Abstract

The objective of this study was to assess if the setting expansion, compressive strength, compressive modulus and Knoop hardness is reduced in Type III, IV and V gypsum products when excess water is added to recommended water/powder (W/P) ratios for full-arch implant master casts. Four properties were measured: linear setting expansion, compressive strength, compressive modulus, and Knoop hardness. Three dental stones were evaluated: ISO Type III, Type IV, and Type V. Water was added to recommended W/P ratios as follows: (1) 0%, the manufacturer’s recommend W/P ratio, (2) 50%, 1.5 times the manufacturer’s recommendation of water, (3) 100%, three times the manufacturer’s recommendation of water, (4) 150%, 2.5 times the manufacturer’s recommendation of water, and (5) 200%, three times the manufacturer’s recommendation of water. For all three gypsum types, 50% water additions minimally affected the setting expansion and compressive modulus (p > 0.05), but lowered compressive strength by 26% to 52% (p < 0.05). Knoop hardness was lowered by 24% and 48% for Types V and III (p < 0.05), whereas Type IV was not significantly affected (p > 0.05). With few exceptions, the physical properties for the three gypsum types reached minimum values at 100% dilution, with few changes noted at higher dilutions. Increased W/P ratios did not adequately reduce the setting expansion and adversely affected other physical properties. Of the gypsums tested, Type IV is still recommended due to its lower setting expansion for full-arch implant master casts.

1. Introduction

Osseointegrated dental implants have been shown to have a high success rate through multiple studies [1,2,3,4,5,6,7], although the criteria used to evaluate success, survival and failure has not always been similarly delineated throughout the dental literature [8,9]. While the success rate may be high, the non-passive fit of the implant-retained prosthesis on the abutments may lead to a delayed component failure [10]. Strategies to improve implant-retained prosthesis fit include ensuring the framework fits the master cast and intraorally [11]. Several studies have looked at fit and improving the accuracy of implant master casts, including using low-fusing alloys [10,12], various gypsum types, [10] the use of different die systems [13], the fabrication of casts from different available materials including resin-containing and epoxy materials [14] and dental plaster [15].

Gypsum products used in dentistry are classified as Types I–V. These classifications include: Type I: impression plaster, Type II: model plaster, Type III: dental stone, Type IV: dental stone, high strength, and Type V: dental stone, high strength, high expansion. Due to the necessity of accuracy and dimensional stability, Type IV dental stone is typically used for implant master casts planned for multiple implant-supported complete dental prostheses [10]. The setting expansion and strength of dental stone are properties of concern when fabricating master casts for implant-supported complete dentures. For an implant-supported complete denture, the most important aspect of success is the accuracy of the implant analog position; therefore, minimizing setting expansion is critical to achieving clinical success.

The International Organization for Standardization Standard 6873 regulates the linear setting expansion of Type III, IV and V dental stone [16]. Type III requires a setting expansion range of 0.00% to 0.20%, the Type IV range is 0.00% to 0.15%, and Type V stone can have a minimum of 0.16% and a maximum of 0.30% [16]. According to the ISO standard, these values are to be obtained 120 min following mixing. However, delayed expansion continues for up to five days, with between 92% and 97% of total linear expansion complete after 72 h [17]. With prosthesis construction expected to transpire well after 120 min following mixing, a more clinically relevant measurement time for gypsum expansion appears to be 72 h.

The introduction of more water during the mixing process may have the effect of lowering expansion, but may potentially affect the mechanical strength, abrasion resistance and surface hardness of the produced cast. For Type II gypsum, increasing volumetric water additions by 1/3 reportedly causes expansion to fall by 43% and compressive strength to decrease by 32% [18]. In Type IV stone, Brinell hardness has been shown to decrease by 26–36% with water increases of 16–17%. [19] With multiple properties affected by changes in water/powder (W/P) ratio, improving the fit of implant-supported prostheses by reducing setting expansion also may be accompanied by reductions in a master cast’s strength and hardness. Unknown is the accompanying change in hardness and strength that occurs in different types of gypsum when water is added to decrease setting expansion, the property most desired in reproducing intraoral implant position within a master cast.

