Techno-Functional Properties of Mexican Cheese Whey Requesón Powder: Effects of Air-Convective Drying and Natural Gum Addition

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Experimental Design

2.3. Chemical Composition and pH

2.4. Water Holding Capacity (WHC)

2.5. Texture

2.6. Color

2.7. Swelling Capacity (SC)

2.8. Emulsifying Capacity (EC)

2.9. X-Ray Diffraction (XRD)

2.10. Scanning Electron Microscopy (SEM)

2.11. Statistical Analysis

3. Results and Discussion

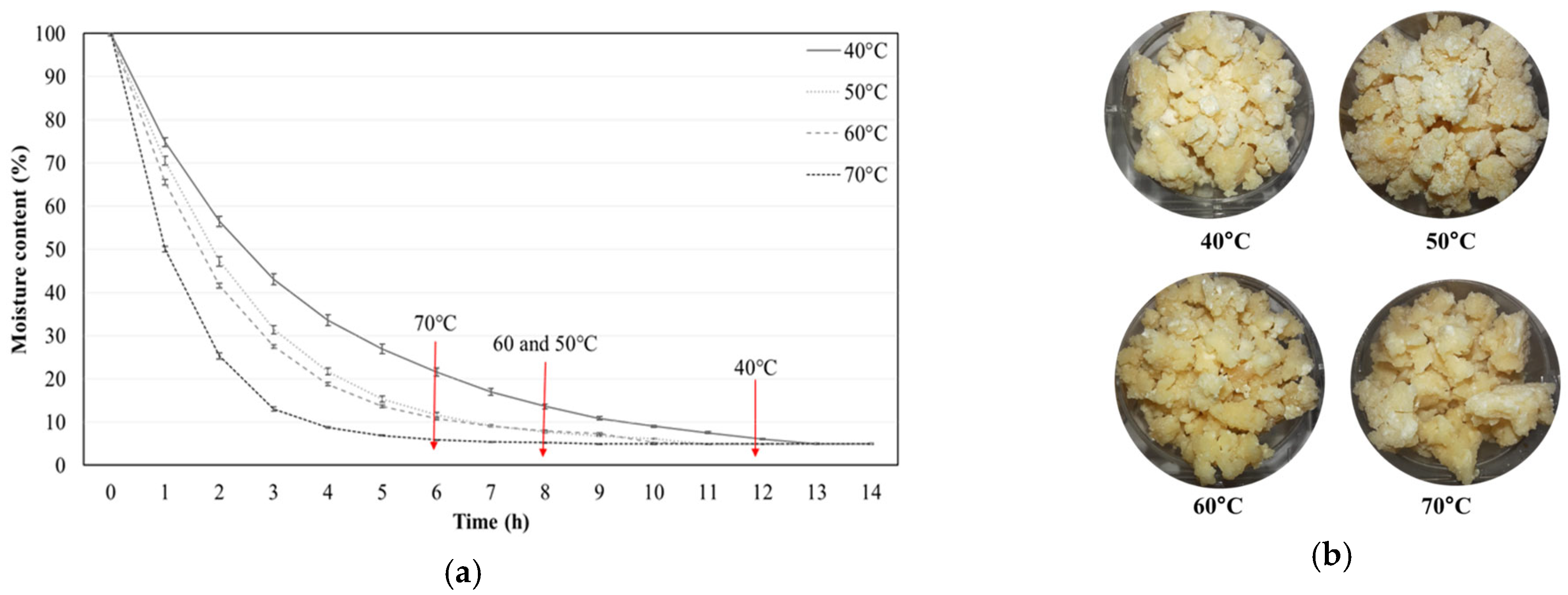

