In calculations to obtain fits of the simulations to the DOP data, the first 40 columns of data on the left-hand side of the sample were ignored. It was discovered that there is a slight left-right asymmetry to the DOP and ROP data. Fits ignoring the first 40 columns of data on the left-hand side or ignoring the first 40 columns of data on the right-hand side gave similar results, with the quality of fits excluding one side or the other being better than for fits that included both left- and right-hand sides. It was decided arbitrarily to use fits that excluded the first 40 columns of data on the left-hand side.

Results

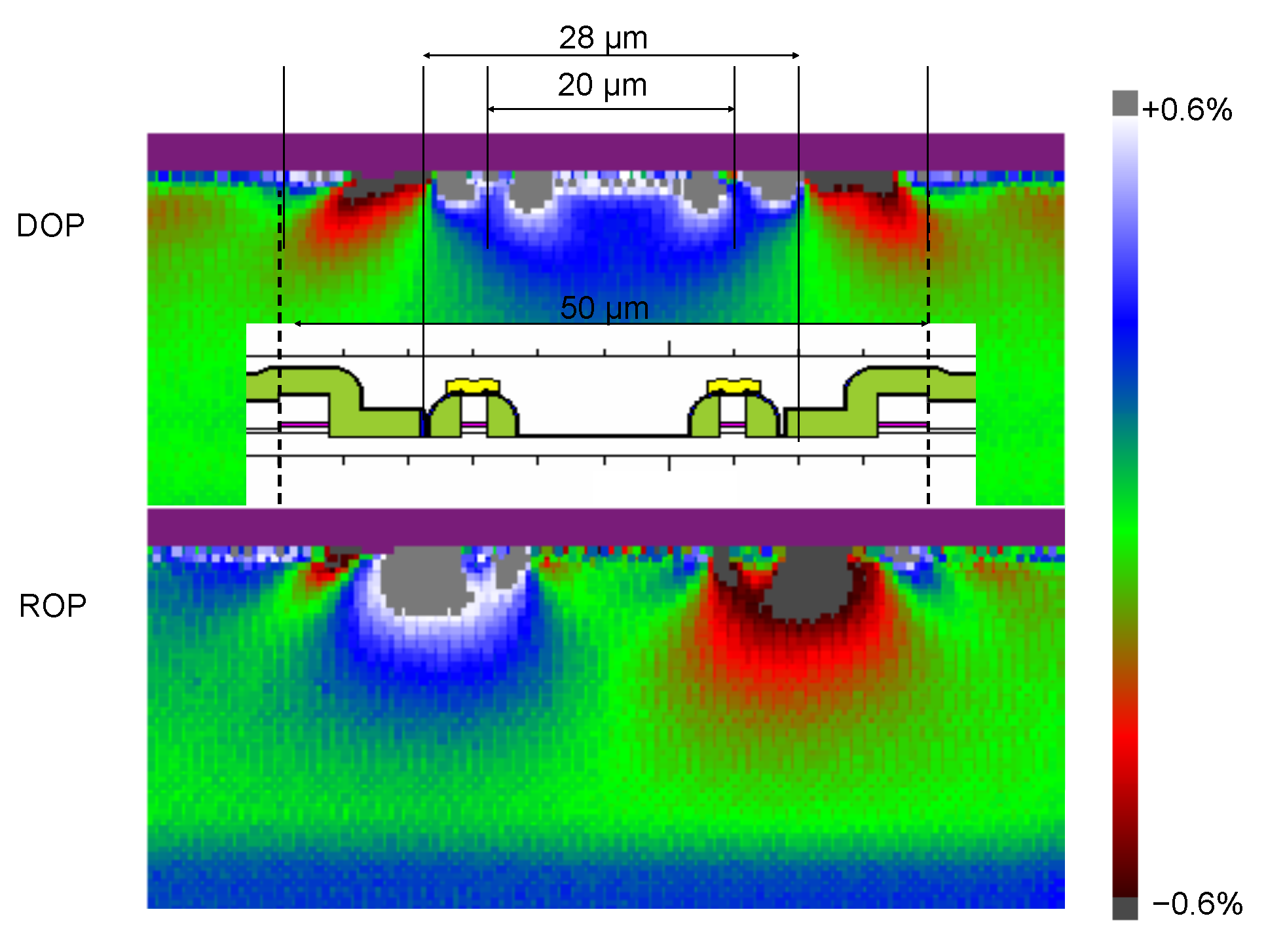

Figure 4 shows false colour maps of the data and best fit 3D simulations of

and

, or just DOP and ROP for brevity, for the facet, which is a

plane. To map data to a colour, a display gain is chosen and the product of the display gain and the data is converted to the nearest integer, which is used to select a colour to represent a data point. All data points are represented by a rectangle of the same size.