Since the full-arch implant master cast should ideally have a minimum expansion and adequate mechanical properties to prevent handling fracture, increasing the W/P ratio of gypsum to reduce the expansion would be ideal for full-arch implant master casts. To date, no published research has assessed simultaneous property changes occurring in different gypsum types when excess water is sequentially added to the manufacturers’ recommended W/P ratios. This study’s purpose is to determine if increasing the W/P ratio can decrease the setting expansion of gypsum materials (Type III, IV and V) used for implant casts, while also monitoring the compressive strength, compressive modulus and Knoop hardness. The primary null hypothesis is that excess water added to the recommended W/P ratios for Types III, IV and V gypsum products will not affect the setting expansion, surface microhardness, compressive modulus or compressive strength of the set stone. A secondary null hypothesis is that no differences in property changes exist among the three gypsum types.

2. Results

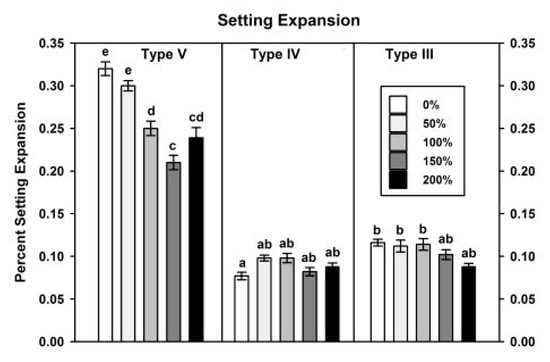

Setting expansion comparisons among materials showed that, overall, the Type V stone expanded 2–3.5 times more than Types III and IV (p < 0.05), whereas the latter two demonstrated relatively few differences between one another at most dilutions (p ≥ 0.05, Figure 1). The sole exception was the 0% Type IV stone (statistical grouping letter (a)), which underwent significantly less expansion than the 0%, 50%, 100% dilutions for Type III stone (letter (b)), (p < 0.05).

Figure 1.

Bar chart of 72 h linear setting expansion for three gypsum types and five water dilutions. Error bars represent standard errors of means; groups with different letters are significantly different at α = 0.05 confidence level. Comparisons are both within and across gypsum types.

In comparing the effects of water additions, different results were recorded for the three types of gypsum. For Type V, a mean setting expansion of 0.33% was recorded for the undiluted mixture (e), and lower expansions were observed for 100% (0.25%) and 150% (0.21%) dilutions ((d) and (c) respectively), (p < 0.05). Interestingly, expansion increased to 0.24% for the 200% diluted mixture, but this was not significantly different from either 100% or 150% dilutions (p ≥ 0.05). For Type III and IV stones, mean values calculated for the linear expansion of all diluted mixtures were not statistically different from those of the undiluted mixtures (p ≥ 0.05). The maximum difference in mean expansion was −0.028% for Type III (200% dilution) and +0.021% for Type IV (50%, 100% dilutions).

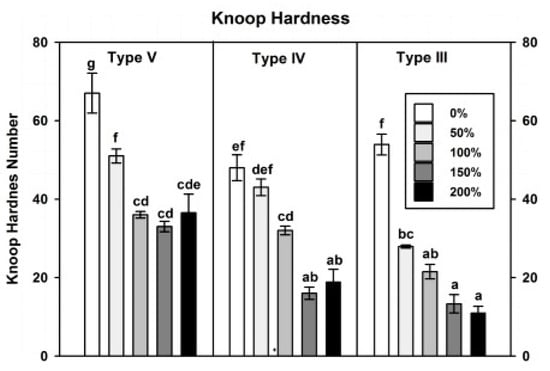

Surface microhardness, as measured by the Knoop hardness test, is shown in Figure 2. At the recommended W/P ratios, the Type V stone’s Knoop Hardness Number (KHN) was 67 (g), which was 1.2–1.4 times harder than Types III (f) and IV (ef), (p < 0.05). No significant differences were noted between the latter two gypsum types (p ≥ 0.05). Fifty percent water additions caused hardness to drop by 24% and 48% in Types V (f) and III stones (bc), respectively (p < 0.05), with minor changes imparted to Type IV. Increasing the dilution factor to 100% produced KHN values of 51 in Type V (22% additional decrease), 44 in Type IV (24%) and 21 in Type III (12%). Further dilutions produced non-significant changes in Type V, whereas the lowest hardness values were recorded at 150% dilution for Type IV (KHN 16, (ab)) and 200% dilution for Type III (KHN 11, (a)). These hardness values were 33% and 20% of undiluted values, respectively.

