Abstract

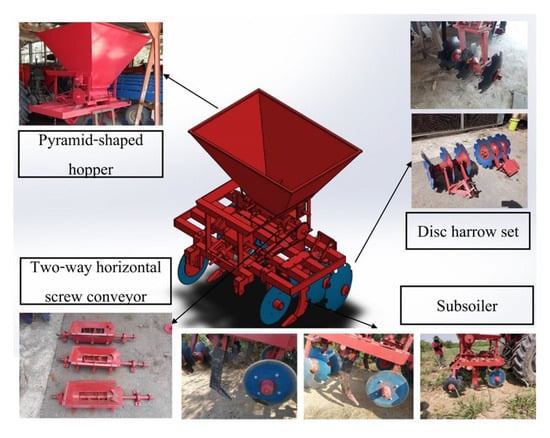

Efficient sugarcane ratooning management requires maintaining soil organic carbon (SOC) balance and improving soil physical properties. Retaining agricultural residues and applying organic fertilizers are essential for sustaining SOC levels. However, excessive soil compaction caused by heavy machinery remains a challenge, and no existing implements are specifically designed to alleviate soil compaction and apply organic fertilizers in sugarcane ratoon fields. This study aimed to design, develop, and evaluate an organic fertilizer applicator capable of performing a single-step operation that integrates subsoiling, fertilizer application, and soil mixing. The developed implement consists of four main components: (1) a pyramid-shaped hopper, (2) a two-way horizontal screw conveyor, (3) a subsoiler, and (4) a disk harrow set. The results indicated that the specific mass flow rate is directly proportional to screw size and inversely proportional to PTO shaft speed. The optimal configuration for the organic fertilizer applicator included an 18-inch harrow set, a 10-degree harrow angle, an inclined-leg subsoiler, and the Low3 gear at 1900 rpm, which required a draft force of 12.75 kN. Field performance tests demonstrated an actual field capacity of 0.89 ha·h−1 and a field efficiency of 66.17%, confirming the implement’s effectiveness in improving soil conditions and integrating tillage with fertilizer application.

1. Introduction

Effectively managing sugarcane ratooning is essential for sustainable production [1,2,3]. However, ratoon fields present multiple challenges, particularly in soil preparation and organic matter management. Unlike plant cane fields, ratoon fields are not cleared, leading to significant obstacles in field operations. One of the most critical concerns is soil compaction, which results from the repeated use of heavy machinery over multiple growing cycles [4,5,6,7]. Additionally, soil organic carbon (SOC) depletion impacts soil health and productivity, necessitating improved ratoon field management practices [8,9,10,11].

Soil compaction presents a significant limitation in ratoon sugarcane production. Continuous field traffic from heavy agricultural machinery compresses soil particles, reducing porosity and increasing the bulk density of the field [4,5,6,7]. This compaction creates a restrictive layer that limits root penetration and hinders moisture exchange between the subsoil and the topsoil, ultimately affecting sugarcane growth [12,13]. In fields cultivated for a long time, the compacted layer often reaches more than 50 cm, significantly affecting ratoon sugarcane productivity [14]. The soil’s penetration resistance should not surpass 2.0 MPa to ensure proper root development [6].

At the same time, the depletion of SOC presents another significant challenge. SOC is a key indicator of soil health and is crucial in maintaining soil fertility and structure [15,16,17,18]. Each year, sugarcane harvesting removes a substantial amount of organic carbon in stalks, with approximately 10–20% of the total biomass remaining as sugarcane trash, such as dried leaves and tops [10]. Despite these residues, SOC levels decline due to slow decomposition rates and continuous field operations. Trash management practices significantly influence SOC levels. Fields with trash mulching generally experience an increase in SOC concentration, whereas those with residue removal or burning exhibit declining SOC levels [19,20,21,22]. Maintaining optimal SOC levels improves soil quality and enhances sugarcane yields, which tend to stabilize at approximately 2% SOC [8]. Additionally, SOC contributes to carbon sequestration, reducing atmospheric carbon dioxide. However, excessive SOC accumulation may lead to methane emissions, exacerbating greenhouse gas effects [17].

Ratoon sugarcane production primarily depends on chemical fertilizers to address soil fertility issues. However, long-term use of these fertilizers alone leads to soil degradation, including reduced organic matter content, declining soil fertility, and lower yields [23]. Studies have shown that continuous application of primary nutrients decreases soil pH by 0.07 per year, whereas organic fertilizers increase soil pH by 0.04 per year [16]. Furthermore, sugarcane trash’s slow decomposition limits organic matter availability for soil improvement [9,19,24]. Organic fertilizers provide a more sustainable alternative by delivering essential nutrients and enhancing soil physical properties. Unlike chemical fertilizers, which supply only primary nutrients, organic fertilizers improve soil structure, water retention, and microbial activity [9,25,26,27]. However, applying organic fertilizers in ratoon sugarcane fields presents challenges due to the row-based planting system and the need for large quantities of organic inputs [28,29].

