A Bioclimatic Design Approach to the Energy Efficiency of Farm Wineries: Formulation and Application in a Study Area

Abstract

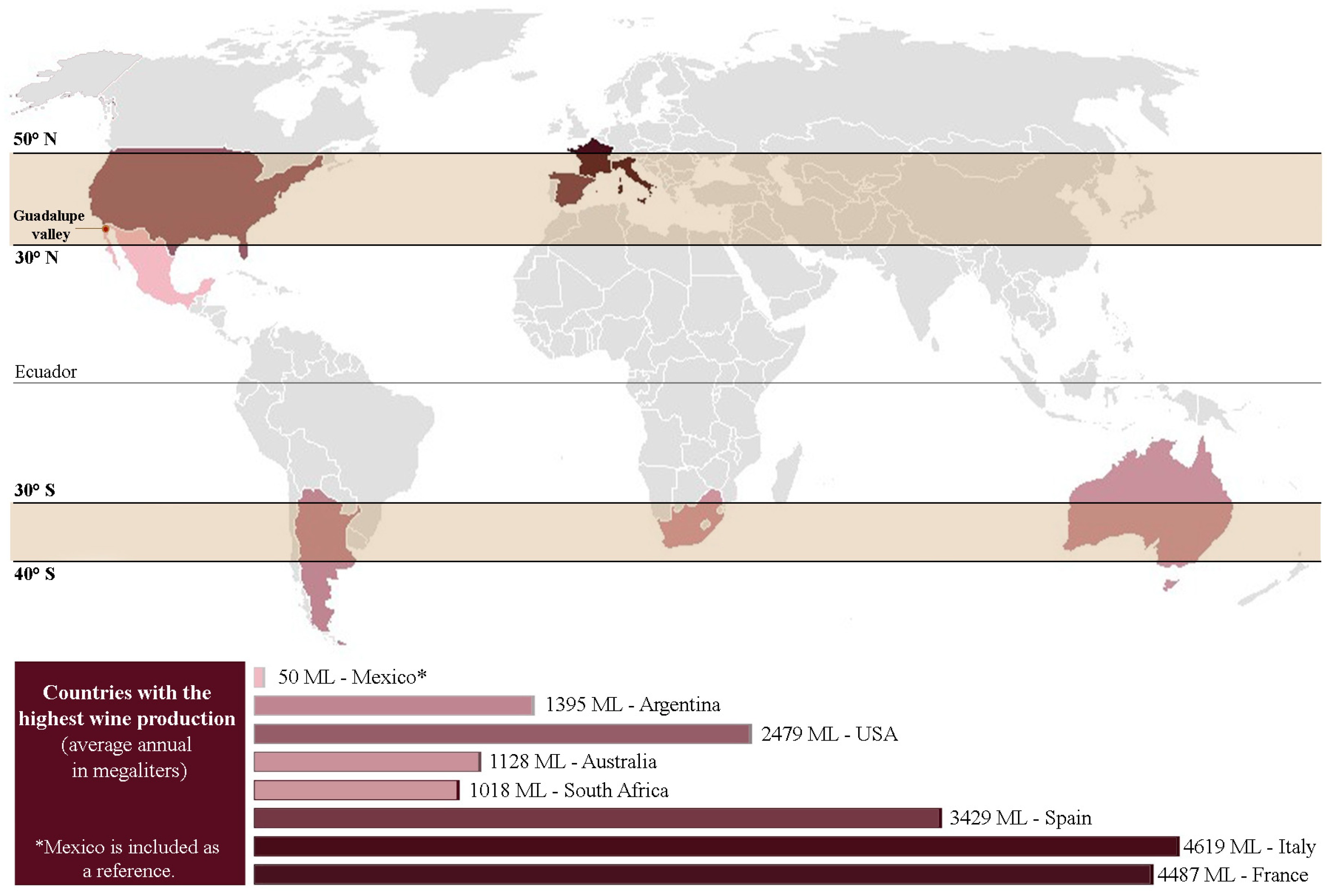

1. Introduction

2. Materials and Methods

- Characterization of the area and the case study;

- Theoretical determination of optimal ranges of the thermal environment for wine;

- Design of a base model of a cellar for the requirements of use and thermal environment for production, aging, and tasting of wine;

- Dynamic simulation of six building models with bioclimatic design strategies;

- Dynamic simulation of the microclimate of the study area validated with monitoring data;

- Analysis of the results obtained with comparisons in percentage differences.

