Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease

Abstract

1. Introduction

2. Materials and Methods

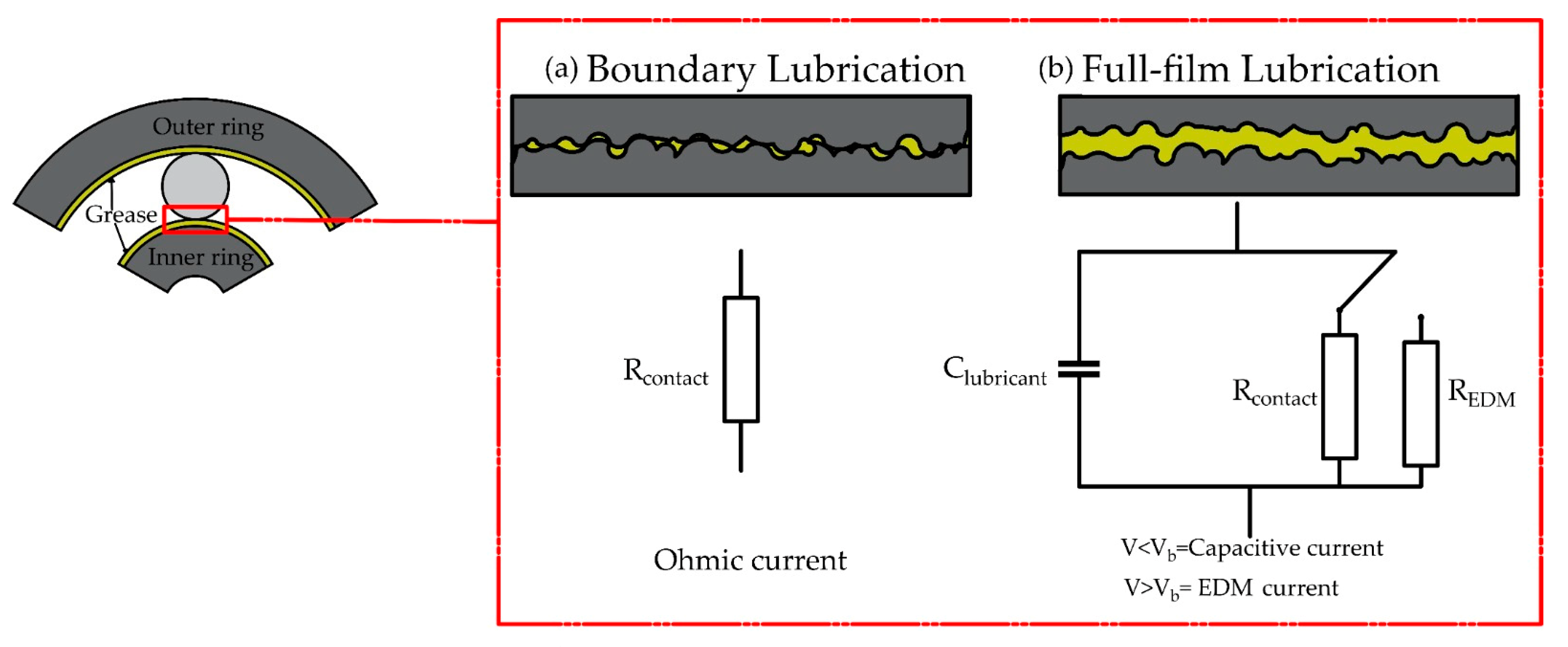

2.1. PWM-Induced Common-Mode Voltages

2.2. Test Set-Up

2.3. Structural Characterization of the Nanomaterials

2.4. Nano-Grease Preparation

2.5. Tribological Characteristics of Grease Blends

2.6. Electrical Test

2.7. Vibration Test Procedure

2.8. Surface Roughness Test

3. Results and Discussion

3.1. Results of the Nanomaterials’ Characterization

3.2. Results of Tribological Testing

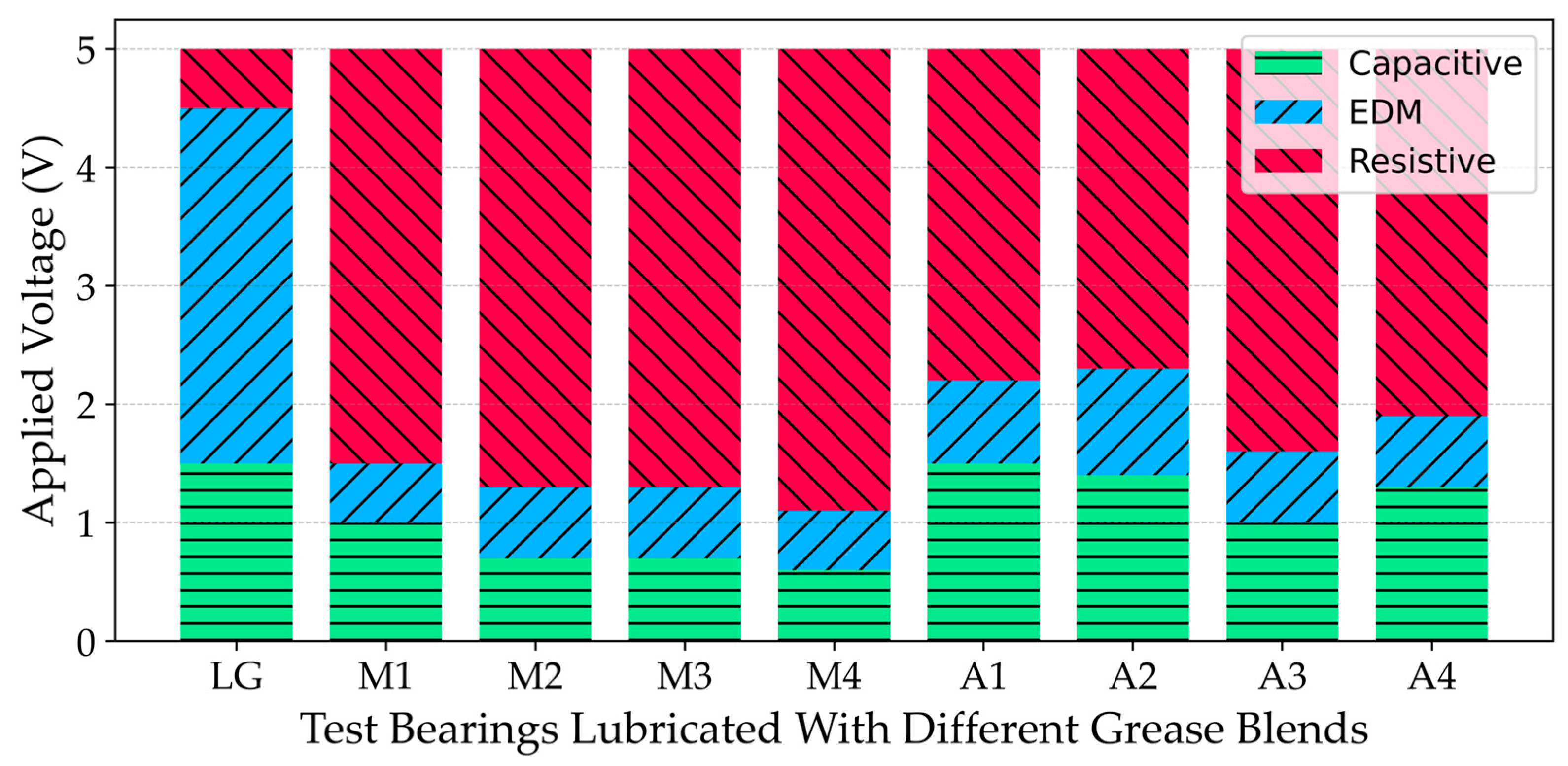

3.3. Results of Electric Discharges’ Test

3.4. Results of Vibration Analysis

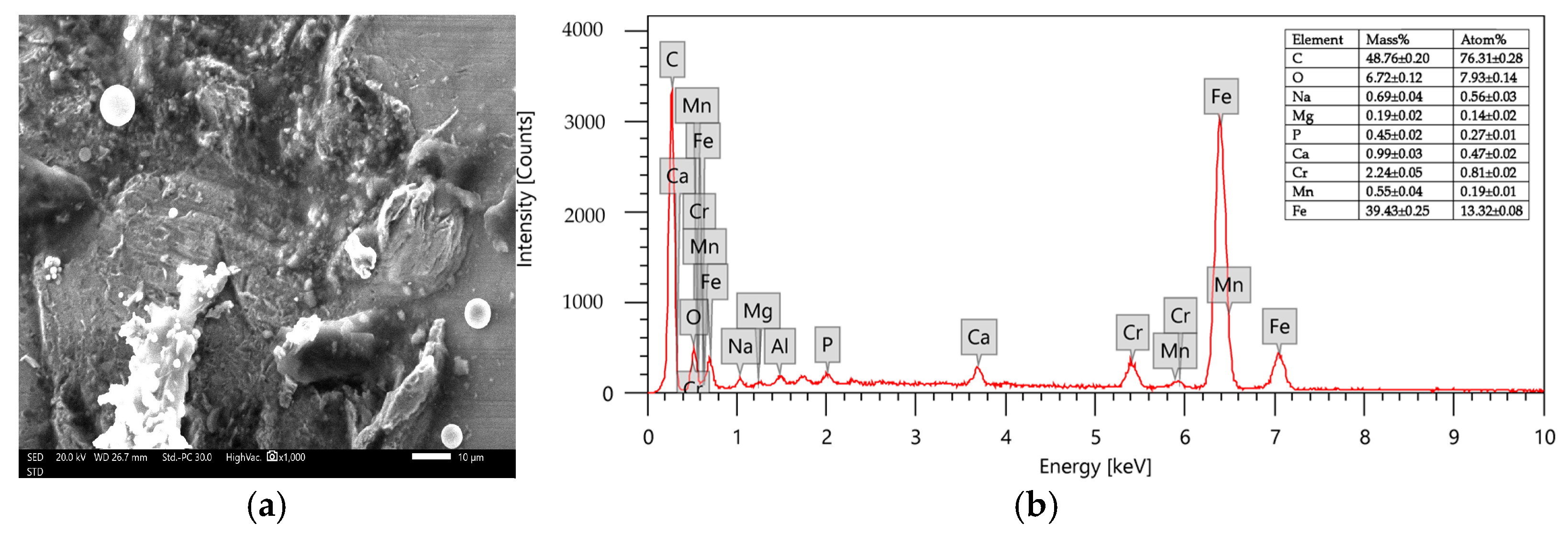

3.5. Results of Surface Wear Analysis

4. Conclusions

