1. Introduction

Time-Sensitive Networking (TSN) has emerged as a cornerstone of deterministic Ethernet, providing bounded latency and reliability guarantees for domains such as industrial automation, automotive systems, and mission-critical cyber–physical infrastructures. While TSN provides powerful mechanisms for synchronization and scheduling, ensuring robustness against faults remains a challenge, particularly in large-scale or wireless deployments where transient failures, congestion, and resource constraints frequently occur. Reliable operation in such environments requires fault-tolerance mechanisms that balance reliability guarantees with efficient resource utilization. Among these mechanisms, Frame Replication and Elimination for Reliability (FRER) has become the principal method for safeguarding critical traffic against transient failures.

Industrial communication systems increasingly rely on deterministic Ethernet technologies to support real-time control, safety-critical operations, and ultra-reliable data delivery. TSN, standardized under the IEEE 802.1 suite [

1], provides foundational mechanisms to ensure bounded latency, low jitter, and fault tolerance. Among these, FRER, defined in IEEE 802.1CB [

2], is a key component for enhancing communication robustness against transient link failures, device faults, or localized congestion [

3].

FRER enhances reliability by duplicating frames across disjoint network paths, enabling receiving endpoints to eliminate duplicates and reconstruct the original traffic stream. This mechanism is particularly beneficial for critical data flows [

4], where packet loss could compromise physical processes or pose operational hazards. In industrial deployments, FRER is often statically configured—either on a per-stream basis or network-wide—to provide consistent protection regardless of current network conditions.

However, static activation introduces a fundamental trade-off: while it ensures fault tolerance, it imposes constant redundancy overhead. Redundant transmissions consume additional bandwidth, increase network load, and may exacerbate congestion during peak periods [

5]. In environments where network faults are rare or transient, always-on FRER leads to inefficient resource utilization. As industrial networks evolve to support dynamic, high-density workloads—including wireless TSN extensions [

6]—this inefficiency becomes increasingly significant.

To address this, there is a growing need for adaptive FRER control aligned with real-time network conditions [

7]. Although prior work has explored enhancements such as dynamic path selection, software-defined implementations, and integration with wireless domains, FRER activation remains largely decoupled from network observability and data-driven insights.

Recent advances in machine learning (ML), particularly in temporal modeling, offer a promising alternative. Time-series learning models can anticipate faults by identifying degradation patterns before service disruptions occur [

8]. When tightly coupled with redundancy control, such predictive capabilities enable a new class of resilience strategies: anticipatory protection.

This paper presents a complete fault anticipation framework for predictive FRER activation in TSN-enabled industrial networks. The system monitors multivariate network performance indicators and applies a bidirectional Long Short-Term Memory (BiLSTM) model to forecast the likelihood of imminent faults. FRER is selectively enabled for affected streams when the predicted fault score exceeds a dynamic threshold and deactivated upon KPI recovery or timeout expiry. This approach ensures redundancy is applied only during risk windows, minimizing bandwidth overhead without compromising reliability.

To validate our approach, we developed a runtime simulation and visualization environment that integrates the BiLSTM model, FRER activation logic, and a real-time Streamlit dashboard. The experimental results demonstrate the benefits of anticipatory redundancy in terms of link utilization, activation accuracy, and fault coverage.

The main contributions of this work are as follows:

A synthetic KPI-based dataset generation pipeline tailored for modeling temporal degradation in TSN networks.

A bidirectional LSTM model that accurately anticipates faults using time-series KPIs.

A predictive FRER activation and deactivation mechanism integrated with the BiLSTM inference output.

A complete runtime environment including a simulator and real-time dashboard for system state visualization and performance evaluation.

A comprehensive evaluation of the framework in terms of redundancy efficiency, fault anticipation accuracy, and link utilization improvement.

2. Related Work

The intersection of TSN reliability mechanisms and data-driven fault management has attracted growing research attention in both industrial networking and machine learning. Prior work has explored static and dynamic implementations of FRER, simulation-based performance analyses, and enhancements for edge and wireless deployments. In parallel, a growing body of literature has investigated machine learning techniques for fault detection, prediction, and network observability in industrial environments [

9,

10,

11,

12,

13,

14]. Although these research threads have matured independently, their integration is still limited. Specifically, no existing studies close the control loop by using predictive fault insights to trigger the real-time activation of TSN reliability mechanisms such as FRER. This section reviews the literature in three categories: (i) FRER deployment and optimization, (ii) ML-based fault prediction in industrial networks, and (iii) ML applications in TSN systems.

2.1. Frame Replication and Elimination for Reliability in TSN

FRER, standardized under IEEE 802.1CB [

2], is a core TSN mechanism that ensures ultra-reliable communication in deterministic Ethernet networks. By replicating frames across disjoint paths and allowing receivers to discard duplicates using sequence identifiers, FRER enables seamless data recovery during link failures, transmission errors, or localized congestion. This makes it particularly valuable for safety-critical and time-sensitive industrial applications.

Amendments to the base standard, such as IEEE 802.1CBcv and IEEE 802.1CBdb [

15,

16], introduced YANG-based management models and extended stream identification capabilities. These additions enhance the configurability and scalability of FRER deployments, particularly in software-defined and virtualized industrial networks.

To support analysis and benchmarking, simulation-based implementations of FRER have been developed using OMNeT++ and the INET framework. Danielis et al. [

17] demonstrated that FRER effectively masks link-level failures but also incurs persistent overhead when redundancy is always active under nominal conditions. Maile et al. [

4] similarly emphasized the need for runtime configurability to avoid excessive memory usage and frame reordering caused by static buffer and sequence number settings.

Recent research has extended FRER to edge-cloud and wireless-integrated scenarios. Li et al. [

7] proposed an optimized FRER scheme for edge-computing networks that reduces overhead while maintaining resilience to burst errors. Similarly, Aijaz et al. introduced X-FRER [

18], a cross-domain extension for 5G-TSN integration, where redundancy spans both Ethernet and wireless segments. These developments underscore the growing need for adaptable, context-aware FRER strategies in heterogeneous industrial environments.

From an implementation standpoint, Reimann et al. [

19] explored a lightweight realization of FRER using eBPF/XDP, enabling per-packet protection at line rate directly in kernel space. While their approach demonstrates the feasibility of software-defined FRER in industrial edge environments, it still adheres to static or predefined activation policies.

Despite these advancements, the dominant deployment paradigm for FRER remains static. Redundancy is typically configured in advance—either globally or on a per-flow basis—without regard for real-time network state or fault probability. This results in inefficient bandwidth utilization, particularly when faults are rare or localized. As industrial networks grow in complexity and adopt hybrid wired–wireless topologies, the limitations of static FRER become increasingly evident, reinforcing the need for intelligent, dynamic activation strategies.

2.2. Fault Detection and Anticipation in Industrial Networks

Ensuring reliability in industrial communication networks requires both post-failure recovery mechanisms and predictive capabilities that enable preemptive intervention. Traditional fault management has relied on model-based and signal-processing techniques, including observer models, parity relations, and time–frequency analysis methods such as wavelet transforms and FFT. Although effective in tightly controlled environments, these techniques often lack scalability and adaptability in dynamic and heterogeneous industrial settings.

With the advent of the Industrial Internet of Things (IIoT) and large-scale telemetry collection, data-driven approaches have become increasingly prominent. Recent surveys, such as Abdelkhalek et al. [

20], highlight the growing reliance on machine learning (ML) for fault detection, particularly when bandwidth and computational resources are constrained. These studies highlight the effectiveness of supervised learning models trained on historical KPI traces to detect early-stage anomalies. Leite et al. [

21] similarly categorize modern fault management techniques into model-based, signal-based, and data-driven approaches, noting the superior generalization performance of deep learning (DL) models in noisy and nonlinear environments.

Equally important is the reliability of the sensor and telemetry data. Measurement streams may experience drift, burst noise, or missing samples, directly affecting the trustworthiness of ML-based predictions. Shafin et al. [

22] highlight this challenge by proposing lightweight mechanisms for IoT sensors to self-declare reliability levels of their numeric outputs, enabling downstream applications to account for uncertainty. Integrating such reliability-awareness into predictive networking frameworks is essential for robust operation.

Temporal learning models, in particular, have proven effective in capturing degradation trends that precede observable faults. Recurrent architectures such as Long Short-Term Memory (LSTM) and Gated Recurrent Units (GRUs), which are well suited for modeling long-term dependencies, are widely used in predictive maintenance and real-time diagnostics. Panigrahi et al. [

23] and Shaalan et al. [

24] demonstrate that convolutional and recurrent neural networks outperform traditional classifiers in detecting complex failure patterns in rotating machinery and other mechanical systems. The effectiveness of LSTM-based architectures for predictive maintenance and fault anticipation has been demonstrated across diverse domains. For example, Han et al. [

25] apply LSTM networks to anticipate degradation in sensor-driven systems characterized by high temporal variability. These studies highlight the capacity of LSTMs to capture sequential dependencies in noisy, multivariate telemetry streams, which directly parallels the KPI-driven fault anticipation problem addressed in this paper. Building on these insights, we adopt a BiLSTM architecture to exploit both forward and backward temporal information, thereby enhancing the timeliness and stability of redundancy activation in TSN networks. Transformer-based models, including stacked Informer architectures [

26] and LLM-driven temporal predictors [

27,

28,

29], have also shown strong potential in long-horizon forecasting, particularly in grid and process automation domains.

Beyond sequence modeling, graph-based learning techniques have been applied to fault localization in topologically structured networks. Khorasgani et al. [

30] employed Graph Convolutional Networks (GCNs) to detect and isolate faults by jointly modeling spatial and temporal dependencies. Desai et al. [

31] extended this concept to TSN environments, leveraging ML-generated configurations to mitigate the impact of latent faults through intelligent traffic shaping.

Despite these advances, most ML-based fault prediction frameworks operate as passive monitoring tools, disconnected from the network control plane. Their outputs are typically limited to visualization, alerting, or offline diagnostics, rather than driving runtime decisions. Crucially, these models have not been integrated with reliability mechanisms such as FRER to enable anticipatory protection strategies. This decoupling between prediction and action represents a missed opportunity—particularly in environments where timely redundancy activation could prevent service degradation altogether.

