Determination of Filtration Grade in Woven Screen Filters: Influence of Material, Weave Pattern, and Filtration Rate

Abstract

1. Introduction

2. Materials and Methods

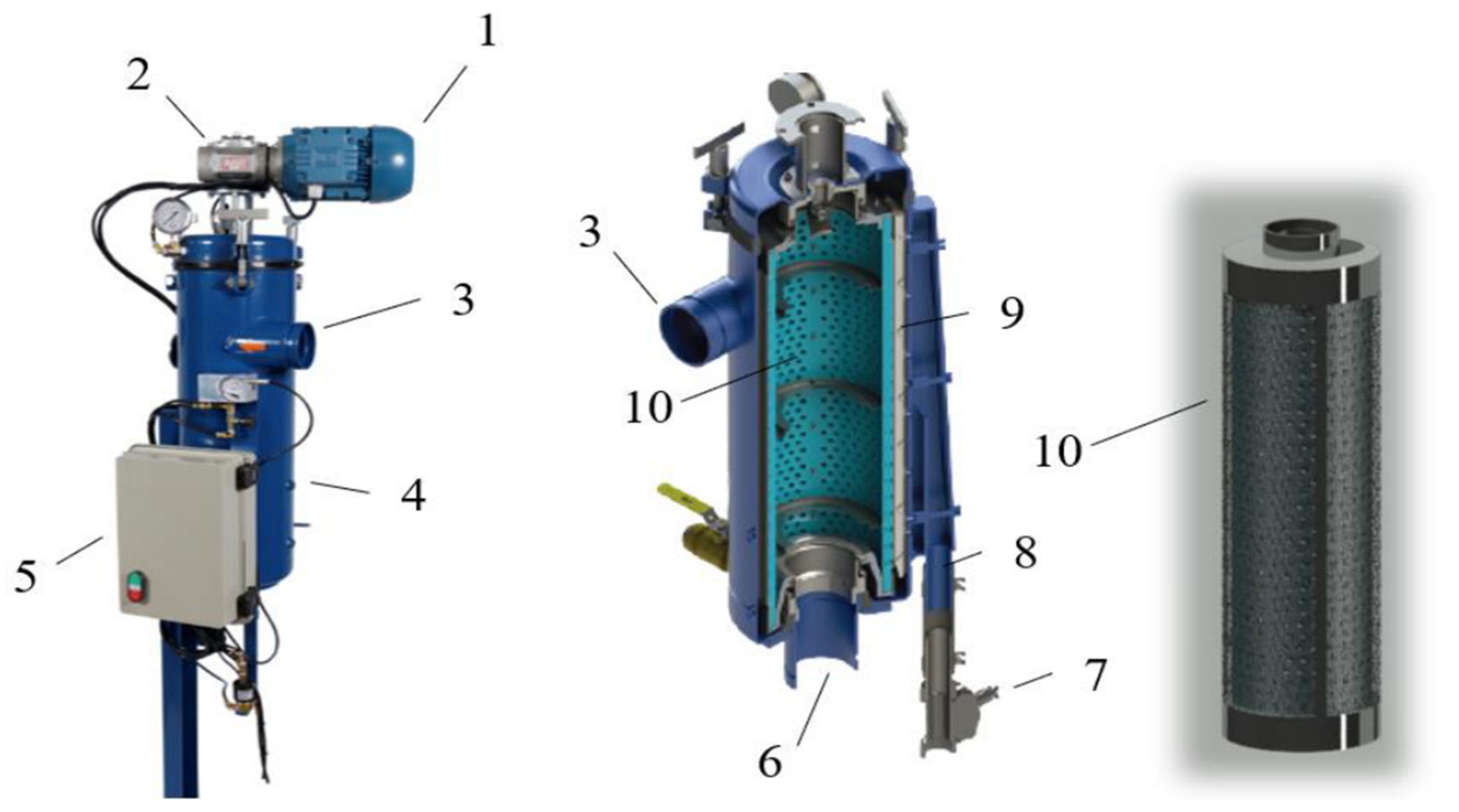

2.1. Filter Description

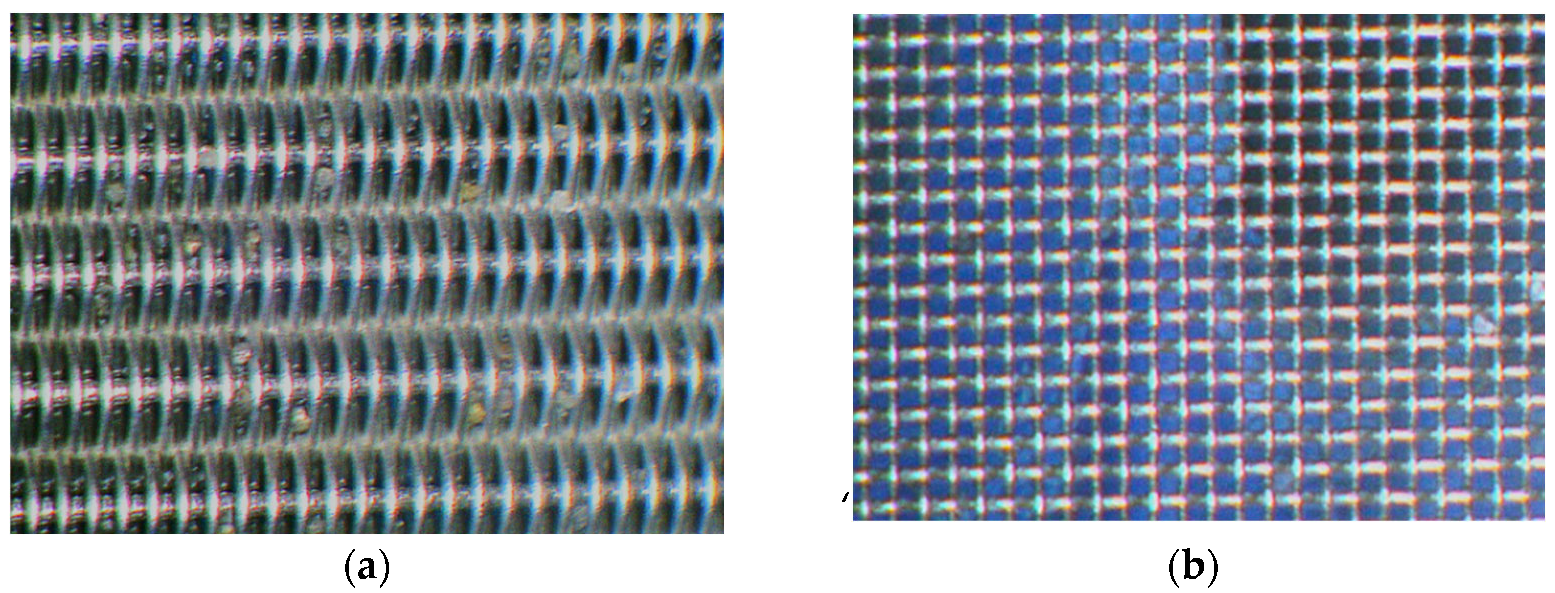

2.2. Filter Elements

2.3. Test Bench

2.4. Hydraulic Conditions for Determining Filtration Efficiency and Effective Filtration Grade

