The Effect of Extrinsic Staining on 3D Printed Provisional Crowns

Abstract

1. Introduction

2. Materials and Methods

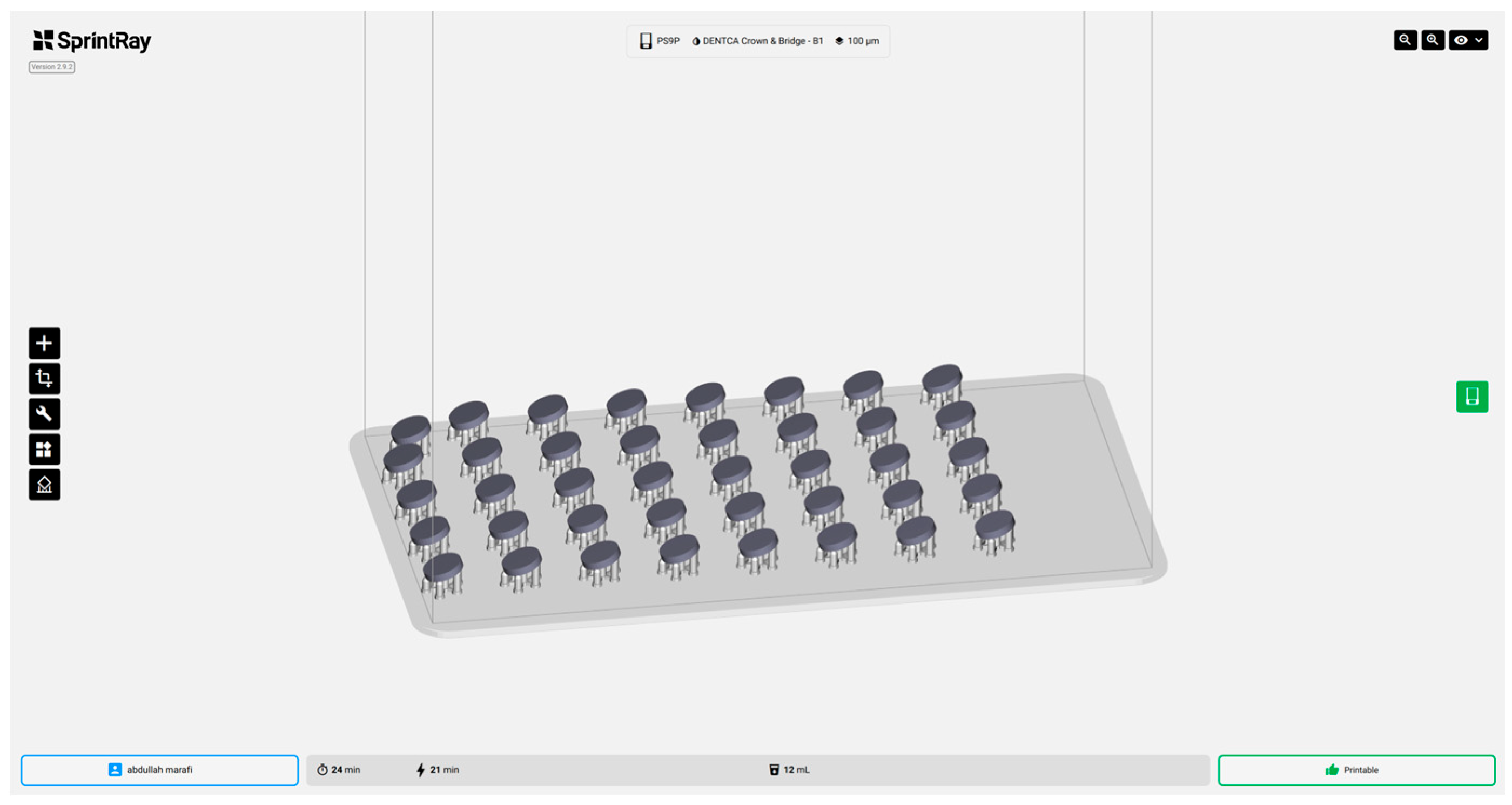

2.1. Designing and Printing

2.2. Specimen Grouping and Solution Selection

2.3. Data Collection

2.4. Statistical Analysis

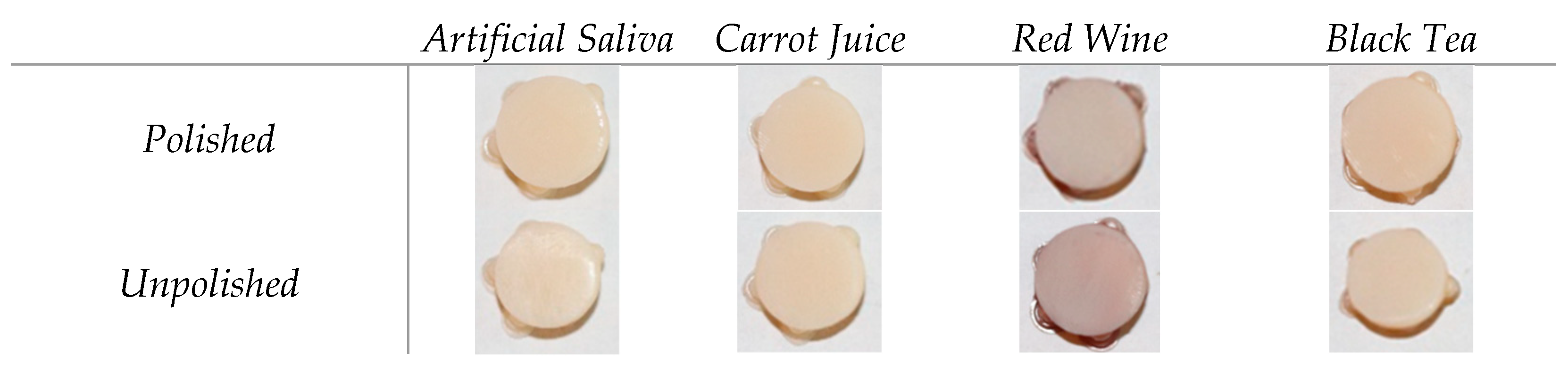

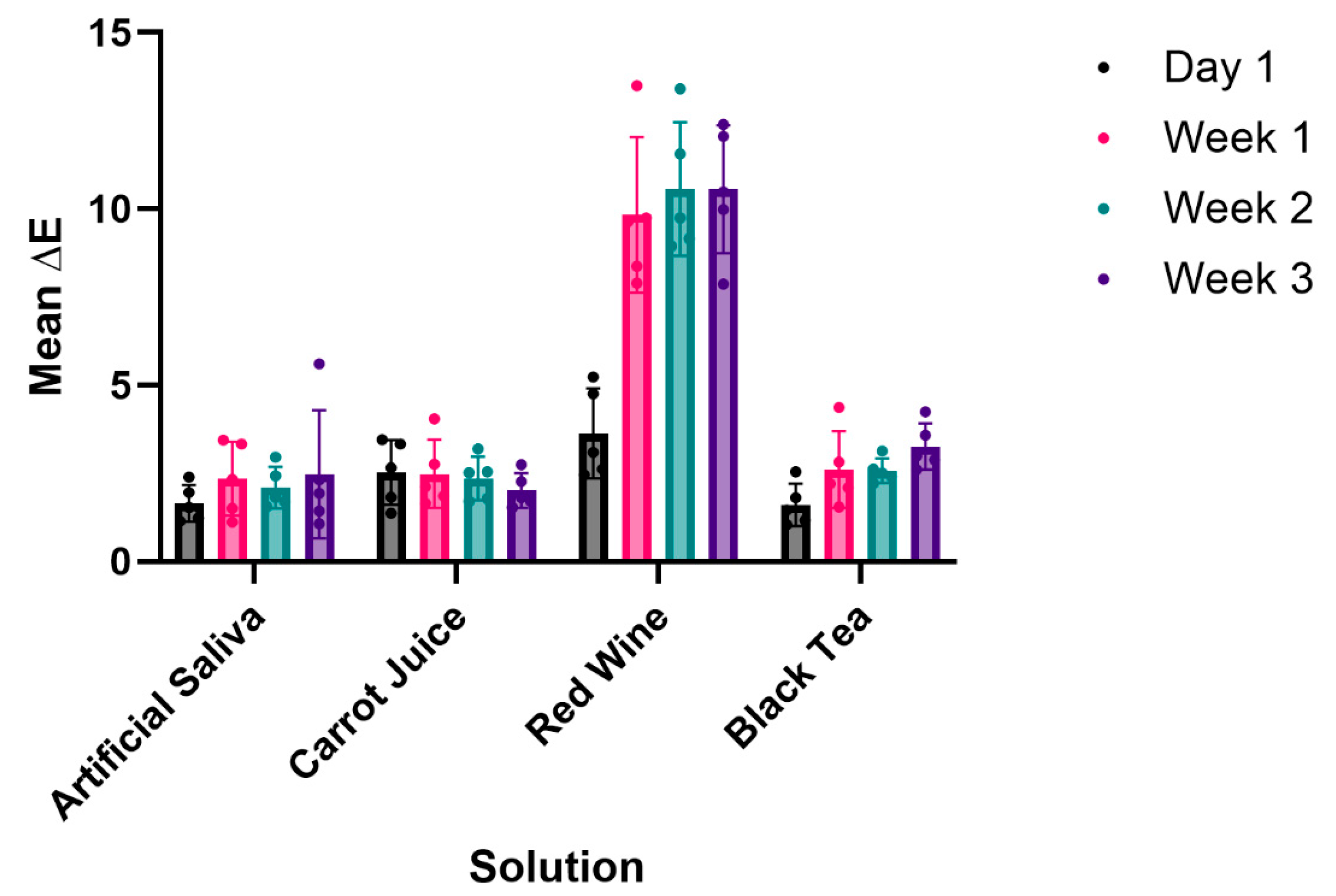

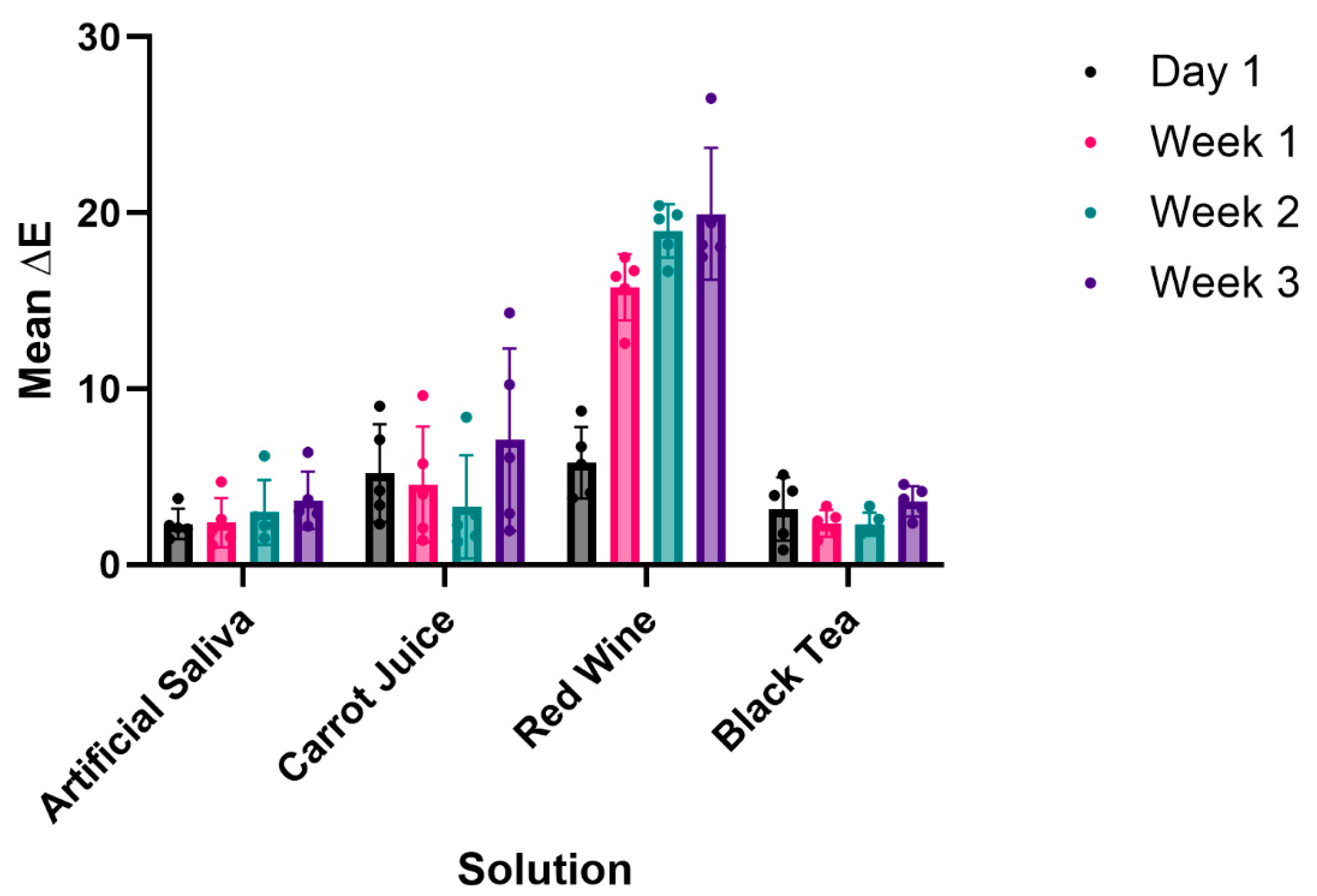

3. Results

4. Discussion

Limitations of the Study and Future Direction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Regish, K.M.; Sharma, D.; Prithviraj, D.R. Techniques of Fabrication of Provisional Restoration: An Overview. Int. J. Dent. 2011, 1, 134659. [Google Scholar] [CrossRef]

- Rosenstiel, S.F. Contemporary Fixed Prosthodontics, 5th ed.; Elsevier: Columbus, OH, USA, 2016; Volume 15, pp. 401–439. [Google Scholar]

- Shillingburg, H.T. Fundamentals of Fixed Prosthodontics, 4th ed.; Quintessence Publishing Company: Batavia, IL, USA, 2012; Volume 15, pp. 241–268. [Google Scholar]

