Productivity and Fermentative and Nutritional Quality of Silages from Biomass Sorghum Intercropped with Tropical Grasses

Abstract

1. Introduction

2. Materials and Methods

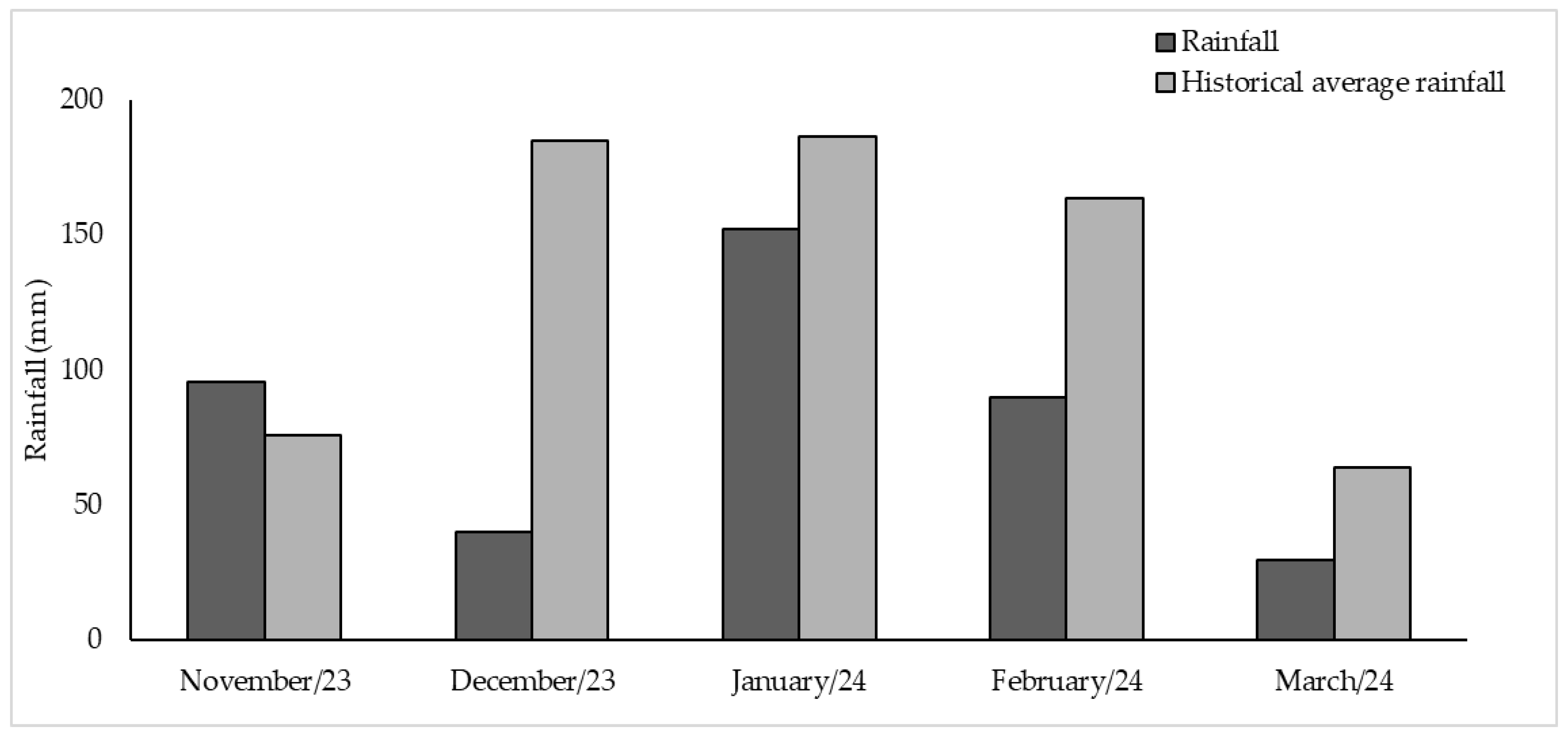

2.1. Experimental Area Characterization

2.2. Soil Sampling and Fertilization

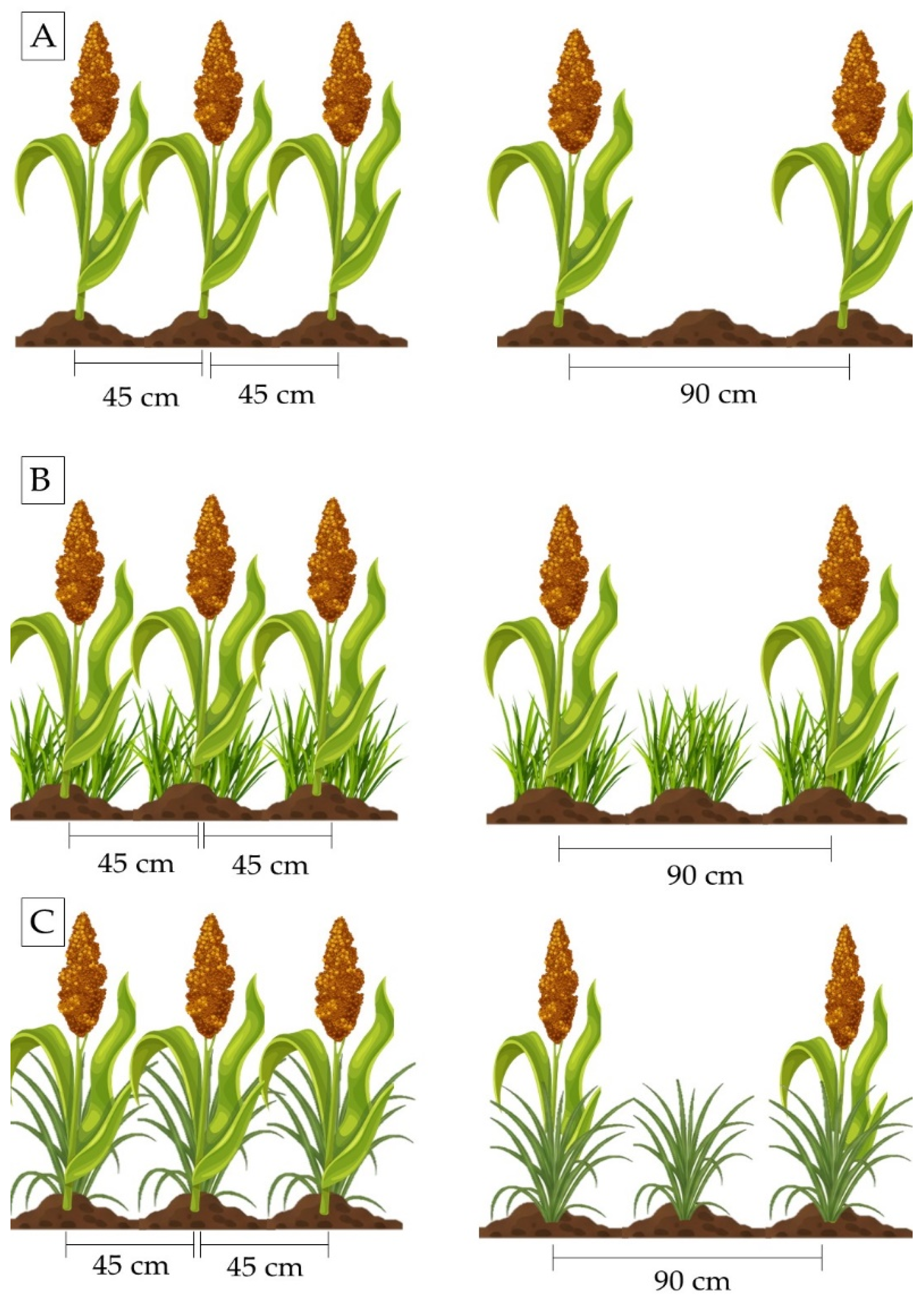

2.3. Experimental Design

2.4. Sample Collection and Chemical–Bromatological Analysis

2.5. Statistical Analysis

3. Results

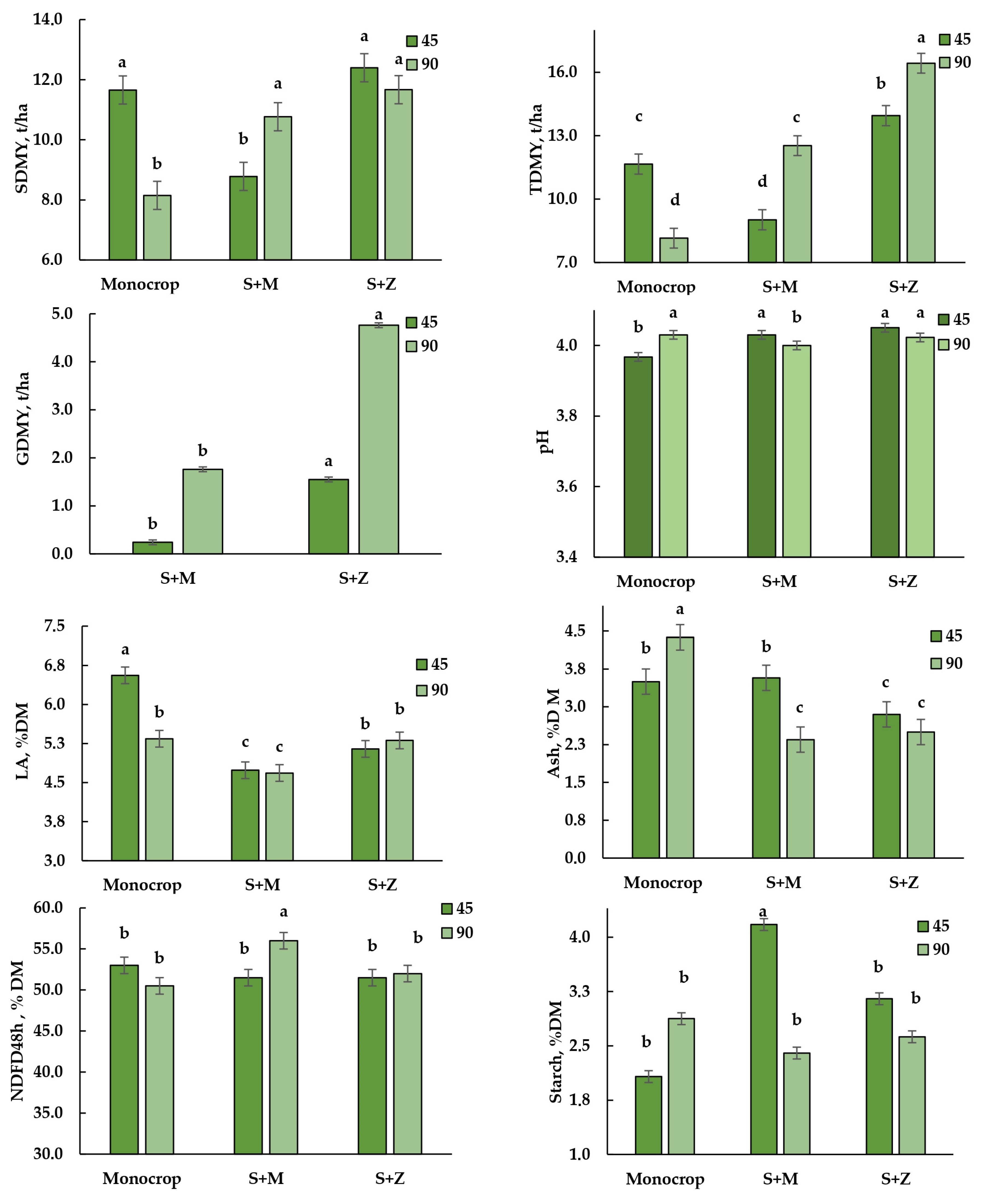

3.1. Productivity of Biomass Sorghum and Grass Intercropping Systems

3.2. Fermentative and Nutritional Parameters of Biomass Sorghum Silages

4. Discussion

4.1. Productivity of Biomass Sorghum and Grass Intercropping Systems

4.2. Fermentative and Nutritional Parameters of Biomass Sorghum Silages

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AA | Acetic Acid |

| ADF | Acid Detergent Fiber |

| BA | Butyric Acid |

| CLI | Crop–Livestock Integration |

| CP | Crude Protein |

| DM | Dry Matter |

| DMR | Dry Matter Recovery |

| EE | Ether Extract |

