Agri-Eco Energy: Evaluating Non-Edible Binders in Coconut Shell Biochar and Cinnamon Sawdust Briquettes for Sustainable Fuel Production

Abstract

1. Introduction

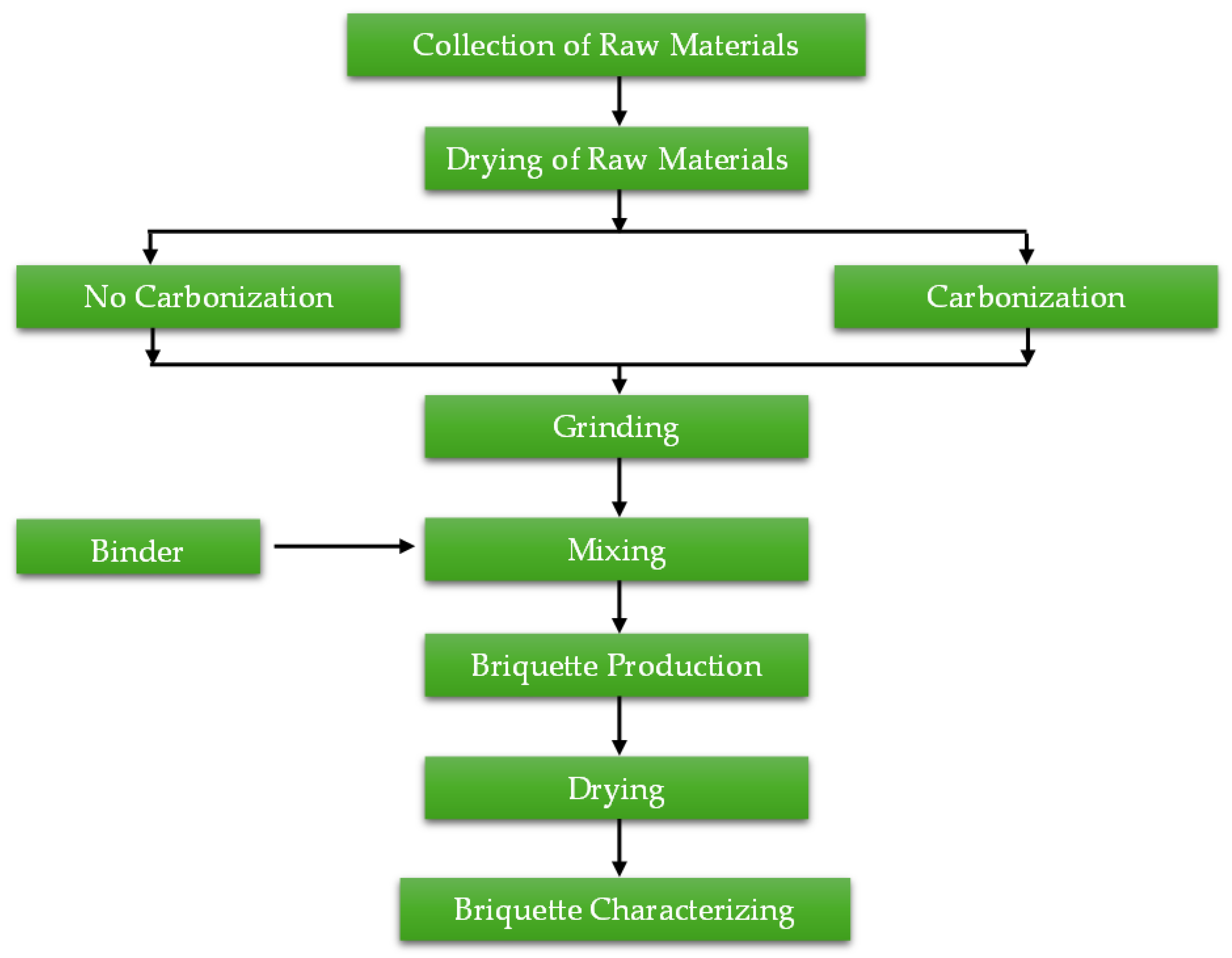

2. Methodology

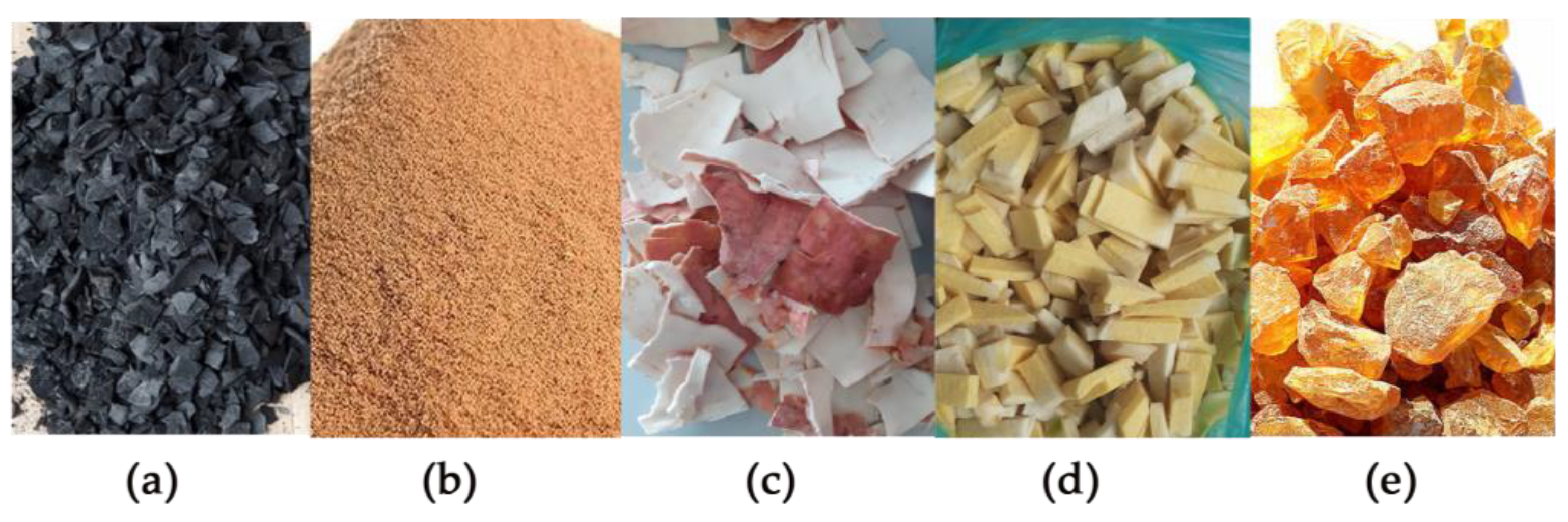

2.1. Material Preparation and Briquette Formulation

2.1.1. Carbonization Process

2.1.2. Crushing/Size Reduction of Char

2.1.3. Sieving of Charcoal Powder and Cinnamon Wood Sawdust

2.1.4. Preparation of Adhesives

2.1.5. Mixing Charcoal, Cinnamon Wood Sawdust, and Adhesives

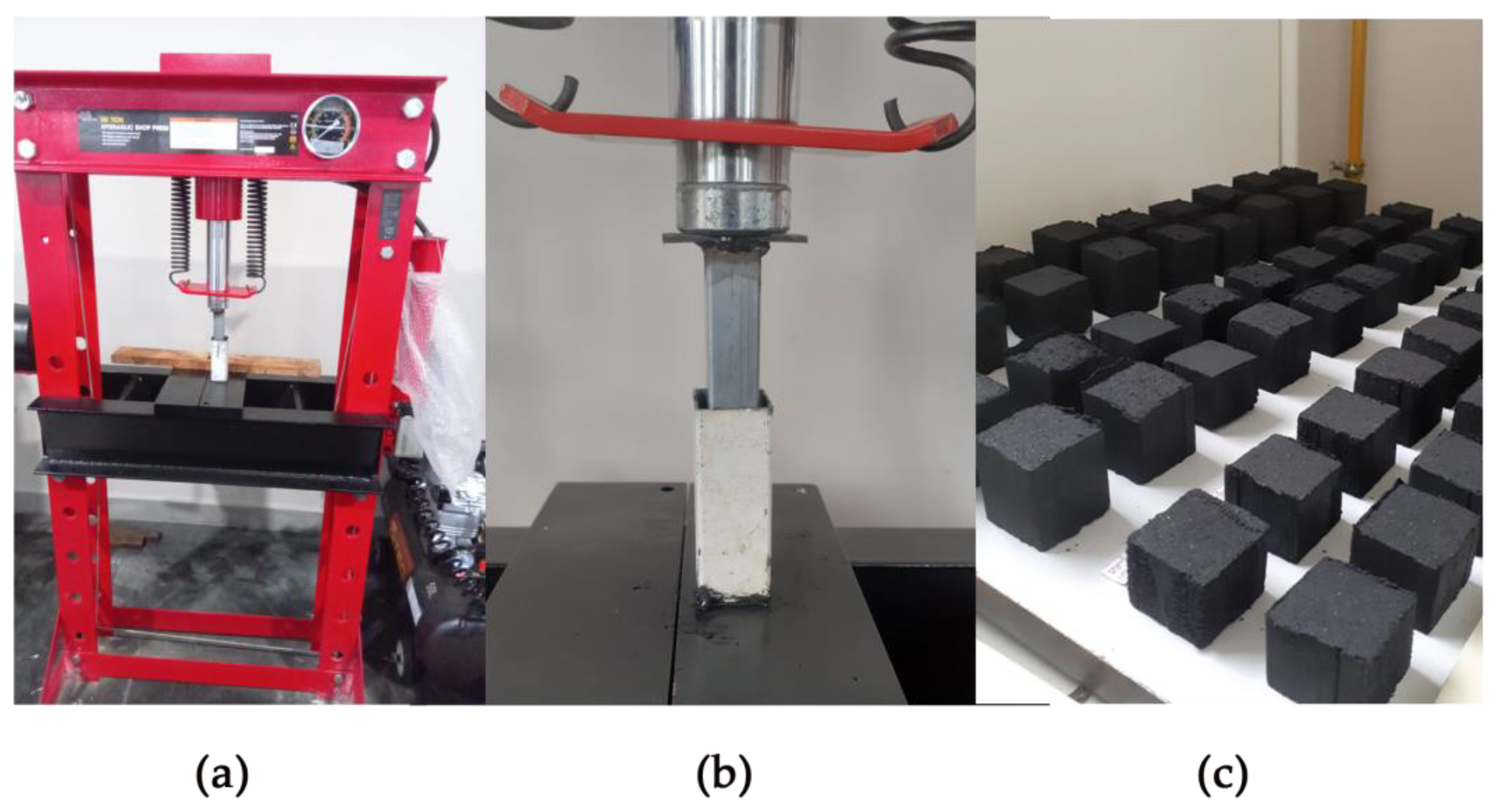

2.2. Molding of Briquettes

2.3. Drying of Briquettes

