Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review

Abstract

1. Introduction

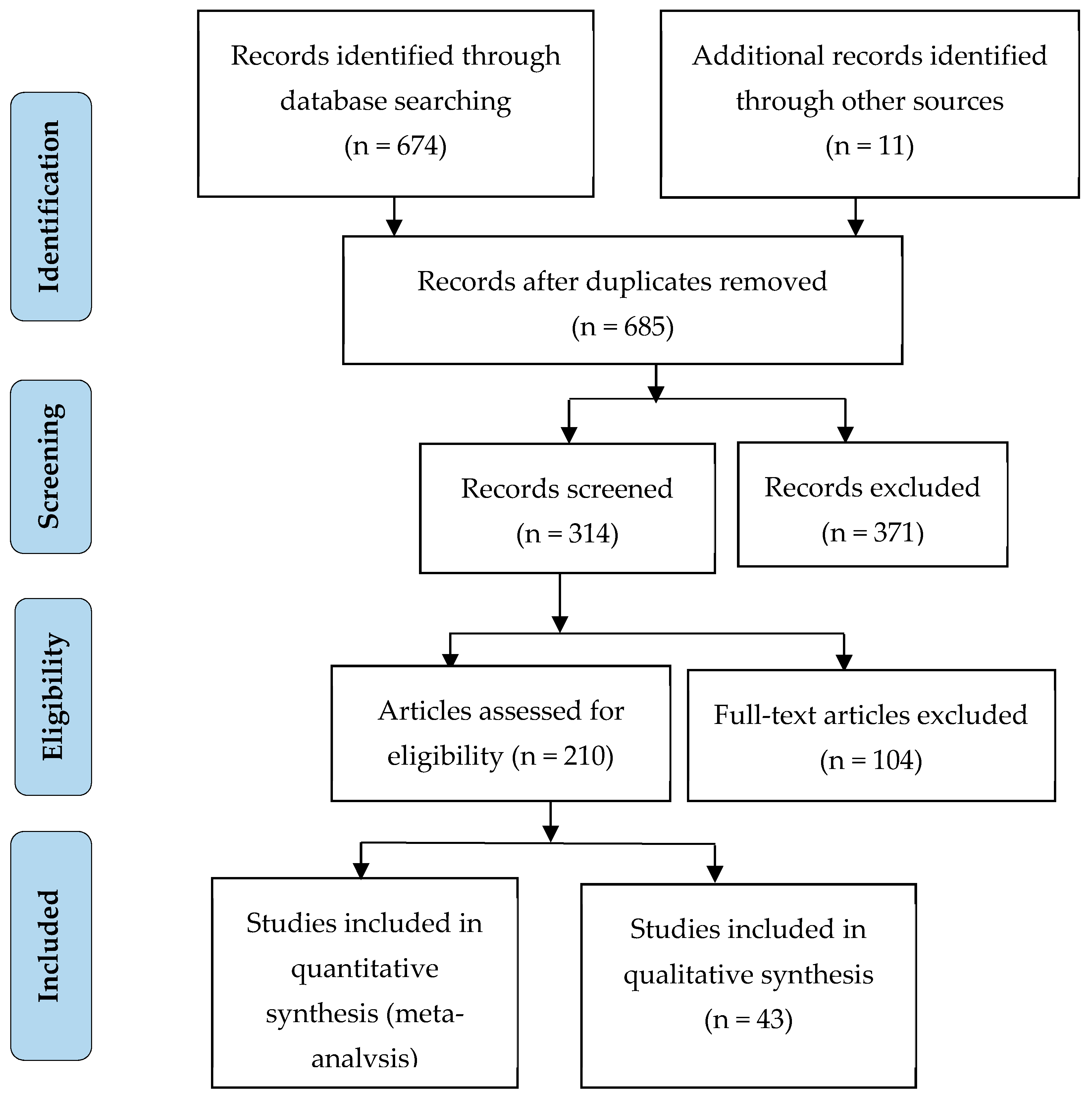

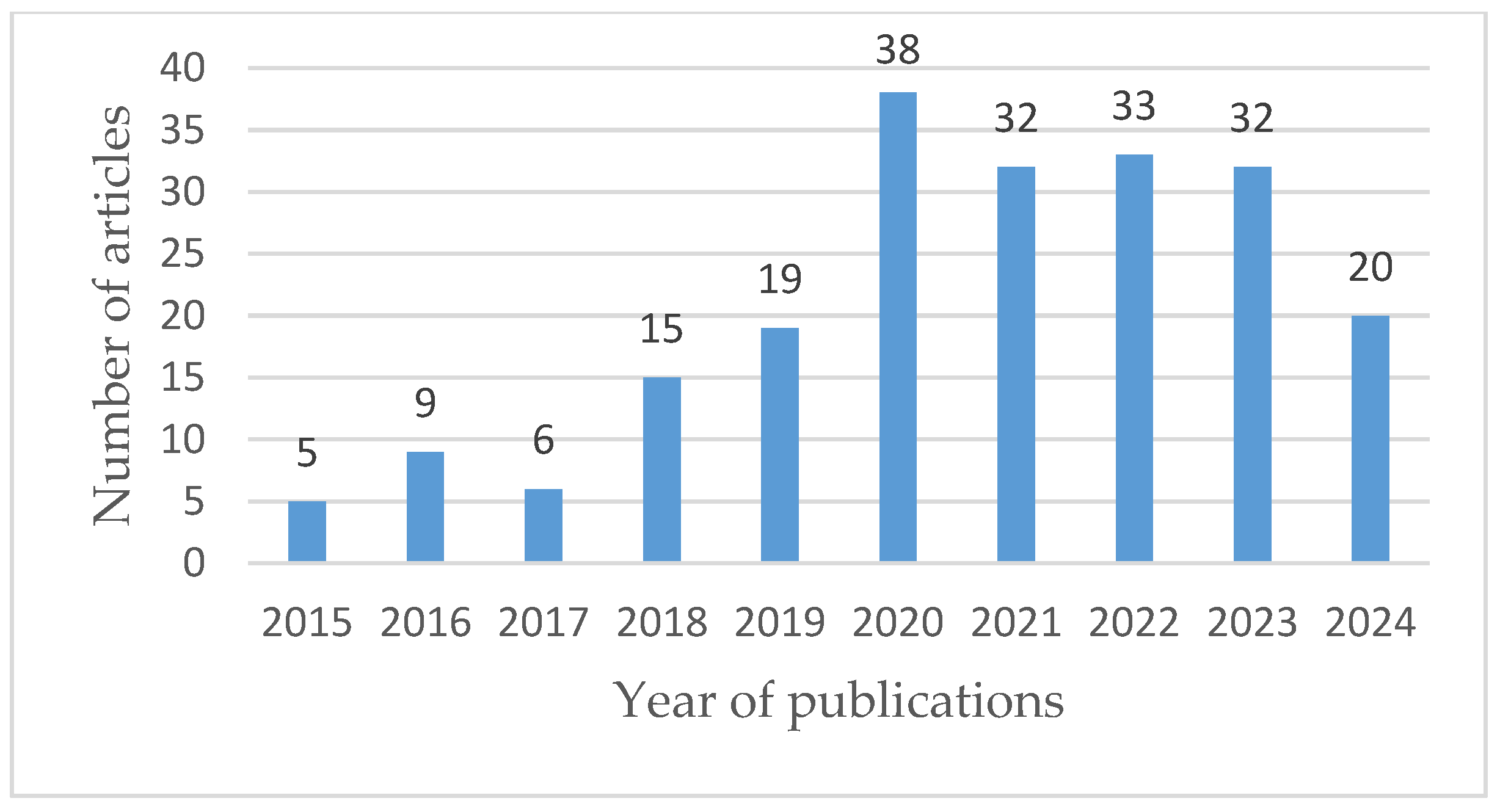

2. Materials and Methods

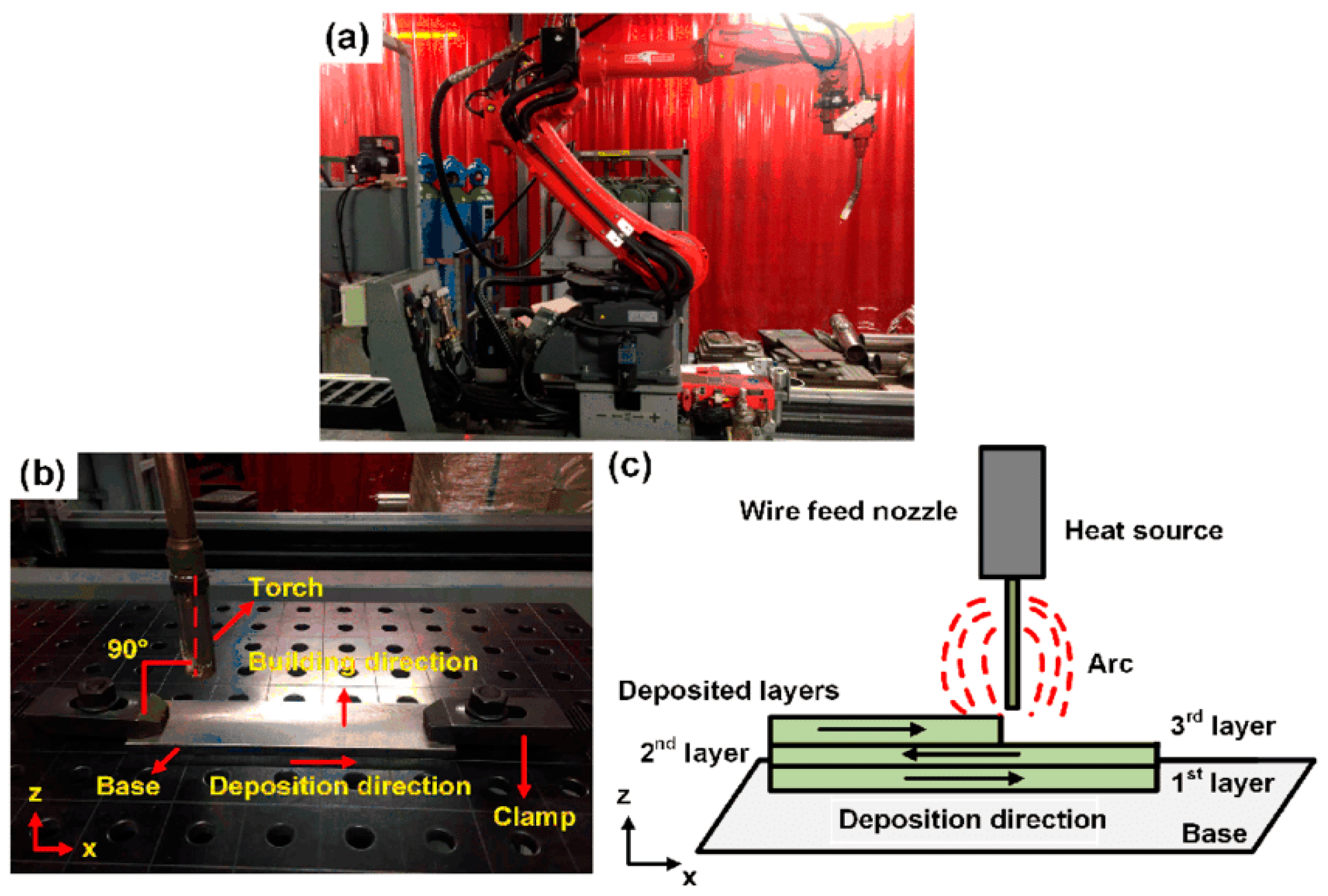

3. Overview of WAAM of Process and Products

3.1. A Robotic System for WAAM

3.2. Residual Stress in WAAMed Products

3.3. Residual Stress-Measurement Methods

3.3.1. Experimental Methods for RS Measurement in WAAM Parts

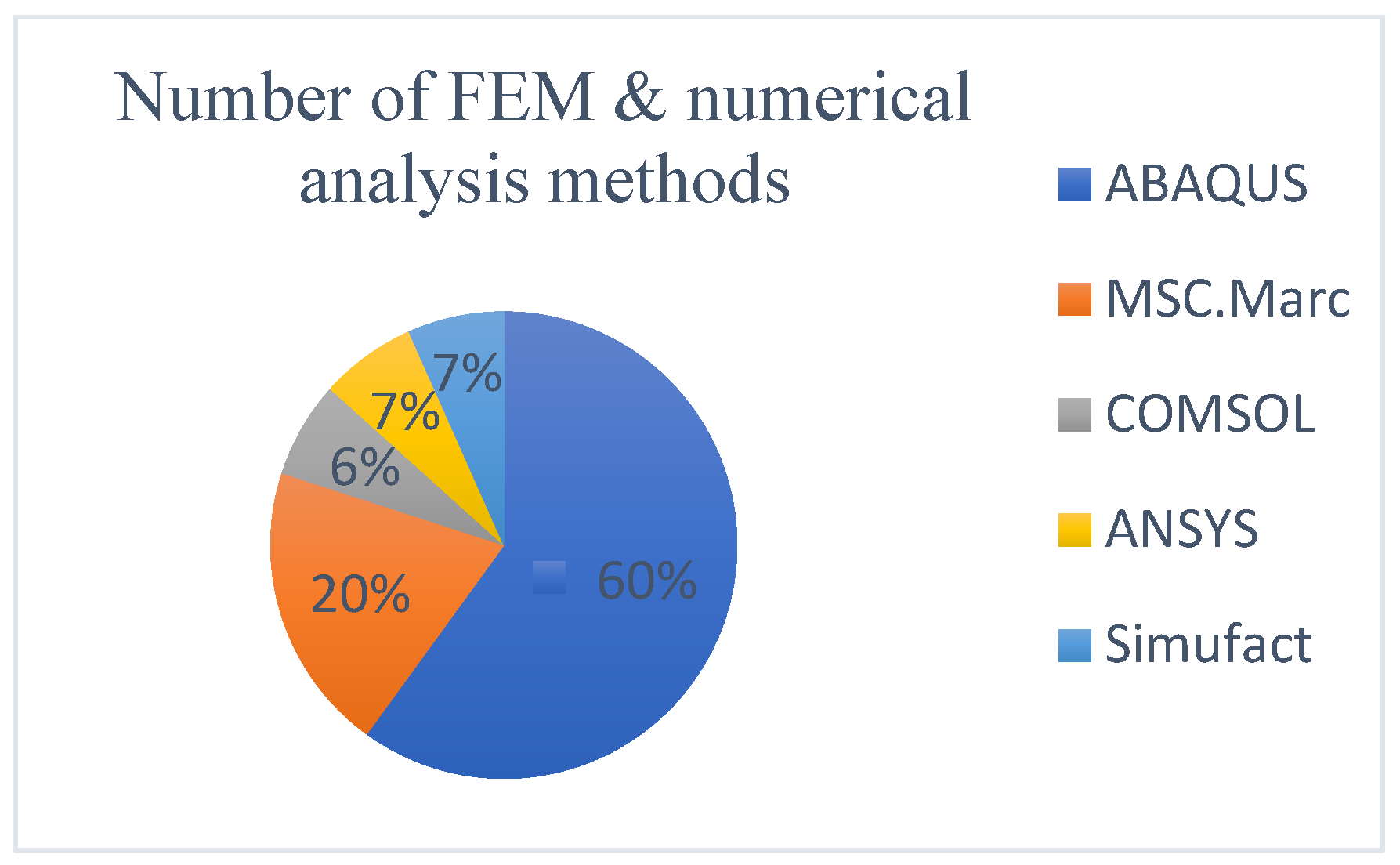

3.3.2. Numerical Analysis of RS in WAAM Products

3.4. Factors Influencing RS in WAAM

4. Impact of RS on Mechanical Properties in WAAM Components

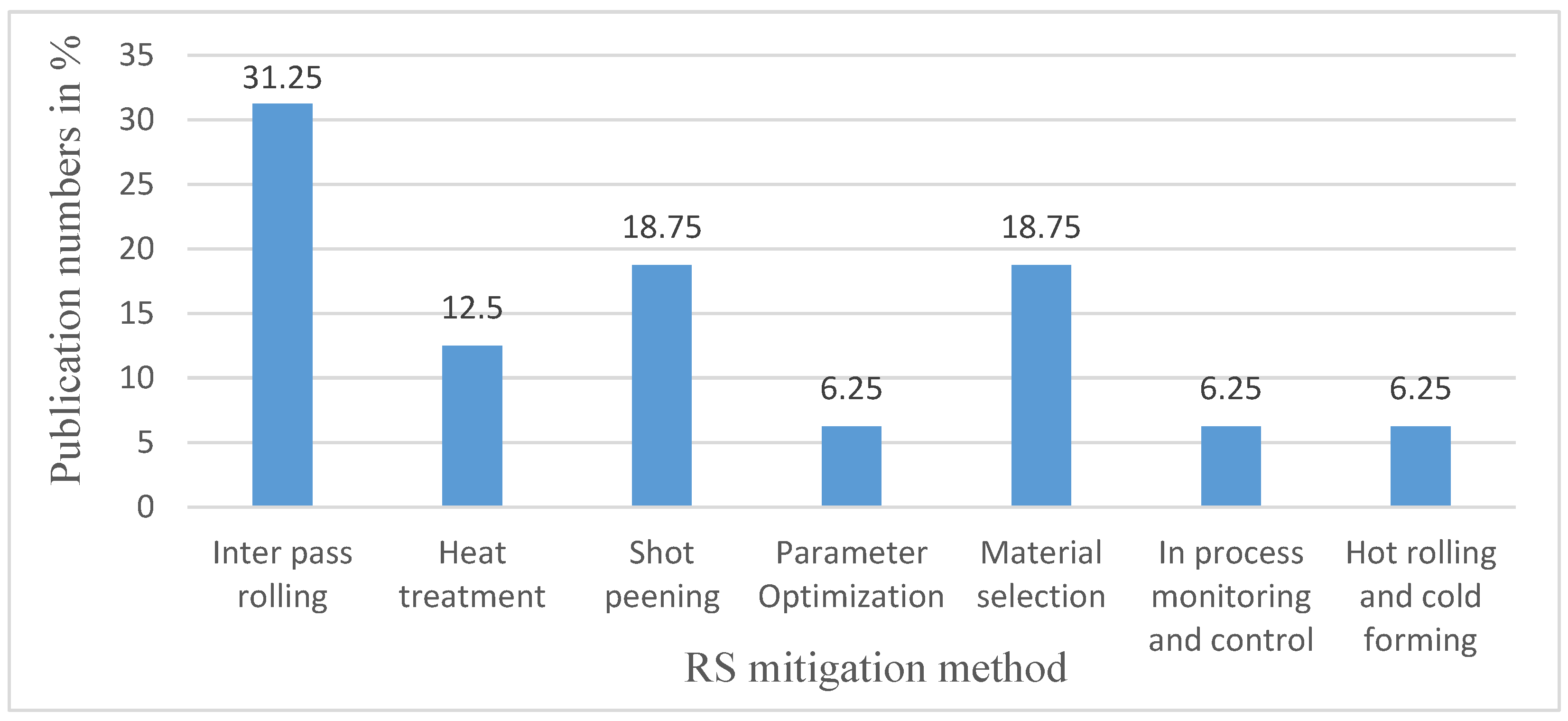

5. Mitigation Strategies for RS in WAAM and Practical Applications

6. Discussion

6.1. Challenges and Limitations

6.2. Future Directions

|

|

|

|

|

|

