Adaptation of Grain Cleaning Equipment for Kalonji and Sesame Seeds

Abstract

1. Introduction

2. Methodology

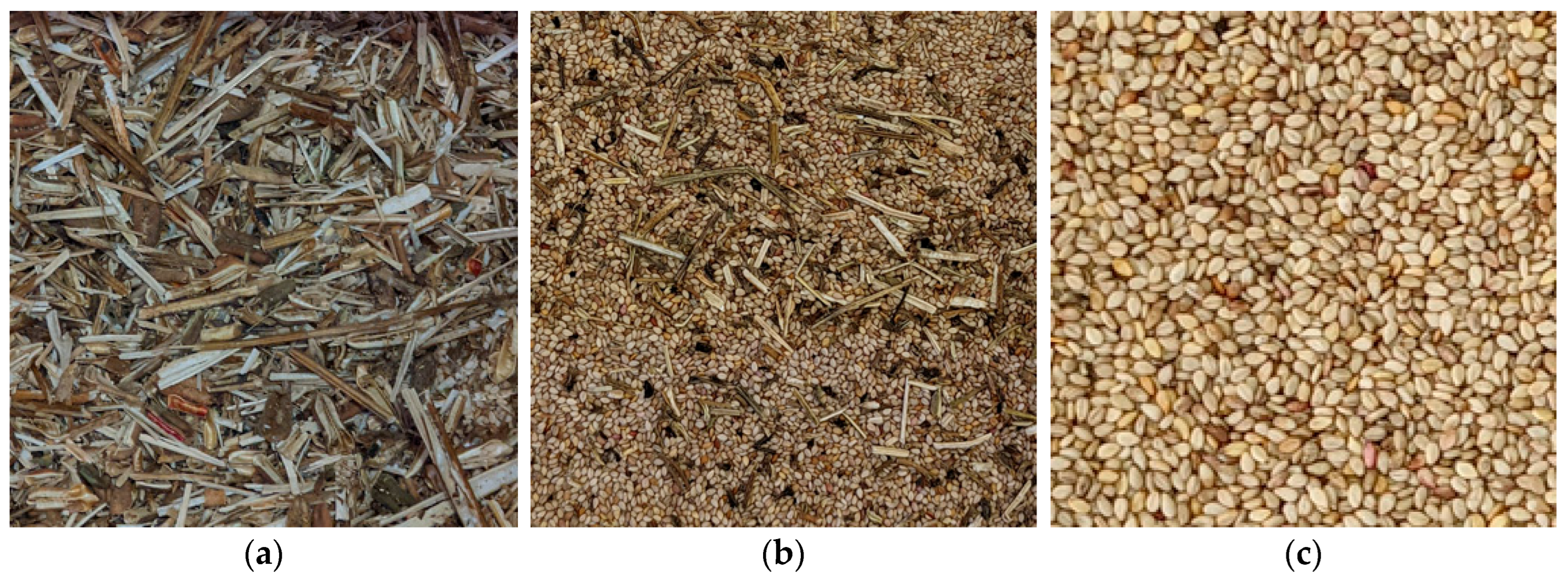

2.1. Research Materials

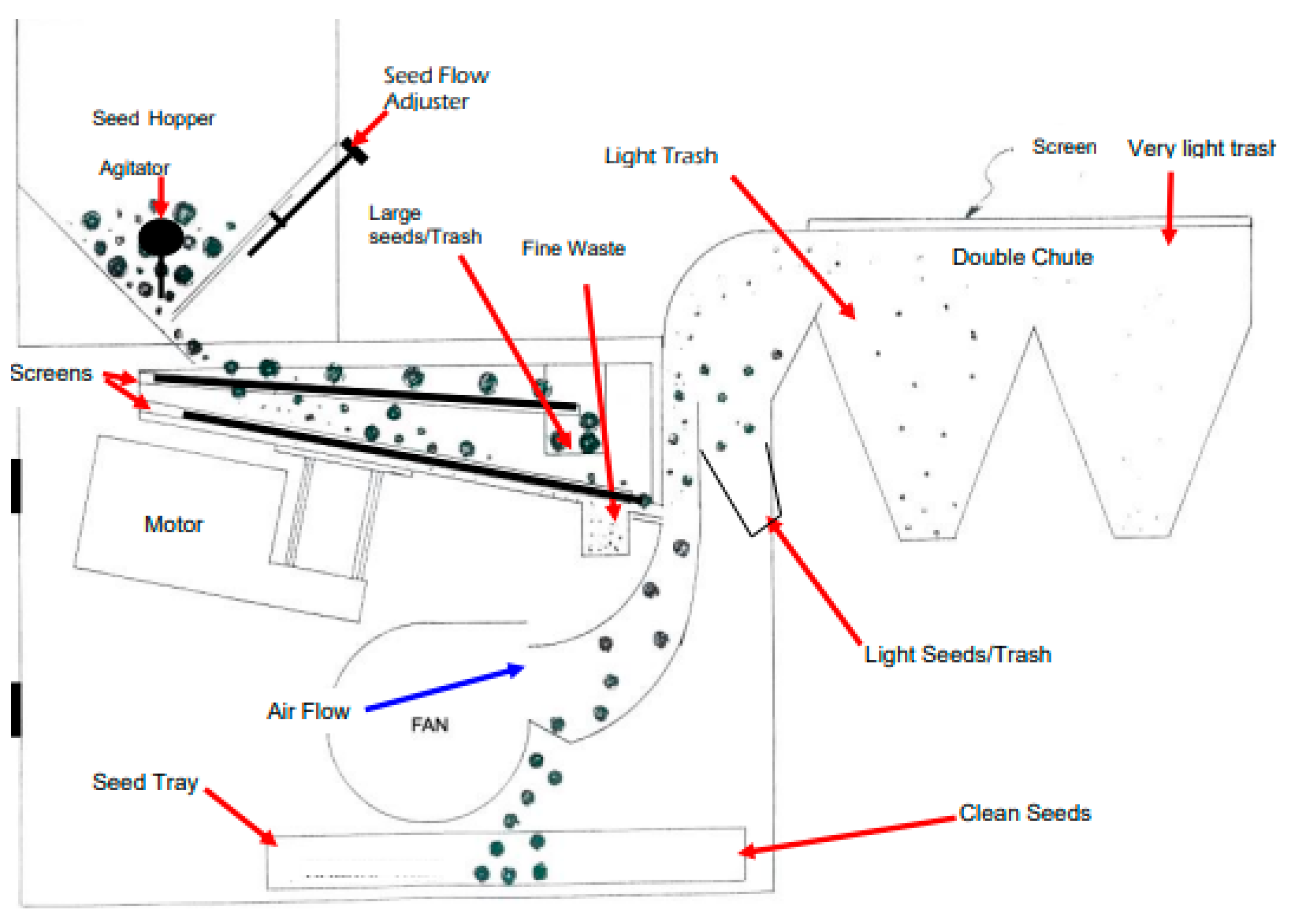

2.2. Cleaning Equipment

2.3. Experimental Design and Procedure

2.4. Performance Parameters and Calculations

3. Results

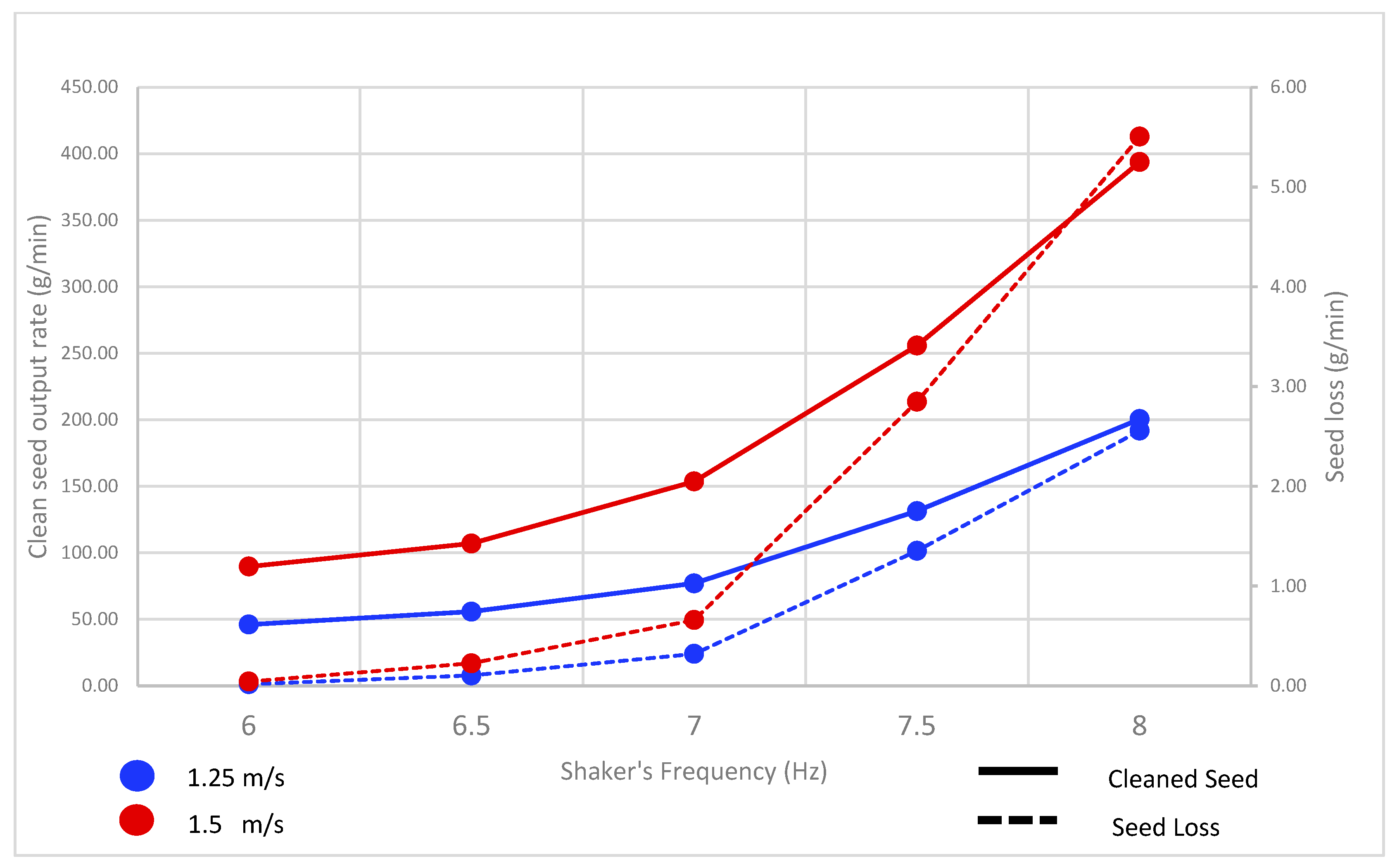

