Economic Feasibility of Solid–Liquid Separation and Hydraulic Retention Time in Composting or Anaerobic Digestion Systems for Recycling Dairy Cattle Manure

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals and Production System

2.2. Evaluated Scenarios

2.3. Monensin Concentration in Manure

2.4. Estimation of Fertilizer and Bioenergy Production

2.5. Economic Feasibility Assessment

3. Results and Discussion

3.1. Cash Flow

3.2. Return and Economic Efficiency Indicators

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| AD20 | Anaerobic digestion with 20-day hydraulic retention time |

| AD30 | Anaerobic digestion with 30-day hydraulic retention time |

| B/C | Benefit–Cost ratio |

| C | Composting as sole treatment |

| C+AD20 | Combined treatment: solid–liquid separation with composting of the solid fraction and anaerobic digestion of the liquid fraction (20-day HRT) |

| C+AD30 | Combined treatment: solid–liquid separation with composting of the solid fraction and anaerobic digestion of the liquid fraction (30-day HRT) |

| DPP | Discounted Payback Period |

| HRT | Hydraulic Retention Time |

| IRR | Internal Rate of Return |

| K | Potassium |

| MIRR | Modified Internal Rate of Return |

| N | Nitrogen |

| NPV | Net Present Value |

| P | Phosphorus |

| PI | Profitability Index |

| TS | Total solids |

| UAE | Uniform Annual Equivalent |

| VS | Volatile solids |

References

- SEEG (Sistema de Estimativas de Emissões de Gases de Efeito Estufa). Emissões do Brasil têm Maior Queda em 15 Anos. Available online: https://oc.eco.br/emissoes-do-brasil-tem-maior-queda-em-15-anos/ (accessed on 1 July 2025).

- Geng, Y.; Bashir, M.A.; Wang, H.; Li, J.; Raza, Q.U.A.; Kan, W.; Tian, S.; Rehim, A.; Yang, L.; Liu, H. Introducing Ferrous Sulfate to Cattle Manure and Corn Straw Composting Reduces Greenhouse Gas Emissions and Ammonia Volatilization. Agronomy 2024, 14, 2867. [Google Scholar] [CrossRef]

- Greene, J.M.; Wallace, J.; Williams, R.B.; Leytem, A.B.; Bock, B.R.; McCully, M.; Kaffka, S.R.; Rotz, C.A.; Quinn, J.C. National Greenhouse Gas Emission Reduction Potential from Adopting Anaerobic Digestion on Large-Scale Dairy Farms in the United States. Environ. Sci. Technol. 2024, 58, 12409–12419. [Google Scholar] [CrossRef] [PubMed]

- Nleya, Y.; Young, B.; Nooraee, E.; Baroutian, S. Anaerobic Digestion of Dairy Cow and Goat Manure: Comparative Assessment of Biodegradability and Greenhouse Gas Mitigation. Fuel 2025, 381, 133458. [Google Scholar] [CrossRef]

- Symeon, G.K.; Akamati, K.; Dotas, V.; Karatosidi, D.; Bizelis, I.; Laliotis, G.P. Manure Management as a Potential Mitigation Tool to Eliminate Greenhouse Gas Emissions in Livestock Systems. Sustainability 2025, 17, 586. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, W.; Qiu, X.; Xu, C. Hydrothermal Treatment of Lignocellulosic Biomass towards Low-Carbon Development: Production of High-Value-Added Bioproducts. EnergyChem 2024, 6, 100133. [Google Scholar] [CrossRef]

- Leite, B.K.V.; Orrico, A.C.A.; Orrico Junior, M.A.P.; Aspilcueta Borquis, R.R.; da Costa, É.C.P.; Menezes, I.d.S.; de Oliveira, J.D.; Macena, I.A. Effect of Monensin Supplementation in the Bovine Diet on the Composition and Anaerobic Digestion of Manure with and without Screening. Fermentation 2024, 10, 474. [Google Scholar] [CrossRef]

- Grell, T.; Harris, P.W.; Marchuk, S.; Jenkins, S.; McCabe, B.K.; Tait, S. Biochemical Methane Potential of Dairy Manure Residues and Separated Fractions: An Australia-Wide Study of the Impact of Production and Cleaning Systems. Bioresour. Technol. 2024, 391, 129903. [Google Scholar] [CrossRef]

- Embrapa. Anuário Leite 2025: Produção de Leite e as Mudanças Climáticas; Embrapa Gado de Leite: Juiz de Fora, Brazil, 2025. [Google Scholar]

- ASAE D384.2 MAR2005 (R2010); Manure Production and Characteristics. American Society of Agricultural and Biological Engineers (ASABE): St. Joseph, MI, USA, 2010.