| FM | Fresh Matter |

| GDMY | Grass Dry Matter Yield |

| LA | Lactic Acid |

| LIG | Lignin |

| NDF | Neutral Detergent Fiber |

| NDFD48h | 48 h in vitro Neutral Detergent Fiber Digestibility |

| NFC | Non-Fibrous Carbohydrates |

| NH3-N | Ammonia Nitrogen |

| S + M | Sorghum intercropped with Urochloa brizantha cv. Marandu |

| S + Z | Sorghum intercropped with Megathyrsus maximus cv. Zuri |

| SDMY | Sorghum Dry Matter Yield |

| SEM | Standard Error of the Mean |

| TDMY | Total Dry Matter Yield |

| TDN | Total Digestible Nutrients |

| TN | Total Nitrogen |

References

- Bolfe, É.L.; Sano, E.E.; Massruhá, S.M.F.S.; de Victoria, D.C.; Silva, G.B.S.; de Oliveira, A.F. Potencial de Expansão Agrícola em Áreas de Pastagem Degradadas no Brasil. Agroanalysis 2024, 44, 25–27. [Google Scholar]

- Sloat, L.L.; Gerber, J.S.; Samberg, L.H.; Smith, W.K.; Herrero, M.; Ferreira, L.G.; Godde, C.M.; West, P.C. Increasing Importance of Precipitation Variability on Global Livestock Grazing Lands. Nat. Clim Change 2018, 8, 214–218. [Google Scholar] [CrossRef]

