Droplet Deposition and Transfer in Coffee Cultivation Under Different Spray Rates and Nozzle Types

Abstract

1. Introduction

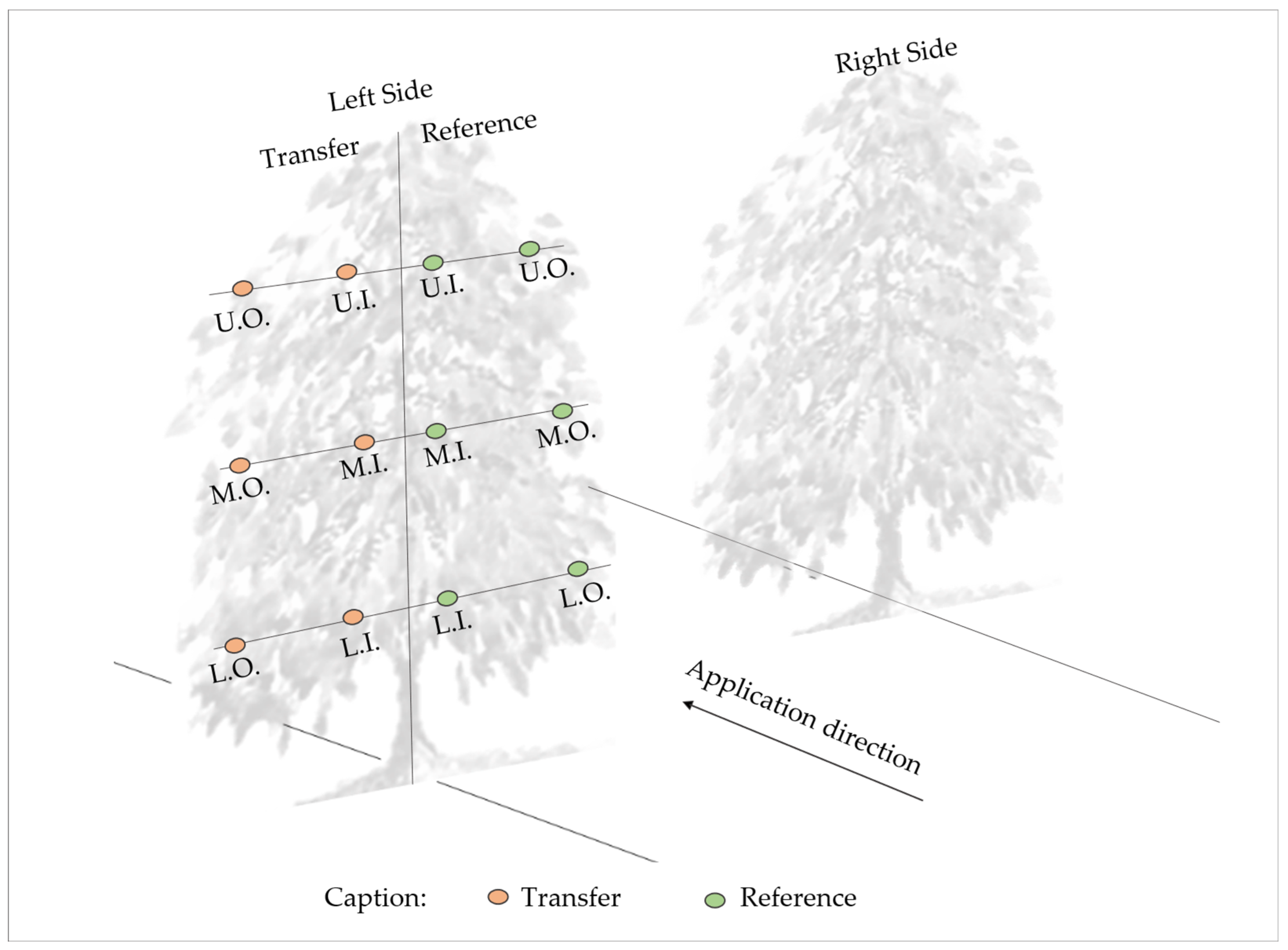

2. Materials and Methods

3. Results

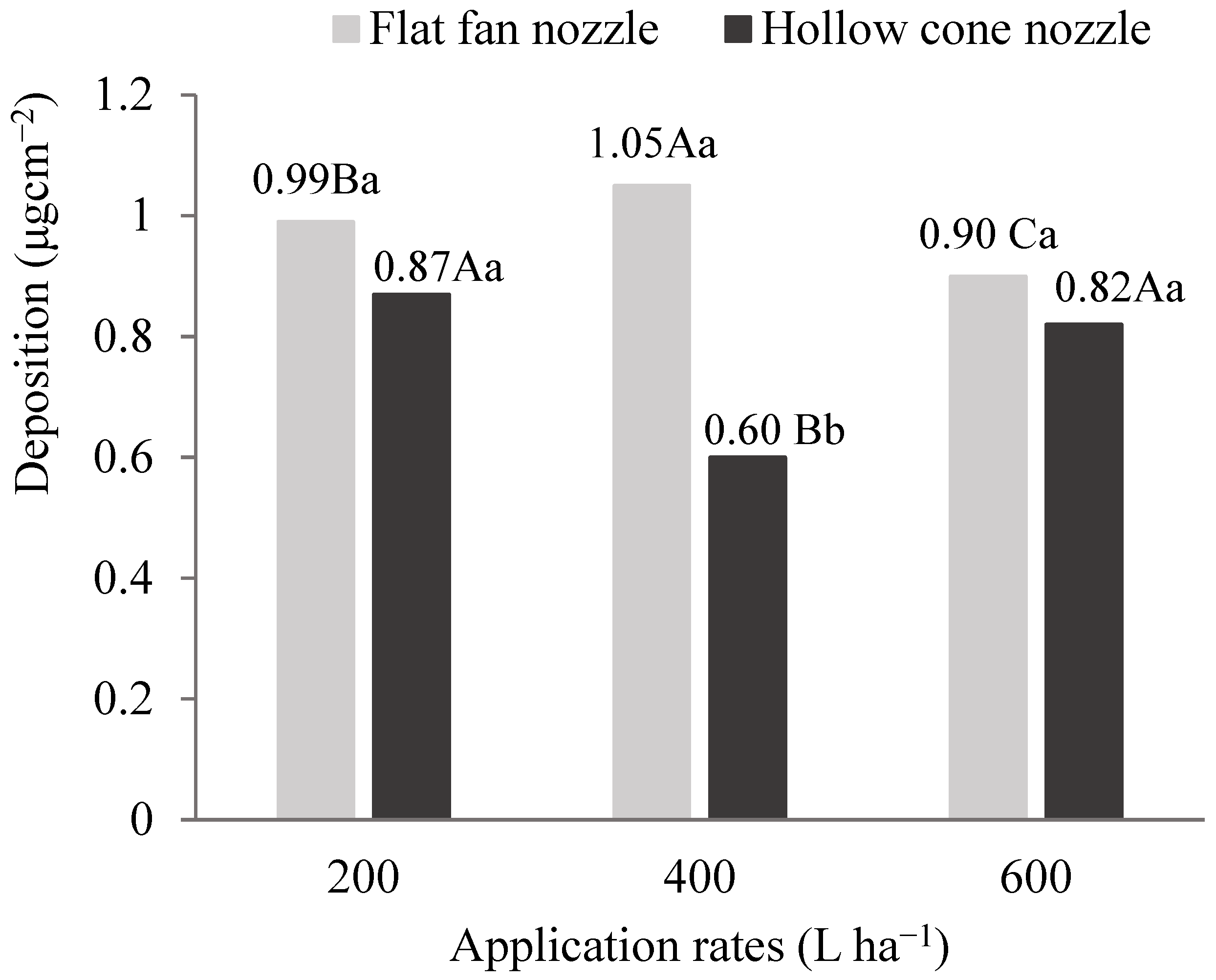

3.1. Deposition in the Reference Fraction Across Nozzle Types and Application Rates

3.2. Deposition in the Reference Fraction at Different Positions on the Plagiotropic Branch

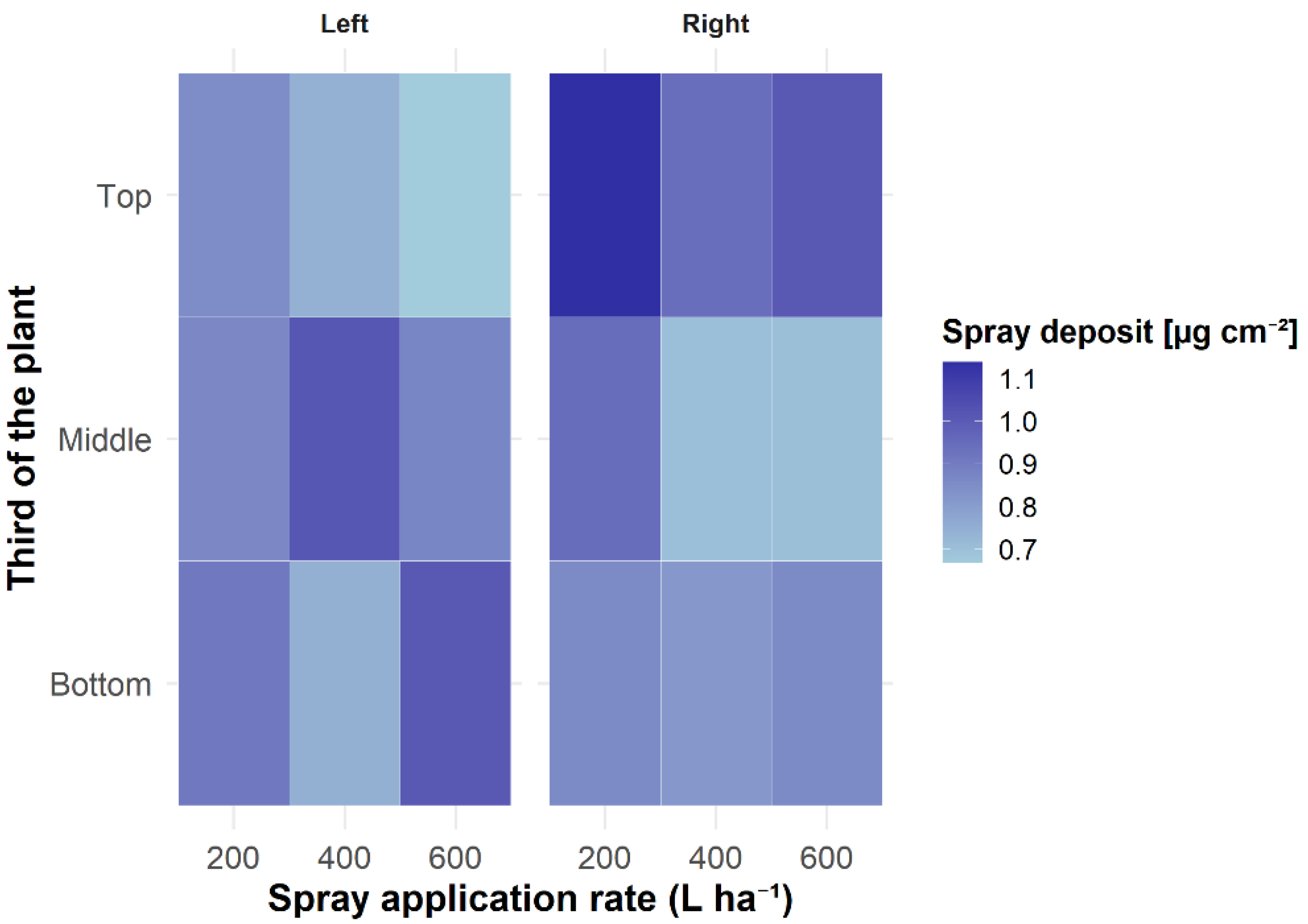

3.3. Deposition in the Reference Fraction as a Function of Application Rates in the Application Sides and Canopy Thirds

3.4. Transfer Through the Sides of the Application Boom