2.5. Determination of Filtration Grade

3. Results

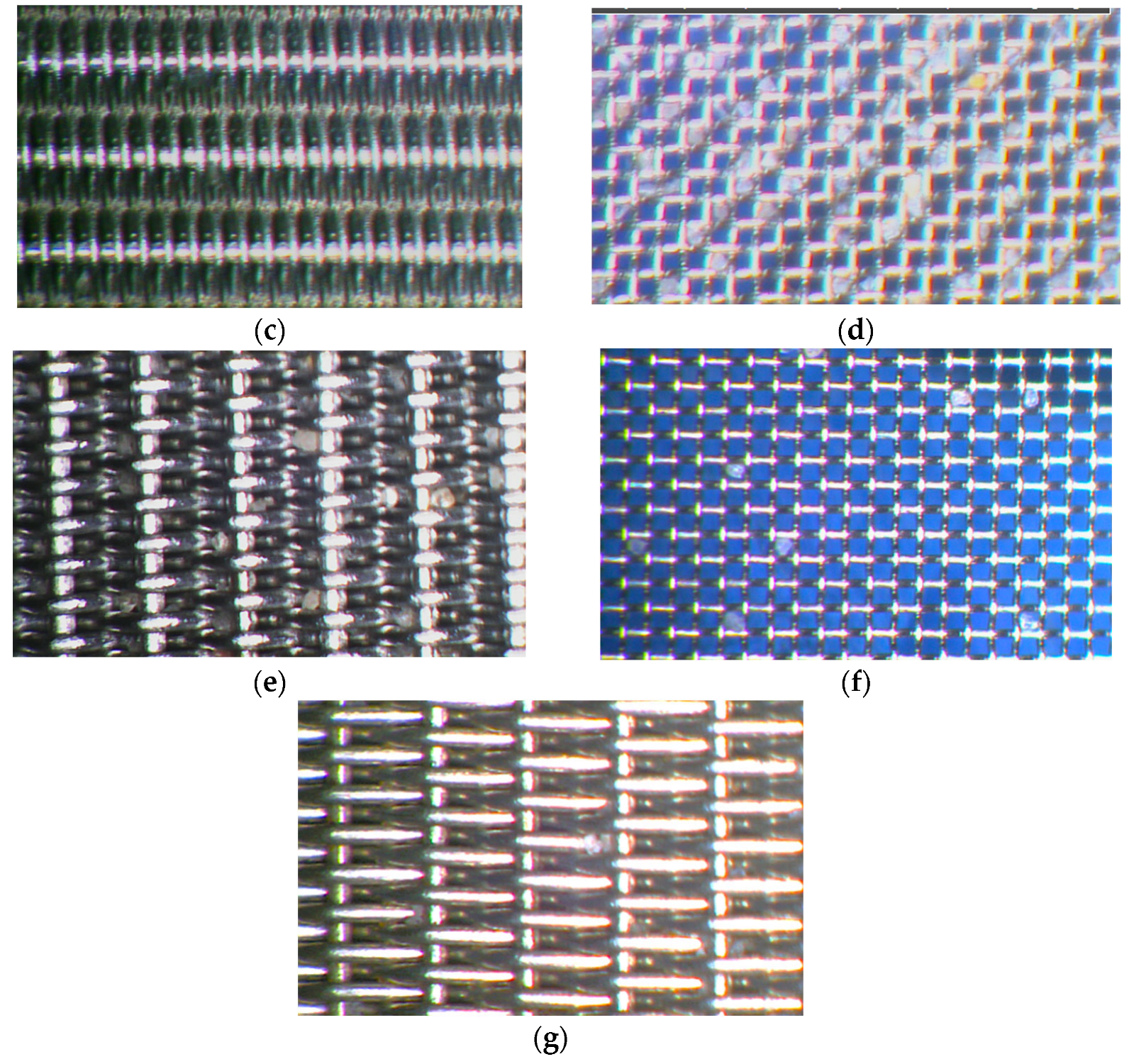

3.1. Filtration Grade and Suspended Solids Removal Efficiency

3.2. Effects of Filtration Rate on Particle Removal Efficiency

4. Discussion

4.1. Filtration Grade and Suspended Solids Removal Efficiency

4.2. Effects of Filtration Rate on Particle Removal Efficiency

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TSS | Total Suspended Solids |

| FM | Flow Meter |

| TT | Temperature Transmitter |

| PTD | Differential Pressure Transmitter |

| DAS | Data Acquisition System |

| PP | Polypropylene |

| NSS | Nylon Super Soft |

| REPS | Reverse Plain Dutch Weave |

References

- ISO 9912-1; Agricultural Irrigation Equipment—Filters for Micro-Irrigation Part 1: Terms, Definitions and Classification. ISO: Geneva, Switzerland, 2024.

