Development and Performance Testing of a Combined Cultivating Implement and Organic Fertilizer Applicator for Sugarcane Ratooning

Abstract

1. Introduction

2. Materials and Methods

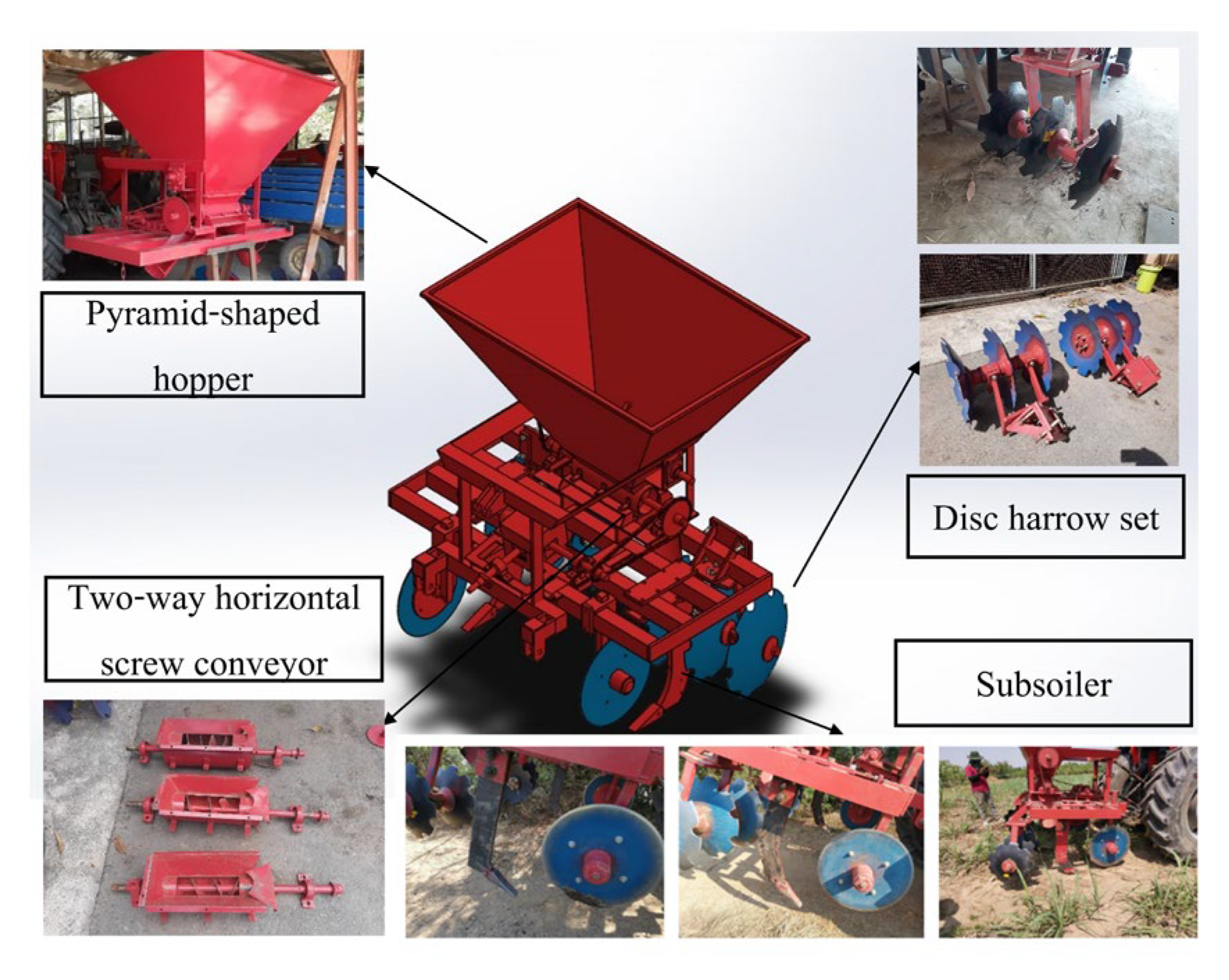

2.1. Overall Design

2.2. The Combined Cultivating Implement

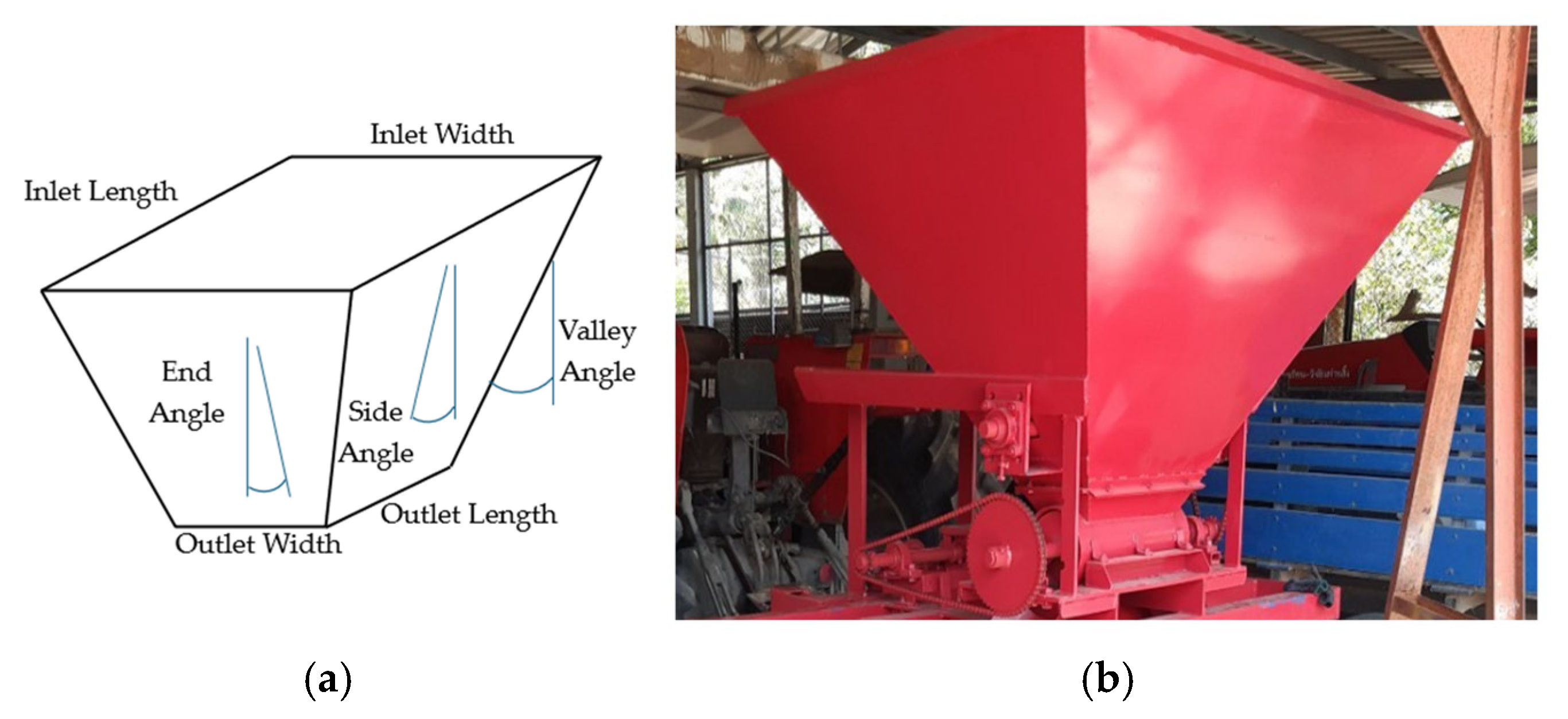