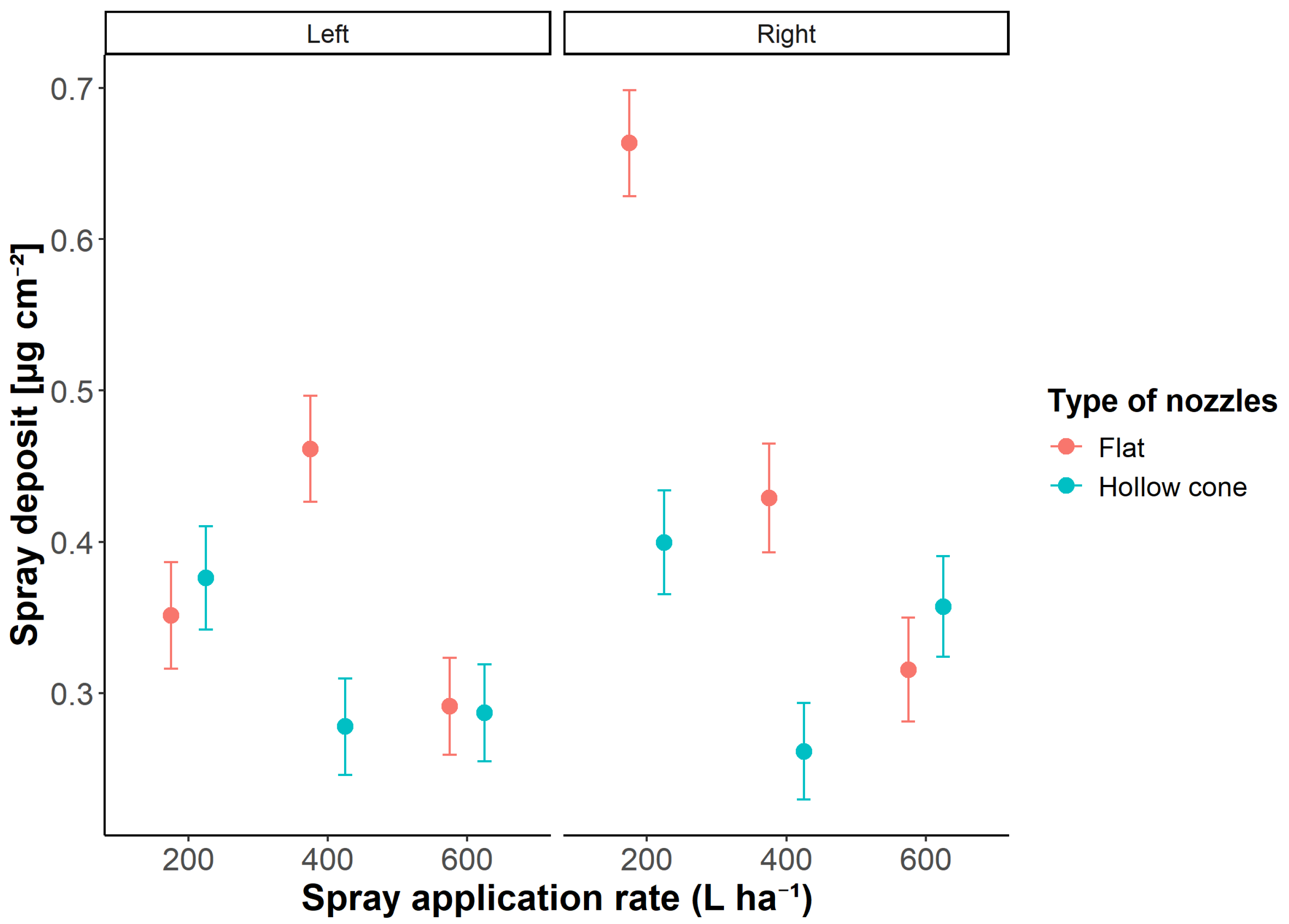

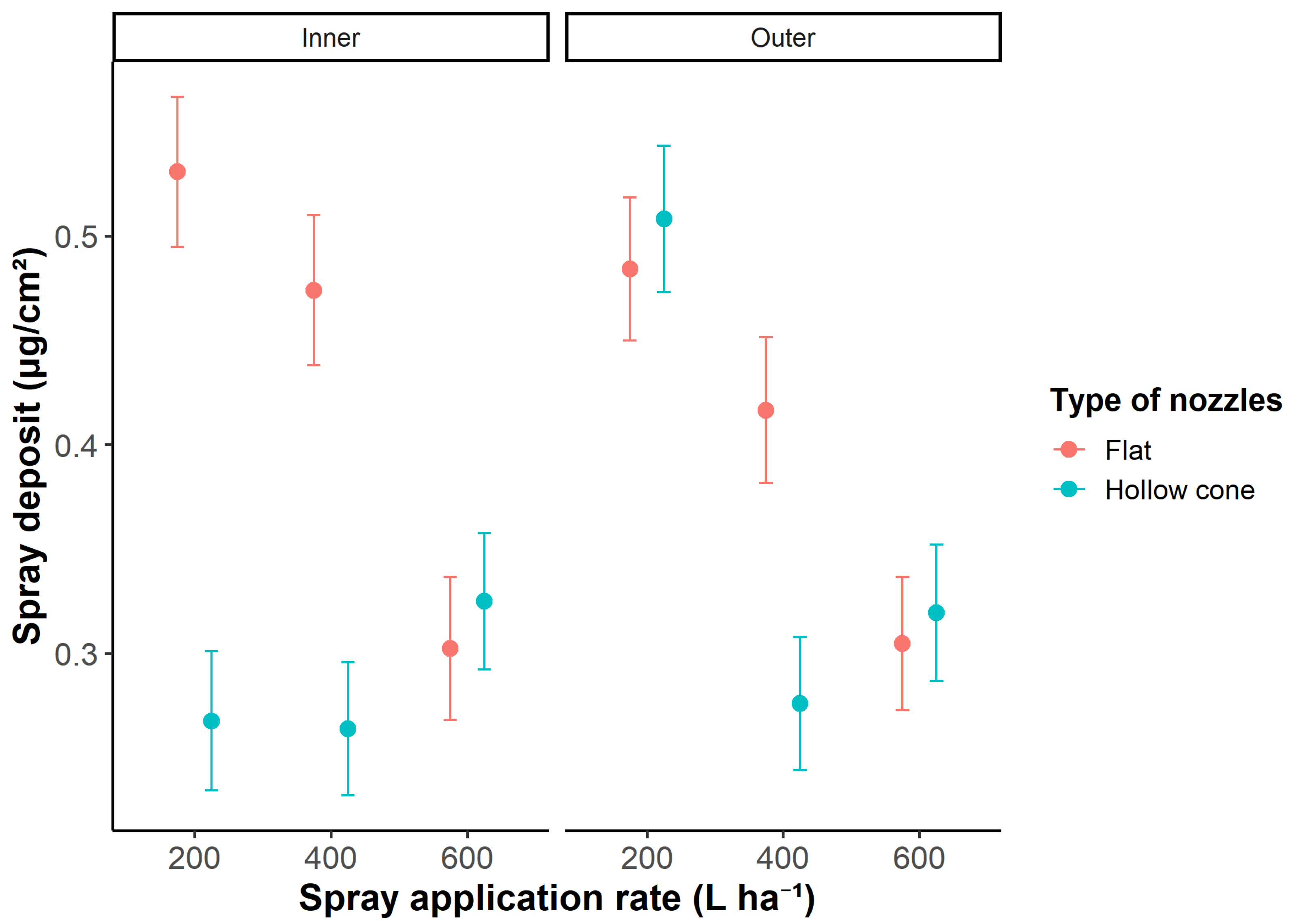

3.5. Transfer at Inner and Outer Canopy Positions

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vitória, E.L.; Krohling, C.A.; Borges, F.R.P.; Ribeiro, L.F.O.; Ribeiro, M.E.A.; Chen, P.; Lan, Y.; Wang, S.; Moraes, H.M.F.; Furtado Júnior, M.R. Efficiency of fungicide application an using an unmanned aerial vehicle and pneumatic sprayer for control of Hemileia vastatrix and Cercospora coffeicola in mountain coffee crops. Agronomy 2023, 13, 340. [Google Scholar] [CrossRef]

