Abstract

Consumption of ultrapasteurized milk is marked by extensive global variability; in the U.S. and U.K., less than 10% of fluid milk is marketed as ultrapasteurized, compared to >80% in France, Spain and Portugal. Fluid milk taste perception amongst U.S. consumers is that high-heat treatment of milk, as in ultrapasteurization, generates undesirable differences in taste compared to low-temperature/conventional pasteurized treatment. Although highly trained experts can distinguish characteristics in controlled studies, it remains unknown if general consumers can detect a difference or are subject to confirmation bias. In testing sensory perception in a defined untrained population, our findings indicate that the general consumer is unable to distinguish ultrapasteurized from pasteurized milk. On this basis, we conclude that presumptive “consumer taste perception” that speciously impacts fluid milk processing types in the U.S. market precludes noted benefits to ultrapasteurization not only in flexibility for storage and distribution, but also in reduction of public health risks.

1. Introduction

Globally, pasteurization and ultrapasteurization have evolved as the two predominant forms of milk heat treatment [1,2,3]. Conventional pasteurization is defined as heating at or above 72 °C for at least 15 s for a continuous process or at 62.8 °C for 30 min for a batch process [4]. As not all bacteria are destroyed by this process, pasteurized milk requires refrigeration after processing and has a shelf life of 10 to 12 d. Ultrapasteurization is defined as treatment at or above 138 °C for at least 2 s. Ultrapasteurized milk can either be marketed in non-sterile containers for an extended refrigerated shelf life of around 60 d [5], or be packaged in aseptic (sterile) containers for a room temperature shelf life of up to 6 mo [6]. The latter is also commonly known as ultra-high temperature (UHT) sterilized milk.

The high-temperatures of ultrapasteurization are known to destroy heat-resistant bacteria and bacterial spores that can otherwise survive the low-temperature pasteurization [7,8,9,10]. Despite the benefits to public health and extended storage shelf-life, consumption of ultrapasteurized milk is marked by extensive global variability. For example, while countries such as Spain, France and Portugal consume over 80% of ultrapasteurized milk (as UHT milk), other countries such as Australia, New Zealand, the UK and the U.S. demonstrate a clear preference for pasteurized milk, with less than 10% ultrapasteurized milk in their total fluid milk markets [11]. In the US, less than 5% of fluid milk is ultrapasteurized, and sale as UHT is so marginal as to not be documented in government reports [12].

The prevailing explanation for consumer resistance in some countries is that the high heat-treatment of ultrapasteurization results in distinct “off flavors” that are unacceptable to consumers [11,13]. Although this is supported by detailed studies on heat-related changes to compounds in milk [14], public perception is extrapolated from sensory studies in which a few individuals with substantial sensory training were specifically tasked with detecting and characterizing “off flavors” that develop in ultrapasteurized milk over the course of non-sterile or sterile product storage [15,16,17,18,19,20].

One early publication that does report on the taste of ultrapasteurized milk immediately after processing relies on anecdotal evidence, with the author observing that ultrapasteurized milk is “markedly unpleasant to taste and smell” [21]. Other sensory studies in which panelists sampled both pasteurized and ultrapasteurized milk focused on their abilities to uncover subtle differences in specific flavors [5,20,22,23].

While a concerted effort has been made to identify and classify the physiochemical properties associated with these “off-flavors” in ultrapasteurized and UHT milk [21,24,25,26,27], it remains to be determined if they are distinct and unacceptable to the sensory experience of general, untrained consumers. Consumer perceptions of product quality are conceptually correlated to selections or purchasing behavior [28]. As taste is a hedonic dimension of quality in the perception and acceptance of dairy products, the prevalence of consumer predictive processing and confirmation bias as a matter of communication affects consumer attitudes regarding the acceptance or rejection of products [29]. Top-down cognitive factors have been found to strongly influence consumer expectation of taste, perceived health of a product, moral satisfaction, and willingness to pay for a product. For example, framing the same beef product as “75% lean” compared to “25% fat” led to consumers evaluating the “75% lean” labeled product more favorably [30]; experienced beer drinkers discriminate and rate their favorite beers higher than the others, but only when the beers are labeled [31]; and extrinsic cues such as brand name, price and region of origin affected taste discrimination and taste preference for orange juice [32]. Similarly, “organic” and “healthy” food labeling has been shown to positively affect consumer perception [33,34,35].