2.3. Selection of the Appropriate Size of a Two-Way Horizontal Screw Conveyor for Conveying the Organic Fertilizer

2.4. Tractor and Experimental Site

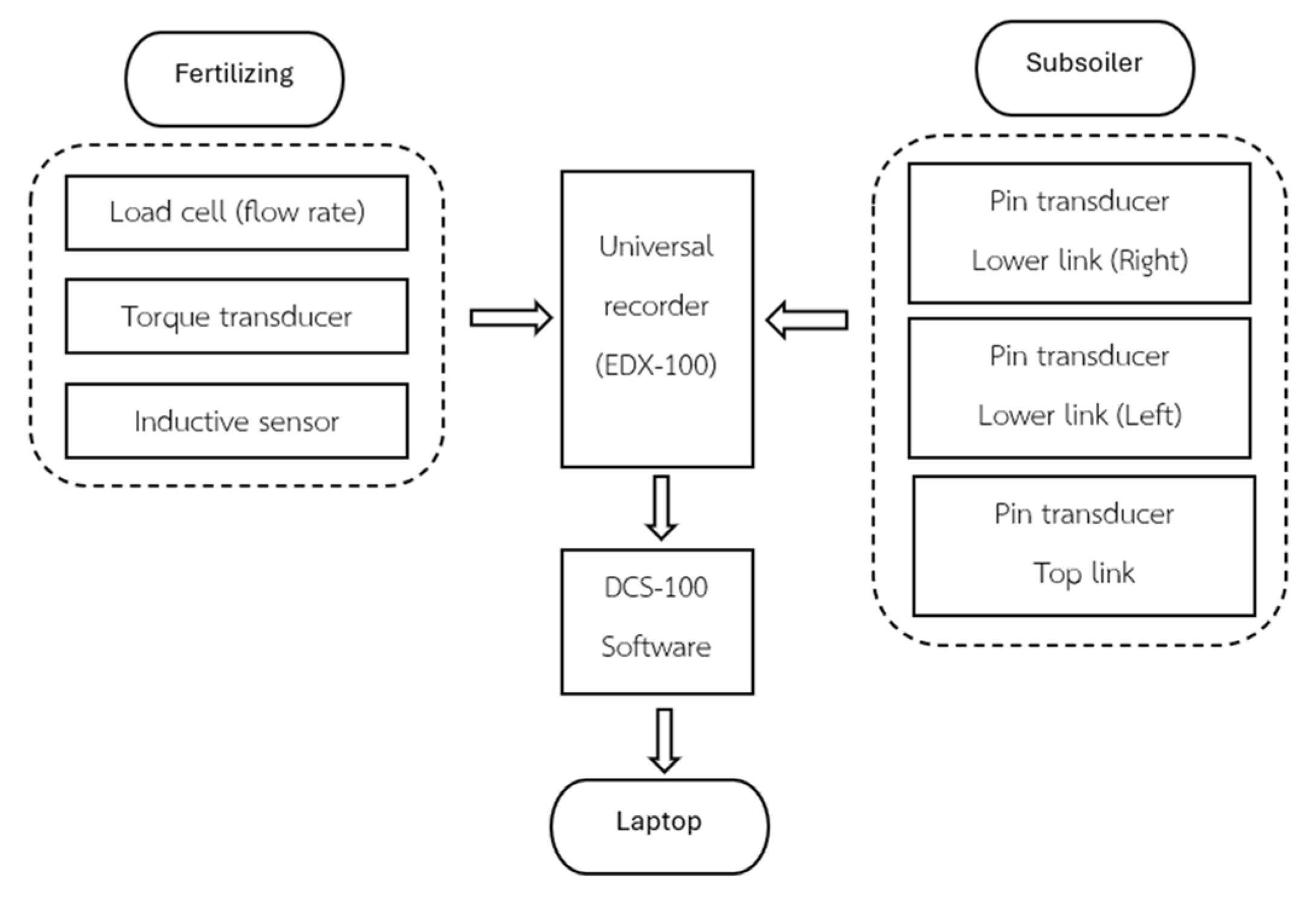

2.5. Instrumentation and Testing Methods

3. Results

3.1. Combined Cultivating Implement Test in a Ratoon Sugarcane Field

3.2. Two-Way Horizontal Screw Conveyor Test

3.3. Field Performance Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, F.; Wang, Z.; Lu, G.; Zeng, R.; Que, Y. Sugarcane Ratooning Ability: Research Status, Shortcomings, and Prospects. Biology 2021, 10, 1052. [Google Scholar] [CrossRef] [PubMed]