- Damasceno, F.A.; Monge, J.L.; Nascimento, J.A.C.; Andrade, R.R.; Barbari, M.; Saraz, J.A.O.; Ferraz, G.A.S. Estimate of Manure Present in Compost Dairy Barn Systems for Sizing of Manure Storage. Agron. Res. 2020, 18, 1213–1219. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Lyons, G.; Bartlett, J. Economic and Environmental Analysis of Small-Scale Anaerobic Digestion Plants on Irish Dairy Farms. Energies 2020, 13, 637. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Palese, A.M.; Di Meo, V.; Pastore, V.; D’Adamo, C.; Celano, G. Composting: The Way for a Sustainable Agriculture. Appl. Soil Ecol. 2018, 123, 744–750. [Google Scholar] [CrossRef]

- Li, Y.; Han, Y.; Zhang, Y.; Luo, W.; Li, G. Anaerobic Digestion of Different Agricultural Wastes: A Techno-Economic Assessment. Bioresour. Technol. 2020, 315, 123836. [Google Scholar] [CrossRef]

- Sharara, M.A.; Owusu-Twum, M.Y.; Runge, T.M.; Larson, R. Planning Methodology for Anaerobic Digestion Systems on Animal Production Facilities under Uncertainty. Waste Manag. 2020, 104, 262–269. [Google Scholar] [CrossRef]

- do Amaral, C.M.C.; do Amaral, L.A.; de Lucas Júnior, J.; do Nascimento, A.A.; Ferreira, D.d.S.; Machado, M.R.F. Biodigestão Anaeróbia de Dejetos de Bovinos Leiteiros Submetidos a Diferentes Tempos de Retenção Hidráulica. Ciência Rural 2004, 34, 1897–1902. [Google Scholar] [CrossRef]

- Arikan, O.A.; Mulbry, W.; Rice, C.; Lansing, S. The Fate and Effect of Monensin during Anaerobic Digestion of Dairy Manure under Mesophilic Conditions. PLoS ONE 2018, 13, e0192080. [Google Scholar] [CrossRef] [PubMed]

- Andriamanohiarisoamanana, F.J.; Saikawa, A.; Kan, T.; Qi, G.; Pan, Z.; Yamashiro, T.; Iwasaki, M.; Ihara, I.; Nishida, T.; Umetsu, K. Semi-Continuous Anaerobic Co-Digestion of Dairy Manure, Meat and Bone Meal and Crude Glycerol: Process Performance and Digestate Valorization. Renew. Energy 2018, 128, 1–8. [Google Scholar] [CrossRef]

- Bułkowska, K.; Mikucka, W.; Pokój, T. Enhancement of Biogas Production from Cattle Manure Using Glycerine Phase as a Co-Substrate in Anaerobic Digestion. Fuel 2022, 317, 123456. [Google Scholar] [CrossRef]

- Nag, R.; Auer, A.; Markey, B.K.; Whyte, P.; Nolan, S.; O’Flaherty, V.; Russell, L.; Bolton, D.; Fenton, O.; Richards, K.; et al. Anaerobic Digestion of Agricultural Manure and Biomass—Critical Indicators of Risk and Knowledge Gaps. Sci. Total Environ. 2019, 690, 460–479. [Google Scholar] [CrossRef]

- Orrico, A.C.A.; Schwingel, A.W.; Gimenes, R.M.T.; Souza, S.V.; Orrico, M.A.P.; Maciel, T.T.B.A.F.R.A.A.L.P.; Borquis, R.R.A.; de Vargas, F.M. Can Adding Liquid Hatchery Waste to Sheep Manure Potentialize Methane Production and Add Value to Sheep Farming? Environ. Technol. Innov. 2021, 24, 101866. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; AOAC International: Arlington, VA, USA, 2005. [Google Scholar]