- Eyvaz, M.; Arslan, S.; Gürbulak, E.; Yüksel, E. Textile Materials in Liquid Filtration Practices: Current Status and Perspectives in Water and Wastewater Treatment. In Textiles for Advanced Applications; InTech: London, UK, 2017. [Google Scholar]

- Lamm, F.R.; Ayars, J.E.; Nakayama, F.S. Microirrigation for Crop Production Design, Operation, and Management, 1st ed.; Lamm, F.R., Ayars, J.E., Nakayama, F.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Pizarro, F. Riegos Localizados de Alta Frecuencia (RLAF) Goteo, Mícroaspersión, Exudación, 3rd ed.; Mundi-Prensa: Madrid, Spain, 1996. [Google Scholar]

- Azizi, F. On the Pressure Drop of Fluids Through Woven Screen Meshes. Chem. Eng. Sci. 2019, 207, 464–478. [Google Scholar] [CrossRef]

- Yang, G.; Xu, R.; Wang, Y.; Zhu, Y.; Ren, F.; Li, C.; Wu, J. Pore-Scale Numerical Simulations of Flow and Convective Heat Transfer in a Porous Woven Metal Mesh. Chem. Eng. Sci. 2022, 256, 117696. [Google Scholar] [CrossRef]

- Hutten, I.M. Properties of Nonwoven Filter Media. In Handbook of Nonwoven Filter Media; Elsevier: Amsterdam, The Netherlands, 2007; pp. 71–102. [Google Scholar]

- Zobel, S.; Gries, T. The Use of Nonwovens as Filtration Materials. In Applications of Nonwovens in Technical Textiles; Elsevier: Amsterdam, The Netherlands, 2010; pp. 160–183. [Google Scholar]

- McKeen, L.W. Liquid Formulations. In Fluorinated Coatings and Finishes Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 147–170. [Google Scholar]

- Cano, N.D.; de Camargo, A.P.; Muniz, G.L.; Guarnizo, J.A.Y.; Frizzone, J.A. Automatic Flushing Strainer-Type Filter: A Method for Actual Filtration Grade Assessment. J. Irrig. Drain. Eng. 2023, 149, 06023001. [Google Scholar] [CrossRef]

- Bächle, V.; Morsch, P.; Fränkle, B.; Gleiß, M.; Nirschl, H. Interaction of Particles and Filter Fabric in Ultrafine Filtration. Eng 2021, 2, 126–140. [Google Scholar] [CrossRef]

- Duran-Ros, M.; Pujol, J.; Pujol, T.; Cufí, S.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Solid Removal across the Bed Depth in Media Filters for Drip Irrigation Systems. Agriculture 2023, 13, 458. [Google Scholar] [CrossRef]

- Mesquita, M.; de Deus, F.P.; Testezlaf, R.; Diotto, A.V. Removal Efficiency of Pressurized Sand Filters during the Filtration Process. Desalination Water Treat. 2019, 161, 132–143. [Google Scholar] [CrossRef]

- Yu, J.; Li, Y.; Liu, Z.; Zhang, W.; Wang, D. Impact of Loading Rate and Filter Height on the Retention Factor in the Model of Total Coliform (TC) Removal in Direct Rapid Sand Filtration. Desalination Water Treat. 2015, 54, 140–146. [Google Scholar] [CrossRef]

- Cano, N.D.; Camargo, A.P.; Ait-Mouheb, N.; Muniz, G.L.; Guarnizo, J.A.Y.; Pereira, D.J.S.; Frizzone, J.A. Optimisation of the Filter Housing Dimensions of an Automatic Flushing Strainer-Type Filter. Biosyst. Eng. 2022, 219, 25–37. [Google Scholar] [CrossRef]

- APHA; AWWA; WEF. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; Baird, R.B., Eaton, A.D., Rice, E.W., Eds.; APHA: Washington, DC, USA, 2017; Volume 186. [Google Scholar]

- ISO 16889; Hydraulic Fluid Power—Filters—Multi-Pass Method for Evaluating Filtration Performance of a Filter Element. ISO: Vernier, Switzerland, 2022.