Considering the challenges of soil compaction, declining SOC levels, and the limitations of conventional fertilizer application, an integrated approach is necessary to enhance ratoon sugarcane productivity. Subsoiling is widely used to relieve soil compaction, improve root penetration, and enhance water movement in the soil profile [13,30,31]. However, current ratoon field management practices rarely combine subsoiling with organic fertilizer application. The compacted soil layer in ratoon sugarcane fields typically lies at a depth of 20–30 cm, aligning with studies that report long-term conventional tillage causing compaction at approximately 20 cm depth [32]. To maintain SOC levels and alleviate soil compaction, ratoon sugarcane fields should be fertilized with organic fertilizers [9,33].

Commercial organic fertilizer applicators in sugarcane fields currently utilize broadcast or sprinkle application methods [28,29,34,35]. Effectively applying organic fertilizers presents a significant challenge in ratoon fields, which require precise row-based applications and higher organic fertilizer inputs than chemical fertilizers [28]. This study introduces the development of an implement designed to apply organic fertilizers in a controlled manner while also breaking up compacted soil layers. A screw conveyor mechanism, commonly used for agricultural material handling, was integrated into the system to manage fertilizer flow and ensure continuous application [36,37]. The system was engineered to operate in two directions simultaneously, applying organic fertilizer to two rows at once. A subsoiler attachment was also tested to determine the optimal working depth and speed, ensuring compatibility with other field equipment.

This study aimed to design, develop, and evaluate an integrated implement capable of applying organic fertilizers and alleviating soil compaction in ratoon sugarcane fields. The research investigated the underlying scientific principles of soil dynamics and property improvements to enhance mechanized soil management techniques. This approach was expected to improve soil health and support ratoon sugarcane cultivation growth by addressing these challenges in one operation.

To achieve these objectives, the study focused on optimizing the screw conveyor specifications to ensure uniform distribution of the organic fertilizer, determining the appropriate subsoiler design and working depth based on soil mechanical properties in ratoon field conditions and evaluating the system’s performance in improving soil properties and retaining organic matter. The findings are anticipated to enhance the scientific understanding of soil amendment practices and their role in improving soil conditions in ratoon sugarcane fields.

2. Materials and Methods

2.1. Overall Design

The combined cultivating implement, and organic fertilizer applicator was designed for sugarcane ratooning fields. It is compatible with category II tractors and operates effectively in fields with a sugarcane row spacing of at least 1.40 m. The implement applies the organic fertilizer to two rows simultaneously, with a flow rate of 3.125 to 6.250 tons per hectare. The organic fertilizer is held in a 1.34 m3 pyramid-shaped hopper. The implement alleviates soil compaction at a depth of 20–30 cm and consists of two main components: the cultivating implement and the organic fertilizer spreader.

The cultivating implement features a front subsoiler that breaks compacted soil in sugarcane ratooning fields, while the rear section mixes organic fertilizer into the topsoil at a depth of 10–15 cm. The organic fertilizer spreader is powered by the tractor’s PTO shaft, with power transmitted via a chain system. A two-way horizontal screw conveyor controls the flow rate. The system is mounted using a category II three-point hitch according to the ASABE standards. This implement integrates soil breaking, fertilizer dispensing, and soil mixing into a single operational step. The structure of the combined cultivating implement and organic fertilizer applicator is shown in Figure 1.

Figure 1.

The structure of the combined cultivating implement and organic fertilizer applicator.

2.2. The Combined Cultivating Implement

The subsoiler is the implement’s most traction-intensive component. Extensive research has been conducted to optimize its design for reduced draft force requirements. Although the draft force can be estimated using Reece’s equation (1965), the operation involves multiple soil-contacting components, necessitating field tests to determine the subsoiler’s draft force under actual conditions. The subsoiler was designed for disassembly and tested in three configurations: straight legs, inclined legs, and curved legs.

The organic fertilizer mixing system was adapted from commercially available disk harrows, which also aid in chopping dry sugarcane leaves. Two disk sizes, 18 and 22 inches, were tested, each with adjustable angles of 10 and 25°. The subsoiler evaluated these configurations to determine the optimal harrow angle, disk size, and working speed for effective fertilizer incorporation. The structure of the combined cultivating implement is shown in Figure 2.

Figure 2.

The structure of the combined cultivating implement: (a) the combined cultivating implement and organic fertilizer applicator; (b) components of the combined cultivating implement.

2.3. Selection of the Appropriate Size of a Two-Way Horizontal Screw Conveyor for Conveying the Organic Fertilizer

Screw conveyors are widely used in agriculture for efficient material transport and controlled flow rates. While commonly used for chemical fertilizers, their application in organic fertilizer spreading is less prevalent due to the higher volume required. Unlike conventional organic fertilizer applicators designed for new plantation plots, this study applies a horizontal screw conveyor for sugarcane ratooning plots. Although theoretical calculations can estimate the appropriate screw diameter, the variability in organic fertilizer properties complicates a precise design.

