High Protein—Low Viscosity? How to Tailor Rheological Properties of Fermented Concentrated Milk Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

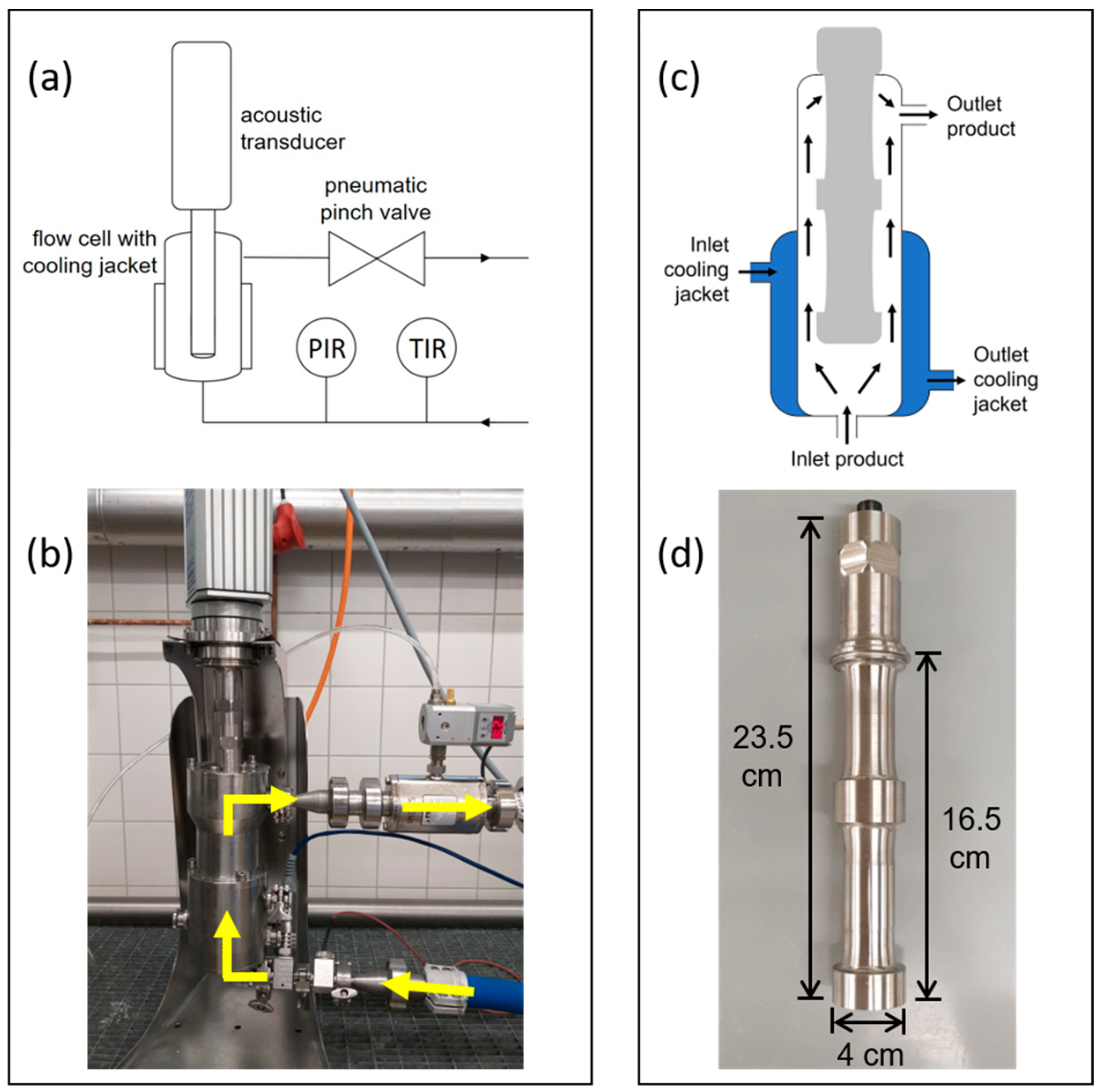

2.2. High-Intensity Ultrasound System

2.2.1. Set-Up

2.2.2. Energy Input

2.3. Analyses

2.3.1. Dry Matter and Protein Content

2.3.2. Particle Size Measurement

2.3.3. Volume Fraction

2.3.4. Rheology

2.4. Statistical Analysis

3. Results and Discussion

3.1. Volume Fraction, Particle Size, and Span

3.2. Rheology

3.3. Comparison to Commercial Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chever, S.; Guyomarc’h, F.; Beaucher, E.; Famelart, M. High-protein fat-free acid milk gels: Control of protein composition and heat treatment. Int. Dairy J. 2014, 37, 95–103. [Google Scholar] [CrossRef]

