A Scoping Review on Accuracy and Acceptance of 3D-Printed Removable Partial Dentures

Abstract

1. Introduction

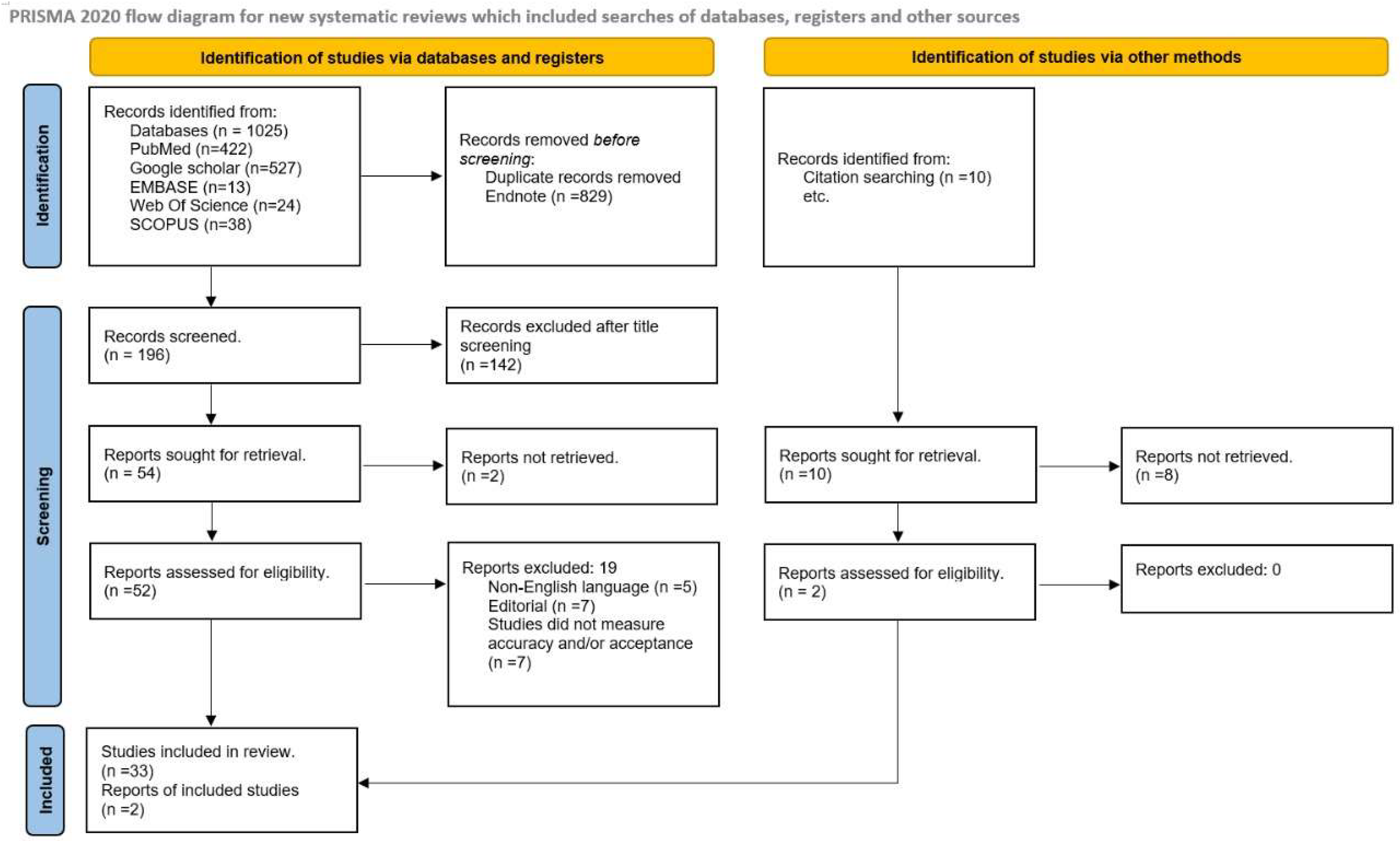

2. Materials and Methods

2.1. Search Strategy

2.2. Inclusion and Exclusion Criteria

2.3. Data Extraction and Clinical Outcomes

3. Results

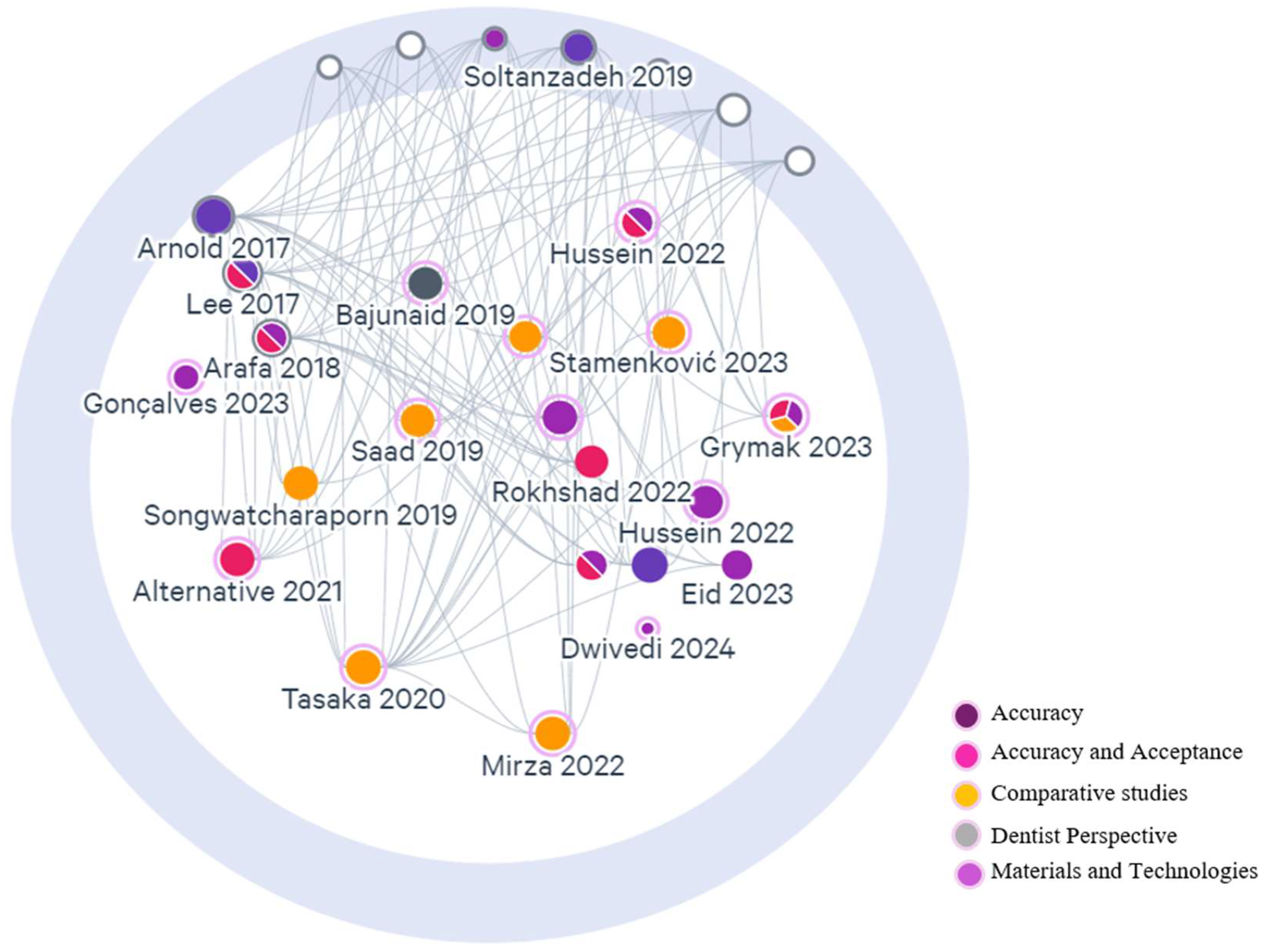

3.1. Characteristics of Included Studies

| Sr No. | Author/Year/Country | Study Design | Kennedy’s Classification | Control Group | Type of 3D Printer | Outcome |

|---|---|---|---|---|---|---|

| 1 | Anan and Saadi 2015 [47]; Syria | In vitro study (Experimental) | Mandibular class III modification 1 | Traditional technique | Light curing model technique | Fit accuracy of 3D-printed RPDs was better than traditional |

| 2 | Lee et al., 2017 [19]; South Korea | Clinical report | Maxillary and mandibular class I | Replica technique | Digital light projection (DLP) | The RPD constructed with the replica technique has varied results |

| 3 | Ye et al., 2017 [46]; China | Randomized control trial | Mandibular class I modification 1 | Lost wax- technique | Stereolithography (SLA) | The single design RPD prepared with a 3D printer was more accurately fit than those with the traditional technique |

| 4 | Arnold et al., 2018 [6]; Germany | Laboratory study | Maxillary class III modification 2 | Lost wax technique | Direct and indirect 3D printing techniques | The 3D-printed RPD has less fit |

| 5 | Soltanzadeh et al., 2018 [50]; USA | Laboratory study | Maxillary class III modification 1 | Lost wax technique | Indirect printing | The conventional RPD was more accurate |

| 6 | Torii et al., 2018 [28]; Japan | Experimental study | First molar simulation | Lost wax technique | indirect printing (CAD) | No significant difference was reported in the accuracy of fit within both techniques |

| 7 | Bajunaid et al., 2019 [10]; Saudi Arabia | Laboratory study | Mandibular class III | Lost wax technique | Direct CAD printers | 3D-printed RPDs are more accurate |

| 8 | Chen et al., 2019 [35]; China | Laboratory study | All classes | Lost wax technique | Direct CAD printing technique | 3D-printed RPDs are less fitting but clinically acceptable |