To evaluate the performance of screw conveyors for organic fertilizer application, preliminary laboratory tests were performed. Three screw conveyors with outer diameters of 4, 6, and 8 inches, a 1.5-inch screw shaft diameter, and a 1:1 pitch-to-diameter ratio were tested. Mass flow rate and torque were measured under varying operational conditions to identify the most suitable screw size.

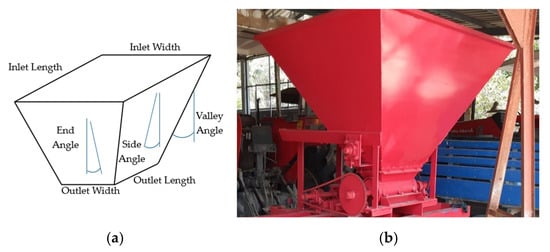

The hopper design significantly influences the fertilizer flow. While conical hoppers are commonly used for chemical fertilizers and wedge-shaped hoppers are suited for full-width applications, a pyramid-shaped hopper was selected for this study. The pyramid shape ensures complete fertilizer discharge due to its four sloping sides. The side, end, and valley angles were designed at 24, 28, and 35°, respectively, corresponding to 66, 62, and 55° relative to the horizontal axis. These angles exceed the angle of repose (37°) and the friction angle (40°) of the organic fertilizer, ensuring uninterrupted material flow. The tested organic fertilizers had a bulk density of 453.67 ± 4.04 kg·m−3, the angle of repose and the friction angle were 37.33 ± 0.58 and 40.33 ± 0.58°, respectively, and a moisture content of 26.67 ± 1.60% dry basis. The description of a pyramid-shaped hopper is shown in Figure 3.

Figure 3.

Description of the pyramid-shaped hopper: (a) angle of the pyramid-shaped hopper; (b) the pyramid-shaped hopper.

2.4. Tractor and Experimental Site

The implement was powered by a Massey Ferguson MF4245 category II tractor, delivering a maximum power of 85 horsepower at 2200 rpm, a PTO shaft speed of 540 rpm at 1900 rpm engine speed, and a peak torque of 310.5 Nm at 1500 rpm.

Field experiments were conducted at two locations in Thailand, each serving a specific purpose in evaluating the implement.

Site 1: parameter optimization (Tha Maka District, Kanchanaburi Province).

The first site, a 40-day-old sugarcane ratooning field in Tha Maka District (13.963961° N, 99.862581° E), was selected for optimizing the operational parameters of the implement’s soil-contacting components. This site featured a 128 m2 (3.2 m × 40 m) test plot with clay loam soil (21.52% sand, 43.37% silt, 35.11% clay). The soil moisture content at a depth of 10–15 cm was 11.2% on a dry basis, the soil bulk density was 1.89 kg·m−3, and the soil strength, which was measured using a soil cone penetrometer, had the highest value of 2.5 MPa at the 10 cm depth. The penetration resistance measurement at the 10 cm depth was chosen to reflect the expected working depth of the soil-contacting components during parameter optimization.

Site 2: performance evaluation (Kamphaeng Saen District, Nakhon Pathom Province).

The second site, located in Kamphaeng Saen District (13.997270° N, 99.967549° E), was used to evaluate the overall performance of the organic fertilizer applicator. This site offered a larger test plot of 5832 m2 (0.58 ha, 54 m × 108 m) with silty clay loam soil (11.37% sand, 53.48% silt, 35.15% clay). The soil moisture content at the 10–15 cm depth was 10.3% on a dry basis, the soil bulk density was 1.97 kg·m−3, and the soil strength, which was measured using a soil cone penetrometer, had the highest value of 4.0 MPa at the depth of 5 cm. The penetration resistance measurement at the 5 cm depth was selected to represent the soil conditions where the fertilizer application would primarily take place.

2.5. Instrumentation and Testing Methods

A real-time load cell system measured the organic fertilizer flow rate and torque. Calibration was performed with a universal testing machine (Instron 5569, Instron, Norwood, MA, USA), and two KYOWA load cells (500 kg capacity each, KYOWA Tokyo, Japan) were used. A proximity switch measured PTO shaft speed, while a KYOWA torque transducer (500 Nm capacity) was installed at the PTO shaft. Data on the mass flow rate (kg·s−1), torque (Nm), and PTO shaft power (kW) were collected and analyzed for three screw conveyor sizes (4, 6, and 8 inches) at five PTO shaft speeds (300, 360, 420, 480, and 540 rpm).

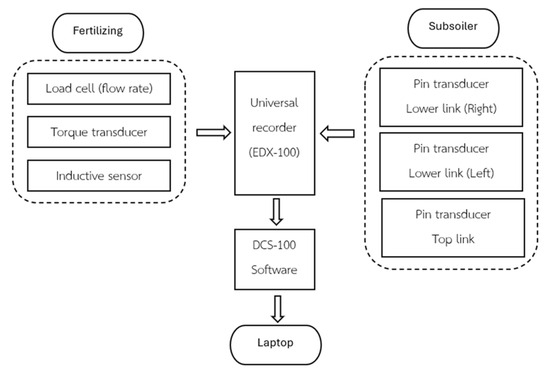

Draft force measurements were conducted using three-pin transducers installed at the tractor’s left lower, right lower, and upper links. These transducers measured horizontal and vertical forces and were calibrated using the Instron 5569 universal testing machine. Data were recorded and analyzed using a KYOWA EDX-100A universal signal recorder.

