Evaluation of Different Weight Configurations and Pass Numbers of a Roller Crimper for Terminating a Cover Crop Mixture in the Vineyard

Abstract

1. Introduction

2. Materials and Methods

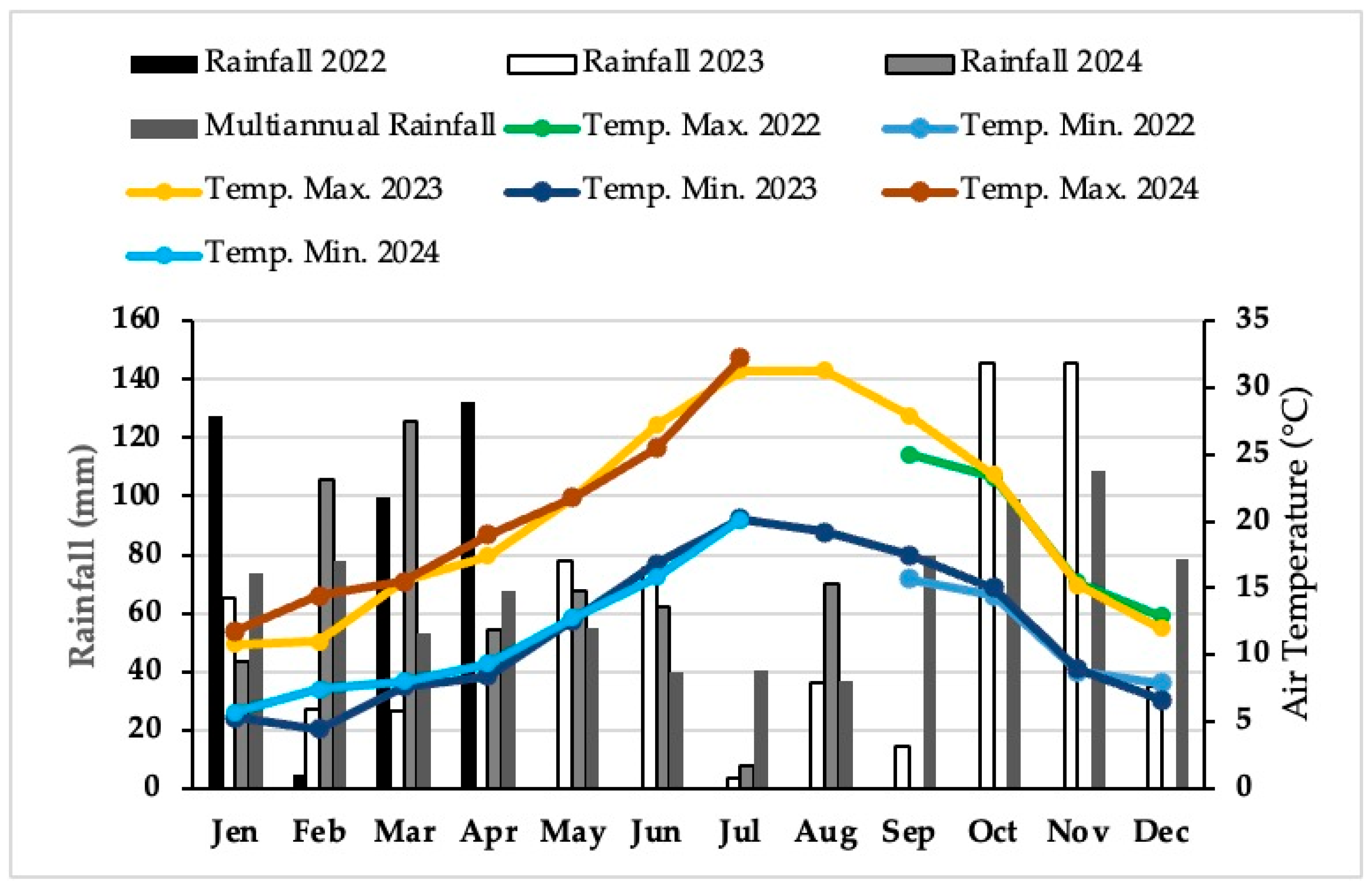

2.1. Experimental Layout

2.2. Description of the Roller Crimper Employed

2.3. Data Collection

2.4. Statistical Analysis

3. Results

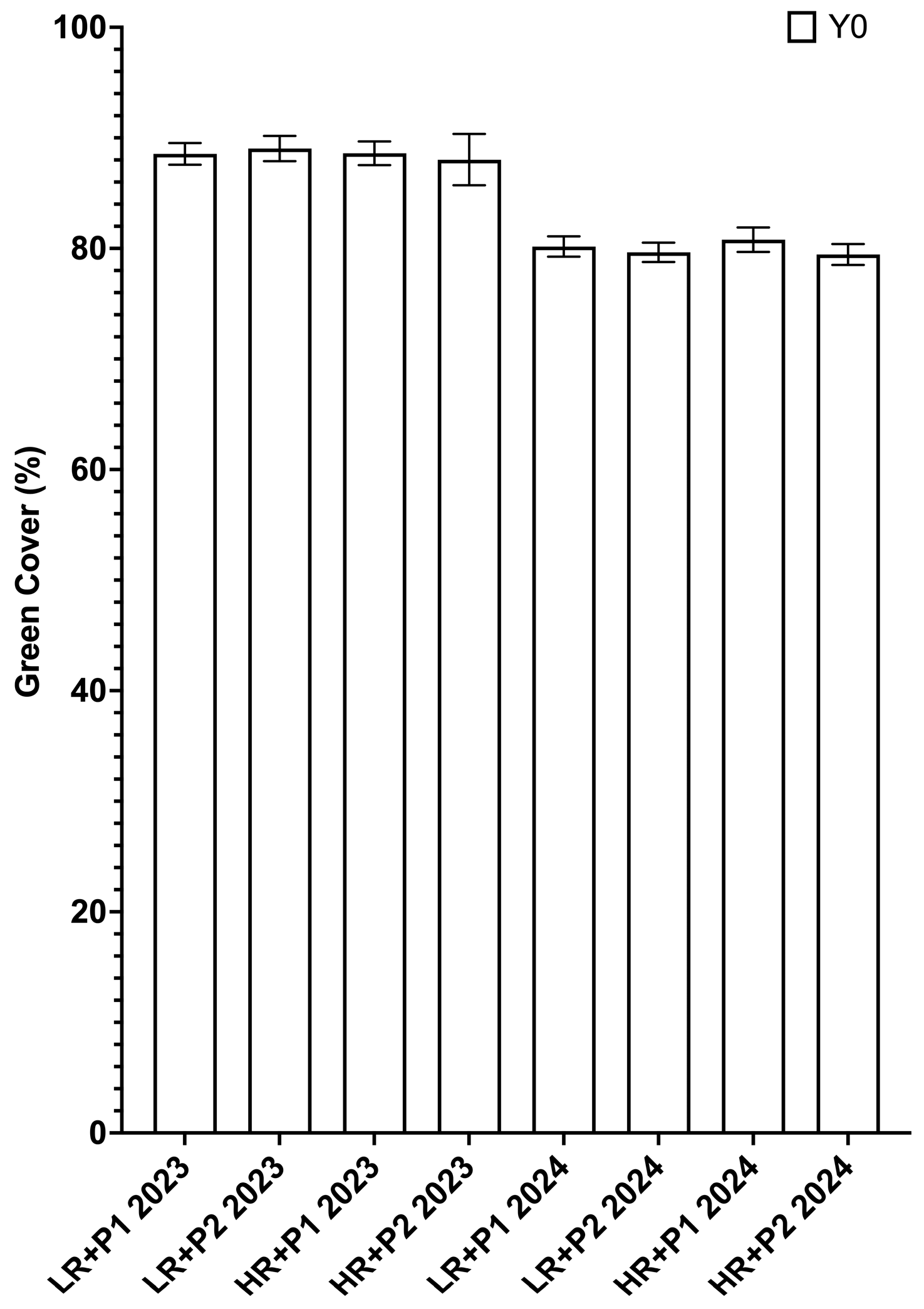

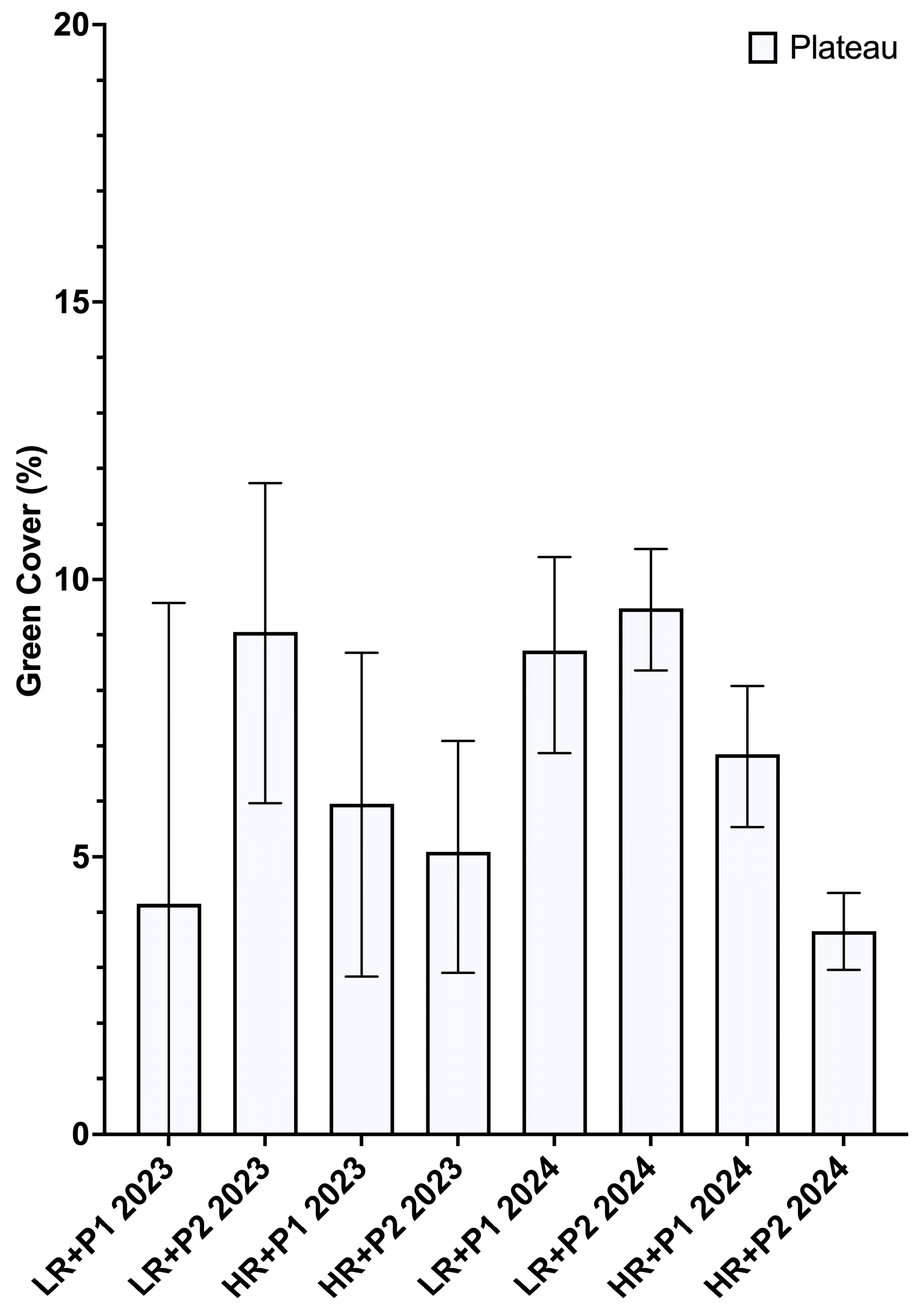

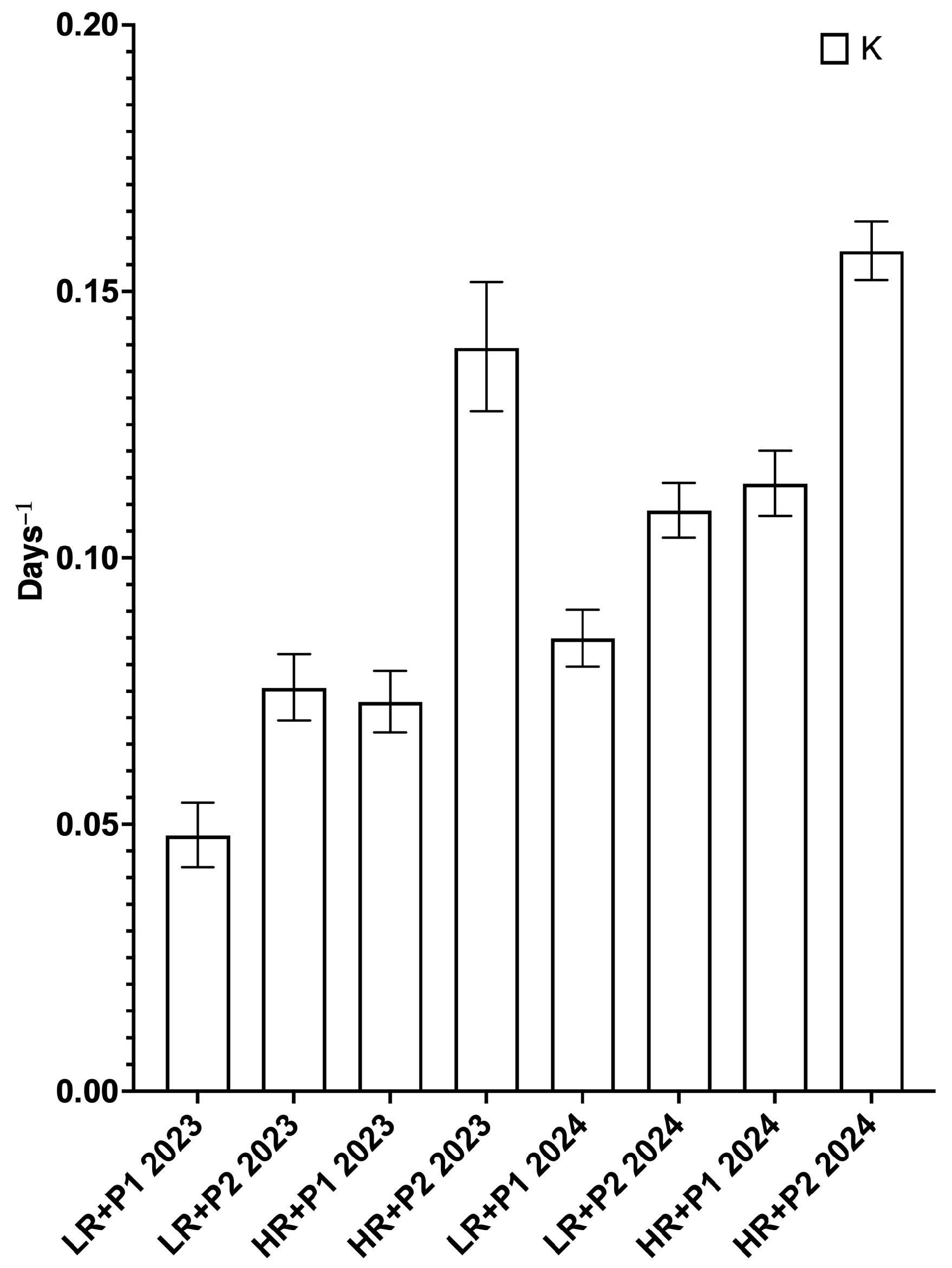

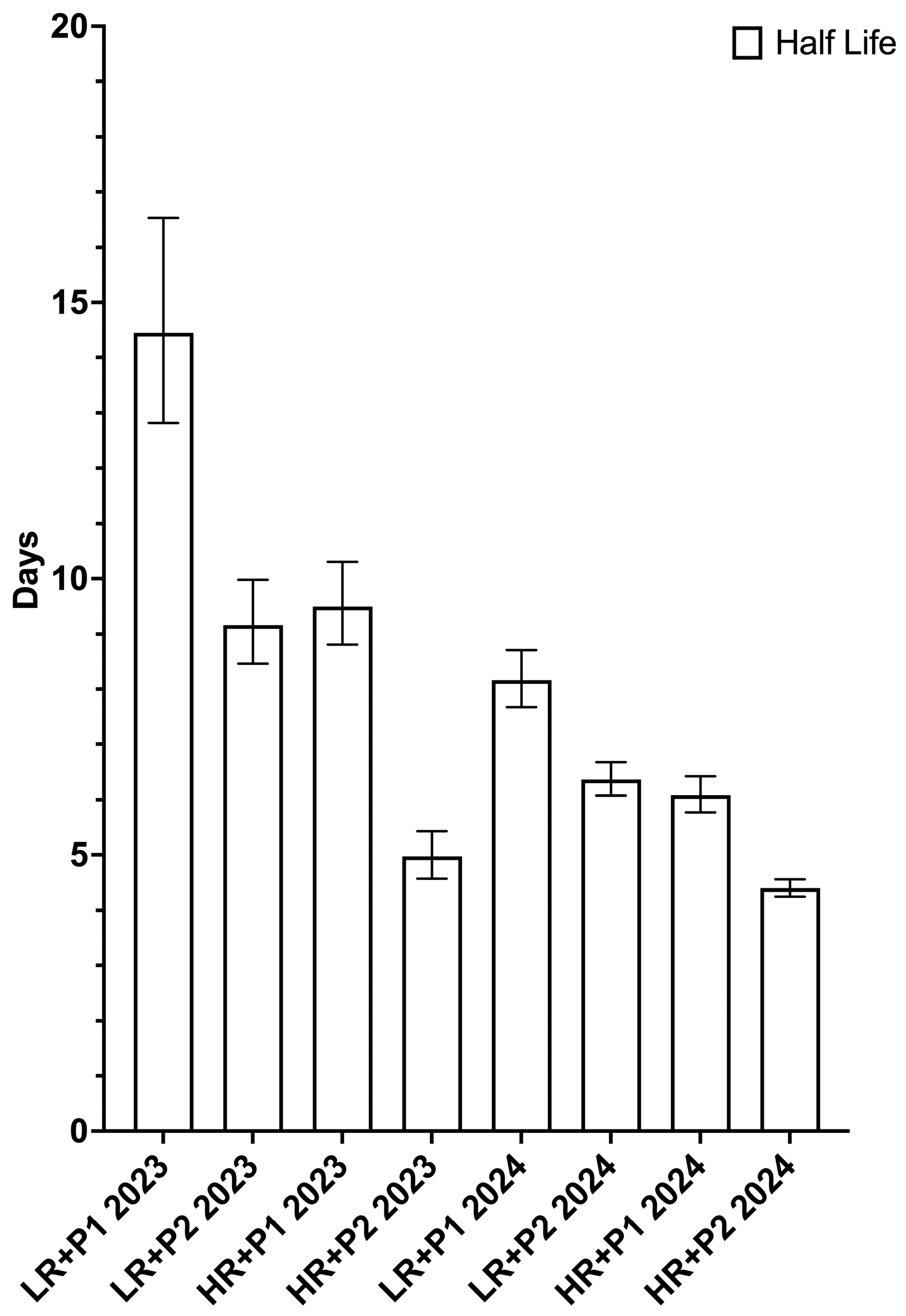

3.1. Effect of the Roller Crimper Different Weight Configurations and Number of Passes on Plant Termination