| 9 | Negm, Aboutaleb, and Alam-Eldein 2019 [22]; Egypt | Laboratory study | Maxillary class I | Stone cast model | Stereolithography (SLA) | RPDs prepared by 3D printers have less accuracy |

| 10 | Carneiro Pereira et al., 2019 [49]; Brazil | Clinical report | Mandibular class III modification 1 | Intra-oral scanner (Patients mouth) | Direct and indirect printing techniques | The 3D-printed RPDs have an acceptable clinical fit |

| 11 | Tregemen et al., 2019 [48]; South Carolina | Clinical trial | Mandibular and maxillary class I, II, and III | Stone cast model | Selective laser melting | 3D-printed RPDs have a better fit |

| 12 | Hayama et al., 2019 [17]; China | Clinical report | Mandibular class I | Intraoral scanners | Direct digital technique | 3D-printed RPD have an acceptable fit |

| 13 | Oka et al., 2019 [13]; Japan | Laboratory study | Mandibular and maxillary class I, II, and III | Lost wax technique | Direct CAD printing technique | 3D-printed RPD have an acceptable fit |

| 14 | Wu et al., 2020 [44]; China | Clinical report | Mandibular class I modification 1 | Intraoral scanners | Selective laser melting | 3D-printed RPD have an acceptable fit |

| 15 | Xie et al., 2020 [39]; China | Laboratory study | First molar simulation | Lost wax technique | Direct CAD printing | 3D-printed RPDs have better fit |

| 16 | Yoon et al., 2021 [40]; China | Laboratory study | Maxillary class I | Stone cast | Direct 3D printing | Acceptable fit |

| 17 | Hussein and Hussein 2022 [11]; Saudi Arabia | Laboratory study | Maxillary class III and Mandibular class 1 | Lost wax technique | Digital light processing | No effect on the accuracy of fit |

| 18 | Saadaldin et al., 2022 [36]; Egypt | Laboratory Study | Not mentioned | Lost wax technique | Selective laser melting technique | Better accuracy fit of SLM-prepared RPDs |

| 19 | Rokshad et al., 2022 [24]; Germany | Laboratory study | Maxillary class III modification 1 | Convectional technique | Digital light processing | Acceptable fit |

| 20 | Peng et al., 2022 [14]; China | Laboratory study | Mandibular class II modification 2 | Lost wax technique | Direct and indirect 3D printing | 3D-printed RPDs have a better fit |

| 21 | Grymak et al., 2023 [32]; New Zealand | Laboratory study | Maxillary class III modification 1 | Stone cast | Selective laser melting | 3D-printed RPDs have better acceptance |

| Sr No. | Author/Year/Country | Study Design | Kennedy’s Classification | Type of 3D Printer | Outcome |

|---|---|---|---|---|---|

| 1. | Kattadiyil et al., 2014 [26]; USA | Clinical report | Maxillary class III | Stereolithographic | The finished prosthesis was successfully placed and used by the patient |

| 2. | Husain Omran 2014 [54]; Saudi Arabia | Case report | Maxillary class I | Digital light prototyping | Well-fitted silicone framework |

| 3. | Lee and Lee 2015 [18]; South Korea | Case report | Maxillary class I | Stereolithographic | Fit accuracy is satisfactory |

| 4. | Mansour et al., 2016 [43]; USA | Clinical report | Maxillary class I modification 1 | Stereolithography (SLA) | Fit of RPD prepared by rapid prototyping was highly satisfactory |

| 5. | Batalha and Araújo 2017 [41]; Brazil | Clinical report | Mandibular class I modification 1 | Digital light projection(DLP) | The accuracy of fit was satisfactory |

| 6. | Hu, Pei, and Wen 2017 [42]; China | Clinical report | Maxillary class I | Stereolithography (SLA) | The 3D-printed RPD is the best alternative to conservative RPD, and the accuracy of fit is acceptable |

| 7. | Gan et al., 2018 [45]; China | Randomized control trials | Dentate | Selective laser melting (SLM) | RPDs designed with 3D printers have an acceptable fit |

| 8. | Katreva et al., 2018 [25]; Bulgaria | Clinical case report | Mandibular class I | Stereolithography (SLA) | 3D-printed RPD appears to be more precise and accurate |

| 9. | Tasaka et al., 2019 [51]; Japan | Laboratory study | Mandibular class II modification 1 | Indirect printing | RPD fabricated by 3D printer has an acceptable fit |

| 10. | Takahashi et al., 2020 [38]; USA | Laboratory study | First molar simulation | Direct and indirect printing | Acceptable fit |

| 11. | Tasaka et al., 2020 [27]; Japan | Laboratory study | Mandibular class II modification 2 | Direct and indirect printing | 3D-printed RPDs have a better fit |

| 12. | Cabrita et al., 2021 [55]; USA | Clinical report | Mandibular class I | Selective laser melting | 3D-printed RPD have an acceptable fit |