The top row of

Figure 4 displays the PL yield for two different values of thresholding. Part (a) shows the PL yield with thresholding of

of the maximum value of the PL. Areas with PL below the threshold level are shown in magenta. This thresholding allows areas of high noise to be suppressed. Part (e) shows the same measured PL yield, but displays the PL yield with a threshold level of

of the maximum value of the PL. This threshold was used to exclude DOP and ROP data from the fits and displays. Any DOP or ROP data that were calculated with a value of the PL yield that was below the threshold value are displayed with a magenta colour. The thresholded data is possibly corrupted by noise or measurement artefacts, and are excluded as this data is considered unreliable.

Figure 4b,f display the measured DOP and ROP data. Note that the aspect ratio of the data was not maintained in the panels of

Figure 4. All panels use the same aspect ratio, but the aspect ratio is not the 105:513 aspect ratio of the real data. The data was measured with 105.1 μm steps in the vertical direction and 171.3 μm steps in the horizontal direction.

Panels (c) and (g) display the best fit DOP and ROP to the measured data. The best fit DOP and ROP are found by assuming boundary conditions for a 3D FEM simulation of the deformation and using the strains determined from the 3D FEM simulation to calculate

and

from Equation (

2). A grid search was used to find the deformation that yielded a minimum mean squared difference,

, between the measured DOP and ROP and the simulated

and

. In comparing panels (c) and (g), and, (d) and (h), it should be noted that the ROP false colour maps were created with a display gain that was

larger that the display gain for the DOP false colour maps. The chi-squared values obtained from the fits are approximately the same for both ROP and DOP. In the calculation of chi-squared, the DOP and ROP data were weighted equally.

Panels (d) and (h) display five times the residue, which was smoothed to remove random noise, with the residue defined as the difference between the measured data and the best fit 3D FEM simulation. The residues provide a visual means to estimate the quality of the fit and to make a connection between the value and the visual quality of the fit. The residues for a perfect fit would be zero and show as a uniform colour, with the same colour as the green tick mark on the colour bar (i). The residues were smoothed by convolving the data with a square, i.e., by averaging each value at over values at , where are integers that define the location of the value of interest.

An examination of panel (d) shows that the simulated DOP is a good approximation, by virtue of the green (zero) over most of the region, to the measured DOP. The simulation is not as good as an approximation near the bonding (lower) surface where non-uniformities are visible. These non-uniformities indicate non-uniform bonding of the chip to the submount. There was no attempt to fit to the non-uniformities, which can be observed in (b) and (d). The fit to the ROP does not seem to be as good, with some difficulty fitting to the right-hand side of the chip. However, it should be remembered that the ROP is displayed with a display gain that is greater than the DOP display gain.

The colour bar (i) is composed of 241 uniquely coloured rectangles plus off-scale black and grey boxes at the top and bottom of the colour bar. Any value that cannot be displayed by one of the 241 colours is assigned to black if the value is more negative than the available colours and grey if the value is more positive. The tic marks on the colour bar have the same height as one unique rectangle of the 241 rectangles that make up the colour bar and help navigate the false-colour mapping.

For the PL yield, the black square at the bottom of the colour bar represents negative vlaues and the white colour just below the grey at the top of the colour bar represents the maximum value that can be uniquely displayed. For displays of the DOP and ROP, the green tic mark in the centre of colour bar represents zero. The full scale values that can be displayed, given the display gains that were chosen, are and for the DOP and ROP, respectively.

False colour maps of the fits of 2D FEM simulations are not visually that different from the 3D fits presented in

Figure 4.

Table 1 presents results for fits of 3D FEM, 2D FEM plane stress, and 2D FEM plane strain simulations to the measured DOP and ROP. In the fitting procedure, the mean square error (mse),

, is minimised, where the subscript

T stands for ‘total’. The values of

,

, and

are reported.

and

are the contributions to

for fits to the DOP and ROP data.

R is the minimum mean square error (mmse) radius of curvature in metres and

e is the mmse biaxial strain.

Appendix A provides information on the elastic constants used for the 3D FEM simulations.

Appendix C and

Appendix D provide the elastic constants used for the 2D plane strain and 2D plane stress FEM simulations.

In comparing the

values, it should be noted that the

confidence interval in a calculation of the standard deviation for the mean of

random draws from a unit normal distribution is approximately

for

[

24] (Table A12). For

= 10,828 the

uncertainty is

.