- The addition of nanoparticles into bearing grease significantly reduces EDM discharge magnitudes compared to LG with the discharge magnitudes decreasing with increasing concentrations of nano-additives across all test cases.

- The root mean square (RMS) vibration levels were also lower in bearings lubricated with nano-additives compared to those lubricated with LG. Specifically, MWCNT reduced the RMS acceleration levels by 65.19% at a volume concentration of 0.4 wt.%, while alumina nanoparticles resulted in a 44.89% reduction.

- Surface analysis indicated increased wear in bearings lubricated with LG relative to those containing nano-additives, suggesting that the latter provide a protective effect against EDM discharges. MWCNTs demonstrated a remarkable 70.67% reduction in surface damage, whereas alumina nanoparticles exhibited a reduction of 37.5%.

- The degree of protection afforded by the nano-additives was evident by the EDX analysis of the worn surface and proved to be contingent upon both the concentration level and the specific type of nano-additive employed. MWCNTs exhibited superior performance compared to alumina (Al2O3), especially at lower concentrations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Global EV Outlook 2024. Available online: https://www.iea.org/reports/global-ev-outlook-2024 (accessed on 29 December 2024).

- Zhan, W.; Wang, Z.; Deng, J.; Liu, P.; Cui, D. Integrating System Dynamics and Agent-Based Modeling: A Data-Driven Framework for Predicting Electric Vehicle Market Penetration and GHG Emissions Reduction under Various Incentives Scenarios. Appl. Energy 2024, 372, 123749. [Google Scholar] [CrossRef]

- Fang, K.; Li, C.; Tang, Y.; He, J.; Song, J. China’s Pathways to Peak Carbon Emissions: New Insights from Various Industrial Sectors. Appl. Energy 2022, 306, 118039. [Google Scholar] [CrossRef]