Figure 2.

Bar chart of five-day Knoop hardness for three gypsum types and five water dilutions. Error bars represent standard errors of means; groups with different letters are significantly different at α = 0.05 confidence level. Comparisons are both within and across gypsum types.

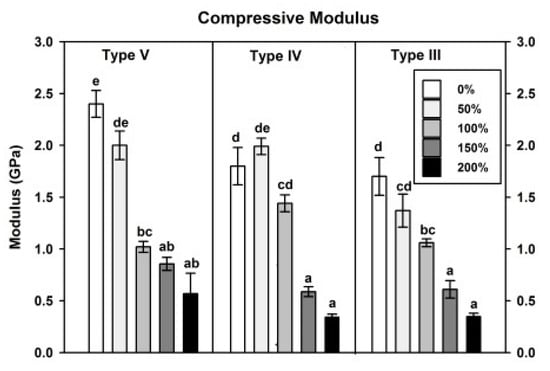

The results for the compressive modulus are presented in Figure 3. For recommended W/P ratios, the mean modulus value for Type V (2.4 GPa, (e)) was significantly higher (p < 0.05) than those for Types IV (1.8 GPa) and III (1.7 GPa), which were not significantly different from each other (both (d)), (p ≥ 0.05). The addition of 50% water produced non-significant changes for all gypsum types, with significant drop-offs in modulus occurring at 100% dilution for Types V (1.0 GPa) and III (1.1 GPA), and at 150% dilution for Type IV (0.6 GPa). The lowest modulus values for all three gypsum types were recorded at 200% dilution, which represented between 76% and 81% decreases from undiluted mixtures.

Figure 3.

Bar chart of one-hour compressive modulus for three gypsum types and five water dilutions. Error bars represent standard errors of means; groups with different letters are significantly different at α = 0.05 confidence level. Comparisons are both within and across gypsum types.

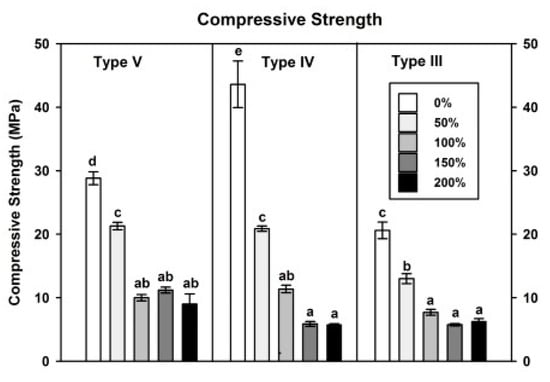

The compressive strength results appear in Figure 4. At recommended W/P ratios, the three gypsum types significantly differed from each other. Mean compressive strength for Type IV gypsum was highest (43.6 MPa, (e)), followed by Type V (28.8 MPa, (d)) and Type III (20.6 MPa, (c)) (p < 0.05). Within each group, compressive strength decreased with 50% water addition, producing mean strength values between 13 MPa and 21.3 MPa. This represented strength decreases ranging from 26% (Type V) to 52% (Type IV). Mean strengths further decreased for 100% dilutions, but no significant differences were noted among 100%, 150% and 200% dilutions.

Figure 4.

Bar chart of one-hour compressive strength for three gypsum types and five water dilutions. Error bars represent standard errors of means; groups with different letters are significantly different at α = 0.05 confidence level. Comparisons are both within and across gypsum types.

3. Discussion

An exact fit of a prosthesis to implant abutments is critical to the delivery of a successful long-term implant-supported or implant tissue-supported prosthesis that spans multiple abutments. Implant-supported prostheses can be either fixed or removable, while implant tissue-supported prostheses are generally only removable in nature. As such, the setting expansion of a cast, particularly a cross-arch expansion, changes the dimensional position of abutments, which contribute to prosthesis misfit.

Two issues are at play in implant complete denture fabrication. Firstly, if a bar-retained implant-supported overdenture is treatment planned, the bar must fit exactly onto the abutments. Ideally, this means the casts must undergo zero expansion to maintain proper distance between the implant analogs. Secondly, for implant tissue-supported overdentures supported by abutments without bars, polymerization shrinkage is offset by the expansion caused by water sorption [18]; therefore, further expansion resulting from gypsum setting also is undesirable.