2.4. Evaluation of Briquette Combustion Properties

2.5. Cost–Benefit Analysis of Briquette Production and Activated Carbon Production

3. Results and Discussion

3.1. Pyrolysis of Coconut Shells

3.2. Evaluation of Briquette Combustion Properties

3.2.1. Calorific Values (CV) of Different Briquette Compositions

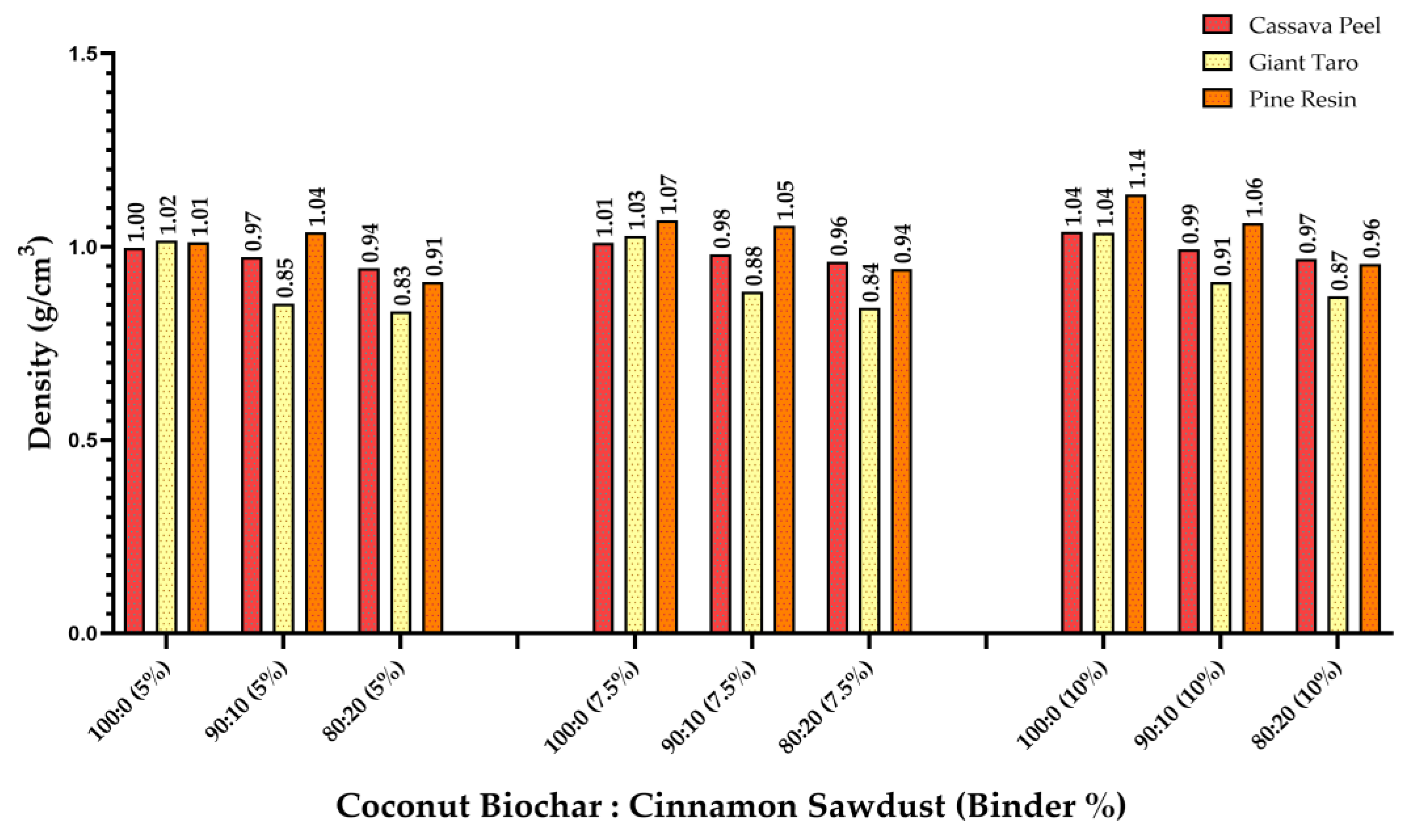

3.2.2. Density of Different Briquette Compositions

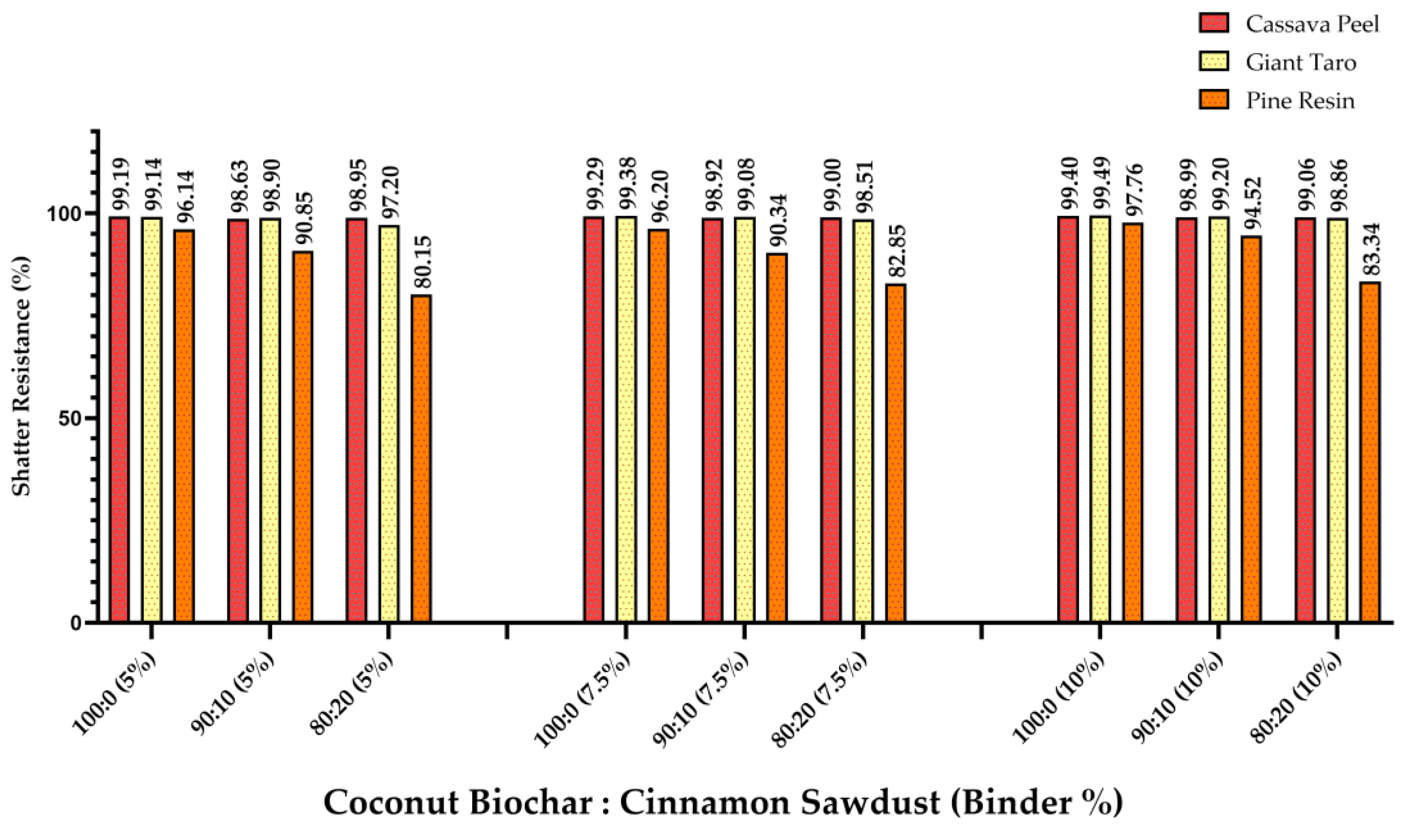

3.2.3. Shatter Index of Different Briquette Compositions

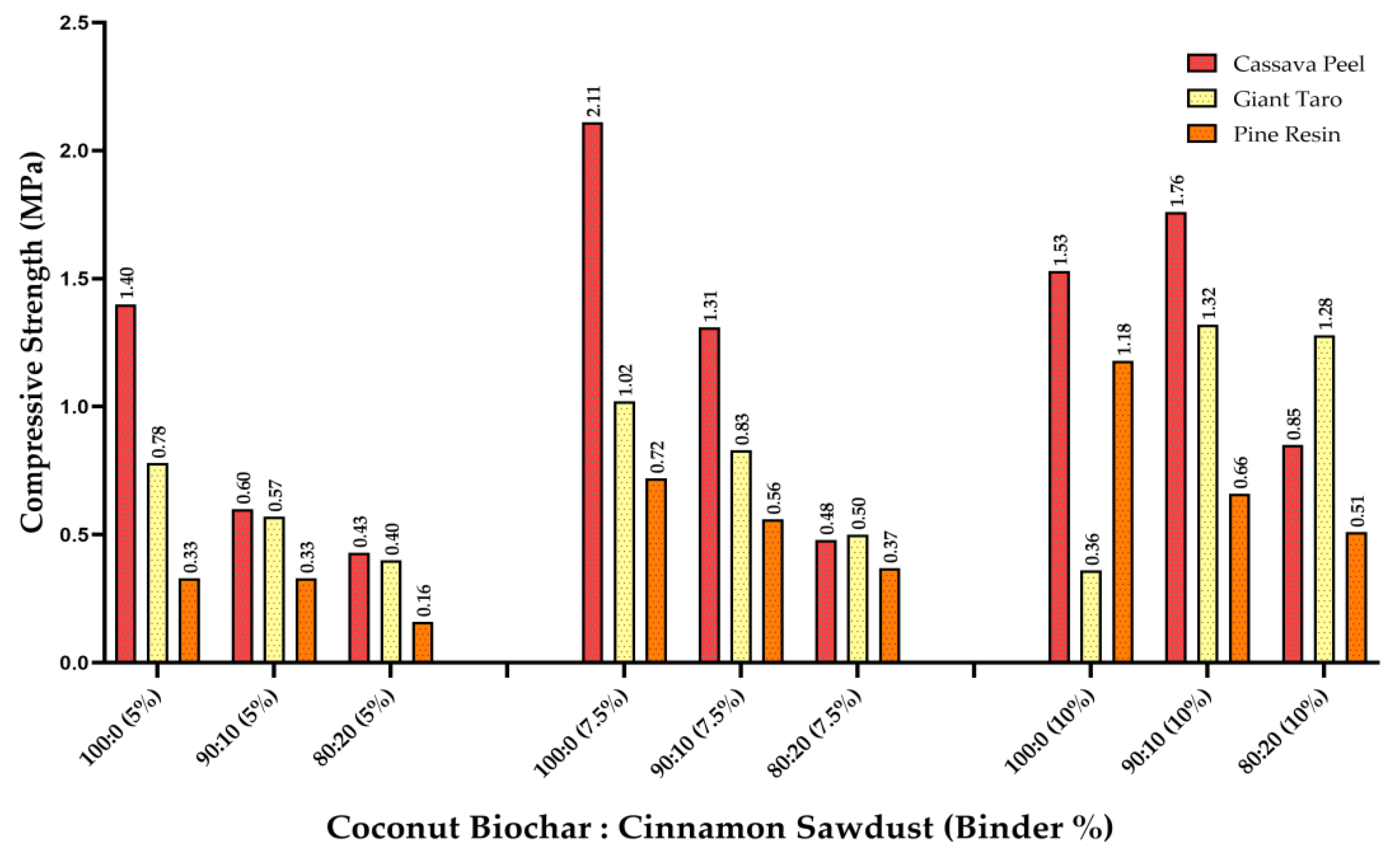

3.2.4. Compressive Strength of Different Briquette Compositions