- Madaram, V.G.; Biswas, P.K.; Sain, C.; Thanikanti, S.B.; Balachandran, P.K. Advancement of Electric Vehicle Technologies, Classification of Charging Methodologies, and Optimization Strategies for Sustainable Development—A Comprehensive Review. Heliyon 2024, 10, e39299. [Google Scholar] [CrossRef] [PubMed]

- Ehsan, F.; Habib, S.; Gulzar, M.M.; Guo, J.; Muyeen, S.M.; Kamwa, I. Assessing Policy Influence on Electric Vehicle Adoption in China: An in-Depth Study. Energy Strategy Rev. 2024, 54, 101471. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical Bearing Failures in Electric Vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Kurt Merve, Ş. The Use of Induction Motors in Electric Vehicles. In Induction Motors—Recent Advances, New Perspectives and Applications; El-Shahat, A., Ed.; IntechOpen: London, UK, 2023; ISBN 978-1-83769-577-5. [Google Scholar]

- Graf, S.; Koch, O.; Sauer, B. Influence of Parasitic Electric Currents on an Exemplary Mineral-Oil-Based Lubricant and the Raceway Surfaces of Thrust Bearings. Lubricants 2023, 11, 313. [Google Scholar] [CrossRef]

- Hadden, T.; Jiang, J.W.; Bilgin, B.; Yang, Y.; Sathyan, A.; Dadkhah, H.; Emadi, A. A Review of Shaft Voltages and Bearing Currents in EV and HEV Motors. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; IEEE: New York, NY, USA, 2016; pp. 1578–1583. [Google Scholar]

- Kalaiselvi, J.; Srinivas, S. Bearing Currents and Shaft Voltage Reduction in Dual-Inverter-Fed Open-End Winding Induction Motor With Reduced CMV PWM Methods. IEEE Trans. Ind. Electron. 2015, 62, 144–152. [Google Scholar] [CrossRef]

- Song, C.; Ren, Y.; Huang, Q.; Zhang, Y.; Li, Y.; Cheng, J.; Pang, X.; Zhang, Y. Effect of Shaft Voltage on Electric Damage of GCr15 Bearing Material. Tribol. Int. 2024, 200, 110139. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Güleç, M.; Sergeant, P. Bearing Current and Shaft Voltage in Electrical Machines: A Comprehensive Research Review. Machines 2023, 11, 550. [Google Scholar] [CrossRef]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor Bearing Damage Induced by Bearing Current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Turzyński, M.; Musznicki, P. A Review of Reduction Methods of Impact of Common-Mode Voltage on Electric Drives. Energies 2021, 14, 4003. [Google Scholar] [CrossRef]

- Wang, Z.; Mao, S.; Tian, H.; Su, B.; Cui, Y. Simulation Analysis and Experimental Research on Electric Thermal Coupling of Current Bearing. Lubricants 2024, 12, 73. [Google Scholar] [CrossRef]

- Berhausen, S.; Jarek, T. Method of Limiting Shaft Voltages in AC Electric Machines. Energies 2021, 14, 3326. [Google Scholar] [CrossRef]

- Puchtler, S.; Maier, R.; Kuhn, M.; Burkhardt, Y. The Influence of Load and Speed on the Initial Breakdown of Rolling Bearings Exposed to Electrical Currents. Lubricants 2023, 12, 1. [Google Scholar] [CrossRef]

- Robles, E.; Fernandez, M.; Andreu, J.; Ibarra, E.; Ugalde, U. Advanced Power Inverter Topologies and Modulation Techniques for Common-Mode Voltage Elimination in Electric Motor Drive Systems. Renew. Sustain. Energy Rev. 2021, 140, 110746. [Google Scholar] [CrossRef]

- Safdarzadeh, O.; Binder, A.; Weicker, M. Measuring Electric Contact in an Axial Ball Bearing at DC Current Flow. IEEE Trans. Ind. Applicat. 2023, 59, 3341–3352. [Google Scholar] [CrossRef]

- Oliver, J.A.; Guerrero, G.; Goldman, J. Ceramic Bearings for Electric Motors: Eliminating Damage with New Materials. IEEE Ind. Appl. Mag. 2017, 23, 14–20. [Google Scholar] [CrossRef]

- Fan, F.; See, K.Y.; Banda, J.K.; Liu, X.; Gupta, A.K. Investigation and Mitigation of Premature Bearing Degradation in Motor Drive System. IEEE Electromagn. Compat. Mag. 2019, 8, 75–81. [Google Scholar] [CrossRef]