- Orrico Júnior, M.A.P.; Orrico, A.C.A.; Lucas Júnior, J. Influência da Relação Volumoso: Concentrado e do Tempo de Retenção Hidráulica sob a Biodigestão Anaeróbia de Dejetos de Bovinos. Eng. Agrícola 2010, 30, 386–394. [Google Scholar] [CrossRef]

- Tan, W.E.; Liew, P.Y.; Tan, L.S.; Woon, K.S.; Mohammad Rozali, N.E.; Ho, W.S.; NorRuwaida, J. Life Cycle Assessment and Techno-Economic Analysis for Anaerobic Digestion as Cow Manure Management System. Energies 2022, 15, 9586. [Google Scholar] [CrossRef]

- Ciuła, J.; Kowalski, S.; Generowicz, A.; Barbusiński, K.; Matuszak, Z.; Gaska, K. Analysis of Energy Generation Efficiency and Reliability of a Cogeneration Unit Powered by Biogas. Energies 2023, 16, 2180. [Google Scholar] [CrossRef]

- Conab (Companhia Nacional de Abastecimento). Norma Metodologia Do Custo de Produção. 2020. Available online: https://www.conab.gov.br/images/arquivos/normativos/30000_sistema_de_operacoes/30.302_Norma_Metodologia_de_Custo_de_Producao.pdf (accessed on 5 August 2025).

- Martins, F.M.; De Oliveira, P.A.V. Análise Econômica da Geração de Energia Elétrica A Partir do Biogás Na Suinocultura. 2011. Available online: www.bcb.gov.br (accessed on 15 July 2025).

- Borgonovo, E.; Plischke, E. Sensitivity Analysis: A Review of Recent Advances. Eur. J. Oper. Res. 2016, 248, 869–887. [Google Scholar] [CrossRef]

- Brealey, R.A.; Myers, S.C.; Allen, F. Princípios de Finanças Corporativas, 12th ed.; McGraw Hill: New York, NY, USA, 2020. [Google Scholar]

- Pindyck, R.S.; Rubinfeld, D.L. Microeconomia, 8th ed.; Pearson Education do Brasil: São Paulo, Brazil, 2018. [Google Scholar]

- Fishman, G.S. Monte Carlo: Concepts, Algorithms, and Applications; Springer International Publishing: New York, NY, USA, 2013. [Google Scholar]

- Glasserman, P. Monte Carlo Methods in Financial Engineering; Springer: New York, NY, USA, 2004. [Google Scholar]

- Spirito, C.M.; Daly, S.E.; Werner, J.J.; Angenent, L.T. Redundancy in Anaerobic Digestion Microbiomes during Disturbances by the Antibiotic Monensin. Appl. Environ. Microbiol. 2018, 84, 3674375. [Google Scholar] [CrossRef] [PubMed]

- Nolan, T.; Troy, S.M.; Gilkinson, S.; Frost, P.; Xie, S.; Zhan, X.; Harrington, C.; Healy, M.G.; Lawlor, P.G. Economic Analyses of Pig Manure Treatment Options in Ireland. Bioresour. Technol. 2012, 105, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the Sustainability of Organic Waste Management Practices in the Food-Energy-Water Nexus: A Comparative Review of Anaerobic Digestion and Composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- Saltelli, A.; Ratto, M.; Andres, T.; Campolongo, F.; Cariboni, J.; Gatelli, D.; Saisana, M.; Tarantola, S. Global Sensitivity Analysis: The Primer; John Wiley & Sons, Ltd.: New York, NY, USA, 2007. [Google Scholar] [CrossRef]

- Palese, A.M.; Persiani, A.; D’Adamo, C.; Pergola, M.; Pastore, V.; Sileo, R.; Ippolito, G.; Lombardi, M.A.; Celano, G. Composting as Manure Disposal Strategy in Small/Medium-Size Livestock Farms: Some Demonstrations with Operative Indications. Sustainability 2020, 12, 3315. [Google Scholar] [CrossRef]