To determine the optimal soil-engaging parameters, field tests evaluated different subsoiler types (straight, inclined, and curved legs), disk harrow sizes (18 and 22 inches), and harrow angles (10° and 25°). Tests were conducted using two tractor gears (L3 and L4) at 1500 and 1900 rpm engine speeds, with three replications per configuration, resulting in 144 tests.

The optimal screw conveyor size for organic fertilizer application was determined through laboratory tests under five PTO speeds (300–540 rpm) using three screw sizes (4, 6, and 8 inches). Each configuration was tested three times, totaling 45 tests. The specific mass flow rate (kg·s−1·kW−1) was analyzed to identify the most efficient screw size.

A field performance test was conducted in a sugarcane ratooning plot measuring 0.58 ha (108 m × 54 m). The test followed the RNAM standards, with a plot length-to-width ratio of 2:1. Data collection included the total working time, turning time, fertilizer application time, working speed, wheel slip percentage, plowing depth and width, and fuel consumption. Theoretical and actual field capacities (ha·h−1) and overall efficiency (%) were analyzed. A block diagram of the sensors and the data acquisition system is shown in Figure 4, and sensors and data acquisition systems are shown in Figure 5.

Figure 4.

Block diagram of the sensors and the data acquisition system.

Figure 5.

Sensors and the data acquisition system.

Data on the draft force (kN), working speed (m·s−1), slip (%), the mass flow rate (kg·s−1), torque (Nm), the PTO power (kW), and the specific mass flow rate (kg·kW−1·s−1) were statistically analyzed using ANOVA.

3. Results

3.1. Combined Cultivating Implement Test in a Ratoon Sugarcane Field

From the test results aimed at selecting the optimal parameters for the combined cultivating implement, it was determined that the preferred harrow angle for the organic fertilizer applicator was 10°. This angle effectively mixed the organic fertilizer and the topsoil thoroughly in the sugarcane furrow. In contrast, while the harrow angle of 25° achieved better soil turnover, the equipment was primarily designed to mix the organic fertilizer and soil. Furthermore, this angle required a higher draft force and resulted in some soil being turned over to cover the sugarcane ratooning, negatively impacting the growth of the sugarcane. Thus, the 10-degree angle was chosen for the next test. The unsuitability of the 25-degree angle during operation is illustrated in Figure 6.

Figure 6.

The unsuitable operation of a 25-degree angle in the operation: (a) field condition before working; (b) field condition after working.

From Table 1, the test at Site 1 was conducted to select the best parameters for the equipment that is in direct contact with the soil; it was found that the 22-inch harrow tends to require more draft force than the 18-inch harrow. In addition, the smaller size of the 18-inch harrow, when working at the same speed, had a higher angular speed than the 22-inch harrow, resulting in better mixing of the organic fertilizer. The type of subsoiler requiring the least draft force is the inclined-leg type. When working at the Low4 gear, at some points of operation, the engine was found to have a glitch and stop, causing the tractor driver to control the hydraulics to control the plowing depth at all times, reducing the work’s efficiency. However, working at the Low3 gear allowed for smooth operation at 1500 and 1900 rpm engine speeds. However, working at the 1500 rpm engine speed, it was found that the sprinkled organic fertilizer was not mixed properly because the low working speed made it difficult to turn over and cover it. Working at the 1900 rpm engine speed, it was found that the organic fertilizer could be turned over and mixed very well. Therefore, the appropriate parameters for the organic fertilizer spreader were an 18-inch harrow set, a 10-degree tillage angle, an inclined-leg subsoiler, and the Low3 gear at 1900 rpm, which requires a draft force of 12.75 kN. The test was conducted in the field, so the draft force measurement error was inevitable. The primary reason for the issue was the nonhomogeneous texture of the soil. The test area was also covered with varying amounts of dry sugarcane leaves. As a result, the force measurement between the machine and the soil may have contained some errors, but these errors remained within an acceptable range. The operation of the organic fertilizer spreader with tillage, when the appropriate parameters are selected, is shown in Figure 7.

Table 1.

Comparative results of the draft force of the combined cultivating implement and organic fertilizer applicator.

Figure 7.

Operation of the organic fertilizer applicator: (a) suitable operation of the combined cultivating implement and organic fertilizer applicator; (b) field condition after working.

3.2. Two-Way Horizontal Screw Conveyor Test

The comparative performance results of each screw size were evaluated by comparing the specific mass flow rate values of each screw size. The specific mass flow rate was evaluated based on the mass flow rate ratio to the power at the tractor’s PTO shaft.

PTO power is in kW, mass flow rate is in kg·s−1, and specific mass flow rate is in kg·kW−1·s−1, as shown in Table 2.

Table 2.

Specific mass flow rate of each screw size.