- Riajaya, P.D.; Hariyono, B.; Cholid, M.; Kadarwati, F.T.; Santoso, B.; Djumali; Subiyakto. Growth and Yield Potential of New Sugarcane Varieties during Plant and First Ratoon Crops. Sustainability 2022, 14, 14396. [Google Scholar] [CrossRef]

- De Aquino, G.S.; de Conti Medina, C.; da Costa, D.C.; Shahab, M.; Santiago, A.D. Sugarcane straw management and its impact on production and development of ratoons. Ind. Crops Prod. 2017, 102, 58–64. [Google Scholar] [CrossRef]

- Bluett, C.; Tullberg, J.N.; McPhee, J.E.; Antille, D.L. Soil and Tillage Research: Why still focus on soil compaction? Soil Tillage Res. 2019, 194, 1–2. [Google Scholar] [CrossRef]

- Aguilera Esteban, D.A.; de Souza, Z.M.; Tormena, C.A.; Lovera, L.H.; de Souza Lima, E.; de Oliveira, I.N.; de Paula Ribeiro, N. Soil compaction, root system and productivity of sugarcane under different row spacing and controlled traffic at harvest. Soil Tillage Res. 2019, 187, 60–71. [Google Scholar] [CrossRef]

- Otto, R.; Silva, A.P.; Franco, H.C.J.; Oliveira, E.C.A.; Trivelin, P.C.O. High soil penetration resistance reduces sugarcane root system development. Soil Tillage Res. 2011, 117, 201–210. [Google Scholar] [CrossRef]

- Silva, R.P.; Rolim, M.M.; Gomes, I.F.; Pedrosa, E.M.R.; Tavares, U.E.; Santos, A.N. Numerical modeling of soil compaction in a sugarcane crop using the finite element method. Soil Tillage Res. 2018, 181, 1–10. [Google Scholar] [CrossRef]

- Oldfield, E.E.; Bradford, M.A.; Wood, S.A. Global meta-analysis of the relationship between soil organic matter and crop yields. Soil 2019, 5, 15–32. [Google Scholar] [CrossRef]

- Surendran, U.; Ramesh, V.; Jayakumar, M.; Marimuthu, S.; Sridevi, G. Improved sugarcane productivity with tillage and trash management practices in semi arid tropical agro ecosystem in India. Soil Tillage Res. 2016, 158, 10–21. [Google Scholar] [CrossRef]

- Yadav, R.L.; Prasad, S.R.; Singh, R.; Srivastava, V.K. Recycling sugarcane trash to conserve soil organic carbon for sustaining yields of successive ratoon crops in sugarcane. Bioresour. Technol. 1994, 49, 231–235. [Google Scholar]

- Shukla, S.K.; Jaiswal, V.P.; Sharma, L.; Tiwari, R.; Pathak, A.D.; Gaur, A.; Awasthi, S.K.; Srivastava, A. Trash management and Trichoderma harzianum influencing photosynthesis, soil carbon sequestration, and growth and yield of sugarcane ratoon in subtropical India. Eur. J. Agron. 2022, 141, 126631. [Google Scholar] [CrossRef]

- Barbosa, L.C.; Magalhães, P.S.G.; Bordonal, R.O.; Cherubin, M.R.; Castioni, G.A.F.; Tenelli, S.; Franco, H.C.J.; Carvalho, J.L.N. Soil physical quality associated with tillage practices during sugarcane planting in south-central Brazil. Soil Tillage Res. 2019, 195, 104383. [Google Scholar] [CrossRef]

- Kaur, R.; Arora, V.K. Deep tillage and residue mulch effects on productivity and water and nitrogen economy of spring maize in north-west India. Agric. Water Manag. 2019, 213, 724–731. [Google Scholar] [CrossRef]