3.2.5. Comparison of Briquette Performance with Common Standards

3.2.6. Proximate Analysis of Different Briquette Compositions

3.2.7. Comparison of Key Properties of Coconut Shell Briquettes and Other Biomass Briquettes

3.3. Suitability of Briquettes of Different Compositions

3.4. Cost–Benefit Analysis Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| BS EN | British Standard European Norm (UK/Europe) |

| C | Carbon |

| CH4 | Methane |

| CH3OH | Methanol |

| CnHm | Hydrocarbons |

| CO | Carbon Monoxide |

| CO₂ | Carbon Dioxide |

| CV | Calorific Value |

| EU | European Union |

| g/cm3 | Grams per cubic centimeter |

| GHG | Greenhouse Gas |

| H2 | Hydrogen |

| H2O | Water |

| JIS | Japanese Industrial Standards |

| MJ | Mega Joules |

| LKR | Sri Lankan Rupee |

| MPa | Megapascals |

| NS | Not Specified |

| O2 | Oxygen |

| SANS | South African National Standards |

| SNI | Standar Nasional Indonesia (Indonesian National Standard) |

References

- Soeherman, G.P.; Putri, P.G.; Joen, D.A.Z.; Indrawan, I.; Pratiwi, N. Characterization of Biobriquette from Carbonized Durian Peel Using Coconut Shell as the Binder. AJARCDE (Asian J. Appl. Res. Community Dev. Empower.) 2023, 7, 129–135. [Google Scholar] [CrossRef]