- İnan, M.; Karci, A. Effects of Optimizing Droplet Distribution at Particular Heights and Speeds Using Proportional-Integral-Derivative (PID) Control Algorithm in Unmanned Aerial Vehicle (UAV) Systems: A Review. J. Agric. Sci. 2025, 31, 612–639. [Google Scholar] [CrossRef]

- Calderone, G.; Ferro, M.V.; Catania, P. A systematic literature review on recent unmanned aerial spraying systems applications in orchards. Smart Agric. Technol. 2025, 10, 00708. [Google Scholar] [CrossRef]

- Cerda, R.; Avelino, J.; Gary, C.; Tixier, P.; Lechevallier, E.; Allinne, C. Primary and secondary yield losses caused by pests and diseases: Assessment and modeling in coffee. PLoS ONE 2017, 12, e0169133. [Google Scholar] [CrossRef]

- Ozkan, E.; Gil, E. Strategies to Minimize Spray Drift for Effective Spraying in Orchards and Vineyards. FABE-533. Ohioline. 2022. Available online: https://ohioline.osu.edu/factsheet/fabe-533 (accessed on 6 February 2025).

- Wei, Z.; Li, R.; Xue, X.; Sun, Y.; Zhang, S.; Li, Q.; Chang, C.; Zhang, Z.; Sun, Y.; Dou, Q. Research status, methods and prospects of air-assisted spray technology. Agronomy 2023, 13, 1407. [Google Scholar] [CrossRef]

- Planas, S.; Román, C.; Sanz, R.; Rosell-Polo, J.R. Bases for pesticide dose expression and adjustment in 3D crops and comparison of decision support systems. Sci. Total Environ. 2022, 806, 150357. [Google Scholar] [CrossRef]

- Salcedo, R.; Fonte, A.; Grella, M.; Garcerá, C.; Chueca, P. Blade pitch and air-outlet width effects on the airflow generated by an airblast sprayer with wireless remote-controlled axial fan. Comput. Electron. Agric. 2021, 190, 106428. [Google Scholar] [CrossRef]

- Deveau, J.; Ledebuhr, M.; Manketelow, D. Airblast 101: Your Guide to Effective and Efficient Spraying, 2nd ed.; Sprayers101: Canadá, 2021; p. 305. Available online: https://sabri.com.br/content/wp-content/uploads/2022/11/2021-a10_Airblast101-2ndEdition-Online-Protected.pdf.pdf (accessed on 10 June 2025).