Additionally, moral satisfaction as induced by perceived ethical origin labels on food (organic, fair trade and locally produced) has been found to correlate with rendering the taste of such “ethical food” as superior to counterparts, which further extends to positively influence the consumer intention to buy such ethical food [36]. Another study found that consumers who scored high on their attitude toward sustainable consumer behavior ranked a coffee labeled as “eco-friendly” as more preferable in taste than a conventional coffee, despite the coffees being identical, and were even willing to pay more for the “eco-friendly” labeled coffee [37]. As such, given the prevalence of influences in consumer predictive processing and confirmation bias as related to food expectations and the sensory experience, it is difficult to conclude if the off flavors detected by sensory experts tasting milk products are also perceptible to untrained/general consumers.

In this study, we test if U.S. consumers can differentiate between ultrapasteurized and pasteurized milk based on taste. Pertinent to this analysis, we also examine the rationale underlying the extrapolation of results from milk sensory studies that involve experts with acute sensory capabilities to the general population. Our findings conclude that adopting ultrapasteurization of fluid milk as a mainstream practice in the U.S. would unlikely have a negative impact on the consumer market, and could provide significant benefits in preventing milk-borne diseases and extending the shelf-life, both of which are important to food security and international commerce.

2. Materials and Methods

2.1. Subjects

Volunteer participants in this study were undergraduate students at Cornell University. A total of 209 students participated, all of whom were recruited by in-person verbal advertising on the same day that the sensory panel was administered (over a period of 7 d). Involvement of participants was based on oral consent, availability and willingness, as well as confirmation that they did not have any prohibitive medical conditions or dietary restrictions (lactose intolerance, vegan diet, etc.). This study was reviewed and approved under the “exempt” category by the Institutional Review Board for human participants at Cornell University.

2.2. Milk Samples

Five whole milk samples that were either pasteurized or ultrapasteurized were used in the sensory evaluation. The three ultrapasteurized milk samples (Full Circle, Horizon, and Organic Valley) and two pasteurized milk samples (Wegman’s Whole Milk and Wellsley Whole Milk) were procured from the refrigerated section of grocery stores. These milk samples were chosen for their common regional market availability to the participants in Ithaca, New York. After purchasing, all milk samples were maintained/stored at 4 °C until sampled by participants well within their expiration dates.

2.3. Procedure

Participants were taken to a dedicated sensory study room and seated at individual tasting stations. To ensure that the study was performed in a blind manner, each station had six plastic disposable cups: Five randomly assigned number codes identified each of the sample cups containing approximately 50 mL of the different milks, and one cup with chilled water to be used in between tastings for palate cleansing. All milk was sampled chilled and within 10 min of being poured into each cup. The sequence in presentation of the five different milk samples were varied/randomized each day of the tastings. Before tasting, all participants were read a statement defining the temperature and time parameters used for pasteurization and ultrapasteurization. Participants were then instructed to taste each milk sample and indicate on a sheet if they thought the milk had undergone pasteurization or ultrapasteurization. Participants were allowed as much time as needed to sample the milk samples, but most completed the tasting and filled in the results within 10 min. All data collected were anonymous, without any personal information about the participants.