- Ezéchiel, K.; Joel, T.K.; Abdon, A.; Roger, D.D. Accessibility and Effects of Binder Types on the Physical and Energetic Properties of Ecological Coal. Heliyon 2022, 8, e11410. [Google Scholar] [CrossRef] [PubMed]

- Ajimotokan, H.A.; Ehindero, A.O.; Ajao, K.S.; Adeleke, A.A.; Ikubanni, P.P.; Shuaib-Babata, Y.L. Combustion Characteristics of Fuel Briquettes Made from Charcoal Particles and Sawdust Agglomerates. Sci. Afr. 2019, 6, e00202. [Google Scholar] [CrossRef]

- Kabir Ahmad, R.; Anwar Sulaiman, S.; Yusup, S.; Sham Dol, S.; Inayat, M.; Aminu Umar, H. Exploring the Potential of Coconut Shell Biomass for Charcoal Production. Ain Shams Eng. J. 2022, 13, 101499. [Google Scholar] [CrossRef]

- Roman, K.; Grzegorzewska, E. Biomass Briquetting Technology for Sustainable Energy Solutions: Innovations in Forest Biomass Utilization. Energies 2024, 17, 6392. [Google Scholar] [CrossRef]

- Deshannavar, U.B.; Hegde, P.G.; Dhalayat, Z.; Patil, V.; Gavas, S. Production and Characterization of Agro-Based Briquettes and Estimation of Calorific Value by Regression Analysis: An Energy Application. Mater. Sci. Energy Technol. 2018, 1, 175–181. [Google Scholar] [CrossRef]

- Handayani, S.A.; Widiati, K.Y.; Putri, F. Quality of Charcoal Briquettes from Sawdust Waste of Ulin (Eusideroxylon Zwageri) and Coconut Shell (Cocos Nucifera) Based on Variations in Ratio and Particle Size. IOP Conf. Ser. Earth Environ. Sci. 2023, 1282, 012049. [Google Scholar] [CrossRef]

- Dewi, R.P. Utilization of Sawdust and Coconut Shell as Raw Materials in Briquettes Production; AIP Publishing: Surakarta, Indonesia, 2019; p. 030004. [Google Scholar]

- Dalimunthe, Y.K.; Kasmungin, S.; Sugiarto, E.; Sugiarti, L.; Lagrama, A. Making Briquettes From Waste of Coconut Shell and Peanut Shell. Indones. J. Urban Environ. Technol. 2021, 4, 196–209. [Google Scholar] [CrossRef]

- Wulandari, A.P.; Rossiana, N.; Zahdi, F.R.M.; Nuraulia, R.; Nur’anifah, R.; Kartika, C.I.; Rahmah, L.A.; Kusmoro, J.; Madihah; Yusnaidar. Formulation and Characterization of Bio-Briquettes and Bio-Pellets from Ramie (Boehmeria Nivea) Biomass as Renewable Fuel. Sustainability 2024, 16, 10930. [Google Scholar] [CrossRef]

- Anis, S.; Fitriyana, D.F.; Bahatmaka, A.; Anwar, M.C.; Ramadhan, A.Z.; Anam, F.C.; Permana, R.A.; Hakim, A.J.; Da Silva Guterres, N.F.; Da Silva, M.d.S. Effect of Adhesive Type on the Quality of Coconut Shell Charcoal Briquettes Prepared by the Screw Extruder Machine. J. Renew. Mater. 2024, 12, 381–396. [Google Scholar] [CrossRef]

- Saputro, E.A.; Wulan, V.D.R.; Winata, B.Y.; Yogaswara, R.R.; Erliyanti, N.K. Process of Activated Carbon Form Coconut Shells Through Chemical Activation. Nat. Sci. J. Sci. Technol. 2020, 9, 23–28. [Google Scholar] [CrossRef]

- Pathiraja, K.; Nilmalgoda, H.; Wijethunga, I.; Koswattage, K. Sustainable Management of Nitrile Butadiene Rubber Waste Through Pyrolysis. Sustainability 2025, 17, 846. [Google Scholar] [CrossRef]

- Ms, I.; S, B.; A, I. Biomass Briquettes as an Alternative Source of Cooking Fuel towards Green Recovery Post COVID-19. Saudi J. Eng. Technol. 2020, 5, 285–290. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Sen, R.; Wiwatpanyaporn, S.; Annachhatre, A.P. Influence of Binders on Physical Properties of Fuel Briquettes Produced from Cassava Rhizome Waste. Int. J. Environ. Waste Manag. 2016, 17, 158–175. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of Briquette Binders and Briquetting Mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Runganga, D.; Okonta, F.; Musonda, I. Strength and Durability Properties of High-Volume Fly Ash (HVFA) Binders: A Systematic Review. CivilEng 2024, 5, 435–460. [Google Scholar] [CrossRef]

- Butler, J.W.; Skrivan, W.; Lotfi, S. Identification of Optimal Binders for Torrefied Biomass Pellets. Energies 2023, 16, 3390. [Google Scholar] [CrossRef]

- Donald, P.; Sanchez, C.; Me, M.; Aspe, T.; Sindol, K.N. An Overview on the Production of Bio-Briquettes from Agricultural Wastes: Methods, Processes, and Quality. J. Agric. Food Eng. 2022, 3, 1–17. [Google Scholar] [CrossRef]

- Nazli, B.; Klass, C.; Chen, T.; Fleck, A.; Aydemir, C.; Karademir, A.; Fleming, P.D. The Effect of Green Biobased Binder on Structural, Mechanical, Liquid Absorption and Wetting Properties of Coated Papers. Clean. Eng. Technol. 2021, 5, 100274. [Google Scholar] [CrossRef]

