Developing an Algorithm Limiting the Longitudinal Acceleration of an Electric Vehicle

Abstract

1. Introduction

2. Derivation of the Longitudinal Acceleration Limiter Controller Equation

- The acceleration of the vehicle while traveling forward is considered;

- The vehicle is travelling on a flat horizontal surface;

- The algorithm that calculates the control action operates when excessive acceleration is detected.

- —longitudinal speed of the wheeled vehicle, m/s;

- —vehicle mass, kg;

- —traction force of driving wheels, N;

- —rolling resistance force of all wheels, N;

- —aerodynamic drag force, N.

- —proportional coefficient;

- —integration constant, sec;

- —control error (mismatch).

3. PI Controller Coefficient Calibration

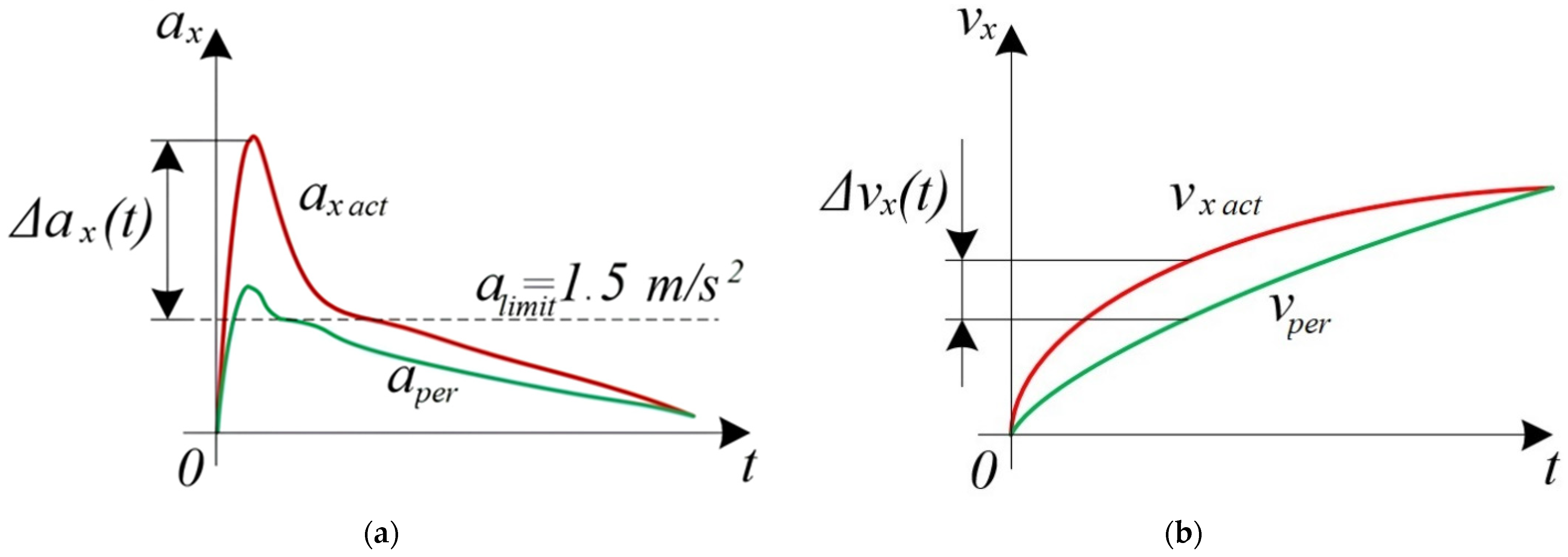

- —maximum acceleration difference, m/s2;

- —derivative of acceleration (jerk) of the vehicle during acceleration reduction, which should not exceed 2 m/s3 [4].

- —the magnitude of the control action at the initial moment of time;

- —the magnitude of the control action when acceleration is limited.