- Van Fan, Y.; Lee, C.T.; Klemeš, J.J.; Bong, C.P.C.; Ho, W.S. Economic Assessment System towards Sustainable Composting Quality in the Developing Countries. Clean Technol. Environ. Policy 2016, 18, 2479–2491. [Google Scholar] [CrossRef]

- Varma, V.S.; Parajuli, R.; Scott, E.; Canter, T.; Lim, T.T.; Popp, J.; Thoma, G. Dairy and Swine Manure Management—Challenges and Perspectives for Sustainable Treatment Technology. Sci. Total Environ. 2021, 778, 146319. [Google Scholar] [CrossRef]

- Dach, J.; Mazurkiewicz, J.; Janczak, D.; Pulka, J.; Pochwatka, P.; Kowalczyk-Jusko, A. Cow Manure Anaerobic Digestion or Composting—Energetic and Economic Analysis. In Proceedings of the 4th International Conference on Green Energy and Applications (ICGEA 2020), Singapore, 7–9 March 2020; pp. 143–147. [Google Scholar] [CrossRef]

| Scenario | Composting 1 | Anaerobic Digestion 1 | Screening 1 | HRT (Days) 2 |

|---|---|---|---|---|

| C | Yes | No | No | - |

| AD20 | No | Yes | No | 20 |

| AD30 | No | Yes | No | 30 |

| C+AD20 | Yes | Yes | Yes | 20 |

| C+AD30 | Yes | Yes | Yes | 30 |

| Parameter | Amount 2 |

|---|---|

| Daily manure production per animal 1 | 19.84 kg animal−1 day−1 |

| Total solids (TS) concentration in manure | 21.74% |

| Daily manure production (TS) per animal | 4.37 kg animal−1 day−1 |

| Daily total manure production (TS) for the herd (200 animals) | 874 kg day−1 |

| Scenario 1 | Methane Production Potential (L CH4 kg−1 TS Added) 2 | TS Concentration in Influent (%) 2 | TS Reduction (%) 2 |

|---|---|---|---|

| C | - | - | 54.28 |

| AD20 | 66.75 | 2.47 | 40.86 |

| AD30 | 102.22 | 2.47 | 55.68 |

| C+AD20 | 110.54 | 1.39 | 45.69 |

| C+AD30 | 145.32 | 1.39 | 59.62 |

| Scenario 1 | Compost-Based Fertilizer (% of Total Solids) 2 | Biofertilizer from Anaerobic Digestion (% of Total Solids) 2 | ||||