- Owino, C.A.; Lubwama, M.; Yiga, V.A.; Were, F.; Bongomin, O.; Serugunda, J. Mechanical and Thermal Properties of Composite Carbonized Briquettes Developed from Cassava (Manihot esculenta) Rhizomes and Groundnut (Arachis hypogea L.) Stalks with Jackfruit (Artocarpus heterophyllus) Waste as Binder. Discov. Appl. Sci. 2024, 6, 428. [Google Scholar] [CrossRef]

- Rudiyanto, B.; Agustina, I.R.; Ulma, Z.; Prasetyo, D.A.; Hijriawan, M.; Piluharto, B.; Prasetyo, T. Utilization of Cassava Peel (Manihot utilissima) Waste as an Adhesive in the Manufacture of Coconut Shell (Cocos nucifera) Charcoal Briquettes. Int. J. Renew. Energy Dev. 2023, 12, 270–276. [Google Scholar] [CrossRef]

- Santoso, H. Study of Making Biomass Briquettes from Coconut Shell and Tapioca Adhesive. BEST J. Appl. Electr. Sci. Technol. 2022, 4, 71–74. [Google Scholar] [CrossRef]

- Pari, G.; Efiyanti, L.; Darmawan, S.; Saputra, N.A.; Hendra, D.; Adam, J.; Inkriwang, A.; Effendi, R. Initial Ignition Time and Calorific Value Enhancement of Briquette with Added Pine Resin. J. Korean Wood Sci. Technol. 2023, 51, 207–221. [Google Scholar] [CrossRef]

- Handra, N.; Hafni, H. Effect of Binder on Combustion Quality on EFB Bio-Briquettes. IOP Conf. Ser. Earth Environ. Sci. 2017, 97. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Oyewusi, T.F.; Osunbitan, J.A.; Ogunjimi, L.A.O. Effect of Binder Type, Binder Concentration and Compacting Pressure on Some Physical Properties of Carbonized Corncob Briquette. Energy Rep. 2019, 5, 909–918. [Google Scholar] [CrossRef]

- Mekonen, A.G.; Berhe, G.G.; Desta, M.B.; Belete, F.A.; Gebremariam, A.F. Production and Characterization of Briquettes from Sugarcane Bagasse of Wonji Sugar Factory, Oromia, Ethiopia. Mater. Renew. Sustain. Energy 2024, 13, 27–43. [Google Scholar] [CrossRef]

- ASTM D3172-13(2021)E1; Test Method for Gross Calorific Value of Coal and Coke. D05 Committee ASTM International: Toronto, ON, Canada, 2021. [CrossRef]

- ASTM D3172-13(2021)E1; Practice for Proximate Analysis of Coal and Coke. D05 Committee ASTM International: Toronto, ON, Canada, 2021. [CrossRef]

- Badan Standar Nasional. Briket Arang Kayu SNI 01-6235-2000; Badan Standarisasi Nasional Indonesia: Jakarta Pusat, Indonesia, 2000.

- Schaffer, S.; Pröll, T.; Al Afif, R.; Pfeifer, C. A Mass- and Energy Balance-Based Process Modelling Study for the Pyrolysis of Cotton Stalks with Char Utilization for Sustainable Soil Enhancement and Carbon Storage. Biomass Bioenergy 2019, 120, 281–290. [Google Scholar] [CrossRef]

- Antal, M.J.; Grønli, M. The Art, Science, and Technology of Charcoal Production. Ind. Eng. Chem. Res. 2003, 42, 1619–1640. [Google Scholar] [CrossRef]

- Olugbade, T.; Ojo, O.; Mohammed, T. Influence of Binders on Combustion Properties of Biomass Briquettes: A Recent Review. Bioenerg. Res. 2019, 12, 241–259. [Google Scholar] [CrossRef]

- Panjaitan, R.; Jaya, A.; Supriyati, W.; Antang, E.U. Chemical Properties of Charcoal Briquette with Composition Types of Gerunggang (Cratoxylon Arborescens) and Tumih (Combretocarpus Rotundatus) Wood from Tropical Peatlands. J. Trop. Peatl. 2020, 10, 17–22. [Google Scholar] [CrossRef]

- Khaeso, K.; Sukhuna, B.; Katekaew, S.; Junsiri, C.; Monatrakul, W.; Srichat, A.; Senawong, K.; Laloon, K. Sustainable Conversion of Agricultural Waste into Solid Fuel (Charcoal) via Gasification and Pyrolysis Treatment. Energy Convers. Manag. X 2024, 24, 100693. [Google Scholar] [CrossRef]

- Appliances, Solid Fuels and Firelighters for Barbecueing Barbecue Charcoal and Barbecue Charcoal Briquettes. Requirements and Test Methods. 2005. Available online: https://www.cleanfuels.nl/Sitepdfs/EN-1860-2_eng_.pdf (accessed on 11 April 2025).

- Wu, S.; Zhang, S.; Wang, C.; Mu, C.; Huang, X. High-Strength Charcoal Briquette Preparation from Hydrothermal Pretreated Biomass Wastes. Fuel Process. Technol. 2018, 171, 293–300. [Google Scholar] [CrossRef]

- Tracked Changes. Appliances, Solid Fuels and Firelighters for Barbecuing. Part 3, Firelighters for Igniting Solid Fuels for Use in Barbecues and Grill Applications. Requirements and Test Methods; British Standards Institution: London, UK, 2023.

- Leokaoke, N.T. Manufacturing and Testing of Briquettes from Inertinite-Rich Low-Grade Coal Fines Using Various Binders. J. South. Afr. Inst. Min. Metall. 2018, 118, 83–88. [Google Scholar] [CrossRef]

- ISO 17831-1: 2015; Solid Biofuels–Determination of Mechanical Durability of Pellets and Briquettes. International Organization for Standardization: Geneva, Switzerland, 2015.