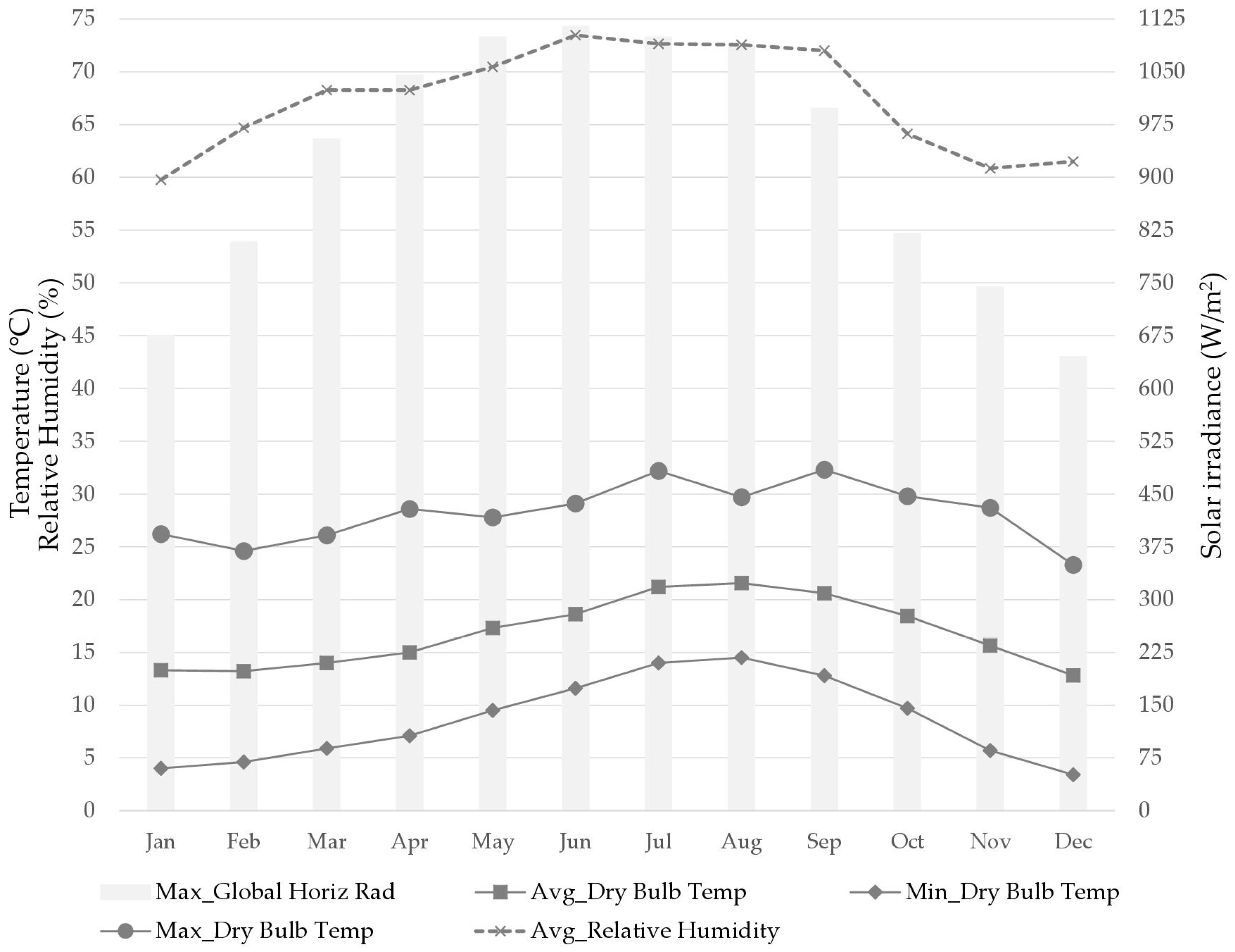

2.1. Study Area

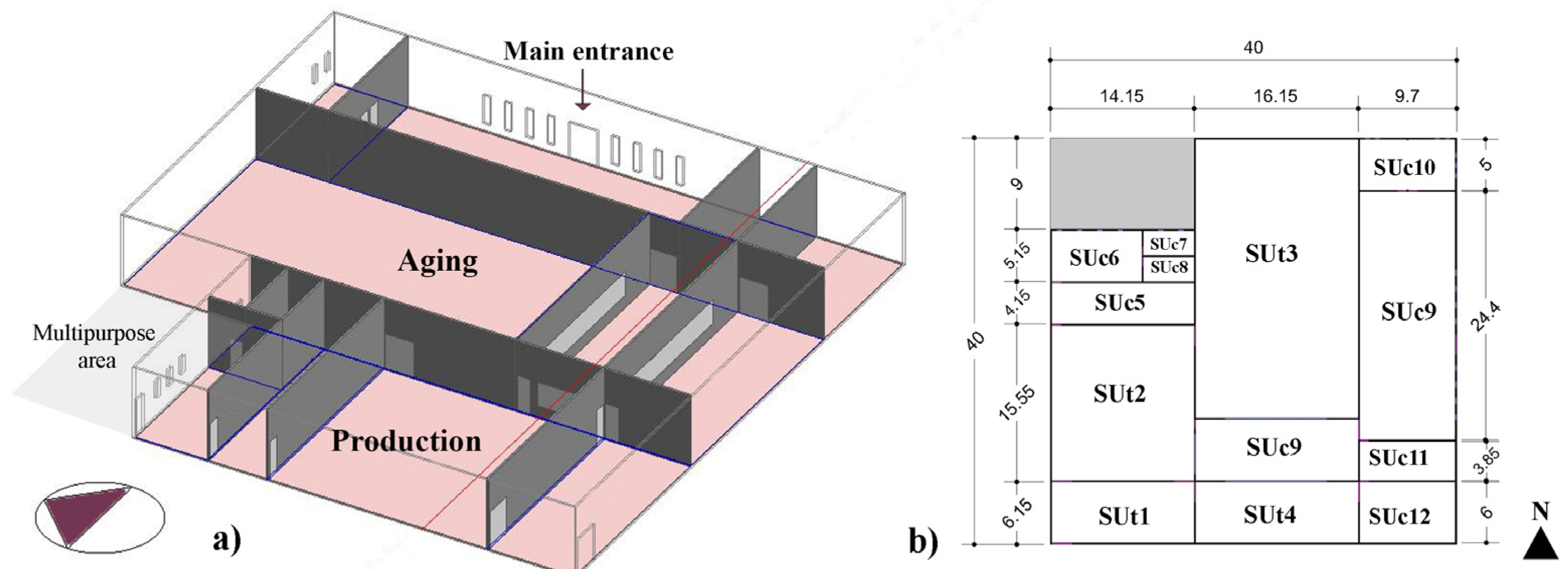

2.2. Typological Model of Wine Cellars

- Semi-buried (earth slopes on walls);

- Underground (aging area);

- Underground with a green roof for the aging area;

- Underground with a double roof and shaded walls for the aging area;

- Underground with 0.10 m of polyurethane on the roof of the aging area;

- Base model without strategies, used as a critical comparison case.

- 7.

