Artificial Intelligence-Guided Supervised Learning Models for Photocatalysis in Wastewater Treatment

Abstract

1. Introduction

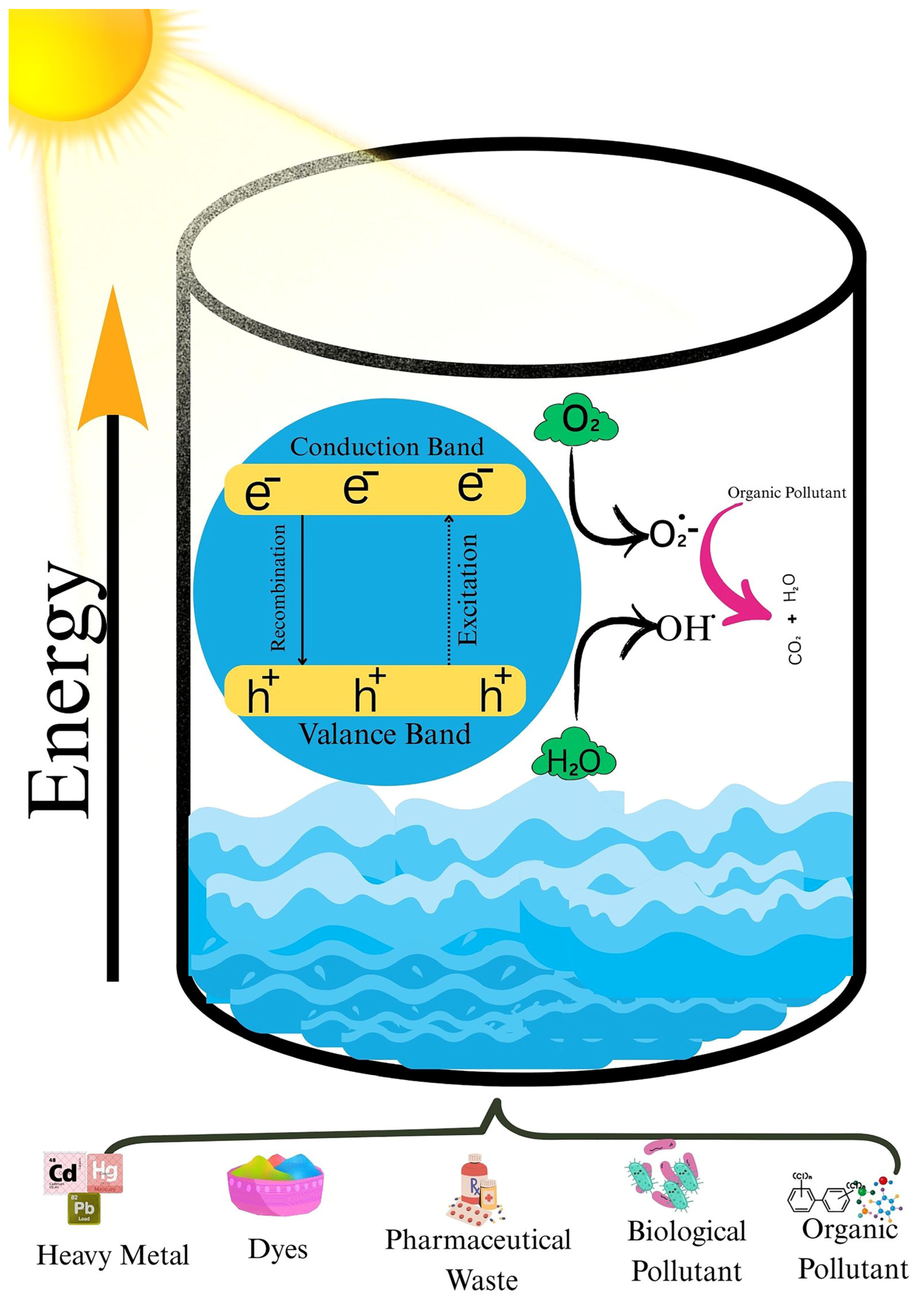

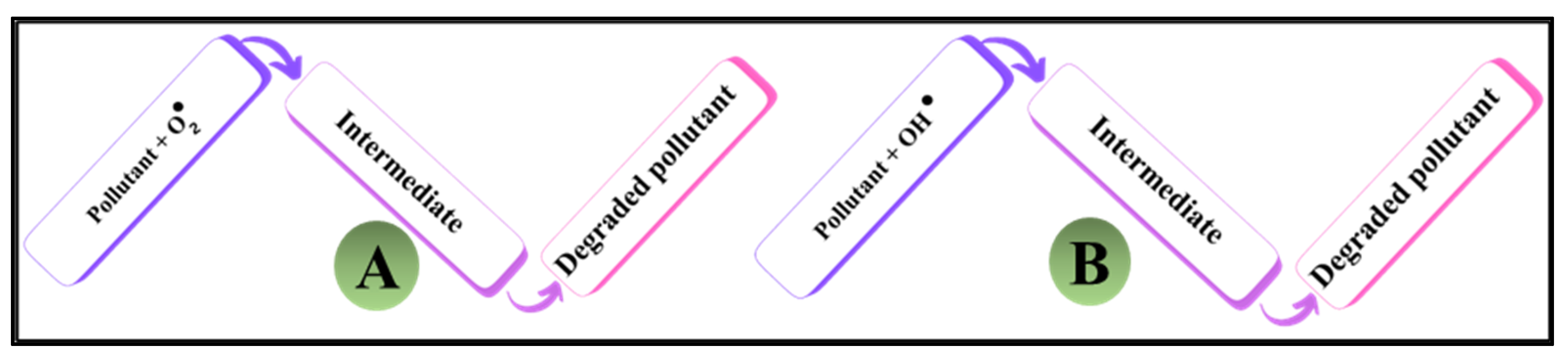

2. Photocatalysis Mechanisms and Dynamics

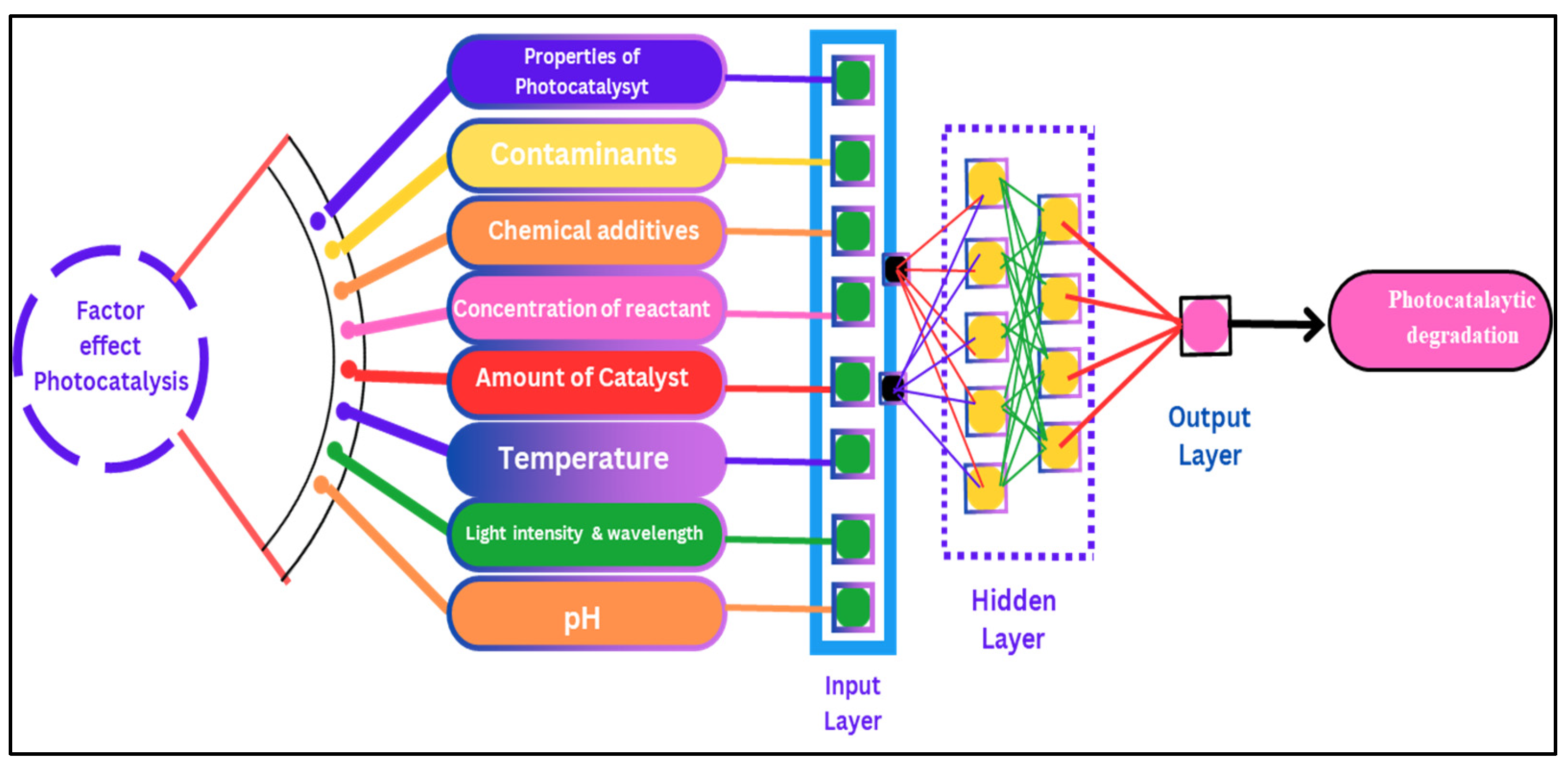

3. Operational Parameters Effects on Artificial Intelligence-Driven Photocatalysis

3.1. pH

3.2. Light Intensity and Wavelength

3.3. Temperature

3.4. Number of Catalysts

3.5. Concentration of Reactants

3.6. Chemical Additives

3.7. Contaminants

3.8. Properties of Photocatalysts