- Chusniyah, D.A.; Pratiwi, R. The Development of Sustainable Energy Briquettes Using Coconut Dregs Charcoal and Tapioca Flour as Adhesives. IOP Conf. Ser. Earth Environ. Sci. 2022, 1104, 012034. [Google Scholar] [CrossRef]

- JIS K 2151:2004; Coke—Testing Methods. Japanese Standard Association: Tokyo, Japan, 2005.

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.-C.; Akinlabi, E.T. Combustion, Physical, and Mechanical Characterization of Composites Fuel Briquettes from Carbonized Banana Stalk and Corncob. Int. J. Renew. Energy Dev. 2022, 11, 435–447. [Google Scholar] [CrossRef]

- Yusuf, M.; Witdarko, Y.; Pamungkas, W.; Parjono, P.; Suryadi, S. Characteristics of Charcoal Briquettes from Rice Husk Waste with Compaction Pressure Variations as an Alternative Fuel. J. Ecol. Eng. 2023, 24, 237–243. [Google Scholar] [CrossRef]

- Shiferaw, Y.; Tedla, A.; Melese, C.; Mengistu, A.; Debay, B.; Selamawi, Y.; Merene, E.; Awoi, N. Preparation and Evaluation of Clean Briquettes from Disposed Wood Wastes. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 2015–2024. [Google Scholar] [CrossRef]

- Birhanu Oliy, G.; Tesfaye Muleta, D. Characterization and Determination of Briquette Fuel Prepared from Five Variety of Corn Cob. Int. J. Sustain. Energy 2020, 9, 59. [Google Scholar] [CrossRef]

| Parameter | SNI 01-6235-2000 (Indonesia) [35] | BS EN 1860-2:2013 (UK/Europe) [36,37] | EN 1860-2:2013 (EU) [38,39] | ISO 17831-1:2025 (South Africa) [40,41] | JIS K 2151:2004 (Japan) [42,43] | Typical Industrial Standards | Current Study |

|---|---|---|---|---|---|---|---|

| CV (MJ/kg) | >20.9 | >24.0 | >24.0 | >24.0 | >20.0 | 25.0–30.0 | 29.9 (max) |

| Moisture (%) | <10.0 | <10.0 | <10.0 | <10.0 | <10.0 | <10.0 | 8.9 (max) |

| Ash Content (%) | <5.0 | <5.0 | <5.0 | <5.0 | NS | <5.0 | 3.3 (max) |

| Binder Content (%) | 3.0–10.0 | NS | NS | NS | NS | 3.0–10.0 | 7.5 (max) |

| Volatile Matter (%) | 20.0–30.0 | NS | NS | NS | NS | 20.0–30.0 | 24.6 (max) |

| Density (g/cm³) | NS | NS | NS | NS | NS | 1.0–1.3 | 1.1 (max) |

| Coconut Shell/Sawdust Ratio (%) | Binder (%) | Binder Type | Moisture Content (%) | Volatile Matter (%) | Ash Content (%) | Fixed Carbon (%) |

|---|---|---|---|---|---|---|

| 100:00 | 5.0 | Cassava Peel | 6.5 | 15.2 | 2.1 | 76.2 |

| 90:10 | 5.0 | 7.1 | 17.5 | 2.4 | 73.0 | |

| 80:20 | 5.0 | 7.8 | 20.4 | 2.8 | 69.0 | |

| 100:00 | 7.5 | 7.0 | 16.8 | 2.3 | 73.9 | |

| 90:10 | 7.5 | 7.5 | 18.9 | 2.6 | 71.0 | |

| 80:20 | 7.5 | 8.3 | 22.0 | 3.0 | 66.7 | |

| 100:00 | 10.0 | 7.4 | 18.0 | 2.5 | 72.1 | |

| 90:10 | 10.0 | 7.9 | 20.1 | 2.8 | 69.2 | |

| 80:20 | 10.0 | 8.6 | 23.5 | 3.2 | 64.7 | |

| 100:00 | 5.0 | Giant Taro Starch | 6.8 | 16.0 | 2.2 | 75.0 |

| 90:10 | 5.0 | 7.4 | 18.3 | 2.5 | 71.8 | |

| 80:20 | 5.0 | 8.0 | 21.2 | 2.9 | 67.9 | |

| 100:00 | 7.5 | 7.2 | 17.4 | 2.4 | 73.0 | |

| 90:10 | 7.5 | 7.7 | 19.7 | 2.7 | 69.9 | |

| 80:20 | 7.5 | 8.5 | 23.1 | 3.1 | 65.3 | |

| 100:00 | 10.0 | 7.6 | 18.6 | 2.6 | 71.2 | |

| 90:10 | 10.0 | 8.1 | 21.0 | 2.9 | 68.0 | |

| 80:20 | 10.0 | 8.9 | 24.6 | 3.3 | 63.2 | |

| 100:00 | 5.0 | Pine Resin | 5.9 | 14.0 | 1.8 | 78.3 |

| 90:10 | 5.0 | 6.4 | 16.4 | 2.1 | 75.1 | |

| 80:20 | 5.0 | 7.2 | 19.1 | 2.5 | 71.2 | |

| 100:00 | 7.5 | 6.3 | 15.5 | 2.0 | 76.2 | |

| 90:10 | 7.5 | 6.8 | 18.0 | 2.3 | 72.9 | |

| 80:20 | 7.5 | 7.6 | 21.0 | 2.7 | 68.7 | |

| 100:00 | 10.0 | 6.7 | 16.7 | 2.2 | 74.4 | |

| 90:10 | 10.0 | 7.2 | 19.3 | 2.5 | 71.0 | |

| 80:20 | 10.0 | 8.0 | 22.7 | 2.9 | 66.4 |

| Property | Coconut Shell Briquette (Current Study) | Banana Stalk (Carbonized) [44] | Rice Husk Briquette [45] | Sawdust Briquette [46] | Corncob Briquette [47] |

|---|---|---|---|---|---|

| Raw Material | Coconut shell charcoal + Cinnamon sawdust | Banana stalk | Rice husk charcoal | Sawdust charcoal | Corncob charcoal |