2.4. Statistics

The null hypothesis was that participants would not be able to distinguish between pasteurized and ultrapasteurized milk. Success rates were used to test if participants could accurately determine if pasteurization type for each of the milks tested in the experiment. In this analysis, a success rate of 0.5 (participants choose the correct and incorrect response equally) would indicate that the population was unable to distinguish the pasteurization type. PROC T-TEST (SAS v9.4; SAS Institute Inc., Cary, NC, USA) was used to establish a set of two different t-tests for differences in success rates based on the pasteurization type or milk brand. In the case where milk pasteurization type was used as the independent variable, two t-test analyses (one for each pasteurization type) were performed, testing the mean success rates for either pasteurization type against the null hypothesis. A two tailed t-test was used in both analyses, distinguishing the null hypothesis as the mean success rate = 0.5. Similarly, a t-test was performed for each of the five milk brands in the experiment to test the null hypothesis. As background analysis to examine if results obtained from each day of the tastings were consistent with the final/cumulative analysis, data from each day were tested as subsets against the null hypothesis as described above. The effect of day on mean success rate was tested for significance by running PROC GLM and using day and mean success rate as the independent and response variable, respectively. Retrospective power calculations were made to examine the post-hoc degree of confidence for the results using a two sample Satterthwaite t test assuming unequal variance within PROC POWER (SAS v9.4; SAS Institute Inc., Cary, NC, USA).

3. Results

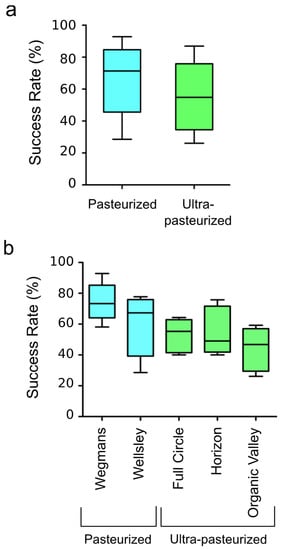

Results of the success rates by pasteurization type are presented in Figure 1a and Table 1. While the mean success rate was significant for pasteurized milk (mean success rate = 0.6764, p < 0.01), it was not significant for ultrapasteurized milk (mean success rate = 0.5060, p = 0.8170). The data were further analyzed to determine if there were differences in success rates by brand (Figure 1b and Table 2).

Figure 1.

Success rates in identifying milk samples by treatment type and brand. (a) Box plots showing the distribution of participant success in correctly identifying pasteurized (blue: Wegmans and Wellsley Whole Milk) and ultrapasteurized (green: Organic Valley, Horizon, Full Circle Whole Milk) samples. Successful identification by study participants was statistically significant for pasteurized (p < 0.05), but not for ultrapasteurized milk samples. (b) Box plots showing the distribution of participant success in correctly identifying the two brands of pasteurized milk (blue; Wegmans and Wellsley Whole Milk) and the three brands of ultrapasteurized milk (green; Organic Valley, Horizon and Full Circle Whole Milk). The pasteurized Wegman’s Whole Milk (p = 0.0002) was the only brand that study participants could identify with significance (p < 0.05).

Table 1.

Mean success rate in identifying pasteurized and ultrapasteurized milk samples.

Table 2.

Mean success rate in identifying pasteurized and ultrapasteurized samples for each milk brand.

Of the two pasteurized milk brands tested, Wegmans Whole Milk was correctly identified as pasteurized with a significant success rate (mean success rate = 0.7412, p < 0.01) while Wellsley Whole Milk was not (mean success rate = 0.6116, p = 0.12). All three of the refrigerated ultrapasteurized milk brands were not successfully identified with significance: Full Circle (mean success rate = 0.5297, p = 0.42), Horizon (mean success rate = 0.5456, p = 0.38), and Organic Valley (mean success rate = 0.4427, p = 0.25). Results from testing the effect of day indicated consistency and without any significant differences to mean success rate, and therefore did not need additional consideration as an independent variable in the cumulative analysis. Post-hoc power analysis indicated that sample size for the two pasteurization types was sufficient to yield a power of greater than 0.95. Further, the sample size among milk brands was large enough to yield a post-hoc power of 0.95.

4. Discussion

In the United States, consumers have contradicted increasing global trends by resisting the consumption of ultrapasteurized milk [11]. It has been broadly posited that this phenomenon is due to ultrapasteurized milk having a distinct and undesirable taste compared to pasteurized milk. However, this claim is derived from sensory studies in which small panels of five to thirty highly trained specialists and experts evaluated and characterized different heat-treated milk samples [22,38,39]. Although the average consumer is distinct from these panelists that have heightened sensory capabilities through training, the results of these studies have percolated into the public psyche, introducing confirmation bias, influencing product perception and patterns of consumer behavior that have directly influenced our food supply chain.