|---|---|---|---|---|---|---|

| N | P | K | N | P | K | |

| C | 2.65 | 2.10 | 1.00 | - | - | - |

| AD20 | - | - | - | 2.17 | 1.63 | 0.95 |

| AD30 | - | - | - | 2.51 | 1.63 | 0.95 |

| C+AD20 | 2.65 | 2.10 | 1.00 | 2.40 | 1.58 | 0.69 |

| C+AD30 | 2.65 | 2.10 | 1.00 | 2.21 | 1.58 | 0.70 |

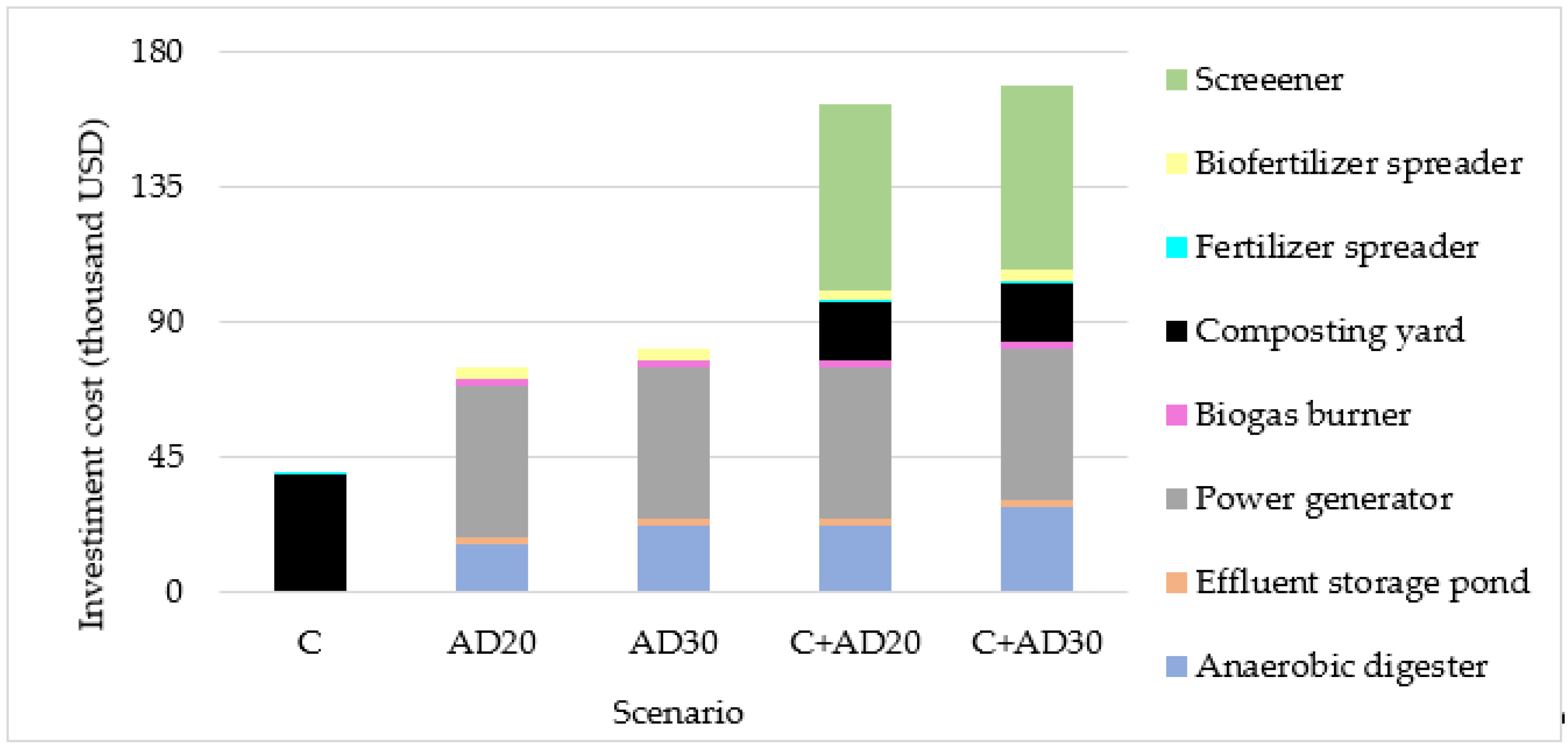

| Equipment | Scenario 1 | ||||

|---|---|---|---|---|---|

| C | AD20 | AD30 | C+AD20 | C+AD30 | |

| Composting yard | 39,286.32 | - | - | 19,050.91 | 19,050.91 |

| Fertilizer spreader | 560.55 | - | - | 560.55 | 560.55 |

| Subtotal (1) | 39,846.87 | - | - | 19,611.46 | 19,611.46 |

| Screener | - | - | - | 61,309.93 | 61,309.93 |

| Anaerobic digester | - | 15,788.47 | 22,103.86 | 22,103.86 | 28,419.25 |

| Biofertilizer spreader | - | 3853.77 | 3853.77 | 3853.77 | 3853.77 |

| Effluent storage pond | - | 2539.98 | 2539.98 | 2539.98 | 2539.98 |

| Power generator | - | 50,403.24 | 50,403.24 | 50,403.24 | 50,403.24 |

| Biogas burner | - | 2347.29 | 2347.29 | 2347.29 | 2347.29 |

| Subtotal (2) | - | 74,932.75 | 81,248.14 | 142,558.07 | 148,873.46 |

| Total | 39,846.87 | 74,932.75 | 81,248.14 | 162,169.53 | 168,484.92 |

| Components | Scenario 1 | ||||

|---|---|---|---|---|---|