- Garlick, P.J. The role of leucine in the regulation of protein metabolism. J. Nutr. 2005, 135, 1553S–1556S. [Google Scholar] [CrossRef] [PubMed]

- Tipton, K.D.; Elliott, T.A.; Cree, M.G.; Aarsland, A.A.; Sanford, A.P.; Wolfe, R.R. Stimulation of net muscle protein synthesis by whey protein ingestion before and after exercise. Am. J. Physiol. Endocrinol. Metab. 2007, 292, E71–E76. [Google Scholar] [CrossRef] [PubMed]

- Benelam, B. Satiation, satiety and their effects on eating behaviour. Nutr. Bull. 2009, 34, 126–173. [Google Scholar] [CrossRef]

- Jørgensen, C.E.; Abrahamsen, R.K.; Rukke, E.-O.; Hoffmann, T.K.; Johansen, A.-G.; Skeie, S.B. Processing of high-protein yoghurt—A review. Int. Dairy J. 2018, 88, 42–59. [Google Scholar] [CrossRef]

- Desai, N.; Shepard, L.; Drake, M. Sensory properties and drivers of liking for Greek yogurts. J. Dairy Sci. 2013, 96, 7454–7466. [Google Scholar] [CrossRef] [PubMed]

- Alsanei, W.A.; Chen, J. Food Structure Development for Specific Population Groups. In Handbook of Food Structure Development; Spyropoulos, F., Lazidis, A., Norton, I., Eds.; Royal Society of Chemistry: Cambridge, UK, 2020; pp. 459–479. [Google Scholar]

- Ney, D.M.; Weiss, J.M.; Kind, A.J.H.; Robbins, J. Senescent swallowing: Impact, strategies, and interventions. Nutr. Clin. Pract. 2009, 24, 395–413. [Google Scholar] [CrossRef] [PubMed]

- Wright, L.; Cotter, D.; Hickson, M. The effectiveness of targeted feeding assistance to improve the nutritional intake of elderly dysphagic patients in hospital. J. Hum. Nutr. Diet. 2008, 21, 555–562. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Hickey, M.; Muir, D.D. Strained fermented milks—A review of existing legislative provisions, survey of nutritional labelling of commercial products in selected markets and terminology of products in some selected countries. Int. J. Dairy Technol. 2014, 67, 305–333. [Google Scholar] [CrossRef]

- Farkye, N.Y. Quark, Quark-like Products, and Concentrated Yogurts. In Cheese; Academic Press: Cambridge, MA, USA, 2017; pp. 1103–1110. [Google Scholar] [CrossRef]

- Schulz-Collins, D.; Senge, B. Acid- and acid/rennet-curd cheeses part A: Quark, cream cheese and related varieties. Cheese Chem. Phys. Microbiol. 2004, 2, 301–328. [Google Scholar] [CrossRef]

- Heck, A.J.; Schäfer, J.; Nöbel, S.; Hinrichs, J. Fat-free fermented concentrated milk products as milk protein-based microgel dispersions: Particle characteristics as key drivers of textural properties. Compr. Rev. Food Sci. Food Saf. 2021, 20, 6057–6088. [Google Scholar] [CrossRef] [PubMed]

- Walstra, P.; Wouters, J.T.M.; Geurts, T.J. Dairy Science and Technology, 2nd ed.; CRC/Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Krieger, I.M.; Dougherty, T.J. A Mechanism for Non-Newtonian Flow in Suspensions of Rigid Spheres. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Loewen, A.; Nöbel, S.; Hinrichs, J. Microgel Particles and Their Effect on the Textural Properties of Foods. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Willenbacher, N.; Vesaratchanon, J.S.; Thorwarth, O.; Bartsch, E. An alternative route to highly concentrated, freely flowing colloidal dispersions. Soft Matter 2011, 7, 5777–5788. [Google Scholar] [CrossRef]

- Dickinson, E. Microgels—An alternative colloidal ingredient for stabilization of food emulsions. Trends Food Sci. Technol. 2015, 43, 178–188. [Google Scholar] [CrossRef]

- Weidendorfer, K.; Bienias, A.; Hinrichs, J. Investigation of the effects of mechanical post-processing with a colloid mill on the texture properties of stirred yogurt. Int. J. Dairy Technol. 2008, 61, 379–384. [Google Scholar] [CrossRef]