- Semi-buried;

- 8.

- Semi-buried with a green roof for the production area;

- 9.

- Semi-buried with 0.10 m of polyurethane on the roof of the production area;

- 10.

- Underground with shaded walls due to the effect of a double roof in the aging area;

- 11.

- Base model without strategies.

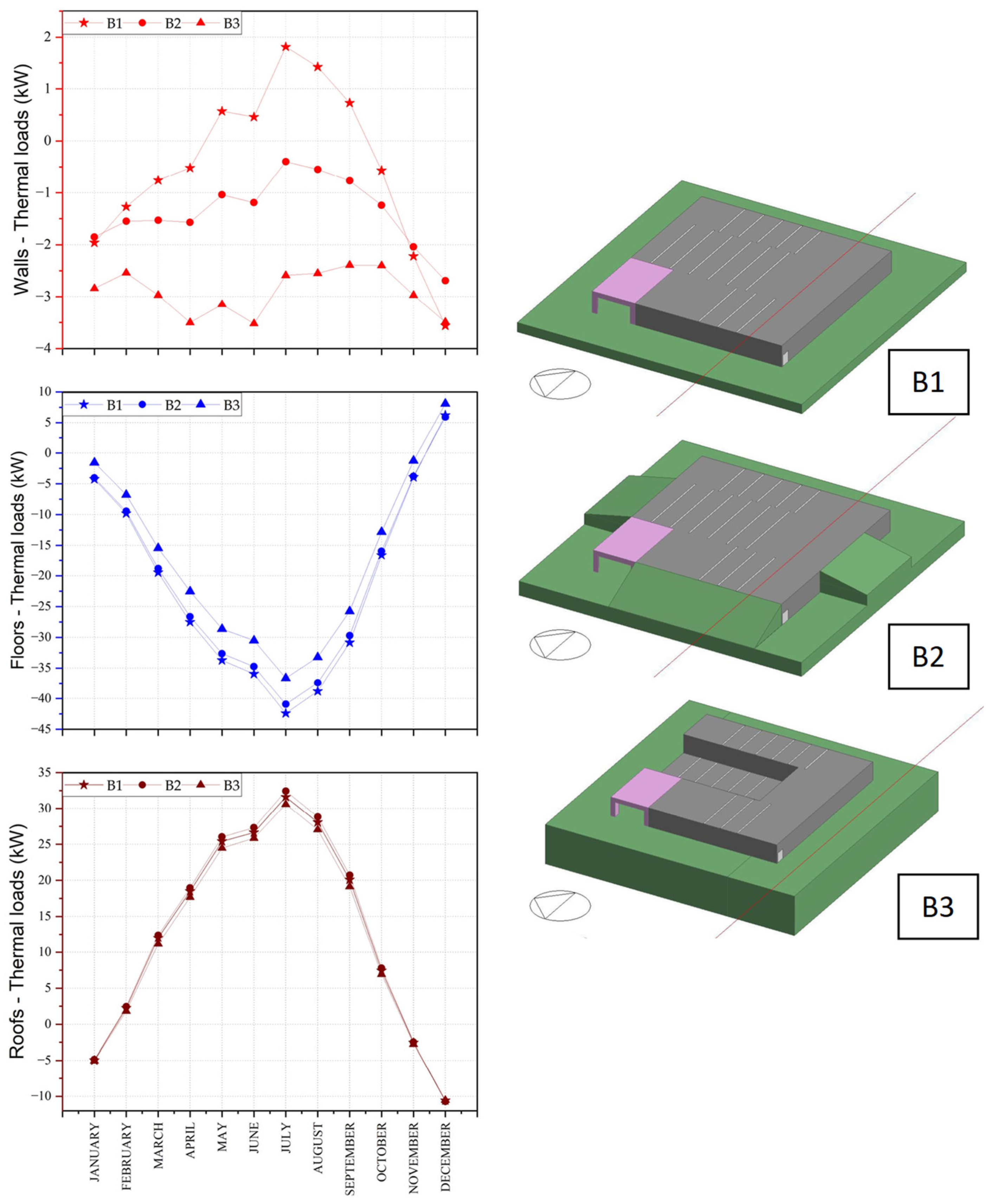

2.3. Thermal Simulation

3. Results and Discussion

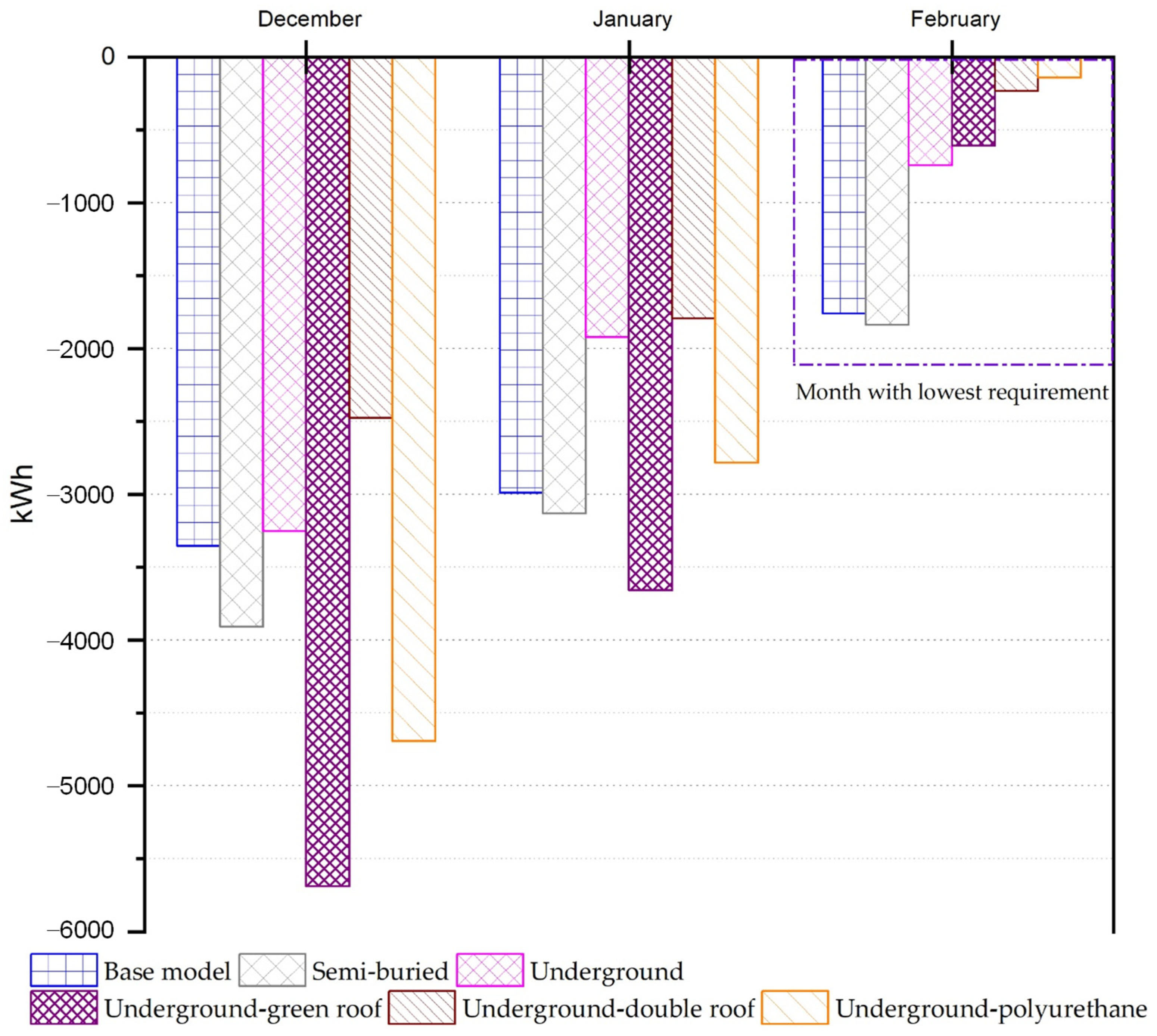

3.1. Cold Period

- Indoor dry bulb temperature (°C);

- Monthly degree-hours (°C h) outside and inside the optimal hygrothermal range for wine;

- Sensible cooling or heating required (kWh).