4. Shaping the Future of Photocatalytic Materials

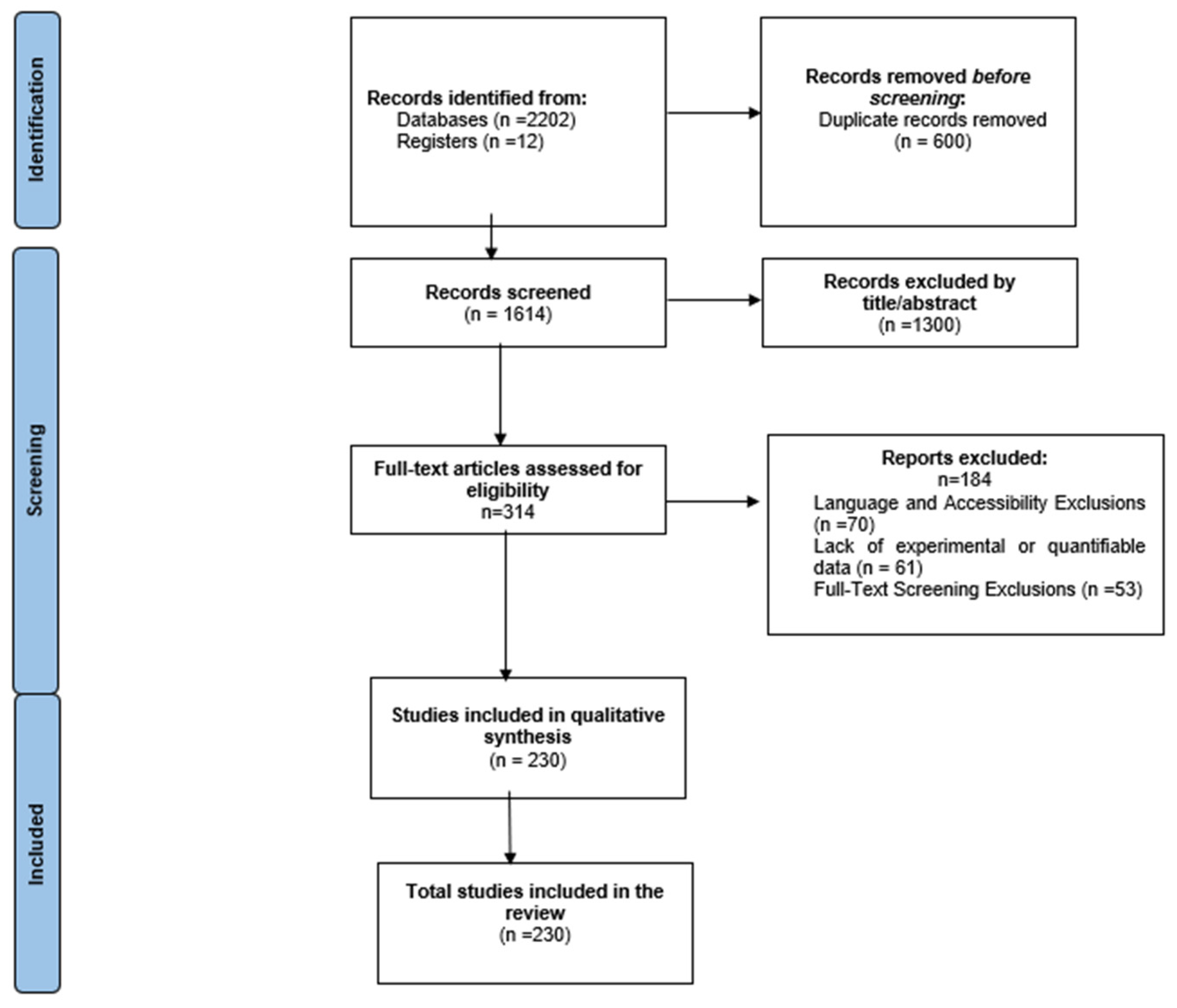

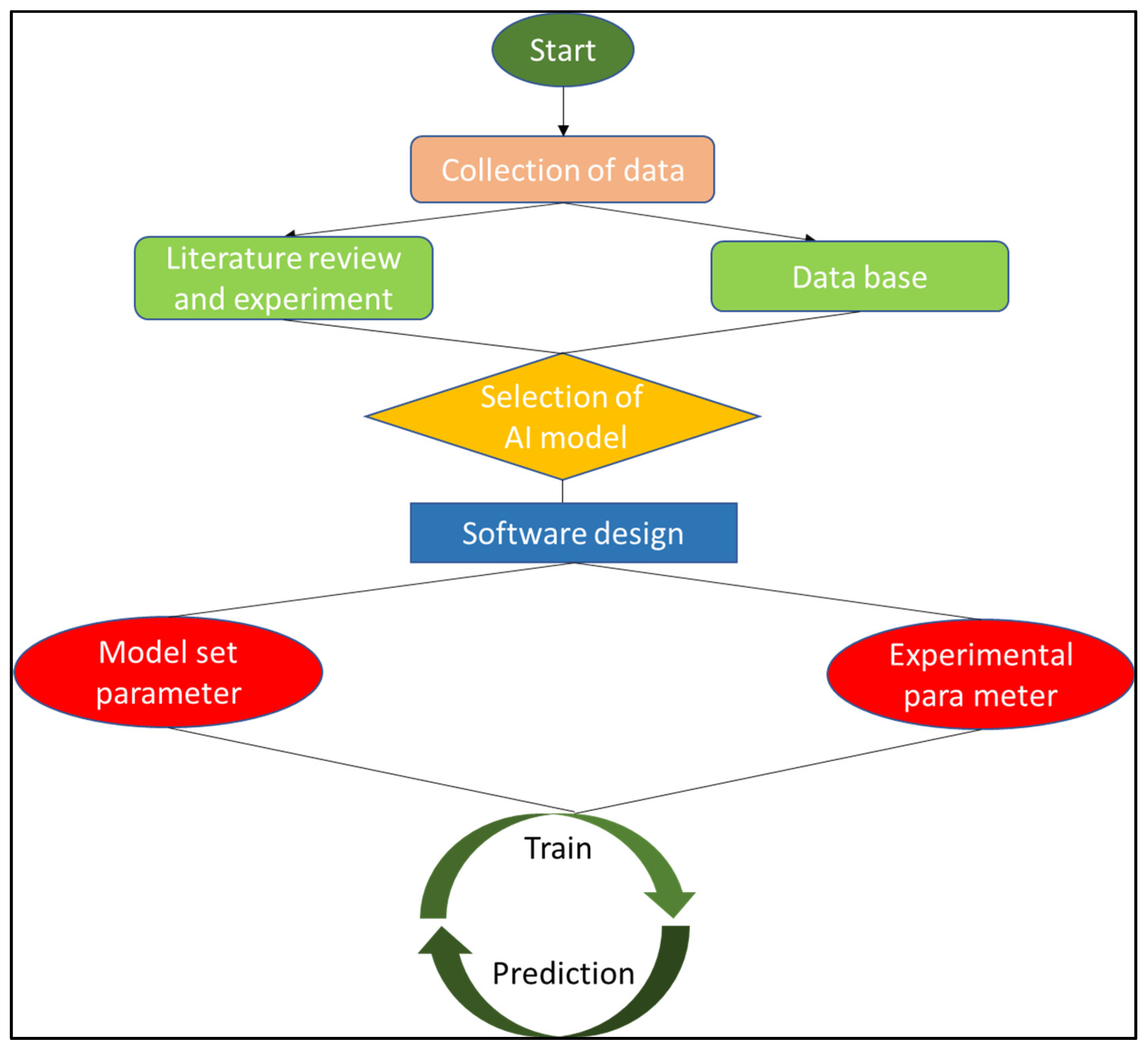

5. Research Methodology

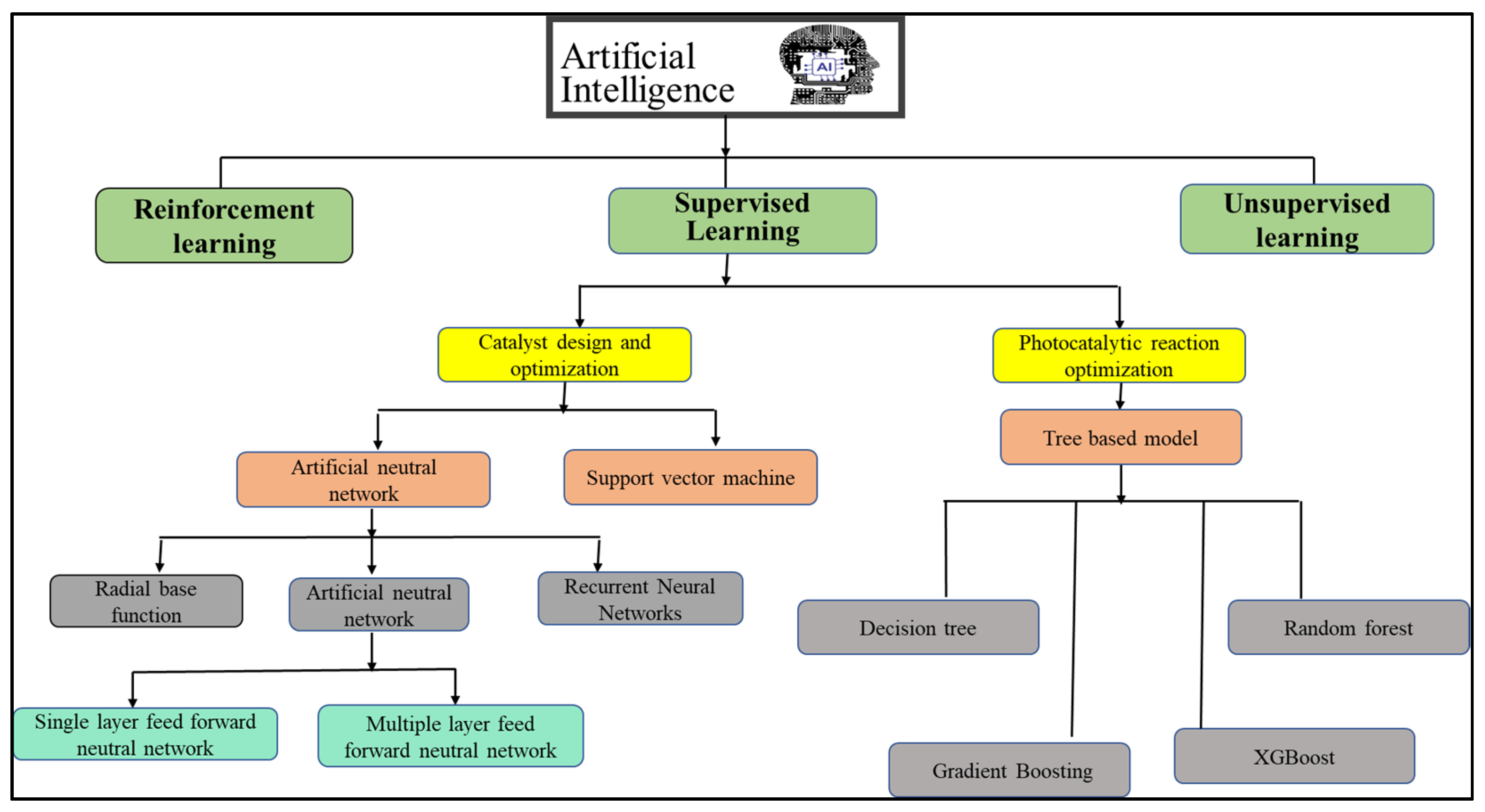

5.1. Artificial Intelligence Models in Photocatalysis

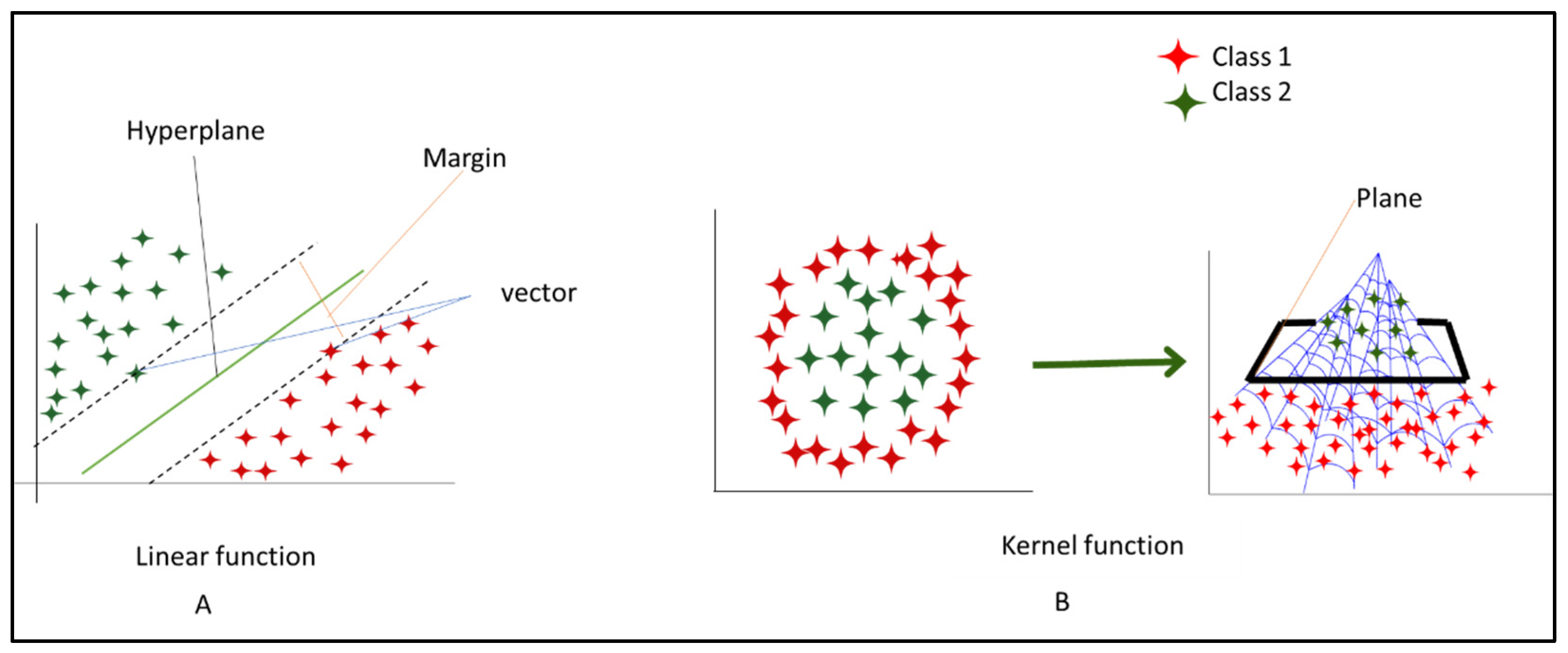

5.2. Support Vector Machines

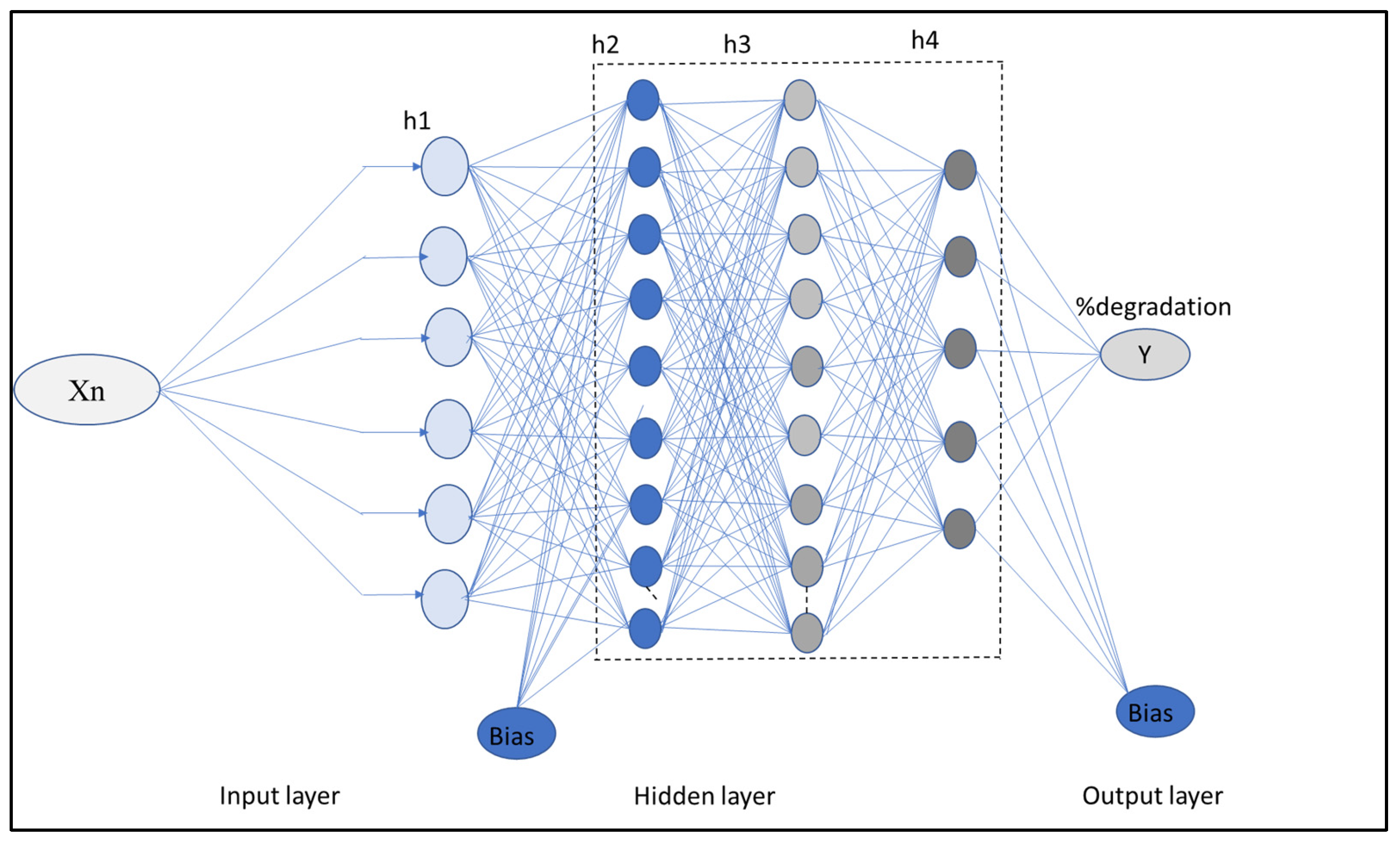

5.3. Artificial Neural Networks (ANNs)

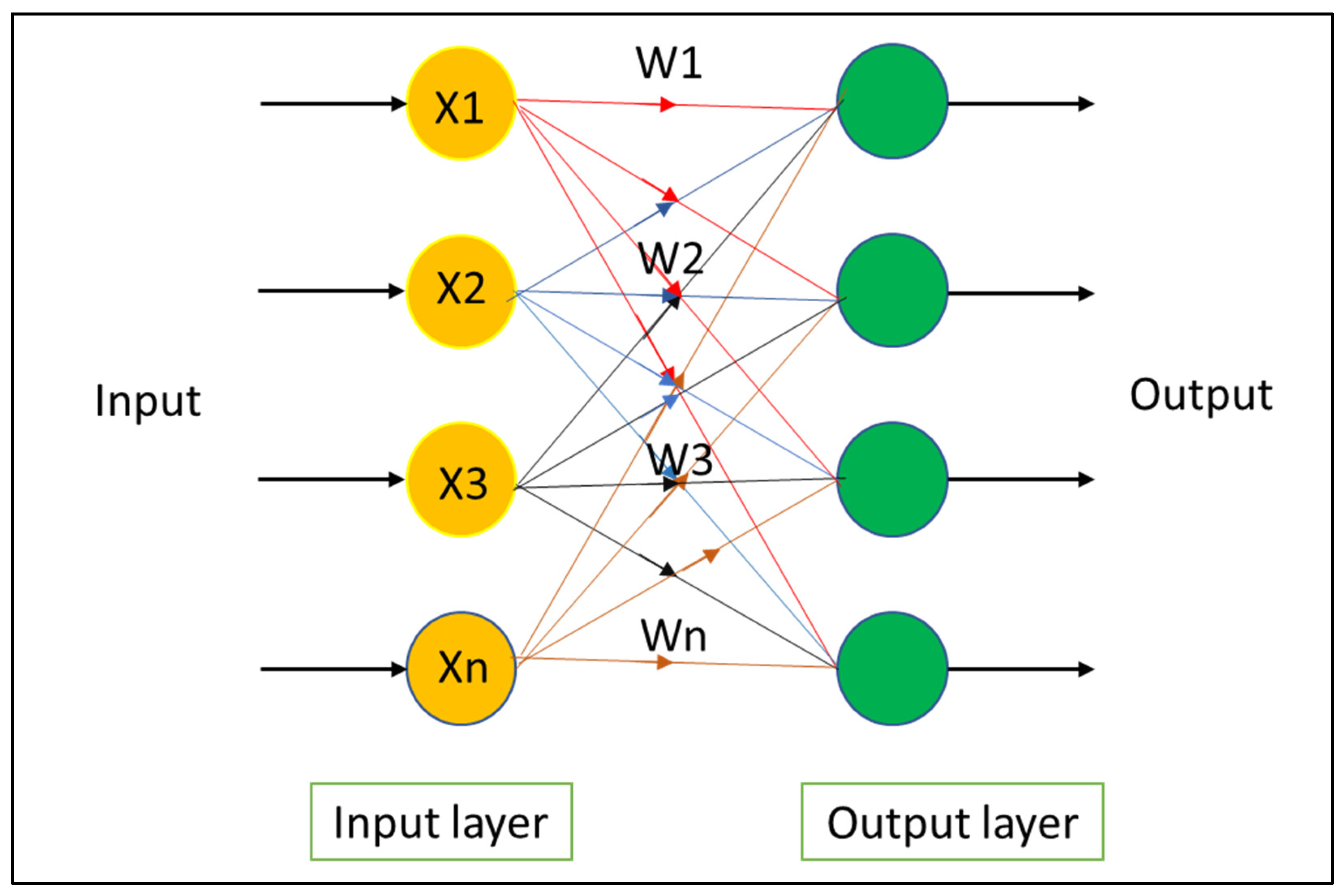

5.4. Diverse Architectures of Artificial Neural Networks (ANNs)

5.4.1. Feed-Forward Neural Networks (FFNNs)

Single-Layer Perceptron (SLP)