In consumer psychology, it is well established that beliefs and preferences have a neurological basis that are strongly influenced by cognitive biases. These biases include the influence of extrinsic factors such as labeling on taste perception, as has been demonstrated with organic labeling on food products [40], and brand, country of origin and price labels on wine [41,42], beer [31], chocolate [43], hazelnut spread [44], and more. Collectively, these studies reveal that what consumers perceive about taste and product quality (as exemplified by the ‘halo effect’ of organic-labeled foods [40]) is strongly influenced by herding biases [45], marketing tactics and cultural stigmas that reinforce our often erroneous cognitive biases. Notably, reliance on these biases results in increased predictive processing (associating labels or stigmas with how something will taste), a behavior believed to be neurologically rooted and an inescapable part of being human [46,47].

In designing this study, we addressed these cognitive biases by intentionally performing a blind study using untrained consumers who were not conditioned in sensory analysis, thus reflecting the average consumer. The results of this study show that overall, while participants could identify if a milk sample was pasteurized, they could not successfully identify if a milk sample was ultrapasteurized with significance; that is, they were unsure if an ultrapasteurized sample was pasteurized or ultrapasteurized. Moreover, analysis comparing pasteurized milk brands revealed participant uncertainty as correct identification was possible only for one of the two pasteurized milk brands tested. Participants could not correctly identify any of the three ultrapasteurized milk brands, revealing uncertainty when sensory training is not provided. We were prepared to investigate if the type of ultrapasteurization (direct or indirect) had an effect on identification success; two of the ultrapasteurized brands were processed by direct treatment (Organic Valley and Horizon), and one by indirect treatment (Full Circle). Given the consistent results across the three ultrapasteurized milk brands, it can be concluded that direct or indirect processing had no significant effect on successful identification.

If the diversity in our untrained participants (n = 209) is indeed reflective of United States consumers, the results indicate that there is an inability of consumers to truly taste and identify a difference between ultrapasteurized and pasteurized milk. Most participants were not aware of the specific type that they were used to consuming, let alone the type of pasteurization. We believe that this is a core strength of this study in that the effect observed is blinded from any prior experience and is highly relevant to extrapolating from the “sample” to the general consumer public. Moreover, if we were to logically consider that ~90% of fluid milk marketed in the U.S. is pasteurized and aligned with the proportion of prior experience in the population and this participant group, the fact that all three ultrapasteurized milk samples could not be correctly identified reinforces the study conclusions. Furthermore, the ability of the same participants to correctly identify pasteurized milk samples (one of the two brands analyzed) supports our consideration of experience profile, which is skewed in that most are regularly exposed to pasteurized milk in the United States.

These findings underscore that confirmation bias is the likely explanation for the argument in which U.S. consumers are claimed to demonstrate low acceptance for ultrapasteurization of milk. That is, consumers believe too much in their previously held/favored belief that high heat-treated milk (ultrapasteurized) tastes distinctly different from low heat-treated (pasteurized) milk. In the U.S., cultural conversations (magazine articles, blog posts, etc.) tend to promote the idea that high heat treatment negatively alters milk, and that ultrapasteurized milk not only has a distinctly unpleasant taste, but also poorer quality nutrition compared to pasteurized milk [48]. When coupled with our inherent inclination for perceived processing, normalization of this commentary has likely resulted in a consumer confirmation bias that there exists a distinct taste difference between ultrapasteurized and pasteurized milk. Notably, confirmation bias with foods is not unique to milk heat treatments, but has also been observed in consumers evaluating food images [49], expectations of wine and beer taste [31,50], and even perception of food safety [51].