- Gianetti, G.W.; Filho, d.J.B.S.F. Pasture Recovery, Emissions, and the Brazilian Paris Agreement Commitments. Land Use Policy 2024, 141, 107118. [Google Scholar] [CrossRef]

- de Figueiredo, E.B.; Jayasundara, S.; de Oliveira Bordonal, R.; Berchielli, T.T.; Reis, R.A.; Wagner-Riddle, C.; La Scala, N. Greenhouse Gas Balance and Carbon Footprint of Beef Cattle in Three Contrasting Pasture-Management Systems in Brazil. J. Clean. Prod. 2017, 142, 420–431. [Google Scholar] [CrossRef]

- Vinholis, M.D.M.B.; Meirelles De Souza, H.; Marcelo, F.; Carrer, J.; Júnior, W.B.; Bernardo, R.; Cardoso, D.; Flávio, R.; Tokuda, S.; José, G.; et al. Adoção de sistemas de integração lavoura-pecuária-floresta (ILPF) em São Paulo; Boletim de Pesquisa e Desenvolvimento, 47; Embrapa Pecuária Sudeste: São Carlos, SP, Brazil, 2020; 56p, Available online: https://www.infoteca.cnptia.embrapa.br/infoteca/handle/doc/1123559 (accessed on 8 October 2025).