- Most researchers frequently used non-destructive methods like XRd, ND, and some other semi-destructive and fully destructive techniques of measuring RS in components’ WAAM. Thus, future studies can perform those techniques listed above.

- In the future, researchers should determine the most suitable quantity and varieties of shielding gas, in addition to other process and input parameters, throughout the WAAM processes.

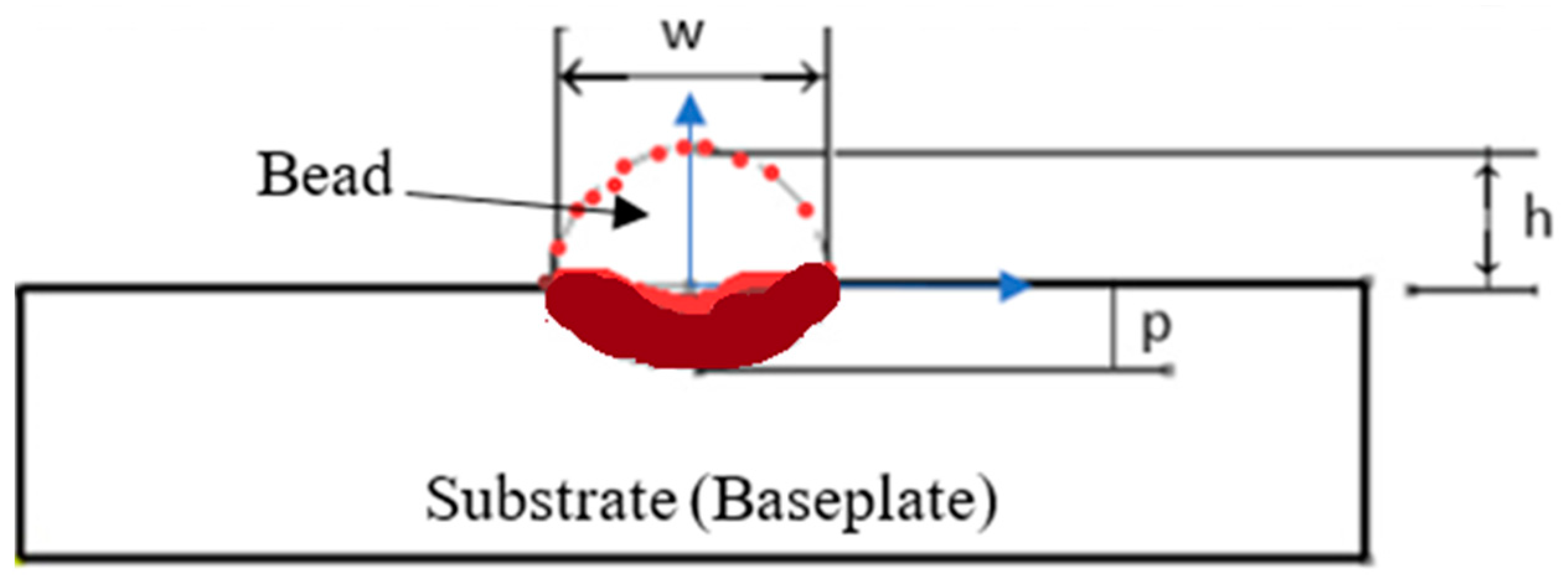

- As explained in Section 5, the mathematical formula provides a particular formation of bead profile and the relationship of wire diameter with the width and thickness (height) of beads. As a result, the wire diameter, thickness, and width of beads can vary. Consequently, heat distribution of the process results in a variation of RS in WAAM parts. Therefore, future research can focus on a variety of wire diameters to reduce RS in WAAM parts with less wire diameter.

