Design and Experiment of the Codonopsis pilosula Outcrop Film-Laying and Transplanting Machine

Abstract

1. Introduction

2. Structure and Working Principle of the Entire Machine

2.1. Agronomic Requirements

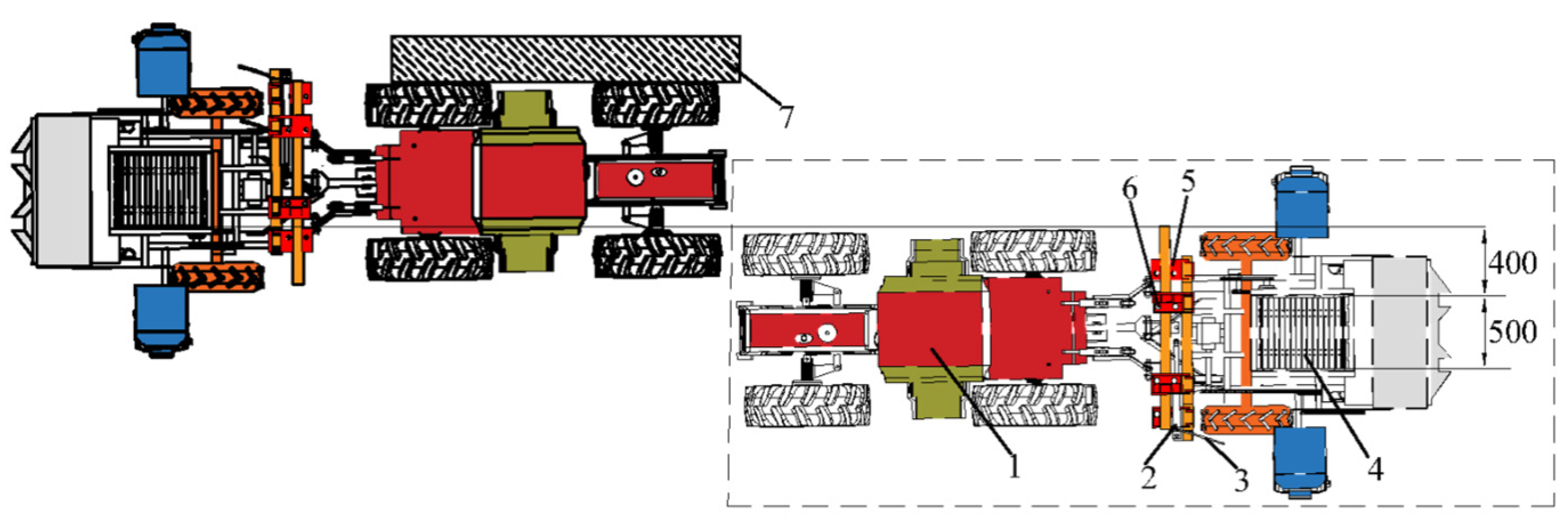

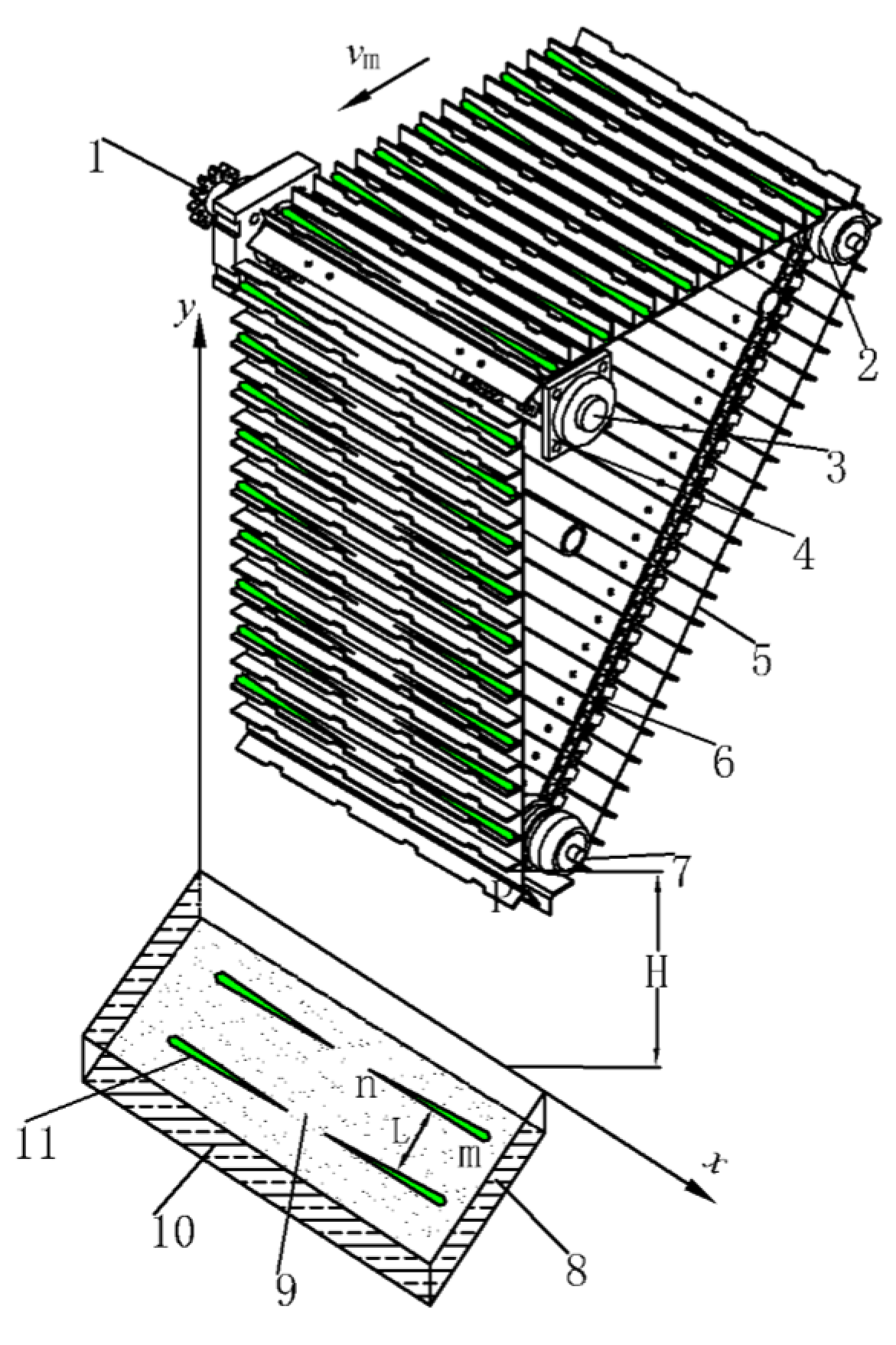

2.2. Structure of the Whole Machine

2.3. Working Principle

2.4. Main Technical Indicators