By comparing pasteurized to ultrapasteurized milk, we inadvertently compared conventional to organic milk, as all organic milks undergo ultrapasteurization. Interestingly, while U.S. consumers reject the idea of ultrapasteurized milk, they have increasingly embraced organic foods, including dairy, as healthier, tastier and more environmentally friendly than conventionally produced foods [40,52,53]. This wide-spread perception has drastically expanded U.S. consumer demand for organic milk resulting in North America now being one of the largest organic dairy markets, with an estimated growth of 14.3 percent between 2016 and 2022, with 2017 total organic milk sales in the U.S. inflating to $2.58 billion [54]. Given this perception and purchasing contradiction, it seems that the halo effect of the “organic” label overrides any perceived differences in milk with different heat treatments, suggesting that cognitive biases strongly influence the perception and actual purchasing behavior of conventional (pasteurized) versus organic (ultrapasteurized) milk. By the same token, ultrapasteurized organic milk is not sold as UHT at room temperature, but in the refrigerator, catering to U.S. consumer custom of purchasing cold milk. The concept of extended shelf-life milk stored at room temperature remains beyond what might be described as the U.S. national comfort level [55].

Nevertheless, in using untrained volunteers, the results of this study are in contrast to previous sensory reports [16,20,22,23,39]; we find that U.S. consumers are more accepting of the taste of ultrapasteurized milk than previously thought. Our findings provide a potential impetus for dairy processors to re-engage increasingly health and environmentally conscious U.S. consumers by extending product life without compromising safety.

5. Conclusions

In the U.S., the fluid milk processing market has contradicted global trends with a claim that consumers resist the consumption of ultrapasteurized milk on the basis that it has a distinctly unpleasant taste compared to pasteurized milk. In using untrained participants, our results refute this mainstream view and expose the possibility of a confirmation bias in U.S. consumer perception. This gives cause to re-evaluate U.S. milk marketing in the context of advantages linked to ultrapasteurization processing. For example, the U.S. dairy industry and USDA could engage in educational marketing efforts to inform consumers about the food safety benefits of ultrapasteurized milk while directly addressing sensory concerns through interactive, blind milk taste testing booths at grocery stores, farmers’ markets, and local and state fairs. At these events, an appeal to ethical consumers could be made by promoting the energy-saving benefits of purchasing ultrapasteurized and sterile packaged milk that is not dependent on a supply cold-chain like pasteurized milk is, and to financially savvy consumers by highlighting the extended shelf life of ultrapasteurized milk. Creating the necessary awareness and building consumer acceptance towards ultrapasteurized milk can be an asset in addressing diverse U.S. food insecurity challenges including food deserts, disaster relief, and rural agrarian areas that are increasingly being affected by unpredictable weather.

Author Contributions

Conceptualization, V.S. and K.M.S.; methodology, K.M.S.; validation K.M.S.; formal analysis, K.M.S. and P.A.L.; investigation, K.M.S.; data curation, K.M.S. and P.A.L.; writing—original draft preparation, K.M.S.; writing—review and editing, V.S.; visualization K.M.S.; supervision, V.S.; project administration, K.M.S. and V.S.; funding acquisition, V.S. All authors have read and agreed to the published version of the manuscript.

Funding

Funding for this study was from the College of Agriculture and Life Sciences, Cornell University, USA.

Institutional Review Board Statement

This study was reviewed and approved under the “exempt” category by the Institutional Review Board for human participants at Cornell University.

Informed Consent Statement

Involvement of participants was based on oral consent, availability and willingness.

Data Availability Statement

All data generated or analyzed during this study are included in this published article.

Conflicts of Interest

The authors declare that there is no conflict of interest that could be perceived as prejudicing the impartiality of the research reported.

References

- North, C.E.; Park, W.H. Standards for milk pasteurization. Amer. J. Epidemiol. 1927, 7, 147–173. [Google Scholar] [CrossRef]

- Westhoff, D.C. Heating Milk for Microbial Destruction: A Historical Outline and Update (1). J. Food Prot. 1978, 41, 122–130. [Google Scholar] [CrossRef] [PubMed]

- Obladen, M. From swill milk to certified milk: Progress in cow’s milk quality in the 19th century. Ann. Nutr. Metab. 2014, 64, 80–87. [Google Scholar] [CrossRef]

- FDA. Grade “A” Pasteurized Milk Ordinance; FDA, US Department of Health and Human Services: Washington, DC, USA, 2015.