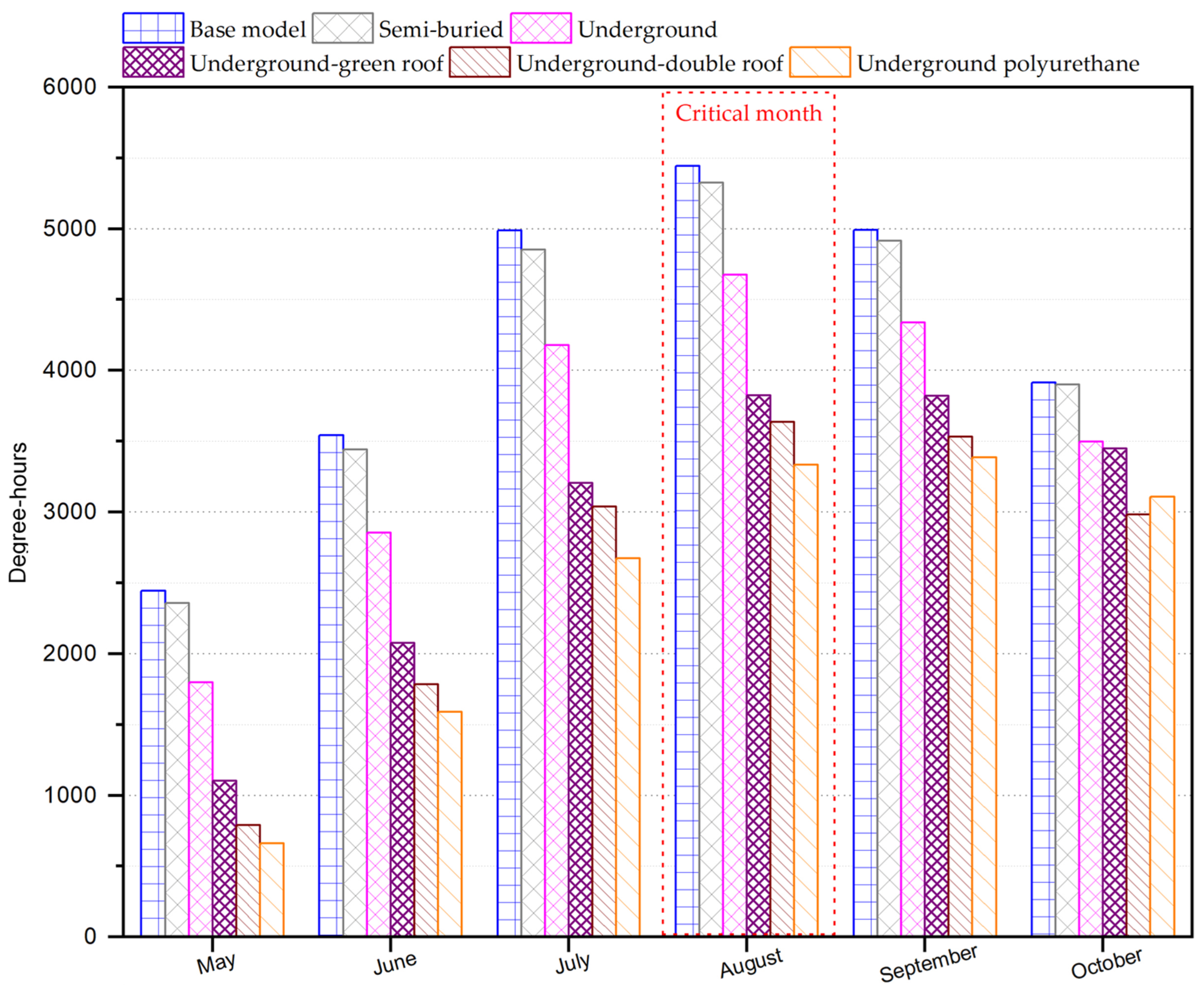

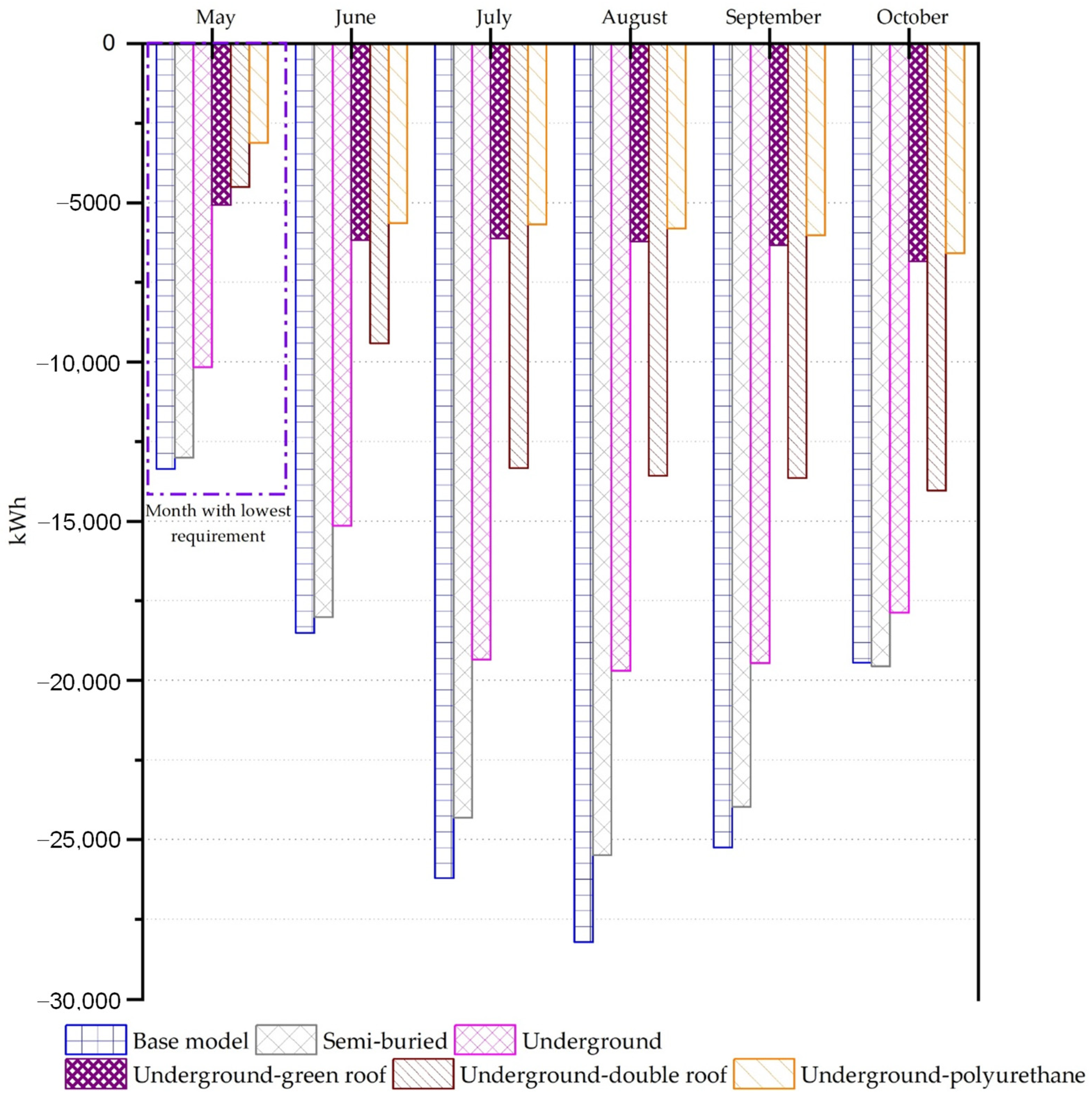

3.2. Warm Period

- Indoor dry bulb temperature (°C);

- Monthly degree-hours (°C h);

- Sensible cooling or heating (kWh).

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barbaresi, A.; Santolini, E.; Agrusti, M.; Bovo, M.; Accorsi, M.; Torreggiani, D.; Tassinari, P. Microventilation System Improves the Ageing Conditions in Existent Wine Cellars. Aust. J. Grape Wine Res. 2020, 26, 417–426. [Google Scholar] [CrossRef]

- Luzzani, G.; Lamastra, L.; Valentino, F.; Capri, E. Development and Implementation of a Qualitative Framework for the Sustainable Management of Wine Companies. Sci. Total Environ. 2021, 759, 143462. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; López-Ocón, E.; Garcimartín, M.A.; Cañas, I. Assessment of Basement Constructions in the Winery Industry. Tunn. Undergr. Space Technol. 2013, 35, 200–206. [Google Scholar] [CrossRef]

- Catrini, P.; Panno, D.; Cardona, F.; Piacentino, A. Characterization of Cooling Loads in the Wine Industry and Novel Seasonal Indicator for Reliable Assessment of Energy Saving through Retrofit of Chillers. Appl. Energy 2020, 266, 114856. [Google Scholar] [CrossRef]