- Materials’ weld ability depends on their physical properties that influence the accumulation of RS in products of WAAM. In the future, further research endeavors should aim to investigate these physical properties of materials, which are listed in Table 3, and other robot-adjustable effects to RS-fabricated components through WAAM.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, M.B.; Sathiya, P.; Senthil, S.M. A critical review of wire arc additive manufacturing of nickel-based alloys: Principles, process parameters, microstructure, mechanical properties, heat treatment effects, and defects. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 1–27. [Google Scholar]

- Tangestani, R.; Farrahi, G.H.; Shishegar, M.; Aghchehkandi, B.P.; Ganguly, S.; Mehmanparast, A. Effects of Vertical and Pinch Rolling on Residual Stress Distributions in Wire and Arc Additively Manufactured Components. J. Mater. Eng. Perform. 2020, 29, 2073–2084. [Google Scholar] [CrossRef]

- Derekar, K.S. Aspects of Wire Arc Additive Manufacturing (WAAM) of Alumnium Alloy 5183. Ph.D. Thesis, Coventry University, Coventry, UK, 2020; pp. 1–227. [Google Scholar]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Laghi, V.; Palermo, M.; Gasparini, G.; Veljkovic, M.; Trombetti, T. Assessment of design mechanical parameters and partial safety factors for Wire-and-Arc Additive Manufactured stainless steel. Eng. Struct. 2020, 225, 111314. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Klobčar, D.; Baloš, S.; Bašić, M.; Djurić, A.; Lindič, M.; Ščetinec, A. WAAM and Other Unconventional Metal Additive Manufacturing Technologies. Adv. Technol. Mater. 2020, 45, 1–9. [Google Scholar] [CrossRef]

- Mathews, R.; Karandikar, J.; Tyler, C.; Smith, S. Residual stress accumulation in large-scale Ti-6Al-4V wire-arc additive manufacturing. Procedia CIRP 2024, 121, 180–185. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; van Duin, S.; Li, H. Thermal Behavior in Wire Arc Additive Manufacturing: Characteristics, Effects and Control. In Transactions on Intelligent Welding Manufacturing; Springer: Singapore, 2019; pp. 3–18. [Google Scholar]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Jimenez, X.; Dong, W.; Paul, S.; Klecka, M.A.; To, A.C. Residual Stress Modeling with Phase Transformation for Wire Arc Additive Manufacturing of B91 Steel. JOM 2020, 72, 4178–4186. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Huang, W.; Wang, Q.; Ma, N.; Kitano, H. Distribution characteristics of residual stresses in typical wall and pipe components built by wire arc additive manufacturing. J. Manuf. Process. 2022, 82, 434–447. [Google Scholar] [CrossRef]

- Mohan Kumar, S.; Rajesh Kannan, A.; Pravin Kumar, N.; Pramod, R.; Siva Shanmugam, N.; Vishnu, A.S.; Channabasavanna, S.G. Microstructural Features and Mechanical Integrity of Wire Arc Additive Manufactured SS321/Inconel 625 Functionally Gradient Material. J. Mater. Eng. Perform. 2021, 30, 5692–5703. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, A.; Bishwakarma, H.; Mandal, A. Simulation of Metallic Wire-Arc Additive Manufacturing (Waam) Process Using Simufact Welding Software. J. Manuf. Eng. 2023, 18, 080–085. [Google Scholar] [CrossRef]

- Knezović, N.; Topić, A. Wire and Arc Additive Manufacturing (WAAM)—A New Advance in Manufacturing. In Lecture Notes in Networks and Systems; Springer International Publishing: New York, NY, USA, 2019; Volume 42, pp. 65–71. [Google Scholar]

- Costello, S.C.A.; Cunningham, C.R.; Xu, F.; Shokrani, A.; Dhokia, V.; Newman, S.T. The state-of-the-art of wire arc directed energy deposition (WA-DED) as an additive manufacturing process for large metallic component manufacture. Int. J. Comput. Integr. Manuf. 2023, 36, 469–510. [Google Scholar] [CrossRef]

- Barath Kumar, M.D.; Manikandan, M. Assessment of Process, Parameters, Residual Stress Mitigation, Post Treatments and Finite Element Analysis Simulations of Wire Arc Additive Manufacturing Technique. Metals and Materials International. Korean Inst. Met. Mater. 2022, 28, 54–111. [Google Scholar] [CrossRef]

- Paskual, A.; Álvarez, P.; Suárez, A. Study on Arc Welding Processes for High Deposition Rate Additive Manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar]

- Shukla, P.; Dash, B.; Kiran, D.V.; Bukkapatnam, S. Arc Behavior in Wire Arc Additive Manufacturing Process. Procedia Manuf. 2020, 48, 725–729. [Google Scholar] [CrossRef]

- Zhao, X.F.; Wimmer, A.; Zaeh, M.F. Experimental and simulative investigation of welding sequences on thermally induced distortions in wire arc additive manufacturing. Rapid Prototype J. 2023, 29, 53–63. [Google Scholar] [CrossRef]

- Cambon, C.; Bendaoud, I.; Rouquette, S.; Soulié, F. A WAAM benchmark: From process parameters to thermal effects on weld pool shape, microstructure and residual stresses. Mater. Today Commun. 2022, 33, 104235. [Google Scholar] [CrossRef]

- Hönnige, J.; Seow, C.E.; Ganguly, S.; Xu, X.; Cabeza, S.; Coules, H.; Williams, S. Study of residual stress and microstructural evolution in as-deposited and inter-pass rolled wire plus arc additively manufactured Inconel 718 alloy after ageing treatment. Mater. Sci. Eng. A 2020, 801, 140368. [Google Scholar] [CrossRef]

- Hönnige, J.R.; Colegrove, P.A.; Ganguly, S.; Eimer, E.; Kabra, S.; Williams, S. Control of Residual Stress and Distortion in Aluminium Wire + Arc Additive Manufacture with Rolling. Addit Manuf. 2018, 22, 775–783. [Google Scholar] [CrossRef]

- Schroepfer, K.W.D.; Wildenhain, R.S.; Kannengiesser, A.H.T.; Hensel, A.K.J. Influence of the WAAM process and design aspects on residual stresses in high—Strength structural steels. Weld World 2023, 67, 987–996. [Google Scholar]

- Geng, R.; Du, J.; Wei, Z.; Xu, S.; Ma, N. Modelling and experimental observation of the deposition geometry and microstructure evolution of aluminum alloy fabricated by wire-arc additive manufacturing. J. Manuf. Process. 2021, 64, 369–378. [Google Scholar] [CrossRef]

- Klein, T.; Spoerk-Erdely, P.; Schneider-Broeskamp, C.; Oliveira, J.P.; Faria, G.A. Residual Stresses in a Wire and Arc-Directed Energy-Deposited Al–6Cu–Mn (ER2319) Alloy Determined by Energy-Dispersive High-Energy X-ray Diffraction. Met. Mater. Trans. A 2024, 55, 736–744. [Google Scholar] [CrossRef]

- Ermakova, A.; Mehmanparast, A.; Ganguly, S.; Razavi, N.; Berto, F. Investigation of mechanical and fracture properties of wire and arc additively manufactured low carbon steel components. Theor. Appl. Fract. Mech. 2020, 109, 102685. [Google Scholar] [CrossRef]

- Derekar, K.S. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Taşdemir, A.; Nohut, S. An overview of wire arc additive manufacturing (WAAM) in shipbuilding industry. Ships Offshore Struct. 2020, 16, 1–18. [Google Scholar] [CrossRef]

- Müller, J.; Grabowski, M.; Müller, C.; Hensel, J.; Unglaub, J.; Thiele, K.; Kloft, H.; Dilger, K. Design and Parameter Identification of Wire and Arc Additively Manufactured (WAAM) Steel Bars for Use in Construction. Metals 2019, 9, 725. [Google Scholar] [CrossRef]

- Abbaszadeh, M.; Hönnige, J.R.; Martina, F.; Neto, L.; Kashaev, N.; Colegrove, P.; Williams, S.; Klusemann, B. Numerical Investigation of the Effect of Rolling on the Localized Stress and Strain Induction for Wire + Arc Additive Manufactured Structures. J. Mater. Eng. Perform. 2019, 28, 4931–4942. [Google Scholar] [CrossRef]

- Song, S.S.; Chen, J.; Quan, G.; Ye, J.; Zhao, Y. Numerical analysis and design of concrete-filled wire arc additively manufactured steel tube under axial compression. Eng. Struct. 2024, 301, 117294. [Google Scholar] [CrossRef]

- Wu, Q.; Mukherjee, T.; De, A.; DebRoy, T. Residual stresses in wire-arc additive manufacturing—Hierarchy of influential variables. Addit. Manuf. 2020, 35, 101355. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.J.; Gibson, I. Wire and arc additive manufacturing: Opportunities and challenges to control the quality and accuracy of manufactured parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Chen, G.; Ding, D.; Yuan, L.; Cuiuri, D.; Li, H. Mitigation of thermal distortion in wire arc additively manufactured Ti6Al4V part using active interpass cooling. Sci. Technol. Weld. Join. 2019, 24, 484–494. [Google Scholar] [CrossRef]

- Rozaimi, M.; Yusof, F. Research challenges, quality control and monitoring strategy for Wire Arc Additive Manufacturing. J. Mater. Res. Technol. 2023, 24, 2769–2794. [Google Scholar]

- Ahmad, B.; Zhang, X.; Guo, H.; Fitzpatrick, M.E.; Neto, L.M.S.C.; Williams, S. Influence of Deposition Strategies on Residual Stress in Wire + Arc Additive Manufactured Titanium Ti-6Al-4V. Metals 2022, 12, 253. [Google Scholar] [CrossRef]

- Schönegger, S.; Moschinger, M.; Enzinger, N. Computational welding simulation of a plasma wire arc additive manufacturing process for high-strength steel. Eur. J. Mater. 2024, 4, 2297051. [Google Scholar] [CrossRef]

- Qvale, P.; Njaastad, E.B.; Bræin, T.; Ren, X. A fast simulation method for thermal management in wire arc additive manufacturing repair of a thin-walled structure. Int. J. Adv. Manuf. Technol. 2024, 132, 1573–1583. [Google Scholar] [CrossRef]

- Wang, C.; Suder, W.; Ding, J.; Williams, S. The effect of wire size on high deposition rate wire and plasma arc additive manufacture of Ti-6Al-4V. J. Am. Acad. Dermatol. 2021, 288, 116842. [Google Scholar] [CrossRef]

- Gupta, A.K.; Bansal, H.; Madan, A. Study on CNC Wire Arc Additive Manufacturing process for Higher Deposition Rate and Mechanical Strength. Adv. Robot. Autom. 2022, 10, 9695. [Google Scholar]

- Ananda, P.A. WAAM Application for EPC Company. MATEC Web Conf. 2019, 269, 05002. [Google Scholar] [CrossRef]

- Li, Y.; Dong, Z.; Miao, J.; Liu, H.; Babkin, A.; Chang, Y. Forming accuracy improvement in wire arc additive manufacturing (WAAM): A review. Rapid Prototyp. J. 2022, 29, 673–686. [Google Scholar] [CrossRef]

- Chaurasia, M.; Sinha, M.K. Investigations on Process Parameters of Wire Arc Additive Manufacturing (WAAM): A Review; Lecture Notes in Mechanical Engineering; Springer Nature: Singapore, 2021; pp. 845–853. [Google Scholar]

- Gowthaman, P.S.; Jeyakumar, S.; Sarathchandra, D. Effect of Heat Input on Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Wire Arc Additive Manufacturing. J. Mater. Eng. Perform. 2024, 33, 5536–5546. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S.; Nath, T. A review on wire arc additive manufacturing: Processing parameters, defects, quality improvement and recent advances. Mater. Today Commun. 2022, 31, 103739. [Google Scholar] [CrossRef]

- Voropaev, A.; Korsmik, R.; Tsibulskiy, I. Features of Filler Wire Melting and Transferring in Wire-Arc Additive Manufacturing of Metal Workpieces. Materials 2021, 14, 5077. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; He, H.; Zhou, S.; Lian, G.; Huang, X.; Feng, M. Prediction of multi-bead profile of robotic wire and arc additive manufactured components recursively using axisymmetric drop shape analysis. Virtual Phys. Prototyp. 2023, 18, 1–24. [Google Scholar] [CrossRef]

- Ayed, A.; Valencia, A.; Bras, G.; Bernard, H.; Michaud, P.; Balcaen, Y.; Alexis, J. Effects of WAAM Process Parameters on Metallurgical and Mechanical Properties of Ti-6Al-4V Deposits. In Advances in Materials, Mechanics and Manufacturing: Proceedings of the Second International Conference on Advanced Materials, Mechanics and Manufacturing (A3M’2018), Hammamet, Tunisia, 17–19 December 2018; Lecture Notes in Mechanical Engineering; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 26–35. [Google Scholar]

