Citrus Waste Valorisation Processes from an Environmental Sustainability Perspective: A Scoping Literature Review of Life Cycle Assessment Studies

Abstract

1. Introduction

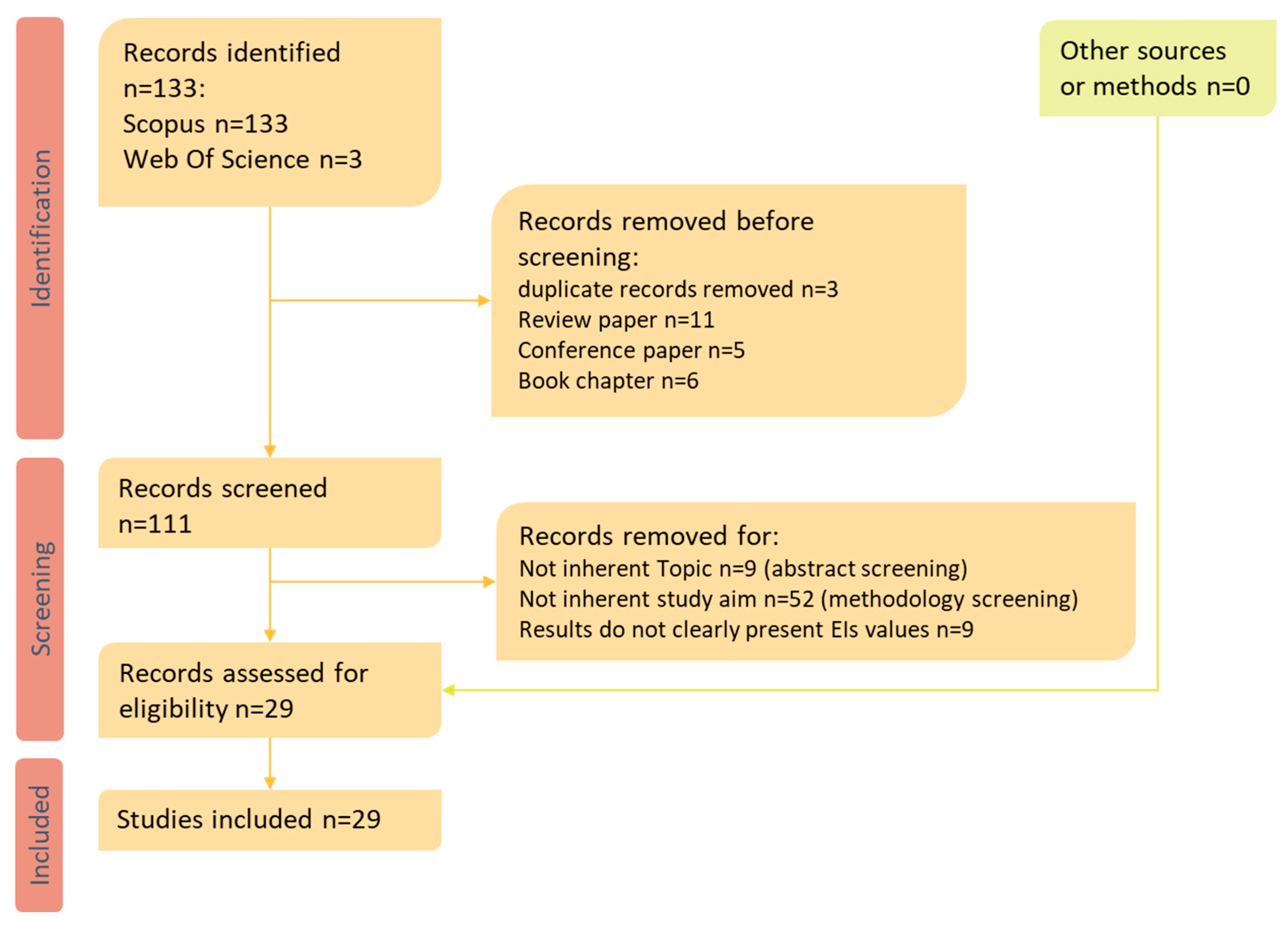

2. Materials and Methods

2.1. Research Strategies and Inclusion–Exclusion Criteria

- In the title, abstract and keywords are as follows: (citrus OR orange OR lemon OR grapefruit) AND (LCA OR (“life cycle assessment”) OR (“carbon footprint”)) AND (peel OR waste OR by-product OR residues OR juice OR pulp);

- Reviews, book chapters, conference proceedings, and conference reviews were excluded;

- Only manuscripts written in English were considered;

- The articles were published between 2013 and 2025.

- Peer-reviewed LCA studies;

- Studies focusing on the valorisation of citrus post-processing biomass, including orange, lemon, and grapefruit residues;

- Articles presenting quantitative environmental impact results (e.g., expressed in standardised units such as kg CO2 eq, kg SO2 eq, MJ, etc.).

- Conference papers and non-peer-reviewed literature;

- Review articles or meta-studies;

- Studies reporting environmental impacts only in normalised or aggregated form, without raw values;

- LCA studies with unconsistent functional units (FU);

- Studies assessing multi-biomass or multi-feedstock valorisation, unless specific data for citrus waste were clearly distinguishable.

