Milling Versus Printing: The Effect of Fabrication Technique on the Trueness and Fitness of Fabricated Crowns (A Comparative In Vitro Study)

Abstract

1. Introduction

2. Materials and Methods

2.1. Tooth Selection and Preparation

2.2. Digital Workflow

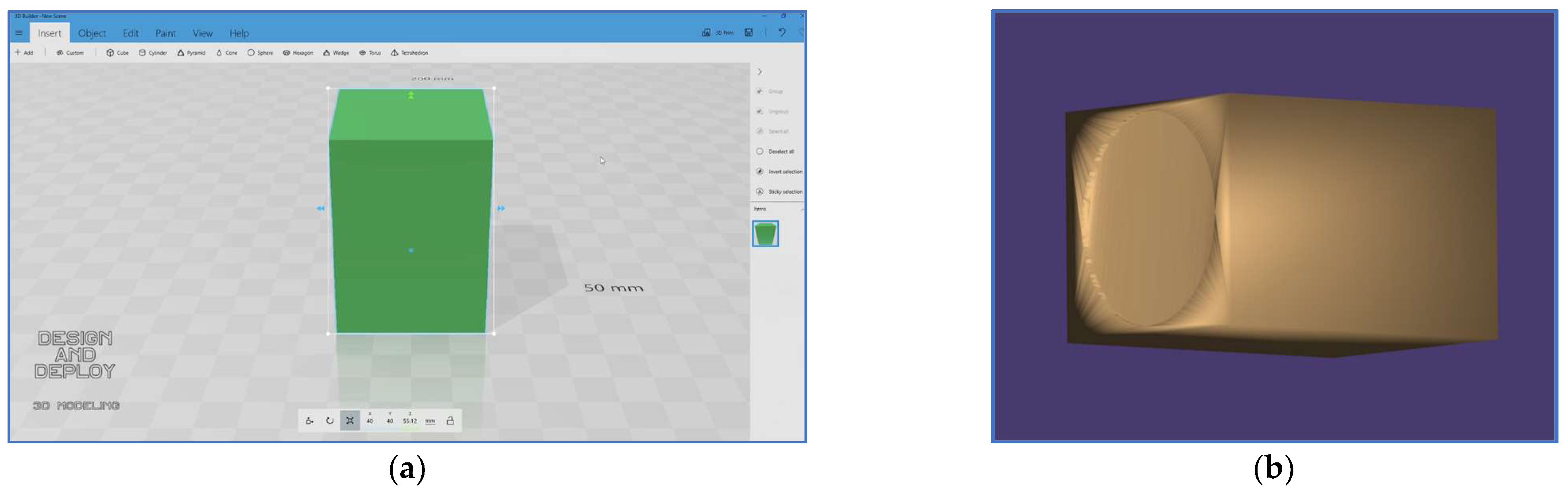

- Designing of CAD/CAM block

- B.

- Designing of crowns

- C.