The false colour maps of the DOP or ROP of

Figure 4 contain

= 17,955 points. Not all of these measurements were used in the least squares fits, as some measurements were excluded owing to thresholding and to avoid asymmetry in the sample. For fits to the DOP or ROP data, the degrees of freedom

= 10,828.

The uncertainty for should be the uncertainty in or as there are twice as many degrees of freedom in the calculation of as there for or .

The 3D

values listed in

Table 1 when associated with the residues, panels (d) and (h) of

Figure 4, allow one to assess visually the quality of the fit. Since the 2D

values differ from the 3D values by ≲0.1 in

, or roughly 1 part in thirty, it is unlikely that a difference between the quality of fits for 2D and 3D simulations can be determined visually.

If one accepts that the uncertainty in

is ≈0.010 from random fluctuations (i.e., noise—see the confidence interval estimation presented four paragraphs above) in the data, then from

Table 1 it would appear that the two 2D FEM simulations fit the data similarly, and that the 2D FEM simulations fit better than the 3D FEM simulation.

It is interesting to note that the best fit values for R and e vary for the three different methods of simulation. The uncertainty in the best-fit values for e were estimated for fits of 2D plane stress simulations to real and synthetic data by holding R equal to the best fit value and varying e until changed by . A similar procedure was used to estimate the uncertainty in R. It is assumed that these 2D plane stress uncertainties are representative of the uncertainties for all best-fit values.

To understand the numbers provided in

Table 1, synthetic data were created and used as inputs to the FEM simulations. The synthetic data were created using the values for

R and

e found from fits of the 3D FEM simulation to the measured DOP and ROP. These

R and

e values were used in a 3D FEM simulation to produced

and

, from Equation (

2). No noise was added to the synthetic data.

The results for fits of the synthetic data for 2D and 3D simulations are contained in

Table 2.

The fits 3D simulations to the synthetic data are as expected. The

values are near zero; for a perfect fit the

values would be zero. The values for

R and

e are within

and

of the values used to create the synthetic data. In an ideal world, the values for

R and

e would match. However, there is ‘noise’ in the synthetic data owing to convergence and gridding issues, and to interpolation issues as the FEM simulations do not use the same grid as the data. Since the variables are not orthogonal, the fitting routine can alter the two variables to minimise the mean square error,

. In mmse fits, there is no guarantee that the mmse fit parameters have the most physical explanation; the best fit parameters are the ones that minimise

. One hopes that the best fit parameters are accurate representations of the physical world [

25] (Section 7.3).

Clearly the 2D FEM simulations do not fit well to the synthetic data. Since the external noise that exists in the measurements has been eliminated, the contributions to are from the quality of the fit, and convergence and gridding issues. It is known from the 3D fits that the convergence and gridding noise add at most 0.004, it is reasonable to assume that the remainder of the contribution to comes from the quality of the fit. The 2D FEM simulations used a finer grid and a smaller convergence limit than the 3D FEM simulations, so one might reasonably expect the convergence and gridding noise to be less in the 2D FEM simulations as compared to the 3D FEM simulations.

The best fit values for R for the 2D FEM simulations are and as compared to a true value of . These R values are significantly different. The best fit values for are and , which are not that different than the true value of .

It is interesting to note that the plane strain approximation () appears to fit the synthetic data better than the plane stress approximation (). This might be somewhat unexpected in that the facet is a free surface with , which is the condition that defines plane stress, and in that the PL data is generated near the facet, in a region where . The stresses as calculated by 3D FEM simulations are given in the next two figures. The second figure is a plot of the stresses using an expanded scale near the facet.

One could try to fit the DOP data with plane stress FEM simulations and use these fits parameters with the plane strain FEM simulations. The concept is that plane stress has the proper boundary condition, , and the plane strain approximation should be appropriate to the chip, far from the boundaries of the chip. This result of this approach was unremarkable in that results were not that different from solely plane stress or solely plane strain simulations.

If one accepts that 3D FEM simulations, once calibrated by fits to the measured DOP data, are a reasonable approximation to the deformation in the sample, then one must conclude that the 2D FEM simulations of the measured DOP at the surface are inadequate.