From Table 2, it was found that the maximum value of the specific mass flow rate of all screw sizes occurred at a PTO shaft speed of 300 rpm, with the 8-inch screw having the maximum value of 7.32 kg·kW−1·s−1, the 6-inch screw having the value of 4.30 kg·kW−1·s−1, and the 4-inch screw having the value of 2.34 kg·kW−1·s−1. The specific mass flow rate value was directly related to the screw size and inversely related to the PTO shaft speed. The measurement error in torque and flow rate was partly attributed to inaccuracies in the measuring devices, specifically the torque transducer and the load cell. Additionally, the nonhomogeneous nature of the tested organic fertilizer contributed to this error. Both factors affected the overall measurement accuracy.

3.3. Field Performance Test

The developed organic fertilizer applicator was attached to two inclined-leg subsoilers, an 8-inch horizontal screw conveyor, two 18-inch mixing organic fertilizer sets, and a 10-degree disk harrow angle. The results of the field performance test are shown in Table 3.

Table 3.

Field performance test of the combined cultivating implement and organic fertilizer applicator.

Table 3 shows the field test at Site 2 to test the performance of the organic fertilizer applicator and shows the field performance test of the combined cultivating implement and organic fertilizer applicator in the sugarcane ratooning field. The organic fertilizer applicator had a field efficiency value of 66.17%, a fuel consumption rate of 13.1 L·ha−1, a theoretical field capacity of 1.35 ha·hr−1, and an actual field capacity of 0.89 ha·hr−1.

4. Discussion

The draft force required for soil tillage is influenced by soil texture, implement design, working speed, and depth, as outlined by the ASABE standards [38]. The developed organic fertilizer applicator incorporates a subsoiler and a mixing unit for organic fertilizer incorporation, which directly interacts with the soil. Previous studies indicated that an inclined-leg subsoiler operating at depths not exceeding 50 cm minimizes draft force [30,39], aligning with the findings of this study. The inclined-leg subsoiler in the developed implement exhibited the lowest draft force requirement at 12.75 kN, ensuring efficient soil loosening without excessive traction demands. Disk harrows were utilized in the organic fertilizer mixing section, and prior research established that draft force increases with disk angle and working speed [40]. The results confirm that a 10-degree disk angle incorporated effective organic fertilizer without excessive draft force. In contrast, a 25-degree angle, despite improving soil turnover, was unsuitable due to the higher draft force requirements and potential adverse effects on sugarcane growth. The selected 10-degree angle ensured optimal mixing while maintaining efficient implement operation.

The specific mass flow rate of the screw conveyor was assessed for various screw sizes and PTO speeds, with results indicating that the highest efficiency was achieved at a PTO speed of 300 rpm. The 8-inch screw conveyor demonstrated the maximum specific mass flow rate of 7.32 kg·kW−1·s−1, significantly outperforming the 6-inch (4.30 kg·kW−1·s−1) and 4-inch (2.34 kg·kW−1·s−1) screws. These findings highlight the direct relationship between screw size and mass flow rate, while an inverse relationship was observed between PTO speed and efficiency. Similar studies on fertilizer applicators in maize cultivation found that increasing the screw diameter improved flow rates but required adjustments to the PTO speed to maintain a uniform distribution [36]. The findings in this study align with such results, reinforcing the significance of optimizing screw dimensions to enhance fertilizer application efficiency.

The field performance test revealed that the organic fertilizer applicator achieved a field efficiency of 66.17%, falling within the 60–80% efficiency range specified for fertilizer spreaders by the ASABE standards [38]. However, the 4.50 km·h−1 working speed was approximately half the typical fertilizer applicator range. This speed reduction was necessary to maintain synchronization with the subsoiler operation, ensuring consistent tillage and fertilizer incorporation. Despite this limitation, the implement demonstrated a theoretical field capacity of 1.35 ha·h−1 and an actual field capacity of 0.89 ha·h−1, indicating a practical balance between efficiency and operational constraints. Compared with other integrated tillage and fertilizer application studies, previous research on conservation tillage systems for sugarcane showed that combining tillage and fertilization can reduce fuel consumption while improving nutrient use efficiency [40]. The developed implement in this study similarly enhanced efficiency by reducing draft force and integrating soil preparation with fertilizer application.

Additionally, prior studies on mechanized sugarcane ratooning management indicated that lowering excessive soil disturbance can lead to higher ratoon survival rates and better crop yields [13,39,41], aligning with the benefits observed in this study. The results confirm that integrating soil tillage and organic fertilizer application into a single implement significantly enhances efficiency and soil management in sugarcane ratooning fields. The developed system reduces draft force requirements, improves nutrient distribution, and minimizes soil disturbance. Future research could explore optimizing implement speed and evaluating long-term soil health benefits to enhance ratoon sugarcane productivity further.

The limitation of using organic fertilizer applicators that affects field efficiency is that adding the organic fertilizer to the hopper relies on the operation of the loader. Additionally, the length of the sugarcane field also impacts the management of organic fertilizer application. If the sugarcane field is shorter than 100 m, organic fertilizers can be applied from only one point. However, if the sugarcane field exceeds 100 m, there must be multiple points for applying organic fertilizers, reducing field efficiency.