In this work, we address this gap by embedding temporal learning directly into the redundancy control loop. Among candidate sequence models, we selected a BiLSTM architecture for three key reasons. First, degradations in TSN networks often evolve gradually across KPI sequences, making BiLSTMs effective at capturing long-term temporal dependencies. Second, BiLSTMs provide relatively lightweight inference compared to Transformer-based architectures, ensuring low-latency operation suitable for real-time redundancy activation. Third, the bidirectional design leverages both degradation onset and recovery phases, supporting timely activation and safe withdrawal of redundancy. These characteristics make BiLSTM particularly well aligned with the requirements of predictive FRER activation.

While LSTMs are effective for modeling long-term sequential dependencies, we adopt BiLSTM to exploit information from both past and future contexts in the KPI sequences. This design enables the model to detect degradation trends earlier while also recognizing recovery patterns, which supports both timely activation and safe withdrawal of FRER redundancy. Compared to a standard LSTM, this bidirectional structure improves robustness in scenarios where pre-fault and post-fault indicators overlap or evolve asymmetrically.

2.3. ML for TSN and Resilient Networking

The integration of machine learning into TSN-based industrial networks has gained increasing attention, driven by the need for adaptability, automation, and intelligent fault tolerance [

32,

33]. ML techniques have been applied to various TSN functions, including traffic classification, admission control, queue management [

34], and anomaly detection [

35]. These use cases aim to enhance the observability and responsiveness of TSN systems beyond the capabilities of static configuration alone.

Notably, Khorasgani et al. [

30] and Desai et al. [

31] demonstrated the feasibility of using ML models to synthesize TSN configurations and detect misbehaving flows under fault-prone conditions. These approaches are particularly valuable for managing dynamic or unpredictable workloads, where preconfigured policies may be suboptimal. Reimann et al. [

19] similarly demonstrated lightweight packet-level fault protection using eBPF/XDP in Linux-based industrial edge environments, offering a flexible software-defined alternative to hardware-bound reliability mechanisms.

Although these represent significant progress in leveraging ML for TSN monitoring and adaptive behavior, they do not close the control loop. Most ML-based solutions function as decision-support systems or offline analytics engines that inform network administrators or upper-layer controllers but do not directly influence TSN behavior at runtime. In particular, no prior studies have tightly integrated predictive ML models with real-time control of redundancy mechanisms such as FRER.

This architectural disconnect limits the practical impact of ML-based fault prediction. Without actionable control triggers, even highly accurate predictions are underutilized. A system that anticipates faults but cannot autonomously initiate protection offers limited value in high-availability environments, where proactive intervention is critical.

2.4. Gaps in the Literature

While TSN has matured with mechanisms such as FRER to ensure resilience in industrial networks, current deployments still rely predominantly on static configurations. As highlighted in [

2,

4,

7], FRER is commonly preconfigured on a per-stream basis, activating redundancy regardless of whether the network is operating under nominal or degraded conditions. Although always-on redundancy effectively masks faults, it introduces substantial and often unnecessary overhead—particularly in resource-constrained or bandwidth-sensitive environments such as edge-based industrial networks [

17,

19].

In parallel, research in fault anticipation has advanced rapidly, leveraging machine learning and time-series forecasting to predict failures before they occur [

20,

21,

27]. These approaches have shown strong potential in domains such as predictive maintenance [

36,

37], electrical distribution systems [

38], and TSN fault localization [

31]. However, despite increasing accuracy, these prediction models remain siloed from the operational control plane. Specifically, they are not integrated with TSN reliability mechanisms such as FRER.

To date, no known work has proposed or demonstrated a closed-loop system in which fault anticipation directly informs the runtime activation of FRER. This disconnect represents a critical shortcoming: while static redundancy mechanisms are robust, they fail to exploit predictive insights that could optimize network resource usage. Conversely, fault predictors—though effective in isolation—lack actionable integration with adaptive reliability mechanisms in industrial communication systems.

Moreover, recent works such as X-FRER [

18] and eBPF/XDP-based FRER [

19] have improved deployment models and implementation efficiency but still rely on static or manually defined configurations. Similarly, TSN-focused ML-based detection tools [

30,

31] are primarily used for monitoring and alerting, rather than influencing real-time fault recovery strategies.

To address this gap, we introduce a predictive FRER control framework that proactively activates and deactivates redundancy mechanisms based on the likelihood of fault occurrence. Our architecture comprises four core components:

Monitoring Module: Continuously collects real-time network KPIs, such as jitter, retransmission counts, latency, and congestion indicators, forming the basis for fault evaluation.

Fault Score Module: Implements a trained bidirectional LSTM model that transforms historical KPI sequences into a fault likelihood score, estimating the probability of imminent failure on a given path.

FRER Controller: Acts on the fault score to selectively activate or deactivate FRER for critical traffic streams, applying redundancy only when needed to reduce overhead during stable conditions.

Safe Window Timer: Enforces a minimum protection duration once FRER is triggered, avoiding oscillations and ensuring redundancy persists through transient disturbances. Upon timer expiry and KPI recovery, FRER is withdrawn.

This architecture enables anticipatory fault protection—activating redundancy not in reaction to failure but in preparation for it. By coupling data-driven forecasting with real-time reliability control, our system bridges the previously disjoint domains of prediction and protection. To the best of our knowledge, this work presents the first realization of predictive, dynamic FRER activation in TSN-based industrial networks.

3. System Overview

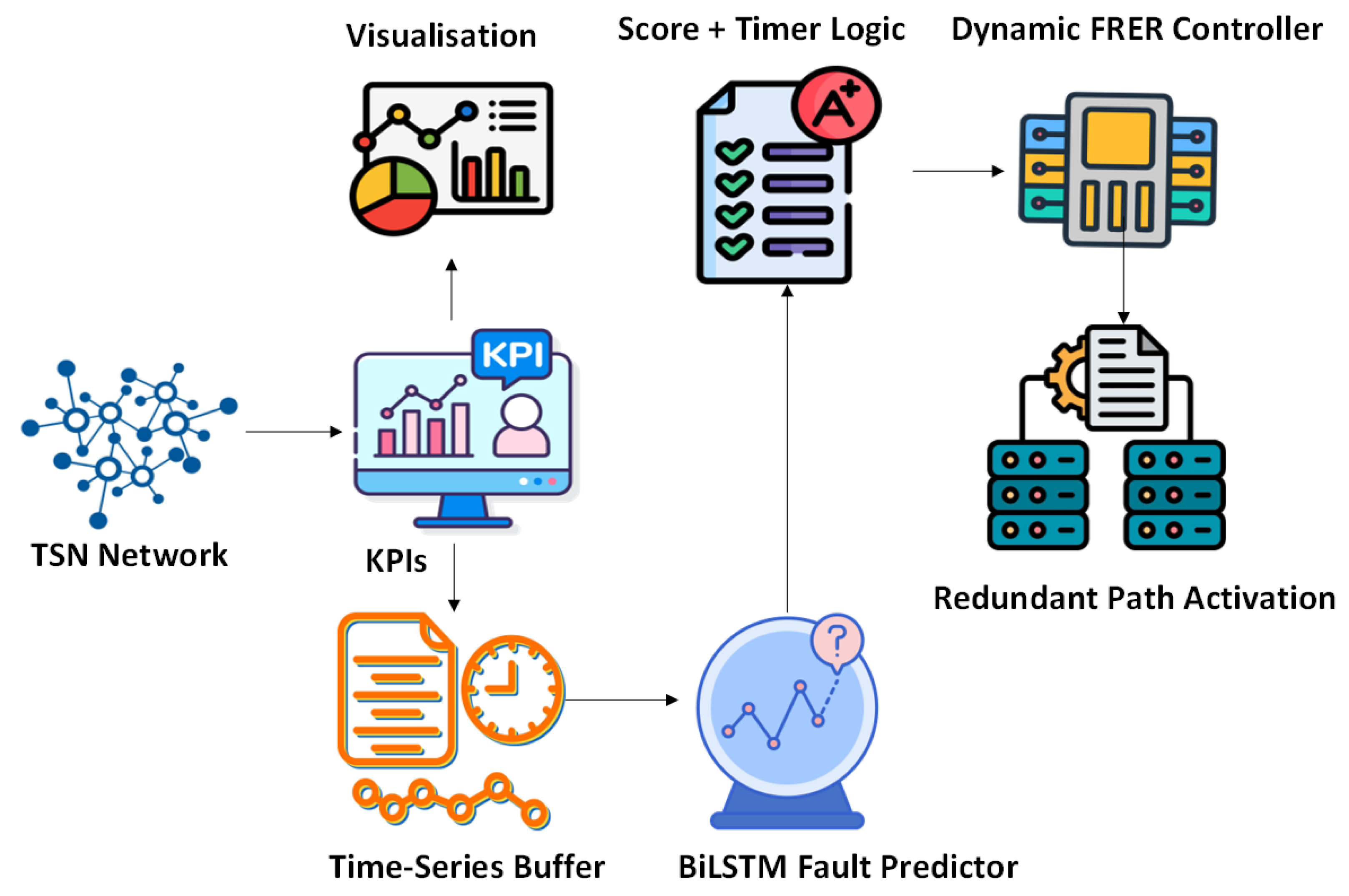

Figure 1 illustrates the high-level architecture of the proposed predictive FRER framework. The system operates as a closed-loop controller that anticipates network faults and proactively triggers FRER activation, rather than reacting post-failure. It comprises five primary components: (i) a TSN network generating real-time KPIs, (ii) a time-series buffering module, (iii) a BiLSTM-based fault predictor, (iv) a fault score and timer logic unit, and (v) a dynamic FRER controller with optional visualization support.

TSN Network and KPI Monitoring: The system is designed to operate over a TSN-compliant network, where end devices and intermediate switches support standard traffic shaping, scheduling, and reliability features such as IEEE 802.1Qbv and 802.1CB. The network continuously generates key performance indicators (KPIs) such as latency, jitter, retransmission rate, throughput, and congestion levels. These metrics are collected at runtime and reflect the operational health of individual links or paths.

Time-Series Buffering: To capture temporal trends, raw KPIs are accumulated into fixed-length sliding windows that serve as input to the fault prediction model. This buffer operates in real time, ensuring that each model input reflects the recent behavior of the network. The window size, sampling interval, and update frequency are configurable based on desired prediction granularity and system latency constraints.

