Thermal and Catalytic Pyrolysis of Urban Plastic Waste: Modified Mordenite and ZSM-5 Zeolites

Abstract

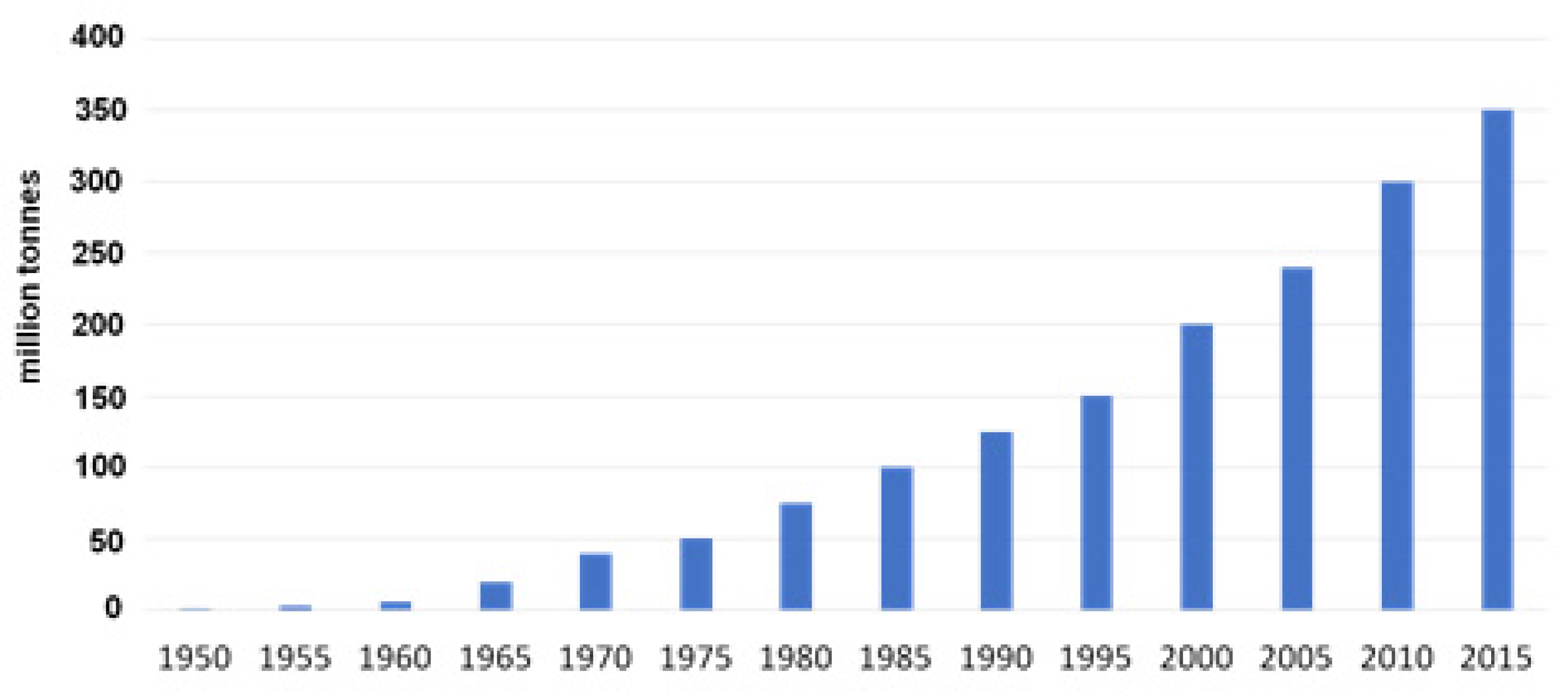

:1. Introduction

2. Results

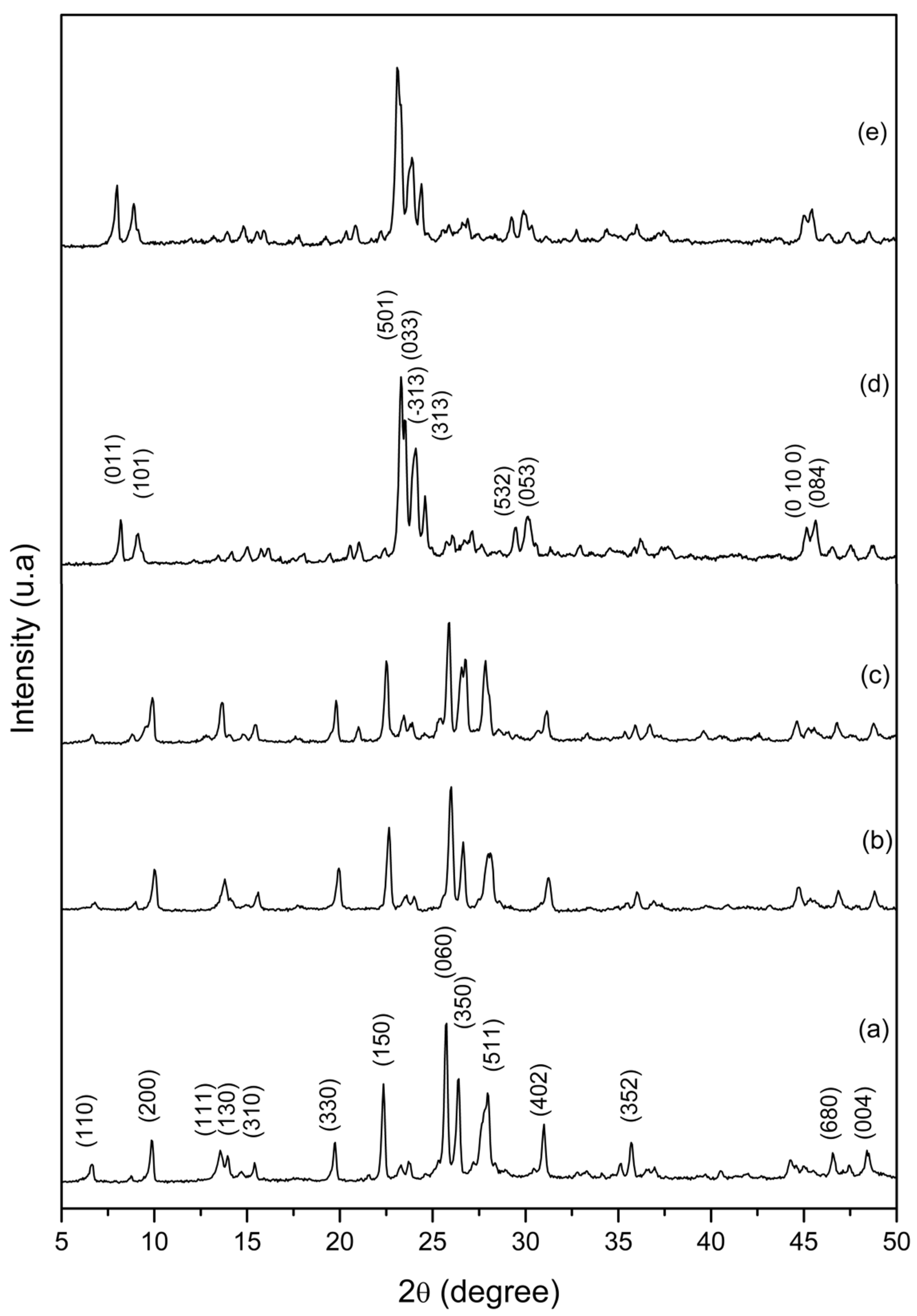

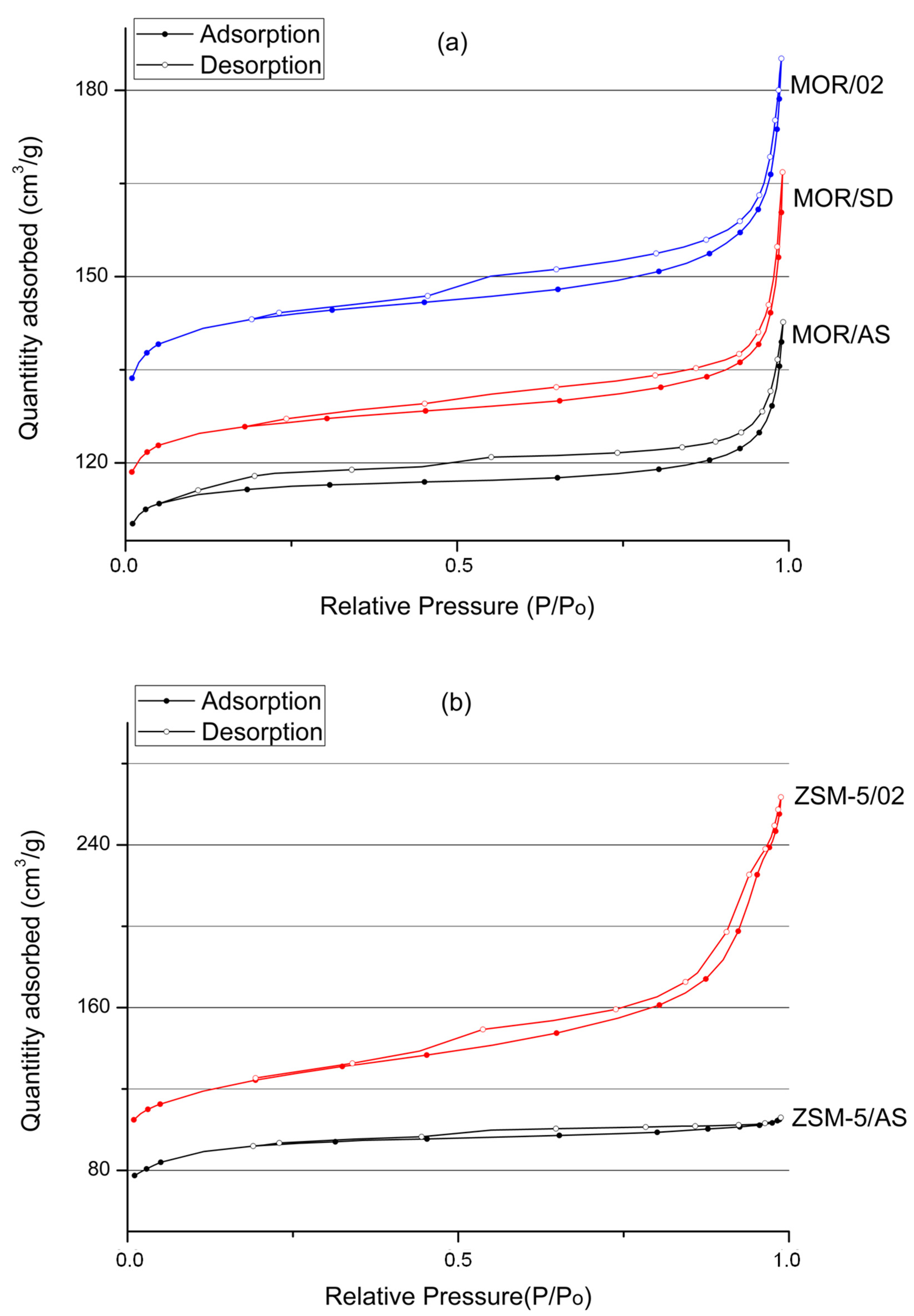

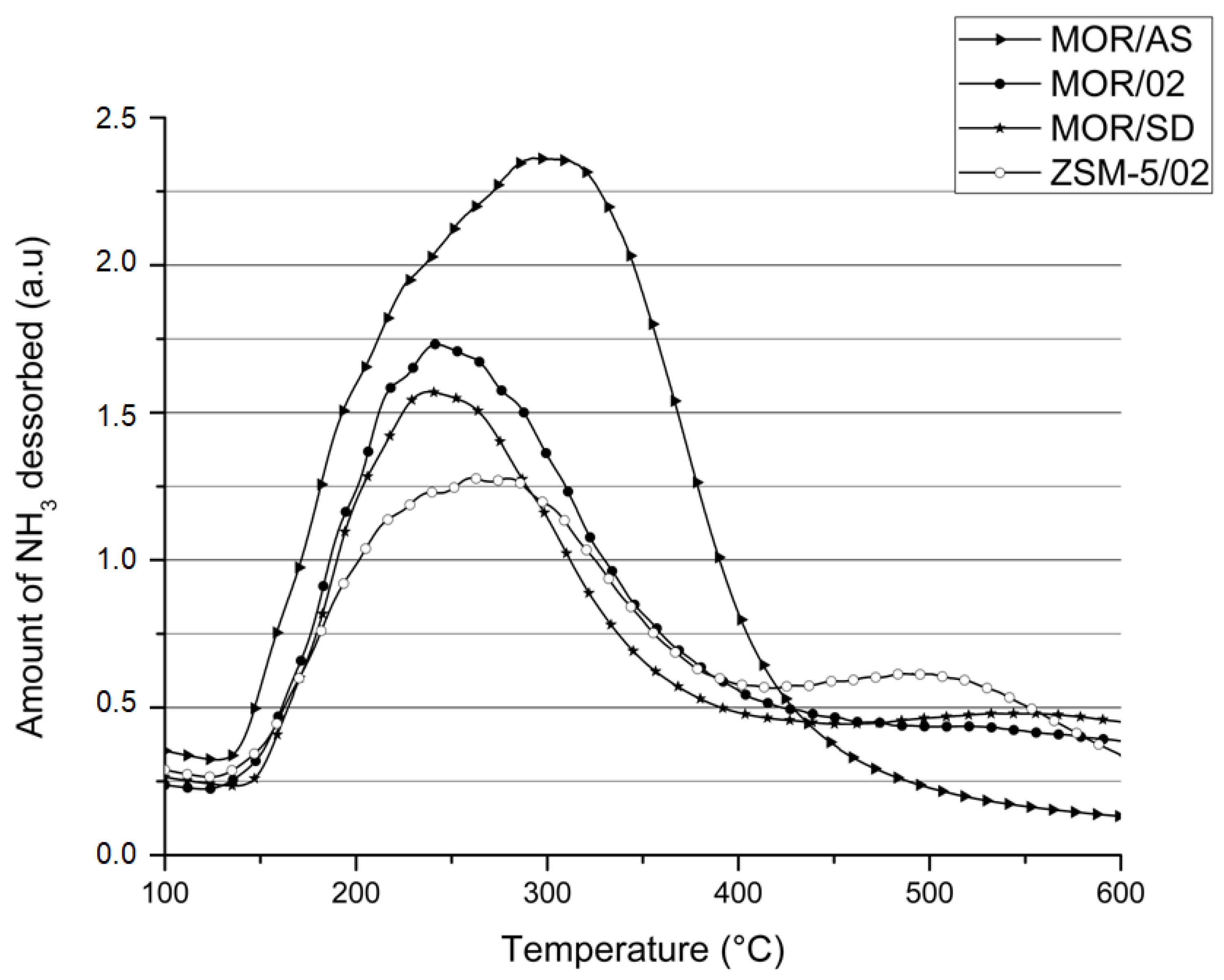

2.1. Catalyst Characterization

2.2. Waste Characterization

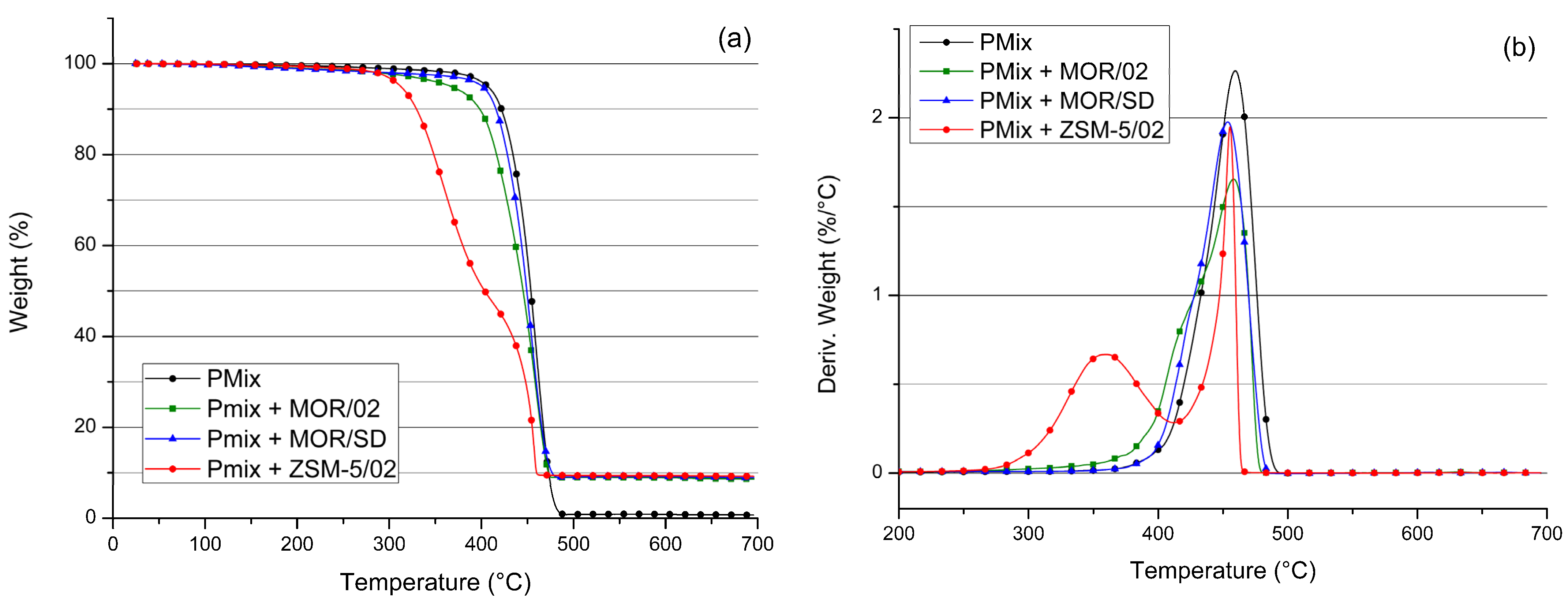

2.3. TGA Pyrolysis

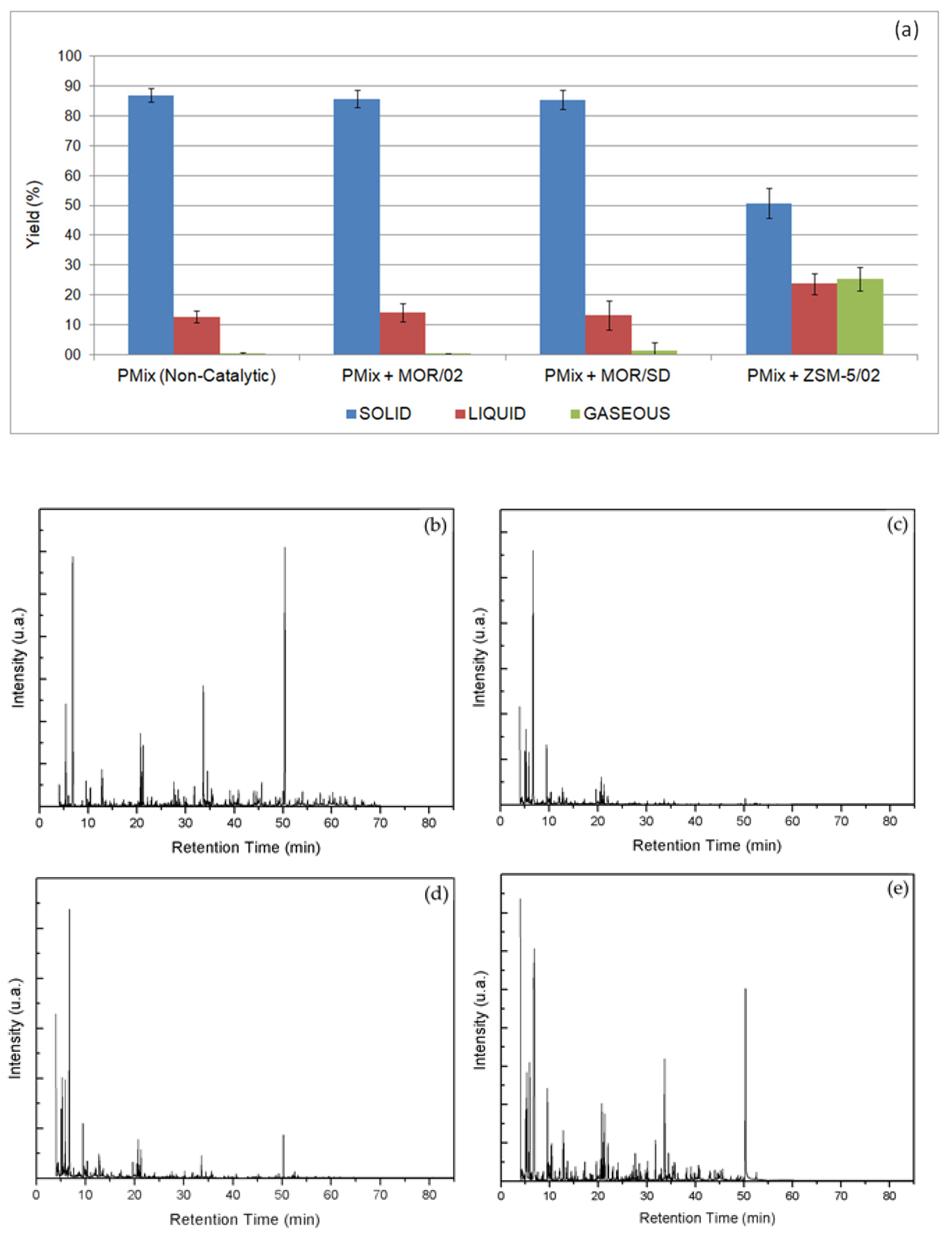

2.4. Pyrolysis in Reactor