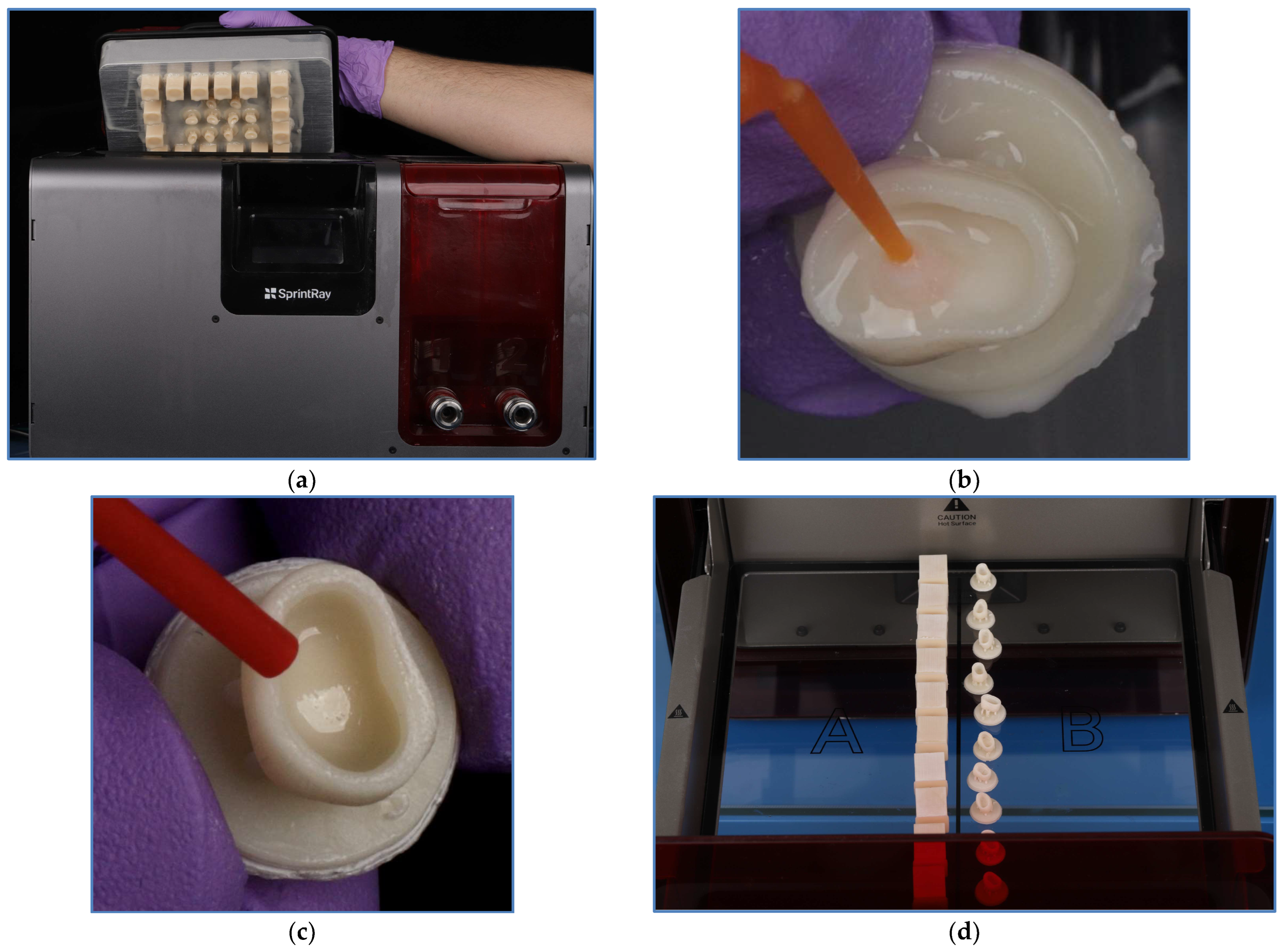

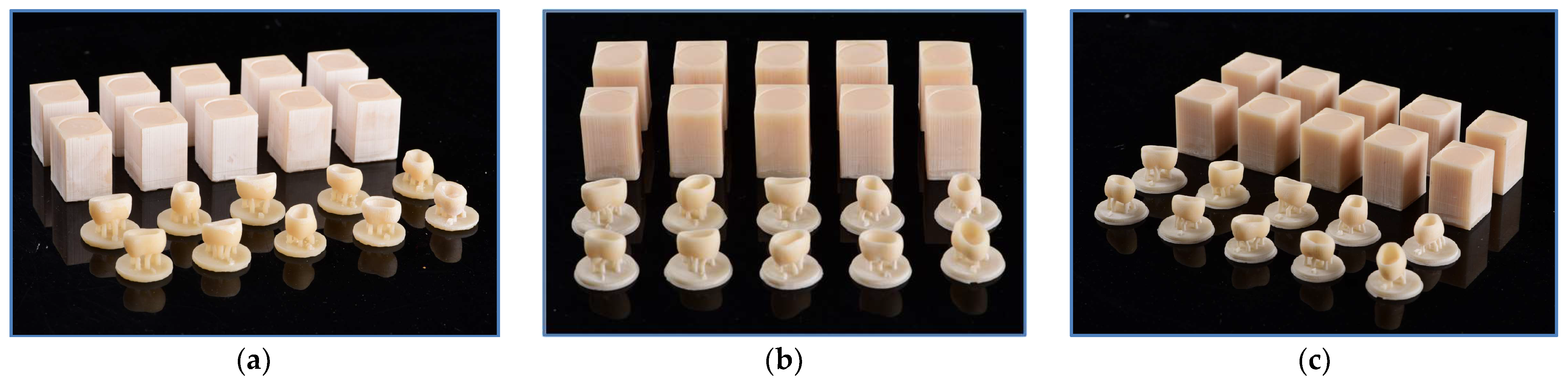

- Printing procedure

- D.