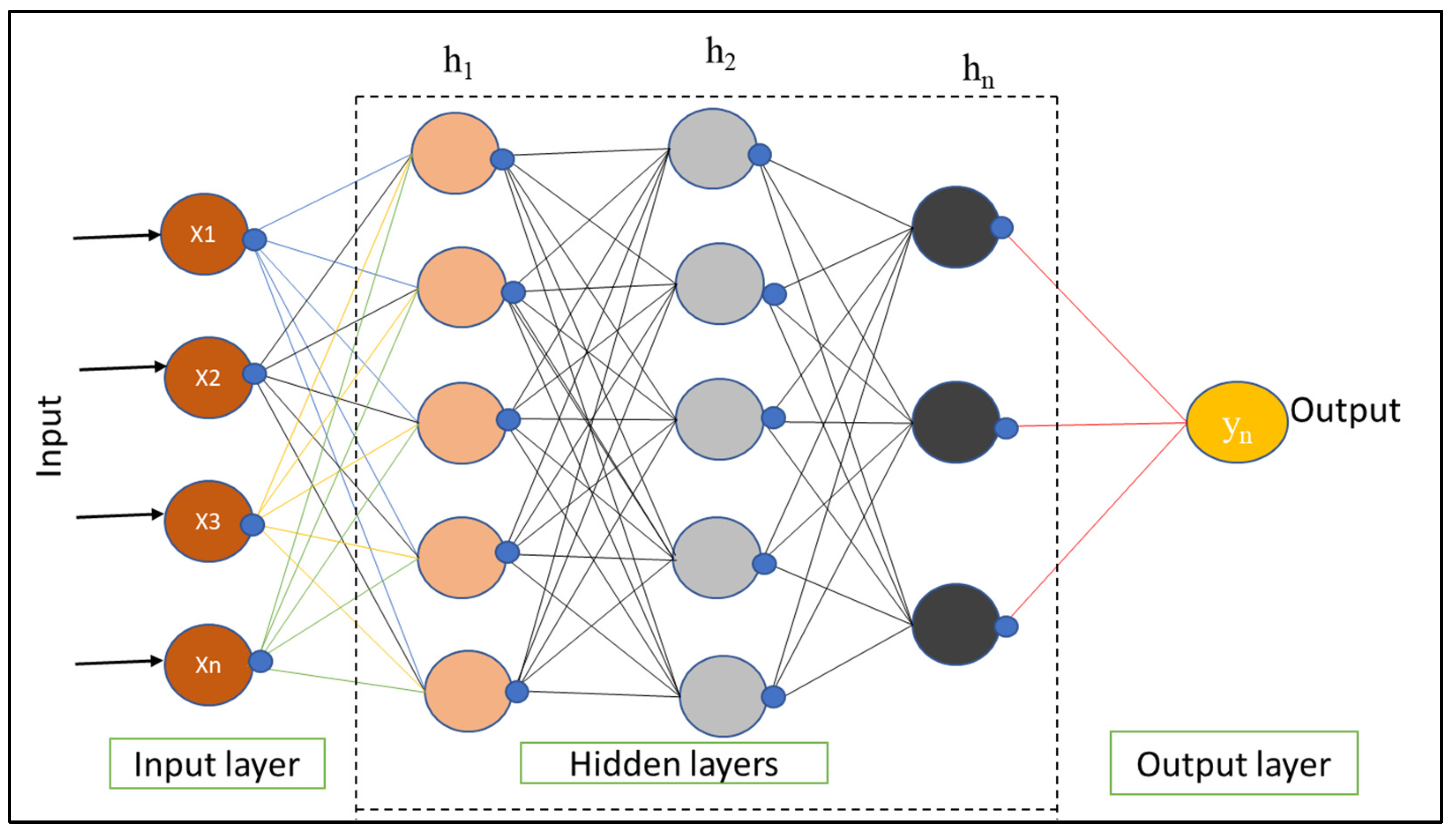

Multi-Layer Perceptron (MLP)

5.4.2. Radial Basis Function (RBF)

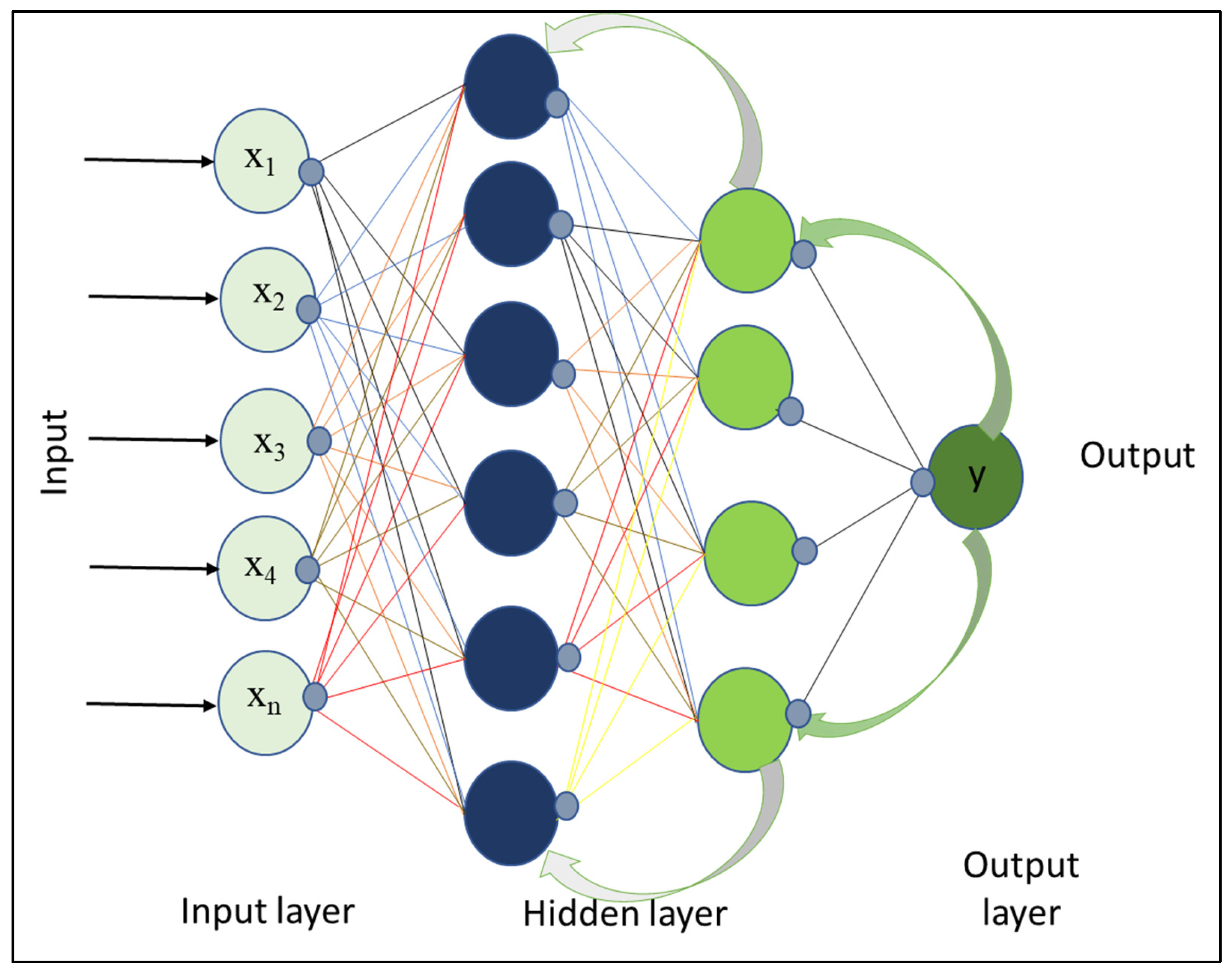

5.4.3. Recurrent Neural Networks (RNNs)

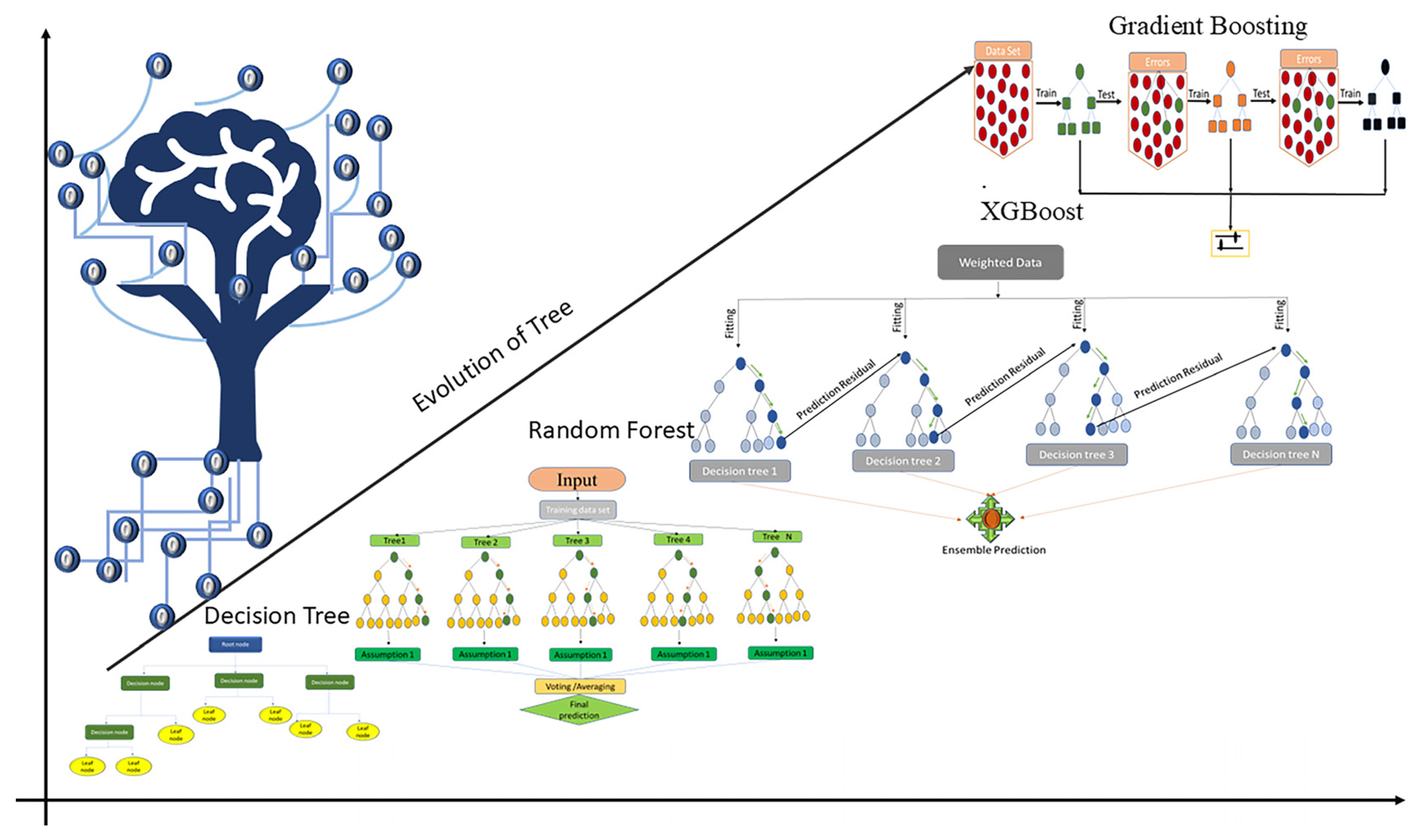

5.5. Tree-Based Models

5.6. AI Model Development and Benchmarking in Photocatalytic Treatment

5.7. Hybrid AI Models

6. Innovative Catalysts for Effective Wastewater Purification

6.1. Titanium Dioxide (TiO2)

6.2. Zinc Oxide (ZnO)

6.3. Cadmium Sulfide (CdS)

6.4. Tungsten Trioxide (WO3)

6.5. Cesium Dioxide

6.6. Zirconium Oxide (ZrO2)

6.7. Limitations and Challenges of Data Sparsity and Overfitting in AI-Driven Photocatalysis: Mitigation Strategies

7. Conclusions

8. Future Perspectives

- As the current model algorithms are only designed for particular stages of the wastewater treatment process, more organized and comprehensive algorithms involving the prediction of pollutant levels, the enhancement of operating parameters, the monitoring of maintenance processes, and the reuse of recyclable polluting substances should be developed.

- Developing combination algorithms and combined optimization approaches that can better monitor and control wastewater treatment systems.

- Using artificial intelligence, which is currently understudied, to design novel, useful materials for wastewater treatment.

- Strong cross-disciplinary collaboration will be necessary for future developments in AI-driven photocatalysis to connect computational predictions with experimental validation successfully. For the results of models to be chemically interpretable, explainable AI must be implemented.

- At the same time, basic research needs to be prioritized to support both deeper mechanistic insights and real-world applications. More replicable and optimized photocatalytic systems will be made possible by striking a balance between theoretical knowledge and innovation. Ultimately, this integrated strategy has the potential to revolutionize sustainable chemical synthesis, wastewater treatment, and energy storage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhattacharjee, J.; Roy, S.; Shaikh, A.A. Artificial Intelligence and Machine Learning for the Optimization of Photocatalytic Performance. Energy 2025, 360, 100027. [Google Scholar] [CrossRef]

- Hicham, N.; Nassera, H.; Karim, S. Strategic framework for leveraging artificial intelligence in future marketing decision-making. J. Intell. Manag. Decis. 2023, 2, 139–150. [Google Scholar] [CrossRef]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial intelligence for sustainability: Challenges, opportunities, and a research agenda. Int. J. Inf. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Shang, Y.; Zhou, S.; Zhuang, D.; Żywiołek, J.; Dincer, H. The impact of artificial intelligence application on enterprise environmental performance: Evidence from microenterprises. Gondwana Res. 2024, 131, 181–195. [Google Scholar] [CrossRef]

- Alprol, A.E.; Mansour, A.T.; Ibrahim, M.E.E.-D.; Ashour, M. Artificial Intelligence Technologies Revolutionizing Wastewater Treatment: Current Trends and Future Prospective. Water 2024, 16, 314. [Google Scholar] [CrossRef]

- Xu, W.-L.; Wang, Y.-J.; Wang, Y.-T.; Li, J.-G.; Zeng, Y.-N.; Guo, H.-W.; Liu, H.; Dong, K.-L.; Zhang, L.-Y. Application and innovation of artificial intelligence models in wastewater treatment. J. Contam. Hydrol. 2024, 267, 104426. [Google Scholar] [CrossRef]

- Huang, C.; Sun, H.; Liu, Y.; Yuan, H. Trace the evolution path of pharmaceutical wastewater treatment technology based on a patent perspective. Water Sci. Technol. 2024, 90, 1985–2001. [Google Scholar] [CrossRef]

- Baskar, G.; Omer, S.N.; Saravanan, P.; Rajeshkannan, R.; Saravanan, V.; Rajasimman, M.; Shanmugam, V. Status and future trends in wastewater management strategies using artificial intelligence and machine learning techniques. Chemosphere 2024, 362, 142477. [Google Scholar] [CrossRef]

- Schossler, R.T.; Ojo, S.; Jiang, Z.; Hu, J.; Yu, X. A novel interpretable machine learning model approach for the prediction of TiO2 photocatalytic degradation of air contaminants. Sci. Rep. 2024, 14, 13070. [Google Scholar] [CrossRef]

- Behera, S.K.; Karthika, S.; Mahanty, B.; Meher, S.K.; Zafar, M.; Baskaran, D.; Rajamanickam, R.; Das, R.; Pakshirajan, K.; Bilyaminu, A.M. Application of artificial intelligence tools in wastewater and waste gas treatment systems: Recent advances and prospects. J. Environ. Manag. 2024, 370, 122386. [Google Scholar] [CrossRef]

- Dashti, A.; Navidpour, A.H.; Amirkhani, F.; Zhou, J.L.; Altaee, A. Application of machine learning models to improve the prediction of pesticide photodegradation in water by ZnO-based photocatalysts. Chemosphere 2024, 362, 142792. [Google Scholar] [CrossRef]

- Mehmet, O.; Yorucu, V. Human Damage to the Global Ecosystem. In From Land Disputes to Sustainable Environmental Development: A Near East Perspective; Springer: Berlin/Heidelberg, Germany, 2024; pp. 151–165. [Google Scholar]

- Roy, B.; Bhunia, B.; Bandyopadhyay, T.K.; Khan, S.A.; Nandi, N.B.; Nath, P.C. Water Pollution by Heavy Metals and Their Impact on Human Health. In Handbook of Water Pollution; Inamuddin, Altalhi, T., Alrooqi, A., Eds.; Scrivener Publishing LLC: Beverly, MA, USA; Wiley: Hoboken, NJ, USA, 2024; pp. 333–352. [Google Scholar]