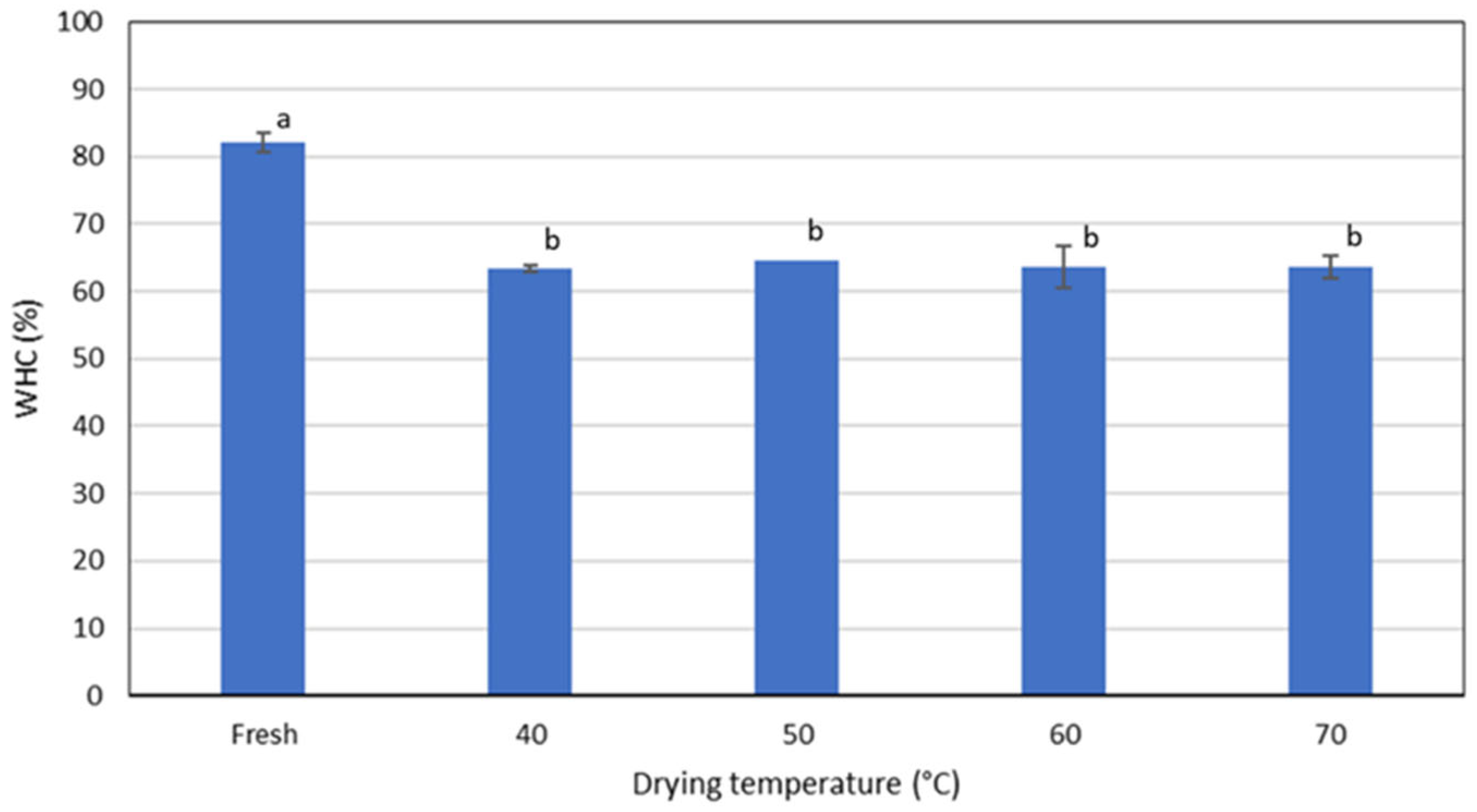

3.1. Thermal Drying and Reconstitution Properties of Requesón

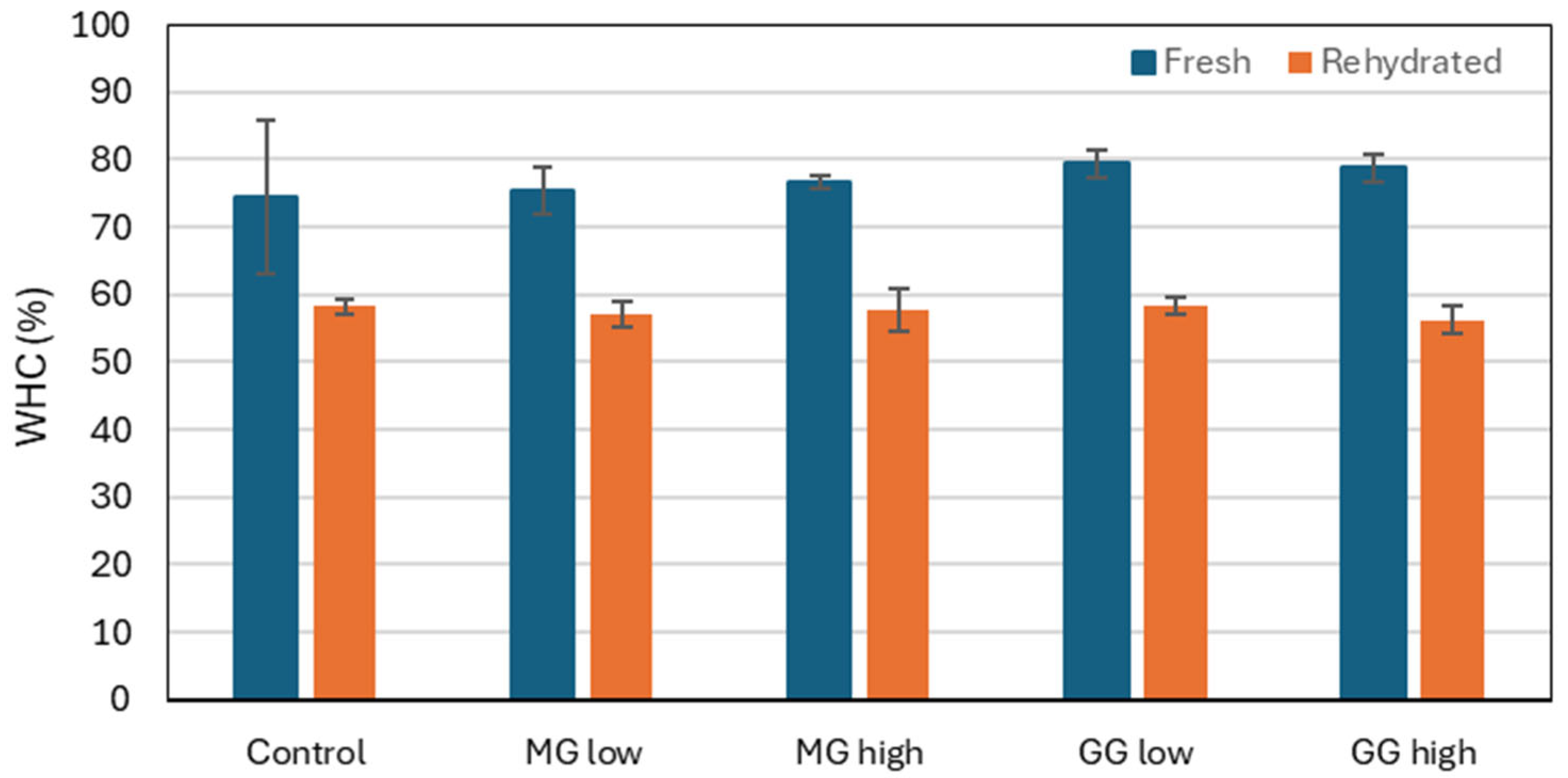

3.2. Protective Effect of Biopolymers on the Functional Properties of Requesón Powder Produced by Thermal Dehydration