- Grella, M.; Marucco, P.; Zwertvaegher, I.; Gioelli, F.; Bozzer, C.; Biglia, A.; Manzone, M.; Caffini, A.; Fountas, S.; Nuyttens, D.; et al. The effect of fan setting, air-conveyor orientation and nozzle configuration on airblast sprayer efficiency: Insights relevant to trellised vineyards. Crop Prot. 2022, 155, 105921. [Google Scholar] [CrossRef]

- Carvalho, F.K.; Mota, A.A.B.; Chechetto, R.G.; Antuniassi, U.R. Entendendo a Tecnologia de Aplicação: Turbopulverizadores, 1st ed.; FEPAF: Botucatu, Brazil, 2023; p. 92. Available online: https://agroefetiva.com.br/entendendo-a-tecnologia-de-aplicacao-turbopulverizadores-1a-edicao/ (accessed on 6 June 2025).

- Cheraiet, A.; Codis, S.; Lienard, A.; Vergès, A.; Carra, M.; Bastidon, D.; Bonicel, J.F.; Delpuech, X.; Ribeyrolles, X.; Douzals, J.P.; et al. EvaSprayViti: A flexible test bench for comparative assessment of the 3D deposition efficiency of vineyard sprayers at multiple growth stages. Biosyst. Eng. 2024, 241, 1–14. [Google Scholar] [CrossRef]

- Crause, D.H.; da Vitória, E.L.; Ribeiro, L.F.O.; Ferreira, F.d.A.; Lan, Y.; Chen, P. Droplet deposition of leaf fertilizers applied by an unmanned aerial vehicle in Coffea Canephora plants. Agronomy 2023, 13, 1506. [Google Scholar] [CrossRef]

- Vigo-Morancho, A.; Videgain, M.; Boné, A.; Vidal, M.; García-Ramos, F.J. Static and dynamic study of the airflow behavior generated by two air assisted sprayers commonly used in 3D crops. Comput. Electron. Agric. 2024, 216, 108535. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Lei, X.; Wang, S.; Li, X.; Norton, T. Canopy segmentation method for determining the spray deposition rate in orchards. Agronomy 2022, 12, 1195. [Google Scholar] [CrossRef]

- Xu, T.; Zhou, H.; Lv, X.; Lei, X.; Tao, S. Study of the distribution characteristics of the airflow field in tree canopies based on the CFD model. Agronomy 2022, 12, 3072. [Google Scholar] [CrossRef]

- Womac, A.R.; Ozkan, E.; Zhu, H.; Kochendorfer, J.; Jeon, H. Status of spray penetration and deposition in dense field crop canopies. J. ASABE 2022, 65, 1107–1117. [Google Scholar] [CrossRef]

- Petre, I.M.; Pop, S.; Boșcoianu, M. Engineering and management of the precision treatments spraying system implementation on horticultural crops. Rezult. Cercet. Noastre Teh. 2023, 71, 249–255. [Google Scholar] [CrossRef]

- Xun, L.; Campos, J.; Salas, B.; Fabregas, F.X.; Zhu, H.; Gil, E. Advanced spraying systems to improve pesticide saving and reduce spray drift for apple orchards. Precis. Agric. 2023, 24, 1526–1546. [Google Scholar] [CrossRef]

- Gu, C.; Zou, W.; Wang, X.; Chen, L.; Zhai, C. Wind loss model for the thick canopies of orchard trees based on accurate variable spraying. Front. Plant Sci. 2022, 13, 1010540. [Google Scholar] [CrossRef] [PubMed]

- Herbst, A.; Bonds, J.; Wang, Z.; Zeng, A.; He, X.; Goff, P. The influence of unmanned agricultural aircraft system design on spray drift. J. Cultiv. Plants/J. Für Kult. 2020, 72, 1–11. [Google Scholar] [CrossRef]

- Wu, X.; Jia, Y.; Luo, B.; Chen, C.; Wang, Y.; Kang, F.; Li, J. Deposition law of flat fan nozzle for pesticide application in horticultural plants. Int. J. Agric. Biol. Eng. 2022, 15, 27–38. Available online: https://ijabe.org/index.php/ijabe/article/view/7502 (accessed on 30 June 2025). [CrossRef]

- Wang, S.; Li, X.; Nuyttens, D.; Zhang, L.; Liu, Y.; Li, X. Evaluationof compact air-induction flat fan nozzles for herbicide applications: Spray drift and biological efficacy. Front. Plant Sci. 2023, 14, 1018626. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Douzals, J.P.; Lan, Y.; Cotteux, E.; Delpuech, X.; Pouxviel, G.; Zhan, Y. Characteristics of unmanned aerial spraying systems and related spray drift: A review. Front. Plant Sci. 2022, 13, 870956. [Google Scholar] [CrossRef]

- Neto, G.J.; da Cunha, J.P.A.R. Spray deposition and chemical control of the coffee leaf-miner with different spray nozzles and auxiliary boom. Eng. Agrícola 2016, 36, 656–663. [Google Scholar] [CrossRef][Green Version]