- Adin, A.; Elimelech, M. Particle Filtration for Wastewater Irrigation. J. Irrig. Drain. Eng. 1989, 115, 474–487. [Google Scholar] [CrossRef]

- Ribeiro, T.A.P.; Paterniani, J.E.S.; Airoldi, R.P.d.S.; Silva, M.J.M.d. Performance of Non Woven Synthetic Fabric and Disc Filters for Fertirrigation Water Treatment. Sci. Agric. 2004, 61, 127–133. [Google Scholar] [CrossRef][Green Version]

- Purchas, D.B.; Sutherland, K. Screens and Meshes. In Handbook of Filter Media; Elsevier: Amsterdam, The Netherlands, 2002; pp. 201–259. [Google Scholar]

- Rahman, M.A.; Kumar, S.; Islam, M.M.; Takebira, U.M.; Mondal, M.I.H. Metal and Metal-Coated Fibres. In Technical Organic and Inorganic Fibres from Natural Resources; Elsevier: Amsterdam, The Netherlands, 2024; pp. 625–646. ISBN 9780443154591. [Google Scholar]

- Liu, Z.; Long, Y.; Li, J.; Liu, D. Analysis of Three-Dimensional Cake Thickness Structure Characteristics in a Screen Filter for Drip Irrigation Based on the CFD—DEM Coupling Method. Biosyst. Eng. 2025, 250, 1–14. [Google Scholar] [CrossRef]

- Sutherland, K. Filters and Filtration Handbook, 5th ed.; ELSEIVER, Ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Stegmaier, T.; Dauner, M.; Von Arnim, V.; Scherrieble, A.; Dinkel Mann, A.; Planck, H. Nanotechnologies for Coating and Structuring of Textiles. In Nanofibers and Nanotechnology in Textiles; Elsevier: Amsterdam, The Netherlands, 2007; pp. 409–427. [Google Scholar]

- Sparks, T.; Chase, G. Filter Media. In Filters and Filtration Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 55–115. [Google Scholar]

- En-Nabety, L.; Boudi, E.M. Separation Efficiency of a Wastewater Bar Screen Based on a 3D Computational Fluid Dynamics Modeling. Desalination Water Treat. 2024, 320, 100788. [Google Scholar] [CrossRef]

- Bennett, J.D.; Wilson, M.C.T.; Kapur, N.; Jimack, P.K.; Maltby, R.P.; Looney, M.K. Computational Modelling and Experimental Validation of Pressure Drop through Multi-Layered Woven Screens for Polymer Melts. Chem. Eng. Res. Des. 2024, 209, 323–333. [Google Scholar] [CrossRef]

- Ncube, P.; Pidou, M.; Stephenson, T.; Jefferson, B.; Jarvis, P. The Effect of High Hydraulic Loading Rate on the Removal Efficiency of a Quadruple Media Filter for Tertiary Wastewater Treatment. Water Res. 2016, 107, 102–112. [Google Scholar] [CrossRef]

- Ängeslevä, M.; Salmimies, R.; Rideal, G.; Hilden, J.; Wagner, C.; Wiegmann, A.; Häkkinen, A. Comparison of Methods for Measuring and Investigating Water Permeability of Woven Filter Media. Chem. Eng. Res. Des. 2023, 190, 520–535. [Google Scholar] [CrossRef]