- Scarpare, F.V.; de Jong van Lier, Q.; de Camargo, L.; Pires, R.C.M.; Ruiz-Corrêa, S.T.; Bezerra, A.H.F.; Gava, G.J.C.; Dias, C.T.S. Tillage effects on soil physical condition and root growth associated with sugarcane water availability. Soil Tillage Res. 2019, 187, 110–118. [Google Scholar] [CrossRef]

- Chen, Z.; Du, Z.; Zhang, Z.; Wang, G.; Li, J. Dynamic changes in soil organic carbon induced by long-term compost application under a wheat-maize double cropping system in North China. Sci. Total Environ. 2024, 913, 169407. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Liu, X.; Zhang, D.; Li, L.; Li, W.; Sheng, L. Effects of long-term application of organic fertilizer on improving organic matter content and retarding acidity in red soil from China. Soil Tillage Res. 2019, 195, 104382. [Google Scholar] [CrossRef]

- Navarro-Pedreño, J.; Almendro-Candel, M.B.; Zorpas, A.A. The Increase of Soil Organic Matter Reduces Global Warming, Myth or Reality? Sci 2021, 3, 18. [Google Scholar] [CrossRef]

- Prout, J.M.; Shepherd, K.D.; McGrath, S.P.; Kirk, G.J.D.; Haefele, S.M. What is a good level of soil organic matter? An index based on organic carbon to clay ratio. Eur. J. Soil Sci. 2020, 72, 2493–2503. [Google Scholar] [CrossRef]

- Robertson, F.A.; Thorburn, P.J. Decomposition of sugarcane harvest residue in different climatic zones. Aust. J. Soil Res. 2007, 45, 1–11. [Google Scholar] [CrossRef]

- Moitinho, M.R.; Ferraudo, A.S.; Panosso, A.R.; Bicalho, E.d.S.; Teixeira, D.D.B.; Barbosa, M.d.A.; Tsai, S.M.; Borges, B.M.F.; Cannavan, F.d.S.; Souza, J.A.M.d.; et al. Effects of burned and unburned sugarcane harvesting systems on soil CO2 emission and soil physical, chemical, and microbiological attributes. CATENA 2021, 196, 104903. [Google Scholar] [CrossRef]

- Panosso, A.R.; Marques, J.; Milori, D.M.B.P.; Ferraudo, A.S.; Barbieri, D.M.; Pereira, G.T.; La Scala, N. Soil CO2 emission and its relation to soil properties in sugarcane areas under Slash-and-burn and Green harvest. Soil Tillage Res. 2011, 111, 190–196. [Google Scholar] [CrossRef]

- Morais, M.C.; Siqueira-Neto, M.; Guerra, H.P.; Satiro, L.S.; Soltangheisi, A.; Cerri, C.E.P.; Feigl, B.J.; Cherubin, M.R. Trade-Offs between Sugarcane Straw Removal and Soil Organic Matter in Brazil. Sustainability 2020, 12, 9363. [Google Scholar] [CrossRef]

- Dlamini, N.E.; Zhou, M. Soils and seasons effect on sugarcane ratoon yield. Field Crops Res. 2022, 284, 108588. [Google Scholar] [CrossRef]

- Dietrich, G.; Sauvadet, M.; Recous, S.; Redin, M.; Pfeifer, I.C.; Garlet, C.M.; Bazzo, H.; Giacomini, S.J. Sugarcane mulch C and N dynamics during decomposition under different rates of trash removal. Agric. Ecosyst. Environ. 2017, 243, 123–131. [Google Scholar] [CrossRef]

- Koorneef, G.J.; Pulleman, M.M.; Comans, R.N.J.; van Rijssel, S.Q.; Barré, P.; Baudin, F.; de Goede, R.G.M. Assessing soil functioning: What is the added value of soil organic carbon quality measurements alongside total organic carbon content? Soil Biol. Biochem. 2024, 196, 109507. [Google Scholar] [CrossRef]