- Beck, H.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Lutsko, N.J.; Dufour, A.; Miralles, D.G. High-resolution (1 km) Köppen-Geiger maps for 1901–2099 based on constrained CMIP6 projections. Sci. Data 2023, 10, 724. [Google Scholar] [CrossRef]

- Wang, M.; Dou, H.; Sun, H.; Zhai, C.; Zhang, Y.; Yuan, F. Calculation method of canopy dynamic meshing division volumes for precision pesticide application in orchards based on LiDAR. Agronomy 2023, 13, 1077. [Google Scholar] [CrossRef]

- ISO 22866:2005; Equipment for Crop Protection—Methods for Field Measurement of Spray Drift, 1st ed. International Organization for Standardization: Geneva, Switzerland, 2005; pp. 1–17. Available online: https://www.iso.org/standard/35161.html (accessed on 25 June 2025).

- ISO 5682-1:2017; Equipment for Crop Protection—Spraying Equipment—Part 1: Test Methods for Sprayer Nozzles, 3rd ed. International Organization for Standardization: Geneva, Switzerland, 2017; pp. 1–35. Available online: https://www.iso.org/standard/60053.html (accessed on 25 June 2025).

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2023; Available online: https://www.R-project.org/ (accessed on 16 October 2024).

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting linear mixed-effects models using lme4. J. Stat. Softw. 2015, 67, 48. [Google Scholar] [CrossRef]

- Ieno, E.N.; Luque, P.L.; Pierce, G.J.; Zuur, A.F.; Santos, M.B.; Walker, N.J.; Saveliev, A.A.; Smith, G.M. Three-way nested data for age determination techniques applied to cetaceans. In Mixed Effects Models and Extensions in Ecology with R; Chapter 19; Statistics for Biology and Health; Springer: Buenos Aires, Argentina, 2009; pp. 459–468. [Google Scholar] [CrossRef]

- Lenth, R.V. Emmeans: Estimated Marginal Means, aka Least Squares Means. R Package Version 1.8.8. 2018. Available online: http://cran.r-project.org/package=emmeans (accessed on 26 October 2024).

- İrsel, G. Design and implementation of low-cost field crop sprayer electronic flow control system. Gazi Univ. J. Sci. 2021, 34, 835–849. [Google Scholar] [CrossRef]

- Kumar, M.; Ajaykumara, K.M. Importance of pesticide dose in pest management. Indian Entomol. 2022, 3, 51–54. Available online: https://www.indianentomologist.org/vol3issue1 (accessed on 27 June 2025).

- Wang, G.; Li, Z.; Jia, W.; Ou, M.; Dong, X.; Zhang, Z. A Review on the Evolution of Air-Assisted Spraying in Orchards and the Associated Leaf Motion During Sprayin. Agriculture 2025, 15, 964. [Google Scholar] [CrossRef]

- Cui, H.; Wang, C.; Yu, S.; Xin, Z.; Liu, X.; Yuan, J. Two-stage CFD simulation of droplet deposition on deformed leaves of cotton canopy in air-assisted spraying. Comput. Electron. Agric. 2024, 224, 109228. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Shi, R.; Dai, S.; Jia, W.; Ou, M.; Dong, X.; Yan, M. A Review of Multiscale Interaction Mechanisms of Wind–Leaf–Droplet Systems in Orchard Spraying. Sensors 2025, 25, 4729. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Niu, C.; Ma, S.; Tan, H.; Xu, L. CFD models as a tool to analyze the deformation behavior of grape leaves under an air-assisted sprayer. Comput. Electron. Agric. 2022, 198, 107112. [Google Scholar] [CrossRef]

- Mahmud, M.S.; Zahid, A.; He, L.; Martin, P. Opportunities and possibilities of developing an advanced precision spraying system for tree fruits. Sensors 2021, 21, 3262. [Google Scholar] [CrossRef]

- Herkins, M.; Zhao, L.; Zhu, H.; Jeon, H.; Castilho-Theodoro, J. Optimization and Evaluation of Electrostatic Spraying Systems and Their Effects on Pesticide Deposition and Coverage Inside Dense Canopy Plants. Agronomy 2025, 15, 1401. [Google Scholar] [CrossRef]

- Santinato, F.; da Silva, C.D.; da Silva, R.P.; Ormond, A.T.S.; Gonasalves, V.A.R.; Santinato, R. Development and technical validation of spray kit for coffee harvester. Afr. J. Agric. Res. 2019, 14, 571–575. [Google Scholar] [CrossRef]