3.2. Effect on Soil Moisture Content and Soil Penetration Resistance

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brunori, E.; Farina, R.; Biasi, R. Sustainable Viticulture: The Carbon-Sink Function of the Vineyard Agro-Ecosystem. Agric. Ecosyst. Environ. 2016, 223, 10–21. [Google Scholar] [CrossRef]

- Giagnoni, L.; Maienza, A.; Baronti, S.; Vaccari, F.P.; Genesio, L.; Taiti, C.; Martellini, T.; Scodellini, R.; Cincinelli, A.; Costa, C.; et al. Long-Term Soil Biological Fertility, Volatile Organic Compounds and Chemical Properties in a Vineyard Soil after Biochar Amendment. Geoderma 2019, 344, 127–136. [Google Scholar] [CrossRef]

- Morris, D.R.; Gilbert, R.A.; Reicosky, D.C.; Gesch, R.W. Oxidation Potentials of Soil Organic Matter in Histosols under Different Tillage Methods. Soil Sci. Soc. Am. J. 2004, 68, 817–826. [Google Scholar] [CrossRef]

- Gagliardi, L.; Luglio, S.M.; Peruzzi, A.; Fontanelli, M.; Frasconi, C.; Raffaelli, M. Comparative Analysis of the Performance of a Chain Mower and Tools That Perform Under-Row Weed Control with Tillage in the Vineyard. Agronomy 2024, 14, 206. [Google Scholar] [CrossRef]

- Boselli, R.; Fiorini, A.; Santelli, S.; Ardenti, F.; Capra, F.; Maris, S.C.; Tabaglio, V. Cover Crops during Transition to No-till Maintain Yield and Enhance Soil Fertility in Intensive Agro-Ecosystems. Field Crops Res. 2020, 255, 107871. [Google Scholar] [CrossRef]

- Agnelli, A.; Bol, R.; Trumbore, S.E.; Dixon, L.; Cocco, S.; Corti, G. Carbon and Nitrogen in Soil and Vine Roots in Harrowed and Grass-Covered Vineyards. Agric. Ecosyst. Environ. 2014, 193, 70–82. [Google Scholar] [CrossRef]

- Rodrigo Comino, J.; Iserloh, T.; Morvan, X.; Malam Issa, O.; Naisse, C.; Keesstra, S.; Cerdà, A.; Prosdocimi, M.; Arnáez, J.; Lasanta, T.; et al. Soil Erosion Processes in European Vineyards: A Qualitative Comparison of Rainfall Simulation Measurements in Germany, Spain and France. Hydrology 2016, 3, 6. [Google Scholar] [CrossRef]