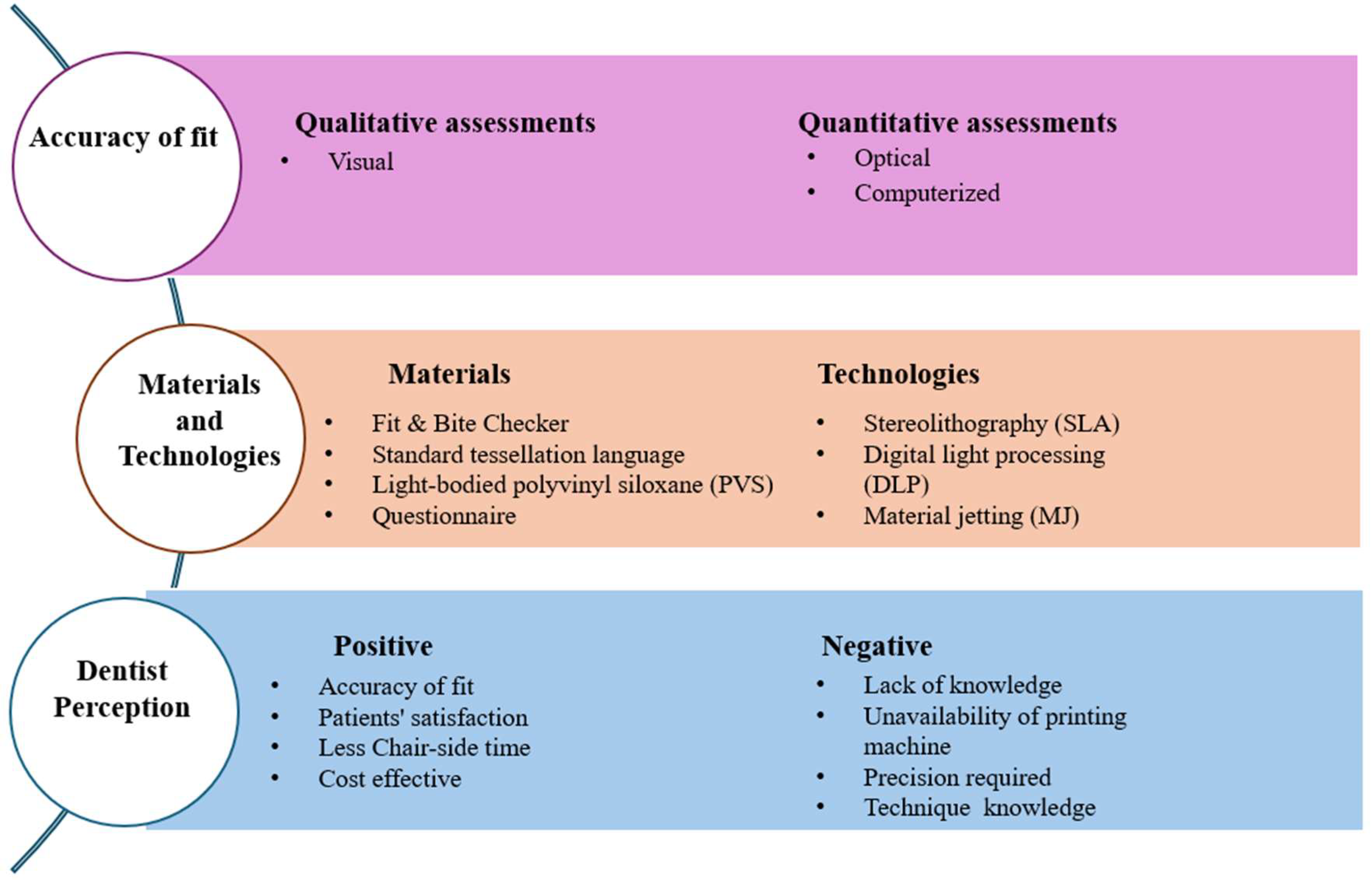

3.2. Comparison of the Method Utilized for Assessment of Fit of 3D-Printed RPDs

3.3. Qualitative Assessment Method (Visual Method)

3.4. Quantitative Assessment Method (Computerized and Optical)

Dentist’s Perception of Acceptance of 3D-Printed RPDs

4. Discussion

5. Conclusions

Supplementary Materials

Funding

Acknowledgments

Conflicts of Interest

References

- ISO 5725-1:1994; Accuracy (Trueness and Precision) of Measurement Methods and Results — Part 1: General Principles and Definitions. International Organization for Standardization: Geneva, Switzerland, 1994.