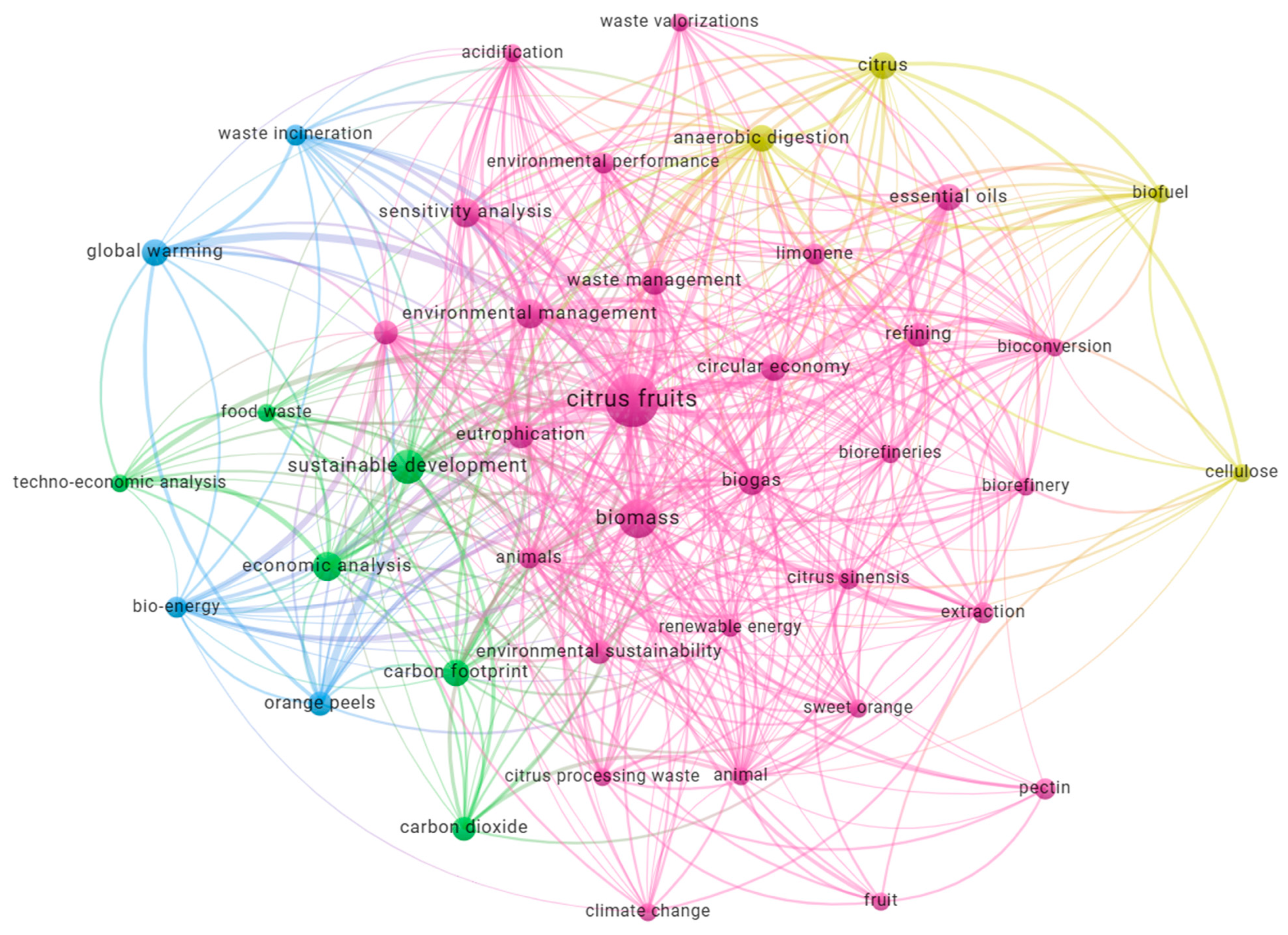

2.2. Bibliometric Analysis

3. Results

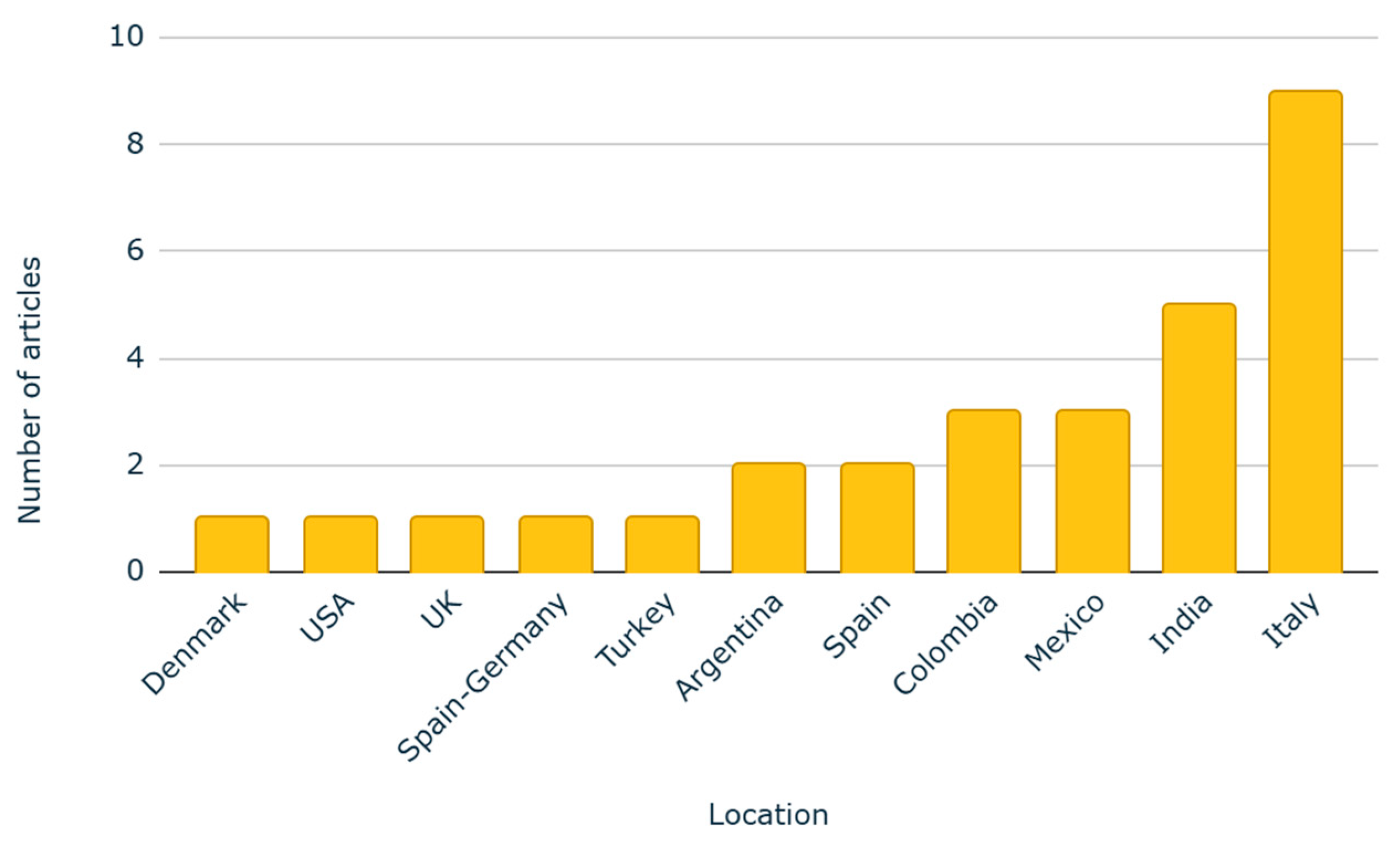

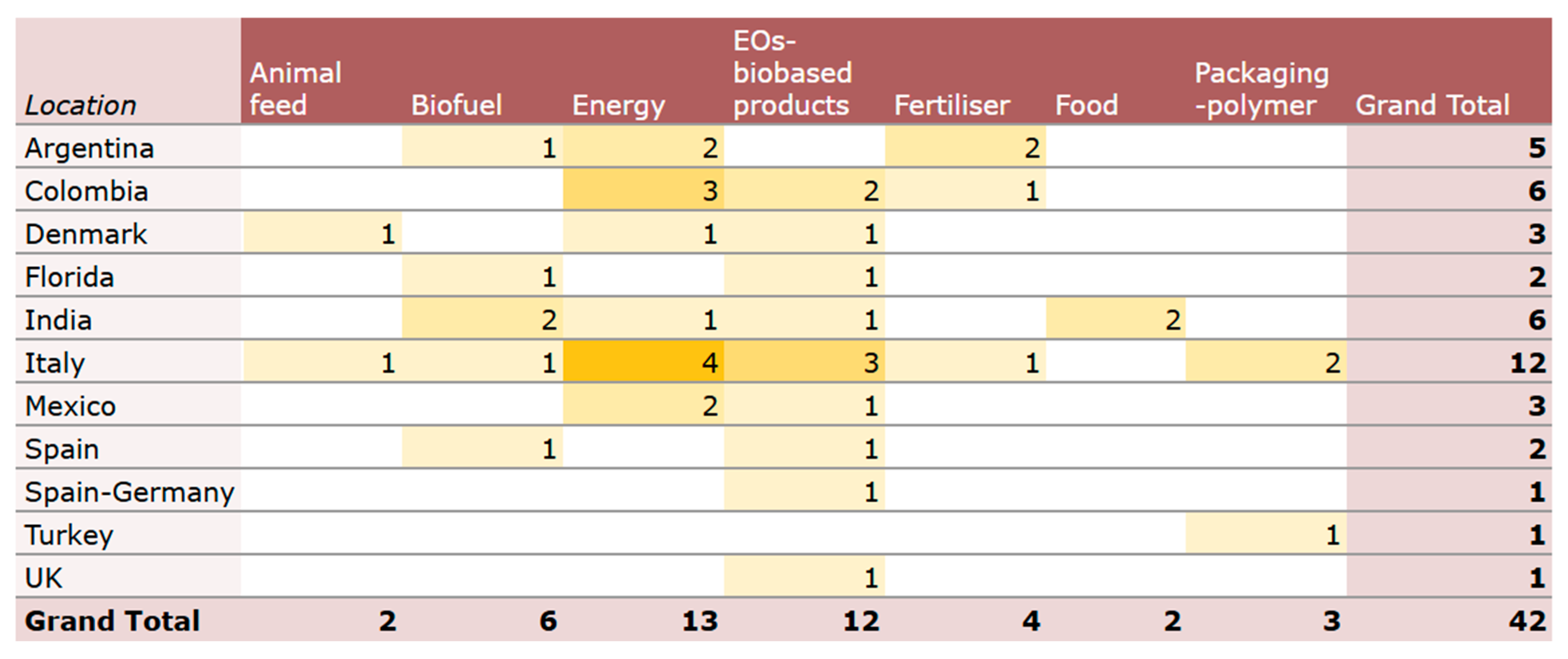

3.1. Bibliographic Research and Article Classification

3.2. Objectives and Findings from Selected Articles

| Ref | Year | Location | Species | Scenarios | Valorisation Aim | Functional Unit | System Boundaries | Best Scenario | LCIA 1 Method | Scale |

|---|---|---|---|---|---|---|---|---|---|---|

| [21] | 2013 | Florida | Citrus | Biomethane, limonene, digestate production (small refinery); small refinery + ethanol (large refinery) | Integrated biorefinery, biofuel and energy production | 1 ton CW for comparison | Cradle-to-gate (Credits for replacing fossil fuels) | Large biorefinery | ISO 14040:2006 [7] | IND |

| [22] | 2016 | Turkey | Orange | Pectin jelly film vs. LDPE 2 | Packaging replacement | 1 m2 film polymer for packaging | Cradle-to-gate + simulated biodegradation | LDPE2 | CML-IA baseline | LAB |

| [15] | 2017 | Italy | Orange | Incineration; limonene extraction; AD; Co-digestion; compost; FEED; LAND | Waste treatment and energy | 1 t OPW wet weight | Zero burden approach | Co-digestion and FEED | IPCC 2007, ReCiPe (2008), CML 2002 | IND |

| [23] | 2018 | United Kingdom | Citrus | PLC from citrus vs. algae | Biopolymer production | 21,600 t PLC/year | Cradle-to-gate | Citrus-based PLC | ReCiPe Midpoint (SimaPro) | IND |

