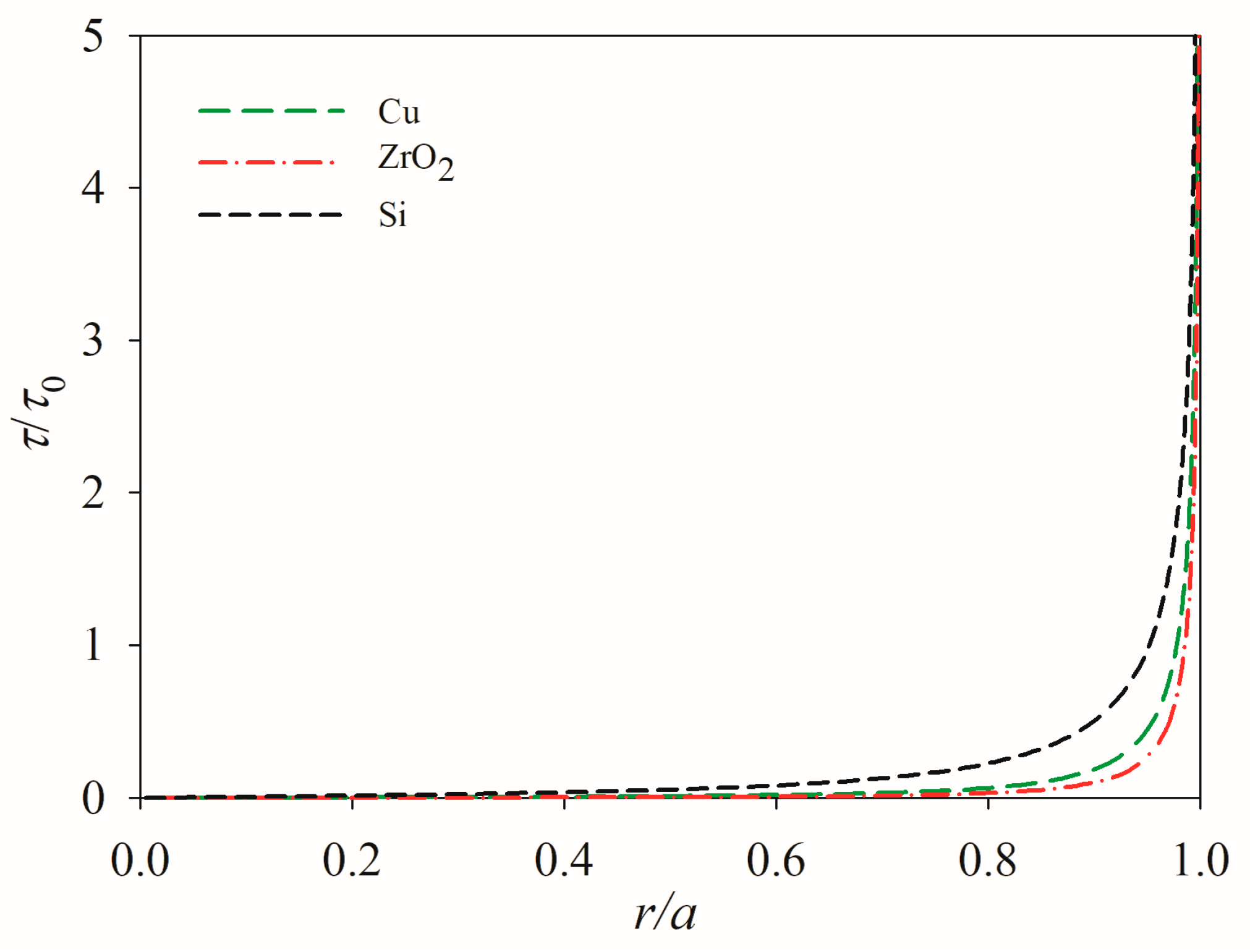

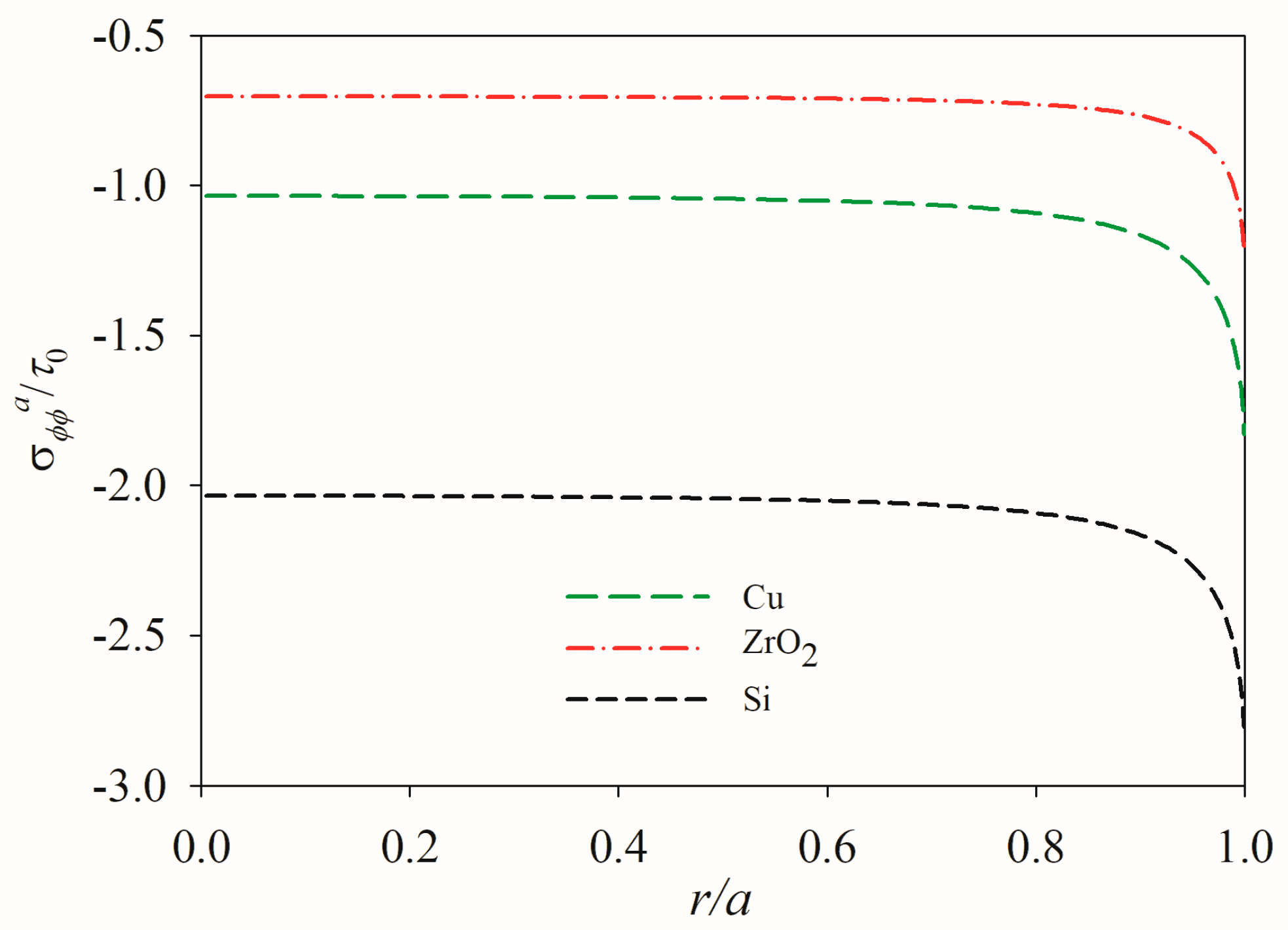

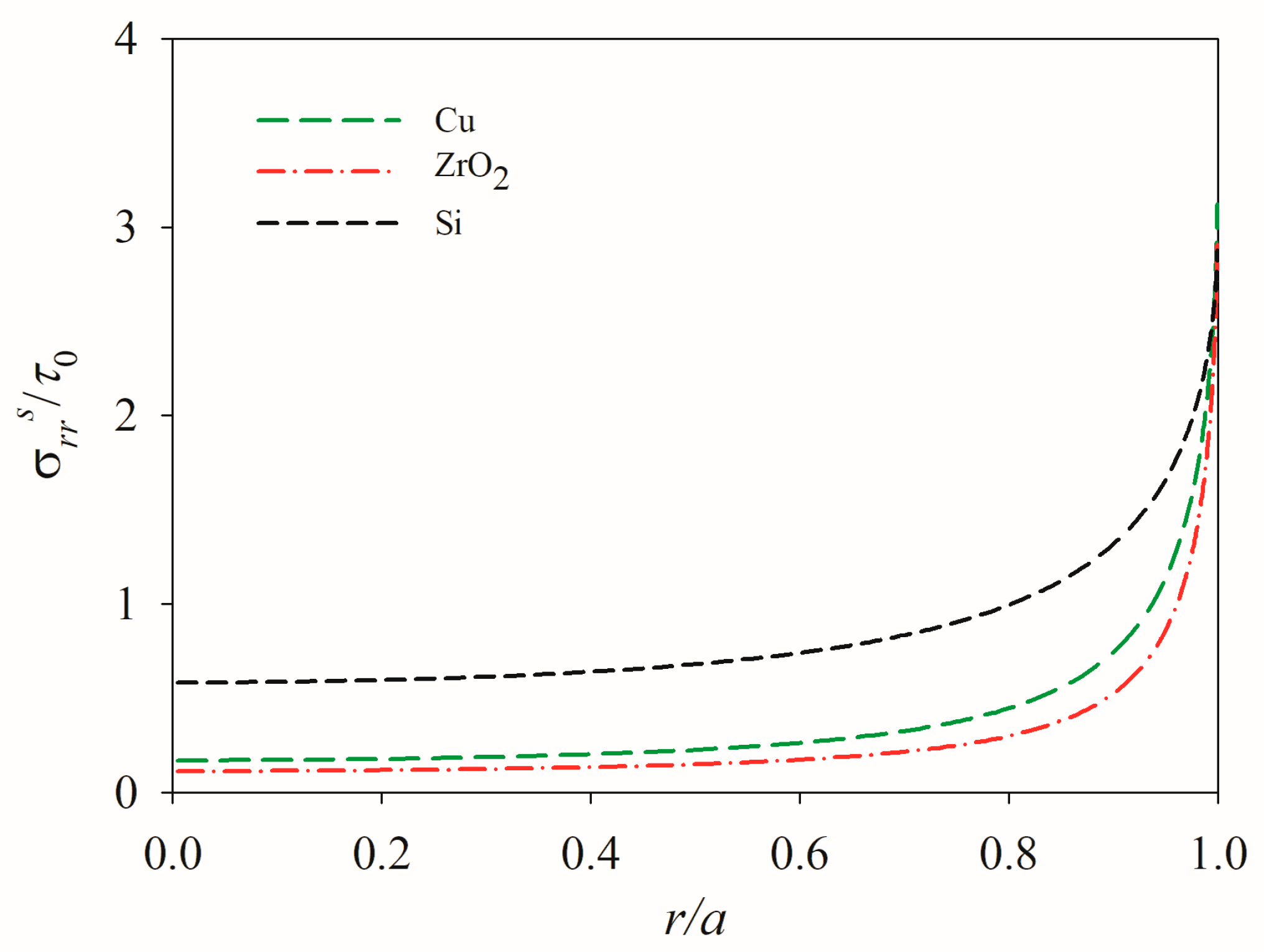

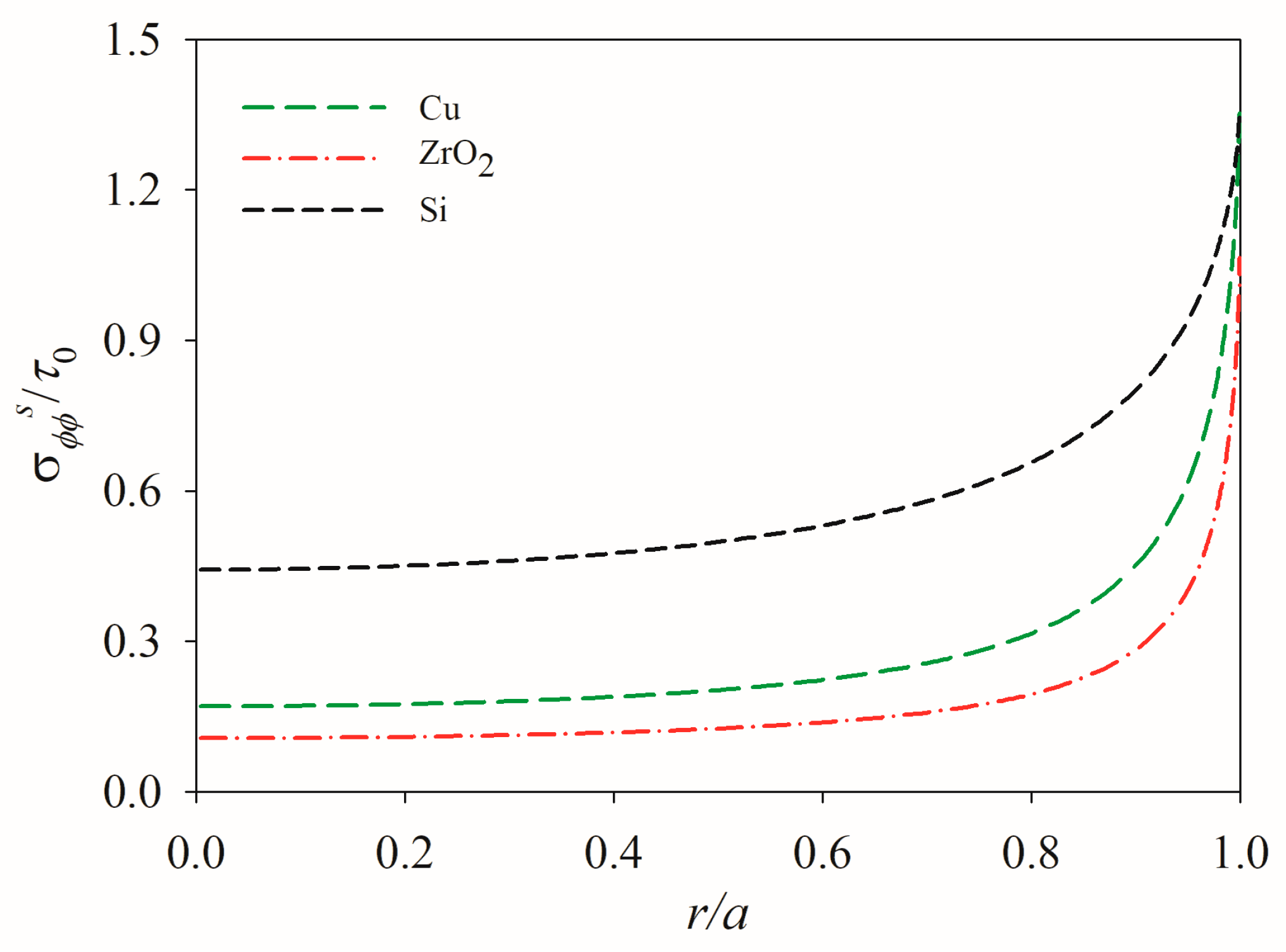

5.2. Influence of Material Mismatch

6. Conclusions

- The proposed analytical model effectively captures the mechanical response of an axisymmetric PTD actuator. Numerical results reveal that interfacial shear stress concentration near the actuator edge periphery governs delamination initiation.

- The total strain exhibits linear dependence on applied multi-physical loads while being modulated by material properties. This linearity enables precise control of mechanical response through load parameter manipulation.