4. Mathematical Modeling of Electric Bus Motion

- —initial moment of time of acceleration exceedance, s;

- —final moment of time of acceleration exceedance, s.

5. Field Tests of the Electric Bus—Justification of Operability and Efficiency of the Developed System

6. Conclusions

- The authors developed a system for limiting longitudinal acceleration, alongside the laws and algorithms of the control system, including the design of a regulator capable of limiting the longitudinal acceleration of a vehicle;

- The concept of total speed was introduced as a criterion for the effectiveness of the system;

- Mathematical modeling methods were used to prove the effectiveness of the algorithm at the stage of creating a system based on a virtual prototype of an electric bus. The relative efficiency of the system was 77.28%;

- The developed system was tested on the KAMAZ 6282 electric bus at the KAMAZ test site. During full-scale tests, the longitudinal acceleration did not exceed 2 m/s2 and then lowered to 1.5 m/s2, which is comfortable. At the same time, the relative efficiency was 51.72%;

- The practical significance of the algorithm for limiting longitudinal acceleration was proven during subsequent introduction into mass production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ovsyannikov, E.M. Traction Electrical Systems of Motor Transport Vehicles: Textbook; Forum, M., Ed.; INFRA-M: Moscow, Russia, 2019; p. 303. ISBN 978-5-00091-527-1. [Google Scholar]

- Bokare, P.S.; Maurya, A.K. Acceleration-Deceleration Behavior of Various Vehicle Types. Transp. Res. Procedia 2017, 25, 4733–4749. [Google Scholar] [CrossRef]

- Damian, F.; Grabski, P.; Jurecki, R.S.; Szumska, E.M. Experimental Study on Longitudinal Acceleration of Urban Buses and Coaches in Different Road Maneuvers. Sensors 2023, 23, 3125. [Google Scholar] [CrossRef] [PubMed]

- Biryukov, V.V. Traction Electric Drive: Textbook for Universities, 2nd ed.; Yurait Publishing House: Moscow, Russia, 2021; p. 315. ISBN 978-5-534-04376-1. [Google Scholar]

- Khajepour, A.; Fallah, S.; Goodarzi, A. Electric and Hybrid Vehicles. Technologies, Modeling and Control: A Mechatronic Approach; John Wiley & Sons Ltd.: Chichester, UK, 2014; 432p, ISBN 978-1-118-34151-3. [Google Scholar]

- Barabino, B.; Eboli, L.; Mazzulla, G.; Mozzoni, S.; Murru, R.; Pungillo, G. An innovative methodology to define the bus comfort level. Transp. Res. Procedia 2019, 41, 461–470. [Google Scholar] [CrossRef]

- Krasna, S.; Keller, A.; Linder, A.; Silvano, A.P.; Xu, J.C.; Tompson, R.; Klug, C. Human Response to Longitudinal Perturbations of Standing Passengers on Public Transport During Regular Operation. Front. Bioeng. Biotechnol. 2021, 9, 680883. [Google Scholar] [CrossRef] [PubMed]

- Lobusov, E.S.; Zhileikin, M.M. Algorithm of definition of actual speed for maintenance of work of the automated control system of movement of a wheeled machine. Izvestiya Vuzov. Mashinostroenie 2017, 7, 34–40. [Google Scholar] [CrossRef]

- Tarasik, V.P. Theory of Car Movement, 2nd ed.; BHV-Peterburg: Berlin, Germany, 2022; p. 576. ISBN 978-5-9775-6817-3. [Google Scholar]

- Larin, V.V. Theory of Motion of All-Wheel Drive Wheeled Machines: A Textbook for Universities; Bauman Moscow State Technical University: Moscow, Russia, 2010; 391p, ISBN 978-5-7038-3389-6. [Google Scholar]

- Ivanov, V.A.; Faldin, N.V. Theory of Optimal Automatic Control Systems; Nauka. Main Editorial Office of Physical and Mathematical Literature: Moscow, Russia, 1981; 336p. [Google Scholar]