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Chemical Treatment of Original Zeolites

4.3. Synthesis of Mordenite

4.4. Catalyst Characterization

4.5. Pyrolysis of Plastic Waste

4.5.1. TGA Pyrolysis

4.5.2. Pyrolysis in Pyrolysis Reactor

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kasar, P.; Sharma, D.K.; Ahmaruzzaman, M. Thermal and catalytic decomposition of waste plastics and its co-processing with petroleum residue through pyrolysis process. J. Clean. Prod. 2020, 265, 121639. [Google Scholar] [CrossRef]

- Melaré, A.V.S.; González, S.M.; Faceli, K.; Casadei, V. Technologies and decision support systems to aid solid-waste management: A systematic review. Waste Manag. 2017, 59, 567–584. [Google Scholar] [CrossRef] [PubMed]

- Fivga, A.; Dimitriou, I. Pyrolysis of plastic waste for production of heavy fuel substitute: A techno-economic assessment. Energy 2018, 149, 865–874. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 25–29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moya, D.; Aldás, C.; López, G.; Kaparaju, P. Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using Waste-To-Energy Technologies. Energy Procedia 2017, 134, 286–295. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, D.; Lei, H.; Villota, E.; Ruan, R. Jet fuel production from waste plastics via catalytic pyrolysis with activated carbons. Appl. Energy 2019, 251, 113337. [Google Scholar] [CrossRef]

- Kaimal, V.K.; Vijayabalan, P. A study on synthesis of energy fuel from waste plastic and assessment of its potential as an alternative fuel for diesel engines. Waste Manag. 2016, 51, 91–96. [Google Scholar] [CrossRef]