- Bilisik, K.; Syduzzaman, M. Knitted Geotextiles. In Advanced Knitting Technology; Elsevier: Amsterdam, The Netherlands, 2021; pp. 345–394. ISBN 9780323855358. [Google Scholar]

- Hassan, M.A.; Yeom, B.Y.; Wilkie, A.; Pourdeyhimi, B.; Khan, S.A. Fabrication of Nanofiber Meltblown Membranes and Their Filtration Properties. J. Memb. Sci. 2013, 427, 336–344. [Google Scholar] [CrossRef]

- Hockenberger, A.S. Surface Modification of Textiles for Composite and Filtration Applications. In Surface Modification of Textiles; Elsevier: Amsterdam, The Netherlands, 2009; pp. 238–268. [Google Scholar]

- Mao, N.; Russell, S.J.; Pourdeyhimi, B. Characterisation, Testing, and Modelling of Nonwoven Fabrics. In Handbook of Nonwovens, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 509–626. ISBN 9780128189122. [Google Scholar]

- Abtew, M.A. A Comprehensive Review on Advancements, Innovations and Applications of 3D Warp Interlock Fabrics and Its Composite Materials. Compos. B Eng. 2024, 278, 111395. [Google Scholar] [CrossRef]

- Khodadadi, A.; Liaghat, G.; Taherzadeh-Fard, A.; Shahgholian-Ghahfarokhi, D. Impact Characteristics of Soft Composites Using Shear Thickening Fluid and Natural Rubber–A Review of Current Status. Compos. Struct. 2021, 271, 114092. [Google Scholar] [CrossRef]

- Patel, D.K.; Waas, A.M.; Yen, C.F. Direct Numerical Simulation of 3D Woven Textile Composites Subjected to Tensile Loading: An Experimentally Validated Multiscale Approach. Compos. B Eng. 2018, 152, 102–115. [Google Scholar] [CrossRef]

- Gao, Z.; Chen, L. A Review of Multi-Scale Numerical Modeling of Three-Dimensional Woven Fabric. Compos. Struct. 2021, 263, 113685. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, L.; Li, Z.; Huang, K.; Guo, L. Experimental Characterization Methods and Numerical Models of Woven Composite Preforms: A Review. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108329. [Google Scholar] [CrossRef]

- Fan, W.; Dong, J.; Wei, B.; Zhi, C.; Yu, L.; Xue, L.; Dang, W.; Li, L. Fast and Accurate Bending Modulus Prediction of 3D Woven Composites via Experimental Modal Analysis. Polym. Test. 2019, 78, 105938. [Google Scholar] [CrossRef]

- Sahami, M.; Jamaati, J.; Bahiraei, M. A Computational Model for Predicting Filtration Performance of 3D-Magnetic Filters Under Different Channel Geometries, Particle Sizes and Flow Conditions. Colloids Surf. A Physicochem. Eng. Asp. 2021, 611, 125844. [Google Scholar] [CrossRef]

- Sheng, Y.; Zhang, L.; Wang, Y.; Miao, Z. Exploration of a Novel Three-Dimensional Knitted Spacer Air Filter with Low Pressure Drop on Cooking Fume Particles Removal. Build. Environ. 2020, 177, 106903. [Google Scholar] [CrossRef]

- Sun, C.; Negro, E.; Nale, A.; Pagot, G.; Vezzù, K.; Zawodzinski, T.A.; Meda, L.; Gambaro, C.; Noto, V. An efficient barrier toward vanadium crossover in redox flow batteries: The bilayer [Nafion/(WO3)x] hybrid inorganic-organic membrane. Electrochim. Acta 2021, 378, 138133. [Google Scholar] [CrossRef]

| ID | Material | Weave Type | Additional Specifications |

|---|---|---|---|

| REPS 14/102 | AISI 304 stainless steel | REPS | Wire diameter: 0.40/0.28 mm |

| T80 | AISI 304 stainless steel | Square twill weave | Number of openings per inch: 80; Wire diameter: 0.14 mm |