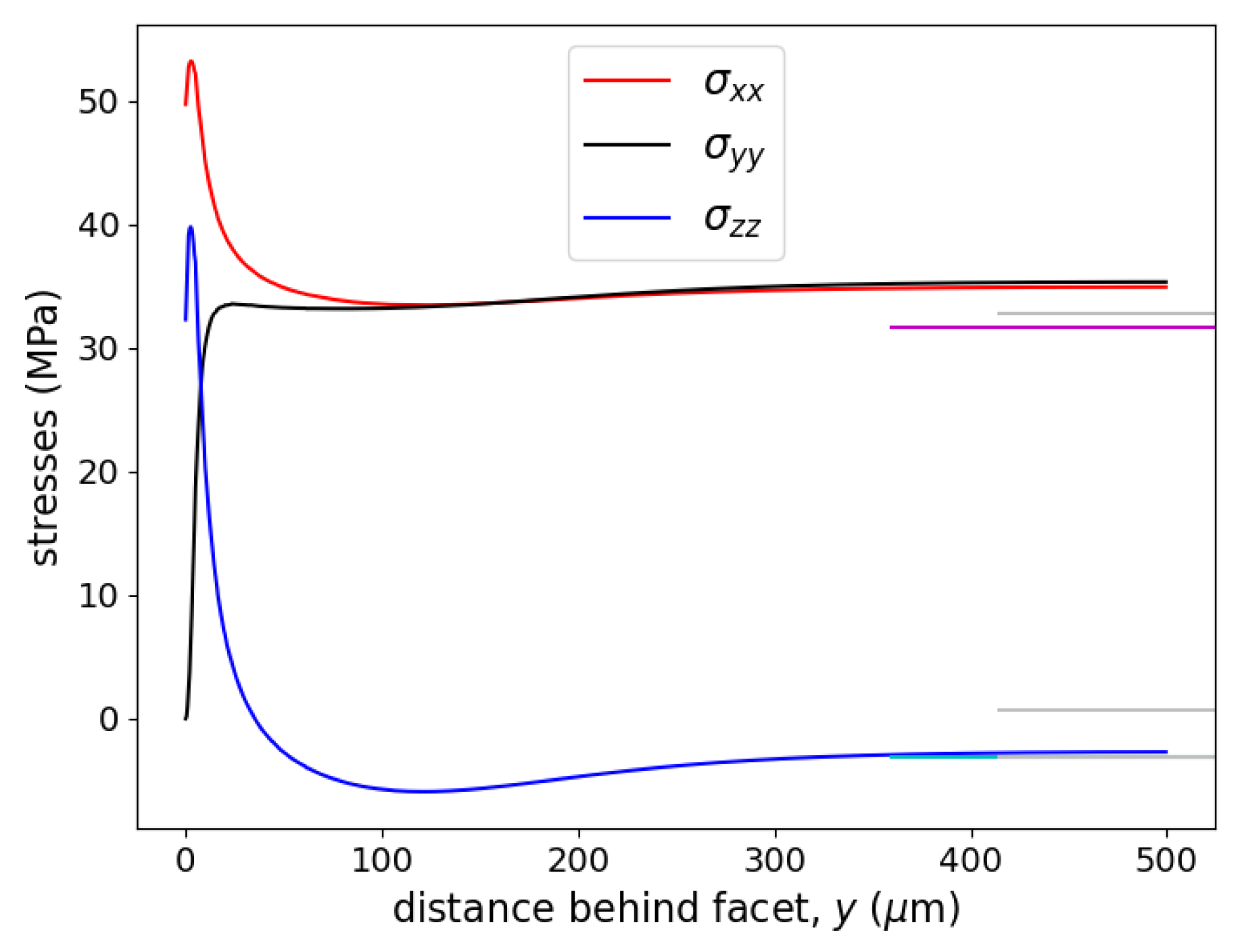

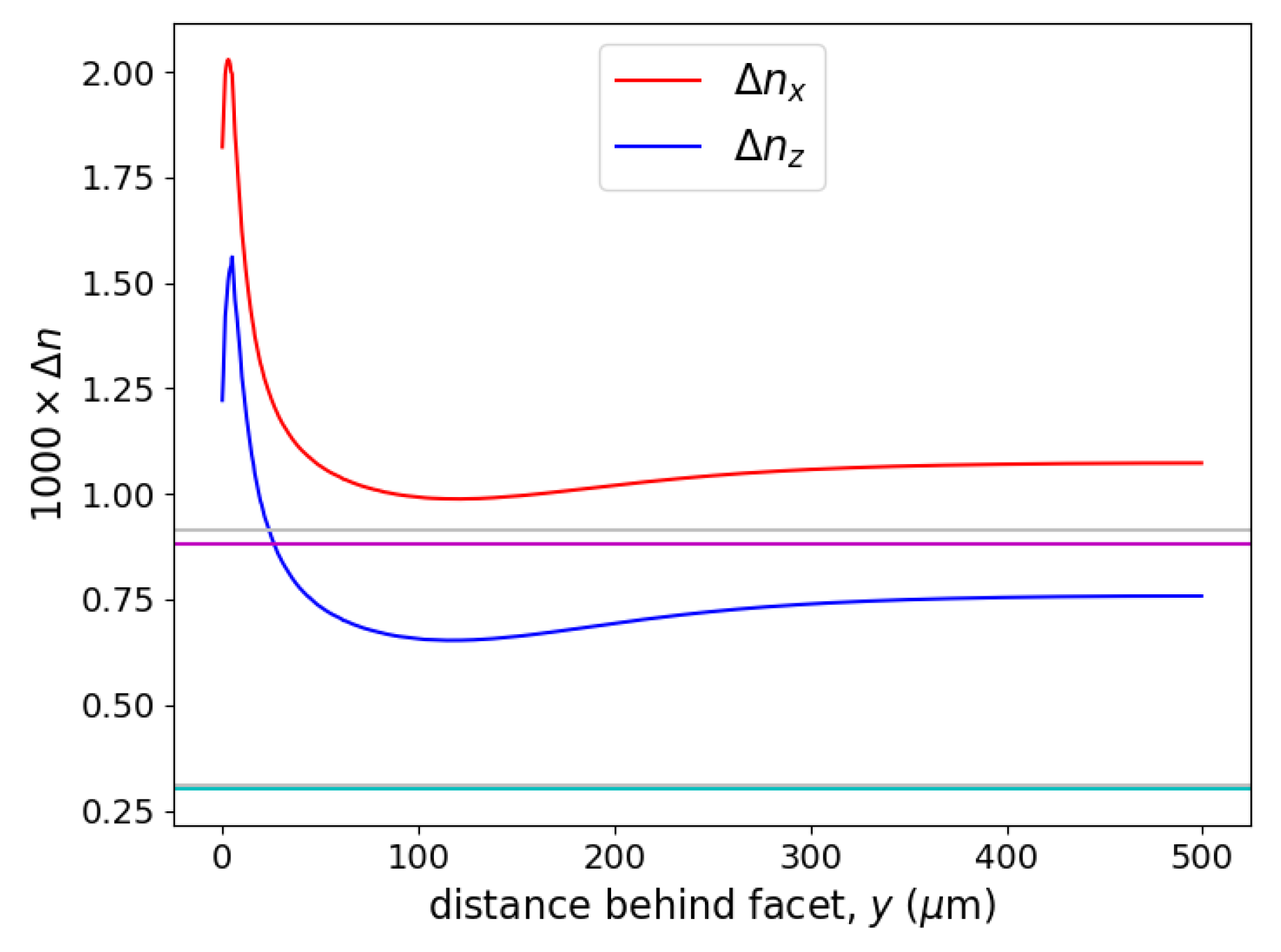

Figure 5 plots 3D estimations of the stresses owing to bonding strain as a function of the distance

y behind the facet. The stresses are plotted for a line that is

m above the bonding surface (the bonding surface is the plane

m) and that is at the midpoint (

) of the chip. 2D FEM simulations are independent of

y as the two dimensions considered are

x and

z. For a plane stress 2D FEM simulation,

MPa,

MPa, and

MPa. The 2D plane strains values of

MPa,

MPa, and

MPa are similar to the plane stress values. The long tic marks on the right-hand side of

Figure 5 mark the stresses from the 2D plane strain (grey) and plane stress (magenta and cyan) approximations. The plots of the 2D values should extend for all values of

y, but this makes the figure too cluttered.