- Gonçalves, F.; Nunes, C.; Carlos, C.; López, Á.; Oliveira, I.; Crespí, A.; Teixeira, B.; Pinto, R.; Costa, C.A.; Torres, L. Do Soil Management Practices Affect the Activity Density, Diversity, and Stability of Soil Arthropods in Vineyards? Agric. Ecosyst. Environ. 2020, 294, 106863. [Google Scholar] [CrossRef]

- Antichi, D.; Sbrana, M.; Martelloni, L.; Abou Chehade, L.; Fontanelli, M.; Raffaelli, M.; Mazzoncini, M.; Peruzzi, A.; Frasconi, C. Agronomic Performances of Organic Field Vegetables Managed with Conservation Agriculture Techniques: A Study from Central Italy. Agronomy 2019, 9, 810. [Google Scholar] [CrossRef]

- Holland, J.M. The Environmental Consequences of Adopting Conservation Tillage in Europe: Reviewing the Evidence. Agric. Ecosyst. Environ. 2004, 103, 1–25. [Google Scholar] [CrossRef]

- Steinwandter, M.; Haas, F.; Degasperi, G.; Kahlen, M.; Rief, A.; Ostermann, V.; Seeber, J. Does Green Manuring Positively Affect the Soil Macro-Invertebrates in Vineyards? A Case Study from Kaltern/Caldaro (South Tyrol, Italy). Gredleriana 2018, 18, 17–26. [Google Scholar]

- Cunial, L.; Diti, I.; Bonini, P.; Patelli, R.; Gatti, M.; Cola, G.; Bordoni, M.; Nguyen, T.N.A.; Meisina, C.; Confalonieri, R.; et al. Novel Termination Techniques of Winter Cover Crops in the Vineyard: Effects on Physiology and Performance of Pinot Noir and Malvasia Di Candia Aromatica Grapevines. Eur. J. Agron. 2025, 164, 127514. [Google Scholar] [CrossRef]

- Cabrera-Pérez, C.; Royo-Esnal, A.; Català, B.; Baraibar, B.; Recasens, J. Cover Crops Terminated with Roller-crimper to Manage Cynodon Dactylon and Other Weeds in Vineyards. Pest Manag. Sci. 2024, 80, 2162–2169. [Google Scholar] [CrossRef]

- Ashford, D.L.; Reeves, D.W. Use of a Mechanical Roller-Crimper as an Alternative Kill Method for Cover Crops. Am. J. Altern. Agric. 2003, 18, 37–45. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Kichler, C.M. Effectiveness of Cover Crop Termination Methods on No-Till Cantaloupe. Agriculture 2022, 12, 66. [Google Scholar] [CrossRef]

- Dondi, Insieme per la Terra Rotovitis. Available online: https://www.dondinet.it/lavorazioni-in-vigneto-e-arboreto/rulli-per-pacciamatura/ (accessed on 5 May 2025).

- Zanon RCV Single, Mulching Roller. Available online: https://www.zanon.it/en/rcv-single/ (accessed on 5 May 2025).

- Clemens Technologies Eco-Roll. Available online: https://www.clemens-online.com/it/prodotti/lavorazioni-interfila/eco-roll/ (accessed on 5 May 2025).

- Soldo, Agricoltura Roller Crimper. Available online: http://www.soldomacchineagricole.it/rulli-costipatori/13-roller-crimper.html (accessed on 5 May 2025).

- Liebert, J.A.; DiTommaso, A.; Ryan, M.R. Rolled Mixtures of Barley and Cereal Rye for Weed Suppression in Cover Crop–Based Organic No-Till Planted Soybean. Weed Sci. 2017, 65, 426–439. [Google Scholar] [CrossRef]

- Mirsky, S.B.; Ryan, M.R.; Curran, W.S.; Teasdale, J.R.; Maul, J.; Spargo, J.T.; Moyer, J.; Grantham, A.M.; Weber, D.; Way, T.R.; et al. Conservation Tillage Issues: Cover Crop-Based Organic Rotational No-till Grain Production in the Mid-Atlantic Region, USA. Renew. Agric. Food Syst. 2012, 27, 31–40. [Google Scholar] [CrossRef]

- Antichi, D.; Carlesi, S.; Mazzoncini, M.; Bàrberi, P. Targeted Timing of Hairy Vetch Cover Crop Termination with Roller Crimper Can Eliminate Glyphosate Requirements in No-till Sunflower. Agron. Sustain. Dev. 2022, 42, 87. [Google Scholar] [CrossRef]

- Miville, D.; Leroux, G.D. Rolled Winter Rye–Hairy Vetch Cover Crops for Weed Control in No-till Pumpkin. Weed Technol. 2018, 32, 251–259. [Google Scholar] [CrossRef]

- Keene, C.L.; Curran, W.S.; Wallace, J.M.; Ryan, M.R.; Mirsky, S.B.; VanGessel, M.J.; Barbercheck, M.E. Cover Crop Termination Timing Is Critical in Organic Rotational No-Till Systems. Agron. J. 2017, 109, 272–282. [Google Scholar] [CrossRef]

- Frasconi, C.; Martelloni, L.; Antichi, D.; Raffaelli, M.; Fontanelli, M.; Peruzzi, A.; Benincasa, P.; Tosti, G. Combining Roller Crimpers and Flaming for the Termination of Cover Crops in Herbicide-Free No-till Cropping Systems. PLoS ONE 2019, 14, e0211573. [Google Scholar] [CrossRef]

- Sportelli, M.; Frasconi, C.; Gagliardi, L.; Fontanelli, M.; Raffaelli, M.; Sbrana, M.; Antichi, D.; Peruzzi, A. Testing of Roller-Crimper-and-Undercutting-Blade-Equipped Prototype for Plants Termination. AgriEngineering 2023, 5, 182–192. [Google Scholar] [CrossRef]

- University of Maryland Extension; Cerruti, R. Offing Cover Crops for Weed Suppression: Featuring the Roller Crimper and Other Mechanical Contraptions. Available online: https://extension.umd.edu/resource/offing-cover-crops-weed-suppression-featuring-roller-crimper-and-other-mechanical-contraptions/ (accessed on 5 May 2025).