- Mai, D.S.; Doan, T.K.; Paris, H. Engineering Science and Technology, an International Journal Wire and arc additive manufacturing of 308L stainless steel components: Optimization of processing parameters and material properties. Eng. Sci. Technol. Int. J. 2021, 24, 1015–1026. [Google Scholar]

- Lin, Z.; Goulas, C.; Ya, W.; Hermans, M.J. Microstructure and Mechanical Properties of Medium Carbon Steel Deposits Obtained via Wire and Arc Additive Manufacturing Using Metal-Cored Wire. Metals 2019, 9, 673. [Google Scholar] [CrossRef]

- Song, G.H.; Lee, C.M.; Kim, D.H. Investigation of Path Planning to Reduce Height Errors of Intersection Parts in Wire-Arc Additive Manufacturing. Materials 2021, 14, 6477. [Google Scholar] [CrossRef]

- Zhou, Z.; Shen, H.; Liu, B.; Du, W.; Jin, J.; Lin, J. Residual thermal stress prediction for continuous tool-paths in wire-arc additive manufacturing: A three-level data-driven method. Virtual Phys. Prototyp. 2022, 17, 105–124. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J.; et al. Additive manufacturing of Ni-based superalloys: Residual stress, mechanisms of crack formation and strategies for crack inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Scotti, F.M.; Teixeira, F.R.; da Silva, L.J.; de Araújo, D.B.; Reis, R.P.; Scotti, A. Thermal management in WAAM through the CMT Advanced process and an active cooling technique. J. Manuf. Process. 2020, 57, 23–35. [Google Scholar] [CrossRef]

- Ahsan, M.R.U.; Tanvir, A.N.M.; Ross, T.; Elsawy, A.; Oh, M.S.; Kim, D.B. Fabrication of bimetallic additively manufactured structure (BAMS) of low carbon steel and 316L austenitic stainless steel with wire + arc additive manufacturing. Rapid Prototype J. 2020, 26, 519–530. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, Z.; Chen, G.; Liu, C.; Ma, D.; Ma, S. Obtaining fine microstructure and unsupported overhangs by low heat input pulse arc additive manufacturing. J. Manuf. Process. 2017, 27, 198–206. [Google Scholar] [CrossRef]

- Doumenc, G.; Couturier, L.; Courant, B.; Paillard, P.; Benoit, A.; Gautron, E.; Girault, B.; Pirling, T.; Cabeza, S.; Gloaguen, D. Investigation of microstructure, hardness and residual stresses of wire and arc additive manufactured 6061 aluminium alloy to cite this version: HAL Id: Hal-03827007. Materialia 2022, 25, 101520. [Google Scholar] [CrossRef]

- Tröger, J.-A.; Hartmann, S.; Treutler, K.; Potschka, A.; Wesling, V. Simulation-based process parameter optimization for wire arc additive manufacturing. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- Nagallapati, V.; Khare, V.K.; Sharma, A.; Simhambhatla, S. Active and Passive Thermal Management in Wire Arc Additive Manufacturing. Metals 2023, 13, 682. [Google Scholar] [CrossRef]

- Ahsan, M.; Seo, G.-J.; Fan, X.; Liaw, P.K.; Motaman, S.; Haase, C.; Kim, D.B. Effects of process parameters on bead shape, microstructure, and mechanical properties in wire + arc additive manufacturing of Al0.1CoCrFeNi high-entropy alloy. J. Manuf. Process. 2021, 68, 1314–1327. [Google Scholar] [CrossRef]

- He, T.; Yu, S.; Shi, Y.; Huang, A. Forming and mechanical properties of wire arc additive manufacture for marine propeller bracket. J. Manuf. Process. 2020, 52, 96–105. [Google Scholar] [CrossRef]

- Su, C.; Chen, X.; Gao, C.; Wang, Y. Effect of heat input on microstructure and mechanical properties of Al-Mg alloys fabricated by WAAM. Appl. Surf. Sci. 2019, 486, 431–440. [Google Scholar] [CrossRef]

- Scharf-Wildenhain, R.; Haelsig, A.; Hensel, J.; Wandtke, K.; Schroepfer, D.; Kromm, A.; Kannengiesser, T. Influence of Heat Control on Properties and Residual Stresses of Additive-Welded High-Strength Steel Components. Metals 2022, 12, 951. [Google Scholar] [CrossRef]

- Javadi, Y.; Smith, M.; Venkata, K.A.; Naveed, N.; Forsey, A.; Francis, J.; Ainsworth, R.; Truman, C.; Smith, D.; Hosseinzadeh, F.; et al. Residual stress measurement round robin on an electron beam welded joint between austenitic stainless steel 316L(N) and ferritic steel P91. Int. J. Press. Vessel. Pip. 2017, 154, 41–57. [Google Scholar]

- Saleh, B.; Fathi, R.; Tian, Y.; Radhika, N.; Jiang, J.; Ma, A. Fundamentals and advances of wire arc additive manufacturing: Materials, process parameters, potential applications, and future trends. In Archives of Civil and Mechanical Engineering; Springer: London, UK, 2023; Volume 23, pp. 1–71. [Google Scholar]

- Rosli, N.A.; Alkahari, M.R.; bin Abdollah, M.F.; Maidin, S.; Ramli, F.R.; Herawan, S.G. Review on effect of heat input for wire arc additive manufacturing process. J. Mater. Res. Technol. 2021, 11, 2127–2145. [Google Scholar] [CrossRef]

- Li, J.Z.; Alkahari, M.R.; Rosli, N.A.B.; Hasan, R.; Sudin, M.N.; Ramli, F.R. Review of Wire Arc Additive Manufacturing for 3D Metal Printing Review of Wire Arc Additive Manufacturing for 3D Metal Printing. Int. J. Autom. Technol. 2019, 13, 346–353. [Google Scholar]

- Woo, W.; Kim, D.-K.; Kingston, E.; Luzin, V.; Salvemini, F.; Hill, M.R. Effect of interlayers and scanning strategies on through-thickness residual stress distributions in additive manufactured ferritic-austenitic steel structure. Mater. Sci. Eng. A 2019, 744, 618–629. [Google Scholar]

- Geng, H.; Li, J.; Gao, J.; Lin, X. Theoretical Model of Residual Stress and Warpage for Wire and Arc Additive Manufacturing Stiffened Panels. Metals 2020, 10, 666. [Google Scholar] [CrossRef]

- Rouquette, S.; Cambon, C.; Bendaoud, I.; Soulié, F. Residual stresses in ss316l specimens after deposition of melted filler wire. In Proceedings of the ICRS 11—The 11th International Conference on Residual Stresses, Nancy, France, 27–30 March 2022. [Google Scholar]

- Kumaran, M.; Senthilkumar, V.; Panicke, C.J.; Shishir, R. Investigating the residual stress in additive manufacturing of repair work by directed energy deposition process on SS316L hot rolled steel substrate. Mater. Today Proc. 2021, 47, 4475–4478. [Google Scholar] [CrossRef]

- Mishurova, T.; Sydow, B.; Thiede, T.; Sizova, I.; Ulbricht, A.; Bambach, M.; Bruno, G. Residual Stress and Microstructure of a Ti-6Al-4V Wire Arc Additive Manufacturing Hybrid Demonstrator. Metals 2020, 10, 701. [Google Scholar] [CrossRef]

- Martina, F.; Roy, M.J.; Szost, B.A.; Terzi, S.; Colegrove, P.A.; Williams, S.W.; Withers, P.J.; Meyer, J.; Hofmann, M. Residual stress of as-deposited and rolled wire + arc additive manufacturing Ti–6Al–4V components. Mater. Sci. Technol. 2016, 32, 1439–1448. [Google Scholar] [CrossRef]

- Liu, C.; Lin, C.; Wang, J.; Wang, J.; Yan, L.; Luo, Y.; Yang, M. Residual stress distributions in thick specimens excavated from a large circular wire plus arc additive manufacturing mockup. J. Manuf. Process. 2020, 56, 474–481. [Google Scholar]

- Yang, Y.; Jin, X.; Liu, C.; Xiao, M.; Lu, J.; Fan, H.; Ma, S. Residual Stress, Mechanical Properties, and Grain Morphology of Ti-6Al-4V Alloy Produced by Ultrasonic Impact Treatment Assisted Wire and Arc Additive Manufacturing. Metals 2018, 8, 934. [Google Scholar] [CrossRef]

- Boruah, D.; Dewagtere, N.; Ahmad, B.; Nunes, R.; Tacq, J.; Zhang, X.; Guo, H.; Verlinde, W.; De Waele, W. Digital Image Correlation for Measuring Full-Field Residual Stresses in Wire and Arc Additive Manufactured Components. Materials 2023, 16, 1702. [Google Scholar] [CrossRef] [PubMed]

- Rani, K.U.; Kumar, R.; Mahapatra, M.M.; Mulik, R.S.; Świerczyńska, A.; Fydrych, D.; Pandey, C. Wire Arc Additive Manufactured Mild Steel and Austenitic Properties and Residual Stresses. Materials 2022, 15, 7094. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Chuang, A.C.; Kenesei, P.; Ren, Z.; Balderson, L.; Sun, T. An operando synchrotron study on the effect of wire melting state on solidification microstructures of Inconel 718 in wire-laser directed energy deposition. Int. J. Mach. Tools Manuf. 2024, 194, 104089. [Google Scholar] [CrossRef]

- Robin, I.K.; Sprouster, D.J.; Sridharan, N.; Snead, L.L.; Zinkle, S.J. Synchrotron based investigation of anisotropy and microstructure of wire arc additive manufactured Grade 91 steel. J. Mater. Res. Technol. 2024, 29, 5010–5021. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, A.; Das, A.K.; Kumar, S. Parametric study and characterization of wire arc additive manufactured steel structures. Int. J. Adv. Manuf. Technol. 2021, 115, 1723–1733. [Google Scholar] [CrossRef]

- Shen, C.; Reid, M.; Liss, K.-D.; Pan, Z.; Ma, Y.; Cuiuri, D.; van Duin, S.; Li, H. Neutron diffraction residual stress determinations in Fe3Al based iron aluminide components fabricated using wire-arc additive manufacturing (WAAM). Addit. Manuf. 2019, 29, 100774. [Google Scholar] [CrossRef]

- Rouquette, S.; Cambon, C.; Bendaoud, I.; Cabeza, S.; Soulié, F. Effect of Layer Addition on Residual Stresses of Wire Arc Additive Manufactured Stainless Steel Specimens. J. Manuf. Sci. Eng. 2024, 146, 1–12. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Farias, F.W.C.; Zhang, K.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Schell, N.; Capek, J.; Polatidis, E.; Santos, T.G.; et al. Wire and arc additive manufacturing of 316L stainless steel/Inconel 625 functionally graded material: Development and characterization. J. Mater. Res. Technol. 2022, 21, 237–251. [Google Scholar] [CrossRef]

- Théodore, J.; Couturier, L.; Girault, B.; Cabeza, S.; Pirling, T.; Frapier, R.; Bazin, G.; Courant, B. Relationship between microstructure, and residual strain and stress in stainless steels in-situ alloyed by double-wire arc additive manufacturing (D-WAAM) process. Materialia 2023, 30, 101850. [Google Scholar] [CrossRef]

- Kumar, M.B.; Manikandan, M. Evaluation of Microstructure, Residual Stress, and Mechanical Properties in Different Planes of Wire + Arc Additive Manufactured Nickel—Based Superalloy. Met. Mater. Int. 2022, 28, 3033–3056. [Google Scholar] [CrossRef]

- Welding Consumables for Steels with Yield Strength > 460 MPa. Available online: https://www.welmet.cz/wp-content/uploads/2019/04/2-SM-pro-oceli-s-mez%C3%AD-kluzu-nad-460-MPa.pdf (accessed on 26 June 2024).