- Alves Êvo, M.T.; Paula, H. Electrostatic Shielding for Bearings Discharge Currents Attenuation: Analysis of Its Effectiveness, Losses and Impact on the Motor Performance—A Study for Design Guidelines. IET Electr. Power Appl. 2020, 14, 1050–1059. [Google Scholar] [CrossRef]

- Qin, C.; Li, X. Improved Control Method of the Paralleled Three-Phase Two-Level Inverters for Common-Mode Voltage and Circulating Current Suppression. ISA Trans. 2024, 151, 423–436. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Xia, Y.; Wang, L. Tribological Properties of Conductive Lubricating Greases. Friction 2014, 2, 343–353. [Google Scholar] [CrossRef]

- Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants 2019, 7, 108. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, J.; Li, X.; Chong, H.; Han, B.; Bai, Q. On the Electric Behaviour of Conductive Grease inside the Contact Zone. Friction 2024, 12, 683–697. [Google Scholar] [CrossRef]

- Tischmacher, H.; Gattermann, S. Investigations on Bearing Currents in Converter-Fed Electrical Motors. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; IEEE: New York, NY, USA, 2012; pp. 1764–1770. [Google Scholar]

- Li, Z.; Guo, F.; Jing, Z.; Li, B.; Zhang, L.; Wang, X. Study on Electric Erosion in Grease Lubrication Using Optical Interference Method. Tribol. Int. 2024, 195, 109596. [Google Scholar] [CrossRef]

- Romanenko, A.; Muetze, A.; Ahola, J. Effects of Electrostatic Discharges on Bearing Grease Dielectric Strength and Composition. IEEE Trans. Ind. Applicat. 2016, 52, 4835–4842. [Google Scholar] [CrossRef]

- Bustami, B.; Rahman, M.M.; Shazida, J.; Islam, M.; Rohan, M.H.; Hossain, S.; Nur, A.S.M.; Younes, H. Recent Progress in Electrically Conductive and Thermally Conductive Lubricants: A Critical Review. Lubricants 2023, 11, 331. [Google Scholar] [CrossRef]

- Christensen, G.; Yang, J.; Lou, D.; Hong, G.; Hong, H.; Tolle, C.; Widener, C.; Bailey, C.; Hrabe, R.; Younes, H. Carbon Nanotubes Grease with High Electrical Conductivity. Synth. Met. 2020, 268, 116496. [Google Scholar] [CrossRef]

- Jackson, R.L.; Coker, A.B.; Tucker, Z.; Hossain, M.S.; Mills, G. An Investigation of Silver-Nanoparticle-Laden Lubricants for Electrical Contacts. IEEE Trans. Compon. Packag. Manufact. Technol. 2019, 9, 193–200. [Google Scholar] [CrossRef]

- Millar, W.; Aman, Z.M.; Atkin, R.; Li, H. Graphite Infused Ionic Liquid Greases. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 130017. [Google Scholar] [CrossRef]

- Reddy, A.B.; Shah, F.U.; Leckner, J.; Rutland, M.W.; Glavatskih, S. Ionic Liquids Enhance Electrical Conductivity of Greases: An Impedance Spectroscopy Study. Colloids Surf. A Physicochem. Eng. Asp. 2024, 683, 132875. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A Review on Potentials and Challenges of Nanolubricants as Promising Lubricants for Electric Vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance Characteristics of Lubricants in Electric and Hybrid Vehicles: A Review of Current and Future Needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Prasad, D.K.; Tiwari, S.; Amarnath, M.; Chelladurai, H.; Vardhaman, B.S.A.; Suresh, B.; Ramkumar, J.; Gupta, M.K. Influence of MWCNTs, ZnO, and Boric Acid Nanomaterial Blend on the Tribological and Thermal Properties of Lithium Grease. Tribol. Int. 2024, 192, 109197. [Google Scholar] [CrossRef]

- Nassef, M.G.A.; Hassan, H.S.; Nassef, G.A.; Nassef, B.G.; Soliman, M.; Elkady, M.F. Activated Carbon Nano-Particles from Recycled Polymers Waste as a Novel Nano-Additive to Grease Lubrication. Lubricants 2022, 10, 214. [Google Scholar] [CrossRef]