- Al Mortadi, N.; Alzoubi, K.H.; Williams, R. A Scoping Review on the Accuracy of Fit of Removable Partial Dentures in a Developing Digital Context. Clin. Cosmet. Investig. Dent. 2020, 12, 551–562. [Google Scholar] [CrossRef]

- Almufleh, B.; Emami, E.; Alageel, O.; de Melo, F.; Seng, F.; Caron, E.; Nader, S.A.; Al-Hashedi, A.; Albuquerque, R.; Feine, J.; et al. Patient satisfaction with laser-sintered removable partial dentures: A crossover pilot clinical trial. J. Prosthet. Dent. 2018, 119, 560–567.e561. [Google Scholar] [CrossRef] [PubMed]

- Dunham, D.; Brudvik, J.S.; Morris, W.J.; Plummer, K.D.; Cameron, S.M. A clinical investigation of the fit of removable partial dental prosthesis clasp assemblies. J. Prosthet. Dent. 2006, 95, 323–326. [Google Scholar] [CrossRef] [PubMed]

- Eggbeer, D.; Bibb, R.; Williams, R. The computer-aided design and rapid prototyping fabrication of removable partial denture frameworks. Proc. Inst. Mech. Eng. H 2005, 219, 195–202. [Google Scholar] [CrossRef]

- Arnold, C.; Hey, J.; Schweyen, R.; Setz, J.M. Accuracy of CAD-CAM-fabricated removable partial dentures. J. Prosthet. Dent. 2018, 119, 586–592. [Google Scholar] [CrossRef]

- Bibb, R.; Eggbeer, D.; Williams, R. Rapid manufacture of removable partial denture frameworks. Rapid Prototyp. J. 2006, 12, 95–99. [Google Scholar] [CrossRef]

- Campbell, S.D.; Cooper, L.; Craddock, H.; Hyde, T.P.; Nattress, B.; Pavitt, S.H.; Seymour, D.W. Removable partial dentures: The clinical need for innovation. J. Prosthet. Dent. 2017, 118, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Williams, R.J.; Bibb, R.; Eggbeer, D.; Collis, J. Use of CAD/CAM technology to fabricate a removable partial denture framework. J. Prosthet. Dent. 2006, 96, 96–99. [Google Scholar] [CrossRef] [PubMed]

- Bajunaid, S.O.; Altwaim, B.; Alhassan, M.; Alammari, R. The Fit Accuracy of Removable Partial Denture Metal Frameworks Using Conventional and 3D Printed Techniques: An In Vitro Study. J. Contemp. Dent. Pract. 2019, 20, 476–481. [Google Scholar] [CrossRef]

- Hussein, M.O.; Hussein, L.A. Trueness of 3D printed partial denture frameworks: Build orientations and support structure density parameters. J. Adv. Prosthodont. 2022, 14, 150. [Google Scholar] [CrossRef]

- Alharbi, N.; Osman, R.B.; Wismeijer, D. Factors Influencing the Dimensional Accuracy of 3D-Printed Full-Coverage Dental Restorations Using Stereolithography Technology. Int. J. Prosthodont. 2016, 29, 503–510. [Google Scholar] [CrossRef] [PubMed]

- Oka, Y.; Sasaki, J.; Wakabayashi, K.; Nakano, Y.; Okamura, S.Y.; Nakamura, T.; Imazato, S.; Yatani, H. Fabrication of a radiopaque fit-testing material to evaluate the three-dimensional accuracy of dental prostheses. Dent. Mater. 2016, 32, 921–928. [Google Scholar] [CrossRef]

- Peng, P.W.; Hsu, C.Y.; Huang, H.Y.; Chao, J.C.; Lee, W.F. Trueness of removable partial denture frameworks additively manufactured with selective laser melting. J. Prosthet. Dent. 2022, 127, 122–127. [Google Scholar] [CrossRef] [PubMed]

- Torabi, K.; Farjood, E.; Hamedani, S. Rapid Prototyping Technologies and their Applications in Prosthodontics, a Review of Literature. J. Dent. 2015, 16, 1–9. [Google Scholar]

- Lang, L.A.; Tulunoglu, I. A critically appraised topic review of computer-aided design/computer-aided machining of removable partial denture frameworks. Dent. Clin. N. Am. 2014, 58, 247–255. [Google Scholar] [CrossRef]

- Hayama, H.; Fueki, K.; Wadachi, J.; Wakabayashi, N. Trueness and precision of digital impressions obtained using an intraoral scanner with different head size in the partially edentulous mandible. J. Prosthodont. Res. 2018, 62, 347–352. [Google Scholar] [CrossRef]

- Lee, J.H. Completely digital approach to fabricating a crown under an existing partial removable dental prosthesis by using an intraoral digital scanner in a single appointment. J. Prosthet. Dent. 2016, 115, 668–671. [Google Scholar] [CrossRef]

- Lee, J.W.; Park, J.M.; Park, E.J.; Heo, S.J.; Koak, J.Y.; Kim, S.K. Accuracy of a digital removable partial denture fabricated by casting a rapid prototyped pattern: A clinical study. J. Prosthet. Dent. 2017, 118, 468–474. [Google Scholar] [CrossRef]

- Mamoun, J.S. The path of placement of a removable partial denture: A microscope-based approach to survey and design. J. Adv. Prosthodont. 2015, 7, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Baig, M.R.; Tan, K.B.; Nicholls, J.I. Evaluation of the marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J. Prosthet. Dent. 2010, 104, 216–227. [Google Scholar] [CrossRef]