- Kornecki, T.S.; Kichler, C.M. Influence of Recurrent Rolling/Crimping of a Cereal Rye/Crimson Clover Cover Crop on No-Till Bush Bean Yield. AgriEngineering 2022, 4, 855–870. [Google Scholar] [CrossRef]

- Davis, A.S. Cover-Crop Roller–Crimper Contributes to Weed Management in No-Till Soybean. Weed Sci. 2010, 58, 300–309. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Arriaga, F.F.; Price, A.J.; Balkcom, K.S. Effects of Recurrent Rolling/Crimping Operations on Cover Crop Termination, Soil Moisture, and Soil Strength for Conservation Organic Systems. Appl. Eng. Agric. 2013, 841–850. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Kichler, C.M. Recurring Rolling/Crimping Effects on Termination Effectiveness of Iron Clay Pea and Pearl Millet Warm-Season Cover Crops. Agriculture 2023, 13, 1949. [Google Scholar] [CrossRef]

- USDA, Natural Resources Conservation Service, US. Department of Agriculture Soil Texture Calculator. Available online: https://www.nrcs.usda.gov/resources/education-and-teaching-materials/soil-texture-calculator (accessed on 1 April 2025).

- Patrignani, A.; Ochsner, T.E. Canopeo: A Powerful New Tool for Measuring Fractional Green Canopy Cover. Agron. J. 2015, 107, 2312–2320. [Google Scholar] [CrossRef]

- Bates, D.; Maechler, M.; Bolker, B.; Walker, S.; Bojesen Christensen, R.H.; Singmann, H.; Dai, B.; Scheipl, F.; Grothendieck, G.; Green, P.; et al. Linear Mixed-Effects Models Using “Eigen” and S4. Package ‘Lme4’. R Package Version 1.1-37. 2025. Available online: https://cran.r-project.org/web/packages/lme4/index.html. (accessed on 5 May 2025).

- Crespo, C.; O’Brien, P.L.; Ruis, S.J.; Kovar, J.L.; Kaspar, T.C. Thermal Time and Precipitation Dictate Cereal Rye Shoot Biomass Production. Field Crops Res. 2024, 315, 109473. [Google Scholar] [CrossRef]

- Chatterjee, N.; Archontoulis, S.V.; Bastidas, A.; Proctor, C.A.; Elmore, R.W.; Basche, A.D. Simulating Winter Rye Cover Crop Production under Alternative Management in a Corn-soybean Rotation. Agron. J. 2020, 112, 4648–4665. [Google Scholar] [CrossRef]

- Holman, J.D.; Assefa, Y.; Obour, A.K. Cover-crop Water Use and Productivity in the High Plains Wheat–Fallow Crop Rotation. Crop Sci. 2021, 61, 1374–1385. [Google Scholar] [CrossRef]

- Kornecki, T.S. Influence of Recurrent Rolling/Crimping on Cover Crop Termination, Soil Strength and Yield in No-Till Cotton. AgriEngineering 2020, 2, 631–648. [Google Scholar] [CrossRef]

- Edwards, A.; Smither-Kopperl, M. Termination Timing for Cover Crops Using a Roller Crimper in California’s Central Valley—One Year Demonstration Results. Available online: https://www.nrcs.usda.gov/plantmaterials/capmcsr14110.pdf (accessed on 5 May 2025).

- Finney, D.M.; White, C.M.; Kaye, J.P. Biomass Production and Carbon/Nitrogen Ratio Influence Ecosystem Services from Cover Crop Mixtures. Agron. J. 2016, 108, 39–52. [Google Scholar] [CrossRef]

- Adhikari, A.D.; Shrestha, P.; Ghimire, R.; Liu, Z.; Pollock, D.A.; Acharya, P.; Aryal, D.R. Cover Crop Residue Quality Regulates Litter Decomposition Dynamics and Soil Carbon Mineralization Kinetics in Semi-Arid Cropping Systems. Appl. Soil Ecol. 2024, 193, 105160. [Google Scholar] [CrossRef]

- Willmott, R.; Valdez-Herrera, J.; Mitchell, J.P.; Shrestha, A. Potential of Cover Crop Use and Termination with a Roller-Crimper in a Strip-Till Silage Maize (Zea mays L.) Production System in the Central Valley of California. Agronomy 2025, 15, 132. [Google Scholar] [CrossRef]

- Mairata, A.; Labarga, D.; Puelles, M.; Rivacoba, L.; Martin, I.; Portu, J.; Pou, A. Impact of Organic Mulches on Grapevine Health, Growth and Grape Composition in Nutrient-Poor Vineyard Soils. OENO One 2024, 58. [Google Scholar] [CrossRef]

- Witzgall, K.; Steiner, F.A.; Hesse, B.D.; Riveras-Muñoz, N.; Rodríguez, V.; Teixeira, P.P.C.; Li, M.; Oses, R.; Seguel, O.; Seitz, S.; et al. Living and Decaying Roots as Regulators of Soil Aggregation and Organic Matter Formation—From the Rhizosphere to the Detritusphere. Soil Biol. Biochem. 2024, 197, 109503. [Google Scholar] [CrossRef]