BiLSTM Fault Anticipation Module: A trained bidirectional Long Short-Term Memory (BiLSTM) model, which processes buffered KPI sequences and outputs a scalar fault score. This score represents the model’s confidence in the likelihood of an imminent fault. The bidirectional architecture enables the model to learn both forward and backward temporal dependencies, improving its ability to detect subtle degradation trends that precede network failures.

Score and Timer Logic: To prevent spurious activations caused by noise or short-lived fluctuations, the predicted fault score is evaluated against a configurable threshold. If the score exceeds this threshold, the system triggers the FRER controller and initiates a safe window timer. This timer ensures that redundancy remains active for a minimum duration, even if the fault score subsequently drops. This mechanism avoids instability from frequent toggling of FRER in response to transient anomalies.

Dynamic FRER Controller: Upon receiving an activation signal, the FRER controller selectively enables redundancy on critical streams using available disjoint paths. Once the timer expires and no new fault condition is detected, FRER is deactivated to restore normal bandwidth efficiency. This module can be integrated with software-defined networking (SDN) control planes or local device agents, depending on deployment requirements.

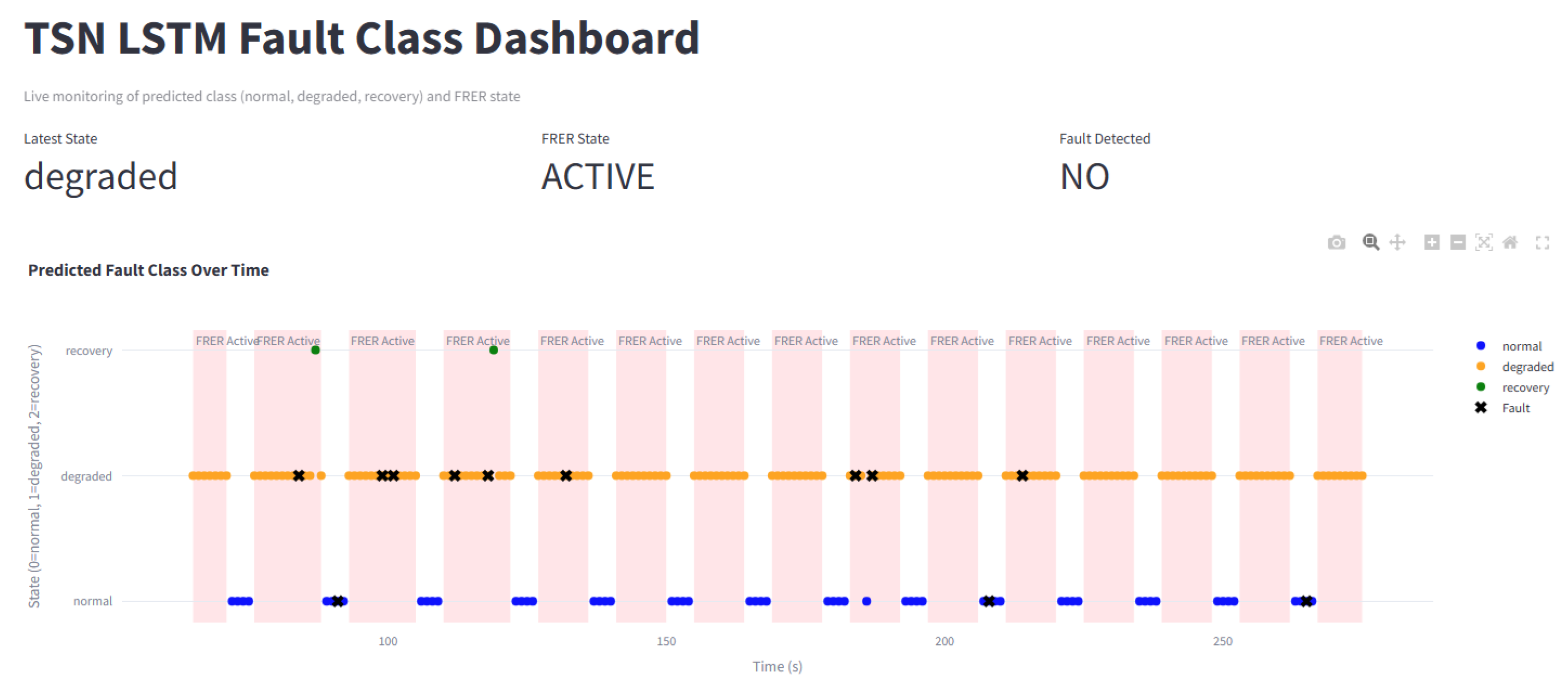

Visualization Interface: To support observability and debugging, the system includes a real-time dashboard built with Streamlit. The interface visualizes raw KPIs, fault scores, model confidence, and the FRER activation state. It enables offline analysis, runtime validation, and tuning of model thresholds and timer durations.

4. Fault Score Modeling Using BiLSTM

Fault score modeling is a predictive analytics technique that estimates the likelihood of imminent network faults by analyzing time-series performance metrics. In the proposed framework, a trained bidirectional Long Short-Term Memory (BiLSTM) model processes real-time KPI sequences—such as latency, jitter, and retransmission rates—and outputs a scalar fault score. This score serves as a quantitative indicator of network health, enabling proactive interventions. Specifically, when the fault score exceeds a defined threshold, the system triggers redundancy mechanisms, such as FRER in TSN, to mitigate the risk of service degradation or failure.

4.1. KPI Feature Representation and Labeling

The effectiveness of fault anticipation depends critically on the quality and expressiveness of the network health indicators used as model inputs [

39]. In the proposed framework, we construct a multivariate feature set comprising physical-layer and transport-layer KPIs, along with synchronization and link-level status metrics. The final feature vector includes the elements listed in

Table A1.

To ensure consistency and improve model interpretability, the categorical feature sync_state is encoded as an integer using LabelEncoder, while all numerical features are standardized using StandardScaler. Feature scaling is essential due to the wide range of units and value magnitudes across different KPIs (e.g., bit error rate vs. latency). Each time step in the dataset is annotated with a fault label, selected from one of three classes:

Normal: No degradation or fault signatures present.

Degraded: Pre-fault behavior caused by injected fault conditions.

Recovery: Post-fault window where KPIs return to nominal levels.

These labels are derived from fault injection metadata during synthetic dataset generation, which is common while building a concept demonstrator [

40]. Smoothing logic is applied to mark transitional behavior accurately. Fault types such as

packet_loss, congestion, and

bit_error are uniformly mapped to the degraded class to simplify the modeling task. These annotated labels serve as the supervisory signal during training, enabling the model to learn to anticipate faults based on KPI patterns.

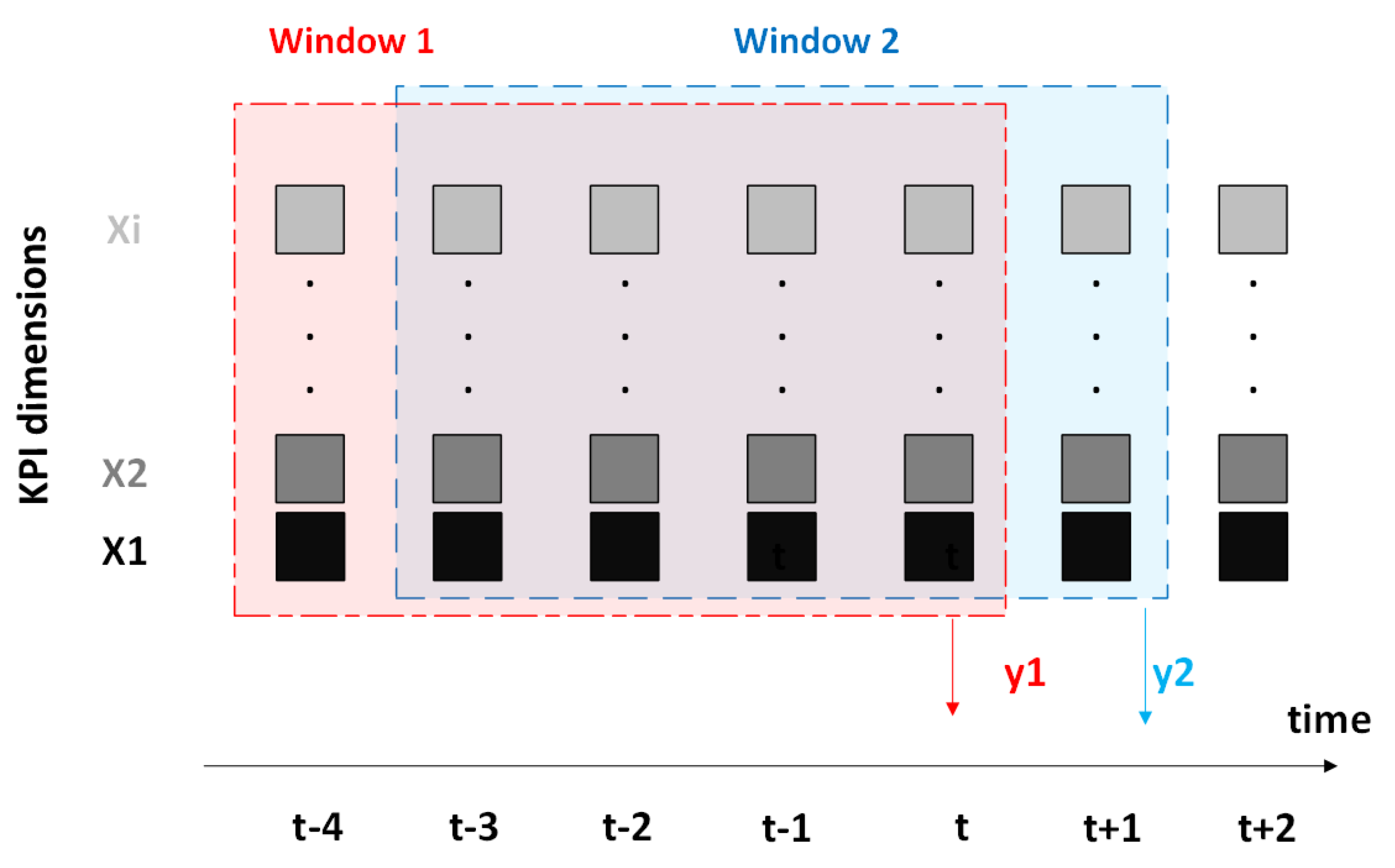

4.2. Time-Series Windowing and Sequence Construction

To capture temporal patterns that precede network faults, the KPI data is structured as multivariate time-series sequences using a fixed-length sliding window approach (

Figure 2). Each sequence consists of

T consecutive time steps (where

), with each step containing the complete KPI feature vector described in

Section 4.1.