3. Design of Main Working Parts

3.1. Bias Pendulum Mechanism

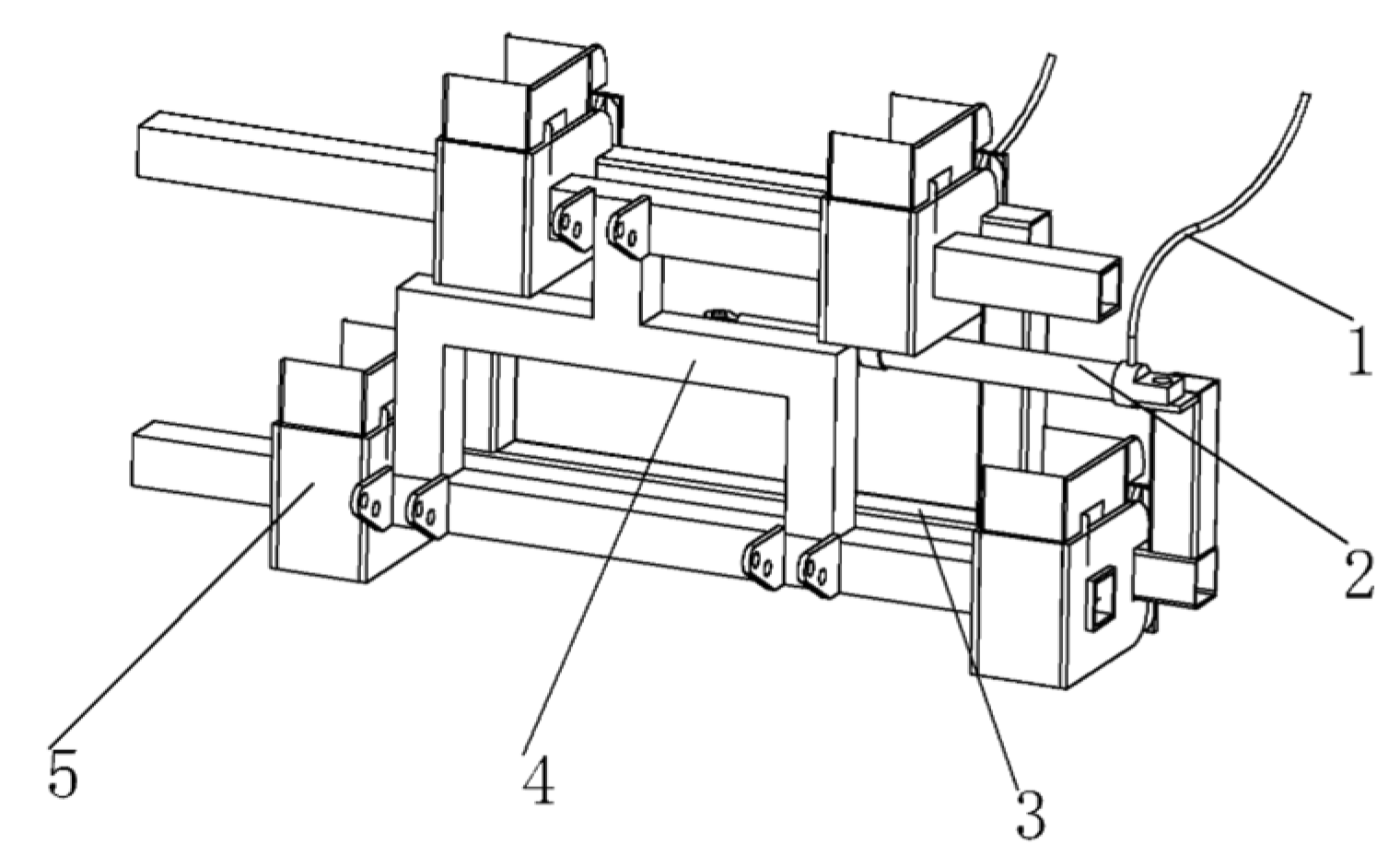

Composition and Working Principle

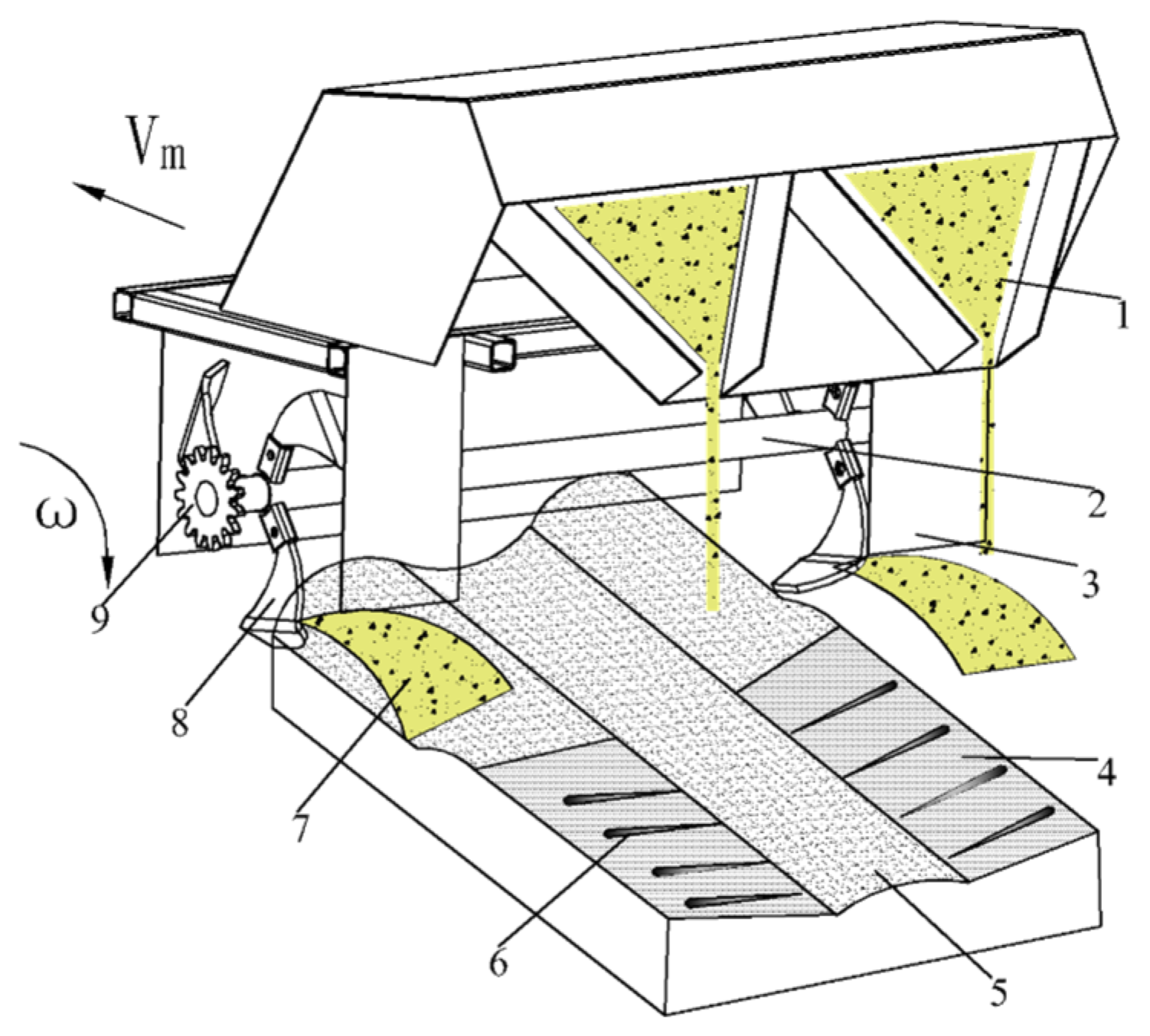

3.2. Seed Bed Preparation Equipment

3.2.1. Structure and Working Principle

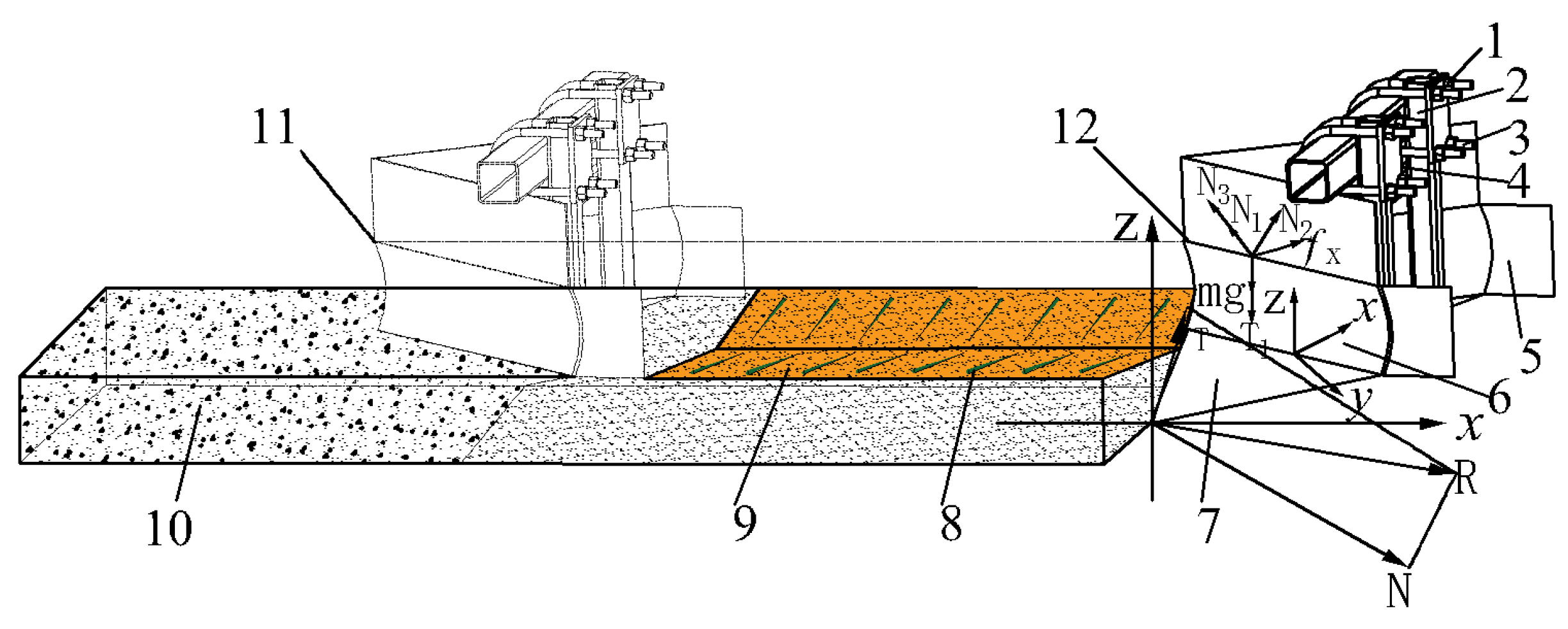

3.2.2. Force Analysis of Seed Bed Preparation Equipment into the Soil