- Sun, J.; Hensel, J.; Köhler, M.; Dilger, K. Residual stress in wire and arc additively manufactured aluminum components. J. Manuf. Process. 2021, 65, 97–111. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Farias, F.W.C.; Avila, J.A.; Maawad, E.; Schell, N.; Santos, T.G.; Oliveira, J.P. Effect of heat treatments on Inconel 625 fabricated by wire and arc additive manufacturing: An in situ synchrotron X-ray diffraction analysis. Sci. Technol. Weld. Join. 2023, 28, 534–539. [Google Scholar] [CrossRef]

- Wandtke, K.; Becker, A.; Schroepfer, D.; Kromm, A.; Kannengiesser, T.; Scharf-Wildenhain, R.; Haelsig, A.; Hensel, J. Residual Stress Evolution during Slot Milling for Repair Welding and Wire Arc Additive Manufacturing of High-Strength Steel Components. Metals 2024, 14, 82. [Google Scholar] [CrossRef]

- Wu, Q.; Mukherjee, T.; Liu, C.; Lu, J.; DebRoy, T. Residual stresses and distortion in the patterned printing of titanium and nickel alloys. Addit. Manuf. 2019, 29, 100808. [Google Scholar] [CrossRef]

- Han, Y. A Finite Element Study of Wire Arc Additive Manufacturing of Aluminum Alloy. Appl. Sci. 2024, 14, 810. [Google Scholar] [CrossRef]

- Khaled, H.; Abusalma, J. Parametric Study of Residual Stresses in Wire and Arc Additive Manufactured Parts. Master’s Thesis, Old Dominion University, Norfolk, VA, USA, 2020. [Google Scholar]

- Saadatmand, M.; Talemi, R. Study on the thermal cycle of Wire Arc Additive Manufactured (WAAM) carbon steel wall using numerical simulation. Frat. Ed Integrita Strutt. 2020, 14, 98–104. [Google Scholar] [CrossRef]

- Eisazadeh, H.; Achuthan, A.; Goldak, J.; Aidun, D. Effect of material properties and mechanical tensioning load on residual stress formation in GTA 304-A36 dissimilar weld. J. Mater. Process. Technol. 2015, 222, 344–355. [Google Scholar] [CrossRef]

- Nezamdost, M.R.; Esfahani, M.R.N.; Hashemi, S.H.; Mirbozorgi, S.A. Investigation of temperature and residual stresses field of submerged arc welding by finite element method and experiments. Int. J. Adv. Manuf. Technol. 2016, 87, 615–624. [Google Scholar] [CrossRef]

- Huang, H.; Ma, N.; Chen, J.; Feng, Z.; Murakawa, H. Toward large-scale simulation of residual stress and distortion in wire and arc additive manufacturing. Addit. Manuf. 2020, 34, 101248. [Google Scholar] [CrossRef]

- Han, Y.S. Wire Arc Additive Manufacturing: A Study of Process Parameters Using Multiphysics Simulations. Materials 2023, 16, 7267. [Google Scholar] [CrossRef] [PubMed]

- Jia, J.; Zhao, Y.; Dong, M.; Wu, A.; Li, Q. Numerical simulation on residual stress and deformation for WAAM parts of aluminum alloy based on temperature function method. Trans. China Weld. Inst. 2020, 29, 1–8. [Google Scholar]

- Feng, G.; Wang, H.W.Y.; Deng, D.; Zhang, J. Numerical Simulation of Residual Stress and Deformation in Wire Arc Additive Manufacturing. Crystals 2022, 12, 803. [Google Scholar] [CrossRef]

- Graf, M.; Pradjadhiana, K.P.; Hälsig, A.; Manurung, Y.H.P.; Awiszus, B. Numerical simulation of metallic wire arc additive manufacturing (WAAM). In AIP Conference Proceedings; AIP Publishing: Long Island, NY, USA, 2018; Volume 960, p. 140010. [Google Scholar]

- Ahmad, S.N.; Manurung, Y.H.; Mat, M.F.; Minggu, Z.; Jaffar, A.; Pruller, S.; Leitner, M. FEM simulation procedure for distortion and residual stress analysis of wire arc additive manufacturing. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 834, p. 012083. [Google Scholar]

- Cadiou, S.; Courtois, M.; Carin, M.; Berckmans, W.; Le masson, P. 3D heat transfer, fluid flow and electromagnetic model for cold metal transfer wire arc additive manufacturing (Cmt-Waam). Addit. Manuf. 2020, 36, 101541. [Google Scholar] [CrossRef]

- Drexler, H.; Haunreiter, F.; Raberger, L.; Reiter, L.; Hütter, A.; Enzinger, N. Numerical Modeling of Distortions and Residual Stresses During Wire Arc Additive Manufacturing of an ER 5183 Alloy with Weaving Deposition. BHM Bergund Hüttenmännische Monatshefte 2024, 169, 38–47. [Google Scholar] [CrossRef]

- Bonifaz, E.A.; Palomeque, J.S. A mechanical model in wire + Arc additive manufacturing process. Prog. Addit. Manuf. 2020, 5, 163–169. [Google Scholar] [CrossRef]

- Reyes-Gordillo, E.; Gómez-Ortega, A.; Morales-Estrella, R.; Pérez-Barrera, J.; Gonzalez-Carmona, J.; Escudero-García, R.; Alvarado-Orozco, J. Effect of Cold Metal Transfer Parameters during Wire Arc Additive Manufacturing of Ti6Al4V Multi-Layer Walls. 2022. Available online: https://www.researchsquare.com/article/rs-1946459/v1 (accessed on 26 June 2024).

- Silva, W.F. Evaluation of the properties of Inconel ® 625 preforms manufactured using WAAM technology. Res. Sq. 2024. Available online: https://www.researchsquare.com/article/rs-3591195/v1 (accessed on 26 June 2024).

- Derekar, K.S.; Addison, A.; Joshi, S.S.; Zhang, X.; Lawrence, J.; Xu, L.; Melton, G.; Griffiths, D. Effect of pulsed metal inert gas (pulsed-MIG) and cold metal transfer (CMT) techniques on hydrogen dissolution in wire arc additive manufacturing (WAAM) of aluminium. Int. J. Adv. Manuf. Technol. 2020, 107, 311–331. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; Ramli, F.R.; Sudin, M.N.; Maidin, S. Influence of Process Parameters in Wire and Arc Additive Manufacturing (WAAM). Process. J. Mech. Eng. 2020, 17, 69–78. [Google Scholar] [CrossRef]

- Derekar, K.S.; Ahmad, B.; Zhang, X.; Joshi, S.S.; Lawrence, J.; Xu, L.; Melton, G.; Addison, A. Effects of Process Variants on Residual Stresses in Wire Arc Additive Manufacturing of Aluminum Alloy 5183. J. Manuf. Sci. Eng. Trans. 2022, 144, 071005. [Google Scholar] [CrossRef]

- Yuan, Q.; Liu, C.; Wang, W.; Wang, M. Residual stress distribution in a large specimen fabricated by wire-arc additive manufacturing. Sci. Technol. Weld. Join. 2023, 28, 137–144. [Google Scholar] [CrossRef]

- Fu, R.; Tang, S.; Lu, J.; Cui, Y.; Li, Z.; Zhang, H.; Xu, T.; Chen, Z.; Liu, C. Hot-wire arc additive manufacturing of aluminum alloy with reduced porosity and high deposition rate. Mater. Des. 2021, 199, 199109370. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Kistler, N.A.; Beese, A.M.; Michaleris, P. Impact of directed energy deposition parameters on mechanical distortion of laser deposited Ti-6Al-4V. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference SFF, Austin, TX, USA, 8–10 August 2016; pp. 670–679. [Google Scholar]

- Xiong, J.; Lei, Y.; Li, R. Finite element analysis and experimental validation of thermal behavior for thin-walled parts in GMAW-based additive manufacturing with various substrate preheating temperatures. Appl. Therm. Eng. 2017, 126, 43–52. [Google Scholar] [CrossRef]

- Zhao, J.; Quan, G.Z.; Zhang, Y.Q.; Ma, Y.Y.; Jiang, L.H.; Dai, W.W.; Jiang, Q. Influence of deposition path strategy on residual stress and deformation in weaving wire-arc additive manufacturing of disc parts. J. Mater. Res. Technol. 2024, 30, 2242–2256. [Google Scholar] [CrossRef]

- Ouellet, T.; Croteau, M.; Bois-Brochu, A.; Lévesque, J. Wire Arc Additive Manufacturing of Aluminium Alloys. Eng. Proc. 2023, 43, 16. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Paddea, S.; Zhang, X. Fatigue crack propagation behaviour in wire+arc additive manufactured Ti-6Al-4V: Effects of microstructure and residual stress. Mater. Des. 2016, 90, 551–561. [Google Scholar] [CrossRef]

- Gu, J.; Gao, M.; Yang, S.; Bai, J.; Zhai, Y.; Ding, J. Microstructure, defects, and mechanical properties of wire + arc additively manufactured Al[sbnd]Cu4.3-Mg1.5 alloy. Mater. Des. 2020, 186, 108357. [Google Scholar] [CrossRef]

- Kindermann, R.M.; Roy, M.J.; Morana, R.; Francis, J.A. Effects of microstructural heterogeneity and structural defects on the mechanical behaviour of wire + arc additively manufactured Inconel 718 components. Mater. Sci. Eng. A 2022, 839, 142826. [Google Scholar] [CrossRef]

- Yildiz, A.S.; Koc, B.I.; Yilmaz, O. Thermal behavior determination for wire arc additive manufacturing process. Procedia Manuf. 2020, 54, 233–237. [Google Scholar] [CrossRef]

- Pawlik, J.; Cieślik, J.; Bembenek, M.; Góral, T.; Kapayeva, S.; Kapkenova, M. On the Influence of Linear Energy/Heat Input Coefficient on Hardness and Weld Bead Geometry in Chromium-Rich Stringer GMAW Coatings. Materials 2022, 15, 6019. [Google Scholar] [CrossRef]

- Romanenko, D.; Prakash, V.J.; Kuhn, T.; Moeller, C.; Hintze, W.; Emmelmann, C. Effect of DED process parameters on distortion and residual stress state of additively manufactured Ti-6Al-4V components during machining. Procedia CIRP 2022, 11, 271–276. [Google Scholar] [CrossRef]

- Mu, H.; Polden, J.; Li, Y.; He, F.; Xia, C.; Pan, Z. Layer-by-layer model-based adaptive control for wire arc additive manufacturing of thin-wall structures. J. Intell. Manuf. 2022, 33, 1165–1180. [Google Scholar] [CrossRef]

- Liu, B.; Lan, J.; Liu, H.; Chen, X.; Zhang, X.; Jiang, Z.; Han, J. The Effects of Processing Parameters during the Wire Arc Additive Manufacturing of 308L Stainless Steel on the Formation of a Thin-Walled Structure. Materials 2024, 17, 1337. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.H.; Han, Y.S. A Finite Element Analysis on the Effect of Scanning Pattern and Energy on Residual Stress and Deformation in Wire Arc Additive Manufacturing of EH36 Steel. Materials 2023, 16, 4698. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; He, T.; Wu, X.; Lei, G. Synergistic effect of carbides and residual strain on the mechanical behavior of Ni-17 Mo-7Cr superalloy made by wire-arc additive manufacturing. Mater Lett. 2021, 287, 129291. [Google Scholar] [CrossRef]

- Winczek, J.; Gucwa, M.; Makles, K.; Mičian, M.; Yadav, A. The amount of heat input to the weld per unit length and per unit volume. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1199, 012067. [Google Scholar] [CrossRef]

- Koli, Y.; Arora, S.; Ahmad, S.; Priya Yuvaraj, N.; Khan, Z.A. Investigations and Multi-response Optimization of Wire Arc Additive Manufacturing Cold Metal Transfer Process Parameters for Fabrication of SS308L Samples. J. Mater. Eng. Perform. 2023, 32, 2463–2475. [Google Scholar] [CrossRef]