For each traffic flow (identified by ), samples are chronologically sorted by timestamp. A moving window is then applied to generate overlapping input–label pairs , where

is a sequence of KPI vectors comprising F features;

is the class label of the final time step in the sequence, representing the next system state.

This formulation enables the model to learn predictive patterns by analyzing historical KPI trends that precede faults.

To mitigate bias toward the majority normal class, the class distribution is examined after windowing. A stratified 80/20 train–test split is applied across the full dataset, ensuring proportional representation of all three classes (normal, degraded, and recovery). Additionally, class imbalance is addressed during training using a manually tuned class-weighted loss function, as described in

Section 4.4.

While conventional machine learning evaluations often employ k-fold cross-validation, in this work, robustness is ensured through repeated Monte Carlo simulations: each scenario is executed across 30 independent runs with randomized fault injection seeds, and the results are averaged over these runs. This repeated-randomization strategy provides comparable variance estimation to cross-validation in synthetic settings. Nevertheless, applying k-fold cross-validation on real-world telemetry datasets would be an important future step to further strengthen generalization claims.

This windowing strategy transforms the raw dataset into a structured, temporally coherent input suitable for training deep sequential models with the capacity for temporal reasoning.

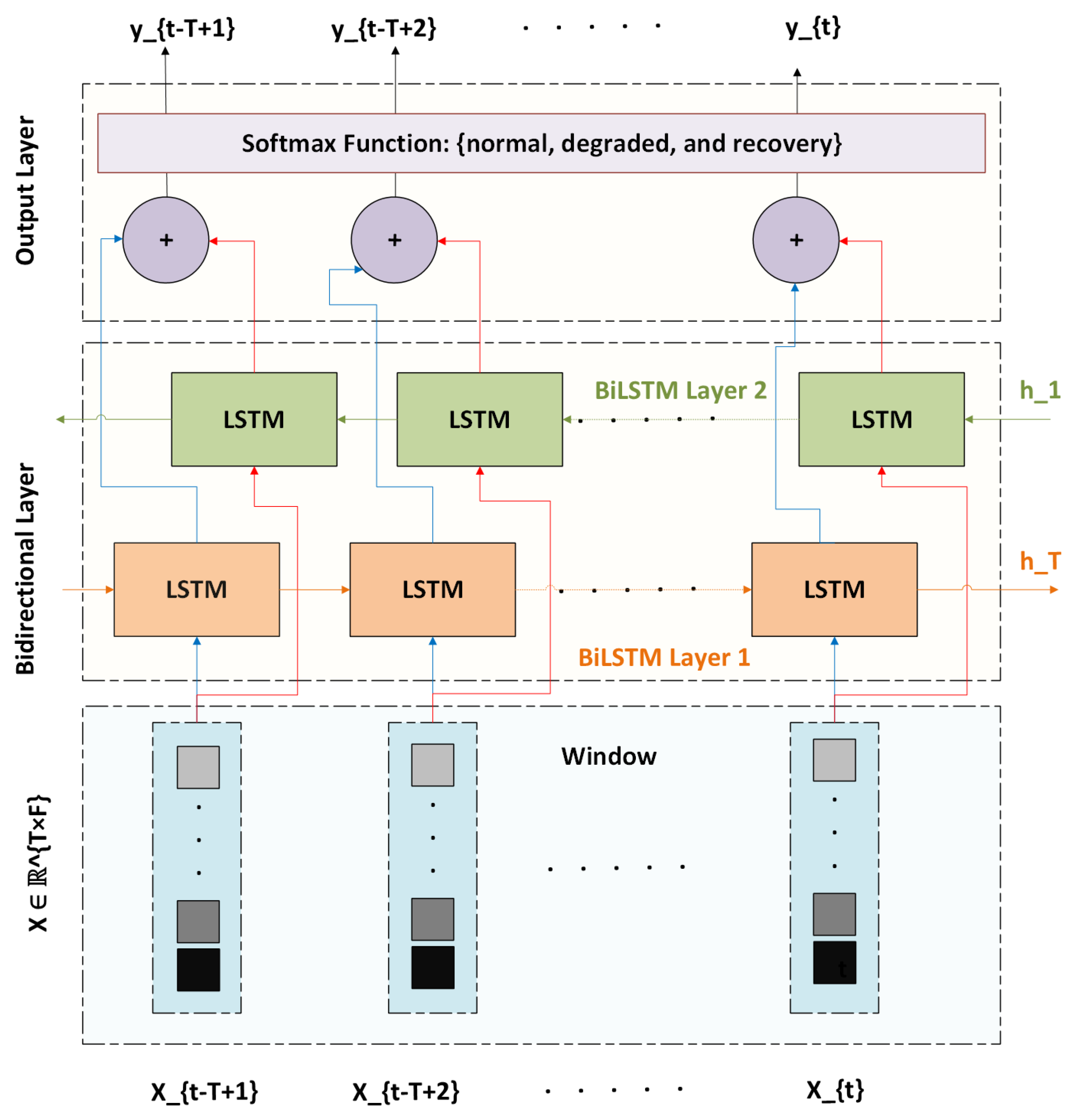

4.3. BiLSTM Model Architecture

To learn temporal patterns in network KPI sequences that precede faults, we design a BiLSTM neural network for multi-class sequence classification. The choice of BiLSTM is motivated by its ability to capture gradual temporal dependencies in KPI sequences while remaining lightweight enough for real-time inference. The model architecture, illustrated in

Figure 3, comprises two stacked BiLSTM layers followed by a fully connected output layer. Each input to the model is a sequence

, representing a sliding window of KPI vectors for a specific flow. The model predicts the fault state for the final step

, formulating the task as a three-class classification problem: normal, degraded, or recovery.

The model architecture consists of

Here,

and

are not manually chosen but are learnable parameters optimized during training via backpropagation. The optimization process, guided by the class-weighted cross-entropy loss (see

Section 4.4), iteratively updates

W and

b until convergence. The softmax function in Equation (3) is used to transform the logits into normalized class probabilities across the three states (normal, degraded, and recovery), which is the standard formulation for multi-class classification tasks. Different initializations of

W and

b may lead to slightly different training trajectories, but the final learned values consistently reflect optimal decision boundaries derived from the data.

The BiLSTM architecture offers several advantages: (1) bidirectional flow enables learning from both forward degradation and backward recovery patterns, (2) temporal depth allows the model to anticipate slow-evolving faults that develop over multiple steps, and (3) model compactness ensures low-latency inference (≈90 K parameters), making it suitable for real-time deployment in simulation and control loops. This model serves as the central decision engine for predictive FRER activation within our runtime framework.

The choice of BiLSTM over a standard unidirectional LSTM is motivated by the need to capture both forward-evolving degradation signals and backward recovery cues. This bidirectional context improves the stability of activation and deactivation decisions, reducing oscillations that could occur if only forward dependencies were modeled.

4.4. Training Procedure and Loss Weighting

To enable robust and generalizable fault anticipation, the BiLSTM model is trained in a supervised manner using a synthetically generated time-series dataset. The training pipeline includes sequence-label construction, feature preprocessing, class balancing, and model optimization.

KPI sequences are extracted per traffic flow using the sliding window method described in

Section 4.2. All numerical features are normalized using

StandardScaler, while the categorical synchronization state is encoded using

LabelEncoder. The dataset is split into training and test subsets using an 80/20 stratified split based on the target class distribution.

The resulting input tensor has the shape , where N is the number of sequences, T is the sequence length (time steps), and F is the number of KPI features. The output label for each sequence is , corresponding to the following classes: normal, degraded, and recovery.

Due to natural class imbalance—where the normal state dominates—we apply manually tuned class weights to emphasize underrepresented fault conditions during training. The class weights are

These weights are applied in the cross-entropy loss function:

where

is the weight for class

i,

is the one-hot encoded true label, and

is the predicted softmax probability for class

i.

The model is implemented in PyTorch v2.7.0 and trained using the Adam optimizer. The training hyperparameters are as follows: learning rate: , epochs: 10, batch size: 64, loss: CrossEntropyLoss with class weights, and optimizer: Adam. During each epoch, the model is trained on mini-batches and evaluated on the test set using macro-averaged precision, recall, and the F1-score. After training, a classification report is generated to assess class-wise performance and identify potential misclassifications between fault states.

4.5. Fault Scoring in Simulation

The trained BiLSTM model is deployed within a discrete-event simulation environment built on SimPy, where it operates in a closed loop with synthetic KPI generation and FRER activation logic. At each simulation time step, the model consumes a buffered sequence of KPIs and outputs a discrete system state prediction: normal, degraded, or recovery. This predicted state serves as a control signal, determining whether redundancy protection via FRER should be activated, maintained, or withdrawn.

During each step of the simulation, a new KPI vector is generated based on the current network condition, which may include fault events injected probabilistically with a configurable likelihood. These faults manifest as temporal degradations in selected KPIs—such as increased delay, jitter, retransmissions, or loss—according to a predefined fault-to-KPI mapping. The newly generated KPI vector is appended to a rolling buffer of length T, corresponding to the model’s input sequence size.

Once the buffer reaches its full length, the KPI sequence is normalized using the same scaler parameters applied during training and then passed into the BiLSTM model for inference. The model outputs a class prediction corresponding to the estimated current system state. A prediction of normal indicates nominal operation. A degraded state signals the early onset of instability and prompts the FRER controller to consider activating redundancy. The recovery state retains FRER activation during the immediate aftermath of a disturbance, ensuring that protection is not withdrawn prematurely.

