The Effect of Impactor Geometry on the Damage Patterns Generated by Low-Velocity Impacts on Composite Pressure Vessels

Abstract

1. Introduction

2. Materials and Experiments

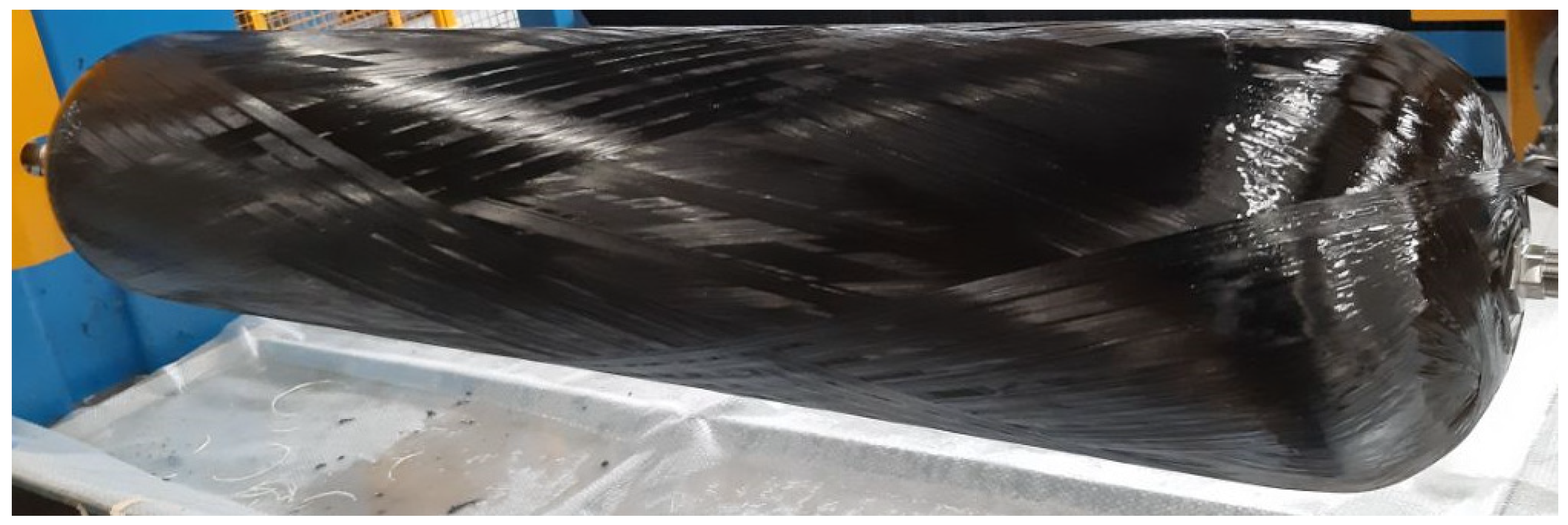

2.1. Manufacturing and Material

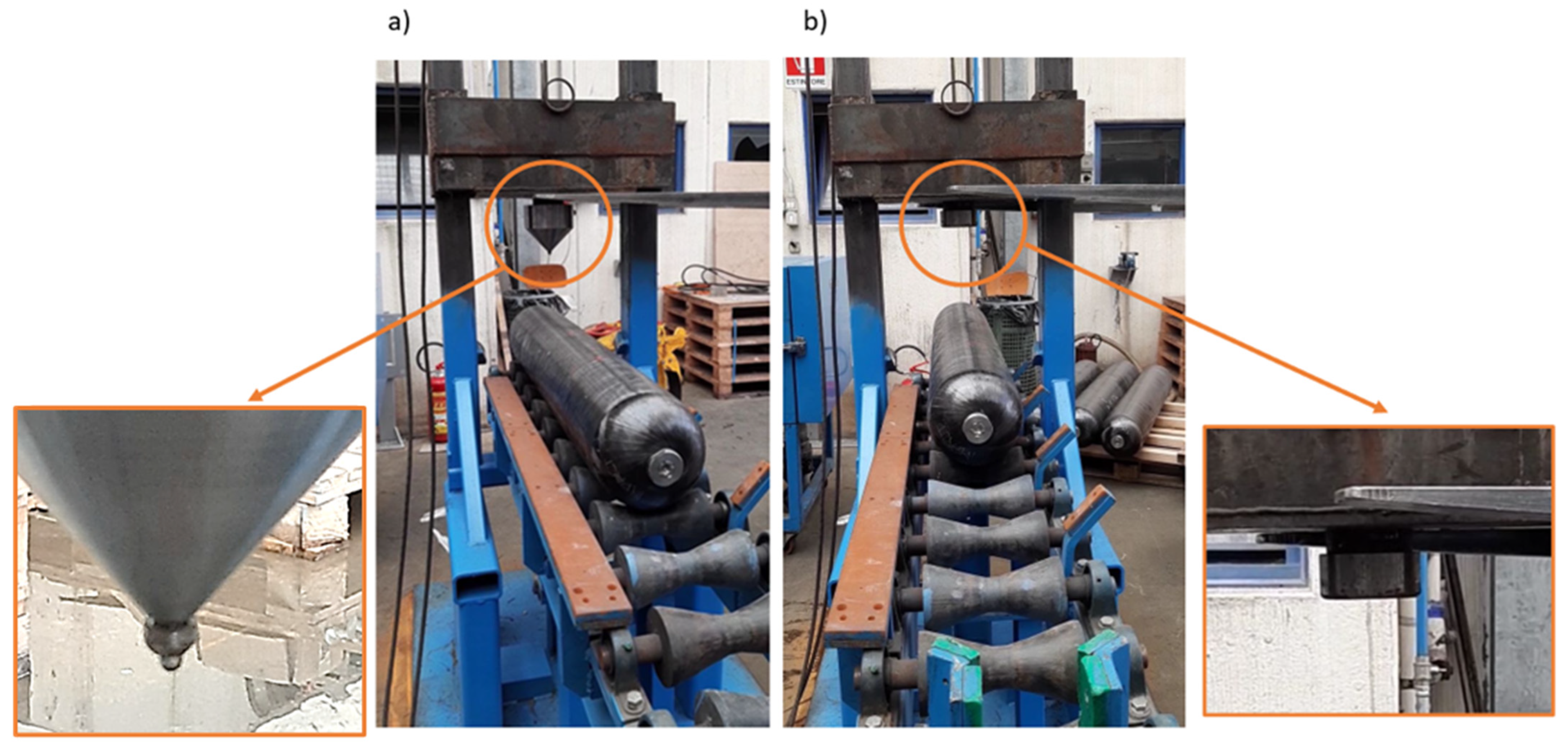

2.2. Experiments

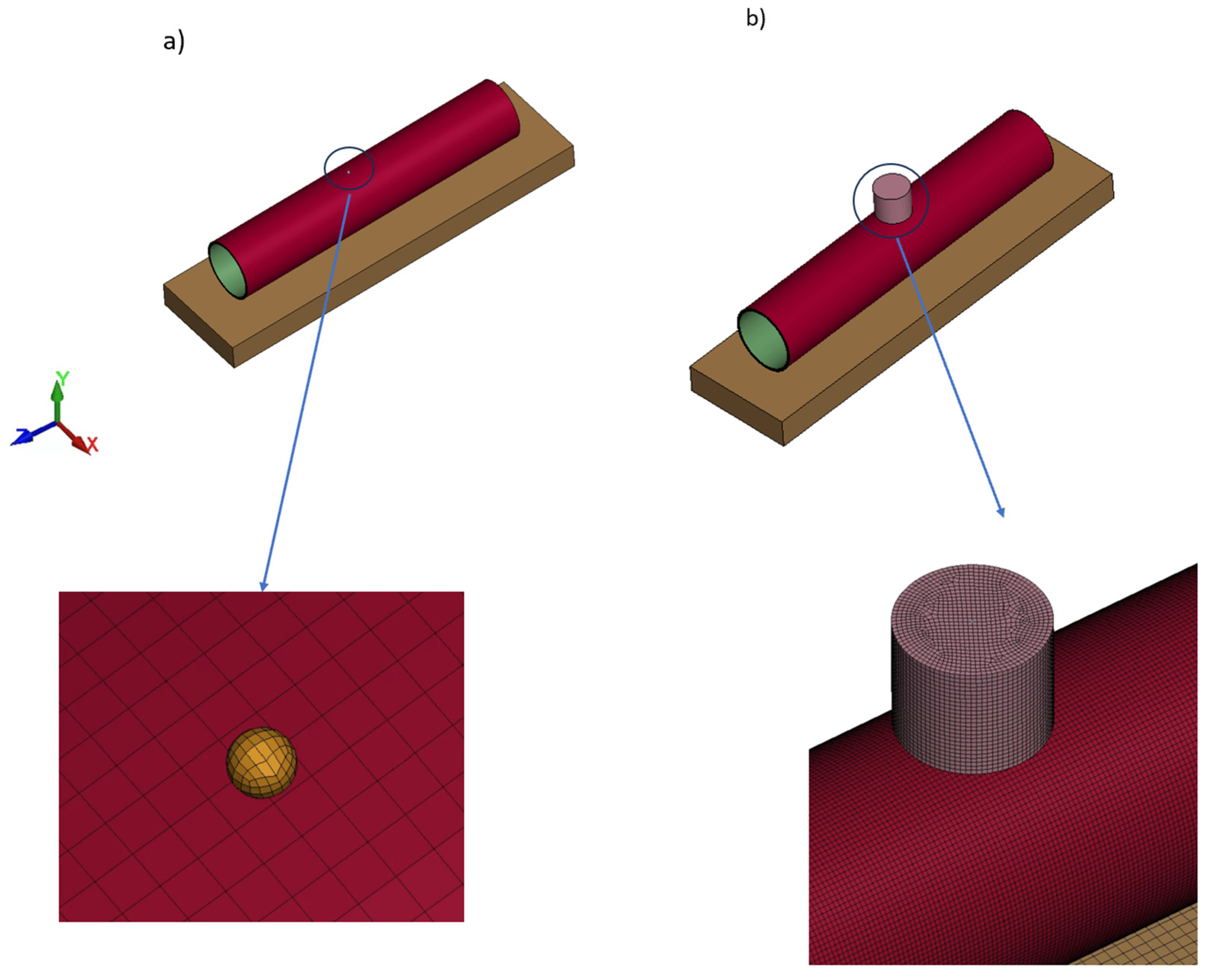

2.3. Numerical Model

3. Results

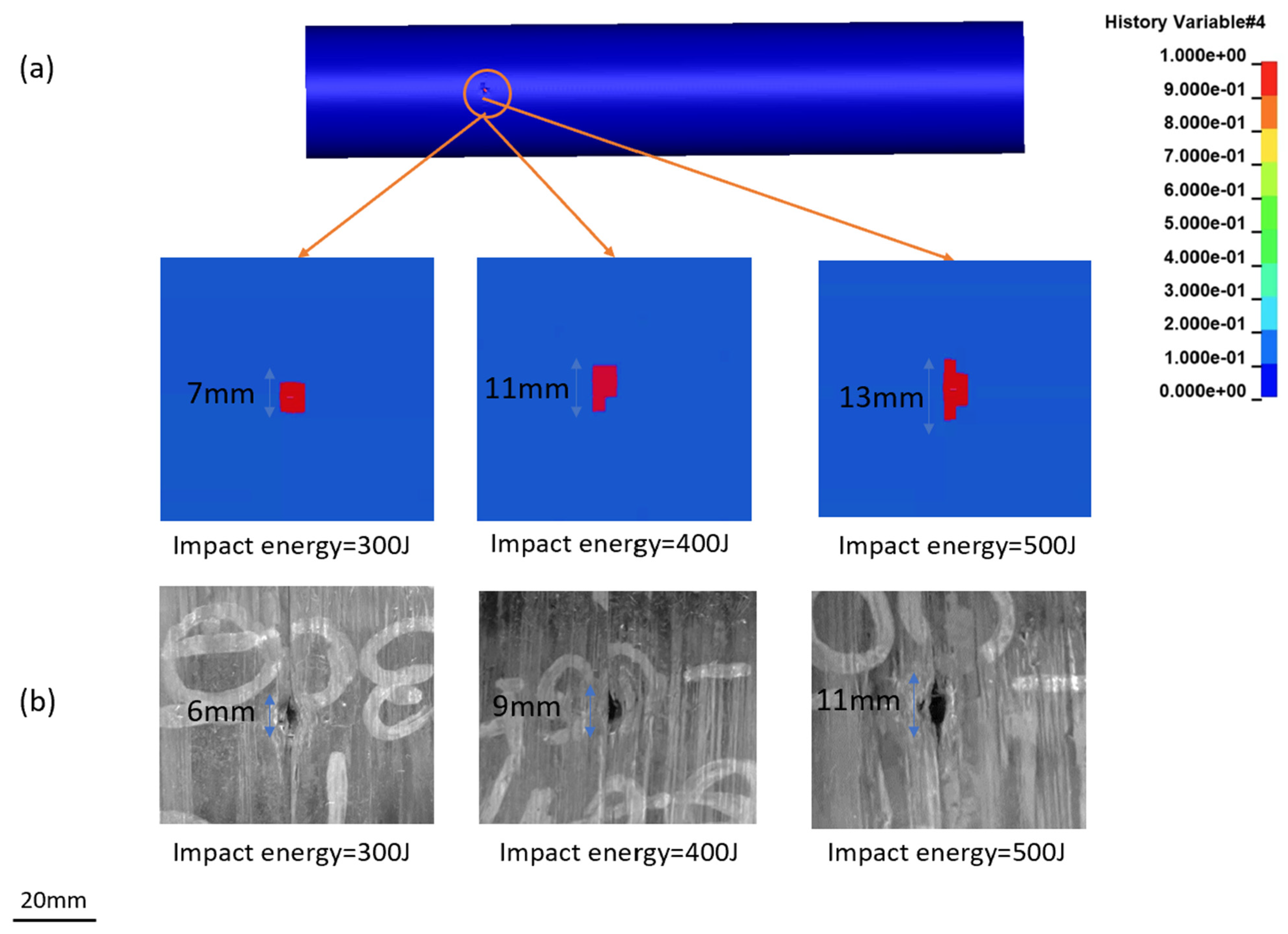

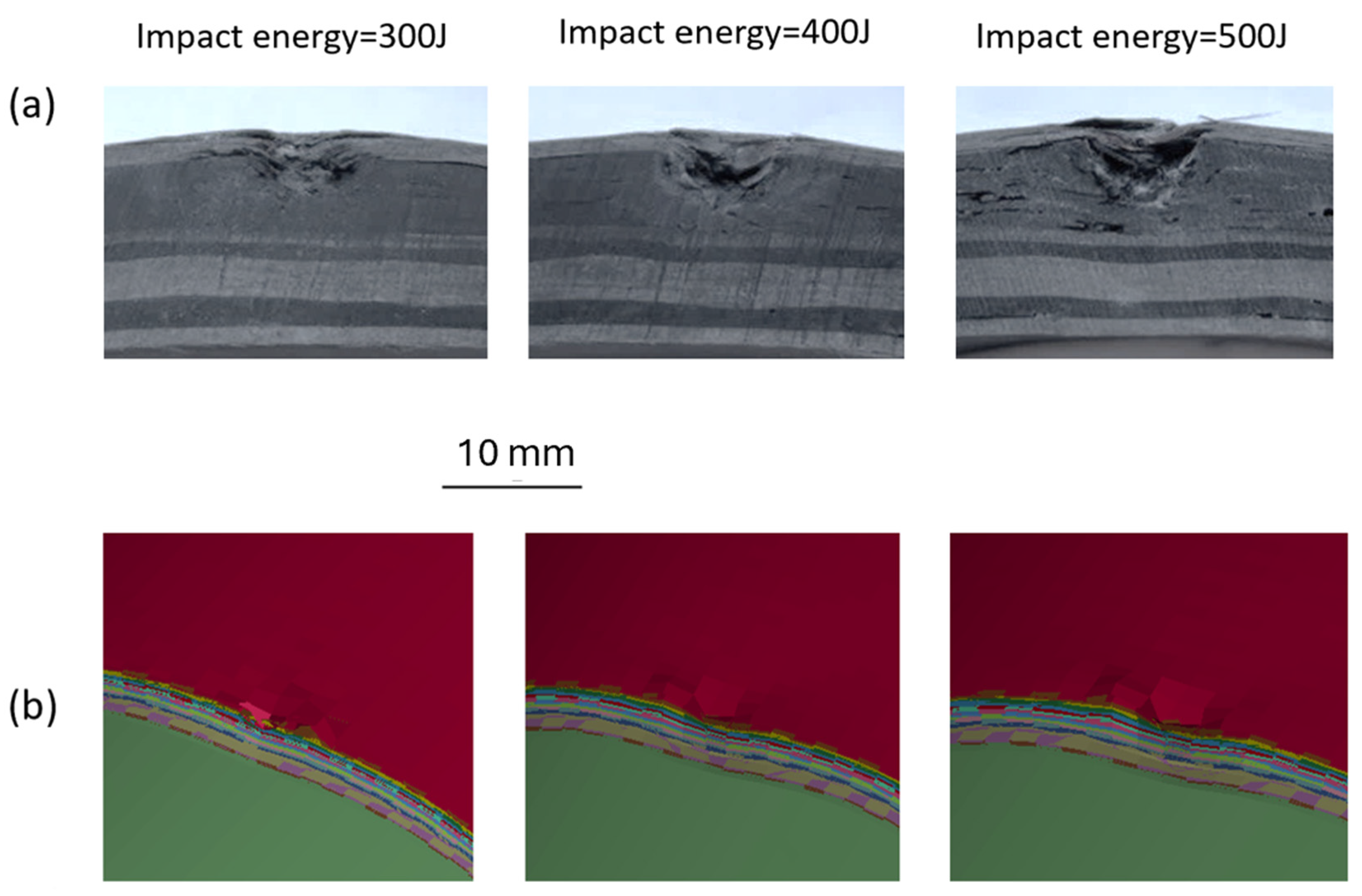