- Cambon, C.; Rouquette, S.; Bendaoud, I.; Bordreuil, C.; Wimpory, R.; Soulie, F. Thermo-mechanical simulation of overlaid layers made with wire + arc additive manufacturing and GMAW-cold metal transfer. Weld World 2020, 64, 1427–1435. [Google Scholar] [CrossRef]

- Omiyale, B.O.; Olugbade, T.O.; Abioye, T.E.; Farayibi, P.K. Wire arc additive manufacturing of aluminium alloys for aerospace and automotive applications: A review. Mater. Sci. Technol. 2022, 38, 391–408. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Carpenter, K.; Han, J.; Wang, Z.; Li, H. Comparative study on crystallographic orientation, precipitation, phase transformation and mechanical response of Ni-rich NiTi alloy fabricated by WAAM at elevated substrate heating temperatures. Mater. Sci. Eng. A 2021, 800, 140307. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Martina, F.; Williams, S.; Wiktorowicz, R.; Palt, M.R. Development of a laminar flow local shielding device for wire + arc additive manufacture. J. Mater. Process. Technol. 2015, 226, 99–105. [Google Scholar] [CrossRef]

- Tonelli, L.; Laghi, V.; Palermo, M.; Trombetti, T.; Ceschini, L. AA5083 (Al–Mg) plates produced by wire-and-arc additive manufacturing: Effect of specimen orientation on microstructure and tensile properties. Prog. Addit. Manuf. 2021, 6, 479–494. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, C.; Hua, X.; Li, F.; Zhang, Y.; Zhu, Y. Influence of wire-arc additive manufacturing path planning strategy on the residual stress status in one single buildup layer. Int. J. Adv. Manuf. Technol. 2020, 111, 797–806. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P.; Palmer, T.A. Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys. J. Mater. Process. Technol. 2015, 215, 123–131. [Google Scholar] [CrossRef]

- Gudur, S.; Nagallapati, V.; Pawar, S.; Muvvala, G.; Simhambhatla, S. A study on the effect of substrate heating and cooling on bead geometry in wire arc additive manufacturing and its correlation with cooling rate. Mater. Today Proc. 2019, 41, 431–436. [Google Scholar] [CrossRef]

- Singh, S.; Jinoop, A.N.; Tarun Kumar, G.T.A.; Palani, I.A.; Paul, C.P.; Prashanth, K.G. Effect of interlayer delay on the microstructure and mechanical properties of wire arc additive manufactured wall structures. Materials 2021, 14, 4187. [Google Scholar] [CrossRef] [PubMed]

- Bermingham, M.J.; Nicastro, L.; Kent, D.; Chen, Y.; Dargusch, M.S. Optimising the mechanical properties of Ti-6Al-4V components produced by wire + arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 2018, 753, 247–255. [Google Scholar] [CrossRef]

- Kumar, A.; Maji, K. Selection of Process Parameters for Near-Net Shape Deposition in Wire Arc Additive Manufacturing by Genetic Algorithm. J. Mater. Eng. Perform. 2020, 29, 3334–3352. [Google Scholar] [CrossRef]

- Ali, Y.; Henckell, P.; Hildebrand, J.; Reimann, J.; Bergmann, J.P.; Barnikol-Oettler, S. Wire arc additive manufacturing of hot work tool steel with CMT process. J. Mater. Process. Technol. 2019, 269, 109–116. [Google Scholar] [CrossRef]

- Laghi, V.; Palermo, M.; Tonelli, L.; Gasparini, G.; Ceschini, L.; Trombetti, T. Tensile properties and microstructural features of 304L austenitic stainless steel produced by wire-and-arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 106, 3693–3705. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

- Naveen Srinivas, M.; Vimal, K.E.K.; Manikandan, N.; Sritharanandh, G. Parametric optimization and multiple regression modelling for fabrication of aluminium alloy thin plate using wire arc additive manufacturing. Int. J. Interact. Des. Manuf. 2022. [Google Scholar] [CrossRef]

- Zavdoveev, A.; Pozniakov, V.; Baudin, T.; Kim, H.S.; Klochkov, I.; Motrunich, S.; Heaton, M.; Aquier, P.; Rogante, M.; Denisenko, A.; et al. Optimization of the pulsed arc welding parameters for wire arc additive manufacturing in austenitic steel applications. Int. J. Adv. Manuf. Technol. 2022, 119, 5175–5193. [Google Scholar] [CrossRef]

- Lu, X.; Li, M.V.; Yang, H. Comparison of wire-arc and powder-laser additive manufacturing for IN718 superalloy: Unified consideration for selecting process parameters based on volumetric energy density. Int. J. Adv. Manuf. Technol. 2021, 114, 1517–1531. [Google Scholar] [CrossRef]

- Vora, J.; Pandey, R.; Dodiya, P.; Patel, V.; Khanna, S.; Vaghasia, V.; Chaudhari, R. Fabrication of Multi-Walled Structure through Parametric Study of Bead Geometries of GMAW-Based WAAM Process of SS309L. Materials 2023, 16, 5147. [Google Scholar] [CrossRef] [PubMed]

- Athaib, N.H.; Haleem, A.H.; Al-Zubaidy, B. A review of Wire Arc Additive Manufacturing (WAAM) of Aluminium Composite, Process, Classification, Advantages, Challenges, and Application. J. Phys. Conf. Ser. 2021, 1973, 012083. [Google Scholar] [CrossRef]

- Scharf-Wildenhain, R.; Haelsig, A.; Hensel, J.; Wandtke, K.; Schroepfer, D.; Kannengiesser, T. Heat control and design-related effects on the properties and welding stresses in WAAM components of high-strength structural steels. Weld World 2023, 67, 55–65. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Wang, X.; Ding, J.; Traoré, Y.; Paddea, S.; Williams, S. Crack path selection at the interface of wrought and wire + arc additive manufactured Ti-6Al-4V. Mater. Des. 2016, 104, 365–375. [Google Scholar] [CrossRef]

- Yang, Y.H.; Guan, Z.P.; Ma, P.K.; Ren, M.W.; Jia, H.L.; Zhao, P.; Zha, M.; Wang, H.Y. Wire arc additive manufacturing of a novel ATZM31 Mg alloy: Microstructure evolution and mechanical properties. J. Magnes. Alloys 2023, 10, 44. [Google Scholar] [CrossRef]

- Koli, Y.; Yuvaraj, N.; Sivanandam, A.; Vipin. Control of humping phenomenon and analyzing mechanical properties of Al–Si wire-arc additive manufacturing fabricated samples using cold metal transfer process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 984–996. [Google Scholar] [CrossRef]

- Jing, Y.; Fang, X.; Xi, N.; Chang, T.; Duan, Y.; Huang, K. Improved tensile strength and fatigue properties of wire-arc additively manufactured 2319 aluminum alloy by surface laser shock peening. Mater. Sci. Eng. A 2023, 864, 144599. [Google Scholar] [CrossRef]

- Chi, J.; Cai, Z.; Wan, Z.; Zhang, H.; Chen, Z.; Li, L.; Li, Y.; Peng, P.; Guo, W. Effects of heat treatment combined with laser shock peening on wire and arc additive manufactured Ti17 titanium alloy: Microstructures, residual stress and mechanical properties. Surf. Coat. Technol. 2020, 396, 125908. [Google Scholar] [CrossRef]

- Sousa, B.M.; Coelho, F.G.F.; Júnior, G.M.M.; de Oliveira, H.C.P.; da Silva, N.N. Thermal and microstructural analysis of intersections manufactured by wire arc additive manufacturing (WAAM). Weld World 2024, 68, 1653–1669. [Google Scholar] [CrossRef]

- Ma, D.; Xu, C.; Sui, S.; Tian, J.; Guo, C.; Wu, X.; Zhang, Z.; Remennik, S.; Shechtman, D. Microstructure evolution and mechanical properties of wire arc additively manufactured Mg-Gd-Y-Zr alloy by post heat treatments. Virtual Phys. Prototyp. 2023, 18, 1–22. [Google Scholar] [CrossRef]

- Szost, B.A.; Terzi, S.; Martina, F.; Boisselier, D.; Prytuliak, A.; Pirling, T.; Hofmann, M.; Jarvis, D.J. A comparative study of additive manufacturing techniques: Residual stress and microstructural analysis of CLAD and WAAM printed Ti-6Al-4V components. Mater. Des. 2016, 89, 559–567. [Google Scholar] [CrossRef]

- Kumar, A.; Maji, K.; Shrivastava, A. Investigations on Deposition Geometry and Mechanical Properties of Wire Arc Additive Manufactured Inconel 625. Int. J. Precis. Eng. Manuf. 2023, 24, 1483–1500. [Google Scholar] [CrossRef]

- Vazquez, L.; Rodriguez, M.N.; Rodriguez, I.; Alvarez, P. Influence of post-deposition heat treatments on the microstructure and tensile properties of ti-6al-4v parts manufactured by cmt-waam. Metals 2021, 11, 1161. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Optimization of wire feed for GTAW based additive manufacturing. J. Mater. Process. Technol. 2017, 243, 40–47. [Google Scholar] [CrossRef]

- Li, R.; Xiong, J.; Lei, Y. Investigation on thermal stress evolution induced by wire and arc additive manufacturing for circular thin-walled parts. J. Manuf. Process. 2019, 40, 59–67. [Google Scholar] [CrossRef]

- Gupta, N.K.; Ganesan, G.B.; Karade, S.; Mehta, A.K.; Karunakaran, K.P. Effect of Multiple Technologies on Minimizing the Residual Stresses in Additive Manufacturing. In Proceedings of the ICRS 11—The 11th International Conference of Residual Stresses, Nancy, France, 27–30 March 2022; p. 040150. [Google Scholar]

- Ali, M.H.; Han, Y.S. Effect of phase transformations on scanning strategy in waam fabrication. Materials 2021, 14, 7871. [Google Scholar] [CrossRef] [PubMed]

- Gornyakov, V.; Sun, Y.; Ding, J.; Williams, S. Modelling and optimising hybrid process of wire arc additive manufacturing and high-pressure rolling. Mater. Des. 2022, 223, 111121. [Google Scholar] [CrossRef]

- Gornyakov, V. Efficient Modelling and Evaluation of Rolling for Mitigation of Residual Stress and Distortion in Wire Arc Additive Manufacturing. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2021. Volume 7. p. 265. [Google Scholar]

- Zhang, T.; Li, H.; Gong, H.; Ding, J.; Wu, Y.; Diao, C.; Zhang, X.; Williams, S. Hybrid wire-arc additive manufacture and effect of rolling process on microstructure and tensile properties of Inconel 718. J. Mater. Process. Technol. 2022, 299, 321–326. [Google Scholar] [CrossRef]

- Srivastava, S.; Garg, R.K.; Sharma, V.S.; Sachdeva, A. Measurement and Mitigation of Residual Stress in Wire-Arc Additive Manufacturing: A Review of Macro-Scale Continuum Modelling Approach. Arch. Comput. Methods Eng. 2021, 28, 3491–3515. [Google Scholar] [CrossRef]

- Montevecchi, F.; Venturini, G.; Scippa, A.; Campatelli, G. Finite Element Modelling of Wire-arc-additive-manufacturing Process. Procedia CIRP 2016, 55, 109–114. [Google Scholar] [CrossRef]

- Bankong, B.D.; Abioye, T.E.; Olugbade, T.O.; Zuhailawati, H.; Gbadeyan, O.O.; Ogedengbe, T.I. Review of post-processing methods for high-quality wire arc additive manufacturing. Mater. Sci. Technol. 2023, 39, 129–146. [Google Scholar] [CrossRef]

- Hönnige, J.R.; Colegrove, P.A.; Ahmad, B.; Fitzpatrick, M.E.; Ganguly, S.; Lee, T.L.; Williams, S.W. Residual stress and texture control in Ti-6Al-4V wire + arc additively manufactured intersections by stress relief and rolling. Mater. Des. 2018, 150, 193–205. [Google Scholar] [CrossRef]