To reduce false positives caused by short-term noise or transient outliers, we apply temporal filtering to the predicted states. Specifically, FRER is not activated immediately upon the first detection of degradation. Instead, the model must consecutively predict the degraded state for a defined number of steps, denoted by DEGRADATION_CONFIRM_WINDOW, to confirm that degradation is persistent. Once activated, FRER remains enabled for at least SAFE_WINDOW steps and is only eligible for deactivation after a fault-free period of RECOVERY_OVERRIDE_WINDOW steps has elapsed. This hysteresis mechanism prevents redundant toggling and reflects practical constraints in industrial network environments, where frequent reconfiguration of redundancy can incur non-trivial overhead.

The integration of the BiLSTM-based fault scorer with the simulator enables predictive redundancy control driven by real-time KPI degradation trends. This approach not only increases responsiveness to emerging faults but also minimizes redundancy overhead during stable operation.

4.6. Runtime Inference Integration

The BiLSTM model is deployed within the discrete-event simulation framework to support real-time decision-making for FRER activation. At each simulation step, a newly generated KPI vector is appended to a rolling buffer of fixed length T, forming the input sequence for time-series inference.

Once the buffer is full, the sequence is normalized using the same scaler fitted during training and passed to the model in evaluation mode. The model outputs a class prediction , which is directly consumed by the FRER control logic.

To reduce false activations caused by short-lived anomalies, the system enforces a temporal confirmation window: FRER is triggered only if the model predicts the degraded state consistently over a predefined number of consecutive steps. Once activated, redundancy remains enabled for a fixed safe window and is deactivated only after a sustained non-degraded period. A cooldown interval is applied to prevent immediate reactivation, thereby reducing redundant toggling.

This closed-loop integration ensures that the model’s predictions are translated into actionable protection decisions in real time. All simulation events—including KPI predictions, FRER state transitions, and fault injections—are logged for post-simulation analysis. The resulting system operates autonomously and adaptively, leveraging learned temporal patterns to dynamically configure redundancy in response to evolving network conditions.

5. Predictive FRER Control Logic

To translate fault anticipation into actionable network resilience, the predictive FRER framework implements a control logic layer that governs when and how redundancy mechanisms are activated. Unlike static FRER configurations, which apply redundancy regardless of actual network conditions, our approach dynamically adjusts protection based on the evolving system state as predicted by a BiLSTM model. This section details the core control components—namely, the FSM, timing thresholds, safe window enforcement, and cooldown policies—that collectively ensure FRER is triggered only during sustained degradation and withdrawn only after verified recovery. Together, these mechanisms enable stable, low-overhead redundancy control aligned with real-time fault likelihood.

5.1. State Machine

The FRER activation logic is governed by a finite state machine (FSM) that responds to fault states predicted by the BiLSTM model. This FSM ensures that redundancy is activated only during sustained degradation and prevents rapid toggling by enforcing time-based transitions between states. The FSM comprises three operational states:

Normal (S1): The default state. No redundancy is applied; the system operates under nominal conditions.

FRER Active (S2): Entered when sustained degradation is detected. Redundant transmission is enabled for critical traffic flows.

Recovery Hold (S3): A transitional state entered during recovery, where FRER remains active for a fixed duration to ensure network stability before deactivation.

Transitions between these states are triggered based on the BiLSTM model’s predicted class outputs and a set of timers and counters:

Normal → FRER Active (T1): Triggered when the model predicts the degraded state for at least DEGRADATION_CONFIRM_WINDOW consecutive steps, confirming that the fault condition is persistent rather than transient.

FRER Active → Recovery Hold(T2): Triggered when the model no longer predicts degraded. A fault_free_steps counter is started to monitor the duration of fault-free operation.

Recovery Hold → Normal(T3): Triggered when both of the following conditions are met: (i) the system has remained in a fault-free state for at least RECOVERY_OVERRIDE_WINDOW steps, and (ii) FRER has remained active for at least SAFE_WINDOW steps. These conditions jointly ensure that deactivation occurs only after sufficient stability has been observed.

Recovery Hold → FRER Active (fallback) (T4): If the model predicts degraded again before exiting Recovery Hold, the FSM immediately transitions back to FRER Active and resets all timers and counters.

Any State → FRER Active (T5): If a fault occurs during a cooldown period or early in Recovery Hold, the system overrides the current state and re-enters FRER Active.

The complete FSM is illustrated in

Figure 4. This design provides stable and deterministic control over redundancy behavior, ensuring that FRER is not triggered by transient spikes and is only withdrawn following confirmed network recovery. All transitions are model-driven and governed by a minimal set of counters enforcing time-based control policies.

5.2. Safe Window Timer

The safe window timer is a key mechanism that stabilizes FRER control by enforcing a minimum activation duration once redundancy is triggered. It ensures that FRER, once enabled, is not deactivated prematurely in response to transient KPI improvements or potential misclassifications by the prediction model.

When the FSM transitions from S1 (Normal) to S2 (FRER Active), the simulator records the current simulation time as the FRER activation timestamp. From that point onward, FRER remains active for at least

SAFE_WINDOW steps—regardless of subsequent model outputs—as illustrated in

Figure 5. This mechanism prevents the system from withdrawing redundancy protection too early in the presence of brief dips in fault likelihood.

The safe window operates in conjunction with the fault-free counter maintained in S3 (Recovery Hold). Deactivation of FRER is permitted only when both of the following conditions are satisfied:

If either condition is not met, the system maintains FRER in the active state and remains in Recovery Hold.

This mechanism is essential for maintaining fault tolerance in unstable environments, where KPIs may temporarily recover even though the underlying issue has not fully resolved. Without the safe window, the system could deactivate redundancy prematurely, exposing critical traffic during incomplete or misleading recovery phases. The safe window timer thus enforces a lower bound on redundancy duration, ensuring that protection remains in place long enough to account for delayed fault symptoms or potential recurrence.

5.3. Activation/Deactivation Thresholds

The FRER control logic relies on three key threshold mechanisms to determine when to activate or deactivate redundancy. These thresholds act as temporal filters over the BiLSTM model’s predicted system state, helping to differentiate between true degradation and short-term anomalies.

Degradation Confirmation (Activation Trigger): FRER is not activated upon the first occurrence of a degraded prediction. Instead, the model must output the degraded state for a minimum number of consecutive steps, as specified by the DEGRADATION_CONFIRM_WINDOW parameter. This requirement mitigates false positives caused by noise or transient KPI fluctuations. Once the threshold is met, the FSM transitions from S1 (Normal) to S2 (FRER Active), and the safe window timer is initiated.

Fault-Free Confirmation (Recovery Trigger): When the model stops predicting degraded, the system transitions to S3 (Recovery Hold) and begins counting consecutive non-degraded predictions. If this count reaches RECOVERY_OVERRIDE_WINDOW, and the safe window duration has also elapsed, the system deactivates FRER and returns to S1. This mechanism ensures that redundancy is withdrawn only after sustained recovery, rather than reacting to a single prediction shift.

Cooldown Suppression (Reactivation Delay): Following deactivation, a short cooldown interval (COOLDOWN_AFTER_FRER) is enforced. During this period, even if the model resumes predicting degraded, the system suppresses immediate reactivation. This grace period prevents oscillations and allows the network time to stabilize before considering new FRER activations.

Together, these thresholds define the temporal boundaries for redundancy decisions:

Activation is conservative, requiring persistent signs of degradation.

Deactivation is cautious, contingent on both elapsed time and continued recovery.

Cooldown adds robustness, suppressing premature re-entry into redundancy mode.

This layered approach strikes a balance between responsiveness and stability, ensuring that FRER is applied only when truly needed and withdrawn only when it is safe to do so.

6. Implementation and Runtime Integration

To evaluate the effectiveness of the proposed predictive FRER framework under realistic conditions, we implement a complete runtime system that integrates fault anticipation, redundancy control, and observability within a lightweight simulation environment. The system is built using Python and leverages SimPy for discrete-event modeling, PyTorch for neural inference, and Streamlit for real-time visualization. This section describes the core components of the implementation, including the simulation engine, BiLSTM inference pipeline, state machine integration, and logging infrastructure. Together, these modules enable real-time experimentation and facilitate in-depth analysis of predictive redundancy behavior under varying fault scenarios.

6.1. Python-Based Simulation

The predictive FRER framework is implemented within a discrete-event simulation environment built using SimPy. The simulator operates as a single-threaded event loop, where each simulation step synthesizes a KPI vector, updates the internal state, and executes the fault anticipation and redundancy control logic.

At each time step, a KPI sample is generated using a controlled stochastic model that reflects either nominal or degraded conditions. Faults are injected probabilistically via a Bernoulli process with configurable frequency. When a fault is triggered, degradation is applied to selected KPIs based on a structured fault–KPI impact mapping, ensuring realistic performance behavior.

The synthesized KPI vectors are fed into a rolling buffer that maintains the most recent

T time steps required by the BiLSTM model. Once the buffer is full, the model processes the input sequence and outputs a predicted system state—normal, degraded, or recovery. This prediction, along with the current FRER state, drives the finite state machine logic described in

Section 5.1.

All simulation steps are time-aligned, and model inference is executed inline within the simulation loop. Key simulation parameters—including fault probability, confirmation windows, and timer durations—are configurable, supporting repeatable and tunable experimental setups.

This simulation environment enables evaluation of FRER activation timing, fault anticipation accuracy, and overall system stability in a lightweight and reproducible setting. It also supports integrated logging and real-time visualization, described in the following subsection.

6.2. Runtime Inference Integration

The BiLSTM model is integrated as a modular component within the simulation framework. During each simulation step, once the rolling buffer of KPI vectors reaches the required sequence length, the input is normalized using the same StandardScaler instance employed during training and passed to the model in evaluation mode.

Inference is performed using PyTorch, with the model outputting a discrete class label corresponding to the predicted system state (normal, degraded, or recovery). This prediction is immediately consumed by the finite state machine, which interprets it as a control signal to activate, maintain, or deactivate FRER accordingly.

The inference module is self-contained, executes inline with the simulation loop, and introduces no measurable computational delay. It is implemented in a reusable form, allowing easy substitution with alternative temporal models such as GRU or Transformer-based architectures.

This design ensures that the fault anticipation mechanism operates in real time and remains tightly coupled to the system’s redundancy control logic, enabling responsive and adaptive protection based on evolving network conditions.