The size of the organic fertilizer applicator can be increased to increase its working capacity in the field. However, the attachment type must be changed from a three-point hitch to a trailer attachment to accommodate more organic fertilizer. The disadvantage of this style is that turning the head of the plot is not as convenient as with the designed organic fertilizer applicator.

The organic fertilizer applicator was designed to break up the compacted soil layer, apply the organic fertilizer, and mix it all in one step. Traditional equipment for applying the organic fertilizer in sugarcane ratoon fields often involves multiple steps or occasionally overlooks specific steps, which can diminish sugarcane productivity and yield.

To improve the accuracy of the organic fertilizer applicator, a promising idea for future research is the development of an automatic system that adjusts fertilizer application based on soil fertility levels. This means that instead of applying a fixed amount of fertilizer everywhere, the system would analyze the soil’s nutrient content and apply fertilizer only where it is needed. This approach could reduce waste, improve soil health, and make farming more efficient.

5. Conclusions

The study evaluated the performance of an integrated tillage and organic fertilizer applicator for sugarcane ratooning fields. The organic fertilizer flow rate test revealed that the highest specific mass flow rate for all screw sizes occurred at a PTO shaft speed of 300 rpm. Among the tested screws, the 8-inch screw exhibited the highest efficiency at 7.32 kg·kW−1·s−1, followed by the 6-inch screw (4.30 kg·kW−1·s−1) and the 4-inch screw (2.34 kg·kW−1·s−1). The results confirmed that the specific mass flow rate is directly proportional to screw size and inversely proportional to PTO speed. In the disk harrow angle test, the 10-degree angle provided optimal soil incorporation without covering the sugarcane ratooning. In contrast, the 25-degree angle resulted in excessive soil turnover, which could negatively impact crop growth. The 18-inch harrow required less draft force than the 22-inch harrow and provided better organic fertilizer mixing due to its higher rotational speed.

The most suitable configuration for the organic fertilizer applicator was identified as an 18-inch harrow set, a 10-degree harrow angle, and an inclined-leg subsoiler. This combination required the lowest draft force (12.75 kN) when operating at the Low3 gear, an engine speed of 1900 rpm, and a working speed of 4.50 km·h−1. Field performance tests demonstrated that the developed implement achieved a field efficiency of 66.17% and an actual field capacity of 0.89 ha·h−1, indicating its effectiveness in integrating tillage and fertilization for improved soil management in sugarcane ratooning fields.

Author Contributions

Conceptualization, P.U., W.A. and K.K.; methodology, P.U., W.A., K.K. and W.S.; software, W.A. and K.K.; validation, W.A. and K.K.; formal analysis, P.U. and K.K.; investigation, P.U., W.A., K.K. and W.S.; resources, P.U., W.A. and W.S.; writing—original draft preparation, P.U., W.A. and K.K.; writing—review and editing, P.U., W.A., K.K. and W.S.; visualization, W.A. and K.K.; supervision, P.U.; project administration, P.U.; funding acquisition, P.U. and W.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Agricultural Research Development Agency (public organization), grant number PRP6205012270, and the Kasetsart University Research and Development Institute under the FF(KU) 51.67 research project.

Data Availability Statement

The data presented in this study can be requested from the authors.

Acknowledgments

The authors would like to acknowledge the support of the Faculty of Engineering at Kamphaeng Saen and the Kasetsart University Research and Development Institute.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xu, F.; Wang, Z.; Lu, G.; Zeng, R.; Que, Y. Sugarcane Ratooning Ability: Research Status, Shortcomings, and Prospects. Biology 2021, 10, 1052. [Google Scholar] [CrossRef] [PubMed]

- Riajaya, P.D.; Hariyono, B.; Cholid, M.; Kadarwati, F.T.; Santoso, B.; Djumali; Subiyakto. Growth and Yield Potential of New Sugarcane Varieties during Plant and First Ratoon Crops. Sustainability 2022, 14, 14396. [Google Scholar] [CrossRef]

- De Aquino, G.S.; de Conti Medina, C.; da Costa, D.C.; Shahab, M.; Santiago, A.D. Sugarcane straw management and its impact on production and development of ratoons. Ind. Crops Prod. 2017, 102, 58–64. [Google Scholar] [CrossRef]

- Bluett, C.; Tullberg, J.N.; McPhee, J.E.; Antille, D.L. Soil and Tillage Research: Why still focus on soil compaction? Soil Tillage Res. 2019, 194, 1–2. [Google Scholar] [CrossRef]

- Aguilera Esteban, D.A.; de Souza, Z.M.; Tormena, C.A.; Lovera, L.H.; de Souza Lima, E.; de Oliveira, I.N.; de Paula Ribeiro, N. Soil compaction, root system and productivity of sugarcane under different row spacing and controlled traffic at harvest. Soil Tillage Res. 2019, 187, 60–71. [Google Scholar] [CrossRef]