- Biratu, G.K.; Elias, E.; Ntawuruhunga, P. Does the application of mineral and organic fertilizer affect cassava tuber quality? An evidence from Zambia. J. Agric. Food Res. 2022, 9, 100339. [Google Scholar] [CrossRef]

- Tröster, M.F.; Pahl, H.; Sauer, J. Effects of application costs on fertilizer application strategy. Comput. Electron. Agric. 2019, 167, 105033. [Google Scholar] [CrossRef]

- Hu, J.; He, J.; Wang, Y.; Wu, Y.; Chen, C.; Ren, Z.; Li, X.; Shi, S.; Du, Y.; He, P. Design and study on lightweight organic fertilizer distributor. Comput. Electron. Agric. 2020, 169, 105149. [Google Scholar] [CrossRef]

- Xu, B.; Cui, Q.; Guo, L.; Hao, L. Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader. Agronomy 2024, 14, 1732. [Google Scholar] [CrossRef]

- Wang, Y.-x.; Chen, S.-p.; Zhang, D.-x.; Yang, L.; Cui, T.; Jing, H.-r.; Li, Y.-h. Effects of subsoiling depth, period interval and combined tillage practice on soil properties and yield in the Huang-Huai-Hai Plain, China. J. Integr. Agric. 2020, 19, 1596–1608. [Google Scholar] [CrossRef]

- Kuzucu, M.; Dökmen, F. The Effects of Tillage on Soil Water Content in Dry Areas. Agric. Agric. Sci. Procedia 2015, 4, 126–132. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Bewsher, S.; Guzzomi, A.L.; Lehane, B.M.; Fourie, A.B.; Riethmuller, G. Evaluation of the dynamic cone penetrometer to detect compaction in ripped soils. Soil Tillage Res. 2018, 175, 150–157. [Google Scholar] [CrossRef]

- Voltr, V.; Menšík, L.; Hlisnikovský, L.; Hruška, M.; Pokorný, E.; Pospíšilová, L. The Soil Organic Matter in Connection with Soil Properties and Soil Inputs. Agronomy 2021, 11, 779. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Q.; Xu, D.; Li, H.; He, J.; Lu, C. Design and experimental research on the counter roll differential speed solid organic fertilizer crusher based on DEM. Comput. Electron. Agric. 2023, 207, 107748. [Google Scholar] [CrossRef]

- Zinkevičienė, R.; Jotautienė, E.; Juostas, A.; Comparetti, A.; Vaiciukevičius, E. Simulation of Granular Organic Fertilizer Application by Centrifugal Spreader. Agronomy 2021, 11, 247. [Google Scholar] [CrossRef]

- Yu, Y.; Arnold, P.C. Theoretical modelling of torque requirements for single screw feeders. Powder Technol. 1997, 93, 151–162. [Google Scholar] [CrossRef]

- Fernandez, J.W.; Cleary, P.W.; McBride, W. Effect of screw design on hopper draw down by a horizontal screw feeder. In Proceedings of the Seventh International Conference on CFD in the Minerals and Process Industries CSIRO, Melbourne, Australia, 9–11 December 2009. [Google Scholar]

- ASABE. Agricultural Machinery Management Data; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009. [Google Scholar]

- Schneider, F.; Don, A.; Hennings, I.; Schmittmann, O.; Seidel, S.J. The effect of deep tillage on crop yield—What do we really know? Soil Tillage Res. 2017, 174, 193–204. [Google Scholar] [CrossRef]

- Damanauskas, V.; Velykis, A.; Satkus, A. Efficiency of disc harrow adjustment for stubble tillage quality and fuel consumption. Soil Tillage Res. 2019, 194, 104311. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Zhang, X. Modelling the interaction of a deep tillage tool with heterogeneous soil. Comput. Electron. Agric. 2017, 143, 130–138. [Google Scholar] [CrossRef]

| Disk Harrow Size | Subsoiler Type | Gear (MF-4245) | Engine Speed, rpm | Working Speed, m·s−1 | % Slip | Draft Force, kN |

