Elaboration and Characterization of Dulce de Leche with Reduced Sugar Content

Abstract

:1. Introduction

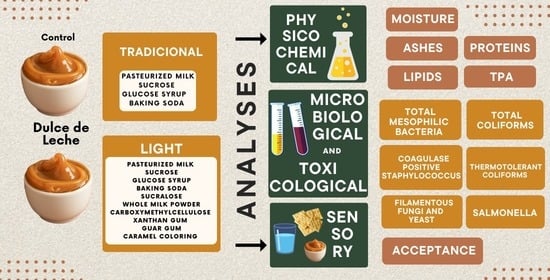

2. Materials and Methods

2.1. Elaboration of Dulce de Leche Formulations

2.2. Physical-Chemical and Nutritional Characterization

2.3. Microbiological and Toxicological Characterization

2.4. Product Acceptance

2.5. Statistical

3. Results and Discussion

3.1. Dulce de Leche Characterization

3.2. Physical-Chemical and Nutritional Characterization

3.3. Microbiological and Toxicological Characterizations

3.4. Product Acceptance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silva, F.L.; Ferreira, H.A.L.; de Souza, A.B.; de Freitas Almeida, D.; Stephani, R.; Pirozi, M.R.; Carvalho, A.F.; Perrone, Í.T. Production of dulce de leche: The effect of starch addition. LWT-Food Sci. Technol. 2015, 62, 417–423. [Google Scholar] [CrossRef]

- Ministério da Agricultura, Pecuária e Abastecimento. Regulamento Técnico para Fixação de Identidade e Qualidade de Doce de Leite. In Diário Oficial da República Federativa do Brasil; Portaria n_ 354, de 04 de setembro de 1997; Ministério da Agricultura, Pecuária e Abastecimento: Brasília, Brazil, 1997. [Google Scholar]

- Ministério da Saúde. Aprova o Regulamento Técnico referente à Informação Nutricional Complementar (declarações relacionadas ao conteúdo de nutrientes), constantes do anexo desta Portaria. In Diário Oficial da União; Portaria n° 27, de 13 de janeiro de 1998; Ministério da Saúde: Brasília, Brazil, 1998. [Google Scholar]

- Silva, A.A.N.; Belluzzo, M.E.C.S.; Bastos, R.A. Consumer behavior towards diet and light products. Res. Soc. Dev. 2023, 12, e9512943237. [Google Scholar] [CrossRef]

- Cañas, G.J.S.; Braibante, M.E.F. A Química dos Alimentos Funcionais. Quím. Nova Esc. 2019, 41, 216–223. [Google Scholar] [CrossRef]

- Ministério da Saúde. Dispõe sobre o Regulamento Técnico sobre Informação Nutricional Complementar. In Diário Oficial da União; Resolução n° 54, de 12 de novembro de 2012; Ministério da Saúde: Brasília, Brazil, 2012. [Google Scholar]

- Milagres, M.P.; Dias, G.; Magalhães, M.A.; Silva, M.O.; Ramos, A.M. Análise físico química e sensorial de doce de leite produzido sem adição de sacarose. Rev. Ceres 2010, 57, 439–445. [Google Scholar] [CrossRef]

- Ministério da Agricultura, Pecuária e Abastecimento. Métodos Analíticos Oficiais Físico-Químicos para Controle de Pescado e seus derivados. In Diário Oficial da União; Instrução Normativa n° 25, de 2 de junho de2011; Ministério da Agricultura, Pecuária e Abastecimento: Brasília, Brazil, 2011. [Google Scholar]

- Ministério da Agricultura, Pecuária e Pesca. Ficam estabelecidos como oficiais os métodos constantes do Manual de Métodos Oficiais para Análise de Alimentos de Origem Animal. In Diário Oficial da União; Instrução Normativa N° 30, de 26 de junho de 2018; Ministério da Agricultura, Pecuária e Pesca: Brasília, Brazil, 2018; p. 9. [Google Scholar]

- AOAC. Association Of Official Analytical Chemists. In Official Methods of Analysis of the Association of Official Analytical Chemistry, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Leddomado, L.S.; Silva, R.; Guimarães, J.T.; Balthazar, C.F.; Ramos, G.L.P.A.; Freitas, M.Q.; Duarte, M.C.K.H.; Neto, R.P.C.; Tavares, M.I.B.; Pimentel, T.C.; et al. Technological benefits of using inulin and xylooligosaccharide in Dulce de leche. Food Hydro. 2021, 110, 106158. [Google Scholar]