- Dörr, A.; Sadiki, A.; Mehdizadeh, A. A discrete model for the apparent viscosity of polydisperse suspensions including maximum packing fraction. J. Rheol. 2013, 57, 743–765. [Google Scholar] [CrossRef]

- Hahn, C.; Nöbel, S.; Maisch, R.; Rösingh, W.; Weiss, J.; Hinrichs, J. Adjusting rheological properties of concentrated microgel suspensions by particle size distribution. Food Hydrocoll. 2015, 49, 183–191. [Google Scholar] [CrossRef]

- Ipsen, R. Microparticulated whey proteins for improving dairy product texture. Int. Dairy J. 2017, 67, 73–79. [Google Scholar] [CrossRef]

- Farris, R.J. Prediction of the Viscosity of Multimodal Suspensions from Unimodal Viscosity Data. Trans. Soc. Rheol. 1968, 12, 281–301. [Google Scholar] [CrossRef]

- Nöbel, S.; Weidendorfer, K.; Hinrichs, J. Apparent voluminosity of casein micelles determined by rheometry. J. Colloid Interface Sci. 2012, 386, 174–180. [Google Scholar] [CrossRef]

- van Marle, M.E.; Ende, D.v.D.; de Kruif, C.G.; Mellema, J. Steady-shear viscosity of stirred yogurts with varying ropiness. J. Rheol. 1999, 43, 1643–1662. [Google Scholar] [CrossRef]

- Körzendörfer, A.; Hinrichs, J. Manufacture of high-protein yogurt without generating acid whey—Impact of the final pH and the application of power ultrasound on texture properties. Int. Dairy J. 2019, 99, 104541. [Google Scholar] [CrossRef]

- Körzendörfer, A.; Schäfer, J.; Hinrichs, J.; Nöbel, S. Power ultrasound as a tool to improve the processability of protein-enriched fermented milk gels for Greek yogurt manufacture. J. Dairy Sci. 2019, 102, 7826–7837. [Google Scholar] [CrossRef] [PubMed]

- Robinson, R.K. Encyclopedia of Food Microbiology; Academic Press: San Diego, CA, USA, 2000. [Google Scholar]

- Chávez-Martínez, A.; Reyes-Villagrana, R.A.; Rentería-Monterrubio, A.L.; Sánchez-Vega, R.; Tirado-Gallegos, J.M.; Bolivar-Jacobo, N.A. Low and High-Intensity Ultrasound in Dairy Products: Applications and Effects on Physicochemical and Microbiological Quality. Foods 2020, 9, 1688. [Google Scholar] [CrossRef] [PubMed]

- Brennen, C.E. Cavitation and Bubble Dynamics; Oxford University Press: New York, NY, USA, 1995. [Google Scholar]

- Peters, D. Ultrasound in materials chemistry. J. Mater. Chem. 1996, 6, 1605–1618. [Google Scholar] [CrossRef]

- Crum, L.A. Comments on the evolving field of sonochemistry by a cavitation physicist. Ultrason. Sonochem. 1995, 2, S147–S152. [Google Scholar] [CrossRef]

- Patist, A.; Bates, D. Industrial Applications of High Power Ultrasonics. In Ultrasound Technologies for Food and Bioprocessing; Feng, H., Ed.; Springer: New York, NY, USA, 2011; pp. 599–616. [Google Scholar]

- DIN EN ISO 5534:2004-09; Cheese and Processed Cheese-Determination of the Total Solids Content. Beuth: Berlin, Germany, 2004. [CrossRef]

- DIN EN ISO 14891:2002-07; Milk and Milk Products-Determination of Nitrogen Content-Routine Method Using Combustion according to the Dumas Principle. Beuth: Berlin, Germany, 2002. [CrossRef]

- Heck, A.; Nöbel, S.; Hitzmann, B.; Hinrichs, J. Volume Fraction Measurement of Soft (Dairy) Microgels by Standard Addition and Static Light Scattering. Food Biophys. 2021, 16, 237–253. [Google Scholar] [CrossRef]

- Sonne, A.; Busch-Stockfisch, M.; Weiss, J.; Hinrichs, J. Improved mapping of in-mouth creaminess of semi-solid dairy products by combining rheology, particle size, and tribology data. LWT 2014, 59, 342–347. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Bhaskaracharya, R.; Kentish, S.; Lee, J.; Palmer, M.; Zisu, B. The ultrasonic processing of dairy products—An overview. Dairy Sci. Technol. 2009, 90, 147–168. [Google Scholar] [CrossRef]