|---|---|---|---|---|---|---|

| 18 inches | Straight | Low3 | 1500 | 0.93 ± 0.03 d | 7.06 ± 1.47 a | 11.80 ± 0.62 a |

| 1900 | 1.19 ± 0.04 d | 7.87 ± 1.13 a | 12.90 ± 0.82 a | |||

| Low4 | 1500 | 1.29 ± 0.04 d | 8.24 ± 0.96 a | 12.95 ± 0.77 a | ||

| 1900 | 1.64 ± 0.04 d | 8.49 ± 1.39 a | 13.20 ± 0.95 a | |||

| Inclined | Low3 | 1500 | 0.95 ± 0.04 c | 8.08 ± 0.88 ab | 11.70 ± 0.60 a | |

| 1900 | 1.20 ± 0.03 c | 7.92 ± 1.43 ab | 12.75 ± 0.80 a | |||

| Low4 | 1500 | 1.22 ± 0.03 c | 8.81 ± 1.39 ab | 12.58 ± 1.01 a | ||

| 1900 | 1.57 ± 0.05 c | 10.26 ± 1.47 ab | 12.95 ± 1.12 a | |||

| Curved | Low3 | 1500 | 0.93 ± 0.02 cd | 6.80 ± 0.60 a | 12.00 ± 0.42 a | |

| 1900 | 1.24 ± 0.02 cd | 7.95 ± 0.75 a | 13.01 ± 0.59 a | |||

| Low4 | 1500 | 1.25 ± 0.04 cd | 8.04 ± 1.54 a | 13.01 ± 0.85 a | ||

| 1900 | 1.58 ± 0.06 cd | 8.89 ± 1.71 a | 13.31 ± 0.91 a | |||

| 22 inches | Straight | Low3 | 1500 | 0.92 ± 0.02 bc | 6.67 ± 0.98 ab | 14.70 ± 0.56 bc |

| 1900 | 1.18 ± 0.04 bc | 8.46 ± 1.04 ab | 14.95 ± 0.95 bc | |||

| Low4 | 1500 | 1.19 ± 0.05 bc | 8.69 ± 1.59 ab | 15.03 ± 1.21 bc | ||

| 1900 | 1.59 ± 0.05 bc | 8.81 ± 1.02 ab | 15.52 ± 1.15 bc | |||

| Inclined | Low3 | 1500 | 0.92 ± 0.02 a | 7.74 ± 0.64 b | 14.30 ± 0.98 b | |

| 1900 | 1.14 ± 0.03 a | 8.91 ± 0.81 b | 14.50 ± 0.82 b | |||

| Low4 | 1500 | 1.18 ± 0.04 a | 8.82 ± 0.93 b | 14.55 ± 0.92 b | ||

| 1900 | 1.51 ± 0.04 a | 10.92 ± 1.33 b | 15.32 ± 1.05 b | |||

| Curved | Low3 | 1500 | 0.91 ± 0.03 ab | 7.25 ± 0.95 ab | 15.26 ± 0.80 c | |

| 1900 | 1.15 ± 0.04 ab | 7.88 ± 1.18 ab | 15.50 ± 1.01 c | |||

| Low4 | 1500 | 1.21 ± 0.04 ab | 9.54 ± 0.96 ab | 15.72 ± 1.20 c | ||

| 1900 | 1.52 ± 0.04 ab | 10.60 ± 1.20 ab | 16.05 ± 1.09 c |

| PTO Shaft Speed, rpm | Screw Size, Inches | Mass flow rate, kg·s−1 | Torque, Nm | PTO Power, kW | Specific mass flow rate, kg·kW−1·s−1 |