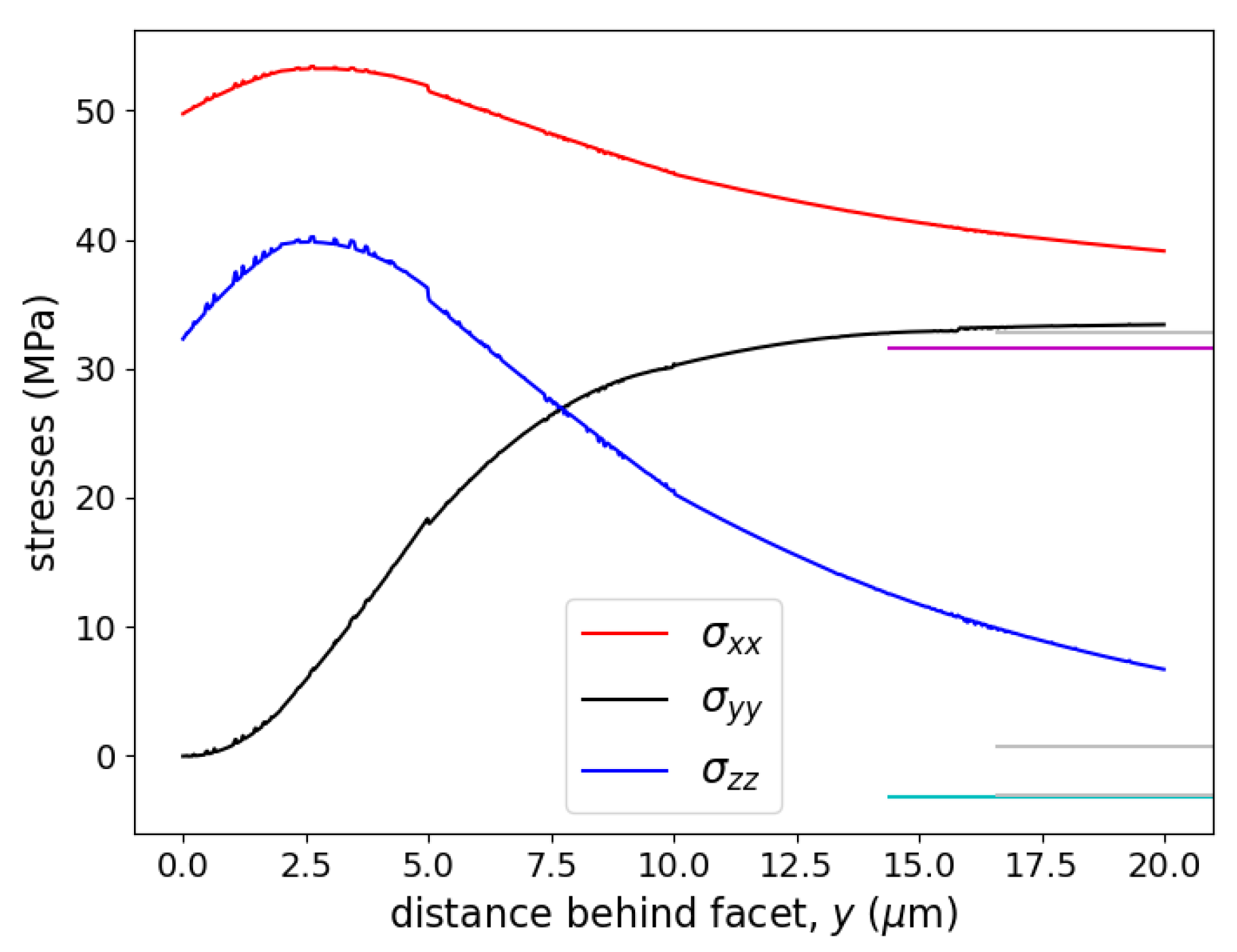

Figure 6 plots the same information as

Figure 5 but on an expanded

y scale and only near the facet, which occurs at

. Since the facet is assumed to be a free surface (the surface tractions are set equal to zero), the normal component of stress must equal zero, i.e.,

. The zoomed version of

Figure 5 clearly shows that the 3D FEM simulation meets the boundary condition of

at the facet, that the deformation of the sample is not uniform along the optic axis (i.e., the normal to the facet or

y direction), and that this non-uniformity extends for a significant distance (>50 wavelengths) beyond the facet.

Note the ‘noise’ associated with the curves in

Figure 6. This is the gridding, convergence, and interpolation noise mentioned in the discussion of the

values for fits of 3D FEM simulations to the synthetic data,

Table 2.