In the current study, excess water addition significantly reduced the setting expansion of Type V dental stone above 50% dilution but rendered little effect on Types IV and III at any dilution. Even with the lowest setting expansion observed at 150% water dilution, Type V linearly expanded by 0.21%, which was 2.6 and 2.4 times greater than the lowest expansions for Types IV and III. If the cross-arch distance between mandibular first molars is estimated at 45 mm, then these measured expansions would produce 95 µm, 36 µm and 54 µm linear misfits for Types V, IV and III, respectively. For the products tested in this study, the undiluted Type IV mixture produced the least dimensional change (0.08%), but its linear expansion was not zero—the goal for optimum abutment–prosthesis fit.

Although alterations in the W/P ratio to reduce the setting expansion and lower misfits between abutments and prostheses were this study’s primary focus, adverse changes to other properties also must be considered. High strength and hardness are key to providing resistance against breakage and the surface abrasion of the cast during model fabrication, handling and articulation. The results presented in Figure 1, Figure 2, Figure 3 and Figure 4 show that the lowest water addition (50%) did not significantly affect expansion, the desired property change, for any gypsum type. However, this same water addition significantly lowered compressive strength for all three gypsum types, and hardness for Types V and III. This distinctly illustrates that water added in excess of recommended W/P ratios is not a successful strategy for controlling setting expansion.

Dissolution–precipitation is the most widely accepted theory for gypsum setting, where hemihydrate powder dissolves into water, and the dihydrate, with a four times lower water solubility, rapidly precipitates [18]. Critical to physical property development is the concentration of dihydrate crystals within a given material volume. Lautenschlager has demonstrated that crystal growth produces micropores, which become more numerous as water is consumed and crystals grow [20]. This effectively increases mass volume as the setting reaction proceeds. At low W/P ratios, many crystals per unit volume form, with small spacings between adjacent crystals. Although crystal growth is impinged, expansion results from the high number of crystals growing within the mass [21]. W/P ratio, and hence dihydrate crystal concentration, are largely controlled by powder shape and density. Type IV and V powders are constructed from densite, where gypsum rock is boiled in a calcium chloride solution and the calcium chloride is later rinsed away [22]. This produces highly dense powders that require low amounts of gauging water, which results in high crystal concentration and low porosity within the set material. With more crystals and less porosity per unit volume, increased strength, hardness and expansion are expected. Type III powder is less dense, requires more gauging water and produces more porous gypsum.

In this study, the observation that setting expansion was largely unaffected by excess water addition was somewhat surprising, since previous works have shown expansion to decrease [18,20,23]. Those studies measured expansion at times no longer than 24 h, whereas expansion was measured at 72 h in this study. With continuous expansion reported to occur over 120 h [17], it is reasonable to conclude that differences in time partly underlie these discrepancies. It is possible that water trapped deep within the mass after setting continues to react over time and therefore elicit continued expansion.

For the three products tested here, the recommended W/P ratios produced setting expansions of 0.32% (V), 0.08% (IV) and 0.12% (III), which were comparable to manufacturers’ stated values of 0.28%, 0.07% and 0.12%, respectively (Table 1). Lower W/P ratios are known to produce higher crystal densities and hence more expansion. This was borne by results presented for Type V and III undiluted mixtures, where Type V, with a lower W/P ratio, was 2.6 times higher (Figure 1). Although Types IV and V have similar W/P ratios, salts are added to Type IV to reduce expansion [19]. This, too, is supported by Figure 1, where mean expansion values for undiluted Type IV are lower than Type V, and similar to Type III. When water is added above the recommended W/P ratio, mass density decreases, which in turn is expected to reduce setting expansion. This was not observed, as expansion did not significantly decrease with 50% water dilution for Type V, and for all dilutions for Types III and IV. This implies that, although fewer dihydrate crystals per unit volume were present, these amounts of excess water permitted unimpinged crystal growth during setting. This phenomenon is consistent with hygroscopic expansion, where excess water lacks adequate surface tension to pull the crystals together [24]. For Type V, dilutions above 50% produced significant drop-offs in expansion, suggesting that crystal growth was more limited than for Types III and IV.

Table 1.

Comparison of properties between manufacturer and this study (mean ± std error).