| REPS 16/126 | AISI 304 stainless steel | REPS | Wire diameter: 0.36/0.23 mm |

| N12 | Nylon (NSS polyamide) | NSS-12 | Number of openings per inch: 112; Wire diameter: 60 µm |

| T120 | AISI 304 stainless steel | Square twill weave | Number of openings per inch: 120; Wire diameter: 0.10 mm |

| PP120 | Polypropylene | Satin weave | Monofilament weave; Basis weight: 300 g/m2; Thickness: 0.57 mm; Air permeability: 40 m3 m−2 min−1 |

| R120 | AISI 304 stainless steel | REPS | Number of openings per inch: 24–110; Wire diameter: 0.38–0.26 mm |

| T150 | AISI 304 stainless steel | Square twill weave | Number of openings per inch: 150; Wire diameter: 0.06 mm |

| R150 | AISI 304 stainless steel | REPS | Number of openings per inch: 30–150; Wire diameter: 0.23–0.18 mm |

| PP200 | Polypropylene | Twill weave | Monofilament weave; Basis weight: 300 g/m2; Thickness: 0.58 mm; Air permeability: 40 m3 m−2 min−1 |

| PP240 | Polypropylene | Satin weave | Monofilament weave; Basis weight: 300 g/m2; Thickness: 0.57 mm; Air permeability: 40 m3 m−2 min−1 |

| ID | Manufacturer-Specified Filtration Grade (μm) | Test Flow Rate (m3 h−1) | Flow Rate (m3 h−1) | ||

|---|---|---|---|---|---|

| 50 | 100 | 50 | 100 | ||

| Experimentally Determined Filtration Grade (μm) | Filter Performance Classification | ||||

| REPS 14/102 | 250 | 177 | 250 | High | High |

| T80 | 177 | 149 | 177 | High | Moderate |

| REPS 16/126 | 177 | 177 | 177 | Moderate | Moderate |

| N12 | 125 | 88 | 88 | High | High |

| T120 | 125 | 105 | 105 | High | Moderate |

| PP120 | 125 | 74 | 88 | High | High |

| R120 | 125 | 125 | 125 | Moderate | Moderate |

| T150 | 105 | 125 | 125 | Moderate | Moderate |

| R150 | 105 | 105 | 105 | Moderate | Moderate |

| PP200 | 74 | 88 | 125 | Low | Low |

| PP240 | 63 | 149 | 149 | Low | Low |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guarnizo, J.A.Y.; Muniz, G.L.; Cano, N.D.; Benitez, J.S.; Camargo, A.P.d. Determination of Filtration Grade in Woven Screen Filters: Influence of Material, Weave Pattern, and Filtration Rate. AgriEngineering 2025, 7, 292. https://doi.org/10.3390/agriengineering7090292

Guarnizo JAY, Muniz GL, Cano ND, Benitez JS, Camargo APd. Determination of Filtration Grade in Woven Screen Filters: Influence of Material, Weave Pattern, and Filtration Rate. AgriEngineering. 2025; 7(9):292. https://doi.org/10.3390/agriengineering7090292

Chicago/Turabian StyleGuarnizo, Jhonnatan Alexander Yepes, Gustavo Lopes Muniz, Nicolás Duarte Cano, Juliana Sanchez Benitez, and Antonio Pires de Camargo. 2025. "Determination of Filtration Grade in Woven Screen Filters: Influence of Material, Weave Pattern, and Filtration Rate" AgriEngineering 7, no. 9: 292. https://doi.org/10.3390/agriengineering7090292

APA StyleGuarnizo, J. A. Y., Muniz, G. L., Cano, N. D., Benitez, J. S., & Camargo, A. P. d. (2025). Determination of Filtration Grade in Woven Screen Filters: Influence of Material, Weave Pattern, and Filtration Rate. AgriEngineering, 7(9), 292. https://doi.org/10.3390/agriengineering7090292