3.2.3. Simulation of the Interaction Mechanism Between Seed Bed Preparation Equipment and Soil

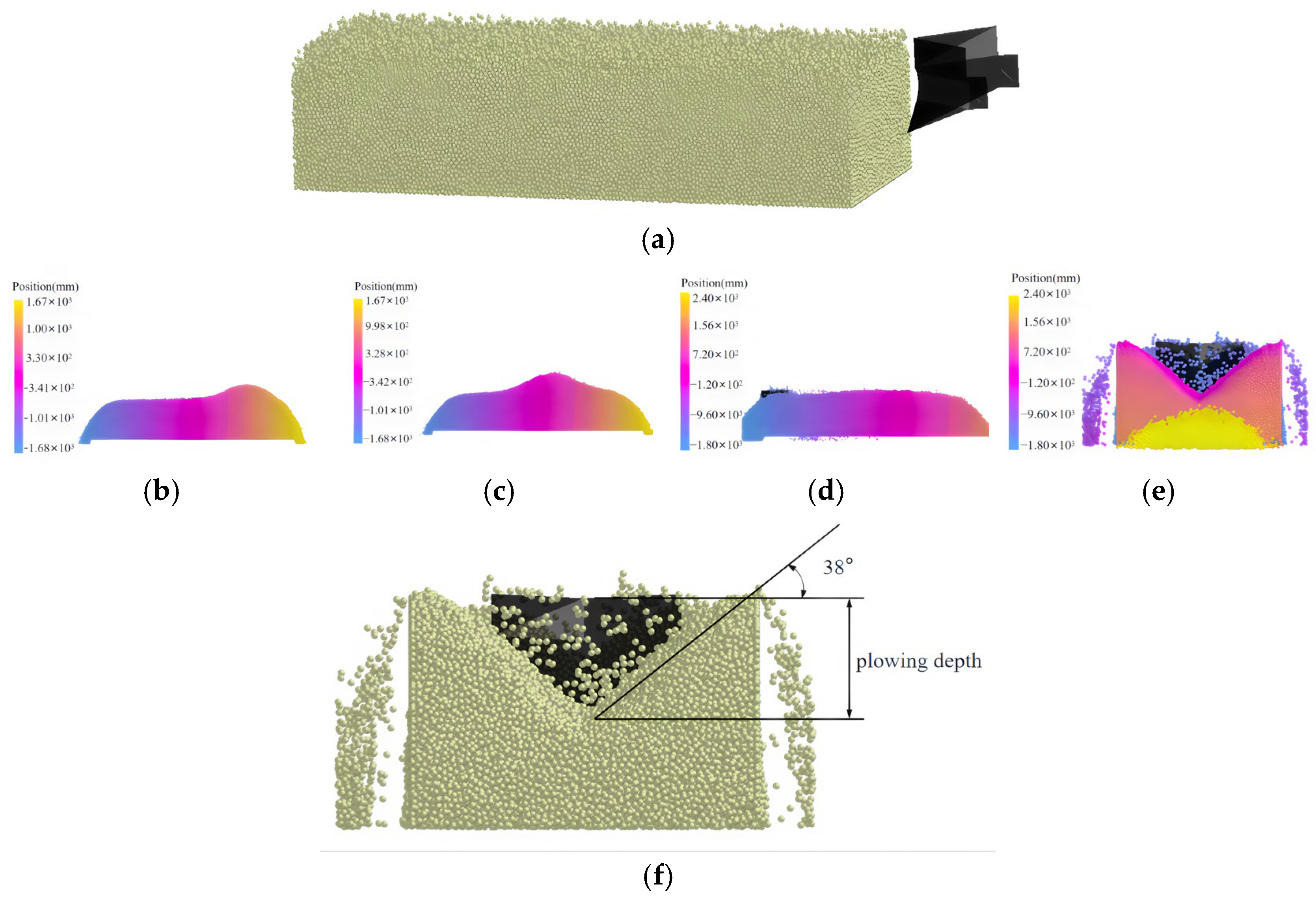

Determination of Soil and Machine Parameters

Discrete Element Simulation Modeling and Analysis

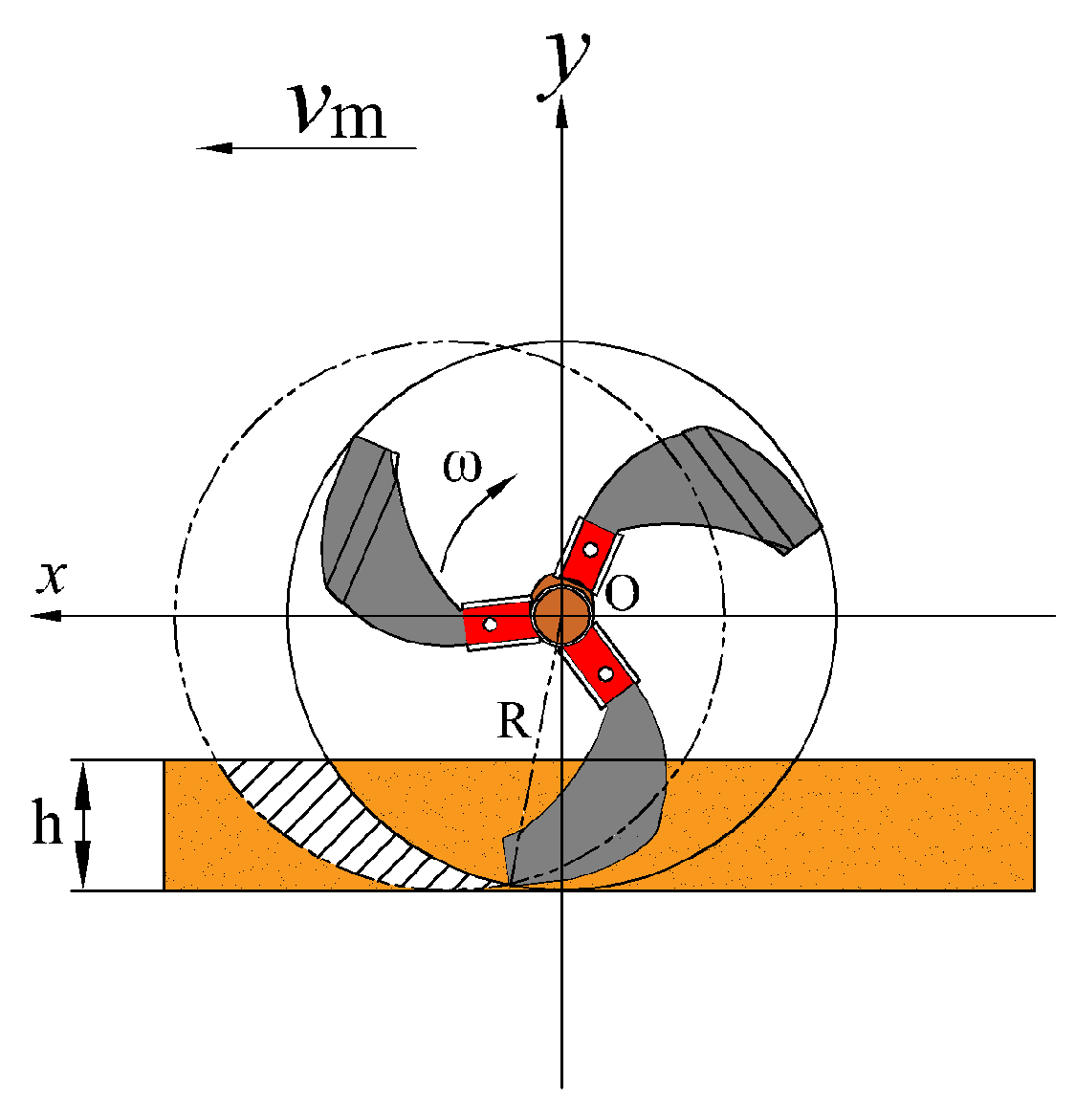

3.3. Seeding Device

3.3.1. Analysis of Seedling Planting Movement

3.3.2. Analysis of Horizontal Direction Planting Movement