- Negm, E.E.; Aboutaleb, F.A.; Alam-Eldein, A.M. Virtual Evaluation of the Accuracy of Fit and Trueness in Maxillary Poly(etheretherketone) Removable Partial Denture Frameworks Fabricated by Direct and Indirect CAD/CAM Techniques. J. Prosthodont. 2019, 28, 804–810. [Google Scholar] [CrossRef] [PubMed]

- Preshaw, P.M.; Walls, A.W.; Jakubovics, N.S.; Moynihan, P.J.; Jepson, N.J.; Loewy, Z. Association of removable partial denture use with oral and systemic health. J. Dent. 2011, 39, 711–719. [Google Scholar] [CrossRef] [PubMed]

- Rokhshad, R.; Tehrani, A.M.; Nahidi, R.; Zarbakhsh, A. Fit of removable partial denture frameworks fabricated from 3D printed patterns versus the conventional method: An in vitro comparison. J. Prosthet. Dent. 2024, 131, 1144–1149. [Google Scholar] [CrossRef]

- Katreva, I.; Dikova, T.; Tonchev, T. 3D printing–an alternative of conventional crown fabrication: A case report. J. IMAB–Annu. Proceeding Sci. Pap. 2018, 24, 2048–2054. [Google Scholar] [CrossRef]

- Kattadiyil, M.T.; Mursic, Z.; AlRumaih, H.; Goodacre, C.J. Intraoral scanning of hard and soft tissues for partial removable dental prosthesis fabrication. J. Prosthet. Dent. 2014, 112, 444–448. [Google Scholar] [CrossRef] [PubMed]

- Tasaka, A.; Shimizu, T.; Kato, Y.; Okano, H.; Ida, Y.; Higuchi, S.; Yamashita, S. Accuracy of removable partial denture framework fabricated by casting with a 3D printed pattern and selective laser sintering. J. Prosthodont. Res. 2020, 64, 224–230. [Google Scholar] [CrossRef] [PubMed]

- Torii, M.; Nakata, T.; Takahashi, K.; Kawamura, N.; Shimpo, H.; Ohkubo, C. Fitness and retentive force of cobalt-chromium alloy clasps fabricated with repeated laser sintering and milling. J. Prosthodont. Res. 2018, 62, 342–346. [Google Scholar] [CrossRef]

- Mai, H.Y.; Mai, H.N.; Kim, H.J.; Lee, J.; Lee, D.H. Accuracy of Removable Partial Denture Metal Frameworks Fabricated by Computer-Aided Design/Computer-Aided Manufacturing Method: A Systematic Review and Meta-Analysis. J. Evid. Based Dent. Pract. 2022, 22, 101681. [Google Scholar] [CrossRef] [PubMed]

- Chobe, A.; Sushma, R.; Shashikiran, N.; Kore, A.R.; Shivakumar, K.; Vande, A. Study to Assess the Knowledge, Attitude and Practices of Additive Manufacturing Technology by Dental Practitioners in Dentistry across India-A Survey. Journal for ReAttach Ther. Dev. Divers. 2023, 6, 759–766. [Google Scholar]

- Urumova, M. Comparative study of retention of telescopic crowns fabricated by 3D printing (in vitro study). J. Int. Dent. Med. Res. 2023, 16, 13–19. [Google Scholar]

- Grymak, A.; Badarneh, A.; Ma, S.; Choi, J.J.E. Effect of various printing parameters on the accuracy (trueness and precision) of 3D-printed partial denture framework. J. Mech. Behav. Biomed. Mater. 2023, 140, 105688. [Google Scholar] [CrossRef]

- Azari, A.; Nikzad, S. The evolution of rapid prototyping in dentistry: A review. Rapid Prototyp. J. 2009, 15, 216–225. [Google Scholar] [CrossRef]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.J.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Li, H.; Zhao, Y.; Zhang, X.; Wang, Y.; Lyu, P. Adaptation of removable partial denture frameworks fabricated by selective laser melting. J. Prosthet. Dent. 2019, 122, 316–324. [Google Scholar] [CrossRef]

- Saadaldin, S.A.; Rizkalla, A.S.; Eldwakhly, E.A.; Soliman, M.; Aldegheishem, A. Assessment of the fitness of removable partial denture frameworks manufactured using additive manufacturing/selective laser melting. Mater. Express 2022, 12, 735–742. [Google Scholar] [CrossRef]

- Soltanzadeh, P.; Su, J.-M.; Habibabadi, S.R.; Kattadiyil, M.T. Obturator fabrication incorporating computer-aided design and 3-dimensional printing technology: A clinical report. J. Prosthet. Dent. 2019, 121, 694–697. [Google Scholar] [CrossRef]

- Takahashi, K.; Torii, M.; Nakata, T.; Kawamura, N.; Shimpo, H.; Ohkubo, C. Fitness accuracy and retentive forces of additive manufactured titanium clasp. J. Prosthodont. Res. 2020, 64, 468–477. [Google Scholar] [CrossRef]