- Merchán-Sanmartín, B.; Álava-Zúñiga, B.; Vallejo-Palomeque, F.; Suárez-Zamora, S.; Aguilar-Aguilar, M.; Morante-Carballo, F. Integrated wastewater management for environmental protection and sustainable ecotourism in an Andean paramo community. Chall. Sustain. 2025, 13, 334–353. [Google Scholar] [CrossRef]

- El Hammoudani, Y.; Dimane, F.; Haboubi, K.; Benaissa, C.; Benaabidate, L.; Bourjila, A.; Achoukhi, I.; El Boudammoussi, M.; Faiz, H.; Touzani, A. Micropollutants in wastewater treatment plants: A bibliometric-bibliographic study. Desalination Water Treat. 2024, 317, 100190. [Google Scholar] [CrossRef]

- Agbasi, J.C.; Ayejoto, D.A.; Egbueri, J.C.; Khan, N.; Abba, S.I.; Ahmad, V.; Abuzinadah, M.F. HERisk and statistical clustering integrated for health risk modelling of PTEs in natural water resources for drinking and sanitary uses. Toxin Rev. 2024, 43, 513–539. [Google Scholar] [CrossRef]

- Sharma, K.; Rajan, S.; Nayak, S.K. Water pollution: Primary sources and associated human health hazards with special emphasis on rural areas. In Water Resources Management for Rural Development; Elsevier: Amsterdam, The Netherlands, 2024; pp. 3–14. [Google Scholar]

- Vosough, M.; Khayati, G.R.; Sharafi, S. A novel nanocomposite for photocatalytic rhodamine B dye removal from wastewater using visible light. Environ. Res. 2024, 249, 118415. [Google Scholar] [CrossRef]

- Hamrayev, H.; Korpayev, S.; Shameli, K. Advances in Synthesis Techniques and Environmental Applications of TiO2 Nanoparticles for Wastewater Treatment: A Review. J. Res. Nanosci. Nanotechnol. 2024, 12, 1–24. [Google Scholar] [CrossRef]

- Ogundele, O.; Oyegoke, D.; Anaun, T. Exploring the potential and challenges of electro-chemical processes for sustainable waste water remediation and treatment. Acadlore Trans. Geosci. 2023, 2, 80–93. [Google Scholar] [CrossRef]

- Coelho, L.L.; Wilhelm, M.; Hotza, D.; de Fátima Peralta Muniz Moreira, R. Oily wastewater treatment by photocatalytic membranes: A review. Environ. Technol. Rev. 2024, 13, 95–119. [Google Scholar] [CrossRef]

- Awad, H.; Mossad, M.; Mahanna, H.; Foad, M.; Alalm, M.G. Comparative assessment of different scenarios for upgrading activated sludge wastewater treatment plants in developing countries. Sci. Total Environ. 2024, 907, 168022. [Google Scholar] [CrossRef]

- Kallawar, G.A.; Bhanvase, B.A. A review on existing and emerging approaches for textile wastewater treatments: Challenges and future perspectives. Environ. Sci. Pollut. Res. 2024, 31, 1748–1789. [Google Scholar] [CrossRef]

- Akinyemi, B.; Ogundele, O.; Afolabi, A. Advancements in sustainable membrane technologies for enhanced remediation and wastewater treatment: A comprehensive review. Acadlore Trans. Geosci. 2023, 2, 196–207. [Google Scholar] [CrossRef]

- Yuan, L.; Yan, P.; Wang, P.; Li, L.; Xiao, X.; Xie, Y. Constructing stable type-II NaLiTi3O7/La2S3 heterojunctions for efficient photocatalytic charge separation and hydrogen production. Int. J. Hydrogen Energy 2024, 64, 958–964. [Google Scholar] [CrossRef]

- Safira, A.R.; Fattah-alhosseini, A.; Kaseem, M. Surface growth of novel MOFs on AZ31 Mg alloy coated via plasma electrolytic oxidation for enhanced corrosion protection and photocatalytic performance. J. Magnes. Alloys 2024, 12, 2413–2432. [Google Scholar] [CrossRef]

- Su, R.; Zhu, Y.; Gao, B.; Li, Q. Progress on mechanism and efficacy of heterogeneous photocatalysis coupled oxidant activation as an advanced oxidation process for water decontamination. Water Res. 2024, 251, 121119. [Google Scholar] [CrossRef]

- Chong, M.N.; Jin, B.; Chow, C.W.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef]

- Kanoun, M.B.; Ahmed, F.; Awada, C.; Jonin, C.; Brevet, P.-F. Band gap engineering of Au doping and Au–N codoping into anatase TiO2 for enhancing the visible light photocatalytic performance. Int. J. Hydrogen Energy 2024, 51, 907–913. [Google Scholar] [CrossRef]

- Liza, T.Z.; Tusher, M.M.H.; Anwar, F.; Monika, M.F.; Amin, K.F.; Asrafuzzaman, F. Effect of Ag-doping on morphology, structure, band gap and photocatalytic activity of bio-mediated TiO2 nanoparticles. Results Mater. 2024, 22, 100559. [Google Scholar] [CrossRef]

- Alhajeri, N.S.; Tawfik, A.; Nasr, M.; Osman, A.I. Artificial intelligence-enabled optimization of Fe/Zn@ biochar photocatalyst for 2, 6-dichlorophenol removal from petrochemical wastewater: A techno-economic perspective. Chemosphere 2024, 352, 141476. [Google Scholar] [CrossRef]

- Esmaeili, N.; Saraei, F.E.K.; Pirbazari, A.E.; Tabatabai-Yazdi, F.-S.; Khodaee, Z.; Amirinezhad, A.; Esmaeili, A.; Pirbazari, A.E. Estimation of 2,4-dichlorophenol photocatalytic removal using different artificial intelligence approaches. Chem. Prod. Process Model. 2023, 18, 247–263. [Google Scholar] [CrossRef]

- Jabbar, Z.H.; Graimed, B.H.; Ammar, S.H.; Sabit, D.A.; Najim, A.A.; Radeef, A.Y.; Taher, A.G. The latest progress in the design and application of semiconductor photocatalysis systems for degradation of environmental pollutants in wastewater: Mechanism insight and theoretical calculations. Mater. Sci. Semicond. Process. 2024, 173, 108153. [Google Scholar] [CrossRef]

- Sun, N.; Si, X.; He, L.; Zhang, J.; Sun, Y. Strategies for enhancing the photocatalytic activity of semiconductors. Int. J. Hydrogen Energy 2024, 58, 1249–1265. [Google Scholar] [CrossRef]

- Vishwanathan, S.; Laxmi, S.; Nandan, S.; Jayan, S.; Lijo, M.; Das, S. Effect of experimental parameters on photocatalytic degradation efficiency of TiO2 nanoparticles synthesized by electrochemical method towards Rhodamine B dye solution under natural sunlight. Environ. Sci. Pollut. Res. 2023, 30, 8448–8463. [Google Scholar]

- Lin, L.; Jiang, W.; Chen, L.; Xu, P.; Wang, H. Treatment of produced water with photocatalysis: Recent advances, affecting factors and future research prospects. Catalysts 2020, 10, 924. [Google Scholar] [CrossRef]

- Yamazaki, S.; Takaki, D.; Nishiyama, N.; Yamazaki, Y. Factors affecting photocatalytic activity of TiO2. In Current Developments in Photocatalysis and Photocatalytic Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 23–38. [Google Scholar]

- Al-Nuaim, M.A.; Alwasiti, A.A.; Shnain, Z.Y. The photocatalytic process in the treatment of polluted water. Chem. Pap. 2023, 77, 677–701. [Google Scholar] [CrossRef]

- Lanjwani, M.F.; Tuzen, M.; Khuhawar, M.Y.; Saleh, T.A. Trends in photocatalytic degradation of organic dye pollutants using nanoparticles: A review. Inorg. Chem. Commun. 2024, 159, 111613. [Google Scholar] [CrossRef]

- Ahmed, S.; Rasul, M.; Brown, R.; Hashib, M. Influence of parameters on the heterogeneous photocatalytic degradation of pesticides and phenolic contaminants in wastewater: A short review. J. Environ. Manag. 2011, 92, 311–330. [Google Scholar] [CrossRef] [PubMed]

- Adnan, M.A.M.; Majnis, M.F.; Adnan, W.N.W.; Abdullah, N.H.; Baharom, A.S.; Julkapli, N.M. Deep Insights into the Integration of Artificial Neural Networks (ANNs) for Predicting the Photocatalytic Activities of Metal-Based Catalysts in Water Pollutant Reduction. J. Environ. Chem. Eng. 2025, 13, 116350. [Google Scholar] [CrossRef]

- Jiang, D.; Otitoju, T.A.; Ouyang, Y.; Shoparwe, N.F.; Wang, S.; Zhang, A.; Li, S. A review on metal ions modified TiO2 for photocatalytic degradation of organic pollutants. Catalysts 2021, 11, 1039. [Google Scholar] [CrossRef]

- Mohammed, N.; Palaniandy, P.; Shaik, F. Optimization of solar photocatalytic biodegradability of seawater using statistical modelling. J. Indian Chem. Soc. 2021, 98, 100240. [Google Scholar] [CrossRef]

- Kumar, A.; Pandey, G. A review on the factors affecting the photocatalytic degradation of hazardous materials. Mater. Sci. Eng. Int. J. 2017, 1, 1–10. [Google Scholar] [CrossRef]

- Mohammadzadeh Kakhki, R.; Zirjanizadeh, S.; Mohammadpoor, M. A review of clinoptilolite, its photocatalytic, chemical activity, structure and properties: In time of artificial intelligence. J. Mater. Sci. 2023, 58, 10555–10575. [Google Scholar] [CrossRef]

- Wang, S.; Mo, P.; Li, D.; Syed, A. Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction. Catalysts 2024, 14, 217. [Google Scholar] [CrossRef]

- Sohrabi, S.; Rahimi, P.; Khedri, M.; Heydari, R.; Mirzaei, M.; Bahrami, A.; Akhlaghian, F.; Taghipoor, M. Evaluation of machine learning and molecular dynamics models for photocatalytic water decontamination. Process Saf. Environ. Prot. 2025, 195, 106780. [Google Scholar]

- Ai, C.; Zhou, D.; Wang, Q.; Shao, X.; Lei, Y. Optimization of operating parameters for photocatalytic degradation of tetracycline using In2S3 under natural solar radiation. Sol. Energy 2015, 113, 34–42. [Google Scholar] [CrossRef]

- Yan, Q.; Wang, X.; Xiong, Q.; Lu, J.; Liao, B. The influences of technological parameters on the ultraviolet photocatalytic reaction rate and photocatalysis-assisted polishing effect for SiC. J. Cryst. Growth 2020, 531, 125379. [Google Scholar] [CrossRef]

- Ali, H.; Yasir, M.; Haq, H.U.; Guler, A.C.; Masar, M.; Khan, M.N.A.; Machovsky, M.; Sedlarik, V.; Kuritka, I. Machine learning approach for photocatalysis: An experimentally validated case study of photocatalytic dye degradation. J. Environ. Manag. 2025, 386, 125683. [Google Scholar] [CrossRef]

- Xu, K.; Pan, B.; Lu, H.; Wang, X.; Zhang, X.; Xie, M.; Yu, J. Machine Learning-Assisted ZnO-Doped Photocatalytic Degradation of Rhodamine B: Prediction, Analysis, and Optimization. Environ. Technol. Innov. 2025, 40, 104425. [Google Scholar] [CrossRef]

- Fuziki, M.E.K.; Ribas, L.S.; Tusset, A.M.; Brackmann, R.; Dos Santos, O.A.; Lenzi, G.G. Pharmaceutical compounds photolysis: pH influence. Heliyon 2023, 9, e13678. [Google Scholar] [CrossRef]

- Gheytanzadeh, M.; Baghban, A.; Habibzadeh, S.; Jabbour, K.; Esmaeili, A.; Mohaddespour, A.; Abida, O. An insight into tetracycline photocatalytic degradation by MOFs using the artificial intelligence technique. Sci. Rep. 2022, 12, 6615. [Google Scholar] [CrossRef]

- Marfur, N.A.; Jaafar, N.F.; Anuar, M.H.; Zulkeffli, N. Effect of pH on the photocatalytic degradation of 2, 4-dichlorophenol via noble metal doped ZnO photocatalyst. AIP Conf. Proc. 2021, 2610, 040015. [Google Scholar]

- Gilani, S.A.B.; Naseeb, F.; Kiran, A.; Ihsan, M.U.; Iqbal, J.; Javed, H.M.A.; Bhatti, H.N.; Karami, A.M.; Hussain, S.; ShabirMahr, M. pH dependent synthesis of ceria nanoparticles for efficient sunlight-driven photocatalysis of methyl orange containing wastewater. Opt. Mater. 2024, 148, 114871. [Google Scholar] [CrossRef]

- Mbuyazi, T.B.; Ajibade, P.A. Photocatalytic degradation of organic dyes by magnetite nanoparticles prepared by co-precipitation. Int. J. Mol. Sci. 2024, 25, 7876. [Google Scholar] [CrossRef]

- Sirota, V.V.; Savotchenko, S.E.; Strokova, V.V.; Vashchilin, V.S.; Podgornyi, D.S.; Limarenko, M.V.; Kovaleva, M.G. Effect of irradiation intensity on the rate of photocatalysis of TiO2 coatings obtained by detonation spraying. Int. J. Appl. Ceram. Technol. 2024, 21, 3335–3345. [Google Scholar] [CrossRef]

- Ramos-Huerta, L.A.; Laureys, L.; Llanos, A.G.; Valadés, P.J.; Ruiz, R.S.; Castillo, C.O. Assessing the effect of light intensity and light wavelength spectra on the photoreduction of formic acid using a graphene oxide material. Int. J. Chem. React. Eng. 2020, 18, 20200008. [Google Scholar] [CrossRef]

- Pirgholi-Givi, G.; Farjami-Shayesteh, S.; Azizian-Kalandaragh, Y. The influence of irradiation intensity and stirring rate on the photocatalytic activity of titanium dioxide nanostructures prepared by the microwave-assisted method for photodegradation of MB from water. Phys. B Condens. Matter 2020, 578, 411886. [Google Scholar] [CrossRef]

- Khataee, A. Photocatalytic removal of CI Basic Red 46 on immobilized TiO2 nanoparticles: Artificial neural network modelling. Environ. Technol. 2009, 30, 1155–1168. [Google Scholar] [CrossRef]

- Chen, Y.-W.; Hsu, Y.-H. Effects of reaction temperature on the photocatalytic activity of TiO2 with Pd and Cu cocatalysts. Catalysts 2021, 11, 966. [Google Scholar] [CrossRef]

- Cho, Y.; Yamaguchi, A.; Sinaga, A.S.; Yang, Y.; Miyauchi, M. Photocatalysis under thermally shifted bandgap. Appl. Catal. A Gen. 2022, 643, 118772. [Google Scholar] [CrossRef]

- Nourizade, M.; Rahmani, M.; Javadi, A. Simulation of a Photocatalytic Reactor Using Finite Volume and Discrete Ordinate Method: A Parametric Study. Amirkabir J. Mech. Eng. 2021, 53, 573–588. [Google Scholar]

- Sorathiya, K.; Mishra, B.; Kalarikkal, A.; Reddy, K.P.; Gopinath, C.S.; Khushalani, D. Enhancement in rate of photocatalysis upon catalyst recycling. Sci. Rep. 2016, 6, 35075. [Google Scholar] [CrossRef]

- Markovskaya, D.; Kozlova, E. Formal Kinetic Description of Photocatalytic Hydrogen Evolution from Ethanol Aqueous Solutions in the Presence of Sodium Hydroxide. Kinet. Catal. 2018, 59, 727–734. [Google Scholar] [CrossRef]

- Wang, C.; Jeon, J.; Seo, E.; Park, J. Ion-concentration-polarization-assisted photocatalytic reactor for highly efficient water purification. Lab Chip 2022, 22, 2962–2970. [Google Scholar] [CrossRef]

- Sieland, F.; Duong, N.A.-T.; Schneider, J.; Bahnemann, D.W. Influence of inorganic additives on the photocatalytic removal of nitric oxide and on the charge carrier dynamics of TiO2 powders. J. Photochem. Photobiol. A Chem. 2018, 366, 142–151. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, L.; Feng, C. Effect of additives on photocatalysis of Cr (VI)-methyl orange. Procedia Environ. Sci. 2013, 18, 625–631. [Google Scholar] [CrossRef][Green Version]