Although a 50% water addition rendered little effect on setting expansion for all gypsum types, one-hour compressive strength was significantly reduced for both 50% and 100% water additions. Gypsum strength is largely attributed to the presence of high dihydrate crystal concentration that grows and interlocks during setting, followed by smaller secondary precipitates that anchor larger crystals as the model dries. Since diluted mixtures contain fewer dihydrate crystals per unit volume to resist applied force, localized stresses become concentrated and fracture occurs with less force. After one hour of setting, there may exist a limiting diluted W/P ratio, where the compressive strength reaches a minimum and does not change with more added water. Support for this notion was observed for all three gypsum types, where compressive strength achieved lowest mean values for 100% water additions and did not significantly change thereafter. It should be noted that manufacturer-reported strength values for Types V and III were 1.75 and 1.5 times higher than for undiluted mixtures measured here, but only 1.1 times higher than Type IV (Table 1). Departures from the ISO standard in test sample geometry and loading regimen may partly account for these differences, but the reasons for these discrepancies are largely unknown.

Compressive modulus was included in this study as means to understand the degree of strain incurred when gypsum was loaded in compression after setting for one hour. In addition to compressive strain occurring where force is applied at the cylinder’s ends, the compression test generates tensile strain along the outer walls of the cylinder and shear strain within the cylinder. These complex strains reflect different directions of dihydrate crystal displacement and deformation under load, depending upon the location within the cylinder. Complex strains also are generated when casts are loaded, thereby providing different axes for crystal movement. If high crystal density is present, little movement and deformation are afforded due to short crystal length and close crystal proximity. This produces high compressive modulus. As water is added, density is reduced, crystals grow longer, are spaced farther apart, and are less interlocked. Under load, this permits more movement and deformation, effectively lowering the modulus. A comparison of Figure 3 with Figure 4 shows that 50% water addition significantly lowered strength but produced non-significant changes in modulus for the three gypsum types. Significant modulus reductions did not take place until 100% dilution for Types V and III, and 150% dilution for Type IV. An explanation for this phenomenon may be related to crystal numbers, lengths and spacings, which, in turn, are related to porosity. At 50% dilution, although fewer crystals with increased lengths are present than for undiluted mixtures, the numbers, spacings and lengths are apparently adequate to prevent substantial crystal deformation and displacement under load. This renders modulus values that are not significantly different from undiluted mixtures. However, with fewer crystals available to interlock and crystal lengths increased, localized stresses on crystals and crystal boundaries are high, causing fracture at lower loads. This, in turn, results in significantly lower strength at the same dilution. It has been documented that regions experiencing high tensile stress undergo intercrystalline fracture, which increases with increased porosity [25]. This is attributed to lower contact area among crystals. At dilutions above 100%, the modulus steadily decreases, while the strength remains unchanged. This suggests that, although the rate of crystal displacement prior to fracture continues to increase, fracture resistance is minimally affected. The underlying reason for this occurrence is unclear.

Surface hardness is an indicator of a model’s ability to resist scratching and limit surface wear. Scratches can adversely alter oral anatomy in key locations and scuffing or wear can change interocclusal relationships, both of which are undesirable. A laboratory hardness test measures a material’s resistance to surface indentation, which is related to both proportional limit and fracture toughness. After five days, the gypsum setting reaction is over 90% complete, and little remaining water remains, rendering physical property development near completion. Resistance to indenter penetration is primarily a function of gypsum density, which reflects proximity and interlocking among dihydrate crystals. As stated previously, hemihydrate powder particle size and density dictate the amount of required gauging water, which ultimately contribute to model density. This is illustrated in Figure 2, where Type V gypsum, formed from smaller and denser powder particles, was significantly harder than Type III. Although hemihydrate powders for Type IV are similar to Type V, salts added to control setting expansion also affect Knoop hardness, as Type IV mean hardness values were lower, and not significantly different from Type III at the same dilutions. Apparently, salt incorporation permits Type IV gypsum to maintain its hardness at low dilutions, as 50% water additions did not significantly reduce its mean hardness values. This was not the case for Types V and III, as significant reductions were observed. Since salt compositions are proprietary information held by manufacturers, the roles played by their additions are unclear.