- Kumar, S.; Panda, A.K.; Singh, R.K. A review on tertiary recycling of high-density polyethylene to fuel. Resour. Conserv. Recycl. 2011, 55, 893–910. [Google Scholar] [CrossRef]

- Budsaereechai, S.; Hunt, A.J.; Ngernyen, Y. Catalytic pyrolysis of plastic waste for the production of liquid fuels for engines. RSC Adv. 2019, 9, 5844–5857. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Lei, J.; Yuan, G.; Weerachanchai, P.; Wang, J.Y.; Zhao, J.; Yang, Y. Fe-, Ti-, Zr- and Al-pillared clays for efficient catalytic pyrolysis of mixed plastics. Chem. Eng. J. 2017, 317, 800–809. [Google Scholar] [CrossRef]

- Obali, Z.; Sezgi, N.A.; Doĝu, T. Catalytic degradation of polypropylene over alumina loaded mesoporous catalysts. Chem. Eng. J. 2012, 207–208, 421–425. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Yadavalli, G.; Zhu, L.; Wei, Y.; Liu, Y. Gasoline-range hydrocarbons produced from microwave-induced pyrolysis of low-density polyethylene over ZSM-5. Fuel 2015, 144, 33–42. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Ismail, I.M.I.; Nizami, A.S. Effect of plastic waste types on pyrolysis liquid oil. Int. Biodeterior. Biodegrad. 2017, 119, 239–252. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Zhou, G.; Wang, W.; Wang, C.; Komarneni, S.; Wang, Y. Catalytic fast pyrolysis of biomass with mesoporous ZSM-5 zeolites prepared by desilication with NaOH solutions. Appl. Catal. A Gen. 2014, 470, 115–122. [Google Scholar] [CrossRef]

- Djinović, P.; Tomše, T.; Grdadolnik, J.; Božič, Š.; Erjavec, B.; Zabilskiy, M.; Pintar, A. Natural aluminosilicates for catalytic depolymerization of polyethylene to produce liquid fuel-grade hydrocarbons and low olefins. Catal. Today 2015, 258, 648–659. [Google Scholar] [CrossRef]

- Santos, B.P.S.; Almeida, D.; Maria de Fatima, V.M.; Henriques, C.A. Petrochemical feedstock from pyrolysis of waste polyethylene and polypropylene using different catalysts. Fuel 2018, 215, 515–521. [Google Scholar] [CrossRef]

- Meier, W.M. The crystal structure of mordenite (ptilolite). Z. Kristallogr. 1961, 115, 439–450. [Google Scholar] [CrossRef]

- Li, X.F.; Prins, R.; Van Bokhoven, J.A. Synthesis and characterization of mesoporous mordenite. J. Catal. 2009, 262, 257–265. [Google Scholar] [CrossRef]

- Gu, F.N.; Wei, F.; Yang, J.Y.; Lin, N.; Lin, W.G.; Wang, Y.; Zhu, J.H. New strategy to synthesis of hierarchical mesoporous zeolites. Chem. Mater. 2010, 22, 2442–2450. [Google Scholar] [CrossRef]

- Cui, Y.; Yao, H.; Gao, B.; Qin, Y.; Zhang, S.; Yang, B.; He, C.; Xu, B.; Hou, J. Fine-Tuned Photoactive and Interconnection Layers for Achieving over 13% Efficiency in a Fullerene-Free Tandem Organic Solar Cell. J. Am. Chem. Soc. 2017, 139, 7302–7309. [Google Scholar] [CrossRef]

- Galarneau, A.; Villemot, F.; Rodriguez, J.; Fajula, F.; Coasne, B. Validity of the t-plot method to assess microporosity in hierarchical micro/mesoporous materials. Langmuir 2014, 30, 13266–13274. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yi, X.; Wang, G.; Tang, X.; Li, G.; Huang, L.; Zheng, A. Roles of 8-ring and 12-ring channels in mordenite for carbonylation reaction: From the perspective of molecular adsorption and diffusion. J. Catal. 2019, 369, 335–344. [Google Scholar] [CrossRef]

- Chaouati, N.; Soualah, A.; Chater, M.; Pinard, L. Beneficial changes in coke properties with alkaline treatment on aluminum-rich mordenite. J. Catal. 2017, 353, 28–36. [Google Scholar] [CrossRef]

- ABIPLAST. Brazilian Plastic Processed and Recycling Industry—Profile 2018; Brazilian Plast Ind Assoc: São Paulo, Brazil, 2018; p. 47. [Google Scholar]

- Paixão, V.; Carvalho, A.P.; Rocha, J.; Fernandes, A.; Martins, A. Modification of MOR by desilication treatments: Structural, textural and acidic characterization. Microporous Mesoporous Mater. 2010, 131, 350–357. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, S.; Chen, J.; Wei, Y.; Li, J.; Fan, D.; Yu, Z.; Qi, Y.; He, Y.; Xu, S.; et al. Synthesis of mesoporous ZSM-5 catalysts using different mesogenous templates and their application in methanol conversion for enhanced catalyst lifespan. RSC Adv. 2014, 4, 21479–21491. [Google Scholar] [CrossRef]

- Schallmoser, S.; Ikuno, T.; Wagenhofer, M.F.; Kolvenbach, R.; Haller, G.L.; Sanchez-Sanchez, M.; Lercher, J.A. Impact of the local environment of Brønsted acid sites in ZSM-5 on the catalytic activity in n-pentane cracking. J. Catal. 2014, 316, 93–102. [Google Scholar] [CrossRef]

- Sadowska, K.; Wach, A.; Olejniczak, Z.; Kuśtrowski, P.; Datka, J. Hierarchic zeolites: Zeolite ZSM-5 desilicated with NaOH and NaOH/tetrabutylamine hydroxide. Microporous Mesoporous Mater. 2013, 167, 82–88. [Google Scholar] [CrossRef]