- Pivetta, D.; Rech, S.; Lazzaretto, A. Choice of the Optimal Design and Operation of Multi-Energy Conversion Systems in a Prosecco Wine Cellar. Energies 2020, 13, 6252. [Google Scholar] [CrossRef]

- Gómez-Villarino, M.T.; Barbero-Barrera, M.M.; Mazarrón, F.R.; Cañas, I. Cost-Effectiveness Evaluation of Nearly Zero-Energy Buildings for the Aging of Red Wine. Agronomy 2021, 11, 687. [Google Scholar] [CrossRef]

- Ciotti, G.; Zironi, A.; Bietresato, M.; Gubiani, R.; Zironi, R. Enhancing Energy Efficiency in Wineries: A Novel Benchmarking Approach. Sustain. Energy Technol. Assess. 2024, 71, 103983. [Google Scholar] [CrossRef]

- Benni, S.; Torreggiani, D.; Barbaresi, A.; Tassinari, P. Thermal Performance Assessment for Energy-Efficient Design of Farm Wineries. Trans. ASABE 2013, 56, 1483–1491. [Google Scholar] [CrossRef]

- Tinti, F.; Barbaresi, A.; Benni, S.; Torreggiani, D.; Bruno, R.; Tassinari, P. Experimental Analysis of Shallow Underground Temperature for the Assessment of Energy Efficiency Potential of Underground Wine Cellars. Energy Build. 2014, 80, 451–460. [Google Scholar] [CrossRef]

- Rubel, F.; Kottek, M. Observed and Projected Climate Shifts 1901-2100 Depicted by World Maps of the Köppen-Geiger Climate Classification. Meteorol. Z. 2010, 19, 135–141. [Google Scholar] [CrossRef]

- Gómez-Villarino, M.T.; Barbero-Barrera, M.D.M.; Cañas, I.; Ramos-Sanz, A.; Baptista, F.; Mazarrón, F.R. Construction Solutions, Cost and Thermal Behavior of Efficiently Designed Above-Ground Wine-Aging Facilities. Buildings 2024, 14, 655. [Google Scholar] [CrossRef]

- Martins, A.A.; Araújo, A.R.; Graça, A.; Caetano, N.S.; Mata, T.M. Towards Sustainable Wine: Comparison of Two Portuguese Wines. J. Clean. Prod. 2018, 183, 662–676. [Google Scholar] [CrossRef]

- Barbosa, F.S.; Scavarda, A.J.; Sellitto, M.A.; Lopes Marques, D.I. Sustainability in the Winemaking Industry: An Analysis of Southern Brazilian Companies Based on a Literature Review. J. Clean. Prod. 2018, 192, 80–87. [Google Scholar] [CrossRef]

- Zimmer, A.; Joseph, R. Mexicans Are Consuming More Wine—And Planting More Vines. Meininger’s International, 11 December 2023. Available online: https://www.meiningers-international.com/wine/insights/mexicans-are-consuming-more-wine-and-planting-more-vines (accessed on 5 February 2025).

- Jiménez-López, V.; Luna-León, A.; Benni, S. A Bioclimatic Approach for Enhanced Wine Cellar Design: General Formulation and Analysis of a Case Study in Mexico. Agriengineering 2024, 6, 2395–2416. [Google Scholar] [CrossRef]

- Hyde, R. Bioclimatic Housing; Routledge: Oxfordshire, UK, 2012; ISBN 9781136571145. [Google Scholar]

- Mazarrón, F.R.; Cañas, I. Seasonal Analysis of the Thermal Behaviour of Traditional Underground Wine Cellars in Spain. Renew. Energy 2009, 34, 2484–2492. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cañas, I. Hygrothermal Conditions for the Aging of Red Wine from Experimental Data. LWT 2023, 173, 114272. [Google Scholar] [CrossRef]

- Arredondo-Ruiz, F.; Cañas, I.; Mazarrón, F.R.; Manjarrez-Domínguez, C.B. Designs for Energy-efficient Wine Cellars (Ageing Rooms): A Review. Aust. J. Grape Wine Res. 2020, 26, 9–28. [Google Scholar] [CrossRef]

- Barbaresi, A.; Dallacasa, F.; Torreggiani, D.; Tassinari, P. Retrofit Interventions in Non-Conditioned Rooms: Calibration of an Assessment Method on a Farm Winery. J. Build. Perform. Simul. 2017, 10, 91–104. [Google Scholar] [CrossRef]

- Torreggiani, D.; Barbaresi, A.; Dallacasa, F.; Tassinari, P. Effects of Different Architectural Solutions on the Thermal Behaviour in an Unconditioned Rural Building. The Case of an Italian Winery. J. Agric. Eng. 2018, 49, 52–63. [Google Scholar] [CrossRef]

- Barbaresi, A.; Torreggiani, D.; Benni, S.; Tassinari, P. Underground Cellar Thermal Simulation: Definition of a Method for Modelling Performance Assessment Based on Experimental Calibration. Energy Build. 2014, 76, 363–372. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Porras-Amores, C.; Cañas-Guerrero, I. Annual Evolution of the Natural Ventilation in an Underground Construction: Influence of the Access Tunnel and the Ventilation Chimney. Tunn. Undergr. Space Technol. 2015, 49, 188–198. [Google Scholar] [CrossRef]

- Porras-Amores, C.; Mazarrón, F.R.; Cañas, I.; Villoría Sáez, P. Natural Ventilation Analysis in an Underground Construction: CFD Simulation and Experimental Validation. Tunn. Undergr. Space Technol. 2019, 90, 162–173. [Google Scholar] [CrossRef]

- Santolini, E.; Barbaresi, A.; Torreggiani, D.; Tassinari, P. Numerical Simulations for the Optimisation of Ventilation System Designed for Wine Cellars. J. Agric. Eng. 2019, 50, 180–190. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry. Energies 2012, 5, 227–242. [Google Scholar] [CrossRef]