4. Materials and Methods

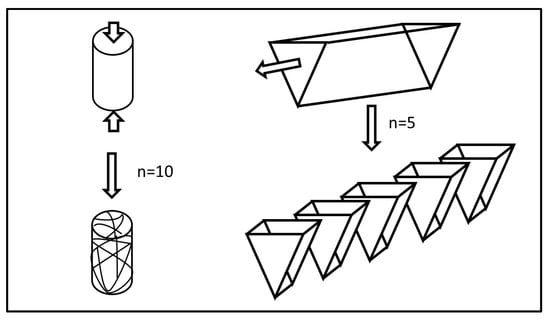

Four properties were measured: 72 h linear setting expansion, one-hour compressive strength and compressive modulus, and Knoop hardness at five days. One-hour compressive properties were chosen based on model fragility expected during de-molding and early handling of a cast. Three dental stones were evaluated: ISO specified Type III, Microstone (Whip Mix Corp., Louisville, KY, USA), Type IV, UltiRock (Whip Mix Corp., Louisville, KY, USA) and Type V, Hard Rock (Whip Mix Corp., Louisville, KY, USA). Different amounts of distilled water additions were chosen to evaluate the effects of different water/powder ratios on the four material properties. The amounts of water added to recommended W/P ratios were as follows: (1) 0%, the manufacturer’s recommend water/powder ratio, (2) 50%, 1.5 times the manufacturer’s recommendation of water, (3) 100%, 2 times the manufacturer’s recommendation of water, (4) 150%, 2.5 times the manufacturer’s recommendation of water, and (5) 200%, 3 times manufacturer’s recommendation of water.

Product literature from Whip Mix Corporation states Microstone, a Type III dental stone, exhibits a setting expansion of 0.12%, Ulti-Rock, a Type IV dental stone, an expansion of 0.07% and Hard Rock, the Type V stone, a setting expansion of 0.28% (Table 1) [26]. For the setting expansion test, five specimens per stone ratio were fabricated. The sample size was chosen based on 80% power to reject the null hypotheses of equal group means when the mean difference between two groups was 0.02% (p < 0.05) [27]. One hundred fifty grams of powder were weighed on an electronic balance (Ohaus Corporation, Pine Brook, NJ, USA). The selected amount of distilled water was settled in a vacuum mixing bowl (Whip Mix Corporation) and stone powder added to the bowl. A hand-spatulated mixing technique was performed for 10 s and the mixing procedure completed under vacuum with a Vacuum Power Mixer Plus (Whip Mix Corporation) for 20 s. Subsequently, the stone was placed into a 37 mm × 53 mm × 100 mm V-shaped trough lined with a natural latex dental dam material (Coltene/Whaledent, Inc., Cuyahoga Falls, OH, USA) attached to a dial gauge expansion instrument (EMI 100; SAM, Prazisionstechnik GMBH, Gauting, Germany), as stated in ISO Standard 6873. The gypsum was allowed to set for 72 h, linear expansion was read from the dial gauge, and the percentage of linear expansion was calculated based on original length.

For compressive strength and modulus tests, ten cylinders per W/P ratio for each gypsum type were fabricated with dimension 12 mm in diameter by 25 mm in height, as reported in previous studies [19,20]. The sample size was chosen based on 80% power to reject the null hypotheses of equal group means when mean compressive strength differences were 7 MPa (p < 0.05) [22]. One hundred grams of powder were added to each of the selected water/powder ratios using the same hand-spatulating and vacuum-mixing protocol previously described. After one hour, each cylinder was loaded in compression at 1 mm/min until failure occurred, using a universal testing machine (5500R, Instron Corp., Norwood, MA, USA). Compressive modulus was calculated as the linear slope of the stress–strain curve and compressive strength was recorded as the maximum stress at failure. Test samples were discarded and remade if porosity was detected on exterior or fracture surfaces.

For the surface microhardness test, 48 h following the measurement of the setting expansion, each V-shaped specimen was cut into 2-cm-thick sections with a sectioning saw (VC-50, Leco Corp., Saint Joseph, MI, USA) and surfaces finished with 600, 900 and 1200 grit Silicon Carbide (SiC) abrasives to produce a surface that would render visible indentations. Five Knoop hardness measurements were made on each section and averaged, with five sections measured for each expansion sample (HMV, Shimadzu Corp. Nakagyo-ku, Kyoto, Japan). Five samples were measured for each group (Figure 5). A 200-g load and 15-s dwell time were applied for each surface microhardness measurement.