- Both material properties and geometric factors significantly influence the mechanical performance. Specifically, thicker PTD actuators bonded to substrates with lower stiffness ratios are more susceptible to edge debonding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.H.; Lv, C.Q.; Liu, T.Y. Indentation response of piezoelectric films. J. Mech. Phys. Solids 2008, 56, 3331–3351. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Shi, Y.; Joe, P.; Ghaffari, R.; Balooch, G.; Usgaonkar, K.; Gur, O.; Tran, P.L.; Crosby, J.R.; Meyer, M.; et al. Conformal piezoelectric systems for clinical and experimental characterization of soft tissue biomechanics. Nat. Mater. 2015, 14, 728–736. [Google Scholar] [CrossRef]

- Jiao, P.; Egbe, K.J.I.; Xie, Y.; Matin Nazar, A.; Alavi, A.H. Piezoelectric sensing techniques in structural health monitoring: A static-of-the-art review. Sensors 2020, 20, 3730. [Google Scholar] [CrossRef] [PubMed]

- Panda, P.K. Piezoceramic materials and devices for aerospace applications. Mater. Mater. Technol. 2017, 1, 501–518. [Google Scholar]

- Liu, N.; Yang, J.S.; Chen, W.Q. Thin-film piezoelectric actuators of nonuniform thickness and nonhomogeneous material properties for modulating actuation stress. Mech. Adv. Mater. Struct. 2015, 22, 803–812. [Google Scholar] [CrossRef]

- Wang, B.L.; Li, J.E. Enhanced piezoelectric coupling by a line inclusion in piezoelectric medium associated with nonlocal theory of elasticity. Theor. Appl. Fract. Mech. 2022, 119, 103301. [Google Scholar] [CrossRef]

- Mohith, S.; Upadhya, A.R.; Navin, K.P.; Kulkarni, S.; Rao, M. Recent trends in piezoelectric actuators for precision motion and their applications: A review. Smart Mater. Struct. 2020, 30, 013002. [Google Scholar] [CrossRef]

- Chen, N.; Yan, P.; Ouyang, J. A generalized approach on bending and stress analysis of beams with piezoelectric material bonded. Sens. Actuators A Phys. 2019, 290, 54–61. [Google Scholar] [CrossRef]

- Huang, G.; Song, F.; Wang, X. Quantitative modeling of coupled piezo-elasto-dynamic behavior of piezoelectric actuators bonded to an elastic medium for structural health monitoring: A review. Sensors 2010, 10, 3681–3702. [Google Scholar] [CrossRef]

- Crawley, E.F.; De Luis, J. Use of piezoelectric actuators as elements of intelligent structures. AIAA J. 1987, 25, 1373–1385. [Google Scholar] [CrossRef]

- Im, S.; Atluri, S.N. Effects of a piezo-actuator on a finitely deformed beam subjected to general loading. AIAA J. 1989, 27, 1801–1807. [Google Scholar] [CrossRef]

- Crawley, E.F.; Anderson, E.H. Detailed models of piezoceramic actuation of beams. J. Intell. Mater. Syst. Struct. 1990, 1, 4–25. [Google Scholar] [CrossRef]

- Wang, X.D.; Meguid, S.A. On the electroelastic behavior of a thin piezoelectric actuator attached to an infinite host structure. Int. J. Solids Struct. 2000, 37, 3231–3251. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, B.; Fan, J. A coupled electromechanical analysis of a piezoelectric layer bonded to an elastic substrate: Part I, development of governing equations. Int. J. Solids Struct. 2003, 40, 6781–6797. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, J.; Fan, J. A coupled electromechancial analysis of a piezoelectric layer bonded to an elastic substrate: Part II, numerical solution and applications. Int. J. Solids Struct. 2003, 40, 6799–6812. [Google Scholar] [CrossRef]

- Qing, X.P.; Chan, H.L.; Beard, S.J.; Ooi, T.K.; Marotta, S.A. Effect of adhesive on the performance of piezoelectric elements used to monitor structural health. Int. J. Adhes. Adhes. 2006, 26, 622–628. [Google Scholar] [CrossRef]