- Abreu, E.; Fidelis, M.Z.; Fuziki, M.; Malikoski, R.; Mastsubara, M.; Imada, R.; de Tuesta, J.D.; Gomes, H.; Anziliero, M.; Baldykowski, B. Degradation of emerging contaminants: Effect of thermal treatment on nb2o5 as photocatalyst. J. Photochem. Photobiol. A Chem. 2021, 419, 113484. [Google Scholar] [CrossRef]

- Krishna, V.; Bai, W.; Han, Z.; Yano, A.; Thakur, A.; Georgieva, A.; Tolley, K.; Navarro, J.; Koopman, B.; Moudgil, B. Contaminant-activated visible light photocatalysis. Sci. Rep. 2018, 8, 1894. [Google Scholar] [CrossRef]

- Rodríguez-González, V.; Obregón, S.; Patrón-Soberano, O.A.; Terashima, C.; Fujishima, A. An approach to the photocatalytic mechanism in the TiO2-nanomaterials microorganism interface for the control of infectious processes. Appl. Catal. B Environ. 2020, 270, 118853. [Google Scholar] [CrossRef]

- Lukic, S.; Menze, J.; Weide, P.; Busser, G.W.; Winterer, M.; Muhler, M. Decoupling the Effects of High Crystallinity and Surface Area on the Photocatalytic Overall Water Splitting over β-Ga2O3 Nanoparticles by Chemical Vapor Synthesis. ChemSusChem 2017, 10, 4190–4197. [Google Scholar] [CrossRef]

- Kumari, N.; Gaurav, K.; Dash, R.; Bhattacharyya, A. Doped mixed phase transition metal oxides for photocatalysis. In Handbook of Emerging Materials for Sustainable Energy; Elsevier: Amsterdam, The Netherlands, 2024; pp. 333–346. [Google Scholar]

- Liu, Z.; Zhuang, Y.; Dong, L.; Mu, H.; Li, D.; Zhang, F.; Xu, H.; Xie, H. Enhancement mechanism of photocatalytic hydrogen production activity of CeO2/CdS by morphology regulation. ACS Appl. Energy Mater. 2023, 6, 7722–7736. [Google Scholar] [CrossRef]

- Ganguli, A.K.; Kunde, G.B.; Raza, W.; Kumar, S.; Yadav, P. Assessment of performance of photocatalytic nanostructured materials with varied morphology based on reaction conditions. Molecules 2022, 27, 7778. [Google Scholar] [CrossRef]

- Ge, L.; Ke, Y.; Li, X. Machine learning integrated photocatalysis: Progress and challenges. Chem. Commun. 2023, 59, 5795–5806. [Google Scholar] [CrossRef]

- Tabatabai-Yazdi, F.-S.; Pirbazari, A.E.; Saraei, F.E.K.; Gilani, N. Construction of graphene based photocatalysts for photocatalytic degradation of organic pollutant and modeling using artificial intelligence techniques. Phys. B Condens. Matter 2021, 608, 412869. [Google Scholar] [CrossRef]

- Xiao, F.; Xiao, T.; Zhao, L.; He, X. Enhanced solar-driven photoelectrochemical water splitting of H/N co-doped TiO2: Role of defect states in a band gap reduction and promotion of charge transfer. Renew. Energy 2024, 230, 120778. [Google Scholar] [CrossRef]

- Fang, W.; Yan, J.; Wei, Z.; Liu, J.; Guo, W.; Jiang, Z.; Shangguan, W. Account of doping photocatalyst for water splitting. Chin. J. Catal. 2024, 60, 1–24. [Google Scholar] [CrossRef]

- She, S.; Chen, L.; Liao, K.; Fu, Y.; Wang, J.; Wu, X. Doping engineering in S–scheme composite for Regulating the selectivity of photocatalytic CO2 reduction. J. Colloid Interface Sci. 2024, 663, 947–960. [Google Scholar] [CrossRef] [PubMed]

- Sen, P.; Bhattacharya, P.; Mukherjee, G.; Ganguly, J.; Marik, B.; Thapliyal, D.; Verma, S.; Verros, G.D.; Chauhan, M.S.; Arya, R.K. Advancements in doping strategies for enhanced photocatalysts and adsorbents in environmental remediation. Technologies 2023, 11, 144. [Google Scholar] [CrossRef]

- Gentili, P.L. Photochromic and luminescent materials for the development of Chemical Artificial Intelligence. Dye. Pigment. 2022, 205, 110547. [Google Scholar] [CrossRef]

- Xu, J.; Su, A.; Huang, P.; Yu, W.; Du, K.; Fan, Z.; Sun, B.; Zhong, Z.; Jin, C.; Su, W. PhotoCat: An Artificial Intelligence-Driven Synthesis Planning Platform for Photocatalysis. ChemRxiv 2023. [Google Scholar] [CrossRef]

- Wei, C.; Song, Z.; Liu, Y.; Zhang, B.; Song, S.; Qin, L.; Zhao, Z. Enhancing photocatalytic performance of Cu6Fe2SnS8 by N doping using magnetic grinding method. Mater. Sci. Semicond. Process. 2024, 176, 108269. [Google Scholar] [CrossRef]

- AlMohamadi, H.; Awad, S.A.; Sharma, A.K.; Fayzullaev, N.; Távara-Aponte, A.; Chiguala-Contreras, L.; Amari, A.; Rodriguez-Benites, C.; Tahoon, M.A.; Esmaeili, H. Photocatalytic Activity of Metal-and Non-Metal-Anchored ZnO and TiO2 Nanocatalysts for Advanced Photocatalysis: Comparative Study. Catalysts 2024, 14, 420. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Machine learning band gaps of doped-TiO2 photocatalysts from structural and morphological parameters. ACS Omega 2020, 5, 15344–15352. [Google Scholar] [CrossRef]

- Lamouadene, H.; Kassaoui, M.E.; El Yadari, M.; El Kenz, A.; Benyoussef, A. Exploring modeling techniques for predicting band gaps of Doped-ZnO: A Machine learning approach. Chem. Phys. 2025, 591, 112603. [Google Scholar] [CrossRef]

- Hafsa, H.; Nasrallah, N.; Zeghbib, S.; Kebir, M.; Tahraoui, H.; Assadi, A.A.; Khezami, L.; Alghamdi, A.; Dahdouh, N.; Lekmine, S. Enhanced Photocatalytic Degradation of Pharmaceutical Pollutants Using Copper-Doped TiO2: Optimization, Machine Learning Integration, and Ecological Safety Assessment. Arab. J. Sci. Eng. 2025, 50, 1–25. [Google Scholar] [CrossRef]

- Bakır, R.; Orak, C.; Horoz, S. Enhancing photocatalytic degradation of hazardous pollutants with green-synthesized catalysts: A machine learning approach. J. Environ. Manag. 2025, 385, 125695. [Google Scholar] [CrossRef]

- Kakhki, R.M.; Mohammadpoor, M.; Faridi, R.; Bahadori, M. The development of an artificial neural network–genetic algorithm model (ANN-GA) for the adsorption and photocatalysis of methylene blue on a novel sulfur–nitrogen co-doped Fe2O3 nanostructure surface. RSC Adv. 2020, 10, 5951–5960. [Google Scholar] [CrossRef]

- Ngulube, K.F.; Abdelhaleem, A.; Fujii, M.; Nasr, M. Synergism of artificial intelligence and techno-economic for sustainable treatment of methylene blue dye-containing wastewater by photocatalysis. Sustainability 2024, 16, 529. [Google Scholar] [CrossRef]

- Hamdy, A.; Mostafa, M.; Nasr, M. Regression analysis and artificial intelligence for removal of methylene blue from aqueous solutions using nanoscale zero-valent iron. Int. J. Environ. Sci. Technol. 2019, 16, 357–372. [Google Scholar] [CrossRef]

- Igwegbe, C.A.; Mohmmadi, L.; Ahmadi, S.; Rahdar, A.; Khadkhodaiy, D.; Dehghani, R.; Rahdar, S. Modeling of adsorption of methylene blue dye on Ho-CaWO4 nanoparticles using response surface methodology (RSM) and artificial neural network (ANN) techniques. MethodsX 2019, 6, 1779–1797. [Google Scholar] [CrossRef] [PubMed]

- Khiam, G.K.; Karri, R.R.; Mubarak, N.M.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Rahman, M.E. Modelling and optimization for methylene blue adsorption using graphene oxide/chitosan composites via artificial neural network-particle swarm optimization. Mater. Today Chem. 2022, 24, 100946. [Google Scholar] [CrossRef]

- Ferk Savec, V.; Mlinarec, K. Experimental work in science education from green chemistry perspectives: A systematic literature review using PRISMA. Sustainability 2021, 13, 12977. [Google Scholar] [CrossRef]

- Sohrabi, C.; Franchi, T.; Mathew, G.; Kerwan, A.; Nicola, M.; Griffin, M.; Agha, M.; Agha, R. PRISMA 2020 statement: What’s new and the importance of reporting guidelines. Int. J. Surg. 2021, 88, 105918. [Google Scholar] [CrossRef] [PubMed]

- Dabodiya, T.S.; Kumar, J.; Murugan, A.V. Contemplation of Photocatalysis Through Machine Learning. In Machine Learning for Advanced Functional Materials; Springer: Berlin/Heidelberg, Germany, 2023; pp. 221–232. [Google Scholar]

- Mustafa, M.; Epelle, E.I.; Macfarlane, A.; Cusack, M.; Burns, A.; Yaseen, M. Innovative approaches to greywater micropollutant removal: AI-driven solutions and future outlook. RSC Adv. 2025, 15, 12125–12151. [Google Scholar] [CrossRef] [PubMed]

- Díez, A.Á.; Rois, R.P.; Landín, S.M.; Montenegro, J.M.F. Reinforcement Learning Based Strategies for Decision Support on Water Treatment Plants. In Proceedings of the International Conference on Water Energy Food and Sustainability, Leiria, Portugal, 10–12 May 2023; pp. 649–659. [Google Scholar]

- Li, X.; Su, J.; Wang, H.; Boczkaj, G.; Mahlknecht, J.; Singh, S.V.; Wang, C. Bibliometric analysis of artificial intelligence in wastewater treatment: Current status, research progress, and future prospects. J. Environ. Chem. Eng. 2024, 12, 113152. [Google Scholar] [CrossRef]

- Palma, D.; Antela, K.U.; Prevot, A.B.; Cervera, M.L.; Morales-Rubio, A.; Sáez-Hernández, R. Artificial neural networks applied to photo-Fenton process: An innovative approach to wastewater treatment. Water Sci. Eng. 2025, 18, 324–334. [Google Scholar] [CrossRef]

- Yazdi, A.A.; Pirbazari, A.E.; Saraei, F.E.K.; Esmaeili, A.; Pirbazari, A.E.; Kohnehsari, A.A.; Derakhshesh, A. Design of 2D/2D β-Ni(OH)2/ZnO heterostructures via photocatalytic deposition of nickel for sonophotocatalytic degradation of tetracycline and modeling with three supervised machine learning algorithms. Chemosphere 2024, 352, 141328. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, D. An accurate detection method for surface defects of complex components based on support vector machine and spreading algorithm. Measurement 2019, 147, 106886. [Google Scholar] [CrossRef]

- Sheikhmohammadi, A.; Khakzad, P.; Rasolevandi, T.; Azarpira, H. Leveraging artificial intelligence models (GBR, SVR, and GA) for efficient chromium reduction via UV/trichlorophenol/sulfite reaction. Results Eng. 2025, 26, 104599. [Google Scholar] [CrossRef]

- Subramanian, Y.; Gajendiran, J.; Veena, R.; Azad, A.K.; Sabarish, V.B.; Muhammed Ali, S.; Kumar, A.; Gubendiran, R.K. Structural, photoabsorption and photocatalytic characteristics of BiFeO3-WO3 nanocomposites: An attempt to validate the experimental data through SVM-based Artificial Intelligence (AI). J. Electron. Mater. 2023, 52, 2421–2431. [Google Scholar] [CrossRef]

- Acosta-Angulo, B.; Lara-Ramos, J.; Niño-Vargas, A.; Diaz-Angulo, J.; Benavides-Guerrero, J.; Bhattacharya, A.; Cloutier, S.; Machuca-Martínez, F. Unveiling the potential of machine learning in cost-effective degradation of pharmaceutically active compounds: A stirred photo-reactor study. Chemosphere 2024, 358, 142222. [Google Scholar] [CrossRef]

- Patel, J.; Gaur, R.; Shahabuddin, S.; Padia, N.; Vakharia, V.; Suhas, P.; Tyagi, I. Predictive Modeling and Analysis of Photocatalytic Degradation Performance of Biochar-ZnO Nanocomposites on Different Agrochemicals. Int. J. Environ. Res. 2025, 19, 66. [Google Scholar] [CrossRef]

- Li, H. Support vector machine. In Machine Learning Methods; Springer: Berlin/Heidelberg, Germany, 2023; pp. 127–177. [Google Scholar]

- Okoye, P.C.; Azi, S.O.; Owolabi, T.O.; Adeyemi, O.W.; Souiyah, M.; Latif, M.B.; Olusayo, O. Modeling Energy Gap of Doped Tin (II) Sulfide Metal Semiconductor Nanocatalyst Using Genetic Algorithm-Based Support Vector Regression. J. Nanomater. 2022, 2022, 8211023. [Google Scholar] [CrossRef]

- Oyehan, T.; Liadi, M.; Alade, I. Modeling the efficiency of TiO2 photocatalytic degradation of MTBE in contaminated water: A support vector regression approach. SN Appl. Sci. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Mahmoodi, N.M.; Abdi, J.; Taghizadeh, M.; Taghizadeh, A.; Hayati, B.; Shekarchi, A.A.; Vossoughi, M. Activated carbon/metal-organic framework nanocomposite: Preparation and photocatalytic dye degradation mathematical modeling from wastewater by least squares support vector machine. J. Environ. Manag. 2019, 233, 660–672. [Google Scholar]

- Vaez, M.; Omidkhah, M.; Alijani, S.; Zarringhalam Moghaddam, A.; Sadrameli, M.; Gholipour Zanjani, N. Evaluation of photocatalytic activity of immobilized titania nanoparticles by support vector machine and artificial neural network. Can. J. Chem. Eng. 2015, 93, 1009–1016. [Google Scholar] [CrossRef]

- Azmil, A.S.; Majnis, M.F.; Adnan, M.A.M.; Ismail, S. Application of Artificial Neural Network for Accurate Prediction of Photocatalytic Dye Degradation. In Proceedings of the 2024 5th International Conference on Artificial Intelligence and Data Sciences (AiDAS), Bangkok, Thailand, 3–4 September 2024; pp. 1–6. [Google Scholar]

- Pravina, R.; Uthayakumar, H.; Sivasamy, A. Hybrid approach based on response surface methodology and artificial neural networks coupled with genetic algorithm (RSM-GA-ANN) for the Prediction and optimization for the Photodegradation of dye using nano ZnO anchored glass fiber under solar light irradiation. J. Taiwan Inst. Chem. Eng. 2023, 153, 105248. [Google Scholar]

- Moslehi, M.H.; Eslami, M.; Ghadirian, M.; Nateq, K.; Ramavandi, B.; Nasseh, N. Photocatalytic decomposition of metronidazole by zinc hexaferrite coated with bismuth oxyiodide magnetic nanocomposite: Advanced modelling and optimization with artificial neural network. Chemosphere 2024, 356, 141770. [Google Scholar] [CrossRef]

- Lianmawii, L.; Singh, N.M. Effect of additives on the photocatalytic degradation of malachite green using NiS:Tb3+ nanoparticle and their photoluminescence properties. J. Mol. Struct. 2025, 1320, 139748. [Google Scholar]

- Heydari, B.; Sharghi, E.A.; Rafiee, S.; Mohtasebi, S.S. Use of artificial neural network and adaptive neuro-fuzzy inference system for prediction of biogas production from spearmint essential oil wastewater treatment in up-flow anaerobic sludge blanket reactor. Fuel 2021, 306, 121734. [Google Scholar]

- Das, S.; Moon, S.; Kaur, R.; Sharma, G.; Kumar, P.; Lavrenčič Štangar, U. Artificial neural network modeling of photocatalytic degradation of pollutants: A review of photocatalyst, optimum parameters and model topology. Catal. Rev. 2024, 67, 544–578. [Google Scholar] [CrossRef]