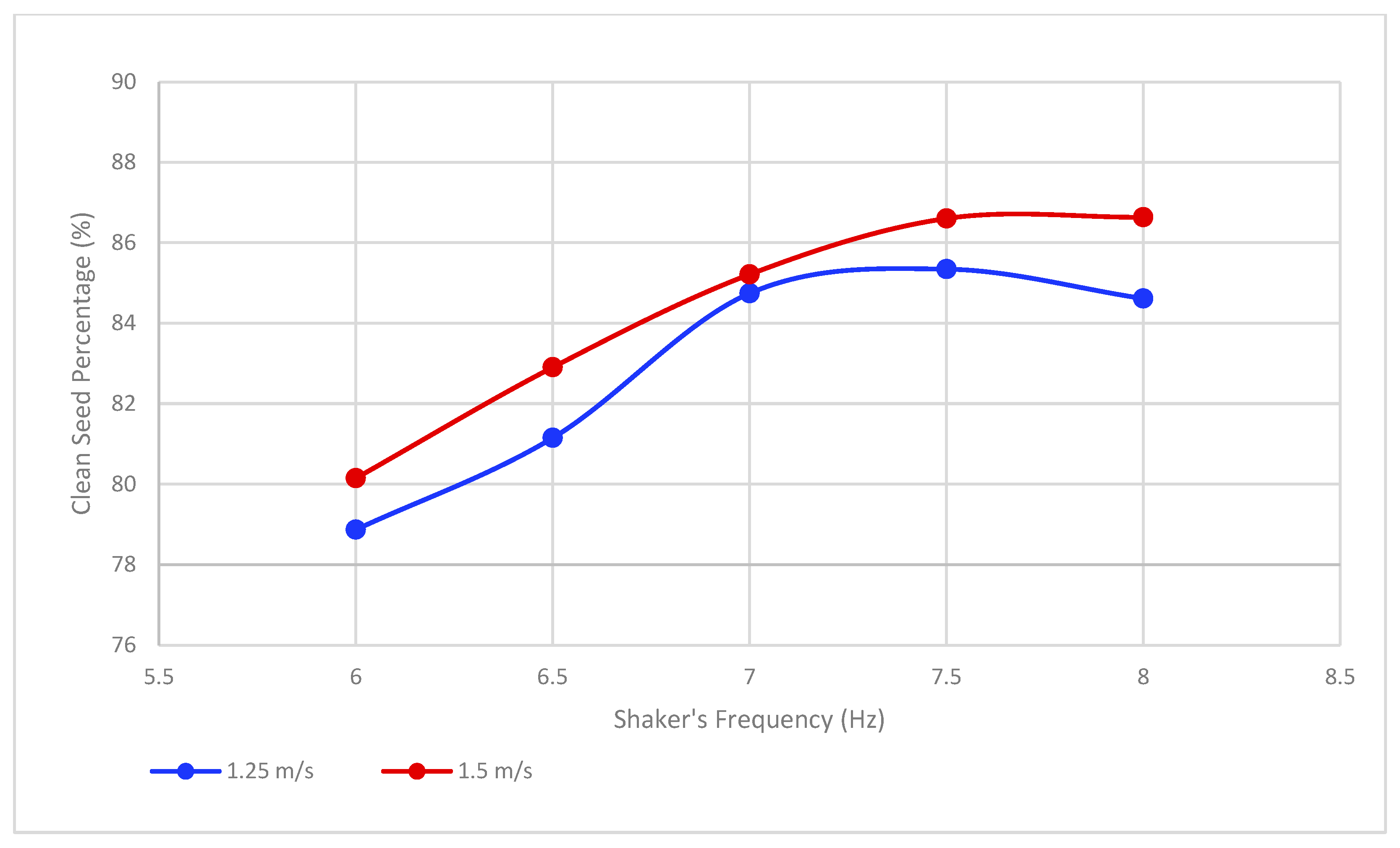

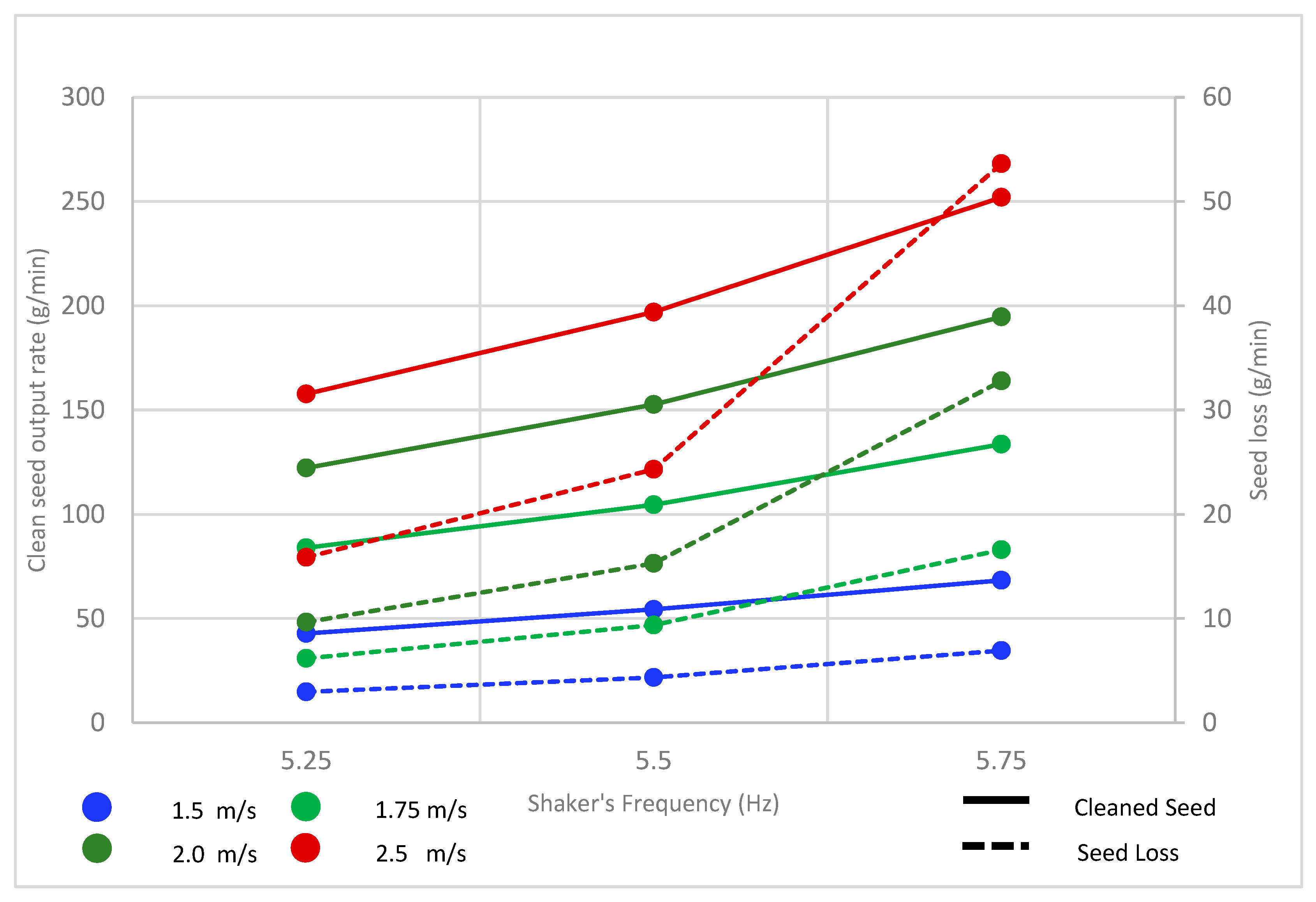

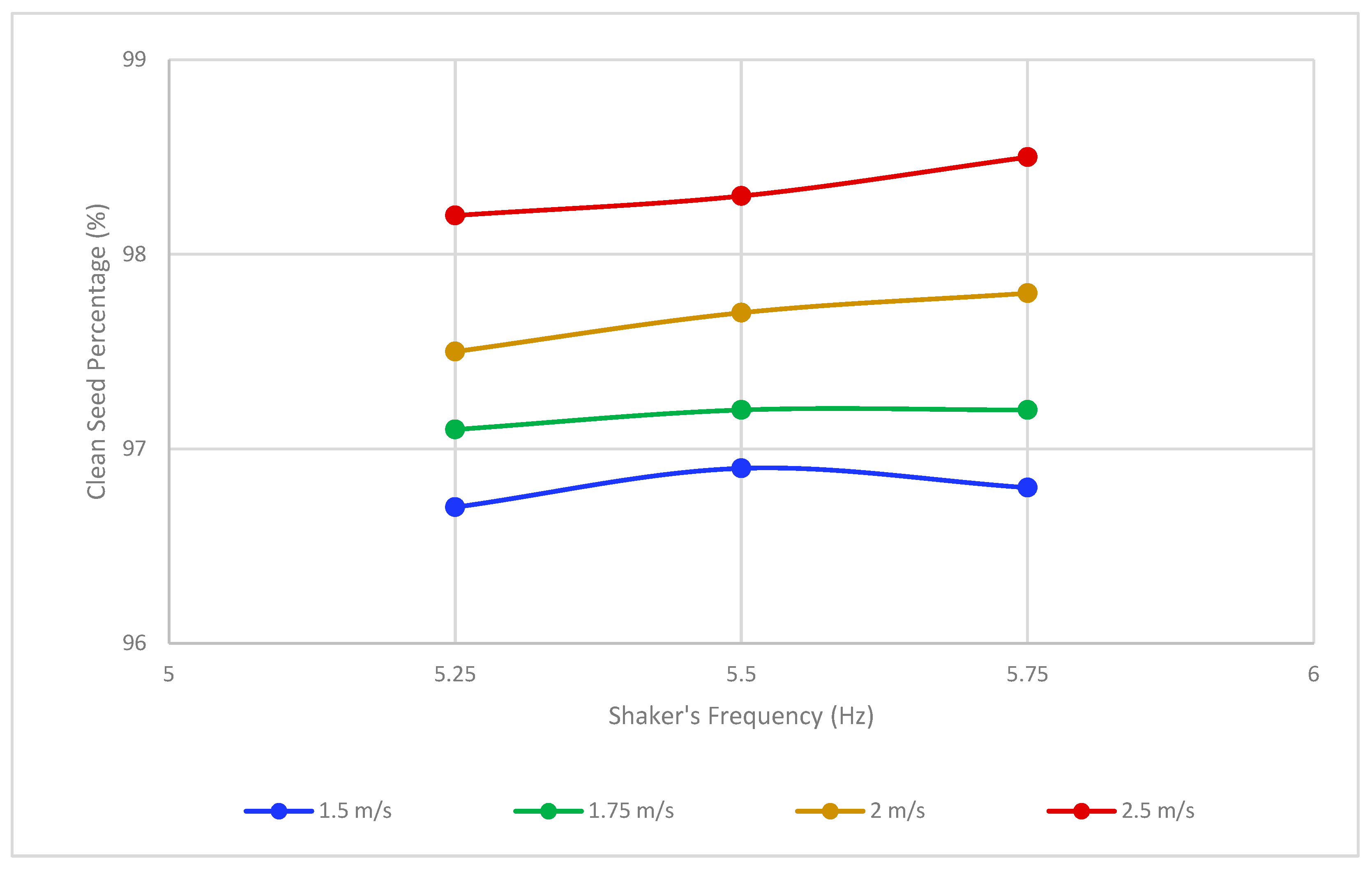

3.1. Sesame Cleaning Results

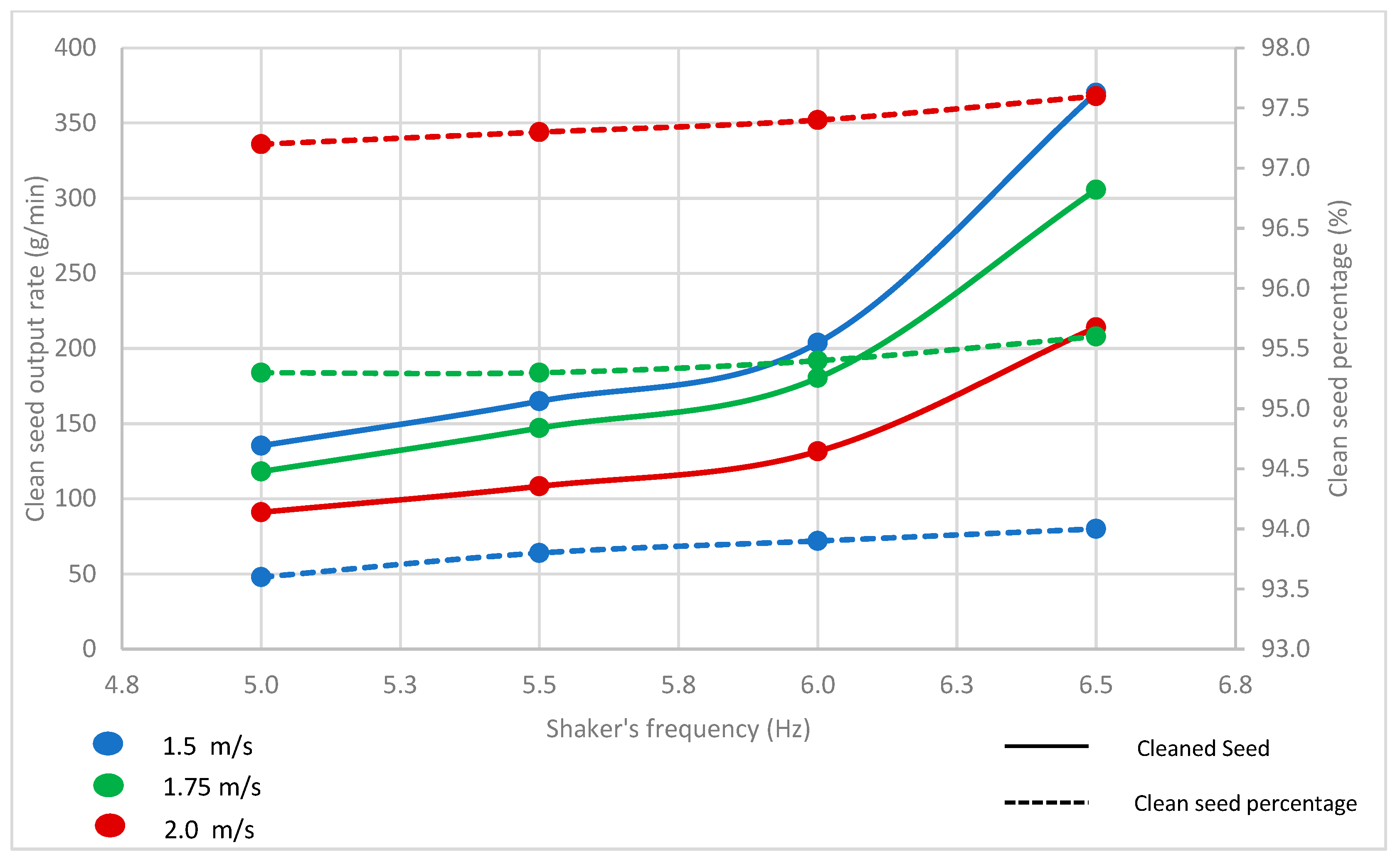

3.2. Result of Cleaning Kalonji

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Astanakulov, K.; Karimov, Y.Z.; Fozilov, G. Design of a grain