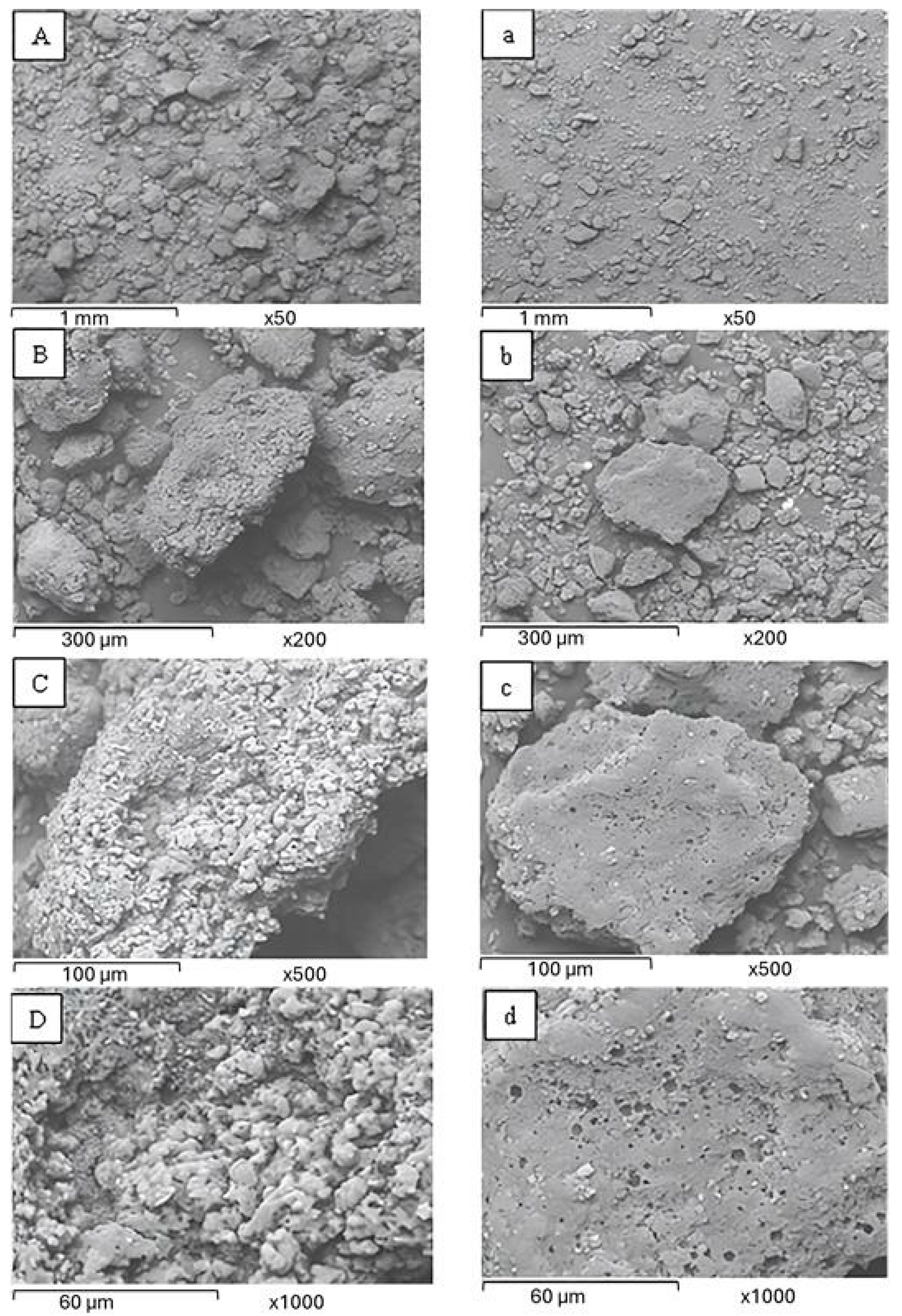

3.3. Structural Properties of Requesón Powders

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- USDA. Available online: https://www.fas.usda.gov/data/production/commodity/0240000 (accessed on 3 May 2025).