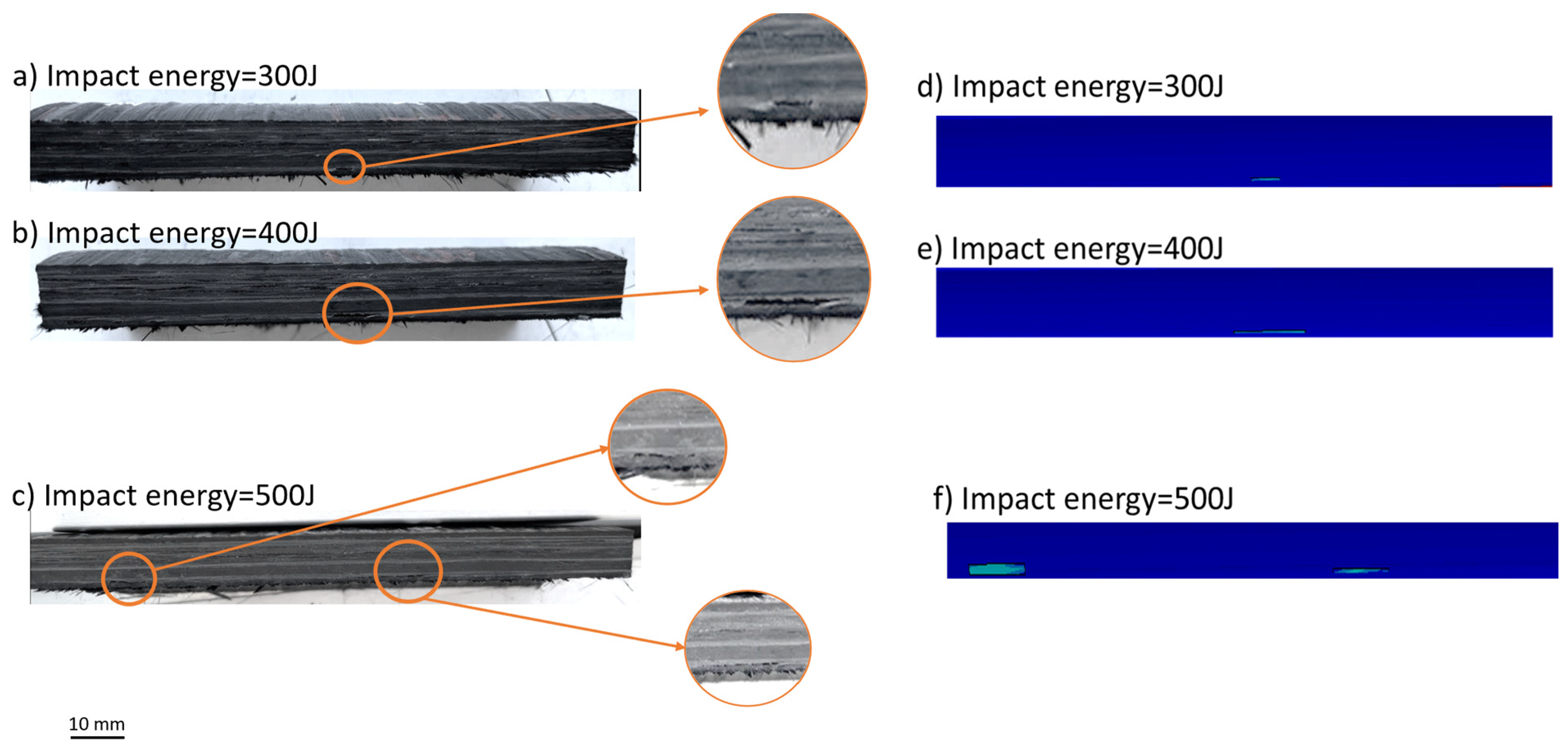

3.1. Comparing Numerical and Experimental Results

3.2. The Influence of Impactor Shape on the Impact Damage

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, J.; Liu, X.; Xu, P.; Liu, P.; Zhao, Y.; Yang, J. Development of high pressure gaseous hydrogen storage technologies. Int. J. Hydrogen Energy 2012, 37, 1048–1057. [Google Scholar] [CrossRef]

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q.; et al. Application