- Boor, K.J.; Nakimbugwe, D.N. Quality and stability of 2% ultrapasteurized fluid milk products. Dairy Food Environ. Sanit. 1998, 18, 78–82. [Google Scholar]

- Burton, H. Bacteriology of the heat sterilization of milk. In Ultra-High-Temperature Processing of Milk and Milk Products; Springer: Boston, MA, USA, 1994. [Google Scholar] [CrossRef]

- Burton, H. An analysis of the performance of an ultra-high-temperature milk sterilizing plant. II. Calculation of bacterial effectiveness. J. Dairy Res. 1958, 25, 324–337. [Google Scholar] [CrossRef]

- Franklin, J.G.; Underwood, H.M.; Perkin, A.G.; Burton, H. Comparison of milks processed by the direct and indirect methods of ultra-high-temperature sterilization. II. The sporicidal efficiency of an experimental plant for direct and indirect processing. J. Dairy Res. 1970, 37, 219–226. [Google Scholar] [CrossRef]

- Williams, D.J.; Franklin, H.R.; Chapman, L.F.L.C. Methods of assessing the sporicidal efficiency of an ultra-high-temperature milk sterilizing plant. I. Experiments with suspensions of spores in water. J. Appl. Bacteriol. 1957, 20, 43–49. [Google Scholar] [CrossRef]

- Speck, M.L. The inactivation of bacteria in milk exposed to ultra high pasteurization temperatures. J. Milk Food Technol. 1961, 24, 358–361. [Google Scholar] [CrossRef]

- Deeth, H. Improving UHT processing and UHT milk products. In Improving the Safety and Quality of Milk; Elsevier Ltd.: Amsterdam, The Netherlands, 2010; Volume 28. [Google Scholar]

- USDA. Estimated Fluid Milk Products Sales Report; USDA Agricultural Marketing Service: Beltsville, MD, USA, 2017.

- Mehta, R.S. Milk Processed at Ultra-High-Temperatures—A Review. J. Food Prot. 1980, 43, 212–225. [Google Scholar] [CrossRef]

- Calvo, M.M. Flavour of heated milks. A review. Int. Dairy J. 1992, 2, 69–81. [Google Scholar] [CrossRef]

- Mehta, R.S.; Bassette, R. Effects of Carton Material and Storage Temperature on the Flavor of UHT-Sterilized Milk. J. Food Prot. 1980, 43, 392–394. [Google Scholar] [CrossRef]

- McKellar, R.C. Development of off-flavors in ultra-high temperature and pasteurized milk as a function of proteolysis. J. Dairy Sci. 1981, 64, 2138–2145. [Google Scholar] [CrossRef]

- Leong, C.; Harte, B.; Partridge, J.; Ott, D.; Downes, T. Off-flavor development in milk packaged in polyethylene-coated paperboard cartons. J. Dairy Sci. 1992, 75, 2105–2111. [Google Scholar] [CrossRef]

- Rysstad, G.; Ebbesen, A.; Eggestad, J. Sensory and chemical quality of UHT-milk stored in paperboard cartons with different oxygen and light barriers. Food Addititves Contam. 1998, 15, 112–122. [Google Scholar] [CrossRef] [PubMed]

- Valero, E.; Villamiel, M.; Miralles, B.; Sanz, J.; Martinez-Castro, I. Changes in flavour and volatile components during storage of whole and skimmed UHT milk. Food Chem. 2001, 72, 51–58. [Google Scholar] [CrossRef]

- Hansen, A.P.; Turner, L.G.; Jones, V.A. Effect of ultra-high temperature steam injection on flavor acceptability of whole and fortified skim milks. J. Dairy Sci. 1974, 57, 280–286. [Google Scholar] [CrossRef]