- Orrico Junior, M.A.P.; Vendramini, J.M.B.; Erickson, J.; Moriel, P.; Silveira, M.L.A.; Aguiar, A.D.; Sanchez, J.M.D.; da Silva, W.L.; da Silva, H.M. Nutritive Value and Fermentation Characteristics of Silages Produced from Different Sweet Sorghum Plant Components with or without Microbial Inoculation. Appl. Anim. Sci. 2020, 36, 777–783. [Google Scholar] [CrossRef]

- Orrico Junior, M.A.P.; Retore, M.; Manarelli, D.M.; De Souza, F.B.; Ledesma, L.L.M.; Orrico, A.C.A. Forage Potential and Silage Quality of Four Varieties of Saccharine Sorghum. Pesqui Agropecu Bras. 2015, 50, 1201–1207. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Hamid, A.; Ahmad, T.; Siddiqui, M.H.; Hussain, I.; Ali, S.; Ali, A.; Ahmad, Z. Forage Sorghum-Legumes Intercropping: Effect on Growth, Yields, Nutritional Quality and Economic Returns. Bragantia 2018, 78, 82–95. [Google Scholar] [CrossRef]

- Herrera, D.M.; Peixoto, W.M.; de Abreu, J.G.; dos Reis, R.H.P.; de Sousa, F.G.; Balbinot, E.; Klein, V.A.C.; Costa, R.P. Is the Integration between Corn and Grass under Different Sowing Modalities a Viable Alternative for Silage? Animals 2023, 13, 425. [Google Scholar] [CrossRef]