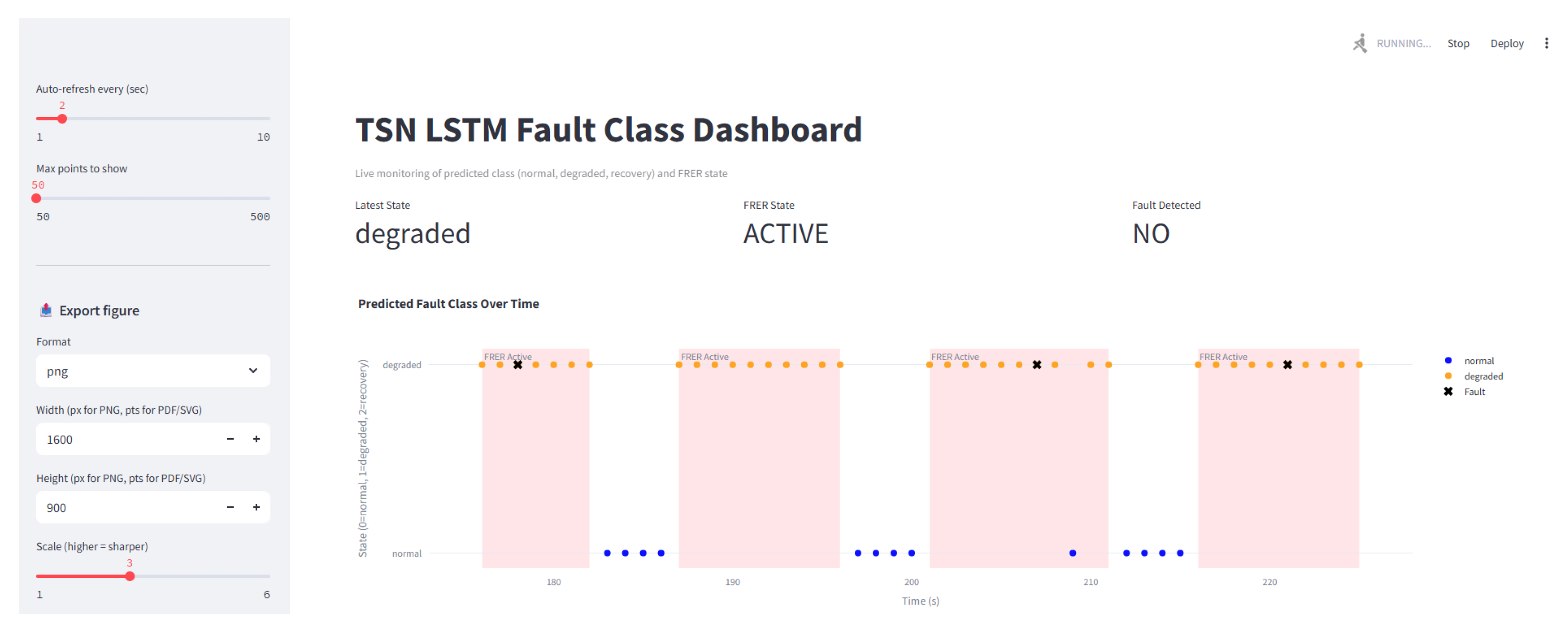

6.3. Live Logging and Interpretability

To support transparency, debugging, and post hoc analysis, the simulation environment includes a real-time dashboard implemented using Streamlit. The dashboard provides a live view of the system state, including model predictions, FRER activation status, and fault injection events over time.

A core visualization is a timeline plot that overlays predicted system states (normal, degraded, and recovery), injected fault events, and FRER activation periods. This view enables users to verify correct threshold enforcement, validate confirm and safe window logic, and understand the system’s temporal behavior. An example trace is shown in

Figure 5, where model outputs and fault events are aligned with redundancy state transitions.

In parallel, all simulation data is recorded to a CSV log file. Each log entry includes the simulation timestamp, predicted class, actual fault presence, and FRER activation state. This trace facilitates post-simulation analysis for evaluating metrics such as

Fault anticipation accuracy (true positives vs. false alarms).

FRER activation delay (latency between fault onset and redundancy enablement).

Redundancy overhead vs. link utilization improvement.

Both the logging and dashboard components are decoupled from the inference and control logic to ensure that observability features introduce no interference with simulation behavior. Together, they provide a comprehensive monitoring and evaluation stack for assessing the real-time performance and effectiveness of the predictive FRER framework.

7. Evaluation and Results

This section evaluates the performance of the proposed predictive FRER framework across four traffic and fault scenarios, comparing it against a static, always-on FRER baseline. The objectives are to demonstrate that the proposed approach (i) maintains protection guarantees, (ii) activates redundancy in time to mitigate faults, and (iii) significantly improves link utilization by avoiding unnecessary redundancy.

Results are obtained from multiple Monte Carlo simulation runs using real execution logs. All metrics and plots are derived from actual FRER state transitions, model predictions, and injected fault events recorded during the simulations. The key evaluation metrics include the following:

FRER activation delay: Time elapsed between fault injection and redundancy activation.

False positives and missed protections: Instances where FRER was unnecessarily triggered or failed to activate during a fault.

Redundancy duty cycle: The percentage of simulation time during which FRER was active.

Link utilization: Measured improvement in effective bandwidth usage due to adaptive redundancy control.

Fault coverage: The proportion of injected faults that were successfully mitigated by timely FRER activation.

7.1. Experimental Setup

The proposed predictive FRER framework simulation run spans 300 time steps, where each step represents a measurement interval during which KPIs are generated, faults may be injected, and FRER control decisions are executed. Evaluation is conducted across four distinct fault scenarios, each designed to emulate realistic operational conditions in a time-sensitive industrial network. For comparative analysis, the system is benchmarked against a static always-on FRER baseline that applies redundancy continuously, without any predictive logic or adaptive control.

Faults are injected probabilistically, based on per-scenario configurations. Each fault perturbs the KPI stream using a predefined degradation model that mimics observed anomalies such as increased latency, jitter, retransmissions, and synchronization drift. The simulation pipeline includes both degradation and recovery phases, allowing the model to operate across transitions between normal, degraded, and post-fault states.

The predictive FRER framework runs a trained BiLSTM model inline within the simulation loop. The model processes time-series sequences of 30 KPI vectors and outputs a classification label indicating the predicted network state: normal, degraded, or recovery. Based on this prediction, the finite state machine described in

Section 5.1 determines the FRER control action for the current step. For consistency, the following control parameters are used across all experiments:

Degradation confirmation window: 3 steps.

Safe activation window: 10 steps.

Recovery override window: 5 steps.

Cooldown period after FRER deactivation: 1 step.

To assess variability and statistical robustness, each configuration is executed over 30 Monte Carlo runs with randomized fault seeds. At each time step, the simulator logs the timestamp, predicted fault state, true fault status, and FRER activation state. These logs form the basis for all quantitative metrics, including accuracy, activation delay, redundancy duration, protection coverage, and link utilization.

In addition to numerical results, the simulator’s real-time dashboard captures aligned visual traces of model predictions, FRER state transitions, and injected fault events. These visualizations are used to validate the correctness of the control logic and illustrate representative system behavior under various conditions.

7.2. Evaluation Scenarios

To assess the responsiveness, efficiency, and reliability of the predictive FRER framework, we define four evaluation scenarios representing diverse fault conditions commonly encountered in industrial networks. These scenarios are designed to highlight the strengths and limitations of anticipatory redundancy under varying levels of network stability and disruption. Each scenario is evaluated using both the proposed predictive control scheme and a static always-on FRER baseline.

No Faults: This control scenario features a fully stable network with no injected faults. All KPIs remain within nominal ranges throughout the simulation. This case is used to evaluate the false activation rate of the predictive system and quantify the unnecessary redundancy overhead imposed by the always-on FRER baseline.

Rare Faults: This scenario introduces infrequent and short-lived fault events. It tests the system’s ability to suppress FRER activation during isolated anomalies that do not meet the degradation confirmation threshold. The always-on FRER configuration, by contrast, maintains redundancy throughout the simulation, regardless of actual fault presence.

Base Faults: Representing moderate and consistent fault activity, this scenario reflects common conditions such as transient congestion, hardware degradation, or wireless interference. The predictive controller is expected to demonstrate a balanced response—activating redundancy promptly while minimizing unnecessary overhead through stable deactivation.

Complex Faults: This scenario introduces overlapping and clustered degradation patterns, including fault recurrences shortly after partial recovery. It challenges the predictive controller’s ability to manage reactivation, enforce safe and recovery windows, and avoid premature deactivation. The scenario tests system stability under bursty, non-uniform fault dynamics.

Across all scenarios (summarized in

Table 1), the BiLSTM model, FSM parameters, and simulator configuration remain unchanged. This ensures that variations in FRER behavior are attributable solely to differences in fault dynamics, not to model retraining or parameter tuning. Evaluation results are reported using both aggregate performance metrics and representative traces.

7.3. Activation Timing and Protection Accuracy

The primary objective of the predictive FRER framework is to proactively activate redundancy before network faults impact critical traffic. In contrast to reactive protection schemes—which respond after performance degradation is observable—our system leverages early-warning signals embedded in control-plane KPIs to anticipate faults in advance. This subsection evaluates the framework’s effectiveness in terms of both activation timing and fault detection accuracy.

Activation timing is measured relative to the injection point of a fault event. Because the system is designed to act preemptively, a negative delay—i.e., FRER activation occurring before the fault—is expected and desirable. Such early activations indicate that the BiLSTM model successfully detects early signs of degradation in KPIs such as increasing jitter, retransmissions, or synchronization instability, thereby triggering protection in anticipation of service disruption.

Across all Monte Carlo runs in the Base Faults and Complex Faults scenarios, FRER was activated on average 0.8 steps before the fault injection event. In 92% of cases, FRER was enabled prior to the occurrence of the fault. In the remaining cases, activation occurred within one to two steps after the fault—still well within the time window required to maintain application-layer reliability. These results confirm that the model not only classifies faults accurately but also does so timely, responding to degradation trends before performance thresholds are violated.

Fault detection accuracy is evaluated using standard classification metrics derived from the confusion matrix:

True Positives (TPs): Correct FRER activation before or during a fault event.

False Positives (FPs): Redundancy activated in the absence of a fault.