- Milling procedure

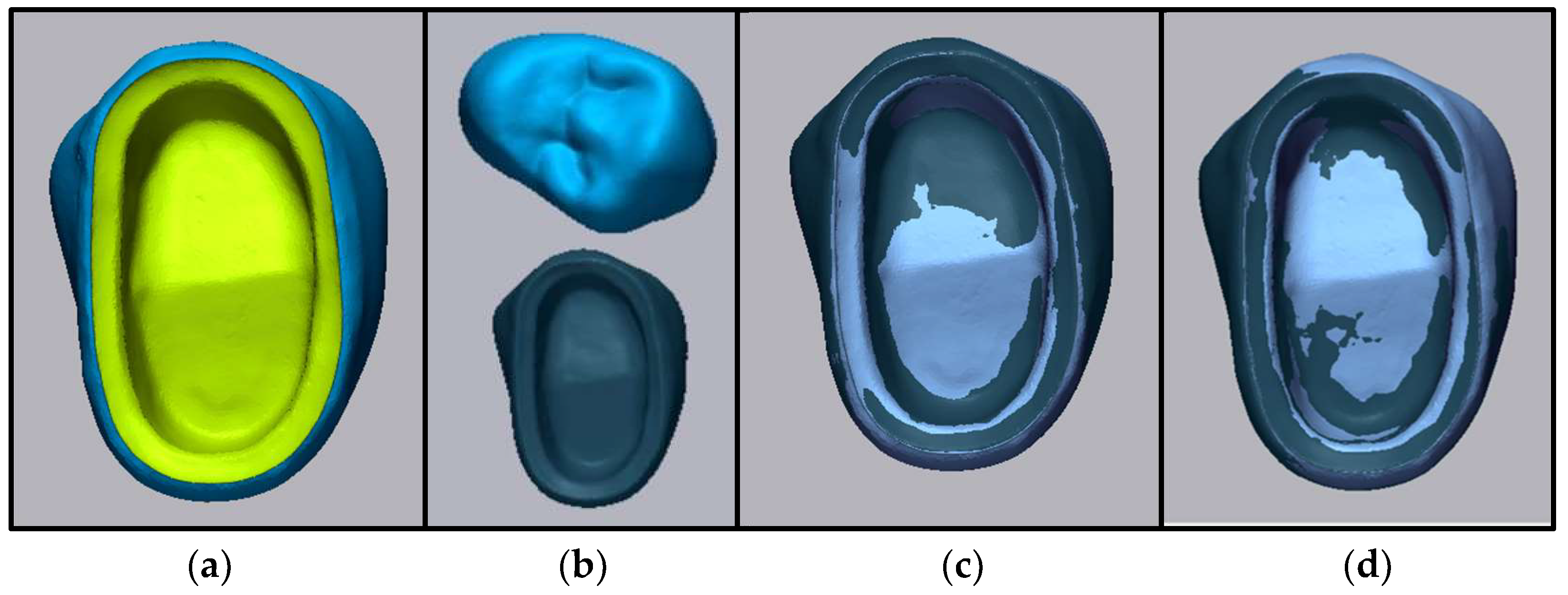

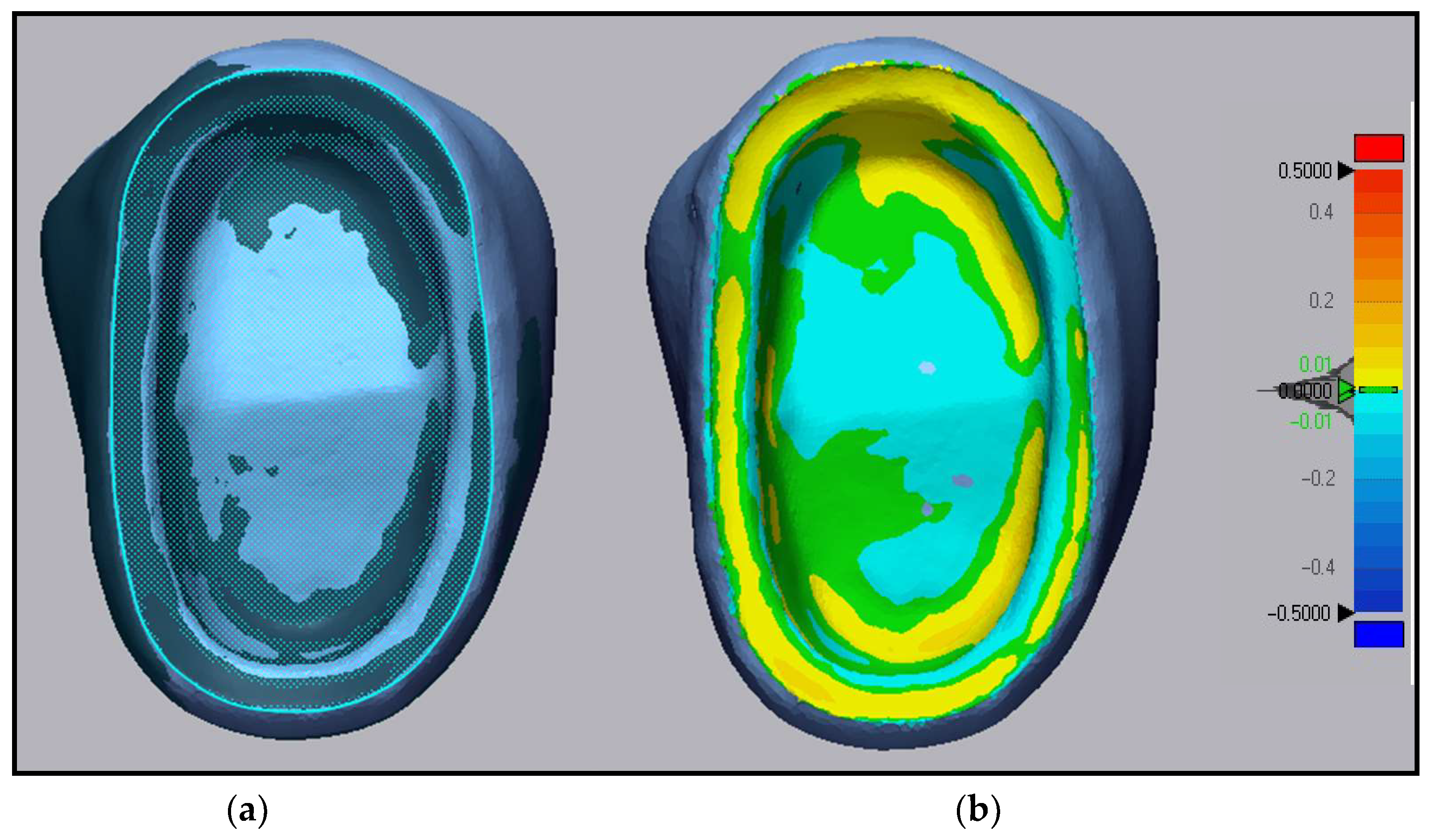

2.3. Trueness Evaluation

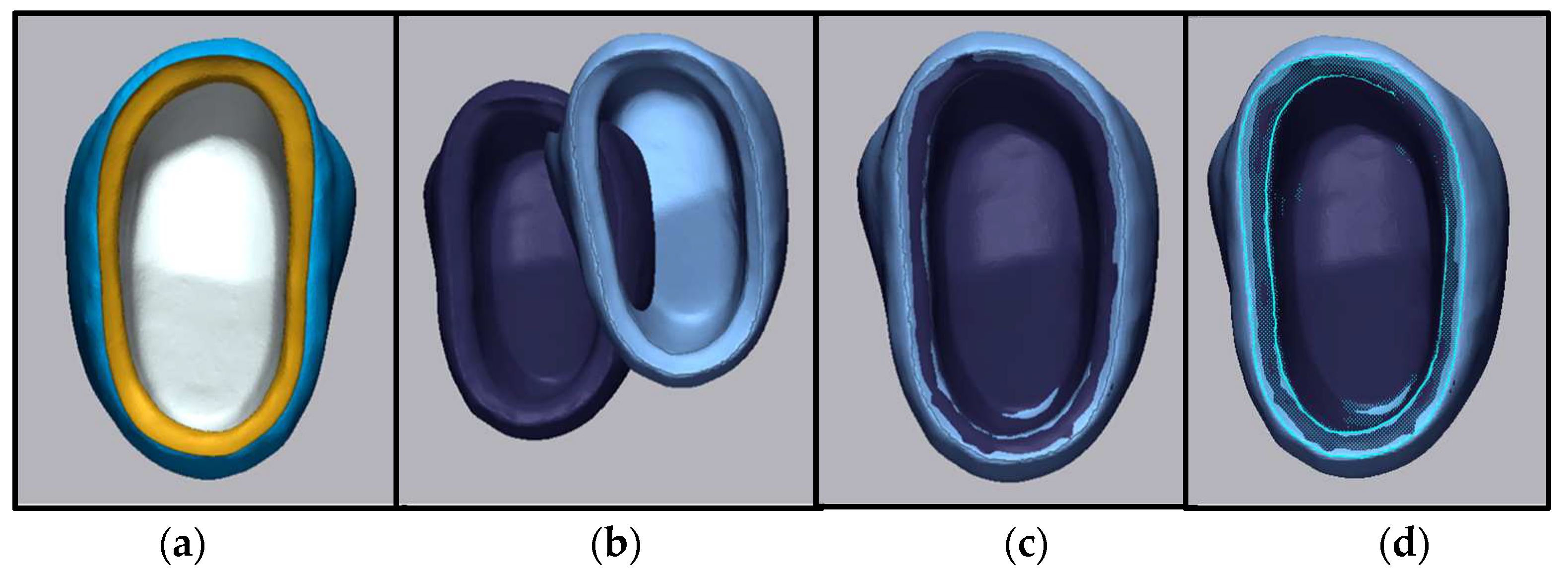

2.4. Internal and Marginal Gap Evaluation

2.5. Statistical Analysis

3. Results

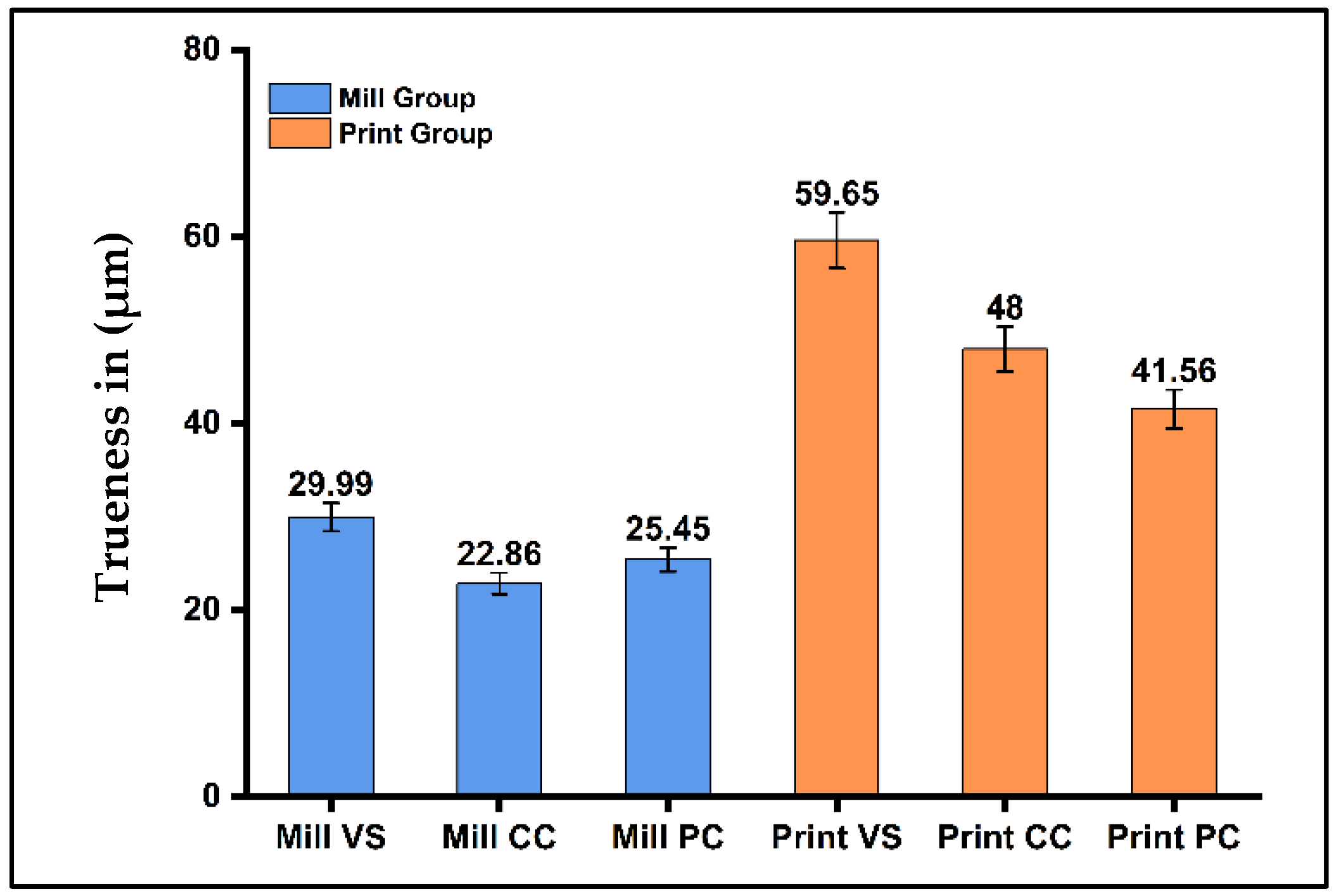

3.1. Trueness

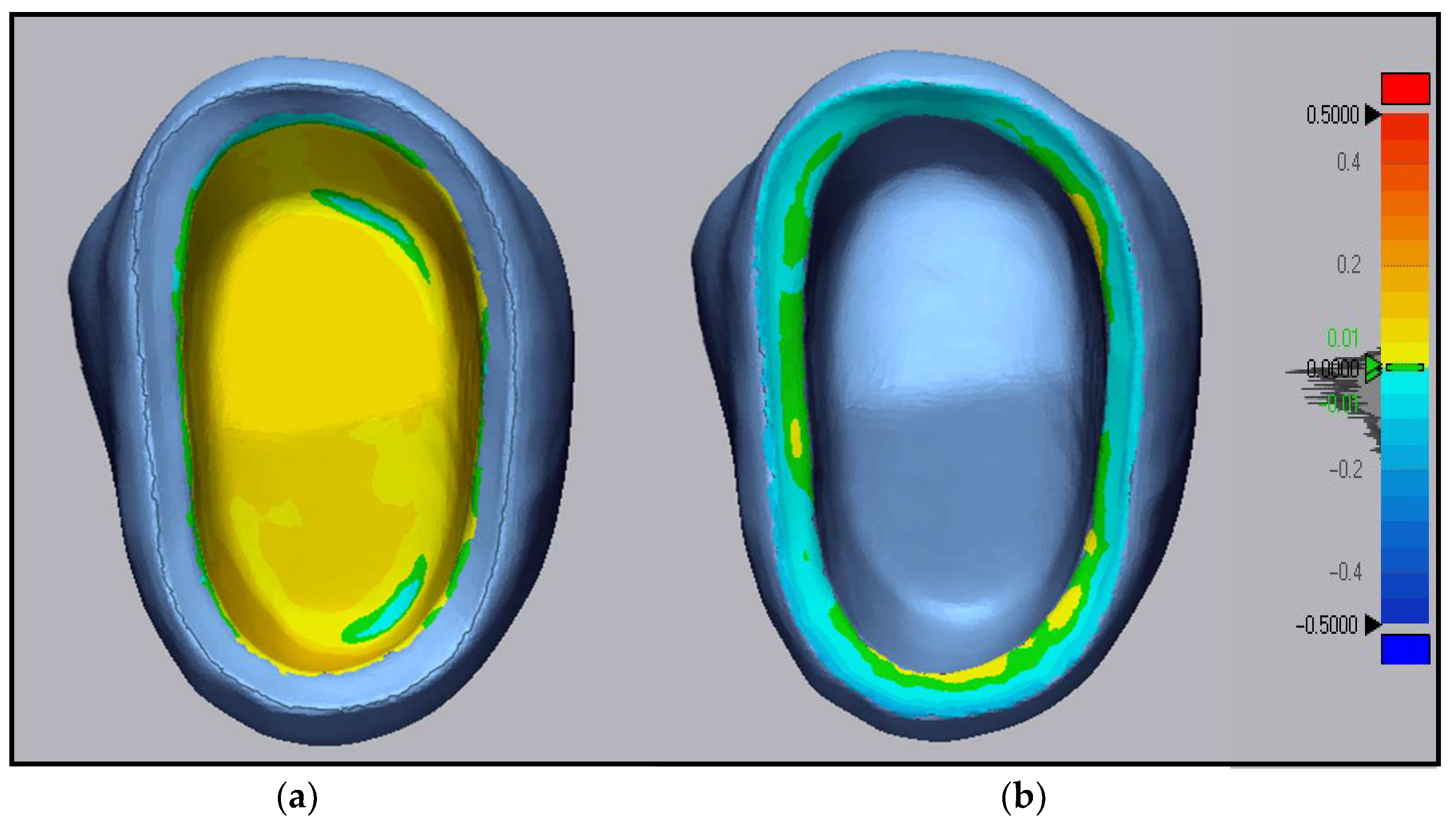

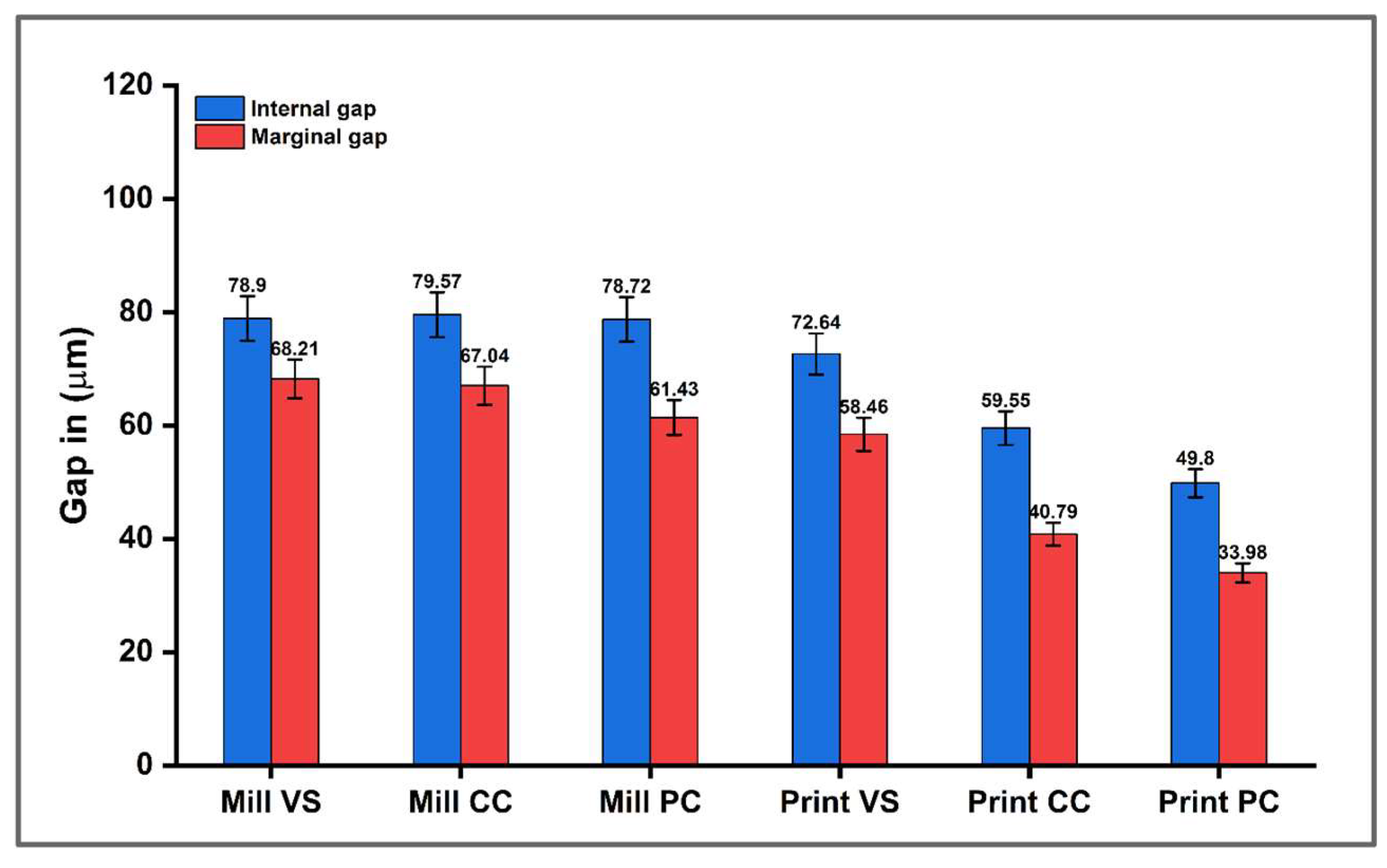

3.2. Internal and Marginal Gap

3.3. Correlation Between Trueness and Internal and Marginal Fitness

4. Discussion

Clinical Implications of the Current Research

5. Conclusions

- Regardless of the fabrication technique or material used, the mean values of trueness, internal gap, and marginal gap of all groups were all below the clinically acceptable limits. This finding supports the suitability of both additive and subtractive techniques for the fabrication of definitive dental restorations using hybrid ceramic materials.

- The fabrication technique had a significant influence on the trueness of the restorations in comparison to the type of material used.

- Subtractive technique produced crowns with significantly higher trueness than the crowns produced by additive technique across most materials.