cleaning machine for small farms. AMA-Agric. Mech. Asia Afr. Lat. Am. 2011, 42, 37. [Google Scholar]

- Elsayed, A.; Abd EL-Wahab, M.; Hanan, M.; Abd Allah, W. Performance cleaning unit for sesame and clover seeds affecting some physical and mechanical properties. Agric. Eng. Int. CIGR J. 2023, 25, 296–311. [Google Scholar]

- Tunde-Akintunde, T.; Akintunde, B. Some physical properties of sesame seed. Biosyst. Eng. 2004, 88, 127–129. [Google Scholar] [CrossRef]

- Al-Mahasneh, M.A.; Ababneh, H.A.; Rababah, T. Some engineering and thermal properties of black cumin (Nigella sativa L.) seeds. Int. J. Food Sci. Technol. 2008, 43, 1047–1052. [Google Scholar] [CrossRef]

- Afify, M.; El-Sharabasy, M.; Ali, M. Development of a local threshing machine suits for threshing black seed (Nigella sativa). Misr J. Agric. Eng. 2007, 24, 699–724. [Google Scholar]

- Liu, X.; Li, X. The Influence of Agricultural Production Mechanization on Grain Production Capacity and Efficiency. Processes 2023, 11, 487. [Google Scholar] [CrossRef]

- Giyevskiy, A.; Orobinsky, V.; Tarasenko, A.; Chernyshov, A.; Kurilov, D. Substantiation of basic scheme of grain cleaning machine for preparation of agricultural crops seeds. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 042035. [Google Scholar] [CrossRef]

- Potts, H. Considerations in Cleaning and Processing Seed. In Proceedings of the Short Course for Seedsmen, Starkville, MS, USA, 11–13 April 1988. [Google Scholar]