- Costa, N.R.; Andreotti, M.; Crusciol, C.A.C.; Pariz, C.M.; Lopes, K.S.M.; Leonardo De Almeida Yokobatake, K.; Ferreira, J.P.; Da Rocha Lima, C.G.; De Souza, D.M. Effect of Intercropped Tropical Perennial Grasses on the Production of Sorghum-Based Silage. Agron J. 2016, 108, 2379–2390. [Google Scholar] [CrossRef]

- Silva, Y.A.; Orrico Junior, M.A.P.; Retore, M.; Ceccon, G.; Fernandes, T.; Orrico, A.C.A. Chemical Composition, Fermentation Parameters and Losses of Silages From Different Hybrids of Biomass Sorghum. Grass Forage Sci. 2025, 80, e12706. [Google Scholar] [CrossRef]

- Fietz, C.R.; Fisch, G.F. O Clima Da Região de Dourados, MS; Embrapa Agropecuária Oeste: Dourados, Brazil, 2008. [Google Scholar]

- dos Santos, H.G.; Jacomine, P.K.T.; dos Anjos, L.H.C.; de Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; de Almeida, J.A.; de Araújo Filho, J.C.; Oliveira, d.J.B.; Cunha, T.J.F. Sistema brasileiro de classificação de solos, 5th ed.; Mattos, J.S.R., Ed.; Embrapa Solos: Rio de Janeiro, Brazil, 2018; ISBN 978-85-7035-817-2. [Google Scholar]

- da Silva, F.C. (Ed.) Manual de Análises Químicas de Solos, Plantas e Fertilizantes, 2nd revised and enlarged edition; Embrapa Informação Tecnológica: Brasília, DF, Brazil; Embrapa Solos: Rio de Janeiro, Brazil, 2009; 627p, ISBN 978-85-7383-430-7. [Google Scholar]

- Jobim, C.C.; Nussio, L.G.; Reis, R.A.; Schmidt, P. Avanços Metodológicos Na Avaliação Da Qualidade Da Forragem Conservada. Revista Brasileira de Zootecnia 2007, 36, 101–119. [Google Scholar] [CrossRef]

- Rosa, d.M.A.B.; Tardin, F.D.; Souza, J.M.S.; Santos, J.A.P.; Macedo, T.F.; Santos, J.; de Freitas, M.; Todescatto, F.; Parrella, R.A.C.; Figueiredo, J.E.F.; et al. Characterization of Forage, Sweet and Biomass Sorghum for Agronomic Performance and Ensilability. Rev. Bras. De Milho E Sorgo 2022, 21, e1239. [Google Scholar] [CrossRef]

- Juliano, C.B.A.; Oliveira, R.M.; Silva, K.M.J.; Alves, D.D.; Alvarenga, R.C.; Borges, G.L.F.N. Consórcio de Forrageiras Tropicais com o Sorgo Granífero em Duas Localidades do Estado de Minas Gerais. Rev. Bras. De Milho E Sorgo 2013, 12, 1–9. [Google Scholar]

- Von Pinho, R.G.V.; Vasconcelos, R.C. Cultura do Sorgo, 1st ed.; Editora UFLA: Lavras, MG, Brazil, 2002; Volume 1. [Google Scholar]

- Embrapa Milho e Sorgo. BRS 373: Híbrido de Sorgo Granífero: Produtividade e Precocidade; Embrapa Milho e Sorgo: Sete Lagoas, Brazil, 2016. [Google Scholar]

- Júnior, I.D.O.A.; dos Santos, S.R.; Kondo, M.K.; de Oliveira, P.M.; Rocha Júnior, V.R. Response of Forage Sorghum to Water Availability in a Typic Quartzipsamment. Rev. Caatinga. 2020, 32, 1015–1026. [Google Scholar] [CrossRef]

- Mu, Y.; Chai, Q.; Yu, A.; Yang, C.; Qi, W.; Feng, F.; Kong, X. Performance of Wheat/Maize Intercropping Is a Function of Belowground Interspecies Interactions. Crop Sci. 2013, 53, 2186–2194. [Google Scholar] [CrossRef]