- Chamundeshwari, J.; Parthasarathi, S.; Ali, R. Spray drying of milk and milk products. In Spray Drying for the Food Industry: Unit Operations and Processing Equipment in the Food Industry; Jafari, S.M., Samborska, K., Eds.; Woodhead Publishing: Cambridge, UK, 2023; Chapter 4; pp. 87–123. [Google Scholar]

- Buchanan, D.; Martindale, W.; Romeih, E.; Hebishy, E. Recent advances in whey processing and valorisation: Technological and environmental perspectives. Int. J. Dairy Technol. 2023, 76, 292–312. [Google Scholar] [CrossRef]

- Bintsis, T.; Papademas, P. Sustainable approaches in whey cheese production: A review. Dairy 2023, 4, 249–270. [Google Scholar] [CrossRef]

- Mazorra-Manzano, M.A.; Ramírez-Montejo, H.; Lugo-Sánchez, M.E.; González-Córdova, A.F.; Vallejo Córdoba, B. Characterization of whey and whey cheese requesón from the production of asadero cheese (cooked cheese) Sonoran region. Nova Sci. 2019, 23, 220–233. [Google Scholar] [CrossRef]

- Alemán-Mateo, H.; Carreón, V.R.; Macías, L.; Astiazaran-García, H.; Gallegos-Aguilar, A.C.; Enríquez, J.R. Nutrient-rich dairy proteins improve appendicular skeletal muscle mass and physical performance and attenuate the loss of muscle strength in older men and women subjects: A single-blind randomized clinical trial. Clin. Interv. Aging. 2014, 12, 1517–1525. [Google Scholar] [CrossRef] [PubMed]

- Félix da Silva, D.; Larsen, F.; Hougaard, A.; Ipsen, R. The influence of raw material, added emulsifying salt and spray drying on cheese powder structure and hydration properties. Int. Dairy J. 2017, 74, 27–38. [Google Scholar] [CrossRef]

- Félix da Silva, D.; Hirschbergb, C.; Ahrné, L.; Hougaard, A.B.; Ipsen, R. Cheese feed to powder: Effects of cheese age, added dairy ingredients and spray drying temperature on properties of cheese powders. J. Food Eng. 2018, 237, 215–225. [Google Scholar] [CrossRef]

- Domínguez-Niño, A.; Buendía-González, A.; Cantú-Lozano, D.; Andrade-González, I.; Luna-Solano, G. Efecto del secado por lecho fluidizado sobre las propiedades fisicoquímicas y microbiológicas de queso fresco mexicano. Rev. Mex. Ing. Quím. 2016, 15, 869–881. [Google Scholar]

- Jaafar, F.E.; Rubaiy, H.H.; Niamah, A.K. Effect of Different Air Oven Temperatures on Chemical, Physical, and Microbial Properties of Dried Bio-Yoghurt Product. Dairy 2024, 5, 44–53. [Google Scholar] [CrossRef]

- Michailidis, P.A.; Krokida, M.K. Drying and Dehydration Processes in Food Preservation and Processing. In Conventional and Advanced Food Processing Technologies; Bhattacharya, S., Ed.; John Willey & Sons, Ltd.: Chichester, UK, 2014; pp. 1–21. [Google Scholar]

- Pinho, A.; Assis, F.; Peres, A.; Pintado, M.; Morais, A.M.M.B. Dehydration of cheese by hot air, microwave and freeze-drying. Chem. Chem. Eng. Biotechnol. Food Ind. 2017, 18, 455–460. [Google Scholar]

- Erbay, Z.; Koca, N. Effects of whey or maltodextrin addition during production on physical quality of white cheese powder during storage. J. Dairy Sci. 2015, 98, 8391–8404. [Google Scholar] [CrossRef]