- Hout, S.; Hamdi, L.; Sebti, A.; Laoufi, A. Experimental investigation and bio-inspired optimization of fixed bed photocatalytic reactor system for chlortoluron removal from water. Int. J. Environ. Sci. Technol. 2025, 1–18. [Google Scholar] [CrossRef]

- Nair, N.G.; Gandhi, V.G.; Modi, S.; Shukla, A.; Shah, K.J. Response Surface Methodology–Artificial Neural Network (RSM-ANN) Approach to Optimise Photocatalytic Degradation of Levofloxacin Using Graphene Oxide-Doped Titanium Dioxide (GO-TiO2). Water 2025, 17, 2362. [Google Scholar] [CrossRef]

- Kumari, P.; Devi, C.; Kumar, M.; Sharma, S.K.; Singh, R.P.; Yadav, K.; Yogesh, G.K. Leveraging machine learning for predicting the photocatalytic performance of a gC3N4/CdS/MoS2-based heterostructure nanocomposite. New J. Chem. 2025, 49, 10287–10308. [Google Scholar] [CrossRef]

- Akinola, A.O.; Prabakaran, E.; Govender, K.; Pillay, K. Magnetically-derived pecan nut shells for the adsorptive removal of cadmium: Artificial neural network modelling and photodegradation of sulfamethoxazole using the spent sorbent. J. Environ. Chem. Eng. 2025, 13, 118057. [Google Scholar] [CrossRef]

- Patel, J.; Parmar, M.; Shahabuddin, S.; Tyagi, I.; Gaur, R. Designing a Z-scheme rGO–SnS2 synergistic photocatalyst for photocatalytic mineralization of atrazine and 2, 4-dichlorophenoxyacetic acid and applying machine learning for predictive modelling of photocatalytic performance. Nanoscale Adv. 2025, 7, 3485–3507. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I.; Cheng, C.K.; Witoon, T. Modeling the effect of process parameters on the photocatalytic degradation of organic pollutants using artificial neural networks. Process Saf. Environ. Prot. 2021, 145, 120–132. [Google Scholar] [CrossRef]

- Das, L.; Maity, U.; Basu, J.K. The photocatalytic degradation of carbamazepine and prediction by artificial neural networks. Process Saf. Environ. Prot. 2014, 92, 888–895. [Google Scholar] [CrossRef]

- Sun, H.; Yan, K.; Yao, C.; Zhang, X.; Gao, Y.; Chen, Z. Feed forward neural network parametrization of the mean radiative properties of the mixture. J. Quant. Spectrosc. Radiat. Transf. 2023, 310, 108740. [Google Scholar] [CrossRef]

- Kassahun, S.K.; Kiflie, Z.; Kim, H.; Baye, A.F. Process optimization and kinetics analysis for photocatalytic degradation of emerging contaminant using N-doped TiO2-SiO2 nanoparticle: Artificial Neural Network and Surface Response Methodology approach. Environ. Technol. Innov. 2021, 23, 101761. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Nawaz, R.; Ikram, A.; Ishaq, Y.; Alothman, A.A.; Mohammad, S.; Anjum, M.; Arshad, U.; Baki, Z.A. TiO2-mediated visible-driven photocatalytic degradation of phenolic compounds: Predictive modeling and optimization via machine learning techniques. Chem. Eng. Commun. 2025, 212, 1–20. [Google Scholar] [CrossRef]

- Nedelkovski, V.; Radovanović, M.; Medić, D.; Stanković, S.; Hulka, I.; Tanikić, D.; Antonijević, M. Enhancing Wastewater Treatment Through Python ANN-Guided Optimization of Photocatalysis with Boron-Doped ZnO Synthesized via Mechanochemical Route. Processes 2025, 13, 2240. [Google Scholar] [CrossRef]

- Raudys, Š. On the universality of the single-layer perceptron model. In Proceedings of the Neural Networks and Soft Computing: Proceedings of the Sixth International Conference on Neural Networks and Soft Computing, Zakopane, Poland, 11–15 June 2002; Springer: Berlin/Heidelberg, Germany, 2003; pp. 79–86. [Google Scholar]

- Toennies, K.D. 7 multi-layer perceptron for image classification. In An Introduction to Image Classification: From Designed Models to End-to-End Learning; Springer: Berlin/Heidelberg, Germany, 2024; pp. 139–167. [Google Scholar]

- Goel, A.; Goel, A.K.; Kumar, A. Performance analysis of multiple input single layer neural network hardware chip. Multimed. Tools Appl. 2023, 82, 28213–28234. [Google Scholar] [CrossRef]

- da Costa Tavares, O.C.; Abidin, A.Z. Artificial Neural Network Multi-Layer Perceptron for Diagnosis of Diabetes Mellitus. JIKO 2024, 7, 19–23. [Google Scholar] [CrossRef]

- Essiet, I.O. Neural classification of good and bad food using a feed-forward multi-layer perceptron with supervised learning. J. Emerg. Trends Eng. Appl. Sci. 2014, 5, 61–65. [Google Scholar]

- Li, K.; Du, H.; Liu, L.; Yang, H.; Fang, J.; Li, D. Research progress of machine learning in the field of photocatalysis applications. J. Ind. Eng. Chem. 2025, in press. [Google Scholar] [CrossRef]

- Alsaffar, M.A.; Ayodele, B.V.; Ghany, M.A.A.; Mustapa, S.I. Modeling the photocatalytic degradation of 1, 2-Dihydroxybenzene using Multilayer Perceptron Neural Networks. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Assiut, Egypt, 11–12 February 2020; p. 012057. [Google Scholar]

- Al Haiqi, O.; Nour, A.H.; Ayodele, B.V.; Bargaa, R. Bayesian regularization-trained multi-layer perceptron neural network predictive modelling of phenol degradation using ZnO/Fe2O3 photocatalyst. J. Phys. Conf. Ser. 2019, 1529, 052058. [Google Scholar] [CrossRef]

- Lenzi, G.; Evangelista, R.; Duarte, E.; Colpini, L.; Fornari, A.; Neto, R.M.; Jorge, L.; Santos, O. Photocatalytic degradation of textile reactive dye using artificial neural network modeling approach. Desalination Water Treat. 2016, 57, 14132–14144. [Google Scholar] [CrossRef]

- Chow, V.; Phan, R.C.-W.; Le Ngo, A.C.; Krishnasamy, G.; Chai, S.-P. Data-driven photocatalytic degradation activity prediction with Gaussian process. Process Saf. Environ. Prot. 2022, 161, 848–859. [Google Scholar] [CrossRef]

- Arora, G.; Bala, K.; Emadifar, H.; Khademi, M. A review of radial basis function with applications explored. J. Egypt. Math. Soc. 2023, 31, 6. [Google Scholar] [CrossRef]

- Ng, K.H.; Gan, Y.; Cheng, C.K.; Liu, K.-H.; Liong, S.-T. Integration of machine learning-based prediction for enhanced Model’s generalization: Application in photocatalytic polishing of palm oil mill effluent (POME). Environ. Pollut. 2020, 267, 115500. [Google Scholar] [CrossRef]

- da Costa, M.F.; Araújo, R.d.S.; Silva, A.R.; Pereira, L.; Silva, G.M. Predictive artificial neural networks as applied tools in the remediation of dyes by adsorption—A review. Appl. Sci. 2025, 15, 2310. [Google Scholar] [CrossRef]

- Sargolzaei, J.; Hedayati Moghaddam, A.; Nouri, A.; Shayegan, J. Modeling the removal of phenol dyes using a photocatalytic reactor with SnO2/Fe3O4 nanoparticles by intelligent system. J. Dispers. Sci. Technol. 2015, 36, 540–548. [Google Scholar] [CrossRef]

- Ni, Y.; Xia, Z.; Kokot, S. A kinetic spectrophotometric method for simultaneous determination of phenol and its three derivatives with the aid of artificial neural network. J. Hazard. Mater. 2011, 192, 722–729. [Google Scholar] [CrossRef]

- Noman, E.A.; Al-Gheethi, A.A.; Alzaeemi, S.A.; Mohamed, R.M.S.R.; Gaik, T.K. Photocatalysis of low-density polyethylene using FKMW-ZnO NPs: Optimization and predication model using a radial basis function neural network ensemble system. Clean Technol. Environ. Policy 2024, 26, 2203–2218. [Google Scholar] [CrossRef]

- Aslam, M.; Lee, J.-M.; Kim, H.-S.; Lee, S.-J.; Hong, S. Deep learning models for long-term solar radiation forecasting considering microgrid installation: A comparative study. Energies 2019, 13, 147. [Google Scholar] [CrossRef]

- Pascanu, R.; Gulcehre, C.; Cho, K.; Bengio, Y. How to construct deep recurrent neural networks. arXiv 2013, arXiv:1312.6026. [Google Scholar]

- Lauria, S.; Saleh, M.F. Conditional recurrent neural networks for broad applications in nonlinear optics. Opt. Express 2024, 32, 5582–5591. [Google Scholar] [CrossRef] [PubMed]

- Jha, S.; Gaur, R.; Shahabuddin, S.; Vakharia, V.; Mohsin, M.E.A. Integration of RNN and CatBoost models in a tea-waste biochar filtration system for toxic organic pollutant removal efficiency prediction. RSC Adv. 2025, 15, 27260–27278. [Google Scholar] [CrossRef] [PubMed]

- Alonso, N.I. The Mathematics of Recurrent Neural Networks. 27 October 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5001243 (accessed on 8 September 2025).

- Jaffari, Z.H.; Abbas, A.; Lam, S.-M.; Park, S.; Chon, K.; Kim, E.-S.; Cho, K.H. Machine learning approaches to predict the photocatalytic performance of bismuth ferrite-based materials in the removal of malachite green. J. Hazard. Mater. 2023, 442, 130031. [Google Scholar] [CrossRef]

- Kumar, P.; Verma, S.; Kaur, R.; Papac, J.; Kušić, H.; Štangar, U.L. Enhanced photo-degradation of N-methyl-2-pyrrolidone (NMP): Influence of matrix components, kinetic study and artificial neural network modelling. J. Hazard. Mater. 2022, 434, 128807. [Google Scholar] [CrossRef]

- Song, C.; Shi, Y.; Li, M.; He, Y.; Xiong, X.; Deng, H.; Xia, D. Prediction of g-C3N4-based photocatalysts in tetracycline degradation based on machine learning. Chemosphere 2024, 362, 142632. [Google Scholar] [CrossRef]

- Navidpour, A.H.; Hosseinzadeh, A.; Huang, Z.; Li, D.; Zhou, J.L. Application of machine learning algorithms in predicting the photocatalytic degradation of perfluorooctanoic acid. Catal. Rev. 2024, 66, 687–712. [Google Scholar] [CrossRef]

- Hou, X.; Lu, H.; Wang, X.; Yu, Z.; Chen, C.; Xu, K.; Wu, H.; He, Y.; Pan, B. Predicting Photocatalytic Degradation Efficiency of Rhodamine: A Machine Learning-Based Model for Composite Catalyst Screening. J. Water Process Eng. 2025, 72, 107512. [Google Scholar]

- Dong, M.; Yao, L.; Wang, X.; Benatallah, B.; Zhang, S.; Sheng, Q.Z. Gradient boosted neural decision forest. IEEE Trans. Serv. Comput. 2021, 16, 330–342. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Wang, H.; Sun, Y.; Dong, F. Prediction and interpretation of photocatalytic NO removal on g-C3N4-based catalysts using machine learning. Chin. Chem. Lett. 2024, 35, 108596. [Google Scholar] [CrossRef]

- Ahmed, Y.; Dutta, K.R.; Nepu, S.N.; Prima, M.; AlMohamadi, H.; Akhtar, P. Optimizing photocatalytic dye degradation: A machine learning and metaheuristic approach for predicting methylene blue in contaminated water. Results Eng. 2025, 25, 103538. [Google Scholar] [CrossRef]

- Javed, M.F.; Shahab, M.Z.; Asif, U.; Najeh, T.; Aslam, F.; Ali, M.; Khan, I. Evaluation of machine learning models for predicting TiO2 photocatalytic degradation of air contaminants. Sci. Rep. 2024, 14, 13688. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. Xgboost: A scalable tree boosting system. In Proceedings of the 22nd Acm Sigkdd International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Abdi, J.; Hadipoor, M.; Hadavimoghaddam, F.; Hemmati-Sarapardeh, A. Estimation of tetracycline antibiotic photodegradation from wastewater by heterogeneous metal-organic frameworks photocatalysts. Chemosphere 2022, 287, 132135. [Google Scholar] [CrossRef]

- Sehrawat, P.; Kansal, Y.; Singhal, N.; Kansal, S.K. Implementation of machine learning models to predict the photocatalytic KTC drug degradation efficiency over Zn0.5Cd0.5S/MoS2 composite. J. Water Process Eng. 2025, 75, 108078. [Google Scholar] [CrossRef]

- Makumbura, R.K.; Mampitiya, L.; Rathnayake, N.; Meddage, D.; Henna, S.; Dang, T.L.; Hoshino, Y.; Rathnayake, U. Advancing water quality assessment and prediction using machine learning models, coupled with explainable artificial intelligence (XAI) techniques like shapley additive explanations (SHAP) for interpreting the black-box nature. Results Eng. 2024, 23, 102831. [Google Scholar] [CrossRef]

- Jaison, A.; Mohan, A.; Lee, Y.-C. Machine learning-enhanced photocatalysis for environmental sustainability: Integration and applications. Mater. Sci. Eng. R Rep. 2024, 161, 100880. [Google Scholar] [CrossRef]

- Mahapatra, D.M.; Kumar, A.; Kumar, R.; Gupta, N.K.; Ethiraj, B.; Singh, L. Artificial intelligence interventions in 2D MXenes-based photocatalytic applications. Coord. Chem. Rev. 2025, 529, 216460. [Google Scholar] [CrossRef]

- Park, J.; Ahn, J.; Kim, J.; Yoon, Y.; Park, J. Prediction and interpretation of water quality recovery after a disturbance in a water treatment system using artificial intelligence. Water 2022, 14, 2423. [Google Scholar] [CrossRef]

- Wang, D.; Thunéll, S.; Lindberg, U.; Jiang, L.; Trygg, J.; Tysklind, M. Towards better process management in wastewater treatment plants: Process analytics based on SHAP values for tree-based machine learning methods. J. Environ. Manag. 2022, 301, 113941. [Google Scholar] [CrossRef] [PubMed]

- Alizamir, M.; Wang, M.; Adnan Ikram, R.M.; Kim, S.; Ahmed, K.O.; Heddam, S. Developing an efficient explainable artificial intelligence approach for accurate reverse osmosis desalination plant performance prediction: Application of SHAP analysis. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2422060. [Google Scholar] [CrossRef]

- Nesfchi, M.M.; Pirbazari, A.E.; Saraei, F.E.K.; Rojaee, F.; Mahdavi, F.; Fa’al Rastegar, S.A. Fabrication of plasmonic nanoparticles/cobalt doped TiO2 nanosheets for degradation of tetracycline and modeling the process by artificial intelligence techniques. Mater. Sci. Semicond. Process. 2021, 122, 105465. [Google Scholar] [CrossRef]

- Oviedo, L.R.; Druzian, D.M.; Dalla Nora, L.D.; da Silva, W.L. Study of machine learning on the photocatalytic activity of a novel nanozeolite for the application in the Rhodamine B dye degradation. Catal. Today 2025, 443, 114986. [Google Scholar] [CrossRef]

- Khataee, A.; Kasiri, M. Artificial neural networks modeling of contaminated water treatment processes by homogeneous and heterogeneous nanocatalysis. J. Mol. Catal. A Chem. 2010, 331, 86–100. [Google Scholar] [CrossRef]

- Zaresefat, M.; Derakhshani, R. Revolutionizing groundwater management with hybrid AI models: A practical review. Water 2023, 15, 1750. [Google Scholar] [CrossRef]

- Hoshino, Y.; Rathnayake, N.; Dang, T.L.; Rathnayake, U. Cascaded-ANFIS and its successful real-world applications. In Fuzzy Logic Controllers and Applications; IntechOpen Limited: London, UK, 2024. [Google Scholar]

- Liang, Y.; Yin, Y.; Deng, Q.; Jiao, S.; Liang, X.; Huo, C.; Luo, Y. Efficient and easily recyclable photocatalytic reduction of Se (IV) from wastewater using stable TiO2/BiOBr/cloth: Mechanism insight and machine learning modeling. Sep. Purif. Technol. 2025, 352, 128021. [Google Scholar] [CrossRef]