- Yin, W.; Chai, Q.; Zhao, C.; Yu, A.; Fan, Z.; Hu, F.; Fan, H.; Guo, Y.; Coulter, J.A. Water Utilization in Intercropping: A Review. Agric. Water Manag. 2020, 241, 106335. [Google Scholar] [CrossRef]

- Nichols, V.A.; Moore, E.B.; Gailans, S.; Kaspar, T.C.; Liebman, M. Site-Specific Effects of Winter Cover Crops on Soil Water Storage. Agrosyst. Geosci. Env. 2022, 5, e20238. [Google Scholar] [CrossRef]

- Yin, W.; Yu, A.; Chai, Q.; Hu, F.; Feng, F.; Gan, Y. Wheat and Maize Relay-Planting with Straw Covering Increases Water Use Efficiency up to 46%. Agron. Sustain. Dev. 2015, 35, 815–825. [Google Scholar] [CrossRef]

- Jank, L.; Santos, M.F.; Braga, G.J. O Capim-BRS Zuri (Panicum Maximum Jacq.) Na Diversificação e Intensificação Das Pastagens; Embrapa Gado de Corte: Campo Grande, Brazil, 2022. [Google Scholar]

- Oliveira, S.; Costa, K.A.; Severiano, E.; da Silva, A.; Dias, M.; Oliveira, G.; Costa, J.V. Performance of Grain Sorghum and Forage of the Genus Brachiaria in Integrated Agricultural Production Systems. Agronomy 2020, 10, 1714. [Google Scholar] [CrossRef]

- Backsman, C.F.C.; Monção, F.P.; Aspiazú, I.; Rocha Júnior, V.R.; Portugal, A.F.; Silva, R.K.O.J.; Rigueira, J.P.S.; Maranhão, C.M.A.; dos Santos, A.S.; Carvalho, C.C.S.; et al. Agronomic Traits, Fermentation Quality, Chemical Composition, and Silage Digestibility of Different Forage Sorghum Genotypes and Biomass in the Semi-Arid Region of Brazil. J. Appl. Anim. Res. 2025, 53, 2462573. [Google Scholar] [CrossRef]

- Muck, R.E.; Nadeau, E.M.G.; McAllister, T.A.; Contreras-Govea, F.E.; Santos, M.C.; Kung, L., Jr. Silage Review: Recent Advances and Future Uses of Silage Additives. J. Dairy Sci. 2018, 101, 3980–4000. [Google Scholar] [CrossRef]

- Kung, L.; Shaver, R.D.; Grant, R.J.; Schmidt, R.J. Silage Review: Interpretation of Chemical, Microbial, and Organoleptic Components of Silages. J. Dairy Science. 2018, 101, 4020–4033. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E.; Schmidt, R.J.; Holmes, B.J.; Muck, R.E. Silage Review: Factors Affecting Dry Matter and Quality Losses in Silages. J. Dairy Sci. 2018, 101, 3952–3979. [Google Scholar] [CrossRef]

- Ashbell, G.; Weinberg, Z.G. Top Silage Losses in Horizontal Silos. Can. Agric. Eng. 1992, 34, 1–5. [Google Scholar]

- Rodrigues, P.H.M.; Pinedo, L.A.; Meyer, P.M.; da Silva, T.H.; Guimarães, I.C.d.S.B. Sorghum Silage Quality as Determined by Chemical–Nutritional Factors. Grass Forage Sci. 2020, 75, 462–473. [Google Scholar] [CrossRef]

- dos Santos Souza, Í.D.A.; Rocha Júnior, V.R.; Monção, F.P.; da Costa Parrella, R.A.; Cordeiro, M.W.S.; da Cunha Siqueira Carvalho, C.; Rigueira, J.P.; Aspiazú, I.; Silva, F.V.e.; de Abreu Delvaux Júnior, N. Yield and nutritional value of biomass sorghum (BRS 716) managed in different row spacing and maturity at harvest in the semiarid region of Brazil. Semin. Ciências Agrárias. 2021, 42, 3463–3484. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. Nutrient Requirements of Beef Cattle, Eighth Revised Edition; The National Academies Press: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. Nutrient Requirements of Dairy Cattle, Eighth Revised Edition; The National Academies Press: Washington, DC, USA, 2021. [Google Scholar] [CrossRef]