- Garcia-Balladares, O.; López-Vidaña, E.C.; Galindo-Luna, Y.R.; Luna-Solano, G.; Pilatowsky-Figueroa, I.; Domínguez-Niño, A. Effect of convective drying conditions on the physicochemical, microbiological, and thermophysical properties of cincho artisanal cheese. Rev. Mex. Ing. Quím. 2022, 21, 1–14. [Google Scholar] [CrossRef]

- AOAC. International, Official Methods of Analysis of the Association of Official Analytical Chemists, 17th ed.; AOAC: Washington, DC, USA, 2000. [Google Scholar]

- Diamantino, V.R.; Beraldo, F.A.; Sunakozawa, T.N.; Penna, A.L.B. Effect of octenyl succinylated waxy starch as a fat mimetic on texture, microstructure and physicochemical properties of Minas fresh cheese. LWT—Food Sci. Technol. 2014, 56, 356–362. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Tharanathan, R.N. Dietary fiber from coconut residue: Effects of different treatments and particle size on the hydration properties. Eur. Food Res. Technol. 2004, 218, 563–567. [Google Scholar] [CrossRef]

- Pacheco-Aguilar, R.; Mazorra-Manzano, M.A.; Ramírez-Suárez, J.C. Functional properties of fish protein hydrolysates from Pacific whiting (Merluccius productus) muscle produced by a commercial protease. Food Chem. 2008, 109, 782–789. [Google Scholar] [CrossRef] [PubMed]

- Silva Borba, K.K.; Silva, F.A.; Madruga, M.S.; Queiroga, C.R.E.R.; Souza, E.L.; Magnani, M. The effect of storage on nutritional, textural and sensory characteristics of creamy ricotta made from whey as well as cow’s milk and goat’s milk. Int. J. Food Sci. Technol. 2014, 49, 1279–1286. [Google Scholar] [CrossRef]

- Wu, C.S.; Guo, J.H.; Lin, M.J. Stability evaluation of pH-adjusted goat milk for developing ricotta cheese with a mixture of cow cheese whey and goat milk. Foods 2020, 9, 366. [Google Scholar] [CrossRef] [PubMed]

- Richards, N.; Barreto, I.; Borges, L.J. Muestras de quesos comerciales deshidratadas por proceso de microondas al vacío. Tecnol. Láctea Latam. 2016, 95, 58–61. [Google Scholar]

- Belsito, P.C.; Ferreira, M.V.S.; Cappato, L.P.; Cavalcanti, R.N.; Vidal, V.A.S.; Pimentel, T.C.; Esmerino, E.A.; Balthazar, C.F.; Neto, R.P.C.; Tavares, M.I.B.; et al. Manufacture of Requeijao cremoso processed cheese with galactooligosaccharide. Carbohydr Polym. 2017, 174, 869–875. [Google Scholar] [CrossRef]

- Hiroshi, S.; Guemra, H.; Bosso, S.; Pádua, A.E.; Ito, M.L.R. Protein and glucose reduction by Maillard reaction in milk with hydrolyzed lactose. Rev. Chil. Nutr. 2020, 47, 14–21. [Google Scholar]

- Ramírez-Rivas, I.K.; Chávez-Martínez, A. Efecto del ultrasonido aplicado al suero de leche previo al calentamiento en la elaboración de requesón. Interciencia 2017, 42, 828–833. [Google Scholar]

- Hesarinejad, M.A.; Lorenzo, J.M.; Rafe, A. Influence of gelatin/guar gum mixture on the rheological and textural properties of restructured ricotta cheese. Carbohydr. Polym. Technol. Appl. 2021, 100162, 2666–8939. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Akshit, F.N.U.; Altay, I.; Huppertz, T. A Review on the Production and Characteristics of Cheese Powders. Foods 2024, 13, 2204. [Google Scholar] [CrossRef] [PubMed]

- Tastemirova, U.; Mukhtarkhanova, R.; Alimardanova, M.; Alibekov, R.; Shingisov, A. Impact of vacuum freeze-drying on the reconstituted camel milk composition. Food Sci. Technol. 2022, 42, e61722. [Google Scholar] [CrossRef]