- Xie, W.; Zheng, M.; Wang, J.; Li, X. The effect of build orientation on the microstructure and properties of selective laser melting Ti-6Al-4V for removable partial denture clasps. J. Prosthet. Dent. 2020, 123, 163–172. [Google Scholar] [CrossRef]

- Yoon, J.-m.; Liu, Y.; Liu, Y.; Sun, Y.; Ye, H.; Zhou, Y. The accuracy of a novel 3D digital evaluation method of intraoral fitness for removable partial dentures. Comput. Biol. Med. 2022, 144, 105348. [Google Scholar] [CrossRef] [PubMed]

- Batalha, A.; Araújo, R.M. Development of removable partial dentures by using additive manufacture and casting processes. Arch. Mater. Sci. Eng. 2017, 87, 33–40. [Google Scholar] [CrossRef]

- Hu, F.; Pei, Z.; Wen, Y. Using Intraoral Scanning Technology for Three-Dimensional Printing of Kennedy Class I Removable Partial Denture Metal Framework: A Clinical Report. J. Prosthodont. 2019, 28, e473–e476. [Google Scholar] [CrossRef] [PubMed]

- Mansour, M.; Sanchez, E.; Machado, C. The Use of Digital Impressions to Fabricate Tooth-Supported Partial Removable Dental Prostheses: A Clinical Report. J. Prosthodont. 2016, 25, 495–497. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Li, Y.; Zhang, Y. Use of intraoral scanning and 3-dimensional printing in the fabrication of a removable partial denture for a patient with limited mouth opening. J. Am. Dent. Assoc. 2017, 148, 338–341. [Google Scholar] [CrossRef]

- Gan, N.; Ruan, Y.; Sun, J.; Xiong, Y.; Jiao, T. Comparison of Adaptation between the Major Connectors Fabricated from Intraoral Digital Impressions and Extraoral Digital Impressions. Sci. Rep. 2018, 8, 529. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.; Ning, J.; Li, M.; Niu, L.; Yang, J.; Sun, Y.; Zhou, Y. Preliminary Clinical Application of Removable Partial Denture Frameworks Fabricated Using Computer-Aided Design and Rapid Prototyping Techniques. Int. J. Prosthodont. 2017, 30, 348–353. [Google Scholar] [CrossRef]

- Anan, M.T.M.; Al-Saadi, M.H. Fit accuracy of metal partial removable dental prosthesis frameworks fabricated by traditional or light curing modeling material technique: An in vitro study. Saudi Dent. J. 2015, 27, 149–154. [Google Scholar] [CrossRef]

- Tregerman, I.; Renne, W.; Kelly, A.; Wilson, D. Evaluation of removable partial denture frameworks fabricated using 3 different techniques. J. Prosthet. Dent. 2019, 122, 390–395. [Google Scholar] [CrossRef]

- Carneiro Pereira, A.L.; Martins de Aquino, L.M.; Carvalho Porto de Freitas, R.F.; Soares Paiva Tôrres, A.C.; da Fonte Porto Carreiro, A. CAD/CAM-fabricated removable partial dentures: A case report. Int. J. Comput. Dent. 2019, 22, 371–379. [Google Scholar]

- Soltanzadeh, P.; Suprono, M.S.; Kattadiyil, M.T.; Goodacre, C.; Gregorius, W. An In Vitro Investigation of Accuracy and Fit of Conventional and CAD/CAM Removable Partial Denture Frameworks. J. Prosthodont. 2019, 28, 547–555. [Google Scholar] [CrossRef]

- Tasaka, A.; Kato, Y.; Odaka, K.; Matsunaga, S.; Goto, T.K.; Abe, S.; Yamashita, S. Accuracy of Clasps Fabricated with Three Different CAD/CAM Technologies: Casting, Milling, and Selective Laser Sintering. Int. J. Prosthodont. 2019, 32, 526–529. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.X.; Zeng, X.Y.; Wang, Z.M.; Guan, K.; Peng, C.W. Fabrication of removable partial denture framework by selective laser melting. Adv. Mater. Res. 2011, 317, 174–178. [Google Scholar] [CrossRef]

- Hussein, M.O.; Hussein, L.A. Optimization of digital light processing three-dimensional printing of the removable partial denture frameworks; the role of building angle and support structure diameter. Materials 2022, 15, 2316. [Google Scholar] [CrossRef] [PubMed]

- Hussein, M.O.; Hussein, L.A. Novel 3D modeling technique of removable partial denture framework manufactured by 3D printing technology. Int. J. Adv. Res. 2014, 9, 686–694. [Google Scholar]

- Cabrita, J.P.; Mendes, T.A.; Martins, J.P.; Lopes, L. Removable partial denture metal framework manufactured by selective laser melting technology—A clinical report. Rev. Port. De Estomatol. Med. Dentária E Cir. Maxilofac. 2021, 62, 109–113. [Google Scholar] [CrossRef]