Figure 5.

Samples and tests used in this study. Left: Cylinder compression test to failure to measure compressive strength and modulus. Right: Upper: V-shaped block constructed to measure 72 h linear setting expansion along length of block (arrow pointing left). Lower: V-block sectioned to produce five sections for Knoop hardness. Five measurements were recorded on each section and averaged to produce one mean measurement per section.

For all properties, means and standard errors were calculated for each group. Mean group differences were assessed by two-way ANOVA, with the two factors being type of stone and amount of water dilution (p < 0.05). Pairwise comparisons of groups were accomplished with the Tukey–Kramer Multiple Comparison test (p < 0.05).

5. Conclusions

In assessing the results reported in this study, increased water/powder ratios did not adequately reduce setting expansion, the study’s primary goal, and adversely affected other key physical properties. The two tested null hypotheses, that sequential water additions to hemihydrate powders do not affect four physical properties and that they rendered no differences among Types III, IV and V gypsum, were rejected. Of the three gypsum types tested in this study, Type IV is recommended to serve as master cast for implant-supported prostheses compared to the other types of gypsum examined.

Author Contributions

Conceptualization, A.G.W., M.W.B.; methodology, A.G.W., B.S. and M.W.B.; software, B.S. and M.W.B.; validation, B.S. and M.W.B.; formal analysis, M.W.B.; investigation, B.S. and M.W.B.; resources, A.G.W. and M.W.B.; data curation, M.W.B.; writing—original draft preparation, J.L.S., A.G.W. and M.W.B.; writing—review and editing, J.L.S., A.G.W. and M.W.B.; visualization, J.L.S., A.G.W. and M.W.B.; supervision, B.S. and M.W.B.; project administration, M.W.B.; funding acquisition, A.G.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors gratefully acknowledge Thiago Carvalho De Sousa, Kevin Vakilzadian and Dayne Thomas for their assistance in conducting the experiments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Misch, C.E.; Perel, M.L.; Wang, H.L.; Sammartino, G.; Galindo-Moreno, P.; Trisi, P.; Steigmann, M.; Rebaudi, A.; Palti, A.; Pikos, M.A.; et al. Implant success, survival, and failure: The international congress of oral implantologists (ICOI) Pisa consensus conference. Implant Dent. 2008, 17, 5–9. [Google Scholar] [CrossRef] [PubMed]

- Moraschini, V.; Poubel, L.D.C.; Ferreira, V.F.; dos Sp Barboza, E. Evaluation of survival and success rate of dental implants reported in longitudinal studies with a follow-up period of at least 10 years: A systematic review. Int. J. Oral. Maxillofac. Surg. 2015, 44, 377–388. [Google Scholar] [CrossRef] [PubMed]

- de Moraes, P.H.; Olate, S.; Lauria, A.; Asprino, L.; de Moraes, M.; de Albergaria-Barbosa, J.R. 8–10 year follow-up survival of dental implants in maxillae with and without autogenous bone graft reconstruction. Int. J. Clin. Exp. Med. 2015, 8, 19282–19289. [Google Scholar] [PubMed]

- Raiker, S.; Talukdar, P.; Kumari, K.; Panda, S.K.; Oommem, V.M.; Prasad, A. Factors affecting the survival rate of dental implants: A retrospective study. J. Int. Soc. Prev. Commun. Dent. 2017, 7, 351–355. [Google Scholar] [CrossRef] [PubMed]

- Albreksson, T. A multicenter report on osseointegrated oral implants. J. Prosthet. Dent. 1988, 60, 75–84. [Google Scholar] [CrossRef]

- Adell, R.; Eriksson, B.; Lekholm, U.; Brånemark, P.-I.; Jemt, T. A long term follow up study of osseointegrated implants in the treatment of totally edentulous jaws. Int. J. Oral. Maxillofac. Implants 1990, 5, 347–359. [Google Scholar] [PubMed]

- Zarb, G.A.; Schmitt, A. The longitudinal clinical effectiveness of osseointegrated dental implants. The Toronto study. Part II: The prosthetic results. J. Prosthet. Dent. 1990, 64, 53–61. [Google Scholar] [CrossRef]