- Ashton, T.R. Practical Experience: The Processing and Aseptic Packaging of Sterile Milk in the United Kingdom. J. Soc. Dairy Technol. 1965, 18, 19. [Google Scholar] [CrossRef]

- Chapman, K.W.; Lawless, H.T.; Boor, K.J. Quantitative descriptive analysis and principal component analysis for sensory characterization of ultrapasteurized milk. J. Dairy Sci. 2001, 84, 12–20. [Google Scholar] [CrossRef]

- Chapman, K.W.; Boor, K.J. Acceptance of 2% Ultra-Pasteurized Milk by Consumers, 6 to 11 Years Old. J. Dairy Sci. 2001, 84, 951–954. [Google Scholar] [CrossRef]

- Shipe, W.F. Off Flavors of Milk: Nomenclature, Standards, and Bibliography. J. Dairy Sci. 1977, 61, 855–869. [Google Scholar] [CrossRef]

- Tarassuk, N.P. Effect of Oxygen on Color and Flavor of Heated Milk. Food Ind. 1947, 19, 781–783. [Google Scholar] [PubMed]

- Hutton, J.T.; Patton, S. The origin of sulfhydryl groups in milk proteins and their contributions to “cooked” flavor. J. Dairy Sci. 1952, 35, 699–705. [Google Scholar] [CrossRef]

- Scanlan, R.A.; Lindsay, R.C.; Libbey, L.M.; Day, E.A. Heat-Induced Volatile Compounds in Milk. J. Dairy Sci. 1968, 51, 1001–1007. [Google Scholar] [CrossRef]

- Zeithaml, V.A. Consumer preceptions of price, quality, and value: A means-end model and synthesis of evidence. J. Mark 1988, 52, 2–22. [Google Scholar] [CrossRef]

- Grunert, K.G.; Bech-Larsen, T.; Bredahl, L. Three issues in consumer quality perception and acceptance of dairy products. Int. Dairy J. 2000, 10, 575–584. [Google Scholar] [CrossRef]

- Levin, I.P.; Gaeth, G.J. How consumers are affected by the framing of attribute information before and after consuming the product. J. Consum. Res. 1988, 15, 374–378. [Google Scholar] [CrossRef] [Green Version]

- Allison, R.I.; Uhl, K.P. Influence of beer brand identification on taste perception. J. Mark. Res. 1964, 1, 36–39. [Google Scholar] [CrossRef]

- Hoegg, J.; Alba, J.W. Taste perception: More than meets the tongue. J. Consum. Res. 2007, 33, 490–498. [Google Scholar] [CrossRef]

- Schuldt, J.P.; Schwarz, N. The “organic” path to obesity? Organic claims influence calorie judgements and exercise recommendations. Judgement Decis. Mak. 2010, 5, 114–150. [Google Scholar]

- Magnusson, M.K.; Arvola, A.; Hursti, U.K.; Aberg, L.; Sjoden, P.O. Choice of organic foods is related to perceived consequences for human health and to environmentally friendly behaviour. Appetite 2003, 40, 109–117. [Google Scholar] [CrossRef]

- Provencher, V.; Polivy, J.; Herman, C.P. Perceived healthiness of food. If it’s healthy, you can eat more! Appetite 2009, 52, 340–344. [Google Scholar] [CrossRef] [PubMed]

- Bratanova, B.; Vauclair, C.M.; Kervyn, N.; Schumann, S.; Wood, R.; Klein, O. Savouring morality. Moral satisfaction renders food of ethical origin subjectively tastier. Appetite 2015, 91, 137–149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sorqvist, P.; Hedblom, D.; Holmgren, M.; Haga, A.; Langeborg, L.; Nostl, A.; Kagstrom, J. Who needs cream and sugar when there is eco-labeling? Taste and willingness to pay for “eco-friendly” coffee. PLoS ONE 2013, 8, e80719. [Google Scholar] [CrossRef] [PubMed]