- Mitra, S.B.; Wu, D.; Holmes, B.N. An application of nanotechnology in advanced dental materials. J. Am. Dent. Assoc. 2003, 134, 1382–1390. [Google Scholar] [CrossRef] [PubMed]

- Joiner, A. Tooth colour: A review of the literature. J. Dent. 2004, 32, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Blatz, M.B.; Chiche, G.; Holst, S.; Sadan, A. Influence of surface treatment and simulated aging on bond strengths of luting agents to zirconia. Quintessence Int. 2007, 38, 745–753. [Google Scholar] [PubMed]

- Shenoy, A.; Rajaraman, V.; Maiti, S. Comparative analysis of various temporary computer-aided design/computer-aided manufacturing polymethyl methacrylate crown materials based on color stability, flexural strength, and surface roughness: An in vitro study. J. Adv. Pharm. Technol. Res. 2022, 13, 130–135. [Google Scholar] [CrossRef]

- Koppaka, R.; Ahmed, N.; Echhpal, U.R. Assessing the Color Stability of Polymethyl Methacrylate (PMMA) Dental Restorations with a Novel Polishing Agent Derived from Pulverized Old Alginate Impressions. Cureus 2024, 23, e67614. [Google Scholar] [CrossRef]

- Fontes, S.T.; Fernández, M.R.; de Moura, C.M.; Meireles, S.S. Color Stability Of a nanofill composite: Effect of different immersion media. J. Appl. Oral Sci. 2009, 17, 388–391. [Google Scholar] [CrossRef]

- Bindl, A.; Mörmann, W.H. Clinical and SEM evaluation of all-ceramic chair-side CAD/CAM-generated partial crowns: CAD/CAM generated partial crowns. Eur. J. Oral Sci. 2003, 111, 163–169. [Google Scholar] [CrossRef]

- Sailer, I.; Fehér, A.; Filser, F.; Gauckler, L.J.; Lüthy, H.; Hämmerle, C.H. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int. J. Prosthodont. 2007, 20, 383–388. [Google Scholar]

- Joda, T.; Bragger, U.; Zitzmann, N.U. CAD/CAM implant crowns in a digital workflow: Five-year follow-up of a prospective clinical trial. Clin. Implant Dent. Relat. Res. 2019, 21, 169–174. [Google Scholar] [CrossRef]

- Moon, J.M.; Jeong, C.S.; Lee, H.J.; Bae, J.M.; Choi, E.J.; Kim, S.T.; Park, Y.B.; Oh, S.H. A Comparative Study of Additive and Subtractive Manufacturing Techniques for a Zirconia Dental Product: An Analysis of the Manufacturing Accuracy and the Bond Strength of Porcelain to Zirconia. Materials 2022, 15, 5398. [Google Scholar] [CrossRef] [PubMed]

- Song, S.Y.; Shin, Y.H.; Lee, J.Y.; Shin, S.W. Color stability of provisional restorative materials with different fabrication methods. J. Adv. Prosthodont. 2020, 12, 259–264. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, N.; Wismeijer, D.; Osman, R.B. Additive Manufacturing Techniques in Prosthodontics: Where Do We Currently Stand? A Critical Review. Int. J. Prosthodont. 2017, 30, 474–484. [Google Scholar] [CrossRef]