| [24] | 2019 | Italy | Citrus | Natural gas vs. gasification + CHP 3 | Energy recovery | 35,000 t citrus peels/year | Partial cradle-to-gate | Integrated system | Carbon footprint | IND |

| [25] | 2019 | Mexico | Orange | Fuel oil vs. orange peel as solid biofuel | Energy and biofuel production | 1 MJ steam | Gate-to-gate | Orange peel biofuel | ISO 14040:2006 | IND |

| [26] | 2020 | India | Orange | EO or pectin extraction to ethanol, limonene, methane | Biorefinery | 2500 kg citrus waste | Gate-to-gate | Microwave-based | ISO 14040:2006 | IND |

| [20] | 2020 | Colombia | Orange | Landfill vs. AD vs. INC | Energy production | 1 L juice | Cradle-to-gate | INC or AD spreading digestate | ILCD | IND |

| [27] | 2020 | Spain | Citrus | Hydro-distillation; cold pressing; ethanol or hexane as solvent extractive agents | D-limonene extraction | 100 kg/h citrus waste | Cradle-to-gate | Cold pressing | CML 2001 v2.05 | IND |

| [28] | 2021 | Italy | Orange | Innovative metal-adsorbent polymer vs. activated carbon | Eos and polymer | 1 kg organic residue | Gate-to-gate | Activated carbon | Midpoint EF 3.0 | LAB |

| [29] | 2021 | Italy | Lemon, orange, olive pomace | Pyrolysis at 400–650 °C of different agro-industrial waste. | Energy | 1 MJ thermal energy | Cradle-to-gate | Orange peel pyrolysed at 500 °C | ILCD 2011 midpoint | LAB |

| [18] | 2020 | Colombia | Orange | LAND vs. complex or high-complex biorefinery + AD (EO, esperidind, pectine, acetone, ethanol, buthanol, biogas, and fertiliser production) | Integrated biorefinery and energy production | 1 L of orange juice | Cradle-to-gate | High-complex biorefinery | ReCiPe midpoint | IND |

| [30] | 2021 | Italy | Citrus | Gasification including and excluding CW drying | Electricity generation | 1 MWh | Cradle-to-gate | Excluding drying | CO2-eq comparison | IND |

| [31] | 2022 | Italy | Orange | Essential oil and pectin production | EOs extraction | 15 kg processed orange | Cradle-to-gate | Steam distillation | ReCiPe 2016 midpoint (H) | IND |

| [32]. | 2022 | Mexico | Orange | LAND vs. wax recovery | Fungicide production | 1 m2 fungicide | Cradle-to-gate | Wax recovery | CML-IA 2016 | LAB |

| [17] | 2022 | Argentina | Lemon | Syngas, biogas, co-digestion | Energy | 1 kg lemon | Cradle-to-gate | Co-digestion | ReCiPe 2016 midpoint (H) | IND |

| [33] | 2022 | Mexico | Orange and sugarcane straw | Heavy fuel oil vs. orange peels + sugarcane straw heat production | Biomass-based heat | 44,150 MWh/year heat | Cradle-to-gate | Orange peels + straw heat recovery | CML-IA baseline | IND |

| [34] | 2022 | Italy | Citrus | Bio-hydrogen from gasification | CHP and hydrogen production | 1 kg H2 | Gate-to-gate | Alternative process | Not specified | IND |

| [35] | 2022 | India | Orange | Biochar-catalysed biodiesel | Biofuel production | 1 kg biodiesel | Well-to-wheel | FW-based biodiesel | ReCiPe 2016 midpoint | LAB |

| [36] | 2022 | Denmark | Orange | Biorefinery, animal feed, incineration | Integrated biorefinery, energy production, and animal feed | 1 t OPW | Cradle-to-gate | Wind + biogas (attributional) | EF method (EU) | LAB |

| [37] | 2023 | India | Orange | Extrusion vs. ultrasonication | SDF from orange peel | 0.1 kg fresh orange peel | Gate-to-gate | Extrusion | CML 2001 | LAB |

| [38] | 2023 | India | Orange | Micronisation, autoclave, hybrid | SDF from orange peel | 0.1 kg fresh orange peel | Gate-to-gate | Hybrid method | CML 2001 | LAB |

| [39] | 2023 | India | Mixed | SDF concentration methods: micronisation, autoclave, extrusion, and ultrasonication | Energy production | Not specified | Cradle-to-gate | Extrusion | Carbon footprint | IND |

| [40] | 2023 | Spain–Germany | Orange | Limonene vs. petrochemical TMB | Eos extraction | 1 t expander molecule | Cradle-to-gate | Limonene-based | Not specified | IND |

| [41] | 2024 | Argentina | Lemon | Conventional, biogas, biomass, compost | Energy, compost | 1 t product | Cradle-to-gate | Biogas, biomass and compost | ISO 14040:2006 | IND |

| [42] | 2024 | Italy | Orange | Pectin + limonene extraction | Biobased chemical production | 300 g OPW | Post-transformation | One-pot extraction | Impact 2002+ | LAB |

| [19] | 2024 | Colombia | Orange | AD, Steam distillation, enzymatic hydrolysis, integrated biorefinery | Integrated biorefinery and energy production | 1 kg orange peel | Gate-to-gate | EO extraction+ AD | ISO 14040:2006 | IND |

| [43] | 2025 | Spain | Orange (and tomato) | Solvent, ultrasound, microwave, subcritical water extraction | Phenolic compound production | 100 t phenolic powder/year | Cradle-to-gate | Microwave | ReCiPe midpoint and endpoint | IND |

| [44] | 2025 | Italy | Grapefruit | Pectin extraction: conventional heating vs. bacteria encapsulation | Bacteria encapsulation | 1 kg encapsulated bacteria | Gate-to-gate | Conventional heating | ILCD 2011 | LAB |