- Bond, S.; Jackson, R.L.; Mills, G. The Influence of Various Grease Compositions and Silver Nanoparticle Additives on Electrically Induced Rolling-Element Bearing Damage. Friction 2024, 12, 796–811. [Google Scholar] [CrossRef]

- Suzumura, J. Prevention of Electrical Pitting on Rolling Bearings by Electrically Conductive Grease. Q. Rep. Railw. Tech. Res. Inst. 2016, 57, 42–47. [Google Scholar] [CrossRef]

- Mohamed, A.; Osman, T.A.; Khattab, A.; Zaki, M. Tribological Behavior of Carbon Nanotubes as an Additive on Lithium Grease. J. Tribol. 2015, 137, 011801. [Google Scholar] [CrossRef]

- Kamel, B.M.; Naeem Awad, M.; Mobasher, A.; Hoziefa, W. Lithium–Calcium Greases Having Carbon Nanotubes and Aluminum Oxide Base Nanoadditives: Preparation and Characteristics of Nanogrease. ACS Omega 2023, 8, 38933–38940. [Google Scholar] [CrossRef] [PubMed]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological Properties of Al2O3 Nanoparticles as Lubricating Oil Additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Tribological Investigations of Nano and Micro-Sized Graphite Particles as an Additive in Lithium-Based Grease. Tribol. Lett. 2020, 68, 124. [Google Scholar] [CrossRef]

- Chebattina, K.R.R.; Srinivas, V.; Rao, N.M. Effect of Size of Multiwalled Carbon Nanotubes Dispersed in Gear Oils for Improvement of Tribological Properties. Adv. Tribol. 2018, 2018, 328108. [Google Scholar] [CrossRef]

- Ge, X.; Xia, Y.; Feng, X. Influence of Carbon Nanotubes on Conductive Capacity and Tribological Characteristics of Poly(Ethylene Glycol-Ran-Propylene Glycol) Monobutyl Ether as Base Oil of Grease. J. Tribol. 2016, 138, 011801. [Google Scholar] [CrossRef]

- Guo, X.; Song, K.; Liang, S.; Wang, X.; Zhang, Y. Effect of Al2 O3 Particle Size on Electrical Wear Performance of Al2O3/Cu Composites. Tribol. Trans. 2016, 59, 170–177. [Google Scholar] [CrossRef]

- Alves Êvo, M.T.; Alzamora, A.M.; Zaparoli, I.O.; Paula, H.D. Inverter-Induced Bearing Currents: A Thorough Study of the Cause-and-Effect Chains. IEEE Ind. Appl. Mag. 2023, 29, 57–66. [Google Scholar] [CrossRef]

- Martin, G.; Becker, F.M.; Kirchner, E. A Novel Method for Diagnosing Rolling Bearing Surface Damage by Electric Impedance Analysis. Tribol. Int. 2022, 170, 107503. [Google Scholar] [CrossRef]

- Gemeinder, Y.; Schuster, M.; Radnai, B.; Sauer, B.; Binder, A. Calculation and Validation of a Bearing Impedance Model for Ball Bearings and the Influence on EDM-Currents. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; IEEE: New York, NY, USA, 2014; pp. 1804–1810. [Google Scholar]

- Nassef, M.G.A.; Soliman, M.; Nassef, B.G.; Daha, M.A.; Nassef, G.A. Impact of Graphene Nano-Additives to Lithium Grease on the Dynamic and Tribological Behavior of Rolling Bearings. Lubricants 2022, 10, 29. [Google Scholar] [CrossRef]

- Bleger, A.; Leighton, M.; Morris, N. Automotive E-Motor Bearing Electrical Discharge Phenomena: An Experimental and Numerical Investigation. Tribol. Int. 2024, 191, 109140. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Wang, J.; Tian, H.; Zhang, B.; Grinkevych, K.; Xu, J. Tribological Properties of Nano-Scale Al2O3 Particles with Different Shapes as Lubricating Oil Additives. J. Mar. Sci. Eng. 2024, 12, 1069. [Google Scholar] [CrossRef]