- Additive technique produced crowns with significantly better internal and marginal fitness compared to the crowns produced by subtractive technique.

- The novel approach of using custom-milled blocks derived from printable resins followed in this study enabled a standardized comparison between both fabrication techniques. By using the same material in both workflows, the study successfully eliminated material-related variables.

- These findings may offer new insights for clinical applications of custom-milled blocks by expanding the versatility of printable materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, B.I.; You, S.G.; Lee, B.I.; You, S.M.; Kang, S.Y.; Kim, J.H. Effect of rinsing time on the accuracy of interim crowns fabricated by digital light processing: An in vitro study. J. Adv. Prosthodont. 2021, 13, 126. [Google Scholar] [CrossRef] [PubMed]

- Al Hamad, K.Q.; Al-Rashdan, R.B.; Al-Rashdan, B.A.; Baba, N.Z. Effect of milling protocols on trueness and precision of ceramic crowns. J. Prosthodont. 2021, 30, 171–176. [Google Scholar] [CrossRef]

- Falih, M.Y.; Majeed, M.A. Trueness and precision of eight intraoral scanners with different finishing line designs: A comparative in vitro study. Eur. J. Dent. 2023, 17, 1056–1064. [Google Scholar] [CrossRef]

- Revilla-León, M.; Methani, M.M.; Morton, D.; Zandinejad, A. Internal and marginal discrepancies associated with stereolithography (SLA) additively manufactured zirconia crowns. J. Prosthet. Dent. 2020, 124, 730–737. [Google Scholar] [CrossRef]

- Asady, A.M.; Al azzawi, H.J. A study to compare the internal fitness and marginal gap between single crowns and crowns within three-unite bridge of zirconia substructure fabricated by CAD-CAM system: An In vitro study. J. Baghdad Coll. Dent. 2017, 29, 27–31. [Google Scholar] [CrossRef]

- Saadallah, S.; Al-Azzawi, A.K.J. The Influence of Different Fabrication and Impression Techniques on the Marginal Adaptation of Lithium Disilicate Crowns: A Comparative in Vitro Study. J. Baghdad Coll. Dent. 2017, 29, 20–26. [Google Scholar] [CrossRef]

- Srimaneepong, V.; Heboyan, A.; Zafar, M.S.; Khurshid, Z.; Marya, A.; Fernandes, G.V.O.; Rokaya, D. Fixed prosthetic restorations and periodontal health: A narrative review. J. Funct. Biomater. 2022, 13, 15. [Google Scholar] [CrossRef]