- Smail, H.; Shareef, K.; Ramli, Z. Synthesis of Mesoporous Mordenite Zeolite by Different Natural Raw Materials. Aust. J. Basic Appl. Sci. 2017, 11, 27–34. [Google Scholar]

- Song, Z.; Takahashi, A.; Mimura, N.; Fujitani, T. Production of propylene from ethanol over ZSM-5 zeolites. Catal. Lett. 2009, 131, 364–369. [Google Scholar] [CrossRef]

- Khatamian, M.; Irani, M. Preparation and characterization of nanosized ZSM-5 zeolite using kaolin and investigation of kaolin content, crystallization time and temperature changes on the size and crystallinity of products. J. Iran. Chem. Soc. 2009, 6, 187–194. [Google Scholar] [CrossRef]

- Alves, I.C.; Nascimento, T.L.P.M.; Veloso, C.O.; Zotin, F.M.Z.; Henriquez, C.A. Mesopore generation in ZSM-5 zeolites and their effects on conversion of ethanol to olefins. Quim. Nova 2012, 35, 1554–1559. [Google Scholar] [CrossRef] [Green Version]

- Frantz, T.S.; Ruiz, W.A.; Rosa, C.A.; Mortola, V.B. Synthesis of ZSM-5 with high sodium content for CO2 adsorption. Microporous Mesoporous Mater. 2016, 222, 209–217. [Google Scholar] [CrossRef]

- Bertrand-Drira, C.; Cheng, X.; Cacciaguerra, T.; Trens, P.; Melinte, G.; Ersen, O.; Minoux, D.; Finiels, A.; Fajula, F.; Gerardin, C. Mesoporous mordenites obtained by desilication: Mechanistic considerations and evaluation in catalytic oligomerization of pentene. Microporous Mesoporous Mater. 2015, 213, 142–149. [Google Scholar] [CrossRef]

- Bohström, Z.; Lillerud, K.P. Preparation of chabazite with mesopores templated from a cationic polymer. Microporous Mesoporous Mater. 2018, 271, 295–300. [Google Scholar] [CrossRef]

- Paula, T.P.; Marques, M.F.V.; Costa Marques, M.R. Influence of mesoporous structure ZSM-5 zeolite on the degradation of Urban plastics waste. J. Therm. Anal. Calorim. 2019, 138, 3689–3699. [Google Scholar] [CrossRef]

- Jin, H.; Ansari, M.B.; Jeong, E.Y.; Park, S.E. Effect of mesoporosity on selective benzylation of aromatics with benzyl alcohol over mesoporous ZSM-5. J. Catal. 2012, 291, 55–62. [Google Scholar] [CrossRef]

- Ivanova, I.I.; Kuznetsov, A.S.; Ponomareva, O.A.; Yuschenko, V.V.; Knyazeva, E.E. Micro/mesoporous catalysts obtained by recrystallization of mordenite. Stud. Surf. Sci Catal. 2005, 158, 121–128. [Google Scholar]

- Ramos, S.; Carvalho, L.; Spieth, E.; Rivadula, R. Efeitos da estabilização do Polipropileno nas propriedades térmicas, mecânicas e termomecânicas de compósitos de Polipropileno/Atapulgita. Polímeros Ciência e Tecnol. 1993, 3, 26–31. [Google Scholar]

- Líbano, E.V.D.G.; Visconte, L.L.Y.; Pacheco, É.B.A.V. Propriedades Térmicas de Compósitos de Polipropileno e Bentonita Organofílica. Polimeros 2012, 22, 430–435. [Google Scholar] [CrossRef]

- Mark, J.E. Polymer Data Handbook, 3rd ed.; Oxford University Press: Oxford, UK, 1999; pp. 829–838. [Google Scholar]

- Manos, G.; Garforth, A.; Dwyer, J. Catalytic degradation of high-density polyethylene over different zeolitic structures. Ind. Eng Chem. Res. 2000, 39, 1198–1202. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltrán, M.I.; Hernández, F.; Navarro, R. HZSM5 and HUSY deactivation during the catalytic pyrolysis of polyethylene. Appl. Catal A Gen. 2004, 278, 37–43. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P.; Escola, J.M.; Peral, A. Catalytic cracking of polyethylene over zeolite mordenite with enhanced textural properties. J. Anal. Appl. Pyrolysis 2009, 85, 352–358. [Google Scholar] [CrossRef]

- Kim, K.; Ryoo, R.; Jang, H.D.; Choi, M. Spatial distribution, strength, and dealumination behavior of acid sites in nanocrystalline MFI zeolites and their catalytic consequences. J. Catal. 2012, 288, 115–123. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P.; Miguel, G.S.; Escola, J.M.; Rodríguez, J.M. Catalytic activity of zeolitic and mesostructured catalysts in the cracking of pure and waste polyolefins. J. Anal. Appl. Pyrolysis 2007, 78, 153–161. [Google Scholar] [CrossRef]

- Chaouati, N.; Soualah, A.; Chater, M.; Tarighi, M.; Pinard, L. Mechanisms of coke growth on mordenite zeolite. J. Catal. 2016, 344, 354–364. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltrán, M.I.; Navarro, R. Effect of regeneration temperature and time on the activity of HUSY and HZSM5 zeolites during the catalytic pyrolysis of polyethylene. J. Anal. Appl. Pyrolysis 2005, 74, 361–369. [Google Scholar] [CrossRef]

- Milato, J.V.; França, R.J.; Marques, M.R.C. Pyrolysis of oil sludge from the offshore petroleum industry: Influence of different mesoporous zeolites catalysts to obtain paraffinic products. Environ. Technol. 2019, 42, 1013–1022. [Google Scholar] [CrossRef]

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of waste plastics to liquid fuel. A suitable method for plastic waste management and manufacture of value-added products-A world prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Ratnasari, D.K.; Nahil, M.A.; Williams, P.T. Catalytic pyrolysis of waste plastics using staged catalysis for production of gasoline range hydrocarbon oils. J. Anal. Appl. Pyrolysis 2017, 124, 631–637. [Google Scholar] [CrossRef]