of filament winding technology in composite pressure vessels and challenges: A review. J. Energy Storage 2022, 49, 103468. [Google Scholar] [CrossRef]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen storage for mobility: A review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef]

- Xu, P.; Zheng, J.; Chen, H.; Liu, P. Optimal design of high pressure hydrogen storage vessel using an adaptive genetic algorithm. Int. J. Hydrogen Energy 2010, 35, 2840–2846. [Google Scholar] [CrossRef]

- Choi, I.H. Low-velocity impact response analysis of composite pressure vessel considering stiffness change due to cylinder stress. Compos. Struct. 2017, 160, 491–502. [Google Scholar] [CrossRef]

- Liao, B.; Jia, L.; Zhou, J.; Lei, H.; Gao, R.; Lin, Y.; Fang, D. An explicit–implicit combined model for predicting residual strength of composite cylinders subjected to low velocity impact. Compos. Struct. 2020, 247, 112450. [Google Scholar] [CrossRef]

- Gemi, D.S.; Şahin, Ö.S.; Gemi, L. Experimental investigation of the effect of diameter upon low velocity impact response of glass fiber reinforced composite pipes. Compos. Struct. 2021, 275, 114428. [Google Scholar] [CrossRef]

- Kim, S.-W.; Kim, E.-H.; Jeong, M.-S.; Lee, I. Damage evaluation and strain monitoring for composite cylinders using tin-coated FBG sensors under low-velocity impacts. Compos. Part B Eng. 2015, 74, 13–22. [Google Scholar] [CrossRef]

- Maziz, A.; Tarfaoui, M.; Gemi, L.; Rechak, S.; Nachtane, M. A progressive damage model for pressurized filament-wound hybrid composite pipe under low-velocity impact. Compos. Struct. 2021, 276, 114520. [Google Scholar] [CrossRef]

- Liao, B.; Jia, L. Finite element analysis of dynamic responses of composite pressure vessels under low velocity impact by using a three-dimensional laminated media model. Thin-Walled Struct. 2018, 129, 488–501. [Google Scholar] [CrossRef]