- Hsu, Y.-T.; Huang, N.-C.; Wang, H.-L. Relationship between periodontics and prosthodontics: The two-way street. J. Prosthodont. Implantol. 2015, 4, 4–11. [Google Scholar]

- Abduo, J.; Lyons, K.; Bennamoun, M. Trends in computer-aided manufacturing in prosthodontics: A review of the available streams. Int. J. Dent. 2014, 2014, 783948. [Google Scholar] [CrossRef] [PubMed]

- Torabi, K.; Farjood, E.; Hamedani, S. Rapid prototyping technologies and their applications in prosthodontics, a review of literature. J. Dent. 2015, 16, 1. [Google Scholar]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.-S.; Jiang, H.B. A review of 3D printing in dentistry: Technologies, affecting factors, and applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef]

- Corbani, K.; Hardan, L.; Skienhe, H.; Özcan, M.; Alharbi, N.; Salameh, Z. Effect of material thickness on the fracture resistance and failure pattern of 3D-printed composite crowns. Int. J. Comput. Dent. 2020, 23, 225–233. [Google Scholar]

- Zimmermann, M.; Ender, A.; Egli, G.; Özcan, M.; Mehl, A. Fracture load of CAD/CAM-fabricated and 3D-printed composite crowns as a function of material thickness. Clin. Oral Investig. 2019, 23, 2777–2784. [Google Scholar] [CrossRef] [PubMed]

- Daher, R.; Ardu, S.; di Bella, E.; Krejci, I.; Duc, O. Efficiency of 3D printed composite resin restorations compared with subtractive materials: Evaluation of fatigue behavior, cost, and time of production. J. Prosthet. Dent. 2024, 131, 943–950. [Google Scholar] [CrossRef]

- Kakinuma, H.; Izumita, K.; Yoda, N.; Egusa, H.; Sasaki, K. Comparison of the accuracy of resin-composite crowns fabricated by three-dimensional printing and milling methods. Dent. Mater. J. 2022, 41, 808–815. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- AlGhamdi, M.A. Additively Fabricated Permanent Crown Materials: An Overview of Literature and Update. Prosthesis 2025, 7, 35. [Google Scholar] [CrossRef]

- Bonfante, E.A.; Calamita, M.; Bergamo, E.T.P. Indirect restorative systems—A narrative review. J. Esthet. Restor. Dent. 2023, 35, 84–104. [Google Scholar] [CrossRef]

- Abdulkareem, M.A.; Al-Shamma, A.M.W. Marginal adaptation and fracture resistance of 3D-printed and CAD/CAM-milled definitive resin matrix ceramic crowns. Int. J. Comput. Dent. 2024, 27, 355–363. [Google Scholar] [PubMed]

- Çakmak, G.; Donmez, M.B.; Cuellar, A.R.; Kahveci, Ç.; Schimmel, M.; Yilmaz, B. Additive or subtractive manufacturing of crown patterns used for pressing or casting: A trueness analysis. J. Dent. 2022, 124, 104221. [Google Scholar] [CrossRef] [PubMed]

- No-Cortes, J.; Ayres, A.P.; Lima, J.; Markarian, R.; Attard, N.; Cortes, A. Trueness, 3D Deviation, Time and Cost Comparisons Between Milled and 3D-Printed Resin Single Crowns. Eur. J. Prosthodont. Restor. Dent. 2021, 29, 107–112. [Google Scholar] [CrossRef]

- Suksuphan, P.; Krajangta, N.; Didron, P.P.; Wasanapiarnpong, T.; Rakmanee, T. Marginal adaptation and fracture resistance of milled and 3D-printed CAD/CAM hybrid dental crown materials with various occlusal thicknesses. J. Prosthodont. Res. 2024, 68, 326–335. [Google Scholar] [CrossRef]

- Hmedat, S.J.A.; Ibraheem, A.F. An in vitro evaluation of fit of the crowns fabricated by zirconium oxide-based ceramic CAD/CAM systems, before and after porcelain firing cycles and after glaze cycles. J. Baghdad Coll. Dent. 2013, 25, 43–48. Available online: https://jbcd.uobaghdad.edu.iq/index.php/jbcd/article/view/137 (accessed on 8 May 2025).

- Bego. Bego Manufactural Instructions; Bego: Bremen, Germany, 2020. [Google Scholar]

- SprintRay. SprintRay Manufactural Instructions; SprintRay: Los Angeles, CA, USA, 2023. [Google Scholar]

- Senertek. Senertek Manufactural Instructions; Senertek: İzmir, Turkey, 2022. [Google Scholar]

- Morón-Conejo, B.; Berrendero, S.; Bai, S.; Martínez-Rus, F.; Pradies, G. Fit comparison of interim crowns manufactured with open and proprietary 3D printing modes versus milling technology: An in vitro study. J. Esthet. Restor. Dent. 2024, 36, 1693–1703. [Google Scholar] [CrossRef] [PubMed]

- Ibraheem, A.F.; Abdulkareem, A.M. Comparison of the marginal fitness of the ceramic crowns fabricated with different CAD/CAM systems: An in vitro study. J. Baghdad Coll. Dent. 2016, 28, 28–33. [Google Scholar]

- Son, K.; Lee, K.-B. Effect of finish line locations of tooth preparation on the accuracy of intraoral scanners. Int. J. Comput. Dent. 2021, 24, 29–40. [Google Scholar] [PubMed]

- Kim, R.J.-Y.; Park, J.-M.; Shim, J.-S. Accuracy of 9 intraoral scanners for complete-arch image acquisition: A qualitative and quantitative evaluation. J. Prosthet. Dent. 2018, 120, 895–903. [Google Scholar] [CrossRef]

- Ali, S.; Majeed, M.A. Trueness of intraoral scanners: Its impact on the trueness and marginal and internal discrepancies of fabricated crowns: A comparative in vitro study. J. Int. Dent. Med. Res. 2024, 17, 1048–1055. [Google Scholar] [CrossRef]

- Jang, D.; Son, K.; Lee, K. A Comparative study of the fitness and trueness of a three-unit fixed dental prosthesis fabricated using two digital workflows. Appl. Sci. 2019, 9, 2778. [Google Scholar] [CrossRef]

- Al-Atyaa, Z.T.; Majeed, M.A. Comparative evaluation of the marginal and internal fitness of monolithic CAD/CAM zirconia crowns fabricated from different conventional impression techniques and digital impression using silicone replica technique: An in vitro study. Biomed. Pharmacol. J. 2018, 11, 477–490. [Google Scholar] [CrossRef]