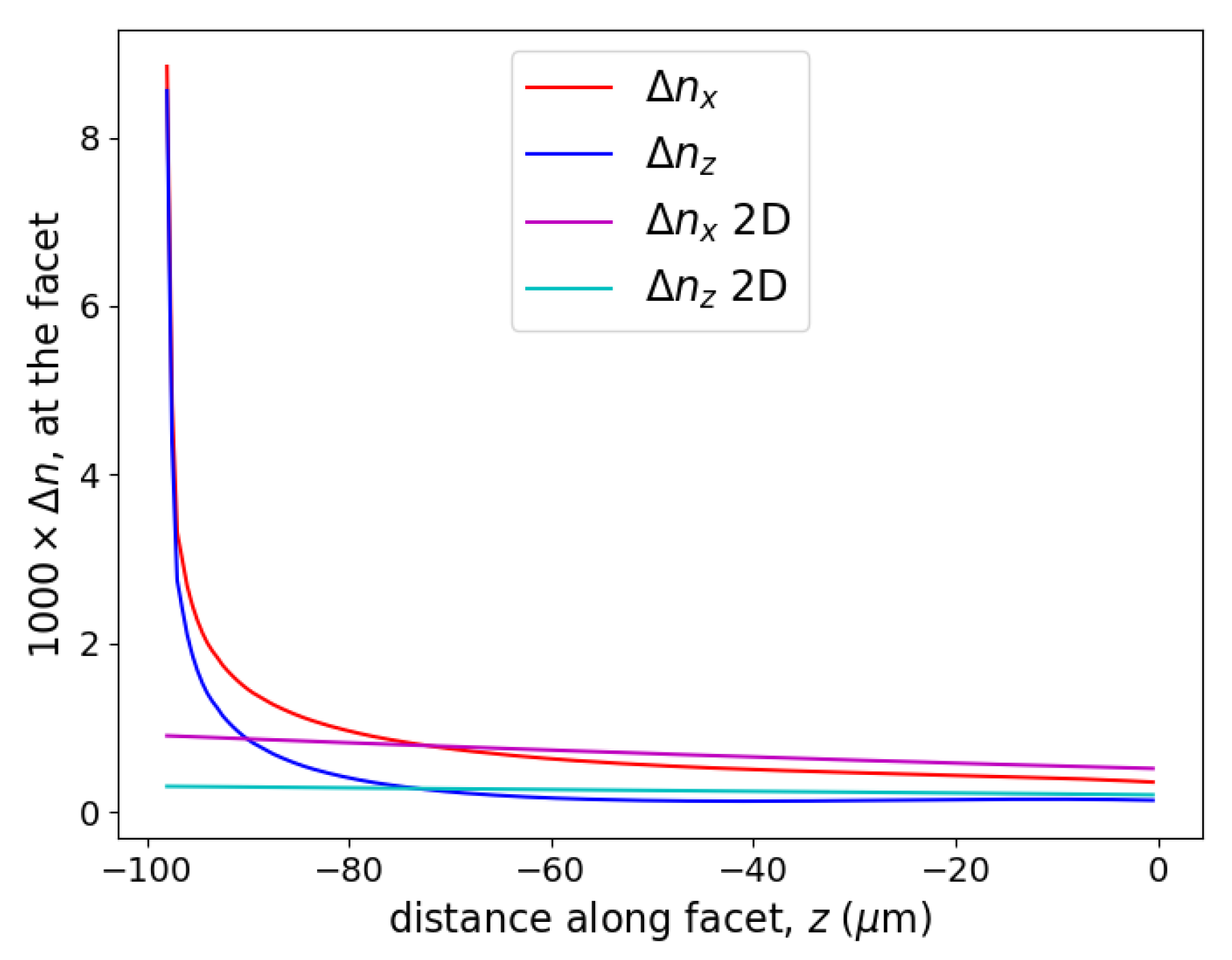

Figure 7 plots 2D and 3D estimates of the changes in the TE (

) and TM (

) refractive indices for a line

m above the bonding surface and in a plane perpendicular to the facet but at the midpoint of the chip. The 2D simulation and the 3D simulation at the midpoint (c.f.

m for

Figure 7) are similar in shape in that the 3D values approach a straight line at the midpoint of the chip but the magnitudes differ by up to >100%. The 2D predictions are indicated by straight lines as 2D simulations assume no

y dependence in the material that is being simulated. The magenta-coloured line near

is

for a plane stress (2D) FEM simulation whereas the cyan coloured line near

is

for the same simulation. The grey lines are values obtained from a plane strain (2D) FEM simulation.

Figure 7 shows that there is little difference in the predicted photoelastic effect for a plane strain and a plane stress simulation, but there is a large discrepancy between the predicted strain-induced refractive index changes (i.e., photoelastic effect) for 3D and 2D FEM simulations.