| C | AD20 | AD30 | C+AD20 | C+AD30 | |

| 1. Total revenue | 9102.02 | 14,359.58 | 18,863.43 | 27,997.69 | 31,993.43 |

| 1.1 Electricity | - | 10,658.54 | 15,933.17 | 16,669.00 | 21,195.66 |

| 1.2 Biofertilizer | - | 3701.04 | 2930.26 | 1900.85 | 1369.93 |

| 1.3 Solid fertilizer | 9102.02 | - | - | 9427.84 | 9427.84 |

| 2. Total cost | 4663.49 | 9699.81 | 10,158.26 | 19,225.65 | 19,683.52 |

| 2.1 Sodium monensin | 476.58 | 476.58 | 476.58 | 476.58 | 476.58 |

| 2.2 Electricity for screener | - | - | - | 209.82 | 209.82 |

| 2.3 Labor | 2668.36 | 1489.06 | 1489.65 | 3297.49 | 3297.49 |

| 2.4 Insurance on fixed capital | 298.85 | 562.00 | 609.36 | 1216.27 | 1263.64 |

| 2.5 Maintenance | 398.47 | 1873.32 | 2031.20 | 4054.24 | 4212.12 |

| 2.6 Depreciation | 821.23 | 5298.85 | 5551.47 | 9971.25 | 10,223.86 |

| 3. Operation profit | 4438.53 | 4659.77 | 8705.17 | 8772.04 | 12,309.91 |

| 4. Income tax 2 | 0 | 0 | 0 | 0 | 1759.64 |

| 5. Operating cash flow | 4438.53 | 4659.77 | 8705.17 | 8772.04 | 10,550.27 |

| 6. Depreciation | 821.23 | 5298.85 | 5551.47 | 9971.25 | 10,223.86 |

| 7. Fixed investment | 0 | 0 | 0 | 0 | 0 |

| 8. Net cash flow to the producer | 5259.76 | 9958.62 | 14,256.63 | 18,743.28 | 20,774.14 |