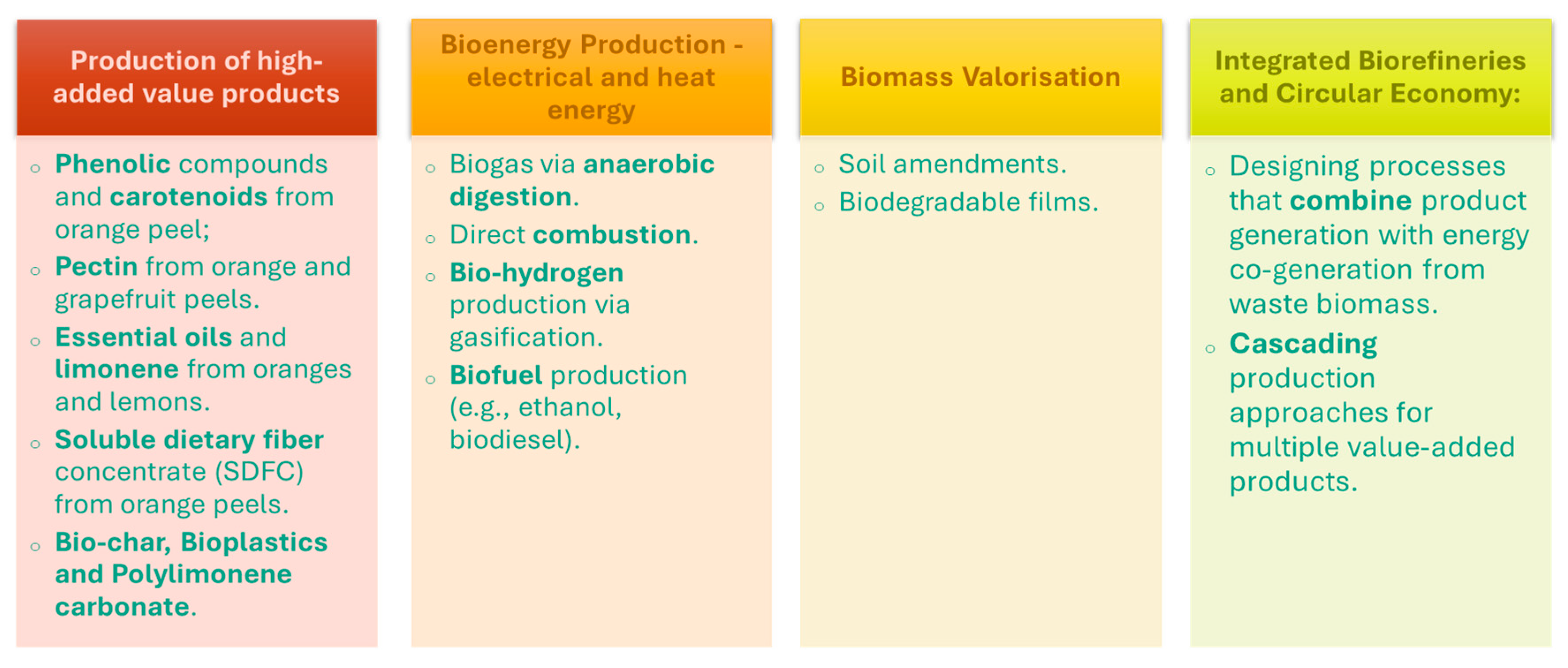

3.3. Technical Differences in the Analysed Citrus Waste Valorisation Processes

- Steam distillation [31]: It represents a traditional method and has low environmental impacts thanks to the simplicity of its application because it does not need organic solvents and it works with low temperatures (about 100 °C).

- Microwave-assisted extraction: It is effective due to the reduced extraction time and the possibility of avoiding solvents. Amato et al. [28] found >90% of ethanol recovery, while Da Costa et al. [31] found higher essential oil yield with ~30–50% of energy savings compared to conventional distillation, and reduced water usage.

- Ultrasonication: It is a practice suitable for its high efficiency and high-quality product production. It was found that the CC impact is about 22.9 g CO2-eq/MJ for limonene while the acetone substitution was >90 g CO2-eq/MJ. Moreover, this technique can increase pectin or EO yield by 10–40% compared to conventional methods, improving mass efficiency [31,42].

- One-pot extraction: It makes it possible to extract multiple chemicals compounds in one line of production [42].

3.4. Summary of Key Findings of Scoping Review

- Biorefinery alternatives are environmentally superior to OPW landfilling.

- Greater complexity in biorefinery configurations may increase the environmental burden attributed to the main citrus product (e.g., juice or marmalade) when using mass allocation. This trend is not observed under economic allocation, which distributes the impacts more favourably due to the inclusion of high-value co-products. Mass allocation is more appropriate when the functional unit is associated with biorefinery-derived products, since these typically represent a small proportion of the total product mass, and allocating impacts by mass better reflects their relative contribution to the system.

- A shift from attributional to consequential analysis is deemed not possible because products like pectin, essential oil, ethanol, butanol, acetone, and orange do not act as inputs to each other’s production processes, making system expansion or substitution approaches methodologically inappropriate. This approach is indeed more suitable for sustainability studies of energy recovery systems.

4. Discussion

- Economic allocation generally results in worse environmental performance (higher impacts per unit) for economically valuable but mass-scarce products (such as essential oils, and limonene), as these are assigned a greater share of impacts based on economic value. This is particularly evident for those articles comparing the two allocation models. Conversely, lower-value products (such as compost or animal feed) receive lower impacts, improving their apparent environmental performance. Economic allocation is to be preferred when the overall circular economy benefits and integrated sustainability of the entire citrus waste valorisation system would be emphasised.