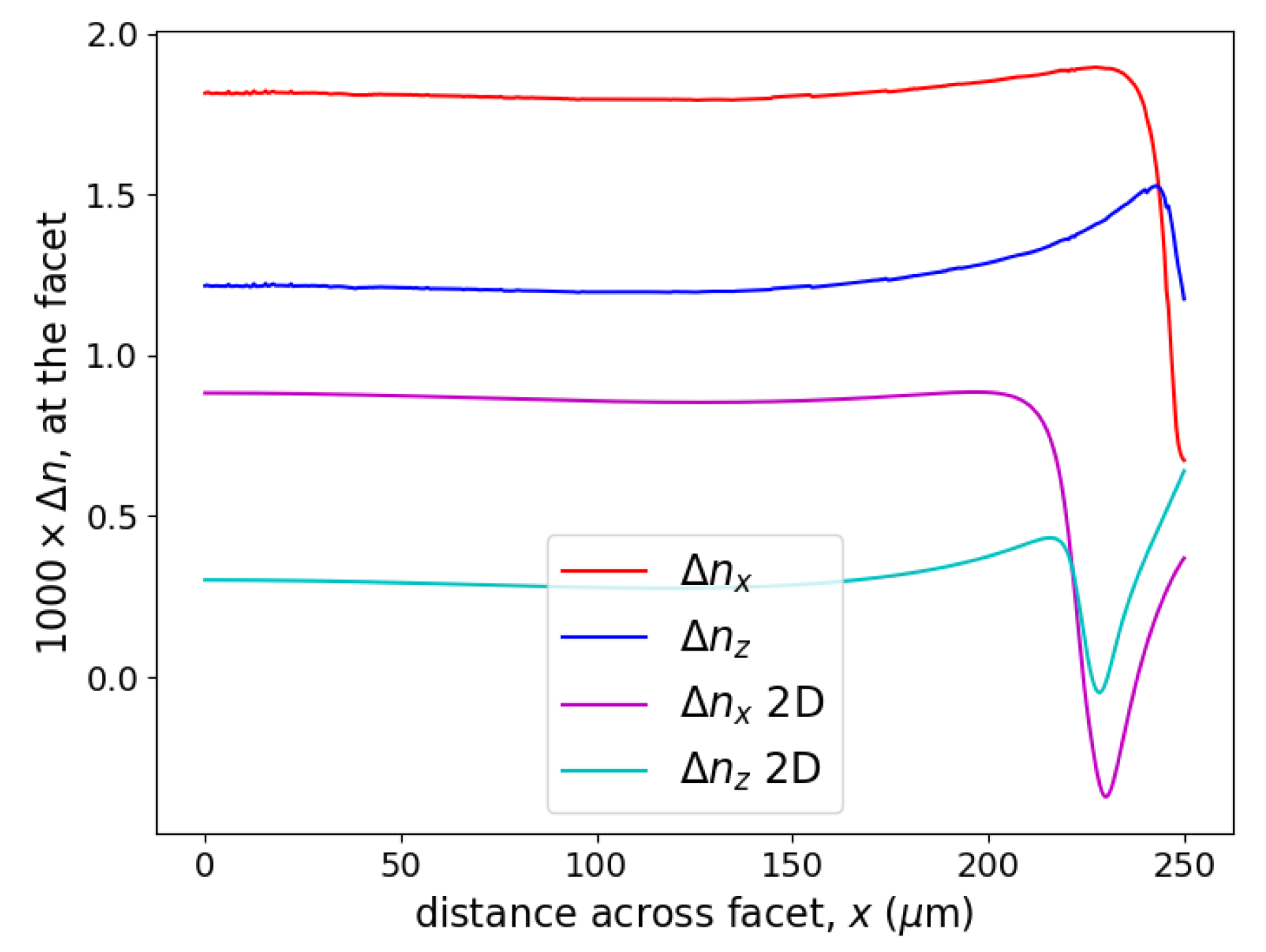

Figure 8 plots the estimated photoelastic index changes in the plane of the facet (i.e., the plane

), from the bonding surface at

m to the top of the chip at

, and at mid-width (

) of the GaAs chip. For the 3D simulations, the refractive index changes,

and

, are ≈

near the bonding surface and decrease rapidly as

z increases from

m to say

m and then decrease slowly to the top of the chip.

Note that this chip was a specially prepared chip. There was no metal or dielectric coatings on the top surface at . Any photoelastic effects from surface tractions on the top surface would add to the effects caused by the bonding. By the principle of linear superposition, one would expect any contribution from the top surface to add linearly as the FEM model is a linear model of elasticity. This sample is somewhat ideal for this investigation in the sense that the simple boundary conditions remove some degrees of freedom and hence simplify explanations and modelling.

The plane stress 2D FEM simulation show that the 2D photoelastic predictions are similar to the 3D predictions far away from the bonding surface but deviate substantially from the 3D predictions within about

m from the bonding surface. This behaviour is similar to stresses in

Figure 6 and the refractive index changes when plotted along

y, as shown in

Figure 7.

Figure 9 plots the 2D and 3D photoelastic effects in the plane of the facet (i.e., the

plane) from the mid-width at

to the edge of the chip at

m. The data are plotted for a line that is

m above the bonding surface. The 2D FEM photoelastic predictions are smaller in magnitude that the 3D FEM photoelastic predictions and are significantly different than the 3D predictions near the free surface at

m, which is the side wall on the right-hand-side of the chip. These differences between the 2D and 3D predictions near a surface are consistent with the results presented in

Figure 7 and

Figure 8, and the stresses presented in

Figure 5 and

Figure 6.