- Ministério da Saúde. Estabelece os padrões microbiológicos dos alimentos. In Diário Oficial da União; Instrução Normativa n° 161, de 1 de julho de 2022; Ministério da Saúde: Brasília, Brazil, 6 July 2022. [Google Scholar]

- APHA. American Public Health Association. In Compendium of Methods for the Microbiological Examination of Foods, 3rd ed.; APHA: Washington, DC, USA, 2015; 1219p. [Google Scholar]

- Pyzik, E.; Marek, A.; Stepien-Psyniak, D.; Urban-Chmiel, R.; Jarosz, L.S.; Jagiello-Podebska, I. Detection of antibiotic resistance and classical enterotoxin genes in coagulase-negative staphylococci isolated from poultry in Poland. J. Vet. Res. 2019, 63, 183. [Google Scholar]

- Moebus, V.F.; Pinto, L.d.A.; Köptcke, F.B.N.; Keller, K.M.; Aronovich, M.; Keller, L.A.M. In Vitro Mycotoxin Decontamination by Saccharomyces cerevisiae Strains Isolated from Bovine Forage. Fermentation 2023, 9, 585. [Google Scholar] [CrossRef]

- Macfie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- Stone, H.; Rebecca, N.B.; Heather, A.T. Sensory Evaluation Practices, 4th ed.; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Agresti, A. Categorical Data Analysis, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2002; 721p. [Google Scholar]

- Shakoor, A.; Zhang, C.; Xie, J.; Yang, X. Maillard reaction chemistry in formation of critical intermediates and flavor compounds and their antioxidant properties. Food Chem. 2022, 393, 133416. [Google Scholar]

- Ranalli, N.; Andrés, S.C.; Califano, A.N. Rheological Behavior of Low-Fat Dulce De Leche with Added Xanthan Gum. J. Food Process. Preserv. 2016, 41, e13011. [Google Scholar] [CrossRef]

- Stephani, R.; Francisquini, J.; Perrone, Í.T.; de Carvalho, A.F.; de Oliveira, L.F.C. Dulce de Leche -chemistry and processing technology. In Milk Production, Processing and Marketing; Javed, K., Ed.; IntechOpen: London, UK, 2019; pp. 1–18. [Google Scholar]

- Carneiro, L.C.M.; Pinto, C.D.A.; Gomes, E.R.; de Paula, I.L.; Wolfschoon Pombo, A.F.; Stephani, R.; Carvalho, A.F.; Perrone, I.T. The chemistry and technology of dulce de leche: A review. Res. Soc. Dev. 2021, 10, e155101119408. [Google Scholar] [CrossRef]

- MERCOSUL. Mercado Comum do Sul. In Resolução Mercosul n° 137, de 13 de dezembro de 1996. Regulamento Técnico MERCOSUL de Identidade e Qualidade de Doce de Leite; MERCOSUL: Montevideo, Uruguay, 1996. [Google Scholar]

- Lambrini, K.; Aikaterini, F.; Konstantinos, K.; Christos, I.; Ioanna, P.V.; Areti, T. Milk Nutritional Composition and Its Role in Human Health. J. Pharm. Pharmacol. 2021, 9, 8–13. [Google Scholar]

- Santos, R.C. O valor energético dos alimentos. Exemplo de uma determinação experimental, usando calorimetria de combustão. Quim. Nova 2010, 33, 220–224. [Google Scholar] [CrossRef]

- Farias, V.M.; Pereira, B.C.d.S.F.; Pinto, L.d.A.; Köptcke, F.B.N.; Keller, L.A.M.; Franco, R.M. Caracterização da micobiota e detecção de aflatoxina M1 em fórmulas infantis. Rev. Caribeña Cienc. Soc. 2023, 12, 1828–1839. [Google Scholar] [CrossRef]

- Sakić-Dizdarević, S.; Dizdarević, T.; Kasumović, E.; Sarić, Z.; Mehmeti, I.; Abrahamsen, R.K.; Narvhus, J.A. Microbiological aspects of the traditional Travnik/Vlašić cheese manufactured in Bosnia and Herzegovina. J. Infect. Dev. Ctries 2023, 17, 236–240. [Google Scholar] [CrossRef]

- Fudali, A.; Chełmecka, I.; Salejda, A.M.; Krasnowska, G. Microbiological Safety and Organoleptic Quality of Homogenized Sausages Manufactured with Commercial Functional Additives. Appl. Sci. 2021, 11, 11662. [Google Scholar] [CrossRef]

- Khilendra, B.; Laura, M.; Sanjeev, A.; Lloyd, M. Effect of midday pasteurizer washing on thermoduric organisms and their progression through Cheddar cheese manufacturing and ripening. J. Dairy Sci. 2022, 105, 109–122. [Google Scholar]