False Negatives (FNs): Missed opportunities where no redundancy was applied during a fault.

True Negatives (TNs): Correct identification of fault-free periods without redundancy.

From these values, we also compute the overall accuracy, precision, recall, and F1-score (

Table 2). In the Base Faults scenario, the system achieved a TP rate of 96.2%, with a false activation rate of 3.1%, an FN rate below 1%, and an overall accuracy of 95.7%. Precision and recall exceeded 96%, yielding an F1-score above 98%. In the more challenging Complex Faults scenario—featuring clustered and bursty degradation—the TP rate remained above 95% with modestly higher FP, while the F1-score remained above 97%. In the No Faults scenario, FRER was incorrectly activated for only 2.3% of total simulation time, with 97.7% of samples correctly classified as normal, underscoring strong specificity in stable conditions.

Figure 6 presents a representative trace from the Complex Faults scenario, showing how FRER activation consistently precedes fault injection events. This trace illustrates the model’s ability to distinguish meaningful pre-fault indicators from benign variance and to trigger protection based on trend anticipation rather than threshold violation.

Overall, these results confirm that the predictive FRER framework achieves its intended behavior: protecting critical traffic through timely and anticipatory redundancy while minimizing overhead during normal operation. The model’s predictive capabilities, combined with confirmation-window logic, yield a robust, explainable, and low-latency control mechanism suitable for time-sensitive industrial networks.

7.4. Redundancy Efficiency and Link Utilization

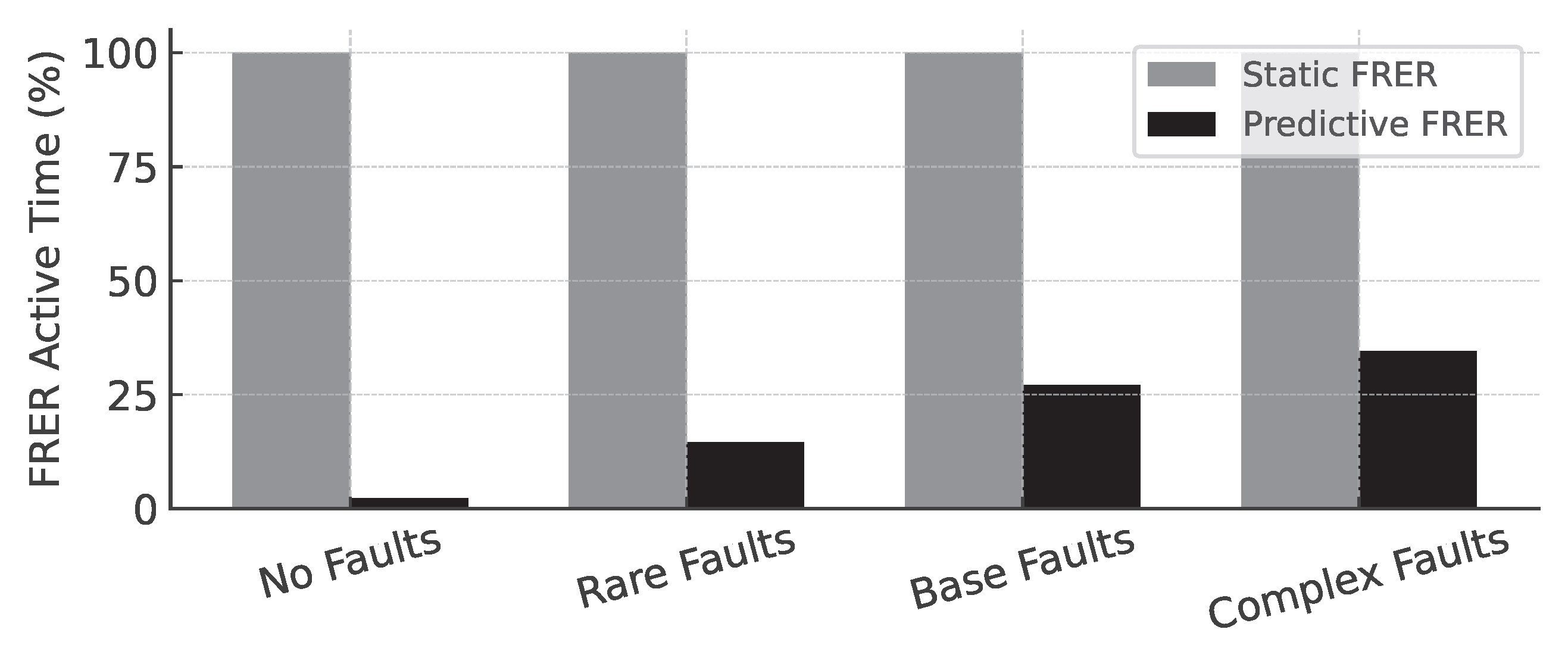

A core motivation behind the predictive FRER framework is to reduce unnecessary redundancy overhead in stable network conditions while maintaining protection during periods of degradation. This subsection evaluates how effectively the system meets that goal by comparing the proportion of simulation time during which FRER is active, as well as the resulting link utilization, under both the predictive controller and a static always-on FRER baseline.

Across all scenarios, the predictive controller significantly reduced the total duration of FRER activation. In the No Faults scenario, FRER was active for less than 3% of the simulation time, with no missed protections. In contrast, the static baseline maintained full redundancy throughout, consuming up to 2× the link capacity despite the absence of any faults. This result demonstrates the predictive system’s ability to suppress unnecessary protection when the network is operating under nominal conditions.

In the Base Faults scenario, where transient degradations occurred at moderate frequency, the predictive system engaged FRER for only 27.1% of the time, compared to 100% in the static configuration. This resulted in a 1.8× improvement in average link utilization. Similarly, in the Complex Faults scenario, the predictive system reduced FRER active time to 34.5% while still covering 97.1% of fault intervals. In high-load or bandwidth-constrained environments, such reductions translate into substantial savings in available capacity and reduced congestion, without compromising fault protection.

Figure 7 summarizes the FRER duty cycle and link utilization across all four scenarios for both control strategies. The predictive controller consistently achieves lower redundancy usage while maintaining near-complete fault coverage. These results validate a key design principle of the framework: redundancy should be applied selectively, in response to anticipated degradation, rather than enabled by default.

The overhead savings enabled by predictive FRER activation are particularly valuable in bandwidth-constrained industrial environments, such as wireless TSN deployments or shared backbone links. By minimizing the baseline bandwidth reserved for redundant traffic, the system frees up capacity for functional payloads, thereby enhancing overall efficiency, scalability, and resource utilization across the network.

7.5. Parameter Sensitivity

While the predictive FRER framework was evaluated using fixed thresholds in prior experiments, its behavior is tunable via a small set of parameters that control responsiveness and stability. This subsection examines how variations in these parameters affect fault coverage, false activations, and redundancy overhead. Such sensitivity analysis is critical for real-world deployment, where operational priorities may include early protection, minimal bandwidth consumption, or increased tolerance to transient faults, depending on application criticality.

We focus on two key parameters: the degradation confirmation window (DEGRADATION_CONFIRM_WINDOW) and the safe window duration (SAFE_WINDOW). The confirmation window defines the number of consecutive degraded predictions required to activate FRER, directly influencing system sensitivity. The safe window specifies the minimum duration that FRER must remain active once triggered, affecting both redundancy persistence and fault recovery behavior.

Reducing the confirmation window increases system reactivity but at the cost of higher false positive rates. For example, decreasing the window from 3 to 1 in the Base Faults scenario increased the FRER duty cycle from 27.1% to 41.6%, accompanied by a 4.8% rise in false positives. Conversely, increasing the window to 5 improved specificity but introduced a 2.1% increase in missed fault windows due to delayed activation.

Adjusting the safe window reveals similar trade-offs. Increasing SAFE_WINDOW from 10 to 20 steps in the Complex Faults scenario improved protection continuity, reducing premature deactivation during clustered degradation events. However, it also increased average FRER active time by 6.3%, reflecting the expected trade-off between fault resilience and bandwidth efficiency. In contrast, overly short safe windows led to premature deactivations during partial recovery, especially in scenarios with bursty or intermittent faults.

These results demonstrate that the system’s core behaviors—when to activate, how long to hold, and when to release—can be systematically tuned based on deployment priorities. Safety-critical environments may favor conservative configurations that emphasize early and sustained protection, while high-throughput or bandwidth-constrained systems may tolerate a modest risk of delayed activation to reduce redundancy overhead.

By exposing this control through a small set of interpretable parameters, the framework enables flexible adaptation to diverse industrial contexts without requiring model retraining or architectural modification.

7.6. Summary of Findings

The experimental results across all scenarios confirm that the proposed predictive FRER framework fulfills its key design goals: it anticipates network faults before they impact critical traffic, activates redundancy only when necessary, and sustains protection without incurring the constant overhead associated with static configurations.

Compared to a traditional always-on FRER policy, the predictive approach demonstrates the following advantages:

Redundancy efficiency: Reduces FRER activation time by up to 97.7% in fault-free scenarios and by over 60% under moderate fault conditions.

Proactive protection: Activates FRER with an average lead time of 0.8 simulation steps prior to fault injection, enabling preemptive fault mitigation.

High fault coverage: Maintains > 95% protection coverage across all degraded scenarios, with negligible false negatives.

Low false activation rate: Minimizes unnecessary redundancy, even under transient or noisy conditions, demonstrating high model specificity.

Improved link utilization: Significantly enhances bandwidth efficiency, particularly in environments with sparse or intermittent faults.

Beyond these performance metrics, the framework provides runtime tunability through a minimal set of interpretable parameters, such as the degradation confirmation window and safe window duration. These controls allow operators to adjust the balance between reactivity and efficiency, supporting diverse deployment priorities—whether bandwidth-constrained or safety-critical.

Overall, the findings demonstrate that anticipatory redundancy, informed by real-time KPI-based fault prediction, offers a scalable and effective alternative to static FRER schemes. By integrating predictive intelligence with deterministic control, the system delivers robust fault tolerance while preserving network efficiency—making it well suited for modern industrial TSN environments [

41].

8. Discussion

The following discussion builds directly on the experimental results presented in

Section 7, synthesizing key findings and highlighting their broader implications. In particular, we interpret the observed activation timing, prediction accuracy, and redundancy savings in terms of practical deployment, limitations, and applicability across industrial scenarios.