| Equipment | Scenario 1 | ||||

|---|---|---|---|---|---|

| C | AD20 | AD30 | C+AD20 | C+AD30 | |

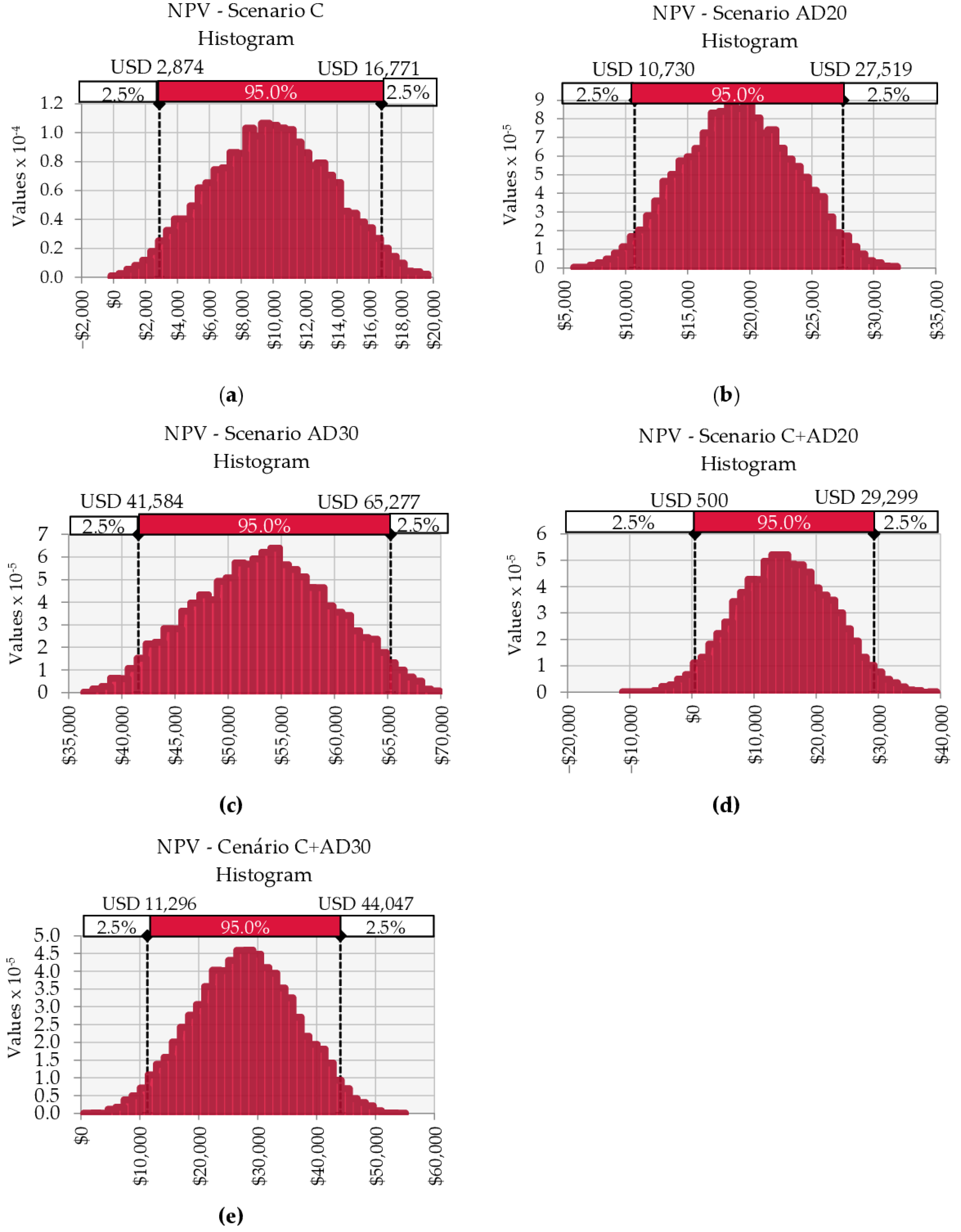

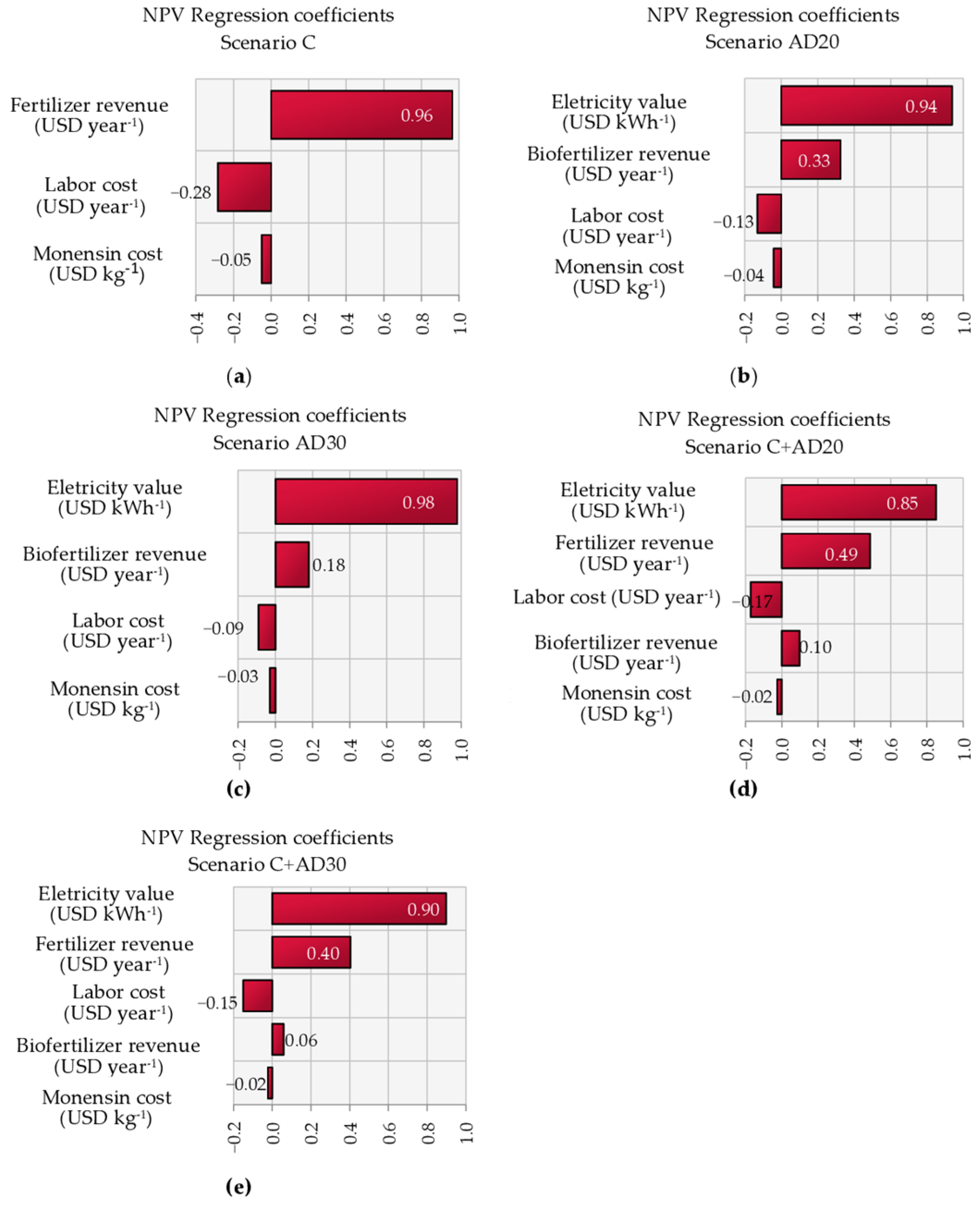

| Internal Rate Return (IRR, %) | 10.07 | 10.19 | 15.54 | 7.82 | 8.90 |

| Net Present Value (NPV, USD) | 9832.0 | 19,127.4 | 53,407.1 | 14,862.6 | 27,728.8 |

| Profitability Index (PI) | 1.25 | 1.26 | 1.66 | 1.09 | 1.16 |

| Benefit–Cost ratio (B/C, USD) | 1.95 | 1.10 | 1.57 | 1.46 | 2.58 |

| Annual Equivalent Value (AEV, USD) | 1040.97 | 2025.12 | 5654.48 | 1573.58 | 2935.79 |

| Modified Internal Rate of Return (MIRR, %) | 7.23 | 7.28 | 9.28 | 6.28 | 6.74 |

| Discounted Payback Period (DPP, years) | 10.72 | 10.62 | 7.33 | 13.04 | 11.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macena, I.A.; Orrico, A.C.A.; Ota, E.d.C.; Gimenes, R.M.T.; Souza, V.; Vargas Junior, F.M.d.; Leite, B.K.V.; Orrico Junior, M.A.P. Economic Feasibility of Solid–Liquid Separation and Hydraulic Retention Time in Composting or Anaerobic Digestion Systems for Recycling Dairy Cattle Manure. AgriEngineering 2025, 7, 306. https://doi.org/10.3390/agriengineering7090306