- Jin, C.R.; Wang, X.D. Analytical modelling of the electromechanical behavior of surface-bonded piezoelectric actuators including the adhesive layer. Eng. Fract. Mech. 2011, 78, 2547–2562. [Google Scholar] [CrossRef]

- Rabinovitch, O. Piezoelectric control of edge debonding in beams strengthened with composite materials: Part I-analytical modeling. J. Compos. Mater. 2007, 41, 525–546. [Google Scholar] [CrossRef]

- Rabinovitch, O. Piezoelectric control of edge debonding in beams strengthened with composite materials: Part II-failure criteria and optimization. J. Compos. Mater. 2007, 41, 657–677. [Google Scholar] [CrossRef]

- Sun, D.; Tong, L.; Atluri, S.N. Effects of piezoelectric sensor/actuator debonding on vibration control of smart beams. Int. J. Solids Struct. 2001, 38, 9033–9051. [Google Scholar] [CrossRef]

- Yu, H.; Wang, X. Modelling and simulation of surface-bonded piezoelectric actuators with bending effects. J. Intell. Mater. Syst. Struct. 2017, 28, 507–520. [Google Scholar] [CrossRef]

- Tylikowski, A. Effects of piezo-actuator delamination on the transfer functions of vibration control systems. Int. J. Solids Struct. 2001, 38, 2189–2202. [Google Scholar] [CrossRef]

- Huang, B.; Kim, H.S.; Yoon, G.H. Modeling of a partially debonded piezoelectric actuator in smart composite laminates. Smart Mater. Struct. 2015, 24, 075013. [Google Scholar] [CrossRef]

- Chen, P.J.; Chen, S.H.; Guo, W.; Gao, F. The interface behavior of a thin piezoelectric film bonded to a graded substrate. Mech. Mater. 2018, 127, 26–38. [Google Scholar] [CrossRef]

- Chen, P.J.; Peng, J.; Liu, H.; Gao, F.; Guo, W. The electromechanical behavior of a piezoelectric actuator bonded to a graded substrate including an adhesive layer. Mech. Mater. 2018, 123, 77–87. [Google Scholar] [CrossRef]

- Chen, P.J.; Peng, J.; Chen, Z.T.; Peng, G.J. On the interfacial behavior of a piezoelectric actuator bonded to a homogeneous half plane with an arbitrarily varying graded coating. Eng. Fract. Mech. 2019, 220, 106645. [Google Scholar] [CrossRef]

- Chen, P.J.; Chen, S.H.; Liu, H.; Peng, J.; Gao, F. The interface behavior of multiple piezoelectric films attaching to a finite-thickness gradient substrate. J. Appl. Mech. 2000, 87, 011003. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, D.; Jiang, Q. Piezoelectric effect on the buckling of piezoelectric thin film with viscoelastic substrate. J. Nanomech. Micromech. 2014, 4, A4013004. [Google Scholar] [CrossRef]

- Alizadeh, M.; Wang, X.D. A nonlinear electromechanical model for partially debonded thin-sheet piezoelectric actuators. Acta. Mech. 2024, 235, 833–850. [Google Scholar] [CrossRef]

- Lanzoni, L.; Radi, E. Thermally induced deformations in a partially coated elastic layer. Int. J. Solids Struct. 2009, 46, 1402–1412. [Google Scholar] [CrossRef]

- Kumar, R.; Chawla, V. Three-dimensional fundamental solution in transversely isotropic thermoelastic diffusion material. Theo. Appl. Fract. Mech. 2012, 39, 165–184. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, V. Green’s function for transversely isotropic thermoelastic diffusion biomaterials. J. Thermal. Stresses. 2014, 37, 1201–1229. [Google Scholar] [CrossRef]

- Nowacki, W. Dynamic problems of thermos diffusion in solids. Proc. Vib. Prob. 1974, 15, 105–128. [Google Scholar]