- Clare, D.A.; Bang, W.S.; Cartwright, G.; Drake, M.A.; Coronel, P.; Simunovic, J. Comparison of sensory, microbiological, and biochemical parameters of microwave versus indirect UHT fluid skim milk during storage. J. Dairy Sci. 2005, 88, 4172–4182. [Google Scholar] [CrossRef] [Green Version]

- Horner, S.A.; Wallen, S.E.; Caporaso, F. Sensory Aspects of UHT Milk Combined with Whole Pasteurized Milk. J. Food Prot. 1980, 43, 54–57. [Google Scholar] [CrossRef]

- Lee, W.-C.J.; Shimizu, M.; Kniffin, K.M.; Wansink, B. You taste what you see: Do organic labels bias taste perceptions? Food Qual. Prefer. 2013, 29, 33–39. [Google Scholar] [CrossRef]

- Schmidt, L.; Skvortsova, V.; Kullen, C.; Weber, B.; Plassmann, H. How context alters value: The brain’s valuation and affective regulation system link price cues to experienced taste pleasantness. Sci. Rep. 2017, 7, 8098. [Google Scholar] [CrossRef] [Green Version]

- Veale, R.; Quester, P. Do consumer expectations match experience? Predicting the influence of price and country of origin on perceptions of product quality. Int. Bus. Rev. 2009, 18, 134–144. [Google Scholar] [CrossRef]

- Otter, V.; Prechtel, B.; Theuvsen, L. Country of Origin Effect for Food Products from Developing and Transition Countries: A PLS Analysis of German Consumers’ Perception. J. Int. Food Agribus. Mark. 2018, 30, 355–381. [Google Scholar] [CrossRef]

- Rossi, P.; Borges, A.; Bakpayev, M. Private labels versus national brands: The effects of branding on sensory perceptions and purchase intentions. J. Retail. Consum. Serv. 2015, 27, 74–79. [Google Scholar] [CrossRef]

- Hansen, H. Informational cascades, herding bias, and food taste evaluations. J. Food Prod. Mark. 2014, 20, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Friston, K. The free-energy principle: A unified brain theory? Nat. Rev. Neurosci. 2010, 11, 127–138. [Google Scholar] [CrossRef] [PubMed]

- Lauwereyns, J. The Anatomy of Bias: How Neural Circuits Weigh the Options; MIT Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Zaitlin, P.; Dwyer, J.; Gleason, G.R. Mistaken beliefs and the facts about milk and dairy foods. Nutr. Today 2013, 48, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Ounjai, K.; Kobayashi, S.; Takahashi, M.; Matsuda, T.; Lauwereyns, J. Active Confirmation Bias in the Evaluative Processing of Food Images. Sci. Rep. 2018, 8, 16864. [Google Scholar] [CrossRef] [PubMed]

- Wansink, B.; Payne, C.R.; North, J. Fine as North Dakota wine: Sensory expectations and the intake of companion foods. Physiol. Behav. 2007, 90, 712–716. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Just, D.; Wansink, B. Confirmatory Bias under Food-Borne Risk: A Lab Experiment; Food and Agriculture Organization of the United Nations: Rome, Italy, 2010. [Google Scholar]

- Stolz, H.; Stolze, M.; Hamm, U.; Janssen, M.; Ruto, E. Consumer attitudes towards organic versus conventional food with specific quality attributes. NJAS-Wagening. J. Life Sci. 2011, 58, 67–72. [Google Scholar] [CrossRef] [Green Version]

- Lynchehaun, F.; Hill, H. Organic milk: Attitudes and consumption patterns. Br. Food J. 2002, 104, 526–542. [Google Scholar] [CrossRef]

- Shahbandeh, M.U.S. Organic Dairy Market- Statistics & Facts; Statista Inc.: New York, NY, USA, 2019. [Google Scholar]

- Tagliabue, J. Unchilled Milk: Not Cool Yet; U.S. Proves to Be a Difficult Market for Parmalat. The New York Times. 1995. Available online: https://www.nytimes.com/1995/06/10/business/international-business-unchilled-milk-not-cool-yet-us-proves-be-difficult-market.html (accessed on 28 March 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).