- Narayanan, R.; Bhattarai, S.; Tram, V.H.; Hunter, L. Adapting grain crop seed threshing equipment for processing sesame for streamlining the mechanisation of post-harvest operations. IOP Conf. Ser. Earth Environ. Sci. 2024, 1290, 012015. [Google Scholar] [CrossRef]

- Langham, D. Technologies Used in the Cultivation of Mechanized Sesame (Sesamum indicum L.); Abarriguda: Campina Grande, Brazil, 2019. [Google Scholar]

- Singh, R.; Vishwakarma, R.; Vishal, M.; Singh, S.; Saharan, V. Moisture dependent physical properties of nigella seeds. Afr. J. Agric. Res. 2015, 10, 58–66. [Google Scholar]

- Kimseed. Seed Cleaner Mk3; Kimseed: Wangara, Australia, 2019; Volume 2025. [Google Scholar]

- Ishpekov, S.S. Releasing of seeds by a lateral mechanical impact for feeding sesame stems into harvester. Agric. Eng. Int. CIGR J. 2017, 19, 54–60. [Google Scholar]

- Thakur, S.; Kaurav, H.; Chaudhary, G. Nigella sativa (Kalonji): A black seed of miracle. Int. J. Res. Rev. 2021, 8, 342–357. [Google Scholar] [CrossRef]

- Zhang, H.; Langham, D.R.; Miao, H. Economic and academic importance of sesame. In The Sesame Genome; Springer: Cham, Switzerland, 2021; pp. 1–18. [Google Scholar]

- Pearce, D.; Jiang, T. Prospects for Australian Emerging Industries; Agrifutures: Wagga Wagga, Australia, 2023. [Google Scholar]

- Al-Shamiry, F.M.S.; Yahya, N.M.A. The performance evaluating of thresher machine attached to the tractor. IJRDO-J. Agric. Res. 2020, 6, 7–16. [Google Scholar]

- Badr, M. Manufacture and performance evaluation of a local threshing and cleaning machine suits medicinal and aromatic plants. Misr J. Agric. Eng. 2012, 29, 927–950. [Google Scholar] [CrossRef]

- Simonyan, J.; Yiljep, D. Investigating grain separation and cleaning efficiency distribution of a conventional stationary rasp-bar sorghum thresher. Agric. Eng. Int. CIGR J. 2008, X. [Google Scholar]

- Kharitonov, M.; Gievsky, A.; Orobinsky, V.; Chernyshov, A.; Baskakov, I. Studying the design and operational parameters of the sieve module of the grain cleaning machine. IOP Conf. Ser. Earth Environ. Sci. 2020, 488, 012021. [Google Scholar] [CrossRef]

- Ali, M.A.; Abd El-Rahman, E.; Nasr, G.E.-D. Design and assessment of a small-scale machine for cleaning wheat grains. Acta Technol. Agric. 2022, 25, 13–19. [Google Scholar] [CrossRef]

- Ghonimy, M.; Rostom, M. Design and performance evaluation of canola-seed cleaning machine. Turk. J. Agric. Eng. Res. 2022, 3, 214–230. [Google Scholar] [CrossRef]

- Hanna, S.; El_Ashmawy, N.M. Selection of the main factors affecting cleaning and grading fennel seeds at inclined sieve oscillation. Misr J. Agric. Eng. 2010, 27, 628–643. [Google Scholar] [CrossRef]

| Parameter Name | Value |

|---|---|

| Number of sieves | 2 |

| Diameter of the top sieve | 380 mm |

| Diameter of the bottom sieve | 247 mm |

| Hole dimension—top sieve | 2.5 mm |

| Hole dimension—bottom sieve | 1.6 mm |

| Hopper height | 1.4 m |

| Vibration frequency | 0.1–10 Hz |

| Airflow | 0.1–10 m/s |

| Hopper volume | 0.018 m3 |

| Angle of inclination of the sieve | 7.3 degree |

| Trial | Setting Parameters | Results | ||||

|---|---|---|---|---|---|---|

| Shaker Frequency (Hz) | Airflow (m/s) | Operation Time (s) | Clean Seed per Hour (g/min) | Seed Loss per Hour (g/min) | Clean Seed Percentage (%) | |