- McLaren, K. XIII-The Development of the CIE 1976 (L a b) Uniform Colour Space and Colour-difference Formula. J. Soc. Dye. Colour. 1976, 92, 338–341. [Google Scholar] [CrossRef]

- Shin, J.W.; Kim, J.E.; Choi, Y.J.; Shin, S.H.; Nam, N.E.; Shim, J.S.; Lee, K.W. Evaluation of the Color Stability of 3D-Printed Crown and Bridge Materials against Various Sources of Discoloration: An In Vitro Study. Materials 2020, 13, 5359. [Google Scholar] [CrossRef]

- ISO/CIE 11664-4:2019; Colorimetry: Part 4: CIE 1976 L*a*b* Colour Space. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO/TR 28642:2016; Guidance on Colour Measurement. International Organization for Standardization: Geneva, Switzerland, 2016.

- Gruber, S.; Kamnoedboon, P.; Özcan, M.; Srinivasan, M. CAD/CAM Complete Denture Resins: An In Vitro Evaluation of Color Stability. J. Prosthodont. 2021, 30, 430–439. [Google Scholar] [CrossRef]

- Raszewski, Z.; Chojnacka, K.; Mikulewicz, M. Effects of Surface Preparation Methods on the Color Stability of 3D-Printed Dental Restorations. J. Funct. Biomater. 2023, 14, 257. [Google Scholar] [CrossRef]

- Tieh, M.T.; Waddell, J.N.; Choi, J.J.E. Optical Properties and Color Stability of Denture Teeth—A Systematic Review. J. Prosthodont. 2022, 31, 385–398. [Google Scholar] [CrossRef]

- Kim-Pusateri, S.; Brewer, J.D.; Davis, E.L.; Wee, A.G. Reliability and accuracy of four dental shade-matching devices. J. Prosthet. Dent. 2009, 101, 193–199. [Google Scholar] [CrossRef]

- Douglas, R.D.; Steinhauer, T.J.; Wee, A.G. Intraoral determination of the tolerance of dentists for perceptibility and acceptability of shade mismatch. J. Prosthet. Dent. 2007, 97, 200–208. [Google Scholar] [CrossRef]

- Hada, T.; Kanazawa, M.; Iwaki, M.; Arakida, T.; Soeda, Y.; Katheng, A.; Otake, R.; Minakuchi, S. Effect of Printing Direction on the Accuracy of 3D-Printed Dentures Using Stereolithography Technology. Materials 2020, 13, 3405. [Google Scholar] [CrossRef]

- Espinar, C.; Bona, A.D.; Pérez, M.M.; Tejada-Casado, M.; Pulgar, R. The influence of printing angle on color and translucency of 3D printed resins for dental restorations. Dent. Mater. 2023, 39, 410–417. [Google Scholar] [CrossRef]

- Lee, E.H.; Ahn, J.S.; Lim, Y.J.; Kwon, H.B.; Kim, M.J. Effect of layer thickness and printing orientation on the color stability and stainability of a 3D-printed resin material. J. Prosthet. Dent. 2022, 127, 784.e1–784.e7. [Google Scholar] [CrossRef]

- Gad, M.M.; Alshehri, S.Z.; Alhamid, S.A.; Albarrak, A.; Khan, S.Q.; Alshahrani, F.A.; Alqarawi, F.K. Water Sorption, Solubility, and Translucency of 3D-Printed Denture Base Resins. Dent. J. 2022, 10, 42. [Google Scholar] [CrossRef]

- SLA vs. DLP: Guide to Resin 3D Printers. Formlabs. 2022. Available online: https://formlabs.com/blog/resin-3d-printer-comparison-sla-vs-dlp/ (accessed on 6 January 2022).

- Kim, H.J.; Lim, S.W.; Lee, M.K.; Ju, S.W.; Park, S.H.; Ahn, J.S.; Hwang, K.G. Which Three-Dimensional Printing Technology Can Replace Conventional Manual Method of Manufacturing Oral Appliance? A Preliminary Comparative Study of Physical and Mechanical Properties. Appl. Sci. 2022, 12, 130. [Google Scholar] [CrossRef]

- Ellakany, P.; Fouda, S.M.; AlGhamdi, M.A.; Aly, N.M. Comparison of the color stability and surface roughness of 3-unit provisional fixed partial dentures fabricated by milling, conventional and different 3D printing fabrication techniques. J. Dent. 2023, 131, 104458. [Google Scholar] [CrossRef]