3.3.3. Vertical Direction Seedling Throwing Motion Analysis

3.4. Covering Device

Kinematic Analysis of Rotary Tiller Blade Motion

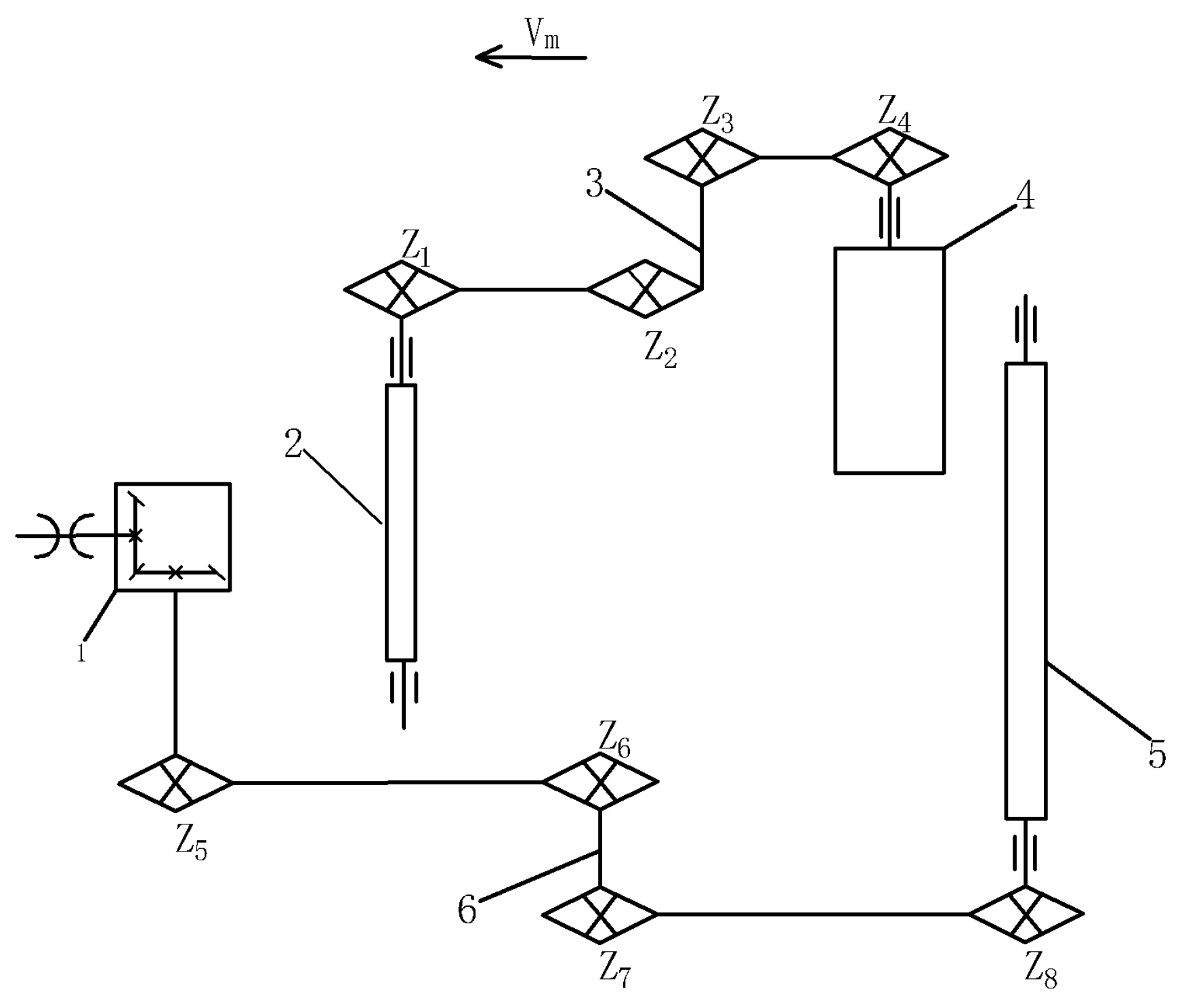

3.5. Transmission System Design

4. Field Experiment

4.1. Experimental Condition

4.2. Experimental Test and Methodology

- Pass rate for planting depth

- H—Planting depth pass rate; in percent (%);

- Hh—The sum of the number of eligible planting depths in each plot, in units of;

- Hz—Total number of plants measured in each plot, in pieces.

- 2.

- Pass rate for spacing

- J—Plant spacing qualified rate; the unit is a percentage (%);

- Jh—Sum of qualified number of plant spacings of each cell, unit is each;

- Jz—The total number of plant spacings was measured in each plot, and the unit was one.