- Han, M.-G.; Chang, S.-H. Failure analysis of a Type III hydrogen pressure vessel under impact loading induced by free fall. Compos. Struct. 2015, 127, 288–297. [Google Scholar] [CrossRef]

- Weerts Ruben, A.J.; Cousigné, O.; Kunze, K.; Geers, M.G.D. A methodological approach to model composite overwrapped pressure vessels under impact condi-tions. Compos. Struct. 2021, 276, 114482. [Google Scholar] [CrossRef]

- Perillo, G.; Grytten, F.; Sørbø, S.; Delhaye, V. Numerical/experimental impact events on filament wound composite pressure vessel. Compos. Part B Eng. 2015, 69, 406–417. [Google Scholar] [CrossRef]

- Gemi, L.; Kayrıcı, M.; Uludağ, M.; Gemi, D.S.; Şahin, Ö.S. Experimental and statistical analysis of low velocity impact response of filament wound composite pipes. Compos. Part B Eng. 2018, 149, 38–48. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, J.; Zhao, C.; Liu, J.; Li, Y.; Jiang, L.; Feng, J.; Xue, Y. Experimental and numerical analysis of low-velocity impact behavior of wound products using multi-filament winding technique. J. Mater. Res. Technol. 2023, 25, 7292–7306. [Google Scholar] [CrossRef]

- Farhood, N.H. Low velocity impact simulation of cylindrical section for type IV composite pressure vessels. AIP Conf. Proc. 2021, 2372, 150001. [Google Scholar]

- Allen, T.; Ahmed, S.; Hepples, W.; Reed, P.A.; Sinclair, I.; Spearing, M. A comparison of quasi-static indentation and low-velocity impact on composite overwrapped pressure vessels. J. Compos. Mater. 2018, 52, 4051–4060. [Google Scholar] [CrossRef]

- Farhood, N.H.; Karuppanan, S.; Ya, H.H.; Ovinis, M. Experimental study of low velocity impact response of carbon/basalt hybrid filament wound composite pipes. Int. J. Struct. Stab. Dyn. 2018, 18, 1850089. [Google Scholar] [CrossRef]

- Farhood, N.H.; Karuppanan, S.; Ya, H.H.; Sultan, M. Experimental investigation on the effects of glass fiber hybridization on the low-velocity impact response of filament-wound carbon-based composite pipes. Polym. Polym. Compos. 2021, 29, 829–841. [Google Scholar] [CrossRef]

- Trevor Matthew, A. Damage Development and Post-Impact Performance of Composite Overwrapped Pressure Vessels Subjected to Low Velocity Impact. Ph.D. Thesis, University of Southampton, Southampton, UK, 2017. [Google Scholar]

- Wu, Q.; Chen, X.; Fan, Z.; Jiang, Y.; Nie, D. Experimental and numerical studies of impact on filament-wound composite cylinder. Acta Mech. Solida Sin. 2017, 30, 540–549. [Google Scholar] [CrossRef]

- Long, B.; Yang, N.; Cao, X. Low-velocity impact damages of filament-wound composite overwrapped pressure vessel (COPV). J. Eng. Fibers Fabr. 2022, 17, 15589250221088895. [Google Scholar] [CrossRef]

- Available online: https://lsdyna.ansys.com/manuals/ (accessed on 1 May 2025).

- Rezaei Akbarieh, S.; Ma, D.; Sbarufatti, C.; Manes, A. Numerical Investigation on the Capability of Modeling Approaches for Composite Cylinders under Low-Velocity Impact Loading. J. Compos. Sci. 2024, 8, 141. [Google Scholar] [CrossRef]