- Tomic, A.; Jerkovic, M.; Kovacic, M.; Kovac, E.B.; Kušić, H.; Peternel, I.; Karamanis, P.; Rasulev, B.; Bozic, A.L. Robust simulation of advanced water treatment employing hybrid modeling approach. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Male, Maldives, 16–18 November 2022; pp. 1–5. [Google Scholar]

- Fidalgo, A.; Letichevsky, S.; Santos, B.F. Assessment of TiO2 band gap from structural parameters using artificial neural networks. J. Photochem. Photobiol. A Chem. 2021, 405, 112870. [Google Scholar] [CrossRef]

- Jarollahi, S.; Nabiyouni, G.; Sorinezami, Z.; Shabani, A. Synthesis and characterization of Fe3O4/TiO2/Ag magnetic nanocomposite with enhanced photocatalytic activity for methylene blue degradation and modeling by an artificial neural network (ANN). J. Nanostructures 2023, 13, 359–372. [Google Scholar]

- Chandrika, K.; Prabhu, T.N.; Kiran, R.S.; Krishna, R.H. Applications of artificial neural network and Box-Behnken Design for modelling malachite green dye degradation from textile effluents using TiO2 photocatalyst. Environ. Eng. Res. 2022, 27, 200553. [Google Scholar]

- Bhagwat, U.O.; Anandan, S.; Goel, S.; Al Souwaileh, A.; Wu, J.J.; Thirunavukarasu, V.; Anandan, S.; Ashokkumar, M. Bi-TiO2 nanomaterials in treating toxic water dye pollutants with Machine learning models. Opt. Mater. 2025, 167, 117231. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Afsharnasab, M.; Rasoulifard, M.H.; Tayebi Jebeli, M. Predicting of acid red 14 removals from synthetic wastewater in the advanced oxidation process using artificial neural networks and fuzzy regression. Rend. Lincei. Sci. Fis. E Nat. 2022, 33, 115–126. [Google Scholar] [CrossRef]

- Esmaeili, A.; Heydari Shalmani, S.; Ebrahimian Pirbazari, A.; Esmaeili Khalil Saraei, F.; Tabatabai-Yazdi, F.-S.; Ebrahimian Pirbazari, A.; Derakhshesh, A. Pharmaceutical wastewater treatment using TiO2 nanosheets deposited by cobalt co-catalyst as hybrid photocatalysts: Combined experimental study and artificial intelligence modeling. Chem. Prod. Process Model. 2023, 18, 611–631. [Google Scholar] [CrossRef]

- Caglar Gencosman, B.; Eker Sanli, G. Prediction of polycyclic aromatic hydrocarbons (PAHs) removal from wastewater treatment sludge using machine learning methods. Water Air Soil Pollut. 2021, 232, 87. [Google Scholar] [CrossRef]

- Ijadpanah-Saravi, H.; Safari, M.; Noruzi-Masir, B.; Darban, A.K.; Bakhshi, P. Intelligent tools to model photocatalytic degradation of beta-naphtol by titanium dioxide nanoparticles. J. Chemom. 2017, 31, e2907. [Google Scholar] [CrossRef]

- Sethi, S.; Dhir, A.; Arora, V. Intervention of artificial intelligence to predict the degradation and mineralization of amoxicillin through photocatalytic route using nickel phosphide-titanium dioxide catalyst. React. Kinet. Mech. Catal. 2023, 136, 549–565. [Google Scholar] [CrossRef]

- Kohzadi, S.; Bundschuh, M.; Rezaee, R.; Marzban, N.; Vahabzadeh, Z.; Johari, S.A.; Shahmoradi, B.; Amini, N.; Maleki, A. Integrating machine learning with experimental investigation for optimizing photocatalytic degradation of Rhodamine B using neodymium-doped titanium dioxide: A comprehensive approach with toxicity assessment. Environ. Sci. Pollut. Res. 2024, 31, 55301–55316. [Google Scholar] [CrossRef]

- Sebti, A.; Souahi, F.; Mohellebi, F.; Igoud, S. Experimental study and artificial neural network modeling of tartrazine removal by photocatalytic process under solar light. Water Sci. Technol. 2017, 76, 311–322. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Z.; Jin, C.; Zhang, J.X. Machine learning assisted dual-functional nanophotonic sensor for organic pollutant detection and degradation in water. Npj Clean Water 2024, 7, 3. [Google Scholar] [CrossRef]

- Saeed, M.H.; Kosar, N.; Hassan, S.-u.; Nadeem, S.; Mohammed, M.A.; Abd Ghani, M.K.; Abdulkareem, K.H. Determination of bandgap of period 3, 4, and 5 transition metal dopants on zinc oxide using an artificial neural network based approach. Chemom. Intell. Lab. Syst. 2023, 242, 104983. [Google Scholar] [CrossRef]

- Martínez-Vargas, B.L.; González Rodríguez, L.M.; Pacheco-Álvarez, M.; Peralta-Hernández, J.M.; Picos, A. Use of artificial intelligence models for the reduction of nanoparticle size in the synthesis of ZnO. J. Chem. Technol. Biotechnol. 2023, 98, 1868–1877. [Google Scholar] [CrossRef]

- Moradi, M.; Moradkhani, M.; Hosseini, S.; Olazar, M. Intelligent modeling of photocatalytically reactive yellow 84 azo dye removal from aqueous solutions by ZnO-light expanded clay aggregate nanoparticles. Int. J. Environ. Sci. Technol. 2023, 20, 3009–3022. [Google Scholar] [CrossRef]

- Tanasa, D.E.; Piuleac, C.G.; Curteanu, S.; Popovici, E. Photodegradation process of Eosin Y using ZnO/SnO2 nanocomposites as photocatalysts: Experimental study and neural network modeling. J. Mater. Sci. 2013, 48, 8029–8040. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Akbari, M. ZnO/Mg-Al layered double hydroxides as a photocatalytic bleaching of methylene orange—A black box modeling by artificial neural network. Bull. Chem. React. Eng. Catal. 2016, 11, 299–315. [Google Scholar] [CrossRef]

- Kahkha, M.R.R.; Piri, J. Comparison of Artificial Neural Network and Neutral-Fuzzy Inference System for photocatalytic removal of reactive red dye. Tech. J. Eng. Appl. Sci 2016, 6, 39–44. [Google Scholar]

- Reddy, B.; Maurya, A.; Narayana, P.; Pasha, S.K.; Reddy, M.; Hatshan, M.R.; Darwish, N.M.; Kori, S.; Cho, K.-K.; Reddy, N. Knowledge extraction of sonophotocatalytic treatment for acid blue 113 dye removal by artificial neural networks. Environ. Res. 2022, 204, 112359. [Google Scholar] [CrossRef] [PubMed]

- Orero, B.; Otieno, B.; Ntuli, F.; Lekgoba, T.; Ochieng, A. UV-photodegradation of R6G dye in three-phase fluidized bed reactor: Modeling and optimization using adaptive neuro-fuzzy inference system and artificial neural network. J. Water Process Eng. 2023, 56, 104453. [Google Scholar] [CrossRef]

- Abdollahi, Y.; Zakaria, A.; Abbasiyannejad, M.; Masoumi, H.R.F.; Moghaddam, M.G.; Matori, K.A.; Jahangirian, H.; Keshavarzi, A. Artificial neural network modeling of p-cresol photodegradation. Chem. Cent. J. 2013, 7, 96. [Google Scholar] [CrossRef]

- Esmaeili, A.; Kiadeh, S.P.H.; Pirbazari, A.E.; Saraei, F.E.K.; Pirbazari, A.E.; Derakhshesh, A.; Tabatabai-Yazdi, F.-S. CdS nanocrystallites sensitized ZnO nanosheets for visible light induced sonophotocatalytic/photocatalytic degradation of tetracycline: From experimental results to a generalized model based on machine learning methods. Chemosphere 2023, 332, 138852. [Google Scholar] [CrossRef]

- Qin, N.; Li, L.; Zheng, H.; Cui, Q. CdS with tunable crystalline phase structures: Controllable preparation and enhanced photocatalytic properties. Res. Chem. Intermed. 2023, 49, 5505–5516. [Google Scholar] [CrossRef]

- Sheng, C.K.; Aziz, N.A.B.; Alrababah, Y.M. Annealing temperature-dependent CdS phase tunability in improving photocatalytic efficiency towards aquatic dye decomposition. Results Mater. 2023, 19, 100445. [Google Scholar] [CrossRef]

- Rasoulifard, M.; Dorraji, M.S.; Amani-Ghadim, A.; Keshavarz-Babaeinezhad, N. Visible-light photocatalytic activity of chitosan/polyaniline/CdS nanocomposite: Kinetic studies and artificial neural network modeling. Appl. Catal. A Gen. 2016, 514, 60–70. [Google Scholar] [CrossRef]

- AttariKhasraghi, N.; Zare, K.; Mehrizad, A.; Modirshahla, N.; Behnajady, M.A. Zeolite 4A supported CdS/g-C3N4 type-II heterojunction: A novel visible-light-active ternary nanocomposite for potential photocatalytic degradation of cefoperazone. J. Mol. Liq. 2021, 342, 117479. [Google Scholar] [CrossRef]

- Tajmiri, S.; Azimi, E.; Hosseini, M.R.; Azimi, Y. Evolving multilayer perceptron, and factorial design for modelling and optimization of dye decomposition by bio-synthetized nano CdS-diatomite composite. Environ. Res. 2020, 182, 108997. [Google Scholar] [CrossRef]

- Firouzi, F.; Pirbazari, A.E.; Saraei, F.E.K.; Tabatabai-Yazdi, F.-S.; Esmaeili, A.; Khodaee, Z. Simultaneous adsorption-photocatalytic degradation of tetracycline by CdS/TiO2 nanosheets/graphene nanocomposites: Experimental study and modeling. J. Environ. Chem. Eng. 2021, 9, 106795. [Google Scholar] [CrossRef]

- Ataei, A.; Mehrizad, A.; Zare, K. Photocatalytic degradation of cefazoline antibiotic using zeolite-supported CdS/CaFe2O4 Z-scheme photocatalyst: Optimization and modeling of process by RSM and ANN. J. Mol. Liq. 2021, 328, 115476. [Google Scholar] [CrossRef]

- Gu, X.; Lin, S.; Qi, K.; Yan, Y.; Li, R.; Popkov, V.; Almjasheva, O. Application of tungsten oxide and its composites in photocatalysis. Sep. Purif. Technol. 2024, 345, 127299. [Google Scholar] [CrossRef]

- Mizar, K.; Mulyati, S.; Arahman, N. Synthesis of Tungsten Trioxide/Hydroxyapatite (WO3/HAp) Photocatalyst For Methylene Blue Degradation. Elkawnie J. Islam. Sci. Technol. 2023, 9, 99–110. [Google Scholar] [CrossRef]

- Li, J.; Luo, N.; Wang, Y.; Li, H.; Zhang, T.; Tang, X.; Hu, Z. Construction of photocatalyst by modification of argentum noble metal and hydrogen doping into WO3 nanoparticles: Enhancing the solar energy utilization. Fuel 2023, 352, 128966. [Google Scholar] [CrossRef]

- Abubakar, H.L.; Tijani, J.O.; Abdulkareem, A.S.; Egbosiuba, T.C.; Abdullahi, M.; Mustapha, S.; Ajiboye, E.A. Effective removal of malachite green from local dyeing wastewater using zinc-tungstate based materials. Heliyon 2023, 9, e19167. [Google Scholar] [CrossRef] [PubMed]

- Sheikhmohammadi, A.; Alamgholiloo, H.; Golaki, M.; Khakzad, P.; Asgari, E.; Rahimlu, F. Cefixime removal via WO3/Co-ZIF nanocomposite using machine learning methods. Sci. Rep. 2024, 14, 13840. [Google Scholar] [CrossRef] [PubMed]

- Kumar, U.; Arunachalam, A.; Feit, C.; Berriel, S.N.; Basu, K.; Banerjee, P.; Seal, S. Real-time artificial intelligence enhanced defect engineering in CeO2 nanostructures. J. Vac. Sci. Technol. A 2023, 41, 062409. [Google Scholar] [CrossRef]

- Fulzele, N.N.; Bhanvase, B.A.; Pandharipande, S.L. Sonochemically prepared rGO/Ag3PO4/CeO2 nanocomposite photocatalyst for effective visible light photocatalytic degradation of methylene dye and its prediction with ANN modeling. Mater. Chem. Phys. 2022, 292, 126809. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Farahani, M.D.; Far, H.S.; Lebouachera, S.E.I. Modeling of textile dye removal from aqueous solution with a Zr-MOF framework: Design of experiments and artificial neural network approaches. Emergent Mater. 2024, 7, 2583–2593. [Google Scholar] [CrossRef]

- da Silva, M.D.C.R.; Druzian, D.M.; Brum, L.F.W.; dos Santos, C.; Pavoski, G.; Espinosa, D.C.R.; Ruiz, Y.P.M.; Galembeck, A.; da Silva, W.L. Green synthesis of ZrO2/PdO-NPs for photodegradation of anionic dyes: Photocatalytic activity and machine learning modelling. J. Mol. Liq. 2024, 410, 125581. [Google Scholar] [CrossRef]

- Nademi, M.; Moradi, G.; Mansouri, M. A comprehensive study on the photocatalytic activity of CuO-doped ZrO2–ZnO nanocomposites under visible light. Inorg. Nano-Met. Chem. 2022, 52, 1383–1395. [Google Scholar] [CrossRef]

- Sethi, S.; Dhir, A.; Arora, V. Photocatalysis based hydrogen production and antibiotic degradation prediction using neural networks. React. Kinet. Mech. Catal. 2023, 136, 3283–3297. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A. Use, potential, needs, and limits of AI in wastewater treatment applications. Water 2025, 17, 170. [Google Scholar] [CrossRef]

- Mai, H.; Le, T.C.; Chen, D.; Winkler, D.A.; Caruso, R.A. Machine learning for electrocatalyst and photocatalyst design and discovery. Chem. Rev. 2022, 122, 13478–13515. [Google Scholar] [CrossRef] [PubMed]

- Ganthavee, V.; Fernando, M.M.; Trzcinski, A.P. Monte carlo simulation, artificial intelligence and machine learning-based modelling and optimization of three-dimensional electrochemical treatment of Xenobiotic Dye wastewater. Environ. Process. 2024, 11, 41. [Google Scholar] [CrossRef]

- Muhammad, R.; Mahboob, M.; Mustafa, K.; Khan, M.; Musaddiq, S.; Mahboob, R.M.S. Artificial Intelligence in Waste Management/Wastewater Treatment. In Omics for Environmental Engineering and Microbiology Systems; CRC Press: Boca Raton, FL, USA, 2022; pp. 493–507. [Google Scholar]

- Qiu, X. The application of artificial intelligence–artificial neural networks–in wastewater treatment. Proc. E3S Web Conf. 2023, 393, 03003. [Google Scholar] [CrossRef]

- Lowe, M.; Qin, R.; Mao, X. A review on machine learning, artificial intelligence, and smart technology in water treatment and monitoring. Water 2022, 14, 1384. [Google Scholar] [CrossRef]