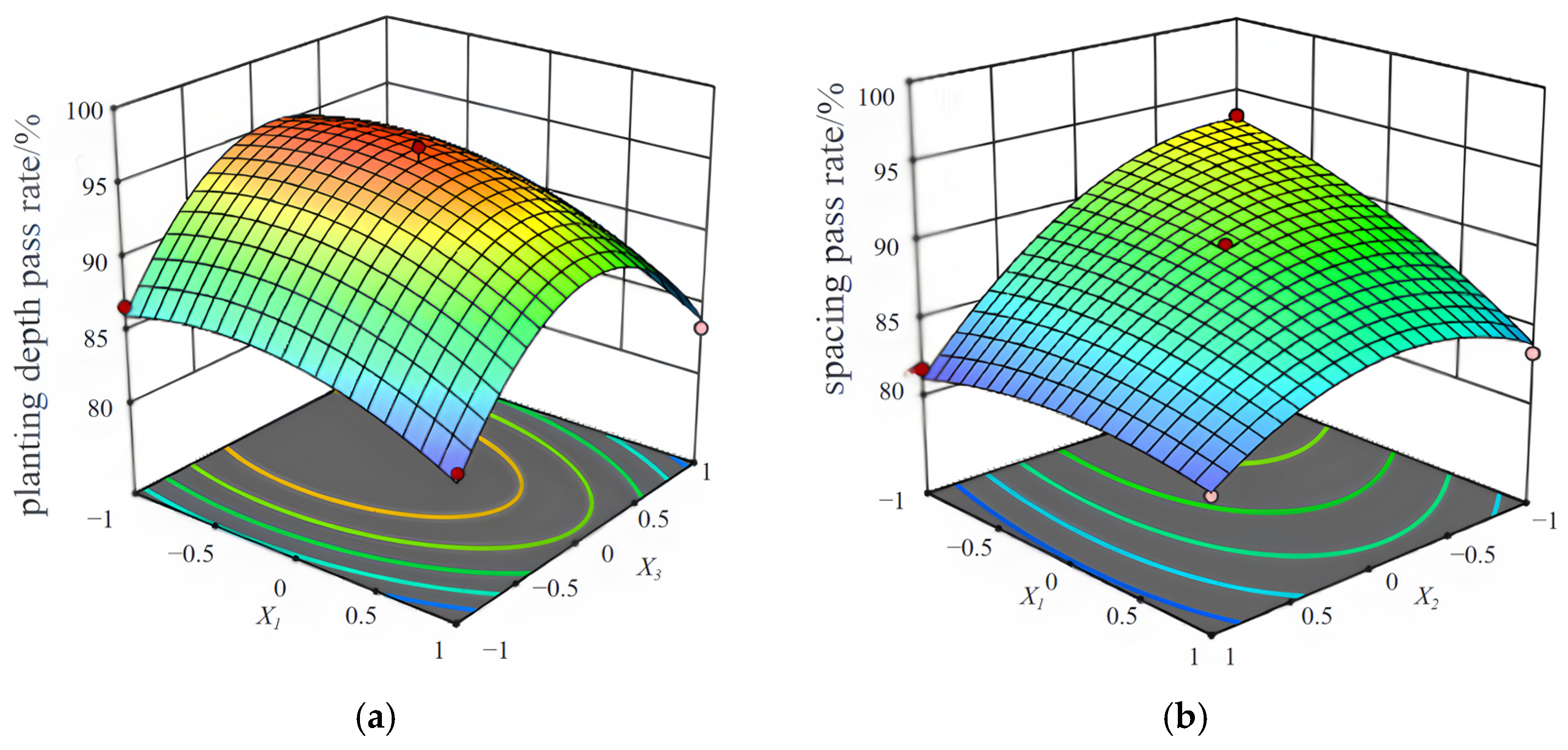

4.3. Analysis of Experimental Results

4.3.1. Experimental Results

4.3.2. Regression Equation Building and Analysis

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, X.L.; Zhang, L.H.; Liu, P.X.; Li, S.L. Analysis of the current status and advantages of mechanised ginseng cultivation in Gansu. J. Promot. Agric. Mach. Sci. Technol. 2022, 29–31. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwP9BkPOK-BT4Q57zmLbmMrhrv_Wxtv_6nBUxd5_BaDECjK_0Z-GIHg9x1DkCc0FPukH6Eyiwg5cASxLpekHEOHOPTdbolJb-0Lr6hztRvnKMAWuwhYeBVJ4jYbLa0TmLTK_z3EjYhCYyRAgzhUaWGlF36WeomiQ6Wzb6ASOqsvwDw==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Lv, G.Q. Gansu ginseng industry technology innovation strategy alliance set up. Gansu Daily News-Lanzhou Morning Post. Available online: https://www.gscn.com.cn/gsnews/system/2018/10/21/012038463.shtml (accessed on 17 December 2024).

- Ma, X.L.; Zhang, L.H.; Liu, P.X.; Li, S.L. Design and Field Experiment of a Combined Film-Mulching and Soil-Covering Machine for Exposed Cultivation of Codonopsis. J. Agric. Mech. Res. 2024, 46, 82–88. [Google Scholar]

- Wang, J.Z.; Sun, W.; Wang, H.C.; Zhang, H.; Liu, X.L. Design and test of seedling transplanting machine for planting soil-covered Codonopsis pilosula in rows with mulch. J. Arid. Reg. Agric. Res. 2020, 38, 289–298. [Google Scholar]

- Minle County Gaoyuanxueqi Chinese Herbal Medicine Farmers’ Professional Cooperative. An Integrated Soil-Covering and Film-Mulching Machine for Astragalus and Codonopsis. No. CN202010438534.8, 23 August 2022. [Google Scholar]

- Kunming University of Science and Technology. A Chain-Clamp Type Panax Notoginseng Transplanter. No. CN202111080485.6, 14 April 2023. [Google Scholar]

- Dingxi Sanniu Agricultural Machinery Manufacturing Co., LTD. A Rotary-Tilling and Oblique-Shifting Six-Row Codonopsis Film-Laying and Fertilizing Planter. No. CN202010912302.1, 8 December 2020. [Google Scholar]

- Inner Mongolia University of Technology. An Astragalus Transplanter. No. CN202110879519.1, 26 November 2021. [Google Scholar]

- Wang, X.J.; Song, J.N.; Liu, C.L. Design and test of tilting transplant opener for liquorice. J. Agric. Eng. 2016, 32, 8. [Google Scholar]

- Nanjing Agricultural Mechanization Research Institute, Ministry of Agriculture and Rural Affairs; Dingxi Sanniu Agricultural Machinery Manufacturing Co., Ltd. A Whole-Roll Laying Type Transplanting Machine and Planting Method for Exposed Film Mulching of Rhizomatous Chinese Medicinal Herbs. No. CN202310031097.1, 4 June 2024. [Google Scholar]

- Wang, C.L.; Chen, Y.G. Standardized Cultivation Techniques for Exposed Film-Mulching of Codonopsis pilosula. Agric. Technol. 2018, 38, 113–114. [Google Scholar]

- Guan, Q.X.; Li, C.D. Technical Regulations for Cultivation of Striped Codonopsis pilosula. Gansu Agric. Sci. Technol. 2016, 83–86. [Google Scholar]

- Sun, L.; Zheng, K.; Zheng, X. Optimised design of a vehicle offset steering system. J. Intern. Combust. Engines Accessories 2023, 54–56. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwMTkoaTf0JE10iYlINJDjYY9fCI5hAsGdwXriJBtYj5rXllxsXCscqg262-5-gyOjo1LuzBEiusNNtrpgYRgWpmQTZEGprtmGgSNagpPGGJwvRwPDpiRPyeobCXd0kbnzIIn7NoBJlIZ5jcGQuNqwUNjI8mJUUXcFpDT3GdyzODXw==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Meng, C.X.; Li, N. Use and maintenance of hydraulic system of agricultural machinery. J. Agric. Mach. Use Maint. 2022, 108–110. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwNzFXUX2Tx0kamw7dIoDjsDZDbAa3xF4wszIXdek6US8W75ERs_0thazIwiqQwrPBYe_IrX-27ydM4KgZHzvxXk8h-fyTGMWPVGVrllnBoZV9kncqV7YSKnrrBAi8F2WKPg9gzwuyD0fggmjS1e2aE33kGQhq6bkRCrAGy3TsEHZg==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Wei, G.L. Working Mechanism and Seed Bed Preparation Technology of Plough-Rotor Combined Buckling and Fencing for Oilseed Rape Direct Seeding Machine. Ph.D. Thesis, Huazhong Agricultural University, Wuhan, China, 2021. [Google Scholar]

- Wang, Q.J.; Li, H.W.; He, J. Design and Experiment of a Concave-Disc Type No-Till Corn Planter for Ridge Tillage. J. Trans. Chin. Soc. Agric. Eng. 2011, 27, 117–122. [Google Scholar]

- Cao, X.D. Structural Optimisation and Experimental Research of Core Spade Furrow Opener. Master’s Thesis, Northwest Agriculture and Forestry University, Yangling, China, 2018. [Google Scholar]

- Chen, H.X.; Qi, W.L.; Wang, J.H. Design of spade trenchers based on discrete element method and response surface method. J. Mech. Des. 2023, 40, 65–71. [Google Scholar]

- Niu, B.Y.; Wang, S.M.; Sun, X.Y. Structural design and mechanical analysis of seed and fertiliser opener for no-tillage planter. J. China-Arab. Sci. Technol. Forum 2021, 105–107. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwNh2cTi7DsHfiy_0tF6lisaVh9EoLJNAHYhdVhaIH66TFBFjfv84Z3NQmVVeASkpdyerD0Fl4SIdqfv2VAx3A4hnBUIa3JOoBpnK-f5FoVCFPU6PzDd2DGBFjtGRbb91VldFa18pgoAXU4f3pY3BgQMaN48VHUr88V5CIKtWSgIqg==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Yao, L.T.; Luo, X.; Cao, X.L. Design and test of 2FF-100 fertiliser mulcher for hilly mountain orchards. J. Jiangxi J. Agric. 2022, 34, 209–213. [Google Scholar]