- Denisenko, V.V. Computer Control of Technological Process, Experiment, Equipment; Hot Line-Telecom: Moscow, Russia, 2011; 608p, ISBN 978-5-9912-006-8. [Google Scholar]

- Büschgens, G.S.; Studnev, R.V. Dynamics of Aircraft. Spatial Motion; Mashinostroenie: Moscow, Russia, 1983; 320p. [Google Scholar]

- Dik, A.B. Calculation of Stationary and Non-Stationary Characteristics of a Braking Wheel in a Drift Motion. Ph.D. Thesis, Siberian State Automobile and Highway University (SibADI), Omsk, Russia, 1988. [Google Scholar]

- Rozhdestvenskiy, Y.L.; Mashkov, K.Y. About the reaction formation when an elastic wheel rolls on a non-deformable support base. Proc. MVTU 1982, 390, 56–64. [Google Scholar]

- Shadrin, S.S. Methodology of Calculation Estimation of Controllability and Stability of a Car. Ph.D. Thesis, Moscow Automobile and Road Construction State Technical University, Moscow, Russia, 2005. [Google Scholar]

- Rajamani, R. Vehicle Dynamics and Control, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2012; 496p, ISBN 978-1-46141433-9. [Google Scholar]

- Jazar, R.N. Vehicle Dynamics. Theory and Application; Springer: Berlin/Heidelberg, Germany, 2008; 1022p, ISBN 987-0-387-74243-4. [Google Scholar]

- Kienke, U.; Nielsen, L. Automotive Control Systems. For Engine, Driveline, and Vehicle, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2005; 512p, ISBN 978-3-540-26484-2. [Google Scholar]

- Kamaz, L.L.C. Characteristics of Electric Bus KAMAZ 6282, Naberezhnye Chelny. Available online: https://kamaz.ru/production/buses/pdf/Электробус%20KAMAZ-6282.pdf (accessed on 9 September 2022).

| Electric Bus 1 | Electric Bus 2 | Relative Efficiency | |

|---|---|---|---|

| Cumulative Velocity |

| Max speed | 72 km/h |

| Vehicle mass | 12,000 kg |

| Type of motor | Synchronous |

| Max peak torque | 390 × 2 N∙m |

| Peak power | 125 × 2 kW |

| Tires | 275/70 R22.5 |

| View of Electric Bus Arrival | With Unlimited Acceleration | With Limited Acceleration | Relative Efficiency |

|---|---|---|---|

| Cumulative Velocity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antonyan, A.; Klimov, A.; Buchkin, A.; Keller, A.; Shadrin, S.; Makarova, D.; Furletov, Y. Developing an Algorithm Limiting the Longitudinal Acceleration of an Electric Vehicle. Vehicles 2025, 7, 7. https://doi.org/10.3390/vehicles7010007

Antonyan A, Klimov A, Buchkin A, Keller A, Shadrin S, Makarova D, Furletov Y. Developing an Algorithm Limiting the Longitudinal Acceleration of an Electric Vehicle. Vehicles. 2025; 7(1):7. https://doi.org/10.3390/vehicles7010007

Chicago/Turabian StyleAntonyan, Akop, Aleksandr Klimov, Andrey Buchkin, Andrey Keller, Sergey Shadrin, Daria Makarova, and Yury Furletov. 2025. "Developing an Algorithm Limiting the Longitudinal Acceleration of an Electric Vehicle" Vehicles 7, no. 1: 7. https://doi.org/10.3390/vehicles7010007

APA StyleAntonyan, A., Klimov, A., Buchkin, A., Keller, A., Shadrin, S., Makarova, D., & Furletov, Y. (2025). Developing an Algorithm Limiting the Longitudinal Acceleration of an Electric Vehicle. Vehicles, 7(1), 7. https://doi.org/10.3390/vehicles7010007