- Abdulrahman, M.; Al-Adel, S. Evaluation of the marginal and internal fitness of full-contour CAD/CAM crowns made from zirconia, lithium disilicate, zirconia-reinforced lithium silicate and hybrid dental ceramic using silicone replica technique: A comparative in vitro study. J. Genet. Environ. Resour. Conserv. 2016, 4, 10–20. [Google Scholar]

- Razali, N.M.; Wah, Y.B. Power comparisons of shapiro-wilk, kolmogorov-smirnov, lilliefors and anderson-darling tests. J. Stat. Model. Anal. 2011, 2, 21–33. [Google Scholar]

- Dunn, O.J. Multiple comparisons using rank sums. Technometrics 1964, 6, 241–252. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using IBM SPSS Statistics; Sage Publications Limited: London, UK, 2024; ISBN 1529668700. [Google Scholar]

- Spearman, C. The Proof and Measurement of Association Between Two Things; Appleton-Century-Crofts: New York, NY, USA, 1961. [Google Scholar]

- Revilla-León, M.; Supaphakorn, A.; Barmak, A.B.; Rutkunas, V.; Kois, J.C. Influence of print orientation on the intaglio surface accuracy (trueness and precision) of tilting stereolithography definitive resin-ceramic crowns. J. Prosthet. Dent. 2023, 133, 246–251. [Google Scholar] [CrossRef] [PubMed]

- Çakmak, G.; Cuellar, A.R.; Donmez, M.B.; Abou-Ayash, S.; Lu, W.E.; Schimmel, M.; Yilmaz, B. Effect of printing layer thickness on the trueness of 3-unit interim fixed partial dentures. J. Prosthet. Dent. 2024, 131, 718–725. [Google Scholar] [CrossRef] [PubMed]

- Mosaddad, S.A.; Peláez, J.; Panadero, R.A.; Ghodsi, S.; Akhlaghian, M.; Suárez, M.J. Do 3D-printed and milled tooth-supported complete monolithic zirconia crowns differ in accuracy and fit? A systematic review and meta-analysis of in vitro studies. J. Prosthet. Dent. 2024, 133, 383–393. [Google Scholar] [CrossRef]

- Kim, C.-M.; Kim, S.-R.; Kim, J.-H.; Kim, H.-Y.; Kim, W.-C. Trueness of milled prostheses according to number of ball-end mill burs. J. Prosthet. Dent. 2016, 115, 624–629. [Google Scholar] [CrossRef]

- Cho, J.H.; Yoon, H.I.; Han, J.S.; Kim, D.J. Trueness of the inner surface of monolithic crowns fabricated by milling of a fully sintered (Y, Nb)-TZP block in chairside CAD-CAM system for single-visit dentistry. Materials 2019, 12, 3253. [Google Scholar] [CrossRef]

- Abualsaud, R.; Alalawi, H. Fit, Precision, and Trueness of 3D-Printed Zirconia Crowns Compared to Milled Counterparts. Dent. J. 2022, 10, 215. [Google Scholar] [CrossRef] [PubMed]

- Andriyani, M.; Harwasih, S.; Inayati, E. Fabrication Technique of Dental Restoration Using Hybrid Ceramic with CAD CAM Method. J. Vocat. Health Stud. 2017, 1, 32–38. Available online: https://e-journal.unair.ac.id/JVHS/article/view/6584 (accessed on 28 April 2025). [CrossRef]

- Refaie, A.; Bourauel, C.; Elshazly, T.; Evers-Dietze, B.; Alhotan, A.; Aldesoki, M. Trueness and precision of digital light processing fabricated 3D printed monolithic zirconia crowns. J. Dent. 2024, 148, 105151. [Google Scholar] [CrossRef]

- Wang, W.; Yu, H.; Liu, Y.; Jiang, X.; Gao, B. Trueness analysis of zirconia crowns fabricated with 3-dimensional printing. J. Prosthet. Dent. 2019, 121, 285–291. Available online: https://www.sciencedirect.com/science/article/pii/S0022391318303500 (accessed on 1 May 2025). [CrossRef]

- Choi, J.W.; Ahn, J.J.; Son, K.; Huh, J.B. Three-dimensional evaluation on accuracy of conventional and milled gypsum models and 3D printed photopolymer models. Materials 2019, 12, 3499. [Google Scholar] [CrossRef]

- Al-Ramadan, A.; Abualsaud, R.; Al-Dulaijan, Y.A.; Al-Thobity, A.M.; Alalawi, H. Accuracy and Fit of Ceramic Filled 3D-Printed Resin for Permanent Crown Fabrication: An In Vitro Comparative Study. Prosthesis 2024, 6, 1029–1041. [Google Scholar] [CrossRef]

- Lim, Y.A.; Kim, J.M.; Choi, Y.; Park, S. Evaluation of Fitness and Accuracy of Milled and Three-Dimensionally Printed Inlays. Eur. J. Dent. 2023, 17, 1029–1036. [Google Scholar] [CrossRef]

- Lerner, H.; Nagy, K.; Pranno, N.; Zarone, F.; Admakin, O.; Mangano, F. Trueness and precision of 3D-printed versus milled monolithic zirconia crowns: An in vitro study. J. Dent. 2021, 113, 103792. [Google Scholar] [CrossRef] [PubMed]

- Noh, M.; Lee, H.; Lee, W.; Kim, J.; Kim, J. Evaluation of Internal and Marginal Accuracy (Trueness and Precision) of Laminates Using DLP Printing and Milling Methods. Biomimetics 2025, 10, 67. [Google Scholar] [CrossRef]

- da Silva, S.E.G.; da Silva, N.R.; Santos, J.V.d.N.; Moreira, F.G.d.G.; Özcan, M.; Souza, R.O.d.A.e. Accuracy, adaptation and margin quality of monolithic zirconia crowns fabricated by 3D printing versus subtractive manufacturing technique: A systematic review and meta-analysis of in vitro studies. J. Dent. 2024, 147, 105089. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0300571224002586?via%3Dihub (accessed on 30 April 2025). [CrossRef] [PubMed]

- Lee, H.B.; Noh, M.J.; Bae, E.J.; Lee, W.S.; Kim, J.H. Accuracy of zirconia crown manufactured using stereolithography and digital light processing. J. Dent. 2024, 141, 104834. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0300571224000046?via%3Dihub (accessed on 30 April 2025). [CrossRef]

- Xiao, P.; Zheng, Z.; Zhang, Y.; Zeng, Y.; Yan, W. Accuracy and adaptation of one-piece endodontic crowns fabricated through 3D printing and milling. J. Prosthet. Dent. 2024, 132, 422–433. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0022391324003639 (accessed on 30 April 2025). [CrossRef] [PubMed]