- Seo, Y.; Lee, K.; Shin, D. Investigation of catalytic degradation of high-density polyethylene by hydrocarbon group type analysis. J. Anal. Appl. Pyrolysis 2003, 70, 383–398. [Google Scholar] [CrossRef]

- Mihalcik, D.J.; Mullen, C.A.; Boateng, A.A. Screening acidic zeolites for catalytic fast pyrolysis of biomass and its components. J. Anal. Appl. Pyrolysis 2011, 92, 224–232. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, A.; Kumar, J.; Bhaskar, T. Catalytic pyrolysis of soda lignin over zeolites using pyrolysis gas chromatography-mass spectrometry. Bioresour. Technol. 2019, 291, 121822. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Lee, Y.; Rezaei, P.S.; Kim, B.S.; Jeon, J.K.; Jae, J.; Jung, S.C.; Kim, S.C.; Park, Y.K. In-situ catalytic copyrolysis of cellulose and polypropylene over desilicated ZSM-5. Catal. Today 2017, 293, 151–158. [Google Scholar] [CrossRef]

- Li, X.; Zhang, H.; Li, J.; Su, L.; Zuo, J.; Komarneni, S.; Wang, Y. Improving the aromatic production in catalytic fast pyrolysis of cellulose by co-feeding low-density polyethylene. Appl. Catal. A Gen. 2013, 455, 114–121. [Google Scholar] [CrossRef]

- Santos, B.P.S.; Almeida, N.C.; Santos, I.S.; Marques, M.F.V.; Fernandes, L.D. Synthesis and Characterization of Mesoporous Mordenite Zeolite Using Soft Templates. Catal. Lett. 2018, 148, 1870–1878. [Google Scholar] [CrossRef]

- Joppert, N.; Silva, A.A.; Marques, M.R.C. Enhanced diesel fuel fraction from waste high-density polyethylene and heavy gas oil pyrolysis using factorial design methodology. Waste Manag. 2015, 36, 166–176. [Google Scholar] [CrossRef]

- Faillace, J.G.; Melo, C.F.; Souza, S.P.L.; Marques, M.R.C. Production of light hydrocarbons from pyrolysis of heavy gas oil and high-density polyethylene using pillared clays as catalysts. J. Anal. Appl. Pyrolysis 2017, 126, 70–76. [Google Scholar] [CrossRef]

| Sample | Si/Al bulk a | Si/Al bulk surface b | Si/Al framework c | EFAL d (%) |

|---|---|---|---|---|

| MOR/AS | 6.6 | 4.5 | - | - |

| MOR/02 | 6.5 | 5.9 | 8.4 | 26.8 |

| MOR/SD | 8.7 | 5.4 | 9.9 | 24.3 |

| ZSM-5/AS | 13.4 | n.d. | - | - |

| ZSM-5/02 | 12.5 | 10.3 | 16.0 | 18.8 |

| Sample | 2θ (°) | β (FWHM) | D (nm) | Crystallinity (%) |

|---|---|---|---|---|

| MOR/AS | 25.71 | 0.2000 | 42.9 | 100 |

| MOR/02 | 25.84 | 0.2338 | 34.8 | 95.1 |

| MOR/SD | 25.98 | 0.2294 | 35.6 | - |

| ZSM-5/AS | 23.39 | 0.4799 | 16.9 | 100 |

| 8.18 | 0.2618 | 30.4 | ||

| ZSM-5/02 | 23.18 | 0.4499 | 18.0 | 97 |

| 7.96 | 0.2393 | 33.3 |

| Catalyst | Surface Area (m²/g) | Pore Volume (cm³/g) | ||

|---|---|---|---|---|

| BET | External (t-Plot) | Micropores (t-Plot) | Mesopores (BJH) | |

| MOR/AS | 344 | 20 | 0.168 | 0.043 |

| MOR/02 | 426 | 39 | 0.201 | 0.072 |

| MOR/SD | 338 | 16 | 0.163 | 0.034 |

| ZSM-5/AS | 278 | 11 | 0.134 | 0.028 |

| ZSM-5/02 | 383 | 153 | 0.100 | 0.253 |

| Sample | Temperature (°C) | Total Acidity (μmol NH3/g) | Weak/Medium Sites (%) * | Strong Sites (%) ** | |