- Mass allocation tends to assign environmental burdens proportionally based on mass, typically distributing impacts more evenly across products, significantly lowering impacts per unit for high-value low-mass products. Usually, this methodological choice leads to better environmental performance (lower impacts per unit) for valuable products due to small mass proportions compared to total processed biomass. Mass allocation is more favourable when assessing or highlighting specific high-value products (such as essential oils or purified compounds like limonene), as this allocation significantly reduces the perceived environmental impacts per unit produced, making these products appear more sustainable individually.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CW | Citrus waste |

| LCA | Life cycle assessment |

| IND | Industrial scale |

| LAB | Laboratory scale |

| EOs | Essential oils |

| GWP | Global Warming Potential |

| AC | Acidification |

| HT | Human toxicity |

| INC | Incineration |

| AD | Anaerobic digestion |

| FEED | Animal feeding |

| LAND | Landfilling |

| LDPE | Low-density polyethylene |

| LCIA | Life cycle impacts assessment |

| FU | Functional units |

References

- Gazal, A.A.; Bonnet, S.; Silalertruksa, T.; Gheewala, S.H. Circular Economy Strategies for Agri-Food Production—A Review. Circ. Econ. Sust. 2025, 5, 2467–2493. [Google Scholar] [CrossRef]

- Kimball, D.A. Citrus Processing: A Complete Guide; Springe: Boston, MA, USA, 1999; ISBN 978-0-8342-1258-9. [Google Scholar]

- Suri, S.; Singh, A.; Nema, P.K. Current Applications of Citrus Fruit Processing Waste: A Scientific Outlook. Appl. Food Res. 2022, 2, 100050. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C.; Chinnici, G.; Selvaggi, R.; Cascone, G.; Arcidiacono, C.; Pecorino, B. Use of Citrus Pulp for Biogas Production: A GIS Analysis of Citrus-Growing Areas and Processing Industries in South Italy. Land Use Policy 2017, 66, 151–161. [Google Scholar] [CrossRef]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of Citrus Processing Waste: A Review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef]

- Cinardi, G.; D’Urso, P.R.; Arcidiacono, C.; Ingrao, C. Accounting for Circular Economy Principles in Life Cycle Assessments of Extra-Virgin Olive Oil Supply Chains–Findings from a Systematic Literature Review. Sci. Total Environ. 2024, 945, 173977. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management–Life Cycle Assessment–Principles and Framework. ISO–International Organization for Standardization: Geneva, Switzerland, 2006.

- Ingrao, C.; Arcidiacono, C.; Siracusa, V.; Niero, M.; Traverso, M. Life Cycle Sustainability Analysis of Resource Recovery from Waste Management Systems in a Circular Economy Perspective Key Findings from This Special Issue. Resources 2021, 10, 32. [Google Scholar] [CrossRef]

- Crovella, T.; Paiano, A.; Falciglia, P.P.; Lagioia, G.; Ingrao, C. Wastewater Recovery for Sustainable Agricultural Systems in the Circular Economy—A Systematic Literature Review of Life Cycle Assessments. Sci. Total Environ. 2024, 912, 169310. [Google Scholar] [CrossRef]

- Xu, G.; Zhao, J.; Shi, K.; Xu, Y.; Hu, H.; Xu, X.; Hu, T.; Zhang, P.; Yao, J.; Pan, S. Trends in Valorization of Citrus By-Products from the Net-Zero Perspective: Green Processing Innovation Combined with Applications in Emission Reduction. Trends Food Sci. Technol. 2023, 137, 124–141. [Google Scholar] [CrossRef]

- Yuan, L.; Ding, Z.; Pan, X.; Shi, C.; Lao, F.; Grundmann, P.; Wu, J. Greenhouse Gas Emissions and Reduction Potentials in the Crop Processing By-Products Utilization Chains: A Review on Citrus and Sugarcane by-Products. Renew. Sustain. Energy Rev. 2025, 217, 115758. [Google Scholar] [CrossRef]

- Manakas, P.; Balafoutis, A.T.; Kottaridi, C.; Vlysidis, A. Sustainability Assessment of Orange Peel Waste Valorization Pathways from Juice Industries. Biomass Convers. Biorefinery 2024, 5, 6525–6544. [Google Scholar] [CrossRef]

- Cinardi, G.; D’Urso, P.R.; Arcidiacono, C.; Muradin, M.; Ingrao, C. A Systematic Literature Review of Environmental Assessments of Citrus Processing Systems, with a Focus on the Drying Phase. Sci. Total Environ. 2025, 974, 179219. [Google Scholar] [CrossRef]

- Sharma, K.; Mahato, N.; Cho, M.H.; Lee, Y.R. Converting Citrus Wastes into Value-Added Products: Economic and Environmently Friendly Approaches. Nutrition 2017, 34, 29–46. [Google Scholar] [CrossRef] [PubMed]

- Negro, V.; Ruggeri, B.; Fino, D.; Tonini, D. Life Cycle Assessment of Orange Peel Waste Management. Resour. Conserv. Recycl. 2017, 127, 148–158. [Google Scholar] [CrossRef]

- Nunes Da Silva, C.; Pina De Almeida, L.M.; Lemes, A.C.; Ribeiro, B.D. Citrus By-Products Valorization Using Deep Eutectic Solvents–A Review. Food Biosci. 2024, 60, 104446. [Google Scholar] [CrossRef]

- Machin Ferrero, L.M.; Wheeler, J.; Mele, F.D. Life Cycle Assessment of the Argentine Lemon and Its Derivatives in a Circular Economy Context. Sustain. Prod. Consum. 2022, 29, 672–684. [Google Scholar] [CrossRef]

- Mariana, O.-S.; Alzate, C.; Ariel, C. Comparative Environmental Life Cycle Assessment of Orange Peel Waste in Present Productive Chains. J. Clean. Prod. 2021, 322, 128814. [Google Scholar] [CrossRef]

- Ortiz-Sanchez, M.; Solarte-Toro, J.C.; Inocencio-García, P.J.; Cardona Alzate, C.A. Sustainability Analysis of Orange Peel Biorefineries. Enzym. Microb. Technol. 2024, 172, 110327. [Google Scholar] [CrossRef]

- Ortiz, D.L.; Batuecas, E.; Orrego, C.E.; Rodríguez, L.J.; Camelin, E.; Fino, D. Sustainable Management of Peel Waste in the Small-Scale Orange Juice Industries: A Colombian Case Study. J. Clean. Prod. 2020, 265, 121587. [Google Scholar] [CrossRef]