- Otto, R.; Silva, A.P.; Franco, H.C.J.; Oliveira, E.C.A.; Trivelin, P.C.O. High soil penetration resistance reduces sugarcane root system development. Soil Tillage Res. 2011, 117, 201–210. [Google Scholar] [CrossRef]

- Silva, R.P.; Rolim, M.M.; Gomes, I.F.; Pedrosa, E.M.R.; Tavares, U.E.; Santos, A.N. Numerical modeling of soil compaction in a sugarcane crop using the finite element method. Soil Tillage Res. 2018, 181, 1–10. [Google Scholar] [CrossRef]

- Oldfield, E.E.; Bradford, M.A.; Wood, S.A. Global meta-analysis of the relationship between soil organic matter and crop yields. Soil 2019, 5, 15–32. [Google Scholar] [CrossRef]

- Surendran, U.; Ramesh, V.; Jayakumar, M.; Marimuthu, S.; Sridevi, G. Improved sugarcane productivity with tillage and trash management practices in semi arid tropical agro ecosystem in India. Soil Tillage Res. 2016, 158, 10–21. [Google Scholar] [CrossRef]

- Yadav, R.L.; Prasad, S.R.; Singh, R.; Srivastava, V.K. Recycling sugarcane trash to conserve soil organic carbon for sustaining yields of successive ratoon crops in sugarcane. Bioresour. Technol. 1994, 49, 231–235. [Google Scholar]

- Shukla, S.K.; Jaiswal, V.P.; Sharma, L.; Tiwari, R.; Pathak, A.D.; Gaur, A.; Awasthi, S.K.; Srivastava, A. Trash management and Trichoderma harzianum influencing photosynthesis, soil carbon sequestration, and growth and yield of sugarcane ratoon in subtropical India. Eur. J. Agron. 2022, 141, 126631. [Google Scholar] [CrossRef]

- Barbosa, L.C.; Magalhães, P.S.G.; Bordonal, R.O.; Cherubin, M.R.; Castioni, G.A.F.; Tenelli, S.; Franco, H.C.J.; Carvalho, J.L.N. Soil physical quality associated with tillage practices during sugarcane planting in south-central Brazil. Soil Tillage Res. 2019, 195, 104383. [Google Scholar] [CrossRef]

- Kaur, R.; Arora, V.K. Deep tillage and residue mulch effects on productivity and water and nitrogen economy of spring maize in north-west India. Agric. Water Manag. 2019, 213, 724–731. [Google Scholar] [CrossRef]

- Scarpare, F.V.; de Jong van Lier, Q.; de Camargo, L.; Pires, R.C.M.; Ruiz-Corrêa, S.T.; Bezerra, A.H.F.; Gava, G.J.C.; Dias, C.T.S. Tillage effects on soil physical condition and root growth associated with sugarcane water availability. Soil Tillage Res. 2019, 187, 110–118. [Google Scholar] [CrossRef]

- Chen, Z.; Du, Z.; Zhang, Z.; Wang, G.; Li, J. Dynamic changes in soil organic carbon induced by long-term compost application under a wheat-maize double cropping system in North China. Sci. Total Environ. 2024, 913, 169407. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Liu, X.; Zhang, D.; Li, L.; Li, W.; Sheng, L. Effects of long-term application of organic fertilizer on improving organic matter content and retarding acidity in red soil from China. Soil Tillage Res. 2019, 195, 104382. [Google Scholar] [CrossRef]

- Navarro-Pedreño, J.; Almendro-Candel, M.B.; Zorpas, A.A. The Increase of Soil Organic Matter Reduces Global Warming, Myth or Reality? Sci 2021, 3, 18. [Google Scholar] [CrossRef]

- Prout, J.M.; Shepherd, K.D.; McGrath, S.P.; Kirk, G.J.D.; Haefele, S.M. What is a good level of soil organic matter? An index based on organic carbon to clay ratio. Eur. J. Soil Sci. 2020, 72, 2493–2503. [Google Scholar] [CrossRef]

- Robertson, F.A.; Thorburn, P.J. Decomposition of sugarcane harvest residue in different climatic zones. Aust. J. Soil Res. 2007, 45, 1–11. [Google Scholar] [CrossRef]

- Moitinho, M.R.; Ferraudo, A.S.; Panosso, A.R.; Bicalho, E.d.S.; Teixeira, D.D.B.; Barbosa, M.d.A.; Tsai, S.M.; Borges, B.M.F.; Cannavan, F.d.S.; Souza, J.A.M.d.; et al. Effects of burned and unburned sugarcane harvesting systems on soil CO2 emission and soil physical, chemical, and microbiological attributes. CATENA 2021, 196, 104903. [Google Scholar] [CrossRef]

- Panosso, A.R.; Marques, J.; Milori, D.M.B.P.; Ferraudo, A.S.; Barbieri, D.M.; Pereira, G.T.; La Scala, N. Soil CO2 emission and its relation to soil properties in sugarcane areas under Slash-and-burn and Green harvest. Soil Tillage Res. 2011, 111, 190–196. [Google Scholar] [CrossRef]