- Prasad, D.K.; Amarnath, M.; Chelladurai, H. Impact of Multi-Walled Carbon Nanotubes as an Additive in Lithium Grease to Enhance the Tribological and Dynamic Performance of Roller Bearing. Tribol. Lett. 2023, 71, 88. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Singh, N.; Singla, A. Effect of Alumina Nanoparticles as Additive on the Friction and Wear Behavior of Polanga-Based Lubricant. SN Appl. Sci. 2019, 1, 281. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Y.; Liu, B.; Yu, L.; Tong, Y.; Yan, M.; Yang, Z.; Hao, Y.; Shangguan, L.; Zhang, S.; et al. Research Progresses of Nanomaterials as Lubricant Additives. Friction 2024, 12, 1347–1391. [Google Scholar] [CrossRef]

- Janik, J.R.; Saha, S.; Jackson, R.L.; Mills, G. Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts. Lubricants 2024, 12, 268. [Google Scholar] [CrossRef]

- JIS B 0601:2013; Geometric Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions, and Surface Texture Parameters. Japanese Standards Association: Tokyo, Japan, 2013.

- Nabhan, A.; Rashed, A.; Ghazaly, N.M.; Abdo, J.; Haneef, M.D. Tribological Properties of Al2O3 Nanoparticles as Lithium Grease Additives. Lubricants 2021, 9, 9. [Google Scholar] [CrossRef]

- Guo, L.; Mol, H.; Nijdam, T.; De Vries, L.; Bongaerts, J. Study on the Electric Discharge Behaviour of a Single Contact in EV Motor Bearings. Tribol. Int. 2023, 187, 108743. [Google Scholar] [CrossRef]

- Xu, Y.; Liang, Y.; Yuan, X.; Wu, X.; Li, Y. Experimental Assessment of High Frequency Bearing Currents in an Induction Motor Driven by a SiC Inverter. IEEE Access 2021, 9, 40540–40549. [Google Scholar] [CrossRef]

- Cao-Romero-Gallegos, J.A.; Taghizadeh, S.; Aguilar-Rosas, O.A.; Dwyer-Joyce, R.S.; Farfan-Cabrera, L.I. The Effect of Electrical Current on Lubricant Film Thickness in Boundary and Mixed Lubrication Contacts Measured with Ultrasound. Friction 2024, 12, 1882–1896. [Google Scholar] [CrossRef]

- Tangboriboon, N.; Uttanawanit, N.; Longtong, M.; Wongpinthong, P.; Sirivat, A.; Kunanuruksapong, R. Electrical and Electrorheological Properties of Alumina/Natural Rubber (STR XL) Composites. Materials 2010, 3, 656–671. [Google Scholar] [CrossRef]

- Maru, M.M.; Castillo, R.S.; Padovese, L.R. Study of Solid Contamination in Ball Bearings through Vibration and Wear Analyses. Tribol. Int. 2007, 40, 433–440. [Google Scholar] [CrossRef]

- Wu, C.; Yang, K.; Chen, Y.; Ni, J.; Yao, L.; Li, X. Investigation of Friction and Vibration Performance of Lithium Complex Grease Containing Nano-Particles on Rolling Bearing. Tribol. Int. 2021, 155, 106761. [Google Scholar] [CrossRef]

- Liu, W. The Prevalent Motor Bearing Premature Failures Due to the High Frequency Electric Current Passage. Eng. Fail. Anal. 2014, 45, 118–127. [Google Scholar] [CrossRef]

- Raadnui, S.; Kleesuwan, S. Electrical Pitting Wear Debris Analysis of Grease-Lubricated Rolling Element Bearings. Wear 2011, 271, 1707–1718. [Google Scholar] [CrossRef]

- Song, C.; Ren, Y.; Huang, Q.; Li, Y.; Cheng, J.; Pang, X.; Zhang, Y. The Evolution Process of Fluting Damage on Bearing Outer Races during Rolling with a Shaft Current. Wear 2024, 556–557, 205502. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Y.; He, Y.; Shi, Y. Nanolubricant Additives: A Review. Friction 2021, 9, 891–917. [Google Scholar] [CrossRef]

- Jason, Y.J.J.; How, H.G.; Teoh, Y.H.; Chuah, H.G. A Study on the Tribological Performance of Nanolubricants. Processes 2020, 8, 1372. [Google Scholar] [CrossRef]