- Pourbafrani, M.; McKechnie, J.; Maclean, H.L.; Saville, B.A. Life Cycle Greenhouse Gas Impacts of Ethanol, Biomethane and Limonene Production from Citrus Waste. Environ. Res. Lett. 2013, 8, 015007. [Google Scholar] [CrossRef]

- Günkaya, Z.; Banar, M. An Environmental Comparison of Biocomposite Film Based on Orange Peel-Derived Pectin Jelly-Corn Starch and LDPE Film: LCA and Biodegradability. Int. J. Life Cycle Assess. 2016, 21, 465–475. [Google Scholar] [CrossRef]

- Zhang, D.; del Rio-Chanona, E.A.; Wagner, J.L.; Shah, N. Life Cycle Assessments of Bio-Based Sustainable Polylimonene Carbonate Production Processes. Sustain. Prod. Consum. 2018, 14, 152–160. [Google Scholar] [CrossRef]

- Galvagno, A.; Prestipino, M.; Maisano, S.; Urbani, F.; Chiodo, V. Integration into a Citrus Juice Factory of Air-Steam Gasification and CHP System: Energy Sustainability Assessment. Energy Convers. Manag. 2019, 193, 74–85. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Magdaleno Molina, M.; Melgarejo Flores, L.A.; Palmerín Ruiz, M.E.; Zermeño EguiaLis, J.A.; Rosas Molina, A.; Aburto, J.; Amezcua-Allieri, M.A. Energy-Water Nexus Strategies for the Energetic Valorization of Orange Peels Based on Techno-Economic and Environmental Impact Assessment. Food Bioprod. Process. 2019, 117, 380–387. [Google Scholar] [CrossRef]

- Joglekar, S.N.; Pathak, P.D.; Mandavgane, S.A.; Kulkarni, B.D. Process of Fruit Peel Waste Biorefinery: A Case Study of Citrus Waste Biorefinery, Its Environmental Impacts and Recommendations. Environ. Sci. Pollut. Res. 2019, 26, 34713–34722. [Google Scholar] [CrossRef]

- Santiago, B.; Moreira, M.T.; Feijoo, G.; González-García, S. Identification of Environmental Aspects of Citrus Waste Valorization into D-Limonene from a Biorefinery Approach. Biomass Bioenergy 2020, 143, 105844. [Google Scholar] [CrossRef]

- Amato, A.; Mastrovito, M.; Becci, A.; Beolchini, F. Environmental Sustainability Analysis of Case Studies of Agriculture Residue Exploitation. Sustainability 2021, 13, 3990. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Longo, S.; Cellura, M.; Guarino, F.; Messineo, A.; Mistretta, M.; Volpe, M. Environmental Assessment of a Waste-to-Energy Practice: The Pyrolysis of Agro-Industrial Biomass Residues. Sustain. Prod. Consum. 2021, 28, 866–876. [Google Scholar] [CrossRef]

- Prestipino, M.; Salmeri, F.; Cucinotta, F.; Galvagno, A. Thermodynamic and Environmental Sustainability Analysis of Electricity Production from an Integrated Cogeneration System Based on Residual Biomass: A Life Cycle Approach. Appl. Energy 2021, 295, 117054. [Google Scholar] [CrossRef]

- da Costa, J.S.; Maranduba, H.L.; de Sousa Castro, S.; de Almeida Neto, J.A.; Rodrigues, L.B. Environmental Performance of Orange Citrus Waste as Raw Material for Pectin and Essential Oil Production. Food Bioprod. Process. 2022, 135, 165–177. [Google Scholar] [CrossRef]

- García-Cruz, A.; Díaz-Jiménez, L.; Ilyina, A.; Carlos-Hernández, S. Prospective Life Cycle Assessment of a Based Orange Wax Fungicide. Ind. Crops Prod. 2022, 180, 114769. [Google Scholar] [CrossRef]

- Navarro, A.; Puig, R.; Martí, E.; Bala, A.; Fullana-i-Palmer, P. Tackling the Relevance of Packaging in Life Cycle Assessment of Virgin Olive Oil and the Environmental Consequences of Regulation. Environ. Manag. 2018, 62, 277–294. [Google Scholar] [CrossRef] [PubMed]

- Prestipino, M.; Piccolo, A.; Polito, M.F.; Galvagno, A. Combined Bio-Hydrogen, Heat, and Power Production Based on Residual Biomass Gasification: Energy, Exergy, and Renewability Assessment of an Alternative Process Configuration. Energies 2022, 15, 5524. [Google Scholar] [CrossRef]

- Rajendran, N.; Kang, D.; Han, J.; Gurunathan, B. Process Optimization, Economic and Environmental Analysis of Biodiesel Production from Food Waste Using a Citrus Fruit Peel Biochar Catalyst. J. Clean. Prod. 2022, 365, 132712. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of High-Value Food Waste and Food Residues Biorefineries with Focus on Unavoidable Wastes from Processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Khanpit, V.V.; Tajane, S.P.; Mandavgane, S.A. Orange Waste Peel to High Value Soluble Dietary Fiber Concentrate: Comparison of Conversion Methods and Their Environmental Impact. Biomass Convers. Biorefinery 2023, 13, 14413–14423. [Google Scholar] [CrossRef]

- Khanpit, V.V.; Tajane, S.P.; Mandavgane, S.A. Production of Soluble Dietary Fiber Concentrate from Waste Orange Peels: Study of Nutritional and Physicochemical Properties and Life Cycle Assessment. Biomass Convers. Biorefinery 2023, 13, 14615–14627. [Google Scholar] [CrossRef]

- Khanpit, V.V.; Tajane, S.P.; Mandavgane, S.A. Technoeconomic and Life Cycle Analysis of Soluble Dietary Fiber Concentrate Production from Waste Orange Peels. Waste Manag. 2023, 155, 29–39. [Google Scholar] [CrossRef]