- Dodds, J. Techniques to analyse particle size of food powders. In Handbook of Food Powders; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 309–338. [Google Scholar]

- Hwang, I.S.; Lee, K.B.; Shin, Y.K.; Baik, M.Y.; Kim, B.Y. Effect of drying and storage on the rheological characteristics of mozzarella cheese. Food Sci. Biotechnol. 2015, 24, 2041–2044. [Google Scholar] [CrossRef]

| Powder | Rehydrated | ||

|---|---|---|---|

| Treatment | Whiteness Index | Treatment | Whiteness Index |

| - | - | Fresh | 84.4 ± 1.03 a |

| Freeze-dry | 82.5 ± 0.82 a | Freeze-dry | 84.5 ± 0.39 a |

| 40 °C | 73.6 ± 2.28 b | 40 °C | 74.9 ± 0.78 c |

| 50 °C | 76.1 ± 1.17 b | 50 °C | 76.8 ± 0.74 b |

| 60 °C | 68.8 ± 2.37 c | 60 °C | 78.2 ± 0.31 b |

| 70 °C | 67.8 ± 2.45 c | 70 °C | 77.0 ± 0.72 b |

| Treatment | Swelling Capacity (mL/g) |

|---|---|

| Freeze-dry (reference) | 4.53 ± 0.07 a |

| 40 °C | 2.93 ± 0.07 c |

| 50 °C | 3.20 ± 0.03 b |

| 60 °C | 3.03 ± 0.03 c |

| 70 °C | 2.97 ± 0.05 c |

| Requesón | WHC (%) | Hardness (N) | Cohesiveness | Adhesiveness (-N) |

|---|---|---|---|---|

| Fresh (control) | 82.1 ± 3.0 | 0.89 ± 0.3 | 0.54± 0.05 | 0.81 ± 0.14 |

| Rehydrated Freeze-dried | 79.2 ± 1.5 | 0.69 ± 0.1 | 0.52 ± 0.02 | 0.39 ± 0.10 |

| Whiteness Index | |||

|---|---|---|---|

| Requesón | Fresh | Powdered | Rehydrated |

| Control | 86.7 ± 0.1 | 81.6 ± 0.9 | 80.9 ± 0.7 |

| MG [0.25 g/L] | 86.5 ± 0.1 | 81.7 ± 0.5 | 80.7 ± 0.1 |

| MG [0.5 g/L] | 85.2 ± 0.1 | 82.5 ± 1.4 | 80.9 ± 0.1 |

| GG [0.25 g/L] | 85.7 ± 0.1 | 83.3 ± 2.5 | 82.1 ± 0.7 |

| GG [0.5 g/L] | 85.5 ± 0.6 | 82.5 ± 1.3 | 82.1 ± 0.1 |

| Requesón | Yield | Moisture | Protein | Fat | Ash | Total Solids Recovery * |

|---|---|---|---|---|---|---|

| Control | 5.4 | 76.2 | 9.4 | 4.0 | 0.4 | 13.2 |

| MG [0.25 g/L] | 5.4 | 75.8 | 9.4 | 5.3 | 0.4 | 13.4 |

| MG [0.5 g/L] | 6.0 | 77.4 | 8.2 | 5.6 | 0.4 | 13.9 |

| GG [0.25 g/L] | 6.3 | 79.0 | 7.6 | 3.6 | 0.5 | 13.0 |

| GG [0.5 g/L] | 6.2 | 80.0 | 7.1 | 3.5 | 0.6 | 13.6 |

| Requesón | Swelling Capacity (mL/g) | Emulsifying Capacity (g oil/100 mL 0.1% Requesón Solution) |