- Anderson, K.; Nelgen, S. Global Wine Markets, 1961 to 2009: A Statistical Compendium: Global Wine Markets, 2007–2009; University of Adelaide Press: Adelaide, Australia, 2011. [Google Scholar]

- Kramer, J. Moon Baja; Avalon Travel: Berkeley, CA, USA, 2017. [Google Scholar]

- Torreggiani, D.; Corzani, V.; Benni, S.; Tassinari, P. Design of Farm Winery Façades for the Optimisation of Indoor Natural Lighting: A Case Study. J. Agric. Eng. 2013, 44, e3. [Google Scholar] [CrossRef][Green Version]

- Torreggiani, D.; Benni, S.; Garcia, A.I.; Ayuga, F.; Tassinari, P. Farm Winery Layout Design: Size Analysis of Base Spatial Units in an Italian Study Area. Trans. ASABE 2014, 57, 625–633. [Google Scholar] [CrossRef]

- de Castro, M.; Baptista, J.; Matos, C.; Valente, A.; Briga-Sá, A. Energy Efficiency in Winemaking Industry: Challenges and Opportunities. Sci. Total Environ. 2024, 930, 172383. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, M.; Chen, J.; Knappenberger, T. Effects of Drying-Induced Shrinkage on Thermal and Hydraulic Properties of Clayey Soils. Soil Tillage Res. 2025, 248, 106415. [Google Scholar] [CrossRef]

- León, G.; Flórez, R.A.; Solano, E.; Blanco, E.; Andrés, M.R.; Flórez Solano, E.; Espinel Blanco, E. Thermal Conductivity of Clay Powders Used in the Ceramic Industry in Ocaña Norte de Santander and the Region; Universidad Francisco de Paula Santander Ocaña: Ocaña, Colombia, 2017. [Google Scholar]

- Choi, E.J.; Park, B.R.; Kim, N.H.; Moon, J.W. Effects of Thermal Comfort-Driven Control Based on Real-Time Clothing Insulation Estimated Using an Image-Processing Model. Build. Environ. 2022, 223, 109438. [Google Scholar] [CrossRef]

- Sailor, D.J. A Green Roof Model for Building Energy Simulation Programs. Energy Build. 2008, 40, 1466–1478. [Google Scholar] [CrossRef]

- Ziogou, I.; Michopoulos, A.; Voulgari, V.; Zachariadis, T. Energy, Environmental and Economic Assessment of Electricity Savings from the Operation of Green Roofs in Urban Office Buildings of a Warm Mediterranean Region. J. Clean. Prod. 2017, 168, 346–356. [Google Scholar] [CrossRef]

- Troost, G. Die Technologie Des Weines; Eugen Ulmer: Stuttgart, Germany, 1953. [Google Scholar]

- Boulton, R.B.; Singleton, V.L.; Bisson, L.F.; Kunkee, R.E. Principles and Practices of Winemaking; Springer: New York, NY, USA, 1999. [Google Scholar]

- Hidalgo Togores, J. Tratado de Enología, 3rd ed.; rev. y ampl.; Mundi-Prensa: Madrid, Spain, 2018. [Google Scholar]

- Mazarron, F.R.; Canas, I. Exponential Sinusoidal Model for Predicting Temperature inside Underground Wine Cellars from a Spanish Region. Energy Build. 2008, 40, 1931–1940. [Google Scholar] [CrossRef]

- Steiner, T.E. What Is the Best Sterilization Option for the Bottling Line? In Winemaking Problems Solved; Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2010; Volume 193, pp. 150–153. [Google Scholar]

- Bondiac, E. Elaboracion de Vinos. Vinificacion Moderna; America Tecnica: Buenos Aires, Argentina, 1953. [Google Scholar]

- Marescalchi, C. Manuale dell Enologo (Winemaking Manual); Fratelli Marescalchi: Casale Monferrato, Italy, 1965. [Google Scholar]

- Marrara, V.; Barreca, F.; Di Fazio, S. Green Roofs in the Sustainable Design of Agri-Food Build-Ings: A Case-Study in Calabria (Italy). In Proceedings of the International Conference of Agricultural Engineering, Zurich, Switzerland, 6–10 July 2014. [Google Scholar]

- Considine, J.A.; Frankish, E. A Complete Guide to Quality in Small-Scale Wine Making; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Vogt, E. El Vino: Obtención, Elaboración y Análisis; Acribia Editorial: Zaragoza, Spain, 1986. [Google Scholar]

- Mateus, N.M.; Pinto, A.; Graça, G.C. da Validation of EnergyPlus Thermal Simulation of a Double Skin Naturally and Mechanically Ventilated Test Cell. Energy Build. 2014, 75, 511–522. [Google Scholar] [CrossRef]

- Ali, M.H.; Abustan, I. A New Novel Index for Evaluating Model Performance. J. Nat. Resour. Dev. 2014, 4, 1–9. [Google Scholar]