- Delmas, H.; Barthe, L. Ultrasonic mixing, homogenization, and emulsification in food processing and other applications. In Power Ultrasonics; Woodhead Publishing: Sawston, UK, 2015; pp. 757–791. [Google Scholar] [CrossRef]

- Wu, J.; Gamage, T.; Vilkhu, K.; Simons, L.; Mawson, R. Effect of thermosonication on quality improvement of tomato juice. Innov. Food Sci. Emerg. Technol. 2008, 9, 186–195. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Mason, T.J.; Lelas, V.; Paniwnyk, L.; Herceg, Z. Effect of ultrasound treatment on particle size and molecular weight of whey proteins. J. Food Eng. 2014, 121, 15–23. [Google Scholar] [CrossRef]

- Mokoonlall, A.; Nöbel, S.; Hinrichs, J. Post-processing of fermented milk to stirred products: Reviewing the effects on gel structure. Trends Food Sci. Technol. 2016, 54, 26–36. [Google Scholar] [CrossRef]

- Genovese, D.B.; Lozano, J.E.; Rao, M.A. The rheology of colloidal and noncolloidal food dispersions. J. Food Sci. 2007, 72, R11–R20. [Google Scholar] [CrossRef] [PubMed]

- Iida, Y.; Tuziuti, T.; Yasui, K.; Towata, A.; Kozuka, T. Control of viscosity in starch and polysaccharide solutions with ultrasound after gelatinization. Innov. Food Sci. Emerg. Technol. 2008, 9, 140–146. [Google Scholar] [CrossRef]

- Körzendörfer, A.; Nöbel, S.; Hinrichs, J. Particle formation induced by sonication during yogurt fermentation—Impact of exopolysaccharide-producing starter cultures on physical properties. Food Res. Int. 2017, 97, 170–177. [Google Scholar] [CrossRef] [PubMed]

- Nöbel, S.; Ross, N.-L.; Protte, K.; Körzendörfer, A.; Hitzmann, B.; Hinrichs, J. Microgel particle formation in yogurt as influenced by sonication during fermentation. J. Food Eng. 2016, 180, 29–38. [Google Scholar] [CrossRef]

- Poslinski, A.J.; Ryan, M.E.; Gupta, R.K.; Seshadri, S.G.; Frechette, F.J. Rheological Behavior of Filled Polymeric Systems I. Yield Stress and Shear-Thinning Effects. J. Rheol. 1988, 32, 703–735. [Google Scholar] [CrossRef]

| Sample | Fat Content * [%] | Protein Content [%] | η’100 s−1, 10 °C [Pa s] | τ0, 10 °C [Pa] |

|---|---|---|---|---|

| Quarg | 0.2 | 12.6 ± 0.1 | 5.5 ± 0.3 | 74.7 ± 2.9 |

| Skyr | 0.2 | 10.1 ± 0.1 | 2.1 ± 0.0 | 22.9 ± 0.0 |

| Greek yogurt | 0.2 | 9.4 ± 0.2 | 2.1 ± 0.0 | 24.6 ± 0.5 |

| Stirred yogurt | 1.5 | 5.6 ± 0.1 | 0.8 ± 0.0 | 9.4 ± 0.2 |

| Yogurt drink | 0.1 | 3.0 ± 0.1 | 0.1 ± 0.0 | 0.3 ± 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piskors, N.; Heck, A.; Filla, J.M.; Atamer, Z.; Hinrichs, J. High Protein—Low Viscosity? How to Tailor Rheological Properties of Fermented Concentrated Milk Products. Dairy 2023, 4, 594-605. https://doi.org/10.3390/dairy4040041

Piskors N, Heck A, Filla JM, Atamer Z, Hinrichs J. High Protein—Low Viscosity? How to Tailor Rheological Properties of Fermented Concentrated Milk Products. Dairy. 2023; 4(4):594-605. https://doi.org/10.3390/dairy4040041

Chicago/Turabian StylePiskors, Nico, Anisa Heck, Jessica M. Filla, Zeynep Atamer, and Jörg Hinrichs. 2023. "High Protein—Low Viscosity? How to Tailor Rheological Properties of Fermented Concentrated Milk Products" Dairy 4, no. 4: 594-605. https://doi.org/10.3390/dairy4040041

APA StylePiskors, N., Heck, A., Filla, J. M., Atamer, Z., & Hinrichs, J. (2023). High Protein—Low Viscosity? How to Tailor Rheological Properties of Fermented Concentrated Milk Products. Dairy, 4(4), 594-605. https://doi.org/10.3390/dairy4040041