- Sherief, H.H.; Saleh, H. A half space problem in the theory of generalized thermoelastic diffusion. Int. J. Solids Struct. 2005, 42, 4484–4493. [Google Scholar] [CrossRef]

- Kuang, Z.B. Variational principles for generalized thermodiffusion theory in pyroelectricity. Acta. Mech. 2010, 214, 275–289. [Google Scholar] [CrossRef]

- Kumar, R.; Chawla, V. General steady-state solution and Green’s function in orthotropic piezothermoelastic diffusion medium. Arch. Mech. 2012, 64, 555–579. [Google Scholar]

- Othman, M.I.A.; Eraki, E.E.M.; Ahmed, E.A.A. Propagation of plane waves of piezothermoelastic diffusive medium under the effect of gravity with dual phase lag model. Microsyst. Technol. 2022, 28, 1701–1713. [Google Scholar] [CrossRef]

- Ahmed, E.A.A.; Eraki, E.E.M.; Othman, M.I.A. Gravity effect in a piezo-thermoelastic diffusive medium with dual-phase-lag model. Int. J. Comput. Mater. Sci. Eng. 2023, 12, 2350008. [Google Scholar] [CrossRef]

- Alinia, Y.; Guler, M.A. On the problem of an axisymmetric thin film bonded to a transversely isotropic substrate. Int. J. Solids Struct. 2022, 248, 111636. [Google Scholar] [CrossRef]

- Hou, P.F.; Jiang, H.Y.; Li, Q.H. Three-dimensional steady-state general solution for isotropic thermoelastic materials with applications I: General solutions. J. Therm. Stress. 2013, 36, 727–747. [Google Scholar] [CrossRef]

- Rekik, M.; Neifar, M.; El-Borgi, S. An axisymmetric problem of an embedded crack in a graded layer bonded to a homogeneous half-space. Int. J. Solids Struct. 2010, 47, 2043–2055. [Google Scholar] [CrossRef]

- Ergogan, F.; Ozturk, M. On the singularity in fracture and contact mechanics. J. Appl. Mech. 2008, 75, 051111. [Google Scholar] [CrossRef]

- Ozturk, M.; Erdogan, F. Axisymmetric crack problem in bonded materials with a graded interfacial region. Int. J. Solids Struct. 1996, 33, 193–219. [Google Scholar] [CrossRef]

- Li, D.K.; Chen, P.J.; Liu, H.; Peng, Z.L.; Guler, M.A.; Chen, S.H. The interfacial behavior of an axisymmetric film bonded to a graded inhomogeneous substrate. Mech. Mater. 2024, 193, 104983. [Google Scholar] [CrossRef]

| Material | E (GPa) | v | a (10−6/K) |

|---|---|---|---|

| Cu | 129 | 0.35 | 17.0 |

| ZrO2 | 244 | 0.29 | 10.6 |

| Si | 169 | 0.22 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zhang, L.; Dang, H.-Y. Three-Dimensional Modelling for Interfacial Behavior of a Thin Penny-Shaped Piezo-Thermo-Diffusive Actuator. Modelling 2025, 6, 78. https://doi.org/10.3390/modelling6030078

Zhang H, Zhang L, Dang H-Y. Three-Dimensional Modelling for Interfacial Behavior of a Thin Penny-Shaped Piezo-Thermo-Diffusive Actuator. Modelling. 2025; 6(3):78. https://doi.org/10.3390/modelling6030078

Chicago/Turabian StyleZhang, Hui, Lan Zhang, and Hua-Yang Dang. 2025. "Three-Dimensional Modelling for Interfacial Behavior of a Thin Penny-Shaped Piezo-Thermo-Diffusive Actuator" Modelling 6, no. 3: 78. https://doi.org/10.3390/modelling6030078

APA StyleZhang, H., Zhang, L., & Dang, H.-Y. (2025). Three-Dimensional Modelling for Interfacial Behavior of a Thin Penny-Shaped Piezo-Thermo-Diffusive Actuator. Modelling, 6(3), 78. https://doi.org/10.3390/modelling6030078