- Rodrigues, E.; Fereidani, N.A.; Fernandes, M.S.; Gaspar, A.R. Diminishing Benefits of Thermal Mass in Iranian Climate: Present and Future Scenarios. Build. Environ. 2024, 258, 111635. [Google Scholar] [CrossRef]

| Building Geometry | Area (m2) | Height (m) | Volume (m3) |

| Above-ground-level building (B1) | 1471.30 | 4.5 | 6620.85 |

| Semi-buried building (B2) | 1471.30 | 4.5 | 6620.85 |

| Underground building (B3) | 1695.30 | 4.5 | 7628.85 |

| Construction U-values (W/m2·K) | B1 | B2 | B3 |

| External walls | 2.32 | 2.32 | 2.562 |

| Internal partitions | 1.606 | 1.606 | 1.606 |

| Roofs | 3.639 | 3.639 | 3.646 |

| Roofs with 0.10 m polyurethane | N/A | 0.373 | 0.373 |

| Green roof | N/A | 0.963 | 0.963 |

| Ground floor | 3.633 | 3.633 | 3.633 |

| Windows | 5.89 | 5.89 | 5.89 |

| Doors | 2.079 | 2.079 | 2.079 |

| Wine barrels | 0.838 | 0.838 | 0.838 |

| Internal loads | Equipment (W/m2) | Occupancy (People/m2) | Lighting (W/m2-100 lux) |

| Aging area | 5 | 0.01 | 2 |

| Production area | 5 | 0.05 | 4 |

| Heating, ventilation, and air conditioning (HVAC) | Aging area | Production area | |

| Type of HVAC system | Packaged Direct Expansion (PDX) | Packaged Direct Expansion (PDX) | |

| Coefficient of performance (COP) | 4 | 4 | |

| Heating | On | On | |

| Winter clothing | 1 clo | 1 clo | |

| Cooling | On | On | |

| Summer clothing | 0.5 clo | 0.5 clo | |

| Cooling setpoint | 15 °C | 25 °C | |

| RH setpoint for humidification | 30% | 30% | |

| RH setpoint for dehumidification | 75% | 75% | |

| Simulation calculation options | |||

| Solution algorithm | Conduction transfer function (CTF) | ||

| Surface convection algorithm—inside | TARP | ||

| Surface convection algorithm—outside | DOE-2 | ||

| Time steps per hour | 2 | ||

| Author (s) | Dry Bulb Temperature (°C) |

|---|---|

| Troost [37] | 9–15 |

| Boulton et al. [38] | 5–15 |

| Hidalgo Togores [39] | 9–12 |

| Mazarrón and Cañas [40] | ≤18 |

| Steiner [41] | 13–20 |

| Bondiac [42] | 10–12 |

| Marescalchi [43] | 15–20 |

| Marrara et al. [44] | 12–16 |

| Considine and Frankish [45] | ≤20 |

| <16 | |

| Vogt [46] | 12 |

| 8–12 |

| Parameter | Warm Period | Cold Period |

|---|---|---|

| Mean error (°C) | 0.54 | 0.26 |

| Mean absolute deviation (°C) | 1.58 | 0.56 |

| Multiple determination coefficient (R2) | 0.04 | 0.16 |

| Mean absolute percentage error (%) | 8.67 | 3.47 |

| Mean error in daily maxima (°C) | 0.50 | 0.10 |

| Mean absolute deviation in daily maxima (°C) | 1.29 | 0.48 |

| Multiple determination coefficient in daily maxima (R2) | 0.002 | 0.27 |

| Mean absolute percentage error in daily maxima (%) | 6.95 | 2.91 |

| Building Model | Maximum Interior DBT * (°C) | Minimum Interior DBT (°C) | Average Interior DBT (°C) | Temperature Oscillation ** (°C) | Hours Outside Optimal Range (%) |

|---|---|---|---|---|---|

| Base building | 19.31 | 13.24 | 15.62 | 6.07 | 62.77 |

| Semi-buried | 19.12 | 13.42 | 15.70 | 5.70 | 69.09 |

| Underground | 18.46 | 13.35 | 15.44 | 5.11 | 53.16 |

| Underground building with green roof | 18.01 | 14.40 | 16.11 | 3.61 | 87.73 |

| Underground with double roof | 18.23 | 12.98 | 15.13 | 5.25 | 21.64 |

| Underground with 0.10 m polyurethane | 18.21 | 14.05 | 15.82 | 2.39 | 69.72 |

| Building Model | Maximum Interior DBT * (°C) | Minimum Interior DBT (°C) | Average Interior DBT (°C) | Temperature Oscillation ** (°C) | Hours Outside Optimal Range (%) |

|---|---|---|---|---|---|

| Base building | 24.87 | 15.10 | 20.83 | 9.77 | 100.00 |

| Semi-buried | 24.57 | 15.14 | 20.69 | 9.43 | 100.00 |

| Underground | 23.23 | 14.83 | 19.86 | 8.40 | 99.75 |

| Underground building with green roof | 21.23 | 15.08 | 18.82 | 6.15 | 100.00 |

| Underground with double roof | 21.43 | 14.00 | 18.48 | 7.43 | 99.42 |

| Underground with 0.10 m polyurethane | 20.59 | 14.59 | 18.23 | 5.99 | 99.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiménez-López, V.; Luna-León, A.; Bojórquez-Morales, G.; Benni, S. A Bioclimatic Design Approach to the Energy Efficiency of Farm Wineries: Formulation and Application in a Study Area. AgriEngineering 2025, 7, 98. https://doi.org/10.3390/agriengineering7040098

Jiménez-López V, Luna-León A, Bojórquez-Morales G, Benni S. A Bioclimatic Design Approach to the Energy Efficiency of Farm Wineries: Formulation and Application in a Study Area. AgriEngineering. 2025; 7(4):98. https://doi.org/10.3390/agriengineering7040098

Chicago/Turabian StyleJiménez-López, Verónica, Anibal Luna-León, Gonzalo Bojórquez-Morales, and Stefano Benni. 2025. "A Bioclimatic Design Approach to the Energy Efficiency of Farm Wineries: Formulation and Application in a Study Area" AgriEngineering 7, no. 4: 98. https://doi.org/10.3390/agriengineering7040098

APA StyleJiménez-López, V., Luna-León, A., Bojórquez-Morales, G., & Benni, S. (2025). A Bioclimatic Design Approach to the Energy Efficiency of Farm Wineries: Formulation and Application in a Study Area. AgriEngineering, 7(4), 98. https://doi.org/10.3390/agriengineering7040098