- Moore, K.J.; Lenssen, A.W.; Fales, S.L. Factors Affecting Forage Quality. In Forages; Moore, K.J., Collins, M., Nelson, C.J., Redfearn, D.D., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2020; pp. 701–717. [Google Scholar] [CrossRef]

- de Souza, J.M.S.; Neto, A.B.; da Rosa, M.A.B.; Tardin, F.D.; Galati, R.L.; Chaves, C.S.; Pereira, D.H. Nutritional Value and Fermentability of Sorghum Silages Grown in the Amazon Biome. Grassl. Sci. 2025, 71, 86–94. [Google Scholar] [CrossRef]

- Saha, S.K.; Pathak, N.N. Fundamentals of Animal Nutrition, 1st ed.; Springer: Singapore, 2021; ISBN 978-981-15-9125-9. [Google Scholar] [CrossRef]

- Noci, F.; Monahan, F.J.; Scollan, N.D.; Moloney, A.P. The Fatty Acid Composition of Muscle and Adipose Tissue of Steers Offered Unwilted or Wilted Grass Silage Supplemented with Sunflower Oil and Fishoil. Br. J. Nutr. 2007, 97, 502–513. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Khan, N.A.; Cone, J.W.; Hendriks, W.H. Stability of Fatty Acids in Grass and Maize Silages after Exposure to Air during the Feed out Period. Anim. Feed. Sci. Technol. 2009, 154, 183–192. [Google Scholar] [CrossRef]

- Ligoski, B.; Gonçalves, L.F.; Claudio, F.L.; Alves, E.M.; Krüger, A.M.; Bizzuti, B.E.; De Mello Tavares Lima, P.; Abdalla, A.L.; Do Prado Paim, T. Silage of Intercropping Corn, Palisade Grass, and Pigeon Pea Increases Protein Content and Reduces in Vitro Methane Production. Agronomy 2020, 10, 1784. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Soil pH (CaCl2) | 4.9 | - |

| Phosphorus | 9.3 | mg/L |

| Potassium | 6.4 | mmolc/L |

| Calcium | 31 | mmolc/L |

| Magnesium | 13.6 | mmolc/L |

| Aluminum | 0.7 | mmolc/L |

| Potential Acidity (H + Al) | 41.5 | mmolc/L |

| Sum of Bases | 51 | mmolc/L |

| Cation Exchange Capacity | 92.5 | mmolc/L |

| Base Saturation | 55.1 | % |

| Aluminum Saturation | 1.4 | % |

| Copper | 0.2 | mmol/L |

| Iron | 0.87 | mmol/L |

| Manganese | 1.75 | mmol/L |

| Zinc | 0.04 | mmol/L |

| Clay | 637 | g/kg |

| Sand | 205 | g/kg |

| Silt | 158 | g/kg |

| Organic Matter | 27.89 | g/kg |

| Parameters | Cropping System (C) | SEM | Row Spacing (R) | SEM | p-Value | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Monocrop | S + M | S + Z | 45 | 90 | C | R | C*R | |||

| SDMY, t/ha | 9.90 | 9.77 | 12.03 | 0.331 | 10.95 | 10.19 | 0.270 | <0.01 | 0.07 | <0.01 |

| TDMY, t/ha | 9.90 | 10.78 | 15.19 | 0.337 | 11.54 | 12.37 | 0.476 | <0.01 | 0.05 | <0.01 |

| GDMY, t/ha | - | 1.00 | 3.15 | 0.168 | 0.59 | 2.17 | 0.137 | <0.01 | <0.01 | <0.01 |

| DMR, % ensiled DM | 93.85 | 94.88 | 95.29 | 0.559 | 94.93 | 94.42 | 0.457 | 0.20 | 0.44 | 0.61 |