- Needleman, I.; Chin, S.; O’Brien, T.; Donos, N. Systematic review of outcome measurements and reference group(s) to evaluate and compare implant success and failure. J. Clin. Periodontol. 2012, 39 (Suppl. S12), 122–132. [Google Scholar] [CrossRef]

- Carr, A.; Wolfaardt, J.; Garrett, N. Capturing patient benefits of treatment. Int. J. Oral. Maxillofac. Implants 2011, 26, 85–92. [Google Scholar]

- Wee, A.G.; Schneider, R.L.; Aquilino, S.A.; Huff, T.L.; Lindquist, T.J.; Williamson, D.L. Evaluation of the accuracy of solid implant casts. J. Prosthet. 1998, 7, 161–169. [Google Scholar] [CrossRef]

- Wee, A.G.; Aquilino, S.A.; Schneider, R.L. Strategies to achieve fit in implant prosthodontics: A review of the literature. Int. J. Prosthodont. 1999, 12, 167–178. [Google Scholar] [PubMed]

- Schneider, R.L.; Wee, A.G. Fabricating low-fusing metal casts for more accurate implant prosthodontics. J. Prosthodont. 1996, 5, 301–303. [Google Scholar] [CrossRef] [PubMed]

- Wee, A.G.; Cheng, A.C.; Eskridge, R.N. Accuracy of 3 conceptually different die systems used for implant casts. J. Prosthet. Dent. 2002, 87, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Duke, P.; Moore, B.K.; Haug, S.P.; Andres, C.J. Study of the physical properties of type IV gypsum, resin-containing, and epoxy die materials. J. Prosthet. Dent. 2000, 83, 466–473. [Google Scholar] [CrossRef]

- Wise, M. Fit of implant-supported fixed prostheses fabricated of master casts made from a dental stone and a dental plaster. J. Prosthet. Dent. 2001, 86, 532–538. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. ISO 6873: Dental Gypsum Products; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Heshmati, R.H.; Nagy, W.W.; Wirth, C.G.; Dhuru, V.B. Delayed linear expansion of improved dental stone. J. Prosthet. Dent. 2002, 88, 26–31. [Google Scholar] [CrossRef] [PubMed]

- Anusavice, K.; Chiayi, S.; Rawls, H.R. Phillip’s Science of Dental Materials, 20th ed.; Elsevier: New York, NY, USA, 2012. [Google Scholar]

- Jayaprakash, K.; Upadhya, P.N.; Nandish, B.T.; Shetty, A.N.; Shetty, K.H.K.; Ginjupalli, K.; Voddya, S.B.; Prabhu, S. Impact of water quality and water powder ratio on the properties of type 4—Dies stones (gypsum products) used in dentistry. Int. J. Health Rehab. Sci. 2014, 3, 75–81. [Google Scholar] [CrossRef]

- Lautenschlager, E.P.; Corbin, F. Investigation on the expansion of dental stone. J. Dent. Res. 1969, 48, 206–210. [Google Scholar] [CrossRef]

- Winkler, M.M.; Monagan, P.; Gilbert, J.L.; Lautenshlager, E.P. Freeze-drying and scanning electron microscopy of setting dental gypsum. Dent. Mater. 1995, 11, 226–230. [Google Scholar] [CrossRef]

- Powers, J.M.; Sakaguchi, R.L. Craig’s Restorative Dental Materials, 20th ed.; Mosby: St. Louis, MI, USA, 2006. [Google Scholar]

- Worner, H.K. Dental plasters, I and II. Aust. J. Dent. 1942, 46, 1–10. [Google Scholar]

- Mahler, D.B.; Ady, A.B. An explanation for the hygroscopic expansion of dental gypsum products. J. Dent. Res. 1960, 39, 578–589. [Google Scholar] [CrossRef] [PubMed]

- Mori, T.; Yamane, M. Fractography of cast gypsum. Aust. Dent. J. 1982, 27, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Whip Mix—The Most Trusted Source for Gypsums. Rock Solid. Available online: http://whipmix.com/wp-content/uploads/Gypsum-Product-Guide-2015041.pdf (accessed on 20 January 2020).

- Azer, S.S.; Kerby, R.E.; Knoblock, L.A. Effect of mixing methods on the physical properties of dental stones. J. Prosthet. Dent. 2008, 36, 736–744. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).