- Sultan, U.; Städtke, K.; Göpfert, A.; Lemmen, D.; Metwali, E.; Maiti, S.; Schlumberger, C.; Yokosawa, T.; Apeleo Zubiri, B.; Spiecker, E.; et al. Substituting Fossil-Based with Bio-Based Chemicals: The Case of Limonene as a Greener Pore Expander for Micellar Templated Silica. RSC Sustain. 2023, 1, 1449–1461. [Google Scholar] [CrossRef]

- Iñigo Martínez, M.E.; Díaz, G.F.; Machado, D.; Garolera De Nucci, P.; Paz, D.; Arena, P. Life Cycle Assessment of Energy Saving and Circular Economy Strategies: Contributions to the Environmental Footprint Lemon and by-Product Production in Argentina. Clean Technol. Environ. Policy 2024, 26, 2033–2057. [Google Scholar] [CrossRef]

- Midolo, G.; Cutuli, G.; Porto, S.M.C.; Ottolina, G.; Paini, J.; Valenti, F. LCA Analysis for Assessing Environmenstal Sustainability of New Biobased Chemicals by Valorising Citrus Waste. Sci. Rep. 2024, 14, 21418. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. Agri-Food Waste to Phenolic Compounds: Life Cycle and Eco-Efficiency Assessments. J. Environ. Manag. 2025, 380, 124935. [Google Scholar] [CrossRef]

- Di Clemente, N.A.; La Cava, E.; Sgroppo, S.; Gomez-Zavaglia, A.; Gerbino, E. Sustainability Assessment of Pectin Extraction from Citrus Paradisi Peel to Support the Encapsulation of Lactic Acid Bacteria. Appl. Food Res. 2025, 5, 100716. [Google Scholar] [CrossRef]

- Salomone, R.; Ioppolo, G. Environmental Impacts of Olive Oil Production: A Life Cycle Assessment Case Study in the Province of Messina (Sicily). J. Clean. Prod. 2012, 28, 88–100. [Google Scholar] [CrossRef]

- Integrating Photovoltaic Systems to Reduce Carbon Footprint in Extra Virgin Olive Oil Production: A Territorial Perspective in the Mediterranean Area. In Lecture Notes in Civil Engineering; Springer Nature: Cham, Switzerland, 2025; pp. 999–1007. ISBN 978-3-031-84211-5.

- Formica, V.; Leoni, F.; Duce, C.; González-Rivera, J.; Onor, M.; Guarnaccia, P.; Carlesi, S.; Bàrberi, P. Controlled Drought Stress Affects Rosemary Essential Oil Composition with Minimal Impact on Biomass Yield. Ind. Crops Prod. 2024, 221, 119315. [Google Scholar] [CrossRef]

| Review | Objectives | Main Results |

|---|---|---|

| [10] | To assess citrus by-products in the context of net-zero emissions and explore innovative low-carbon processing technologies. | Highlighted the potential of citrus by-products for carbon footprint reduction in food systems, energy production, and sustainable materials through green processing and renewable energy use. |

| [11] | To evaluate GHG reduction potentials in citrus and sugarcane by-product valorisation pathways using bioconversion and biorefinery approaches. | Bioconversion methods like fermentation and anaerobic digestion have lower emissions than chemical methods; biorefineries show great sustainability potential. |

| [12] | To assess the sustainability of orange peel waste valorisation via mass flow and LCA analysis. | Innovative technologies outperformed conventional ones in energy efficiency, yield, and environmental impact; complex biorefineries show environmental benefits but higher costs. |

| [13] | To systematically review LCA studies on citrus processing, focusing on the drying phase. | Drying is the most energy-intensive phase; gasification and biodiesel production are less sustainable valorisation practices; animal feed and anaerobic co-digestion are more favourable practices, particularly with optimised drying. |

| [5] | To analyse citrus peel waste characteristics and valorisation methods across different uses. | Direct uses (e.g., animal feed and compost) are widespread; high-value compound extraction is promising but often not economically viable due to processing costs and storage challenges. |

| [14] | To review methods for extracting value-added products from citrus waste and their applications. | Citrus waste contains bioactive compounds suitable for food, pharma, and energy; enzymatic and chemical extraction methods are discussed along with the need for D-limonene removal in bioethanol production. |

| [15] | To evaluate limonene recovery from citrus waste and its implications for energy valorisation. | Limonene extraction is crucial before anaerobic digestion or fermentation; greener methods are needed to avoid solvent pollution and energy loss. |

| [16] | To assess the potential of deep eutectic solvents in green extraction of bioactive compounds from citrus by-products. | Deep eutectic solvents offer a sustainable alternative to conventional solvents, improving extraction efficiency and environmental safety while reducing process costs and toxicity. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cinardi, G.; D’Urso, P.R.; Cascone, G.; Arcidiacono, C. Citrus Waste Valorisation Processes from an Environmental Sustainability Perspective: A Scoping Literature Review of Life Cycle Assessment Studies. AgriEngineering 2025, 7, 335. https://doi.org/10.3390/agriengineering7100335

Cinardi G, D’Urso PR, Cascone G, Arcidiacono C. Citrus Waste Valorisation Processes from an Environmental Sustainability Perspective: A Scoping Literature Review of Life Cycle Assessment Studies. AgriEngineering. 2025; 7(10):335. https://doi.org/10.3390/agriengineering7100335

Chicago/Turabian StyleCinardi, Grazia, Provvidenza Rita D’Urso, Giovanni Cascone, and Claudia Arcidiacono. 2025. "Citrus Waste Valorisation Processes from an Environmental Sustainability Perspective: A Scoping Literature Review of Life Cycle Assessment Studies" AgriEngineering 7, no. 10: 335. https://doi.org/10.3390/agriengineering7100335

APA StyleCinardi, G., D’Urso, P. R., Cascone, G., & Arcidiacono, C. (2025). Citrus Waste Valorisation Processes from an Environmental Sustainability Perspective: A Scoping Literature Review of Life Cycle Assessment Studies. AgriEngineering, 7(10), 335. https://doi.org/10.3390/agriengineering7100335