- Morais, M.C.; Siqueira-Neto, M.; Guerra, H.P.; Satiro, L.S.; Soltangheisi, A.; Cerri, C.E.P.; Feigl, B.J.; Cherubin, M.R. Trade-Offs between Sugarcane Straw Removal and Soil Organic Matter in Brazil. Sustainability 2020, 12, 9363. [Google Scholar] [CrossRef]

- Dlamini, N.E.; Zhou, M. Soils and seasons effect on sugarcane ratoon yield. Field Crops Res. 2022, 284, 108588. [Google Scholar] [CrossRef]

- Dietrich, G.; Sauvadet, M.; Recous, S.; Redin, M.; Pfeifer, I.C.; Garlet, C.M.; Bazzo, H.; Giacomini, S.J. Sugarcane mulch C and N dynamics during decomposition under different rates of trash removal. Agric. Ecosyst. Environ. 2017, 243, 123–131. [Google Scholar] [CrossRef]

- Koorneef, G.J.; Pulleman, M.M.; Comans, R.N.J.; van Rijssel, S.Q.; Barré, P.; Baudin, F.; de Goede, R.G.M. Assessing soil functioning: What is the added value of soil organic carbon quality measurements alongside total organic carbon content? Soil Biol. Biochem. 2024, 196, 109507. [Google Scholar] [CrossRef]

- Biratu, G.K.; Elias, E.; Ntawuruhunga, P. Does the application of mineral and organic fertilizer affect cassava tuber quality? An evidence from Zambia. J. Agric. Food Res. 2022, 9, 100339. [Google Scholar] [CrossRef]

- Tröster, M.F.; Pahl, H.; Sauer, J. Effects of application costs on fertilizer application strategy. Comput. Electron. Agric. 2019, 167, 105033. [Google Scholar] [CrossRef]

- Hu, J.; He, J.; Wang, Y.; Wu, Y.; Chen, C.; Ren, Z.; Li, X.; Shi, S.; Du, Y.; He, P. Design and study on lightweight organic fertilizer distributor. Comput. Electron. Agric. 2020, 169, 105149. [Google Scholar] [CrossRef]

- Xu, B.; Cui, Q.; Guo, L.; Hao, L. Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader. Agronomy 2024, 14, 1732. [Google Scholar] [CrossRef]

- Wang, Y.-x.; Chen, S.-p.; Zhang, D.-x.; Yang, L.; Cui, T.; Jing, H.-r.; Li, Y.-h. Effects of subsoiling depth, period interval and combined tillage practice on soil properties and yield in the Huang-Huai-Hai Plain, China. J. Integr. Agric. 2020, 19, 1596–1608. [Google Scholar] [CrossRef]

- Kuzucu, M.; Dökmen, F. The Effects of Tillage on Soil Water Content in Dry Areas. Agric. Agric. Sci. Procedia 2015, 4, 126–132. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Bewsher, S.; Guzzomi, A.L.; Lehane, B.M.; Fourie, A.B.; Riethmuller, G. Evaluation of the dynamic cone penetrometer to detect compaction in ripped soils. Soil Tillage Res. 2018, 175, 150–157. [Google Scholar] [CrossRef]

- Voltr, V.; Menšík, L.; Hlisnikovský, L.; Hruška, M.; Pokorný, E.; Pospíšilová, L. The Soil Organic Matter in Connection with Soil Properties and Soil Inputs. Agronomy 2021, 11, 779. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Q.; Xu, D.; Li, H.; He, J.; Lu, C. Design and experimental research on the counter roll differential speed solid organic fertilizer crusher based on DEM. Comput. Electron. Agric. 2023, 207, 107748. [Google Scholar] [CrossRef]

- Zinkevičienė, R.; Jotautienė, E.; Juostas, A.; Comparetti, A.; Vaiciukevičius, E. Simulation of Granular Organic Fertilizer Application by Centrifugal Spreader. Agronomy 2021, 11, 247. [Google Scholar] [CrossRef]

- Yu, Y.; Arnold, P.C. Theoretical modelling of torque requirements for single screw feeders. Powder Technol. 1997, 93, 151–162. [Google Scholar] [CrossRef]

- Fernandez, J.W.; Cleary, P.W.; McBride, W. Effect of screw design on hopper draw down by a horizontal screw feeder. In Proceedings of the Seventh International Conference on CFD in the Minerals and Process Industries CSIRO, Melbourne, Australia, 9–11 December 2009. [Google Scholar]

- ASABE. Agricultural Machinery Management Data; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009. [Google Scholar]

- Schneider, F.; Don, A.; Hennings, I.; Schmittmann, O.; Seidel, S.J. The effect of deep tillage on crop yield—What do we really know? Soil Tillage Res. 2017, 174, 193–204. [Google Scholar] [CrossRef]

- Damanauskas, V.; Velykis, A.; Satkus, A. Efficiency of disc harrow adjustment for stubble tillage quality and fuel consumption. Soil Tillage Res. 2019, 194, 104311. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Zhang, X. Modelling the interaction of a deep tillage tool with heterogeneous soil. Comput. Electron. Agric. 2017, 143, 130–138. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).