|---|---|---|---|---|---|

| 300 | 4 | 0.27 ± 0.02 a | 3.67 ± 0.61 a | 0.12 ± 0.02 a | 2.34 ± 0.27 a |

| 6 | 0.94 ± 0.02 b | 7.03 ± 0.71 b | 0.22 ± 0.02 b | 4.30 ± 0.41 b | |

| 8 | 2.13 ± 0.02 c | 9.33 ± 0.85 c | 0.29 ± 0.03 c | 7.32 ± 0.72 c | |

| 360 | 4 | 0.32 ± 0.02 a | 8.33 ± 0.95 a | 0.31 ± 0.04 a | 1.02 ± 0.18 a |

| 6 | 1.12 ± 0.02 b | 11.87 ± 1.05 b | 0.45 ± 0.04 b | 2.52 ± 0.23 b | |

| 8 | 2.61 ± 0.02 c | 20.87 ± 1.46 c | 0.79 ± 0.05 c | 3.32 ± 0.23 c | |

| 420 | 4 | 0.38 ± 0.01 a | 20.00 ± 1.80 a | 0.88 ± 0.08 a | 0.43 ± 0.03 a |

| 6 | 1.31 ± 0.02 b | 23.90 ± 1.23 b | 1.05 ± 0.05 b | 1.24 ± 0.06 b | |

| 8 | 2.96 ± 0.02 c | 36.43 ± 1.81 c | 1.60 ± 0.08 c | 1.85 ± 0.09 c | |

| 480 | 4 | 0.43 ± 0.02 a | 31.37 ± 2.85 a | 1.58 ± 0.14 a | 0.28 ± 0.04 a |

| 6 | 1.50 ± 0.02 b | 39.13 ± 2.15 b | 1.97 ± 0.11 b | 0.77 ± 0.04 b | |

| 8 | 3.22 ± 0.02 c | 47.57 ± 1.45 c | 2.39 ± 0.07 c | 1.35 ± 0.04 c | |

| 540 | 4 | 0.48 ± 0.02 a | 45.67 ± 3.35 a | 2.58 ± 0.19 a | 0.19 ± 0.02 a |

| 6 | 1.69 ± 0.02 b | 55.20 ± 2.56 b | 3.12 ± 0.14 b | 0.54 ± 0.03 b | |

| 8 | 3.42 ± 0.02 c | 64.47 ± 1.55 c | 3.65 ± 0.09 c | 0.94 ± 0.02 c |

| Description | Unit | Value |

|---|---|---|

| Field width | m | 54 |

| Field length | m | 108 |

| Test area | ha | 0.58 |

| Sugarcane row distance | m | 1.5 |

| Quantity | rows | 36 |

| Slip | % | 7.7 |

| Working speed | m·s−1 (km·hr−1) | 1.25 (4.50) |

| Tillage depth | cm | 25 |

| Fuel consumption | L·ha−1 | 13.1 |

| Returning time | s | 795 |

| Working time | s | 2350 |

| Theoretical field capacity | ha·hr−1 | 1.35 |

| Actual field capacity | ha·hr−1 | 0.89 |

| Field efficiency | % | 66.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullakasim, W.; Khongman, K.; Sukcharoenvipharat, W.; Usaborisut, P. Development and Performance Testing of a Combined Cultivating Implement and Organic Fertilizer Applicator for Sugarcane Ratooning. AgriEngineering 2025, 7, 105. https://doi.org/10.3390/agriengineering7040105

Abdullakasim W, Khongman K, Sukcharoenvipharat W, Usaborisut P. Development and Performance Testing of a Combined Cultivating Implement and Organic Fertilizer Applicator for Sugarcane Ratooning. AgriEngineering. 2025; 7(4):105. https://doi.org/10.3390/agriengineering7040105

Chicago/Turabian StyleAbdullakasim, Wanrat, Kawee Khongman, Watcharachan Sukcharoenvipharat, and Prathuang Usaborisut. 2025. "Development and Performance Testing of a Combined Cultivating Implement and Organic Fertilizer Applicator for Sugarcane Ratooning" AgriEngineering 7, no. 4: 105. https://doi.org/10.3390/agriengineering7040105

APA StyleAbdullakasim, W., Khongman, K., Sukcharoenvipharat, W., & Usaborisut, P. (2025). Development and Performance Testing of a Combined Cultivating Implement and Organic Fertilizer Applicator for Sugarcane Ratooning. AgriEngineering, 7(4), 105. https://doi.org/10.3390/agriengineering7040105