- Vyavhare, K.; Aswath, P.B. Tribological Properties of Novel Multi-Walled Carbon Nanotubes and Phosphorus Containing Ionic Liquid Hybrids in Grease. Front. Mech. Eng. 2019, 5, 15. [Google Scholar] [CrossRef]

- He, Q.; Wang, Z.; Li, A.; Guo, Y.; Liu, S. Tribological Properties of Nanometer Al2 O3 and Nanometer ZnO as Additives in Lithium-Based Grease. Ind. Lubr. Tribol. 2018, 70, 953–960. [Google Scholar] [CrossRef]

- Kałużny, J.; Kulczycki, A.; Dzięgielewski, W.; Piasecki, A.; Gapiński, B.; Mendak, M.; Runka, T.; Łukawski, D.; Stepanenko, O.; Merkisz, J.; et al. The Indirect Tribological Role of Carbon Nanotubes Stimulating Zinc Dithiophosphate Anti-Wear Film Formation. Nanomaterials 2020, 10, 1330. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Yang, M.; Yuan, J.; Guo, F.; Men, X. Friction and Wear Behaviors of MoS2-Multi-Walled-Carbonnanotube Hybrid Reinforced Polyurethane Composite Coating. Friction 2019, 7, 316–326. [Google Scholar] [CrossRef]

- Senatore, A.; Hong, H.; D’Urso, V.; Younes, H. Tribological Behavior of Novel CNTs-Based Lubricant Grease in Steady-State and Fretting Sliding Conditions. Lubricants 2021, 9, 107. [Google Scholar] [CrossRef]

- Gegner, J. Tribological Aspects of Rolling Bearing Failures. In Tribology—Lubricants and Lubrication; IntechOpen: London, UK, 2011. [Google Scholar]

| Component | Specification |

|---|---|

| Electric motor | FELM (3.5 kW, and 1440 rpm) |

| Shaft | SUS 420 stainless steel |

| Baseplate | C45 carbon steel |

| Support bearings | NU1011M roller bearing (SKF) |

| Signal generator | (Max voltage: 60 V; max current: 3.2 A) (Tektronix) |

| Oscilloscope | TBS 1152B (150 MHz, 2 GS/s) (Tektronix) |

| Current probe | RT-ZCO3 (Max current: 20 A) (Rhode and Schwarz) |

| Dimensions | d | D | B | r |

|---|---|---|---|---|

| 30 mm | 55 mm | 13 mm | 1 mm | |

| Race Type | Plain | |||

| Weight (kg) | 0.116 kg | |||

| Dynamic Loading | 13.8 kN | |||

| Static Loading | 8.3 kN | |||

| Radial Clearance | C3 | |||

| Characteristics | Manufacturer Specifications |

|---|---|

| Base oil | Mineral oil |

| Thickener | Lithium soap |

| Base oil viscosity @ 40 °C | 110 mm2/s |

| Base oil viscosity @ 100 °C | 12 mm2/s |

| Penetration | 220–250 (0.1 mm) |

| Drop point | ≥180 °C |

| Average Surface Roughness | ||||||||

|---|---|---|---|---|---|---|---|---|

| LG | MWCNT | Al2O3 | ||||||

| - | 0.1wt.% | 0.2wt.% | 0.3wt.% | 0.4wt.% | 0.1 wt.% | 0.2 wt.% | 0.3wt.% | 0.4wt% |

| 2.08 | 0.78 | 0.75 | 0.64 | 0.61 | 1.64 | 1.52 | 1.45 | 1.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jonjo, E.R.; Ali, I.; Megahed, T.F.; Nassef, M.G.A. Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease. Vehicles 2025, 7, 19. https://doi.org/10.3390/vehicles7010019

Jonjo ER, Ali I, Megahed TF, Nassef MGA. Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease. Vehicles. 2025; 7(1):19. https://doi.org/10.3390/vehicles7010019

Chicago/Turabian StyleJonjo, Emmanuel R., Islam Ali, Tamer F. Megahed, and Mohamed G. A. Nassef. 2025. "Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease" Vehicles 7, no. 1: 19. https://doi.org/10.3390/vehicles7010019

APA StyleJonjo, E. R., Ali, I., Megahed, T. F., & Nassef, M. G. A. (2025). Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease. Vehicles, 7(1), 19. https://doi.org/10.3390/vehicles7010019