- Rodríguez-Ivich, J.; Razaghy, M.; Henriques, B.; Magne, P. Accelerated Fatigue Resistance of Bonded Composite Resin and Lithium Disilicate Screw-Retained Incisor Crowns with Long and Short Titanium Bases. Int. J. Periodontics Restor. Dent. 2022, 42, 459–469. [Google Scholar] [CrossRef]

- Poggio, C.; Arciola, C.R.; Rosti, F.; Scribante, A.; Saino, E.; Visai, L. Adhesion of Streptococcus mutans to different restorative materials. Int. J. Artif. Organs 2009, 32, 671–677. [Google Scholar] [CrossRef]

- Iorgulescu, G. Saliva between normal and pathological. Important factors in determining systemic and oral health. J. Med. Life 2009, 2, 303–307. [Google Scholar]

| Staining Solution | Manufacturer |

|---|---|

| Artificial Saliva | Artificial Saliva, Biochemazone, Chemazone INC, Canada |

| Carrot Juice | Bolthouse Farms, Bakersfield, California |

| Red Wine | Cabernet Sauvignon, Bota Box Vineyards, Mentaca, California |

| Black Tea | Pure Leaf Iced Tea, PespsiCo, Purchase, New York |

| MEAN ΔE (SD) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Day 1 | Week 1 | Week 2 | Week 3 | |||||

| Solution | P | UP | P | UP | P | UP | P | UP |

| Artificial Saliva | 1.65 (0.52) | 2.32 (0.86) | 2.34 (1.04) | 2.39 (1.40) | 2.09 (0.59) | 2.98 (1.84) | 2.47 (1.82) | 3.65 (1.63) |

| Carrot Juice | 2.52 (0.91) | 5.20 (2.77) | 2.48 (0.96) | 4.56 (3.28) | 2.35 (0.62) | 3.28 (2.92) | 2.02 (0.49) * | 7.10 (5.18) * |

| Red Wine | 3.63 (1.27) | 5.80 (2.03) | 9.82 (2.20) * | 15.77 (1.88) * | 10.56 (1.89) * | 18.97 (1.52) * | 10.56 (1.82) * | 19.94 (3.75) * |

| Black Tea | 1.60 (0.60) | 3.16 (1.79) | 2.60 (1.08) | 2.35 (0.76) | 2.57 (0.34) | 2.31 (0.65) | 3.26 (0.66) | 3.60 (0.86) |

| Tukey’s Test, Unpolished Red Wine vs: | ||||

|---|---|---|---|---|

| ANOVA | Artificial Saliva | Carrot Juice | Black Tea | |

| Day 1 | 0.0421 | 0.0593 (NS) | 0.9623 (NS) | 0.9623 (NS) |

| Week 1 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Week 2 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Week 3 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Tukey’s Test, Polished Red Wine vs: | ||||

| ANOVA | Artificial Saliva | Carrot Juice | Black Tea | |

| Day 1 | 0.0068 | 0.0126 | 0.2331 (NS) | 0.0106 |

| Week 1 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Week 2 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Week 3 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marafi, A.; Manna, S.; Kunkel, T.; Azarbal, M.; Sukotjo, C.; Wee, A.G.; Antonopoulou, S. The Effect of Extrinsic Staining on 3D Printed Provisional Crowns. Prosthesis 2025, 7, 47. https://doi.org/10.3390/prosthesis7030047

Marafi A, Manna S, Kunkel T, Azarbal M, Sukotjo C, Wee AG, Antonopoulou S. The Effect of Extrinsic Staining on 3D Printed Provisional Crowns. Prosthesis. 2025; 7(3):47. https://doi.org/10.3390/prosthesis7030047

Chicago/Turabian StyleMarafi, Abdullah, Samantha Manna, Thomas Kunkel, Mohsen Azarbal, Cortino Sukotjo, Alvin G. Wee, and Stavroula Antonopoulou. 2025. "The Effect of Extrinsic Staining on 3D Printed Provisional Crowns" Prosthesis 7, no. 3: 47. https://doi.org/10.3390/prosthesis7030047

APA StyleMarafi, A., Manna, S., Kunkel, T., Azarbal, M., Sukotjo, C., Wee, A. G., & Antonopoulou, S. (2025). The Effect of Extrinsic Staining on 3D Printed Provisional Crowns. Prosthesis, 7(3), 47. https://doi.org/10.3390/prosthesis7030047