- Son, K.J.-M.L. Marginal and Internal Fit and Intaglio Surface Trueness of Temporary Crowns Fabricated with Stereolithography, Digital Light Processing, and Milling Technology. Int. J. Prosthodont. 2022, 35, 697–701. [Google Scholar] [CrossRef]

- Revilla-León, M.; Özcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef]

- Baig, M.R.; Akbar, A.A.; Sabti, M.Y.; Behbehani, Z. Evaluation of Marginal and Internal Fit of a CAD/CAM Monolithic Zirconia-Reinforced Lithium Silicate Porcelain Laminate Veneer System. J. Prosthodont. Off. J. Am. Coll. Prosthodont. 2022, 31, 502–511. [Google Scholar] [CrossRef]

- Borges, G.A.; Sophr, A.M.; De Goes, M.F.; Sobrinho, L.C.; Chan, D.C.N. Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J. Prosthet. Dent. 2003, 89, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Hoang, L. Accuracy and Precision of Die Spacer Thickness with Combined Computer-Aided Design and 3-D Printing Technology. Master’s Thesis, Marquette University, Milwaukee, WI, USA, 2014. [Google Scholar]

- Baig, M.R.; Tan, K.B.C.; Nicholls, J.I. Evaluation of the marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J. Prosthet. Dent. 2010, 104, 216–227. [Google Scholar] [CrossRef] [PubMed]

- Santos, M.; Navarro, M.F.; Tam, L.; McComb, D. The effect of dentin adhesive and cure mode on film thickness and microtensile bond strength to dentin in indirect restorations. Oper. Dent. 2005, 30, 50. [Google Scholar]

- Mosa, M.O.; Ibraheem, A.F.; Hussein, H.M. Effect of Marginal Cement Space Thickness and Type of Zirconia on the Marginal and Internal Fit of 3-Unit Monolithic Fixed Dental Prosthesis: An In Vitro Study; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar]

- Bindl, A.; Mörmann, W.H. Marginal and internal fit of all-ceramic CAD/CAM crown-copings on chamfer preparations. J. Oral Rehabil. 2005, 32, 441–447. [Google Scholar] [CrossRef]

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef]

- Su, S.; Dudley, J. The marginal gaps of lithium disilicate crowns constructed by different scanner and milling unit combinations. Aust. Dent. J. 2022, 67, 125–131. [Google Scholar] [CrossRef]

- Rödiger, M.; Schneider, L.; Rinke, S. Influence of material selection on the marginal accuracy of CAD/CAM-fabricated metal- and all-ceramic single crown copings. BioMed Res. Int. 2018, 2018, 2143906. [Google Scholar] [CrossRef]

| Properties | Varseosmile Crown Plus (VS) | Ceramic Crown (CC) | P-Crown V2 Ceramic (PC) |

|---|---|---|---|

| Ceramic content | Inorganic fillers account for 30–50% of the mass. | More than 50% of the mass. | 65% nanoceramic rate. |

| Chemical composition | Esterification products of 4.4′-isopropylidiphenol, ethoxylated and 2-methylprop-2-enoic acid. Silanized dental glass, methyl benzoylformate, diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide. | Oligomers (20–60%), Monomers (20–50%), Photoinitiators (0.1–10%), Additives (10–60%). The specific chemical identity is withheld because it is trade secret information of SprintRay. | Polymer matrix and Inorganic fillers. The specific chemical identity is withheld because it is trade secret information of Senertek. |

| Flexural Strength | 116–150 MPa | 150 ± 25 MPa | 410.00 MPa |

| Flexural Modulus | 4090 MPa | 7800 ± 500 MPa | >9500 MPa |

| Hardness | ≥90 Shore D | ≥90 Shore D | ≥95 Shore D |

| Water Solubility | <1 µg/mm3 | 2.16 ± 1.30 µg/mm3 | <0.09 µg/mm3 |

| Water sorption | <12 µg/mm3 | 17.35 ± 2.56 µg/mm3 | <1.2 µg/mm3 |

| Viscosity | 2500–6000 mPa*s | 2500–6000 mPa*s | ~3500 mPa*s |

| LOT number | 600721 | SRI-0202086 | SNR202300030 |

| Groups | Subgroups Mean ± SD | ||

|---|---|---|---|

| Mill | Mill VS 29.99 ± 3.98 aA | Mill CC 22.86 ± 2.49 aA | Mill PC 25.45 ± 1.91 aA |

| Print VS 59.65 ± 4.7 bA | Print CC 48 ± 4.92 bA | Print PC 41.56 ± 4.83 aA | |

| Groups | Subgroups Internal Gap Mean ± SD | Subgroups Marginal Gap Mean ± SD | ||||

|---|---|---|---|---|---|---|

| Mill | Mill VS 78.9 ± 5.02 aA | Mill CC 79.57 ± 4.59 aA | Mill PC 78.72 ± 4.74 aA | Mill VS 68.21 ± 6.38 aA | Mill CC 67.04 ± 6.46 aA | Mill PC 61.43 ± 5.72 aA |

| Print VS 72.64 ± 5.74 aA | Print CC 59.55 ± 6.81 bB | Print PC 49.8 ± 6.63 bC | Print VS 58.46 ± 8.44 bA | Print CC 40.79 ± 7.54 bB | Print PC 33.98 ± 7.23 bB | |

| Variable | Spearman’s Corr. | p-Value | Interpretation |

|---|---|---|---|

| Internal | −0.77 | 0.0004 | significant |

| Marginal | −0.78 | 0.0001 | significant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.H.; Majeed, M.A. Milling Versus Printing: The Effect of Fabrication Technique on the Trueness and Fitness of Fabricated Crowns (A Comparative In Vitro Study). Prosthesis 2025, 7, 107. https://doi.org/10.3390/prosthesis7050107

Ali MH, Majeed MA. Milling Versus Printing: The Effect of Fabrication Technique on the Trueness and Fitness of Fabricated Crowns (A Comparative In Vitro Study). Prosthesis. 2025; 7(5):107. https://doi.org/10.3390/prosthesis7050107

Chicago/Turabian StyleAli, Mohammed Hassen, and Manhal A. Majeed. 2025. "Milling Versus Printing: The Effect of Fabrication Technique on the Trueness and Fitness of Fabricated Crowns (A Comparative In Vitro Study)" Prosthesis 7, no. 5: 107. https://doi.org/10.3390/prosthesis7050107

APA StyleAli, M. H., & Majeed, M. A. (2025). Milling Versus Printing: The Effect of Fabrication Technique on the Trueness and Fitness of Fabricated Crowns (A Comparative In Vitro Study). Prosthesis, 7(5), 107. https://doi.org/10.3390/prosthesis7050107