| pH | 4.00 | 4.02 | 4.04 | 0.009 | 4.02 | 4.02 | 0.012 | <0.01 | 0.87 | <0.01 |

| LA, % DM | 5.95 | 4.71 | 5.23 | 0.113 | 5.48 | 5.11 | 0.092 | <0.01 | 0.01 | <0.01 |

| AA, % DM | 0.84 | 0.60 | 0.78 | 0.103 | 0.91 | 0.56 | 0.089 | 0.27 | <0.01 | 0.42 |

| BA, % DM | ND * | ND | ND | ND | ND | ND | ND | - | - | - |

| NH3-N, % TN | 0.42 a | 0.30 b | 0.38 a | 0.020 | 0.36 | 0.36 | 0.167 | <0.01 | 0.65 | 0.21 |

| DM, % FM | 27.42 b | 28.97 a | 29.41 a | 0.310 | 28.45 | 28.75 | 0.253 | <0.01 | 0.41 | 0.16 |

| Ash, % DM | 3.94 | 2.96 | 2.55 | 0.177 | 3.30 | 2.99 | 0.145 | <0.01 | 0.14 | <0.01 |

| CP, % DM | 9.10 a | 8.68 b | 8.66 b | 0.127 | 8.78 | 8.84 | 0.104 | 0.04 | 0.70 | 0.16 |

| NDF, % DM | 63.61 | 62.33 | 62.64 | 0.440 | 63.01 | 62.71 | 0.359 | 0.13 | 0.56 | 0.28 |

| ADF, % DM | 41.46 a | 39.44 b | 40.16 b | 0.378 | 40.72 | 39.99 | 0.308 | <0.01 | 0.11 | 0.32 |

| Lignin, % DM | 7.55 a | 6.99 b | 7.45 a | 0.131 | 7.33 | 7.33 | 0.107 | 0.02 | 0.96 | 0.47 |

| NFC, % DM | 21.85 b | 25.03 a | 24.79 a | 0.480 | 23.37 | 24.41 | 0.392 | <0.01 | 0.08 | 0.22 |

| Starch, % DM | 2.48 | 3.29 | 2.89 | 0.291 | 3.13 | 2.63 | 0.238 | 0.17 | 0.15 | 0.02 |

| EE, % DM | 3.41 a | 3.10 b | 3.21 b | 0.058 | 3.317 | 3.17 | 0.047 | <0.01 | 0.04 | 0.06 |

| NDFD48h, % DM | 51.75 | 53.75 | 51.75 | 0.712 | 52.00 | 52.83 | 0.581 | 0.10 | 0.32 | <0.01 |

| TDN, % DM | 58.13 b | 60.13 a | 59.75 a | 0.289 | 59.17 | 59.50 | 0.236 | <0.01 | 0.33 | 0.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muglia, G.R.P.; Orrico Junior, M.A.P.; Retore, M.; Ceccon, G.; da Silva, Y.A.; Orrico, A.C.A.; Amaral, I.P.d.O.; de Oliveira, V.G. Productivity and Fermentative and Nutritional Quality of Silages from Biomass Sorghum Intercropped with Tropical Grasses. AgriEngineering 2025, 7, 345. https://doi.org/10.3390/agriengineering7100345

Muglia GRP, Orrico Junior MAP, Retore M, Ceccon G, da Silva YA, Orrico ACA, Amaral IPdO, de Oliveira VG. Productivity and Fermentative and Nutritional Quality of Silages from Biomass Sorghum Intercropped with Tropical Grasses. AgriEngineering. 2025; 7(10):345. https://doi.org/10.3390/agriengineering7100345

Chicago/Turabian StyleMuglia, Giuliano Reis Pereira, Marco Antonio Previdelli Orrico Junior, Marciana Retore, Gessí Ceccon, Yara América da Silva, Ana Carolina Amorim Orrico, Isabele Paola de Oliveira Amaral, and Verônica Gleice de Oliveira. 2025. "Productivity and Fermentative and Nutritional Quality of Silages from Biomass Sorghum Intercropped with Tropical Grasses" AgriEngineering 7, no. 10: 345. https://doi.org/10.3390/agriengineering7100345

APA StyleMuglia, G. R. P., Orrico Junior, M. A. P., Retore, M., Ceccon, G., da Silva, Y. A., Orrico, A. C. A., Amaral, I. P. d. O., & de Oliveira, V. G. (2025). Productivity and Fermentative and Nutritional Quality of Silages from Biomass Sorghum Intercropped with Tropical Grasses. AgriEngineering, 7(10), 345. https://doi.org/10.3390/agriengineering7100345