- Hutchinson, M.; Antono, E.; Gibbons, B.; Paradiso, S.; Ling, J.; Meredig, B. Overcoming data scarcity with transfer learning. arXiv 2017, arXiv:1711.05099. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, J.; Tong, M.; Samia, A.C.; Zhang, H.; Yu, X. A novel machine learning model to predict the photo-degradation performance of different photocatalysts on a variety of water contaminants. Catalysts 2021, 11, 1107. [Google Scholar] [CrossRef]

| Sr# | Dopant | AI Model | Degradation Efficiency | Time | Reference |

|---|---|---|---|---|---|

| 1 | Sulfur–nitrogen codoped Fe2O3 nanostructure | ANN | 95% | 5 min | [90] |

| 2 | ZnO/MgO | ANN | 99% | 174 min | [91] |

| 3 | Nanoscale zero-valent iron (nZVI) | ANN | 100% | 30 min | [92] |

| 4 | Ho-CaWO4 nanoparticles | ANN | 71.17% | 15.16 min | [93] |

| 5 | Graphene oxide/chitosan (GO/CS) | ANN | 90.34% | 125 min | [94] |

| Platform/Tool | Type | Key Features | Application Areas | Ref (Accessed on 8 September 2025) |

|---|---|---|---|---|

| Materials Project | Database and ML Tools | Materials database based on DFT with machine learning methods for predicting properties | Battery materials, thermodynamic stability, and crystal structures | https://next-gen.materialsproject.org/ml |

| AFLOW | Framework and Database | Data production for material attributes that is automated | Analysis of mechanical properties, symmetry, and high-throughput screening | https://aflowlib.org/ |

| Citrination | AI/ML Platform | Materials discovery powered by machine learning (Citrine Informatics) | Material selection, property prediction, and process optimization | https://citrine.io/ |

| NOMAD | Repository and Toolkit | ML-ready data and analysis tools for materials | Analysis of electronic structures and dataset benchmarking | https://nomad-lab.eu/nomad-lab/ |

| Matminer | Python Library | Tools for materials data feature extraction and machine learning | Feature development and data mining | https://pypi.org/project/matminer/ |

| Atomate | Workflow Automation | Handles procedures for high quantities of materials | Electronic framework and synthesis path modeling | https://atomate.org/ |

| ASE | Python Library | Setting up and analyzing an atomic model | Simulations using DFT/MD and modeling of the manufacturing process | https://pypi.org/project/ase/ |

| MODNet | ML Model Framework | Property prediction using materials descriptors | Supervised learning from structured data | https://github.com/ZHKKKe/MODNet |

| DeepChem | ML Library | Deep learning in chemistry and materials science | Quantum chemistry and molecule/material property prediction | https://deepchem.io/ |

| Open Catalyst Project | Dataset + Model | ML models for catalyst discovery | Reaction energy prediction and catalyst screening | https://opencatalystproject.org/ |

| MEGNet | Graph Neural Network | GNN models for material property predictions | Prediction from atomic connectivity graphs | https://opencatalystproject.org/ |

| QMOF Database | Dataset + Models | Data about MOFs from quantum chemistry | Gas storage and electronic and thermal properties | https://github.com/Andrew-S-Rosen/QMOF |

| SISSO | Compressed Sensing ML Tool | Identifying descriptors using sparsifying agents | Predicting material efficiency with regression modeling | https://github.com/rouyang2017/SISSO |

| SchNetPack | Deep Learning Model | Learning fundamental interactions from start to finish | Dynamics of molecules and property forecasting | https://schnetpack.readthedocs.io/en/latest/ |

| TPOT | AutoML Tool | Optimizing ML pipelines with genetic programming | Predicting the behavior of materials and creating auto models | https://epistasislab.github.io/tpot/latest/ |

| Polymer Genome | ML Platform | ML for predicting polymer properties | Electrical power, thermal energy, and mechanical characteristics | https://www.polymergenome.org/ |

| BigSMILES | Polymer Representation | Polymer uniform representation for machine learning input | Modeling the structure and properties of polymers | https://olsenlabmit.github.io/BigSMILES/docs/line_notation.html |

| Framework/Tool | Type | Key Features | Use in Materials Science | Ref (Accessed on 8 September 2025) |

|---|---|---|---|---|

| Scikit-learn | ML Library (Python) | Traditional machine learning algorithms (e.g., SVM, RF, PCA) | Quick prototyping, grouping, regression, and classification | https://scikit-learn.org/stable/ |

| TensorFlow | Deep Learning Framework | Building neural networks and machine learning from scratch | Virtual models, GNNs, and deep neural networks for predicting properties | https://www.tensorflow.org/ |

| Keras | High-level DL API | Neural network protocol that is simple to use (TensorFlow as backend) | CNNs/RNNs for structure–property estimates and spectral information | https://keras.io/ |

| PyTorch | Deep Learning Framework | A flexible deep learning system based on graphs | GNNs and deep learning for simulated and structured recognition | https://pytorch.org/ |

| XGBoost | Gradient Boosting Framework | Effective gradient boosting for classification and regression | Quick and precise material property prediction | https://xgboost.ai/ |

| LightGBM | Gradient Boosting Framework | Acceleration and memory efficiency optimization | Predicting properties with high-dimensional information | https://lightgbm.readthedocs.io/en/stable/ |

| Auto-sklearn | AutoML Library | Hyperparameter-tuning and robotic machine learning | Quick creation of forecasting models | https://pypi.org/project/auto-sklearn/ |

| DGL | GNN Framework | Performing deep learning using graphs (supports PyTorch/TensorFlow) | Crystal framework and interatomic interactions modeling | https://www.dgl.ai/ |

| PyCaret | ML Library | ML model assessment and training made simpler | Rapid implementation of models and assessment | https://pycaret.org/ |

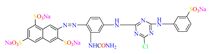

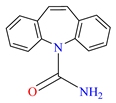

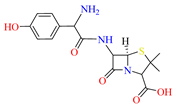

| Sr# | Pollutant Degraded | Structure of Pollutant | Catalyst | AI Method Used | Light Source | Factor Effects | Ref. |

|---|---|---|---|---|---|---|---|

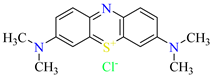

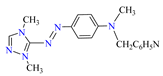

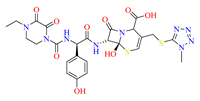

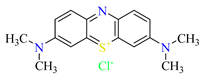

| 1 | Methylene Blue |  | Fe3O4TiO2 Ag magnetic nanocomposite | ANN | UV lamp | Initial dye concentration, pH, and temperature | [177] |

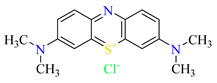

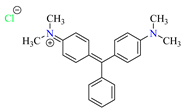

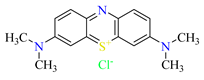

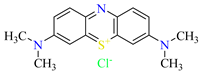

| 2 | Malachite green dye |  | TiO2 | ANN, BBD | UV light | Catalyst dosage, time, and initial dye concentration | [178] |

| 3 | Selenium Se (VI) | _ | TiO2BiOBr fabric | ANN, LSTM | Visible light | Machine learning models, recyclability, light, and catalyst stability | [174] |

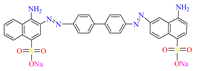

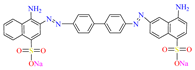

| 4 | Congo red |  | Bi–TiO2 nanomaterials | RF, GBDT, XG Boost | Visible light | Initial dye concentration, pH, and temperature | [179] |

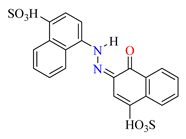

| 5 | Acid red 14 (AR14) |  | TiO2 | RBF, ANFIS | UV light | Irradiation time, flow rate, and catalyst concentration | [180] |

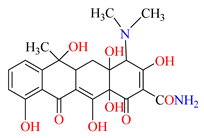

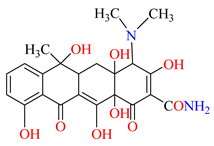

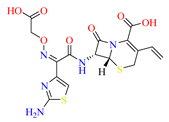

| 6 | Tetracycline (TC) |  | Cobalt atoms as a co-catalyst on TiO2 nanosheets | ANN, ANFIS | UV, visible light | Co catalyst dose, time of irradiation | [181] |

| 7 | Polycyclic aromatic hydrocarbons (PAHs) | _ | Rutile TiO2 | ANN | UV-C light | UV wavelength, temperature, and catalyst concentration | [182] |

| 8 | Beta-naphthol |  | (TiO2) NPs | ANN-PSO and ANFIS-PSO | UV light | Aeration rate, acidity, catalyst content, and impurity concentration | [183] |

| 9 | Amoxicillin (AMX) |  | Ni2P–TiO2 (NPT) | ANN | UV irradiation | pH, catalyst dose, and irradiation time | [184] |

| 10 | Rhodamine B (RhB) |  | Nd-TiO2 | ANN | UV light, solar light | Doping concentration, light source, presence of humic acid, and CaCl2 | [185] |

| 11 | Tartrazine |  | TiO2 | ANN | Solar light | pH, TiO2 concentration, initial pollutant concentration, and solar radiation intensity | [186] |

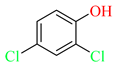

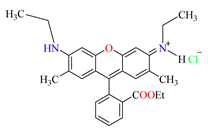

| 12 | 2,4-dichlorophenol (2,4-DCP) |  | (Fe3O4/TiO2/Ag), TiO2 | SGB, ANN, ANFIS, GA-ANFIS, PSO-ANFIS | UV, visible light | pH, temperature, light intensity, pollutant nature, and type of catalyst | [32] |

| 13 | Cetirizine hydrochloride |  | (Cu–TiO2) nanoparticles | SVM with IGWO | UV, visible light | Copper loading, solution pH, catalyst dosage, and initial pollutant concentration | [88] |

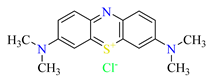

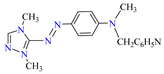

| Sr# | Pollutant Degraded | Structure of Pollutant | Catalyst | AI Method Used | Light Source | Factor Effect | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Methylene blue (MB) |  | ZnO/MgO | ANN | UV light | Catalyst dose, initial dye concentration level, and photodegradation time | [91] |

| 2 | Yellow 84 dye |  | (ZnO) NPs | (GPR), RBF, ANF, MLP | UV light | Catalyst dose, initial dye concentration level, and photodegradation time | [190] |

| 3 | Low-density polyethylene (LDPE) | _ | FKMW-ZnO NPs | RBFNNES | _ | Pollutant concentrations, catalyst concentrations, time, and pH | [145] |

| 4 | Eosin Y |  | ZnO/SnO2 nanocomposites | FFNN | UV light | Crystallite size, surface area, absorption edge, TOC values, time of reaction, and catalyst concentration | [191] |

| 5 | Methylene Orange |  | ZnO-MgAl layered double hydroxides | ANN | UV light | Temperature, irradiation time, catalyst amount, and dye concentration | [192] |

| 6 | Red dye |  | ZnO | ANN, ANFIS | UV light | pH, amount of ZnO, and initial dye concentration | [193] |

| 7 | Acid blue 113 (AB113) dye |  | ZnO | ANN | Ultrasound irradiation | Reaction time, pH, ZnO dosage, ultrasonic power, and persulphate dosage | [194] |

| 8 | Rhodamine 6G dye |  | TiO2-ZnO/BAC composite | ANFIS, ANN | UV light | Coupling of material, support of material, and light intensity | [195] |

| 9 | p-cresol |  | ZnO | ANN | UV irradiation | Irradiation time, pH, photocatalyst amount, and concentration of pollutant | [196] |

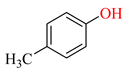

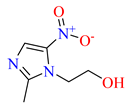

| 10 | Metronidazole (MNZ) |  | ZnFe12O19/BiOI nanocomposite | ANN | UV irradiation | Contaminant concentration, pH, nanocomposite dosage, and retention time | [115] |

| 11 | Pesticide photodegradation | _ | ZnO | CSA-LSSVM, RBF, PSO-ANFIS, MLP-ANN | UV, VIS light | Irradiation time, pH, light source, dopant mass proportion, catalyst dose, and starting pesticide concentration | [11] |

| 12 | Tetracycline |  | CdS/ZnO nanosheets | ANN and GBRT | VIS light | Temperature, pH, and light intensity | [197] |

| 13 | Phenol |  | ZnOFe2O3 | ANN, MLPNN | Solar irradiation | Initial pollutant concentration, photocatalyst dosage, photocatalysis irradiation time, and solution pH | [137] |

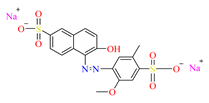

| Sr# | Pollutant Degraded | Structure of Pollutant | Catalyst | AI Method Used | Light Source | Factor Effect | Reference |

|---|---|---|---|---|---|---|---|

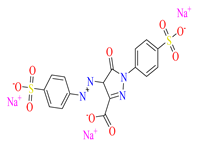

| 1 | Cefoperazone |  | CdSg-C3N4 | ANN | Visible light | pH, irradiation period, and catalyst dose | [201] |

| 2 | Methylene blue |  | Nano CdS diatomite | ANN | UV light | Composite weight, pH level, dye concentration, and light intensity | [202] |

| 3 | Reactive Blue 19 (RB19) |  | CS/PAni/CdS nanocomposite | ANN | Visible light | Light intensity and nanocomposite dosage | [200] |

| 4 | Tetracycline (TC) |  | CdS/ZnO nanosheets | ANN and GBRT | UV and ultrasonic light | Catalyst surface area and light source | [197] |

| 5 | Tetracycline (TC) |  | CdS/TiO2 nanosheets/graphene nanocomposites | ANN, ANFIS | Visible light | CdS molar ratio, surface area, and light intensity | [203] |

| 6 | Cefazoline (CFZ) |  | CdS-ZnFe2O4 nanocomposites | ANN | Visible light | pH, time, catalyst concentration, and pollutant concentration | [204] |

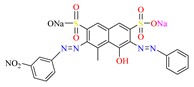

| Sr# | Pollutant Degraded | Structure of Pollutant | Catalyst | AI Method Used | Light Source | Factor Effect | Reference |

|---|---|---|---|---|---|---|---|

| 1 | Malachite green |  | ZnWO4 | ANN | Uv | pH, contact duration, nano adsorbent dosage, initial MG concentration, and temperature | [208] |

| 2 | Cefixime |  | WO3/Co-ZIF nanocomposite | ANN, SVR | UV | pH level, reaction time, and catalyst amount | [209] |

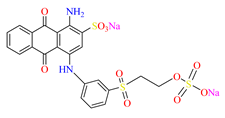

| 3 | Methylene blue (MB) |  | BiFeO3-WO3 nanocomposite | AI(SVM) | Sunlight | Light intensity, dye concentration, and temperature | [105] |

| 4 | Methylene blue (MB) |  | CuWO4@TiO2 | HGB model | UV | Light intensity, dye concentration, and temperature | [158] |

| Sr# | Pollutant Degraded | Structure of Pollutant | Catalyst | AI Method Used | Light Source | Factor Effect | Reference |

|---|---|---|---|---|---|---|---|

| 1 | Acid Orange 7 (AO7) dye |  | CeO2 | ANN | UV light | Reaction time and pH | [88] |

| 2 | Methylene blue (MB) dye |  | rGO/Ag3PO4/CeO2 nanocomposite | ANN | Visible light | Initial dye concentration, pH, reaction time, and temperature | [211] |

| 3 | Cefazoline (CFZ) |  | CdS-CaFe2O4-CP | ANN | Visible light | pH of the solution | [204] |

| Sr# | Pollutant Degraded | Structure of Pollutant | Catalyst | AI Method Used | Light Source | Factor Effect | Reference |

|---|---|---|---|---|---|---|---|

| 1 | Organic dyes * | _ | Zr-MOF | ANN | - | pH, contact time, MOF content, and dye concentration | [212] |

| 2 | Congo red |  | ZrO2/PdO-NPs | RF, XGB, GBR | Visible | pH, CR concentration, catalyst concentration, and irradiation time | [213] |

| 3 | Carbamazepine |  | TiO2/ZrO2 nano composite | ANN | UV radiation | Initial concentration of pollutant, pH of the solution, catalyst concentration, and time of UV irradiation | [125] |

| 4 | Basic red 46 |  | CuO-doped ZrO2–ZnO (ZZC) nanocomposites | ANN | LED visible irradiation | Initial concentration of pollutant, pH, time, and catalyst loading | [214] |

| 5 | Amoxicillin (AMX) |  | ZrO2 | ANN | UV light | pH, catalyst dose, and time | [215] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, A.; Iqbal, M.A.; Haider, M.T.; Majeed, A. Artificial Intelligence-Guided Supervised Learning Models for Photocatalysis in Wastewater Treatment. AI 2025, 6, 258. https://doi.org/10.3390/ai6100258

Rehman A, Iqbal MA, Haider MT, Majeed A. Artificial Intelligence-Guided Supervised Learning Models for Photocatalysis in Wastewater Treatment. AI. 2025; 6(10):258. https://doi.org/10.3390/ai6100258

Chicago/Turabian StyleRehman, Asma, Muhammad Adnan Iqbal, Mohammad Tauseef Haider, and Adnan Majeed. 2025. "Artificial Intelligence-Guided Supervised Learning Models for Photocatalysis in Wastewater Treatment" AI 6, no. 10: 258. https://doi.org/10.3390/ai6100258

APA StyleRehman, A., Iqbal, M. A., Haider, M. T., & Majeed, A. (2025). Artificial Intelligence-Guided Supervised Learning Models for Photocatalysis in Wastewater Treatment. AI, 6(10), 258. https://doi.org/10.3390/ai6100258