- Pereira, R.N.; Teixeira, J.A.; Vicente, A.A.; Cappato, L.P.; Ferreira, M.V.S.; Rocha, R.S.; Cruz, A.G. Ohmic heating for the dairy industry: A potential technology to develop probiotic dairy foods in association with modifications of whey protein structure. Curr. Opin. Food Sci. 2018, 22, 95–101. [Google Scholar] [CrossRef]

- Białkowska, A.; Majewska, E.; Olczak, A.; Twarda-clapa, A. Ice binding proteins: Diverse biological roles and applications in different types of industry. Biomolecules 2020, 10, 274. [Google Scholar] [CrossRef]

- Said, M.I. Role and function of gelatin in the development of the food and non-food industry: A review. IOP Conf. Ser. Earth Environ. Sci. 2020, 492, 012086. [Google Scholar] [CrossRef]

- Jayasena, D.D.; Kim, H.J.; Yong, H.I.; Park, S.; kim, K.; Choe, W.; Jo, C. Flexible thin-layer dielectric barrier discharge plasma treatment of pork butt and beef loin: Effects on pathogen inactivation and meat-quality attributes. Food Microbiol. 2015, 46, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Mizzi, L.; Maniscalco, D.; Gaspari, S.; Chatzitzika, C.; Gatt, R.; Valdramidis, V.P. Assessing the individual microbial inhibitory capacity of different sugars against pathogens commonly found in food systems. Lett. Appl. Microbiol. 2020, 71, 251–258. [Google Scholar] [CrossRef] [PubMed]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of water activity (aw) on microbial stability as a hurdle in food preservation. In Water Activity in Foods: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 323–355. [Google Scholar]

- Ali, N.M.; Sarwar, K.; Mazhar, S.A.; Liaqat, I.; Andleeb, S.; Mazhar, B.; Kalim, B. Effect of medicinal plants, Heavy metals and antibiotics against pathogenic bacteria isolated from raw, Boiled and pasteurized milk. Pak. J. Pharm. Sci. 2017, 30, 2173–2182. [Google Scholar]

- Osman, K.M.; Pires, Á.; Franco, O.L.; Orabi, A.; Hanafy, M.H.; Marzouk, E.; Hussien, H.; Alzaben, F.A.; Almuzaini, A.M.; Elbehiry, A. Enterotoxigenicity and Antibiotic Resistance of Coagulase-Negative Staphylococci Isolated from Raw Buffalo and Cow Milk. Microb. Drug Resist. 2020, 26, 520–530. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Jin, J.; Li, X.; Zhang, H.; Shi, X.; Zhao, C. Prevalence, antibiotic resistance, and enterotoxin genes of Staphylococcus aureus isolated from milk and dairy products worldwide: A systematic review and meta-analysis. Food Res. Inter. 2022, 162, 111969. [Google Scholar] [CrossRef] [PubMed]

- Muaz, K.; Riaz, M.; Rosim, R.E.; Akhtar, S.; Corassin, C.H.; Gonçalves, B.L.; Oliveira, C.A.F. In vitro ability of nonviable cells of lactic acid bacteria strains in combination with sorbitan monostearate to bind to aflatoxin M1 in skimmed milk. LWT Food Sci. Technol. 2021, 147, 111666. [Google Scholar] [CrossRef]

- IARC. Some naturally occurring substances: Food items and constituents, heterocyclic aromatic amines and mycotoxins. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; IARC: Lyon, France, 1993; Volume 56. [Google Scholar]

- Turna, N.S.; Wu, F. Aflatoxin M1 in milk: A global occurrence, intake, & exposure assessment. Trends Food Sci. Technol. 2021, 110, 183–192. [Google Scholar]

| Traditional Dulce de Leche | Light Dulce de Leche | ||

|---|---|---|---|

| Pasteurized Milk | 3.0 L | Pasteurized Milk | 3.0 L |

| Sucrose | 500.0 g | Sucrose | 250.0 g |

| Glucose syrup | 100.0 g | Glucose syrup | 50.0 g |

| Baking soda | 2.4 g | Baking soda | 2.4 g |

| - | - | Sucralose | 30.0 g |

| - | - | Whole milk powder | 279.0 g |

| - | - | Carboxymethylcellulose | 10.84 g |

| - | - | Xanthan gum | 0.51 g |

| - | - | Guar gum | 0.51 g |

| - | - | Caramel coloring (INS 150a) | q.s.p. |

| Moisture | Ashes | Lipids | Proteins | |

|---|---|---|---|---|

| MERCOSUL Legislation * | <30.00% | <2.00% | 6.00–9.00% | >5.00% |

| Traditional Dulce de Leche | 29.88 ± 0.93% | 1.42 ± 0.11% | 2.65 ± 0.23% | 7.54 ± 0.55% |