|---|---|---|

| Fresh (w/o biopolymer) | -- | 71.7 ± 1.0 ab |

| Powder (w/o biopolymer) | 2.84 ± 0.06 c | 60.8 ± 2.5 d |

| Powder MG [0.25 g/L] | 3.11 ± 0.07 bc | 66.3 ± 1.6 c |

| Powder MG [0.5 g/L] | 3.44 ± 0.37 b | 67.8 ± 1.2 b |

| Powder GG [0.25 g/L] | 3.11 ± 0.14 bc | 71.0 ± 1.4 b |

| Powder GG [0.5 g/L] | 3.81 ± 0.24 a | 73.5 ± 1.0 ab |

| Hardness (N) | Cohesiveness | Adhesiveness (-N) | ||||

|---|---|---|---|---|---|---|

| Requesón | Fresh | Rehydrated | Fresh | Rehydrated | Fresh | Rehydrated |

| Control | 1.72 ± 0.2 a | 2.41 ± 0.2 ab | 0.54 ± 0.1 a | 0.30 ± 0.1 b | 1.83 ± 0.7 a | 1.59 ± 0.8 a |

| MG low level | 1.97 ± 0.1 a | 2.76 ± 0.3 ab | 0.54 ± 0.1 a | 0.33 ± 0.1 b | 2.43 ± 0.3 a | 1.66 ± 0.9 a |

| MG high level | 1.64 ± 0.2 a | 2.17 ± 0.3 b | 0.47 ± 0.1 a | 0.37 ± 0.1 ab | 1.58 ±0.7 a | 1.20 ± 0.2 a |

| GG low level | 1.58 ± 0.1 a | 1.48 ± 0.4 c | 0.55 ± 0.1 a | 0.41 ± 0.1 ab | 1.64 ± 0.3 a | 1.74 ± 0.6 a |

| GG high level | 0.85 ± 0.3 b | 1.74 ± 0.3 bc | 0.58 ± 0.1 a | 0.49 ± 0.1 a | 0.70 ± 0.2 a | 2.40 ± 0.3 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazorra-Manzano, M.A.; Martínez-García, A.; Torres-Llanez, M.J.; Ramírez-Suárez, J.C.; López-Franco, Y.L.; Brown-Bojórquez, F.; Teutle-Paredes, J.G.; Lugo-Sánchez, M.E. Techno-Functional Properties of Mexican Cheese Whey Requesón Powder: Effects of Air-Convective Drying and Natural Gum Addition. Dairy 2025, 6, 32. https://doi.org/10.3390/dairy6040032

Mazorra-Manzano MA, Martínez-García A, Torres-Llanez MJ, Ramírez-Suárez JC, López-Franco YL, Brown-Bojórquez F, Teutle-Paredes JG, Lugo-Sánchez ME. Techno-Functional Properties of Mexican Cheese Whey Requesón Powder: Effects of Air-Convective Drying and Natural Gum Addition. Dairy. 2025; 6(4):32. https://doi.org/10.3390/dairy6040032

Chicago/Turabian StyleMazorra-Manzano, Miguel A., Angelica Martínez-García, María J. Torres-Llanez, Juan C. Ramírez-Suárez, Yolanda L. López-Franco, Francisco Brown-Bojórquez, José G. Teutle-Paredes, and María E. Lugo-Sánchez. 2025. "Techno-Functional Properties of Mexican Cheese Whey Requesón Powder: Effects of Air-Convective Drying and Natural Gum Addition" Dairy 6, no. 4: 32. https://doi.org/10.3390/dairy6040032

APA StyleMazorra-Manzano, M. A., Martínez-García, A., Torres-Llanez, M. J., Ramírez-Suárez, J. C., López-Franco, Y. L., Brown-Bojórquez, F., Teutle-Paredes, J. G., & Lugo-Sánchez, M. E. (2025). Techno-Functional Properties of Mexican Cheese Whey Requesón Powder: Effects of Air-Convective Drying and Natural Gum Addition. Dairy, 6(4), 32. https://doi.org/10.3390/dairy6040032