| Binder Material(s) | Cassava peel starch/Giant taro starch/Pine resin | Gelatinized cassava starch | Cassava starch/Clay | Cassava starch/Corn starch | Cassava starch |

| Binder Content (%) | 5.00, 7.50, 10.00 | 5.00 | 5.00–10.00 | 5.00–10.00 | 6.00–10.00 |

| Calorific Value (MJ/kg) | 26.07–31.60 | 17.51 | 25.12–27.21 | 28.46–30.12 | 27.21–29.29 |

| Density (g/cm3) | 0.83–1.14 | 0.32–1.39 | 0.70–0.90 | 0.70–0.90 | 0.80–1.00 |

| Compressive Strength (MPa) | 0.16–2.11 | 0.04–0.10 | 0.50–0.80 | 0.80–1.10 | 0.60–0.90 |

| Ash Content (%) | 1.80–3.30 | 4.44 | 15.00–20.00 | 5.00–10.00 | 8.00–12.00 |

| Moisture Content (%) | 5.90–8.90 | 11.43 | 6.72–7.62 | 6.00–10.00 | 7.00–11.00 |

| Volatile Matter (%) | 14.00–24.60 | 32.46 | 20.00–30.00 | 18.00–25.00 | 20.00–28.00 |

| Fixed Carbon (%) | 63.20–78.30 | 51.67 | 50.00–60.00 | 60.00–70.00 | 55.00-65.00 |

| Application | Best Briquette Composition |

|---|---|

| High Energy Output (Calorific Value) | Pine Resin (100:0, 10%) |

| Longer Burning Time (High Density & Strength) | Cassava Peel (100:0, 7.5%) |

| High Mechanical Durability (Shatter Resistance) | Cassava Peel or Giant Taro (100:0, 5%) |

| Balanced Performance (Good Energy & Strength) | Cassava Peel (90:10, 7.5%) |

| Lower-Cost Option (Acceptable Quality) | Giant Taro (90:10, 10%) |

| Cost Category | Coconut Shell Biochar Briquette Per 1 kg | Activated Charcoal Per 1 kg |

|---|---|---|

| Coconut Shell | USD 0.21 | USD 0.21 |

| Cinnamon Sawdust | USD 0.00 (Free) | USD 0.00 (Not used) |

| Cassava Peel Flour (Binder) | USD 0.00 (Free) | USD 0.00 (Not used) |

| Giant Taro Flour (Binder) | USD 0.00 (Free) | USD 0.00 (Not used) |

| Pine Resin (Binder) | USD 0.000083 | USD 0.00 (Not used) |

| Activation Energy (Heat) | USD 0.00027 | USD 0.001 |

| Activation Chemicals | USD 0.00 | USD 0.00667 |

| Labor Costs | USD 0.067 | USD 0.083 |

| Equipment Costs | USD 0.00167 | USD 0.00333 |

| Environmental Waste Management | USD 0.00667 | USD 0.00667 |

| Total Raw Material Cost | USD 0.21 | USD 0.22 |

| Total Additional Production Costs (energy, labor, equipment, activation chemicals) | USD 0.075 | USD 0.1077 |

| Total Production Cost | USD 0.285 | USD 0.324 |

| Selling Price (per kg) | USD 0.67 | USD 1.17 |

| Revenue (per kg) | USD 0.67 | USD 1.17 |

| Net Revenue (per kg) | USD 0.38 | USD 0.84 |

| Key Considerations | ||

| Market Demand | Local market, stable but competitive | High demand in export markets (air/water purification, medical, industrial use) |

| Export/Local Focus | Local market focus (BBQ, heating) | Primarily for export (high-value applications) |

| Scale Effects | Lower costs on a scale; economies of scale possible | Higher capital requirements for scaling; potential diseconomies at large scale |

| Supply Chain Risks | Less dependent on global markets; mostly local inputs | Dependent on international supply chains for chemicals and shipping |

| Environmental Impact | Lower energy and chemical use; relatively low emissions | Higher energy use; potential for more emissions and waste |

| Market Fluctuations | Less price volatility in local markets | Subject to global demand fluctuations, international trade issues |

| Sustainability Considerations | Less environmental footprint, local sourcing | Potential higher environmental impact due to chemicals and energy intensity |

| Global Competition | Moderate; local competition from other fuels | Strong international competition in activated carbon markets |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madhusanka, L.; Nilmalgoda, H.; Wijethunga, I.; Ampitiyawatta, A.; Koswattage, K. Agri-Eco Energy: Evaluating Non-Edible Binders in Coconut Shell Biochar and Cinnamon Sawdust Briquettes for Sustainable Fuel Production. AgriEngineering 2025, 7, 132. https://doi.org/10.3390/agriengineering7050132

Madhusanka L, Nilmalgoda H, Wijethunga I, Ampitiyawatta A, Koswattage K. Agri-Eco Energy: Evaluating Non-Edible Binders in Coconut Shell Biochar and Cinnamon Sawdust Briquettes for Sustainable Fuel Production. AgriEngineering. 2025; 7(5):132. https://doi.org/10.3390/agriengineering7050132

Chicago/Turabian StyleMadhusanka, Lasitha, Helitha Nilmalgoda, Isuru Wijethunga, Asanga Ampitiyawatta, and Kaveenga Koswattage. 2025. "Agri-Eco Energy: Evaluating Non-Edible Binders in Coconut Shell Biochar and Cinnamon Sawdust Briquettes for Sustainable Fuel Production" AgriEngineering 7, no. 5: 132. https://doi.org/10.3390/agriengineering7050132

APA StyleMadhusanka, L., Nilmalgoda, H., Wijethunga, I., Ampitiyawatta, A., & Koswattage, K. (2025). Agri-Eco Energy: Evaluating Non-Edible Binders in Coconut Shell Biochar and Cinnamon Sawdust Briquettes for Sustainable Fuel Production. AgriEngineering, 7(5), 132. https://doi.org/10.3390/agriengineering7050132