|---|---|---|---|---|---|

| MOR/AS | 288.7 | 511.8 | 2586 | 99.8 | 0.2 |

| MOR/02 | 241.6 | 521.1 | 2207 | 71.4 | 28.6 |

| MOR/SD | 264.3 | 584.8 | 2093 | 66.3 | 33.7 |

| ZSM-5/AS | - | - | - | - | - |

| ZSM-5/02 | 262.4 | 502.6 | 1965 | 68.7 | 31.3 |

| Extrusions | Tonset (°C) | T10% (°C) | T50% (°C) | TMax (°C) | Residue (%) |

|---|---|---|---|---|---|

| PMix | 432.1 | 421.5 | 453.5 | 459.4 | 0.89 |

| PMix + MOR/AS | 429.6 | 422.9 | 456.0 | 461.0 | 9.62 |

| PMix + MOR/02 | 417.4 | 398.3 | 445.1 | 458.2 | 8.99 |

| PMix + MOR/SD | 423.0 | 411.2 | 449.3 | 456.4 | 8.90 |

| PMix + ZSM-5/02 | 387.1 | 329.5 | 403.7 | 455.4 | 9.40 |

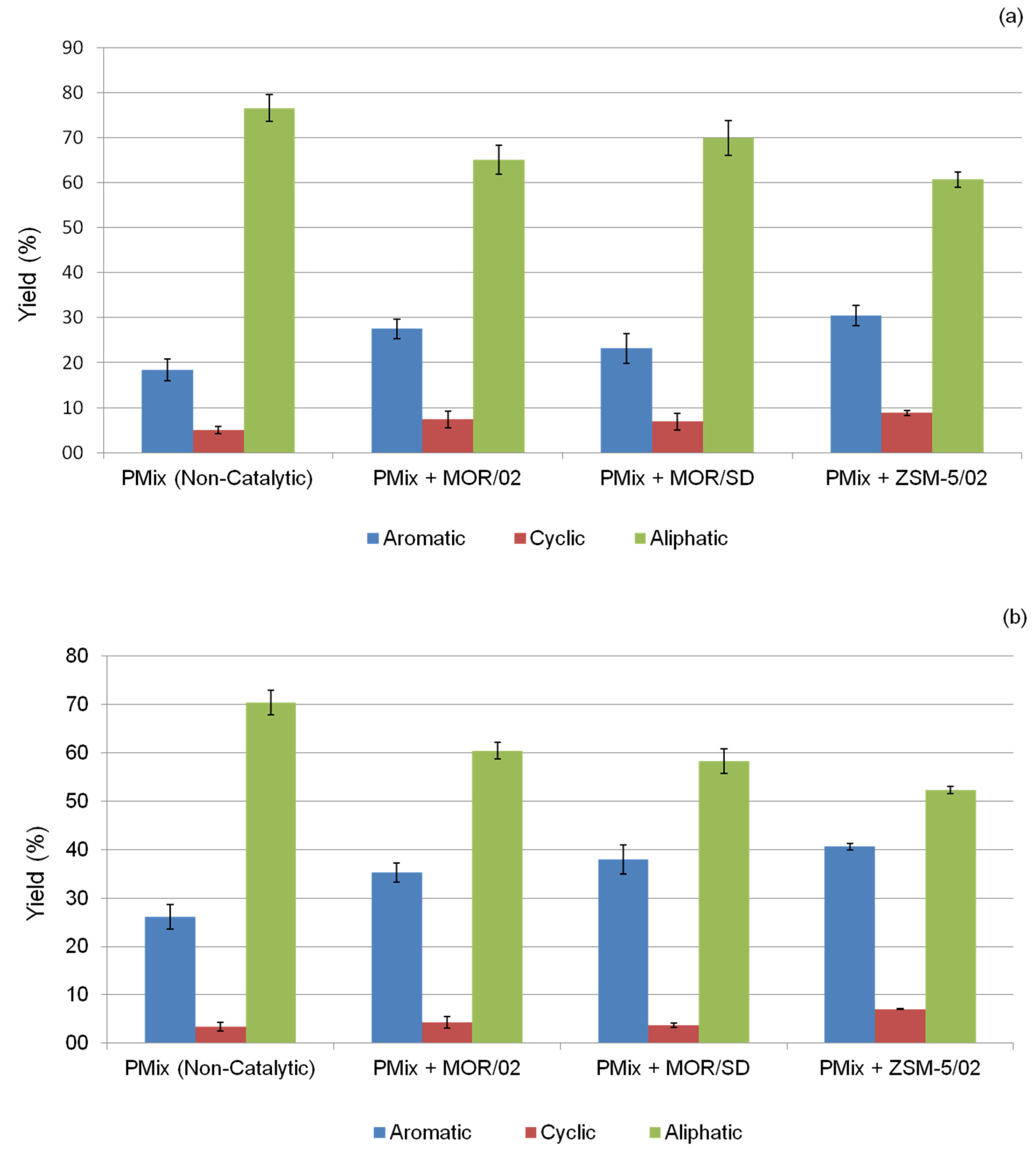

| Conversion (%) | Fraction C10-24 (%) | Fraction C > 24 (%) | Light Fraction (C10-24) | |||

|---|---|---|---|---|---|---|

| Aromatic (%) | Cyclic (%) | Aliphatic (%) | ||||

| PMix | 12.9 ± 2.0 | 69.7 ± 2.8 | 27.6 ± 2.8 | 26.1 ± 2.5 | 3.4 ± 0.9 | 70.4 ± 2.5 |

| PMix + MOR/02 | 14.3 ± 2.3 | 81.5 ± 1.9 | 18.5 ± 1.9 | 35.3 ± 1.9 | 4.3 ± 1.2 | 60.4 ± 1.7 |

| PMix + MOR/SD | 14.5 ± 2.9 | 75.1 ± 2.1 | 24.9 ± 2.1 | 38.0 ± 2.9 | 3.7 ± 0.4 | 58.3 ± 2.6 |

| PMix + ZSM-5/02 | 49.2 ± 2.7 | 80.4 ± 1.3 | 22.4 ± 1.3 | 40.6 ± 0.6 | 7.1 ± 0.1 | 52.3 ± 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paula, T.P.; Marques, M.d.F.V.; Marques, M.R.d.C.; Oliveira, M.S.; Monteiro, S.N. Thermal and Catalytic Pyrolysis of Urban Plastic Waste: Modified Mordenite and ZSM-5 Zeolites. Chemistry 2022, 4, 297-315. https://doi.org/10.3390/chemistry4020023

Paula TP, Marques MdFV, Marques MRdC, Oliveira MS, Monteiro SN. Thermal and Catalytic Pyrolysis of Urban Plastic Waste: Modified Mordenite and ZSM-5 Zeolites. Chemistry. 2022; 4(2):297-315. https://doi.org/10.3390/chemistry4020023

Chicago/Turabian StylePaula, Taihana Parente, Maria de Fatima Vieira Marques, Mônica Regina da Costa Marques, Michelle Souza Oliveira, and Sergio Neves Monteiro. 2022. "Thermal and Catalytic Pyrolysis of Urban Plastic Waste: Modified Mordenite and ZSM-5 Zeolites" Chemistry 4, no. 2: 297-315. https://doi.org/10.3390/chemistry4020023

APA StylePaula, T. P., Marques, M. d. F. V., Marques, M. R. d. C., Oliveira, M. S., & Monteiro, S. N. (2022). Thermal and Catalytic Pyrolysis of Urban Plastic Waste: Modified Mordenite and ZSM-5 Zeolites. Chemistry, 4(2), 297-315. https://doi.org/10.3390/chemistry4020023