- Li, K.; Klecka, M.A.; Chen, S.; Xiong, W. Wire-arc additive manufacturing and post-heat treatment optimization on microstructure and mechanical properties of Grade 91 steel. Addit. Manuf. 2021, 37, 101734. [Google Scholar] [CrossRef]

- Nie, L.; Wu, Y.; Gong, H.; Chen, D.; Guo, X. Effect of shot peening on redistribution of residual stress field in friction stir welding of 2219 aluminum alloy. Materials 2020, 13, 3169. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Zhu, Y.; Guo, W.; Peng, P.; Cong, B.; Sun, J.; Che, Z.; Li, B.; Guo, C.; et al. Microstructure, residual stress and tensile properties control of wire-arc additive manufactured 2319 aluminum alloy with laser shock peening. J. Alloys Compd. 2018, 747, 255–265. [Google Scholar] [CrossRef]

- Ermakova, A.; Razavi, N.; Cabeza, S.; Gadalinska, E.; Reid, M.; Paradowska, A.; Ganguly, S.; Berto, F.; Mehmanparast, A. The effect of surface treatment and orientation on fatigue crack growth rate and residual stress distribution of wire arc additively manufactured low carbon steel components. J. Mater. Res. Technol. 2023, 24, 2988–3004. [Google Scholar] [CrossRef]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and mechanical property considerations in additive manufacturing of aluminum alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Ding, J. Designing a WAAM based manufacturing system for defence applications. Procedia CIRP 2015, 37, 48–53. [Google Scholar] [CrossRef]

- Abusalma, H.; Eisazadeh, H.; Hejripour, F.; Bunn, J.; Aidun, D. Parametric study of residual stress formation in Wire and Arc Additive Manufacturing. J. Manuf. Process. 2022, 75, 863–876. [Google Scholar] [CrossRef]

- Kyvelou, P.; Huang, C.; Li, J.; Gardner, L. Residual stresses in steel I-sections strengthened by wire arc additive manufacturing. In Structures; Elsevier: Amsterdam, The Netherlands, 2024; Volume 60. [Google Scholar]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Donoghue, J.; Martina, F.; Gu, J.; Prangnell, P.; Hönnige, J. Application of bulk deformation methods for microstructural and material property improvement and residual stress and distortion control in additively manufactured components. Scr. Mater. 2017, 135, 111–118. [Google Scholar] [CrossRef]

- Karmuhilan, M.; Sood, A.K. Intelligent process model for bead geometry prediction in WAAM. Mater. Today Proc. 2018, 5, 24005–24013. [Google Scholar] [CrossRef]

- Tang, S.; Wang, G.; Huang, C.; Li, R.; Zhou, S.; Zhang, H. Investigation, modeling and optimization of abnormal areas of weld beads in wire and arc additive manufacturing. Rapid Prototyp J. 2020, 26, 183–195. [Google Scholar] [CrossRef]

- Veiga, F.; Suárez, A.; Aldalur, E.; Bhujangrao, T. Effect of the metal transfer mode on the symmetry of bead geometry in waam aluminum. Symmetry 2021, 13, 1245. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot Comput. Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Geng, H.; Xiong, J.; Huang, D.; Lin, X.; Li, J. A prediction model of layer geometrical size in wire and arc additive manufacture using response surface methodology. Int. J. Adv. Manuf. Technol. 2017, 93, 175–186. [Google Scholar] [CrossRef]

- Banaee, S.A.; Kapil, A.; Marefat, F.; Sharma, A. Generalised overlapping model for multi-material wire arc additive manufacturing (WAAM). Virtual Phys. Prototyp. 2023, 18, e2210541. [Google Scholar] [CrossRef]

- Surovi, N.A.; Soh, G.S. Acoustic feature based geometric defect identification in wire arc additive manufacturing. Virtual Phys. Prototyp. 2023, 18, e2210553. [Google Scholar] [CrossRef]

- Zhao, Y.T.; Li, W.G.; Liu, A. Optimization of geometry quality model for wire and arc additive manufacture based on adaptive multi-objective grey wolf algorithm. Soft Comput. 2020, 24, 17401–17416. [Google Scholar] [CrossRef]

- Alomari, Y.; Birosz, M.T.; Andó, M. Part orientation optimization for Wire and Arc Additive Manufacturing process for convex and non-convex shapes. Sci. Rep. 2023, 13, 2203. [Google Scholar] [CrossRef] [PubMed]

- Wani, Z.K.; Abdullah, A.B. Bead Geometry Control in Wire Arc Additive Manufactured Profile—A Review. Pertanika J. Sci. Technol. 2024, 32, 917–942. [Google Scholar] [CrossRef]

- Vora, J.; Parikh, N.; Chaudhari, R.; Patel, V.K.; Paramar, H.; Pimenov, D.Y.; Giasin, K. Optimization of bead morphology for GMAW-based wire-arc of 2.25 Cr-1.0 Mo steel using metal-cored wires. Appl. Sci. 2022, 12, 5060. [Google Scholar] [CrossRef]

- Wang, C.; Bai, H.; Ren, C.; Fang, X.; Lu, B. A comprehensive prediction model of bead geometry in wire and arc additive manufacturing. J. Phys. Conf. Ser. 2020, 1624, 022018. [Google Scholar] [CrossRef]

- Chintala, A.; Tejaswi Kumar, M.; Sathishkumar, M.; Arivazhagan, N.; Manikandan, M. Technology Development for Producing Inconel 625 in Aerospace Application Using Wire Arc Additive Manufacturing Process. J. Mater. Eng. Perform. 2021, 30, 5333–5341. [Google Scholar] [CrossRef]

- Hamrani, A.; Bouarab, F.Z.; Agarwal, A.; Ju, K.; Akbarzadeh, H. Advancements and applications of multiple wire processes in additive manufacturing: A comprehensive systematic review. Virtual Phys. Prototyp. 2023, 18, e2273303. [Google Scholar] [CrossRef]

- Queguineur, A.; Rückert, G.; Cortial, F.; Hascoët, J.Y. Evaluation of wire arc additive manufacturing for large-sized components in naval applications. Weld World 2018, 62, 259–266. [Google Scholar] [CrossRef]

- Li, J.; Cui, Q.; Pang, C.; Xu, P.; Luo, W.; Li, J. Integrated vehicle chassis fabricated by wire and arc additive manufacturing: Structure generation, printing radian optimisation, and performance prediction. Virtual Phys. Prototyp. 2024, 19, e2301483. [Google Scholar] [CrossRef]

- Singh, S.R.; Khanna, P. Wire arc additive manufacturing (WAAM): A new process to shape engineering materials. Mater. Today Proc. 2021, 44, 118–128. [Google Scholar] [CrossRef]

- Vishnukumar, M.; Pramod, R.; Rajesh Kannan, A. Wire arc additive manufacturing for repairing aluminium structures in marine applications. Mater. Lett. 2021, 299, 130112. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Boţilă, L.N. Considerations regarding aluminum alloys used in the aeronautic/aerospace industry and use of wire arc additive manufacturing WAAM for their industrial applications. Test 2020, 4, 9–24. [Google Scholar]

- Liu, J.; Xu, Y.; Ge, Y.; Hou, Z.; Chen, S. Wire and arc additive manufacturing of metal components: A review of recent research developments. Int. J. Adv. Manuf. Technol. 2020, 111, 149–198. [Google Scholar] [CrossRef]

- Arana, M.; Ukar, E.; Rodriguez, I.; Aguilar, D.; Álvarez, P. Influence of deposition strategy and heat treatment on mechanical properties and microstructure of 2319 aluminium WAAM components. Mater. Des. 2022, 221, 110974. [Google Scholar] [CrossRef]

- Thapliyal, S. Challenges associated with the wire arc additive manufacturing (WAAM) of Aluminum alloys. Mater. Today Proc. 2019, 221, 112006. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, F.; Chen, S.; Lu, Z. Unit block–based process planning strategy of WAAM for complex shell–shaped component. Int. J. Adv. Manuf. Technol. 2019, 104, 3915–3927. [Google Scholar] [CrossRef]

- Pant, H.; Arora, A.; Gopakumar, G.S.; Chadha, U.; Saeidi, A.; Patterson, A.E. Applications of wire arc additive manufacturing (WAAM) for aerospace component manufacturing. Int. J. Adv. Manuf. Technol. 2023, 127, 4995–5011. [Google Scholar] [CrossRef]

- Bachus, N.A.; Strantza, M.; Clausen, B.; D’Elia, C.R.; Hill, M.R.; Ko, J.P.; Pagan, D.C.; Brown, D.W. Novel bulk triaxial residual stress mapping in an additive manufactured bridge sample by coupling energy dispersive X-ray diffraction and contour method measurements. Addit. Manuf. 2024, 83, 104070. [Google Scholar] [CrossRef]

- Gordon, J.V.; Haden, C.V.; Nied, H.F.; Vinci, R.P.; Harlow, D.G. Fatigue crack growth anisotropy, texture and residual stress in austenitic steel made by wire and arc additive manufacturing. Mater. Sci. Eng. A 2018, 115, 60–66. [Google Scholar] [CrossRef]

| Methods | Materials | Results | Refs. |

|---|---|---|---|

| ND | 316L stainless steel | The process parameters’ influence on RS is barely noticeable in the melted zone. | [22] |

| Fe3Al alloy | Large columnar grains result in anisotropy and RS is tensile in the building direction, and the tension to compression progressively moves up from the beginning to the end of the deposition way. | [23] | |

| AA6061 | RS indicates the occurrence of tensile stresses with a greater magnitude in the constructed parts, while the substrate exhibits fewer compressive stresses. No significant dissimilarities were seen in mechanical properties. | [59] | |

| 2319 aluminum alloy | RS along the build direction in the deposited wall is tensile stress, extending up to the floor. The inter-pass rolled walls reduced RS to enhanced strength in the longitudinal direction. | [24] | |

| Fe3Al | RS and distortions resulting from the WAAM process are major concerns as they not only influence the part tolerance but can also cause premature failure in the final component during service. | [83] | |

| stainless steel 304L | The alteration of RS in the specimen after introducing a new deposit. Longitudinal stress was predominantly tensile, reaching its peak at the boundary between the parent material and the layers where the thermal loads were applied. | [84] | |

| Inconel 625 | Measurements showed that lower RS formed in the direct interface functionally graded materials (FGM) compared to the smooth gradient FGM. | [85] | |

| Contour and ND | Ti-6Al-4V alloy, stainless steel | The stress in the baseplate varies RS. The lattice parameters were not valid in the baseplate for ND measurements. Cutting out a stress-free exit was used to correct reference samples. | [73,74,86] |

| XRD | Alloy C-276 | The amplitude of tensile RS was perceived in the travel direction compared to the build orientation. The residual strain in the lattice reveals the RS in the material. The larger amplitude of compressive RS was found in the build axis. | [87] |

| Al-5356 alloy | The height of the beam can impact both the level and pattern of longitudinal RS in both the substrate and the beam. This variation primarily affects transverse RS in the substrate and has minimal influence on the beam itself. | [88] | |

| G 79 5 M21 Mn4Ni1.5CrMo (EN ISO 16834-A) [89] | RS, hardness, and microstructure are influenced by welding parameters, geometry, and component design. Heat input causes decreased tensile RS, which causes unfavorable grain structure and mechanical response. | [25] | |

| SS308L austenitic stainless steel (SS) | Accumulation of compressive RS attributed to elevated heat input and rapid cooling rates. Greater stress happened closer to the welding base than in other areas. | [26] | |

| Al–6Cu–Mn alloy | The advancement of RS indicates that the most crucial area of the sample is near the substrate, where significant tensile stresses near the material’s yield strength are dominant. | [27] | |

| Grade 91 (modified 9Cr–1Mo) -steel | RS varies the characteristics of the material and its microscopic structure WAAMed ferritic/martensitic (FM). The heat treatment applied to the originally manufactured steel did not remove its anisotropic properties. | [80] | |