- Dou, J.L. Design and test of no-till sectional seeding opener for corn. J. Agric. Mach. Use Maint. 2023, 15–17. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwPQ036_1QziMJIj0E4BvlKmEBe-hVYJ4y0goeZUFQH6Z2uHLXD2zBIk33zwZC1cugkUAra0_XouTAsyS0DWwjnoKJvirxKwiDLK8iNWYbFykQ1PbDo-nURVK33DCba_B2UesriUuT_Ls2Pw1qwjoeuBsA5p45koy-yvO049TGwTMw==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Li, Y.D.; Sun, X.Z. Simulation study of seed discharge process of air suction seed discharger based on EDEM. J. Mod. Agric. Mach. 2023, 71–74. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwOluezAfuFZ6AGsVzYCWSesjI1hIVqu9Uwgmg14pRe65xhBgs-e06qbpFr1jVayVB65R2eG1Gxtj_T_YLQQRAVDofdANCNJeVNKBSXnoVFTKxOhMOCqGZigb3Ug5i7_3iNkeawxQ0V08C0PkG95DZYTNA9VeJhQ0gJO4JKuy_suEw==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Liu, F.Y.; Zhang, S.; Li, B. Discrete element parameter analysis and calibration of wheat based on stacking test. J. Agric. Eng. 2016, 32, 247–253. [Google Scholar]

- Shi, L.R.; Zhao, W.Y.; Sun, W. Discrete element-based particle contact modelling and parameter calibration of farmland soils in the Northwest dry zone. J. Agric. Eng. 2017, 33, 181–187. [Google Scholar]

- Song, Z.H.; Li, H.; Yan, Y.F. Calibration and test of the parameters of a discrete elemental simulation model for non-equal-sized particles in mulberry soil. J. Agric. Mach. 2022, 53, 21–33. [Google Scholar]

- Tao, L.M.; Shi, Y.Q.; Huang, L.Y. Parameter calibration of a discrete meta-simulation model for sugarcane cultivation soil in coastal area of Guangxi. J. Jiangxi J. Agric. 2022, 34, 94–100. [Google Scholar]

- Ucgul, M.; Fielke, J.M. Saunders, C. 3D DEM tillage simulation: Validation for a sweep tool for a cohesionless soil. J. Soil Till Res. 2014, 144, 220–227. [Google Scholar] [CrossRef]

- Li, G.; Yang, C.; He, Q.; Liu, J. Ag-based photocatalytic heterostructures: Construction and photocatalytic energy conversion application. J. Environ. Chem. Eng. 2022, 10, 107374. [Google Scholar] [CrossRef]

- Hu, J.P.; Liu, Y.T.; Liu, W.; Zhang, S.W.; Han, L.H.; Zeng, T.Y. Experimental study on combined seedling extraction device for automatic vegetable transplanting machine. J. Agric. Mach. 2022, 53, 110–117+184. [Google Scholar]

- Jiang, Y.; Sima, Y.; Liu, L.; Zhou, C.; Shi, S.; Wan, K.; Chen, A.; Tang, N.; He, Q.; Liu, J. Research progress on portable electrochemical sensors for detection of mycotoxins in food and environmental samples. Chem. Eng. J. 2024, 149860. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1385894724013457 (accessed on 17 December 2024). [CrossRef]

- Zuo, J.; Feng, J.; Gameiro, M.G.; Tian, Y.; Liang, J.; Wang, Y.; Ding, J.; He, Q. RFID-based sensing in smart packaging for food applications: A review. J. Future Foods 2022, 6, 100198. [Google Scholar] [CrossRef] [PubMed]

- Ning, J.; He, Q.; Luo, X.; Wang, M.; Liu, D.; Wang, J.; Liu, J.; Li, G. Rapid and Sensitive Determination of Vanillin Based on a Glassy Carbon Electrode Modified with Cu2O-Electrochemically Reduced Graphene Oxide Nanocomposite Film. Sensors 2018, 18, 2762. [Google Scholar] [CrossRef]

- Tang, N.; Wei, Y.; He, Q.; Shi, S.; Zhou, C.; Chen, A.; Liu, J. Facile electrochemical determination of sertraline at nanomolar concentration using bimetallic MXene NbTiCTx and MWCNTs hybridized electrodes as sensing platform. J. Mater. Today Chem. 2024, 36, 101901. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, D.; Wen, Y.S. Design and test of air-blowing vibration composite seedling picking mechanism for vegetable transplanter. J. Agric. Mach. 2019, 50, 80–87. [Google Scholar]

- Xiong, P.Y. Research on Three-Way Working Resistance and Wear Resistance of Rotary Ploughing Knives. Ph.D. Thesis, South China Agricultural University, Guangzhou, China, 2019. [Google Scholar]

- Ding, W.M.; Wang, Y.H.; Peng, S.S. Performance analysis of forward and reverse rotary ploughing knives and comparative test of cutting torque. J. Nanjing Agric. Univ. 2001, 113–117. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwOZvRDt-85hHrWNA6w991aB8ctdNHbp8DS6ImhK8XRp5QXbvG9F_qIZzGKKGLp-riYfPrN1DH9b1IK8IE6feIN9CcQX-Tr3ykph1TOJE3Qj3SGI5G4Wfa3VbIFtjVTsRhTBSGeDYysHR1MKLLG3T8mElZIE7-zIGC315vi1IYUE9g==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Wang, M.H.; Feng, B.H.; Ma, Q.B. Design and Analysis of Roller Chain Drives in Agricultural Machinery. China Mech. Eng. 2025, 24–27. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwMjOYvWn-gYqNc4DcSa-8CplLEBAdL9a1akED65pQtkFng9AnMnY4heIR0AM-U6KVE1Av4qkhCYRKR6DfFjuJXplSfcpaoenvoI8jYlhUbOuETrVvh3CB4DKJ32KYFXMLfhiCejgKch1oa65zQL4wZhDl1lOdvAdlYoiujP9pYVCg==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

- Li, W.K. Research on transmission system of 4M-2 potato combine harvester. J. Mach. Res. Appl. 2008, 63–66. Available online: https://kns.cnki.net/kcms2/article/abstract?v=cwBM1amFwwMOpbavmZZKFoOmGp24JBysGASH8RWohrAc4TNRFjMiVJq21GT_ffaaHx6w6oArw9WULwpz89bhHOsIQRi5TRgAxGNv448Iql9-ZVatFdlUMdLRbtWTjHdlrXVh17Infp-O1kPBSanGosQkO4ILzeyVI5JMWtJHkaxk3cEqJWEyhQ==&uniplatform=NZKPT&language=CHS (accessed on 17 December 2024).