- Van Huyssteen, L. Interpretation and Use of Penetrometer Data to Describe Soil Compaction in Vineyards. SAJEV 1983, 4, 59–65. [Google Scholar] [CrossRef][Green Version]

- Zyl, J.V.; Hoffman, E. Root Development And The Performance Of Grapevines In Response To Natural As Well As Man-Made Soil Impediments. In Proceedings of the GiESCO 2019, Thessaloniki, Greece, 23–28 June 2019. [Google Scholar]

- Gianessi, L.P.; Reigner, N.P. The Value of Herbicides in U.S. Crop Production. Weed Technol. 2007, 21, 559–566. [Google Scholar] [CrossRef]

- Panagos, P.; Borrelli, P.; Poesen, J.; Ballabio, C.; Lugato, E.; Meusburger, K.; Montanarella, L.; Alewell, C. The New Assessment of Soil Loss by Water Erosion in Europe. Environ. Sci. Policy 2015, 54, 438–447. [Google Scholar] [CrossRef]

| LR + P1 | LR + P2 | HR + P1 | HR + P2 | |

|---|---|---|---|---|

| 8 June 2023 | ✔ | ✔ | ✔ | ✔ |

| 20 June 2023 | - | ✔ | - | ✔ |

| 7 June 2024 | ✔ | ✔ | ✔ | ✔ |

| 21 June 2024 | - | ✔ | - | ✔ |

| Plant Biomass (g d.m. m−2) | ||

|---|---|---|

| 2023 | 2024 | |

| Value (SE) | Value (SE) | |

| Triticale | 129.52 (14.57) | 361.20 (42.33) |

| Hungarian vetch | 235.62 (16.98) | 84.34 (15.40) |

| Phacelia | 24.16 (5.84) | 30.92 (8.99) |

| Weeds | 440.54 (36.60) | 177.73 (21.28) |

| Total cover crop biomass | 389.30 | 476.46 |

| Total plant community biomass | 829.84 | 654.19 |

| LR + P1 | LR + P2 | HR + P1 | HR + P2 | LR + P1 | LR + P2 | HR + P1 | HR + P2 | |

|---|---|---|---|---|---|---|---|---|

| 2023 | 2023 | 2023 | 2023 | 2024 | 2024 | 2024 | 2024 | |

| Degrees of Freedom | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| R2 | 0.986 | 0.987 | 0.988 | 0.967 | 0.990 | 0.992 | 0.989 | 0.994 |

| Adjusted R2 | 0.985 | 0.987 | 0.988 | 0.967 | 0.990 | 0.992 | 0.989 | 0.994 |

| Before the First Roller Crimper Pass | Before the Second Roller Crimper Pass | the End of the Trial | |

|---|---|---|---|

| p-Value | p-Value | p-Value | |

| Factors | |||

| Weight | 0.641 | 0.891 | 0.922 |

| Soil moisture depth | 0.063 | 0.638 | 0.861 |

| Year | 0.923 | 0.053 | 0.145 |

| Weight × Soil moisture depth | 0.990 | 0.989 | 0.826 |

| Weight × Year | 0.903 | 0.650 | 0.730 |

| Soil moisture depth × Year | 0.270 | 0.151 | 0.846 |

| Weight × Soil moisture Depth × Year | 0.333 | 0.437 | 0.984 |

| Passes | - | - | 0.624 |

| Weight × Passes | - | - | 0.963 |

| Soil moisture depth × Passes | - | - | 0.989 |

| Year × Passes | - | - | 0.650 |

| Weight × Soil moisture depth × Passes | - | - | 0.236 |

| Weight × Year × Passes | - | - | 0.670 |

| Soil moisture depth × Year × Passes | - | - | 0.962 |

| Weight × Soil moisture depth × Year × Passes | - | - | 0.469 |

| Before the First Roller Crimper Pass | Before the Second Roller Crimper Pass | End of the Trial | |||||

|---|---|---|---|---|---|---|---|

| Value (%) | SE | Value (%) | SE | Value (%) | SE | ||

| 2023 | LR + P1 | 11.97 | 0.15 | 13.47 | 0.07 | 10.83 | 0.19 |

| LR + P2 | 9.54 | 0.45 | 15.09 | 0.20 | 12.22 | 0.10 | |

| HR + P1 | 8.52 | 0.29 | 13.33 | 0.06 | 9.93 | 0.34 | |

| HR + P2 | 10.50 | 0.21 | 14.23 | 0.02 | 15.88 | 0.08 | |

| 2024 | LR + P1 | 12.60 | 0.18 | 11.43 | 0.10 | 7.90 | 0.28 |

| LR + P2 | 12.28 | 0.15 | 10.11 | 0.06 | 5.84 | 0.22 | |

| HR + P1 | 11.08 | 0.19 | 11.54 | 0.03 | 4.88 | 0.03 | |

| HR + P2 | 12.05 | 0.23 | 12.38 | 0.21 | 7.24 | 0.27 | |

| Before the First Roller Crimper Pass | After the Second Roller Crimper Pass | |||

|---|---|---|---|---|

| 2023 | 2024 | 2023 | 2024 | |

| p-Value | p-Value | p-Value | p-Value | |

| Factors | ||||

| Weight | 0.776 | 0.418 | 0.305 | 0.304 |

| Passes | - | - | 0.758 | 0.666 |

| Weight × Passes | - | - | 0.211 | 0.128 |

| HR + P1 | HR + P2 | LR + P1 | LR + P2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 2023 | Depth (cm) | Value (kPa) | SE | Value (kPa) | SE | Value (kPa) | SE | Value (kPa) | SE |