| Inconel 625 | Post-treatment heat processes can enhance corrosion resistance and alleviate RS. Measurements indicated that the smooth-gradient approach produced secondary phases like d-phase (Ni3Nb) and carbides, which were absent in the direct interface method. | [85,90] | |

| DIC | Mild steel (AWS ER70S-6) | DIC was employed to oversee the flexural distortion of WAAM components while being released from the clamped H-profiles, and residual tensions were deduced from the strain distribution observed during the unclamping process. | [77,91] |

| Deep hole drilling | Mild steel (G3Si1) & austenitic SS (SS304) | RSs are under compression in the mild steel section and under tension in the austenitic stainless steel (SS) section. These stresses fluctuate across the thickness because of differences in cooling rates on the interior and exterior surfaces. | [78] |

| Hole drilling | Ti-6Al-4V | Grain size decreased after ultrasonic impact therapy and RS of fabricated parts in WAAM after post-UIT are improved. | [76,92] |

| Thermomechanical coupling & Contour | Stainless steels (SS) SUS308LSi | RS is tensile in the layers bordering the surface’s upper surface, compressive in the layers near the substrate surface, and tensile near the underside of the substrate. | [13] |

| FEM Softwares | Material | Summary | Ref. |

|---|---|---|---|

| ANSYS 2019 | B91 steel (ER90S-B91 steel) | A thermomechanical assessment of WAAM B91 steel was performed sequentially to assess the variation in residual stress throughout the component. | [11] |

| Simufact Additive 2023.2 | Steels | The dynamic temperature changes, alteration, stress accumulation, and deformation hold significant importance for applications involving high-strength steels. | [40] |

| ABAQUS 2019 | Aluminum alloy | Deposition pattern and travel speed have an impact on RS and warpage in WAAM parts. Results of thermomechanical FE simulations show that the out–in deposition pattern leads to the highest levels of RS and warpage. Increasing travel speed lowers peak temperature and thermal gradient in deposition, reducing RS. | [94] |

| Inconel 718 | Utilized a comprehensive 3D transient heat-transfer model to calculate the temperature distribution and gradient in the WAAM process for various process parameters, which results in RS. The derived temperature data were utilized in a mechanical model to forecast RS and distortion. | [95] | |

| Carbon steel | The modeling outcomes indicate that as the count of deposited layers rises, the maximum temperature rises, resulting in RS, while the average cooling rate decreases. | [96] | |

| ABAQUS 2010 | Austenitic stainless steel (304) and low Carbon steel (A36) | By systematically altering one mechanical property at a time, we isolated the influence of each on RS formation in dissimilar welds. Results show that longitudinal residual stress in both alike and different welds can be diminished within the weld zone by an amount equivalent to the stress caused by applied mechanical tensile force once the tensioning force is released post-cooling. | [97] |

| API X65 steel | Thermal conditions and RS are forecasted precisely to allow for the regulation of the fusion zone’s shape, microstructure, and mechanical characteristics in the Submerged Arc Welding joint. | [98] | |

| ABAQUS 2019 | Structural steel ER70S-6 wire | The residual stress and deformation of two extensive builds were examined, revealing highly consistent numerical findings and favorable correspondence with experimental outcomes. | [99] |

| EH36 steel | The effect of the scanning speed on thermal profiles and RS indicates that higher scan speeds result in reduced peak temperatures and heightened cooling rates, thus leading to a rise in the volume portion of martensite within the deposition. | [100] | |

| Aluminum alloy | The RS and deformation were computed using the moving heat sources (MHS) method and the segmented temperature function (STF) method. | [101] | |

| Ti-6Al-4V, S355JR steel & AA2319 | Reduced profile radii of roller effectively eliminate almost all tensile RS near the surfaces. | [32] | |

| MSC. Marc 2021 | Y309L | Elevated RS is generated within the deposition layers and also within the middle of the substrate. | [102] |

| MSC. Marc 2014.2.0 | Welding filler G3Si1 | Simulation and validation regarding geometry and microstructure variations within the welding passes were conducted with RS reality and simulation using measurement inertia of the thermocouples. | [103] |

| S316L | The variances in RS are influenced by both the fluctuating temperature distribution during the freezing phase and the forces applied to the WAAM structure following the cooling process. | [104] | |

| COMSOL-5.4 2018 | 304 Stainless steel | Large-scale images and high-speed recordings were used for the wall constructed to verify the accuracy of the measurements of the molten pool and the form of the deposition determined, which decided the RS in parts. | [105] |

| Process Parameters and Other Factors | Short Description | Refs. |

|---|---|---|

| Material properties: weldability of the materials | Not all materials are equally suitable for WAAM. The process often requires materials with good weldability characteristics, such as low susceptibility to cracking and good fusion properties. For instance, materials’ thermal conductivity, coefficient of thermal expansion, and phase transformations can impact RS induced. | [13,34,129,130] |

| Deposition power: Arc current & voltage | In the WAAM process, controlling the heat input is critical to prevent overheating, distortion, and metallurgical issues, such as excessive grain growth or phase transformations. Variations in heat input alter materials’ weldability consequences of RS. | [25,65,66,114,130,131] |

| Speed: wire feed speed, welding travel speed, and deposition rate | Rapid deposition and cooling can lead to increased RS, especially near the deposition zone. The rapid solidification and higher deposition rate can cause thermal gradients and differential cooling rates, resulting in higher levels of tensile RS. Increasing the welding travel speed reduces the amount of time the material spends in the high-temperature zone and leads to the lowering of the magnitude of RS. | [113,132,133,134] |

| Shielding gas: types of shielding gas, and shielding gas flow rate | Shielding gas plays a crucial role in WAAM processes as it protects the molten weld pool from atmospheric contamination and influences the heat-transfer characteristics during deposition. The type of shielding gas, gas-flow rates such as argon and helium, and reactive gases like CO2 and O2 can have significant effects on RS formation in WAAM products. | [3,37,135] |

| Nozzle distance: Nozzle tip to work distance (Welding torch distances) | The welding torch distance in WAAM processes can have a significant influence on RS in the final products. Optimizing the nozzle tip to work distance in WAAM processes involves balancing the heat input, cooling rates, distortion control, interlayer bonding, and defect formation to minimize RS and ensure the production of high-quality parts. | [23,24] |

| Printing position: Electrode to layer angle (wire) (θ) and layer height | The printing position affects heat dissipation and buildup, influencing the cooling rate and thermal gradients within the part. The printing position affects the flow of molten metal and the geometry of the deposited beads results in variation of RS. | [36,64,128,136,137] |

| Layer thickness: Substrate thickness, deposition thickness | Decreasing the layer thickness in WAAM fabrication can lead to shorter thermal cycles and reduced heat input per layer. This may result in lower overall RS due to less thermal distortion and reduced HAZ size. | [124,138] |

| Cooling rate: Deposition of layer time, dwell time between layers | The rapid heating and cooling cycles involved in WAAM can lead to the development of significant RS and distortion in the fabricated parts. These can adversely affect the structural integrity and dimensional accuracy of the components, making it challenging to achieve desired weld properties and, as a result, change the RS in printed parts. | [57,58,59,60,102,136] |

| Preheating substrate (Baseplate) | Preheating the substrate in WAAM processes offers several benefits for managing RS in the final products. By reducing thermal gradients, mitigating distortion, improving metallurgical bonding, enhancing ductility, and optimizing cooling rates, preheating helps to create parts with lower levels of RS and improved mechanical properties. | [96,137,138] |

| Part geometry: Printed part shapes & volume of the parts | The geometry of printed parts in WAAM processes significantly influences RS. Understanding how shape complexity, part orientation, volume, and material-accumulation patterns affect thermal gradients and cooling rates is crucial for managing RS and ensuring the production of high-quality parts with desired mechanical properties and dimensional accuracy in WAAM. | [9,26] |

| Post-Weld Heat Treatment (PWHT) | PWHT plays a crucial role in managing RS in WAAM products. By subjecting the parts to controlled heating and cooling cycles, PWHT can effectively alleviate RS, improve material properties, and enhance the overall quality and implementation of the manufactured parts. | [1,4,60,112,139] |

| Scanning pattern | The scanning pattern plays a crucial role in influencing heat accumulation, cooling rates during AM deposition, and, consequently, the formation of RS. | [100] |

| Wire filler: wire filler diameters and wire grade | The filler wire diameter and wire grade are two key factors that can significantly influence RS in WAAM products. | Not studied |

| Methods | Material and Strategies | Practical Applications and Results | Refs. |

|---|---|---|---|

| Inter pass rolling | Ti-6Al-4V alloy | Enhances the bonding and adhesion between the successive layers of material. It also helps redistribute stresses by applying compressive force, leading to refined grain structures and minimizing distortion results in RS. | [24,75,76,171] |

| Heat treatment (HT) | Grade 91 steel, Ti-6Al-4V | HT post-processing involves controlled heating and cooling cycles to relieve RS. HT is extensively utilized within the aerospace sector to reduce RS in WAAM to produce turbine blades, improving fatigue life and performance. | [82,139,172] |

| Shot peening | 2319 aluminum alloy | Shot peening entails subjecting the surface of a component to bombardment with small, high-velocity particles to induce compressive stresses that counteract tensile RS. It is employed in the automotive sector to enhance the fatigue resistance of WAAM-produced suspension components. | [173,174] |

| Rolling and laser shock peening | Low carbon steel | The methods eliminate harmful tensile RS at the top of the WAAM wall, thereby enhancing fatigue life and slowing down crack growth rates. The bottom region of the WAAM wall demonstrates improved RS conditions, leading to enhanced fatigue performance, all achieved without surface rolling treatment. | [175] |

| Rolling | AA2319, S335JR steel | Increased rolling loads result in elevated maximum equivalent plastic strain and deeper penetration of the equivalent plastic strain results in RS. | [32] |

| Parameter optimization | Al-Cu4.3-Mg1.5 alloy | Adjusting WAAM process parameters, such as deposition speed and layer thickness, can optimize the build conditions to diminish RS. Systematic parameter optimization is applied in the construction industry to reduce RS in large-scale WAAM-printed metal structures. | [36] |

| Material selection | aluminum alloys | Choosing materials with tailored properties, such as low thermal-expansion coefficients, can minimize RS formation during WAAM. Specialized materials are used in the energy sector to create high-performance WAAM components with reduced RS. | [176,177] |

| In-process monitoring and control | IN718 Superalloy | Real-time monitoring and control systems adjust process parameters during WAAM to minimize RS formation. In-process monitoring and control are used in aerospace manufacturing to reduce RS variations in critical engine components. | [178] |

| Hot-rolling and cold-forming | ER70S-6 welding wire | The incorporation of WAAM stiffeners at the flange tips of hot-rolled I-sections is demonstrated to result in the creation of favorable tensile RS, which are beneficial for structural stability, reaching maximum values equivalent to the material’s yield strength. | [179] |

| Peening and UITs | Ti alloy & Al alloy | Through Ultrasonic Impact Treatment (UIT), grain refinement and the randomization of orientation are accomplished, contributing to the enhancement of RS and mechanical strength. | [180] |

| Rolling | Titanium alloys | Offer substantial advantages such as diminishing RS and distortion, as well as refining grain structure. | [181] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurmesa, F.D.; Lemu, H.G.; Adugna, Y.W.; Harsibo, M.D. Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review. Appl. Mech. 2024, 5, 420-449. https://doi.org/10.3390/applmech5030025

Gurmesa FD, Lemu HG, Adugna YW, Harsibo MD. Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review. Applied Mechanics. 2024; 5(3):420-449. https://doi.org/10.3390/applmech5030025

Chicago/Turabian StyleGurmesa, Fakada Dabalo, Hirpa Gelgele Lemu, Yosef Wakjira Adugna, and Mesfin Demise Harsibo. 2024. "Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review" Applied Mechanics 5, no. 3: 420-449. https://doi.org/10.3390/applmech5030025

APA StyleGurmesa, F. D., Lemu, H. G., Adugna, Y. W., & Harsibo, M. D. (2024). Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review. Applied Mechanics, 5(3), 420-449. https://doi.org/10.3390/applmech5030025