| Parameter | Numerical Value |

|---|---|

| Dimension of the whole machine (length × width × height)/mm | 2000 × 1650 × 1100 |

| Machine mass/kg | 5000 |

| Structure form | Suspension type |

| Matching power range/kW | ≥25.7 (with crawler gear) |

| Operating speed range/m.s−1 | 0.25~1.11 |

| Working width/cm | 90 |

| Planting rows | 2 |

| Row spacing/cm | Wide range: 50; narrow range: 40 |

| Hourly productivity/hm2.h−1 | 0.19~0.38 |

| Parameter | Value |

|---|---|

| Soil particle density (kg.m−3) | 2600 |

| Soil yield strength (MPa) | 0.23 |

| Soil coefficient of restitution | 0.6 |

| Steel density (kg.m−3) | 7850 |

| Steel Poisson ratio | 0.3 |

| Steel shear modulus (MPa) | 7.9 × 104 |

| Coefficient of static friction between soil and implements | 0.5 |

| Coefficient of dynamic friction between soil and implements | 0.05 |

| Coefficient of restitution between soil and implements | 0.6 |

| Actual Particle Size/mm | Diameter of Simulated Particles/mm | Mass Fraction/% |

|---|---|---|

| 0~0.1 | 1 | 13.81 |

| 0.1~0.5 | 3 | 28.89 |

| 0.5~1.0 | 7.5 | 26.57 |

| 1.0~2.0 | 15 | 14.04 |

| >2.0 | 20 | 16.72 |

| Levels | Machine Forward Speed X1/(m·s−1) | Speed of the Seedling Chain X2/(m·s−1) | Embedded Depth X3/mm |

|---|---|---|---|

| −1 | 0.25 | 0.09 | 45 |

| 0 | 0.3 | 0.11 | 50 |

| 1 | 0.35 | 0.13 | 55 |

| Serial Number | X1 | X2 | X2 | Y1 | Y2 |

|---|---|---|---|---|---|

| 1 | −1 | 1 | 0 | 95 | 83.3 |

| 2 | 0 | −1 | −1 | 88.3 | 93.3 |

| 3 | 0 | 1 | −1 | 85 | 90 |

| 4 | 1 | 0 | −1 | 83.3 | 86.7 |

| 5 | 1 | −1 | 0 | 90 | 81.7 |

| 6 | 0 | 0 | 0 | 96.7 | 90 |

| 7 | 0 | 0 | 0 | 95 | 90 |

| 8 | 0 | 0 | 0 | 95 | 88.3 |

| 9 | −1 | 0 | 1 | 88.3 | 96.7 |

| 10 | 0 | 1 | 1 | 90 | 93.3 |

| 11 | 0 | 0 | 0 | 96.7 | 90 |

| 12 | 0 | −1 | 1 | 90 | 96.7 |

| 13 | 1 | 1 | 0 | 93.3 | 81.7 |

| 14 | −1 | −1 | 0 | 96.7 | 93.3 |

| 15 | 0 | 0 | 0 | 95 | 90 |

| 16 | −1 | 0 | −1 | 86.7 | 93.3 |

| 17 | 1 | 0 | 1 | 83.3 | 88.3 |

| Test Indicators | Source of Variation | Square Sum | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|---|

| Planting depth pass rate | model | 347.59 | 9 | 38.62 | 27.81 | 0.0001 ** |

| X1 | 35.28 | 1 | 35.28 | 25.41 | 0.0015 ** | |

| X2 | 0.3612 | 1 | 0.3612 | 0.2601 | 0.6257 | |

| X3 | 8.61 | 1 | 8.61 | 6.20 | 0.0416 * | |

| X1X2 | 6.25 | 1 | 6.25 | 4.50 | 0.0716 | |

| X1X3 | 0.6400 | 1 | 0.6400 | 0.4609 | 0.5190 | |

| X2X3 | 2.72 | 1 | 2.72 | 1.96 | 0.2042 | |

| X12 | 24.81 | 1 | 24.81 | 17.87 | 0.0039 ** | |

| X22 | 1.04 | 1 | 1.04 | 0.7505 | 0.4150 | |

| X32 | 259.63 | 1 | 259.63 | 186.97 | <0.0001 ** | |

| residual | 9.72 | 7 | 1.39 | |||

| incoherent | 6.25 | 3 | 2.08 | 2.40 | 0.2080 | |

| inaccuracy | 3.47 | 4 | 0.8670 | |||

| aggregate | 357.31 | 16 |

| Test Indicators | Source of Variation | Square Sum | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|---|

| Spacing pass rate | Model | 327.56 | 9 | 36.40 | 57.39 | <0.0001 ** |

| X1 | 99.40 | 1 | 99.40 | 156.74 | <0.0001 ** | |

| X2 | 34.86 | 1 | 34.86 | 54.97 | 0.0001 ** | |

| X3 | 17.11 | 1 | 17.11 | 26.98 | 0.0013 ** | |

| X1X2 | 25.00 | 1 | 25.00 | 39.42 | 0.0004 ** | |

| X1X3 | 0.8100 | 1 | 0.8100 | 1.28 | 0.2957 | |

| X2X3 | 0.0025 | 1 | 0.0025 | 0.0039 | 0.9517 | |

| X12 | 47.75 | 1 | 47.75 | 75.29 | <0.0001 ** | |

| X22 | 7.03 | 1 | 7.03 | 11.09 | 0.0126 | |

| X32 | 103.48 | 1 | 103.48 | 163.16 | <0.0001 ** | |

| residual | 4.44 | 7 | 0.6342 | |||

| incoherent | 2.13 | 3 | 0.7092 | 1.23 | 0.4091 | |

| inaccuracy | 2.31 | 4 | 0.5780 | |||

| aggregate | 332.00 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Sun, W.; Zhao, M.; Zhang, L.; Wang, J.; Simionescu, P.A. Design and Experiment of the Codonopsis pilosula Outcrop Film-Laying and Transplanting Machine. AgriEngineering 2025, 7, 131. https://doi.org/10.3390/agriengineering7050131

Bai J, Sun W, Zhao M, Zhang L, Wang J, Simionescu PA. Design and Experiment of the Codonopsis pilosula Outcrop Film-Laying and Transplanting Machine. AgriEngineering. 2025; 7(5):131. https://doi.org/10.3390/agriengineering7050131

Chicago/Turabian StyleBai, Jiajia, Wei Sun, Ming Zhao, Luhai Zhang, Juanling Wang, and Petru Aurelian Simionescu. 2025. "Design and Experiment of the Codonopsis pilosula Outcrop Film-Laying and Transplanting Machine" AgriEngineering 7, no. 5: 131. https://doi.org/10.3390/agriengineering7050131

APA StyleBai, J., Sun, W., Zhao, M., Zhang, L., Wang, J., & Simionescu, P. A. (2025). Design and Experiment of the Codonopsis pilosula Outcrop Film-Laying and Transplanting Machine. AgriEngineering, 7(5), 131. https://doi.org/10.3390/agriengineering7050131