- Akbarieh, S.R.; Ma, D.; Sbarufatti, C.; Manes, A. Numerical model of curved composite tiles under low-velocity impact loading. J. Compos. Mater. 2024, 59, 661–680. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Density | 1.8 |

| Longitudinal Tensile Strength | 2450 |

| Longitudinal Compressive Strength | 1570 |

| Longitudinal Young Modulus | 125 G |

| Transverse/Normal Young Modulus | 7800 |

| Transverse Compressive Strength | 150 |

| Transverse Tensile Strength | 70 |

| Shear Strength | 98 |

| Shear Failure Stress | |

| Normal Failure Stress |

| Layer Number | Angle (°) | Minimum Thickness (mm) |

|---|---|---|

| 1 | 90 | 0.90 |

| 2 | 18 | 0.75 |

| 3 | 90 | 2.00 |

| 4 | 20 | 0.80 |

| 5 | 70 | 0.80 |

| 6 | 40 | 0.80 |

| 7 | 27 | 0.80 |

| 8 | 32 | 0.80 |

| 9 | 18 | 0.80 |

| 10 | 90 | 0.85 |

| Impactor Shape/Size | Results | Surface Damage | Delamination | Indentation | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impact Energy (J) | Impact Energy (J) | ||||||||||||

| 300 | 400 | 500 | 300 | 400 | 500 | ||||||||

| Impact Energy (J) | |||||||||||||

| Length (mm) | Width (mm) | Length (mm) | Width (mm) | Length (mm) | Width (mm) | Length (mm) | Length (mm) | Length (mm) | |||||

| 300 | 400 | 500 | |||||||||||

| 6 mm Spherical | Experimental | 6 | 3 | 9 | 4 | 11 | 6 | 7.6 | 4.2 | 32 | 2.3 | 3.5 | 4.8 |

| Numerical | 7 | 5 | 10 | 6 | 13 | 6 | 8.2 | 5 | 34 | 3.1 | 4.7 | 5.5 | |

| 120 mm Cylindrical | Experimental | - | 2.6 | 8 | 6–6.6 | - | |||||||

| Numerical | 3.2 | 9.5 | 7–8.5 | ||||||||||

| Impactor Diameter (mm) | Impact Energy (J) | Matrix Damage Area (mm2) | Delamination Area (mm2) | Fiber Breakage Area (mm2) | |

|---|---|---|---|---|---|

| Spherical Impactor | 6 | 300 | 2880 | 4050 | 40 |

| 400 | 3520 | 5152 | 47 | ||

| 500 | 5655 | 5890 | 52 | ||

| 50 | 300 | 3888 | 7830 | 110 | |

| 400 | 4784 | 10,664 | 168 | ||

| 500 | 7208 | 11,189 | 230 | ||

| 120 | 300 | 4368 | 5712 | 132 | |

| 400 | 4940 | 10,836 | 192 | ||

| 500 | 6600 | 12,062 | 247 | ||

| Cylindrical Impactor | 6 | 300 | 1908 | 988 | 30 |

| 400 | 5192 | 2112 | 156 | ||

| 500 | 5166 | 7616 | 182 | ||

| 50 | 300 | 5032 | 528 | 169 | |

| 400 | 5700 | 10,010 | 210 | ||

| 500 | 7480 | 14288 | 288 | ||

| 120 | 300 | 8580 | 1260 | 60 | |

| 400 | 9088 | 2720 | 76 | ||

| 500 | 9920 | 8448 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbarieh, S.R.; Ma, D.; Sbarufatti, C.; Manes, A. The Effect of Impactor Geometry on the Damage Patterns Generated by Low-Velocity Impacts on Composite Pressure Vessels. Modelling 2025, 6, 41. https://doi.org/10.3390/modelling6020041

Akbarieh SR, Ma D, Sbarufatti C, Manes A. The Effect of Impactor Geometry on the Damage Patterns Generated by Low-Velocity Impacts on Composite Pressure Vessels. Modelling. 2025; 6(2):41. https://doi.org/10.3390/modelling6020041

Chicago/Turabian StyleAkbarieh, Shiva Rezaei, Dayou Ma, Claudio Sbarufatti, and Andrea Manes. 2025. "The Effect of Impactor Geometry on the Damage Patterns Generated by Low-Velocity Impacts on Composite Pressure Vessels" Modelling 6, no. 2: 41. https://doi.org/10.3390/modelling6020041

APA StyleAkbarieh, S. R., Ma, D., Sbarufatti, C., & Manes, A. (2025). The Effect of Impactor Geometry on the Damage Patterns Generated by Low-Velocity Impacts on Composite Pressure Vessels. Modelling, 6(2), 41. https://doi.org/10.3390/modelling6020041