| 1 | 6 | 1.25 | 185 | 46.05 | 0.02 | 78.87 |

| 2 | 6 | 1.5 | 180 | 43.67 | 0.03 | 80.15 |

| 3 | 6.5 | 1.25 | 140 | 55.71 | 0.10 | 81.15 |

| 4 | 6.5 | 1.5 | 137 | 51.24 | 0.12 | 82.91 |

| 5 | 7 | 1.25 | 92 | 76.96 | 0.32 | 84.75 |

| 6 | 7 | 1.5 | 90 | 76.67 | 0.34 | 85.22 |

| 7 | 7.5 | 1.25 | 53 | 131.32 | 1.35 | 85.34 |

| 8 | 7.5 | 1.5 | 54 | 124.44 | 1.49 | 86.61 |

| 9 | 8 | 1.25 | 35 | 200.57 | 2.56 | 86.32 |

| 10 | 8 | 1.5 | 37 | 193.33 | 2.95 | 86.64 |

| Trial | Setting Parameters | Results | ||||

|---|---|---|---|---|---|---|

| Shaker Frequency (Hz) | Airflow (m/s) | Operation Time (s) | Clean Seed (g/min) | Seed Loss (g/min) | Clean Seed Percentage (%) | |

| 1 | 5.25 | 1.5 | 14 | 42.86 | 2.99 | 96.70 |

| 2 | 5.25 | 1.75 | 14 | 41.10 | 3.21 | 97.10 |

| 3 | 5.25 | 2 | 14 | 38.32 | 3.48 | 97.50 |

| 4 | 5.25 | 2.5 | 14 | 35.47 | 6.21 | 98.20 |

| 5 | 5.5 | 1.5 | 10 | 54.40 | 4.36 | 96.90 |

| 6 | 5.5 | 1.75 | 11 | 50.20 | 5.02 | 97.20 |

| 7 | 5.5 | 2 | 10 | 48.08 | 5.92 | 97.70 |

| 8 | 5.5 | 2.5 | 11 | 44.31 | 9.02 | 98.30 |

| 9 | 5.75 | 1.5 | 8 | 68.35 | 6.94 | 96.80 |

| 10 | 5.75 | 1.75 | 8 | 65.31 | 9.66 | 97.20 |

| 11 | 5.75 | 2 | 8 | 61.06 | 16.19 | 97.80 |

| 12 | 5.75 | 2.5 | 8 | 57.32 | 20.84 | 98.50 |

| Trial | Setting Parameters | Results | ||||

|---|---|---|---|---|---|---|

| Shaker Frequency (Hz) | Airflow (m/s) | Operation Time (s) | Clean Seed (g/min) | Seed Loss (g/min) | Clean Seed Percentage (%) | |

| 1 | 5 | 1 | 195 | 135.38 | 4.68 | 93.61 |

| 2 | 5 | 1.5 | 196 | 118.16 | 7.44 | 95.28 |

| 3 | 5 | 1.75 | 193 | 91.09 | 10.40 | 97.18 |

| 4 | 5.5 | 1 | 156 | 165.00 | 6.86 | 93.81 |

| 5 | 5.5 | 1.5 | 155 | 147.10 | 10.00 | 95.32 |

| 6 | 5.5 | 1.75 | 155 | 108.39 | 13.53 | 97.27 |

| 7 | 6 | 1 | 123 | 203.90 | 9.64 | 93.91 |

| 8 | 6 | 1.5 | 125 | 180.48 | 13.13 | 95.43 |

| 9 | 6 | 1.75 | 124 | 131.61 | 17.65 | 97.38 |

| 10 | 6.5 | 1 | 65 | 370.15 | 19.64 | 94.03 |

| 11 | 6.5 | 1.5 | 64 | 305.63 | 28.50 | 95.58 |

| 12 | 6.5 | 1.75 | 65 | 214.15 | 35.78 | 97.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narayanan, R.; Tram, V.H.; Trotter, T.; Rixon, C.; Raveendran, G.; Umansky, F.; Bhattarai, S.P. Adaptation of Grain Cleaning Equipment for Kalonji and Sesame Seeds. AgriEngineering 2025, 7, 179. https://doi.org/10.3390/agriengineering7060179

Narayanan R, Tram VH, Trotter T, Rixon C, Raveendran G, Umansky F, Bhattarai SP. Adaptation of Grain Cleaning Equipment for Kalonji and Sesame Seeds. AgriEngineering. 2025; 7(6):179. https://doi.org/10.3390/agriengineering7060179

Chicago/Turabian StyleNarayanan, Ramadas, Vu Hoan Tram, Tieneke Trotter, Charissa Rixon, Gowrishankaran Raveendran, Federico Umansky, and Surya P. Bhattarai. 2025. "Adaptation of Grain Cleaning Equipment for Kalonji and Sesame Seeds" AgriEngineering 7, no. 6: 179. https://doi.org/10.3390/agriengineering7060179

APA StyleNarayanan, R., Tram, V. H., Trotter, T., Rixon, C., Raveendran, G., Umansky, F., & Bhattarai, S. P. (2025). Adaptation of Grain Cleaning Equipment for Kalonji and Sesame Seeds. AgriEngineering, 7(6), 179. https://doi.org/10.3390/agriengineering7060179