| 0.0 | 310.67 | 111.06 | 218.33 | 75.31 | 299.00 | 94.19 | 230.00 | 50.01 | |

| 2.5 | 448.67 | 206.67 | 345.33 | 34.67 | 494.33 | 167.14 | 402.67 | 70.09 | |

| 5.0 | 437.00 | 162.19 | 494.67 | 8997 | 460.33 | 98.35 | 460.00 | 46.00 | |

| 7.5 | 494.33 | 102.25 | 494.67 | 89.97 | 390.67 | 80.67 | 471.67 | 109.63 | |

| 10.0 | 540.33 | 102.18 | 471.33 | 98.16 | 356.67 | 69.81 | 437.00 | 128.06 | |

| 12.5 | 471.67 | 57.33 | 379.33 | 86.89 | 333.33 | 60.60 | 345.33 | 103.33 | |

| 15.0 | 471.33 | 114.67 | 345.33 | 86.89 | 264.33 | 30.30 | 287.33 | 80.33 | |

| 17.5 | 471.67 | 22.67 | 437.00 | 82.93 | 264.67 | 99.95 | 322.00 | 63.76 | |

| 20.0 | 402.67 | 11.33 | 425.33 | 80.48 | 379.67 | 99.59 | 322.00 | 82.93 | |

| 22.5 | 402.33 | 30.30 | 483.00 | 155.83 | 564.00 | 121.70 | 333.33 | 100.56 | |

| 25.0 | 460.00 | 30.62 | 667.00 | 201.75 | 66700 | 92.00 | 379.67 | 121.26 | |

| 27.5 | 885.33 | 11.67 | 736.33 | 174.15 | 656.00 | 159.35 | 678.67 | 149.33 | |

| 30.0 | 1495.00 | 237.56 | 1346.00 | 421.60 | 1000.67 | 527.98 | 1115.33 | 196.71 | |

| 2024 | Depth (cm) | ||||||||

| 0.0 | 149.33 | 41.42 | 471.33 | 100.56 | 288.00 | 121.70 | 322.00 | 109.44 | |

| 2.5 | 460.33 | 41.42 | 655.33 | 52.81 | 437.33 | 267.32 | 747.67 | 212.89 | |

| 5.0 | 575.33 | 57.33 | 862.67 | 224.39 | 598.00 | 179.64 | 954.33 | 180.72 | |

| 7.5 | 724.67 | 110.75 | 885.33 | 316.49 | 598.33 | 113.14 | 966.33 | 189.86 | |

| 10.0 | 644.00 | 23.00 | 805.33 | 242.13 | 782.00 | 11.67 | 908.33 | 19.92 | |

| 12.5 | 609.33 | 23.33 | 804.67 | 154.88 | 782.00 | 30.62 | 759.00 | 71.74 | |

| 15.0 | 793.33 | 242.13 | 736.33 | 154.56 | 517.67 | 19.92 | 632.67 | 69.81 | |

| 17.5 | 747.33 | 265.10 | 655.33 | 381.75 | 483.00 | 39.84 | 505.67 | 41.42 | |

| 20.0 | 828.00 | 363.24 | 632.33 | 109.63 | 494.33 | 30.55 | 471.67 | 94.29 | |

| 22.5 | 896.67 | 381.75 | 678.33 | 247.53 | 51767 | 19.92 | 552.33 | 110.75 | |

| 25.0 | 874.00 | 224.16 | 586.67 | 206.67 | 402.67 | 11.33 | 712.67 | 80.48 | |

| 27.5 | 977.67 | 213.07 | 678.67 | 128.18 | 586.67 | 111.06 | 781.67 | 132.78 | |

| 30.0 | 1161.33 | 383.06 | 736.33 | 80.33 | 667.00 | 116.66 | 908.33 | 129.45 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gagliardi, L.; Luglio, S.M.; Tramacere, L.G.; Antichi, D.; Fontanelli, M.; Frasconi, C.; Peruzzi, A.; Raffaelli, M. Evaluation of Different Weight Configurations and Pass Numbers of a Roller Crimper for Terminating a Cover Crop Mixture in the Vineyard. AgriEngineering 2025, 7, 295. https://doi.org/10.3390/agriengineering7090295

Gagliardi L, Luglio SM, Tramacere LG, Antichi D, Fontanelli M, Frasconi C, Peruzzi A, Raffaelli M. Evaluation of Different Weight Configurations and Pass Numbers of a Roller Crimper for Terminating a Cover Crop Mixture in the Vineyard. AgriEngineering. 2025; 7(9):295. https://doi.org/10.3390/agriengineering7090295

Chicago/Turabian StyleGagliardi, Lorenzo, Sofia Matilde Luglio, Lorenzo Gabriele Tramacere, Daniele Antichi, Marco Fontanelli, Christian Frasconi, Andrea Peruzzi, and Michele Raffaelli. 2025. "Evaluation of Different Weight Configurations and Pass Numbers of a Roller Crimper for Terminating a Cover Crop Mixture in the Vineyard" AgriEngineering 7, no. 9: 295. https://doi.org/10.3390/agriengineering7090295

APA StyleGagliardi, L., Luglio, S. M., Tramacere, L. G., Antichi, D., Fontanelli, M., Frasconi, C., Peruzzi, A., & Raffaelli, M. (2025). Evaluation of Different Weight Configurations and Pass Numbers of a Roller Crimper for Terminating a Cover Crop Mixture in the Vineyard. AgriEngineering, 7(9), 295. https://doi.org/10.3390/agriengineering7090295