Macena IA, Orrico ACA, Ota EdC, Gimenes RMT, Souza V, Vargas Junior FMd, Leite BKV, Orrico Junior MAP. Economic Feasibility of Solid–Liquid Separation and Hydraulic Retention Time in Composting or Anaerobic Digestion Systems for Recycling Dairy Cattle Manure. AgriEngineering. 2025; 7(9):306. https://doi.org/10.3390/agriengineering7090306

Chicago/Turabian StyleMacena, Isabelly Alencar, Ana Carolina Amorim Orrico, Erika do Carmo Ota, Régio Marcio Toesca Gimenes, Vanessa Souza, Fernando Miranda de Vargas Junior, Brenda Kelly Viana Leite, and Marco Antonio Previdelli Orrico Junior. 2025. "Economic Feasibility of Solid–Liquid Separation and Hydraulic Retention Time in Composting or Anaerobic Digestion Systems for Recycling Dairy Cattle Manure" AgriEngineering 7, no. 9: 306. https://doi.org/10.3390/agriengineering7090306

APA StyleMacena, I. A., Orrico, A. C. A., Ota, E. d. C., Gimenes, R. M. T., Souza, V., Vargas Junior, F. M. d., Leite, B. K. V., & Orrico Junior, M. A. P. (2025). Economic Feasibility of Solid–Liquid Separation and Hydraulic Retention Time in Composting or Anaerobic Digestion Systems for Recycling Dairy Cattle Manure. AgriEngineering, 7(9), 306. https://doi.org/10.3390/agriengineering7090306