| Light Dulce de Leche | 35.63 ± 1.60% | 2.88 ± 0.02% | 3.50 ± 0.33% | 12.07 ± 0.19% |

| Microorganisms | Brazilian Legislation * | Fluid Milk | Powdered Milk | Traditional Dulce de Leche | Light Dulce de Leche |

|---|---|---|---|---|---|

| Total mesophilic bacteria 1 | - | 4.08 ± 0.08 | 2.40 ± 2.40 | <1.0 | <1.0 |

| Coagulase-positive Staphylococcus 1 | 2.0 | <1.0 | 2.05 ± 2.05 | <1.0 | <1.0 |

| Total coliforms 1 | 2.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Thermotolerant coliforms 1 | 2.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Filamentous fungi and yeast 1 | 2.0 | 2.08 ± 0.12 | 3.15 ± 3.05 | <1.0 | <1.0 |

| Salmonella spp. 1 | Absent | Absent | Absent | Absent | Absent |

| Microorganisms | Brazilian Legislation * | 15 Days Storage | 30 Days Storage | ||

|---|---|---|---|---|---|

| Traditional Dulce de Leche | Light Dulce de Leche | Traditional Dulce de Leche | Light Dulce de LECHE | ||

| Total mesophilic bacteria 1 | - | <1.0 | <1.0 | <1.0 | <1.0 |

| Coagulase-positive Staphylococcus 1 | 2.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Total coliforms 1 | 2.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Thermotolerant coliforms 1 | 2.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Filamentous fungi and yeast 1 | 2.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Salmonella spp. 1 | Absent | Absent | Absent | Absent | Absent |

| Score | Acceptance | Flavor | Texture | Appearance |

|---|---|---|---|---|

| 1 | 26.7% | 33.3% | 33.3% | 30.0% |

| 2 | 46.7% | 36.7% | 30.0% | 33.3% |

| 3 | 23.3% | 26.7% | 23.3% | 30.0% |

| 4 | - | - | 3.3% | 3.3% |

| 5 | 3.3% | 3.3% | 3.3% | - |

| 6 | - | - | 3.3% | 3.3% |

| 7 | - | - | 3.3% | - |

| 8 | - | - | - | - |

| 9 | - | - | - | - |

| Average Score | 2.1 ± 0.89 | 2.0 ± 0.95 | 2.4 ± 1.49 | 2.2 ± 1.11 |

| Score | Acceptance | Flavor | Texture | Appearance |

|---|---|---|---|---|

| 1 | 6.7% | 10.0% | 10.0% | 13.3% |

| 2 | 6.7% | 13.3% | 13.3% | 3.3% |

| 3 | 26.7% | 16.7% | 20.0% | 20.0% |

| 4 | 16.7% | 23.3% | 16.7% | 10.0% |

| 5 | 33.3% | 20.0% | 13.3% | 6.7% |

| 6 | 6.7% | 6.7% | 23.3% | 30.0% |

| 7 | - | 6.7% | - | 13.3% |

| 8 | 3.3% | - | 3.3% | - |

| 9 | - | 3.3% | - | 3.3% |

| Average Score | 4.0 ± 1.51 | 4.0 ± 1.87 | 4.0 ± 1.80 | 4.6 ± 2.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moebus, V.F.; Pinto, L.A.; Köptcke, F.B.N.; Keller, L.A.M. Elaboration and Characterization of Dulce de Leche with Reduced Sugar Content. Dairy 2023, 4, 619-629. https://doi.org/10.3390/dairy4040043

Moebus VF, Pinto LA, Köptcke FBN, Keller LAM. Elaboration and Characterization of Dulce de Leche with Reduced Sugar Content. Dairy. 2023; 4(4):619-629. https://doi.org/10.3390/dairy4040043

Chicago/Turabian StyleMoebus, Victor F., Leonardo A. Pinto, Felipe B. N. Köptcke, and Luiz A. M. Keller. 2023. "Elaboration and Characterization of Dulce de Leche with Reduced Sugar Content" Dairy 4, no. 4: 619-629. https://doi.org/10.3390/dairy4040043

APA StyleMoebus, V. F., Pinto, L. A., Köptcke, F. B. N., & Keller, L. A. M. (2023). Elaboration and Characterization of Dulce de Leche with Reduced Sugar Content. Dairy, 4(4), 619-629. https://doi.org/10.3390/dairy4040043