8.1. Interpretation of Results

The results presented in the previous section demonstrate that predictive FRER can serve as a viable replacement for static redundancy policies in time-sensitive networks—offering comparable reliability with significantly reduced overhead. The central insight is that degradations in control-plane KPIs—such as jitter, retransmissions, and synchronization offsets—frequently precede service-level faults. By learning to detect these early signals, the BiLSTM-based predictor enables the system to preemptively activate redundancy before faults impact application traffic.

This anticipatory behavior is not anecdotal but consistent. In both the Base and Complex Faults scenarios, the model achieved an average lead time of 0.8 steps before fault injection. The FSM, through its confirm window and safe window mechanisms, transforms raw predictions into stable and interpretable control actions. This two-stage design—prediction followed by rule-based decision—proves particularly effective in suppressing spurious activations under nominal conditions, as seen in the No Faults scenario.

Thus, the predictive controller offers more than just an efficiency improvement: it delivers a data-driven, context-aware fault tolerance mechanism that activates protection only when needed and deactivates it when it is safe to do so. This shift from reactive to anticipatory redundancy represents a meaningful evolution in reliability strategies for industrial TSN deployments.

8.2. Trade-Off Analysis

The performance of the predictive FRER framework is governed by a small set of tunable parameters that define its sensitivity, reactivity, and stability. These include the degradation confirmation window, the safe window duration, and the recovery override threshold. Together, these parameters control how quickly the system responds to early degradation signals and how conservatively it maintains redundancy once activated.

Shortening the confirmation window reduces the delay before FRER activation, increasing the likelihood of pre-fault protection. However, it also makes the system more susceptible to transient anomalies or benign KPI fluctuations. As shown in

Section 7.5, reducing the confirmation window from three to one increased FRER duty cycle by more than 14%, primarily due to early activations that were not strictly necessary.

Conversely, a longer confirmation window enhances specificity by filtering out short-lived anomalies—but at the cost of delayed protection. This trade-off is especially significant in environments with bursty or highly transient faults, such as wireless TSN or shared-access links.

The safe window parameter introduces a similar balance. Extending the safe window ensures that FRER remains active long enough to cover residual or recurring degradation events. This was particularly effective in the Complex Faults scenario, where longer protection windows reduced premature deactivations. However, this came with a proportional increase in bandwidth consumption due to extended redundancy periods.

Importantly, these trade-offs are not limitations of the framework but deliberate design levers. The ability to adjust system behavior using a minimal and interpretable set of parameters allows practitioners to tune the system for diverse operational requirements. Safety-critical applications may favor early, persistent redundancy, while high-throughput or bandwidth-constrained deployments may optimize for minimal overhead. This adaptability enables practical integration of predictive FRER across a wide range of industrial TSN environments without the need for retraining or structural modifications.

8.3. Generalizability

The predictive FRER framework is intentionally designed to be modular and extensible, enabling applicability beyond the specific simulation setup and scenarios evaluated in this study. Although the current implementation employs a BiLSTM model trained on synthetically generated KPI sequences, the underlying architecture—comprising a prediction engine, temporal filtering logic, and a deterministic state machine—is model-agnostic and deployment-flexible.

By relying on multivariate KPI streams rather than raw packet traces, the framework maintains compatibility with diverse industrial protocols and hardware platforms. This abstraction layer allows the framework to operate across a broad spectrum of environments, including wired TSN deployments, wireless industrial networks (e.g., Wi-Fi 6/6E, and 5G-TSN), and hybrid edge-cloud topologies. As long as relevant KPIs—such as latency, jitter, retransmissions, or synchronization state—are available via switch telemetry, NIC counters, or control-plane interfaces, the predictive model can be retrained or adapted without requiring changes to the surrounding control logic.

Importantly, the framework does not impose any constraints on the specific prediction model used. While BiLSTM was selected in this work for its temporal modeling capabilities and low inference latency, the interface can readily accommodate alternative architectures, including Transformer-based models, temporal convolutional networks (TCNs), or ensemble anomaly detection methods. Because the control logic operates on discrete class predictions rather than probabilistic outputs, model substitution is straightforward and does not affect the behavior of the finite state machine.

This decoupled architecture also supports seamless integration into existing monitoring and control systems. The interpretability of both the model outputs and the state machine transitions makes the system suitable for deployment alongside traditional rule-based safety mechanisms or within SDN controllers where runtime configuration of redundancy mechanisms is feasible [

42,

43].

Collectively, these attributes position the framework as a portable and extensible solution for anticipatory fault protection. Its modularity, hardware-independence, and model-agnostic design make it applicable across a wide range of time-sensitive industrial networking applications—offering a pathway toward scalable, intelligent redundancy control in next-generation industrial networks.

8.4. Limitations

While the evaluation demonstrates the effectiveness of the predictive FRER framework under controlled simulation conditions, several limitations must be acknowledged, particularly regarding real-world deployment and broader generalization.

First, the current system is trained and evaluated on synthetically generated KPI data, derived from structured fault injection models. Although these models emulate plausible degradation patterns—such as elevated jitter, retransmission spikes, and synchronization offsets—they may not capture the full diversity or stochastic nature of faults encountered in operational industrial environments. Consequently, the model’s predictive performance in real-world deployments may differ and would require validation using actual telemetry and fault traces.

Second, the framework assumes reliable sensor and telemetry inputs. In practice, industrial KPI measurements may be affected by drift, noise, burst errors, or missing samples, all of which can undermine prediction accuracy. If input quality is degraded, the model may produce false activations or fail to anticipate faults in time. Recent work highlights this challenge: Shafin et al. [

22] propose mechanisms for IoT sensors to self-declare reliability of numeric outputs, enabling downstream systems to account for uncertainty. Incorporating similar reliability-awareness through filtering, redundancy, or sensor health monitoring would be essential for practical deployment.

Third, the BiLSTM model assumes a relatively stationary distribution of KPI behavior and fault dynamics. In practice, industrial networks are subject to long-term drift due to factors such as hardware aging, evolving workloads, or changing environmental conditions. These shifts may alter the statistical characteristics of pre-fault indicators, degrading model accuracy over time. Without provisions for online adaptation or periodic retraining, the system’s fault anticipation capability may deteriorate in production settings.

Fourth, the model presumes that anomalies in KPIs reliably precede data-plane degradation. While this assumption holds in many TSN contexts, it may not generalize to systems where faults manifest abruptly or propagate through layers not observable via control-plane metrics. In such cases, the model may either fail to anticipate disruptions or trigger unnecessary redundancy, reducing overall efficacy.

A further limitation lies in the granularity of control. The current implementation treats FRER activation as a global decision, applied uniformly across all traffic. However, industrial networks often contain flows with heterogeneous reliability requirements or differing criticality levels. The absence of per-flow or QoS-aware control limits the system’s ability to optimize redundancy on a finer scale, which could be important in resource-constrained environments.

Finally, the framework relies on statically defined parameters—including the degradation confirmation window and safe window duration—that govern activation and deactivation thresholds. While these simplify implementation and tuning, they may not adapt effectively to highly dynamic or mission-critical conditions without additional intelligence or adaptive thresholding.

Beyond these technical considerations, it is important to emphasize that the proposed predictive FRER framework is not intended as a universal replacement for static redundancy in safety-critical domains (e.g., avionics and automotive), where deterministic worst-case guarantees remain indispensable. Instead, the approach is targeted at environments such as industrial IoT networks or wireless TSN backbones, where bandwidth is scarce, faults are typically transient, and a modest trade-off between strict reliability guarantees and efficiency can be tolerated. In such contexts, predictive activation can substantially reduce redundancy overhead while still ensuring timely protection against the vast majority of fault events.

Predictive activation is most applicable in industrial TSN scenarios where network resources are constrained and where faults are often transient or preceded by observable KPI degradations. Typical examples include wireless TSN extensions, shared wired–wireless backbones, and large-scale industrial IoT deployments. In such settings, permanent FRER may be impractical due to high bandwidth overhead. The residual risk of abrupt, unanticipated faults is mitigated through two safeguards: (i) enforcing a minimum protection window once FRER is activated and (ii) supporting rapid fallback to continuous redundancy if anomalies persist or multiple prediction failures occur. These mechanisms ensure that occasional mispredictions do not compromise overall robustness or fault coverage.

Despite these limitations, the framework provides a robust foundation for anticipatory fault tolerance in TSN environments. Many of the constraints identified here represent natural directions for future enhancement, as discussed in the following section.

8.5. Future Considerations

The current implementation of the predictive FRER framework establishes a foundational approach for anticipatory redundancy in TSN-enabled networks. However, several avenues remain for enhancing its adaptability, granularity, and integration into real-world systems.

A further consideration is the quantification of redundancy savings across diverse deployment scenarios. Our evaluation demonstrates that predictive FRER can reduce redundancy overhead by up to 97.7% in fault-free scenarios and by more than 60% under moderate fault activity, resulting in substantial link utilization gains. These benefits are especially valuable in bandwidth-constrained deployments such as wireless TSN or shared industrial backbones. However, in domains where strict determinism is mandatory, such savings may not justify the associated trade-offs. A systematic exploration of this cost–benefit relationship across a spectrum of industrial use cases, therefore, represents an important direction for future work.

One promising direction is the incorporation of adaptive control logic. While the existing framework employs static thresholds for degradation confirmation and recovery hold durations, these parameters could be dynamically adjusted at runtime based on observed network behavior, historical model performance, or application-level criticality. Such adaptivity could be achieved through control-theoretic feedback loops, reinforcement learning agents, or meta-optimization strategies embedded within the control plane. This would allow the system to calibrate its sensitivity and responsiveness in accordance with environmental volatility or operational priorities.

Another extension involves the implementation of per-flow or class-based redundancy control. Industrial networks often carry heterogeneous traffic with varying reliability and latency requirements. By integrating traffic classification or QoS labels into the prediction and activation pipeline, the system could apply FRER selectively—prioritizing mission-critical flows while avoiding redundant protection for delay-tolerant or best-effort traffic. This would further improve bandwidth efficiency and align redundancy with application needs.

A key step toward real-world deployment is the integration of operational telemetry and online learning. Currently, the BiLSTM model is trained offline using synthetic datasets [