- Alves, T.C.; Cunha, J.P.A.R.; Alves, G.S.; Silva, S.M.; Lemes, E.M. Canopy volume and application rate interaction on spray deposition for different phenological stages of coffee crop. Coffee Sci. 2020, 15, e151777. [Google Scholar] [CrossRef]

- Rathnayake, A.P.; Chandel, A.K.; Schrader, M.J.; Hoheisel, G.A.; Khot, L.R. Spray patterns and perceptive canopy interaction assessment of commercial airblast sprayers used in Pacific Northwest perennial specialty crop production. Comput. Electron. Agric. 2021, 184, 106097. [Google Scholar] [CrossRef]

- Khot, L.R. Air-assisted velocity profiles and perceptive canopy interactions of commercial airblast sprayers used in Pacific Northwest perennial specialty crop production. Agric. Eng. Int. CIGR J. 2022, 24, 78–89. [Google Scholar]

- İtmeç, M.; Bayat, A.; Bolat, A.; Toraman, M.C.; Soysal, A. Assessment of Spray Drift with Various Adjuvants in a Wind Tunnel. Agronomy 2022, 12, 2377. [Google Scholar] [CrossRef]

- Milanowski, M.; Subr, A.; Combrzyński, M.; Różańska-Boczula, M.; Parafiniuk, S. Effect of Adjuvant, Concentration and Water Type on the Droplet Size Characteristics in Agricultural Nozzles. Appl. Sci. 2022, 12, 5821. [Google Scholar] [CrossRef]

- Xue, X.; Zeng, K.; Li, N.; Luo, Q.; Ji, Y.; Li, Z.; Lyu, S.; Song, S. Parameters optimization and performance evaluation model of air-assisted electrostatic sprayer for citrus orchards. Agriculture 2023, 13, 1498. [Google Scholar] [CrossRef]

- Patil, S.S.; Patil, Y.; Patil, S.B. Review on automatic variable-rate spraying systems based on orchard canopy characterization. Inform. Autom. 2023, 22, 57–86. [Google Scholar] [CrossRef]

| Treatment | Rate (L ha−1) | Nozzle Type | Tip | Flow (L min−1) | Pressure (kPa) |

|---|---|---|---|---|---|

| 1 | 200 | Flat fan nozzle | BD 01 | 0.34 | 207 |

| 2 | 400 | Flat fan nozzle | BD 02 | 0.68 | 207 |

| 3 | 600 | Flat fan nozzle | BD 025 | 1.02 | 289 |

| 4 | 200 | Hollow cone nozzle | MAG 1 | 0.34 | 413 |

| 5 | 400 | Hollow cone nozzle | MAG 1.5 | 0.68 | 723 |

| 6 | 600 | Hollow cone nozzle | MAG 2 | 1.02 | 1.034 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faria, L.O.; de Alvarenga, C.B.; Ribeiro, G.M.; Zampiroli, R.; Carvalho, F.J.; Barbosa, D.P.L.; de Lima Lopes, L.; da Cunha, J.P.A.R.; Rinaldi, P.C.N. Droplet Deposition and Transfer in Coffee Cultivation Under Different Spray Rates and Nozzle Types. AgriEngineering 2025, 7, 337. https://doi.org/10.3390/agriengineering7100337

Faria LO, de Alvarenga CB, Ribeiro GM, Zampiroli R, Carvalho FJ, Barbosa DPL, de Lima Lopes L, da Cunha JPAR, Rinaldi PCN. Droplet Deposition and Transfer in Coffee Cultivation Under Different Spray Rates and Nozzle Types. AgriEngineering. 2025; 7(10):337. https://doi.org/10.3390/agriengineering7100337

Chicago/Turabian StyleFaria, Layanara Oliveira, Cleyton Batista de Alvarenga, Gustavo Moreira Ribeiro, Renan Zampiroli, Fábio Janoni Carvalho, Daniel Passarelli Lupoli Barbosa, Luana de Lima Lopes, João Paulo Arantes Rodrigues da Cunha, and Paula Cristina Natalino Rinaldi. 2025. "Droplet Deposition and Transfer in Coffee Cultivation Under Different Spray Rates and Nozzle Types" AgriEngineering 7, no. 10: 337. https://doi.org/10.3390/agriengineering7100337

APA StyleFaria, L. O., de Alvarenga, C. B., Ribeiro, G. M., Zampiroli, R., Carvalho, F. J., Barbosa, D. P. L., de Lima Lopes, L., da Cunha, J. P. A. R., & Rinaldi, P. C. N. (2025). Droplet Deposition and Transfer in Coffee Cultivation Under Different Spray Rates and Nozzle Types. AgriEngineering, 7(10), 337. https://doi.org/10.3390/agriengineering7100337