- Ahmed, N.; Abbasi, M.S.; Haider, S.; Ahmed, N.; Habib, S.R.; Altamash, S.; Zafar, M.S.; Alam, M.K. Fit Accuracy of Removable Partial Denture Frameworks Fabricated with CAD/CAM, Rapid Prototyping, and Conventional Techniques: A Systematic Review. Biomed. Res. Int. 2021, 2021, 3194433. [Google Scholar] [CrossRef]

- Rudd, R.W.; Rudd, K.D. A review of 243 errors possible during the fabrication of a removable partial denture: Part I. J. Prosthet. Dent. 2001, 86, 251–261. [Google Scholar] [CrossRef]

- Wang, C.; Shi, Y.-F.; Xie, P.-J.; Wu, J.-H. Accuracy of digital complete dentures: A systematic review of in vitro studies. J. Prosthet. Dent. 2021, 125, 249–256. [Google Scholar] [CrossRef]

- Brudvik, J.S.; Reimers, D. The tooth-removable partial denture interface. J. Prosthet. Dent. 1992, 68, 924–927. [Google Scholar] [CrossRef]

| Author | Method of Assessment | Type of Measurement | Area of Measurement |

|---|---|---|---|

| Kattadiyil et al., 2014 [26] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Hussain Orman et al., 2014 [54] | Optical (Microscope) | Accuracy and adaptation | Overall |

| Batalha and Araújo 2017 [41] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Hu, Pei, and Wen 2017 [42] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Lee et al., 2017 [19] | Optical (Stereomicroscope) | Internal discrepancy | All components |

| Ye et al., 2017 [46] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Batalha and Araújo 2017 [26] | Optical (Stereomicroscope) | Gap distance | Different sections |

| Arnold et al., 2018 [6] | Optical (Light microscope) | Gap distance | Clasp |

| Gan et al., 2018 [45] | Optical (Stereomicroscope) | Gap distance | All components |

| Soltanzadeh et al., 2018 [50] | Computerized (Geomagic) | Gap distance | All components |

| Torii et al., 2018 [28] | Optical (Profile projector) | Gap distance | Rest, 3-point clasp |

| Bajunaid et al., 2019 [10] | Optical (Digital microscope) | Gap distances | Rest |

| Chen et al., 2019 [35] | Computerized (Geomagic NX image) | Gap distance | Overall |

| Negm, Aboutaleb, and Alam-Eldein 2019 [22] | Computerized (Geomagic) | Gap distance | Overall |

| Oka et al., 2019 [13] | Computerized | Adaptation | Overall |

| Soltanzadeh et al., 2018 [35] | Computerized (Geomagic) | Trueness | All components |

| Carneiro Pereira et al., 2019 [49] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Tasaka et al., 2019 [51] | Computerized (GOM Inspect) | Average deviation | All components |

| Tregemen et al., 2019 [48] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Takahashi et al., 2020 [38] | Optical (Profile projector) | Gap distance | Clasp |

| Tasaka et al., 2020 [27] | Computerized (GOM Inspect) | Average deviation | Clasp |

| Wu et al., 2020 [44] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Xie et al., 2020 [39] | Optical (Stereomicroscope) | Gap distance | 3-point clasp |

| Cabrita et al., 2021 [55] | Visual inspection (mouth mirror and probe) | Adaptation | Overall |

| Peng et al., 2022 [14] | Computerized (Geomagic) | Trueness | Overall |

| Rokshad et al., 2022 [24] | Computerized (Geomagic Control X) | Adaptation and Gap measurement | All areas |

| Grymak et al., 2023 [32] | Computerized (Geomagic Control X) | Adaptation | Overall |

| Hussain and Hussain 2022 [11] | Computerized (Geomagic Control X) | Trueness | Overall |

| Authors | Study Design | Dentist Perception | Long-Term Prognosis |

|---|---|---|---|

| Urumova et al., 2021 [30]; Bulgaria | Questionnaire | Cost effective and reduces chair-side timing | More clinical studies are required for the analysis of long-term prognosis |

| Chobe et al., 2023 [31]; India | Questionnaire | Cost effective and easily acceptable | Not mentioned |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porwal, A. A Scoping Review on Accuracy and Acceptance of 3D-Printed Removable Partial Dentures. Prosthesis 2025, 7, 16. https://doi.org/10.3390/prosthesis7010016

Porwal A. A Scoping Review on Accuracy and Acceptance of 3D-Printed Removable Partial Dentures. Prosthesis. 2025; 7(1):16. https://doi.org/10.3390/prosthesis7010016

Chicago/Turabian StylePorwal, Amit. 2025. "A Scoping Review on Accuracy and Acceptance of 3D-Printed Removable Partial Dentures" Prosthesis 7, no. 1: 16. https://doi.org/10.3390/prosthesis7010016

APA StylePorwal, A. (2025). A Scoping Review on Accuracy and Acceptance of 3D-Printed Removable Partial Dentures. Prosthesis, 7(1), 16. https://doi.org/10.3390/prosthesis7010016