Experimental Study on Working Solution Recovery in an Innovative Spraying Machine

Abstract

1. Introduction

2. Materials and Methods

- Design and construction of an experimental setup that accurately simulates real-world conditions for grapevine treatment with recovery of the working solution.

- Selection of a multifactorial experimental design and execution of research using the experimental setup.

- Analysis of research data to develop a mathematical model and identify the optimal parameter values for the vineyard treatment process.

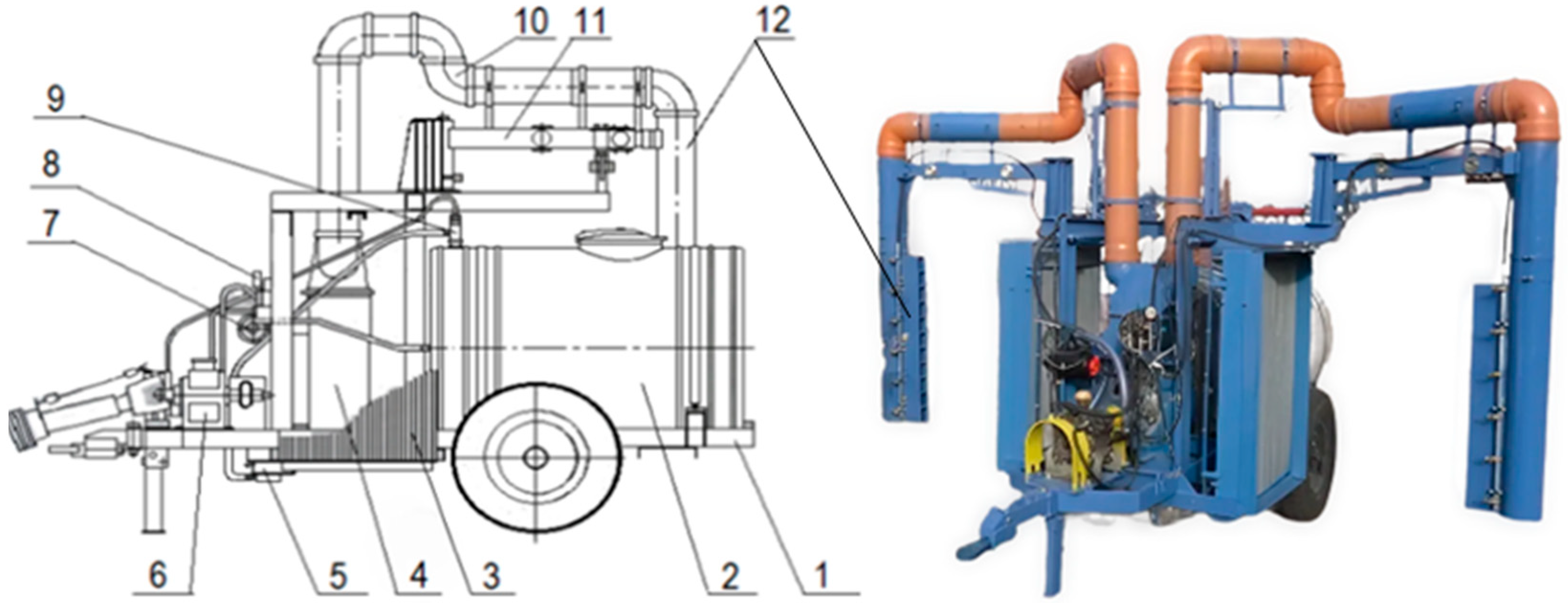

- Design and fabrication of an experimental sprayer model equipped with a working solution recovery system.

2.1. Experimental Research

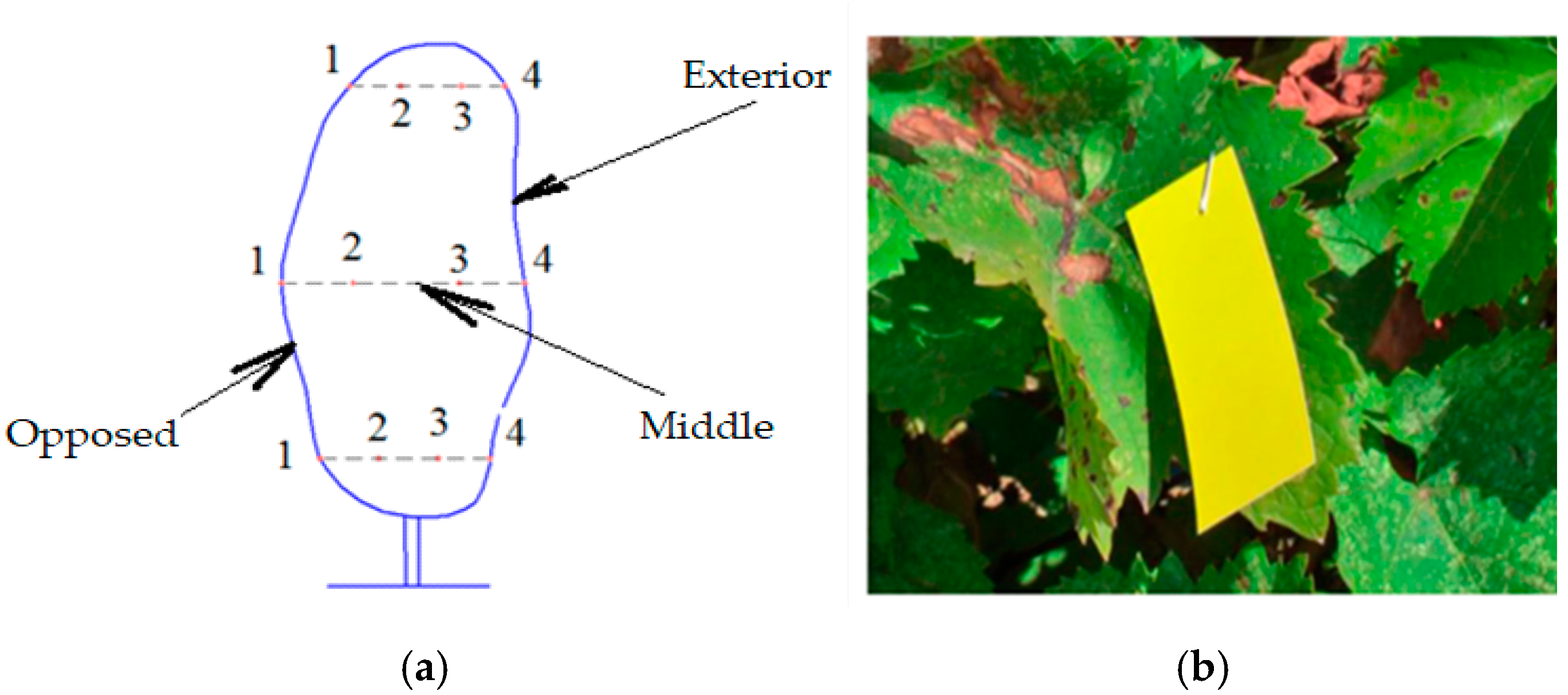

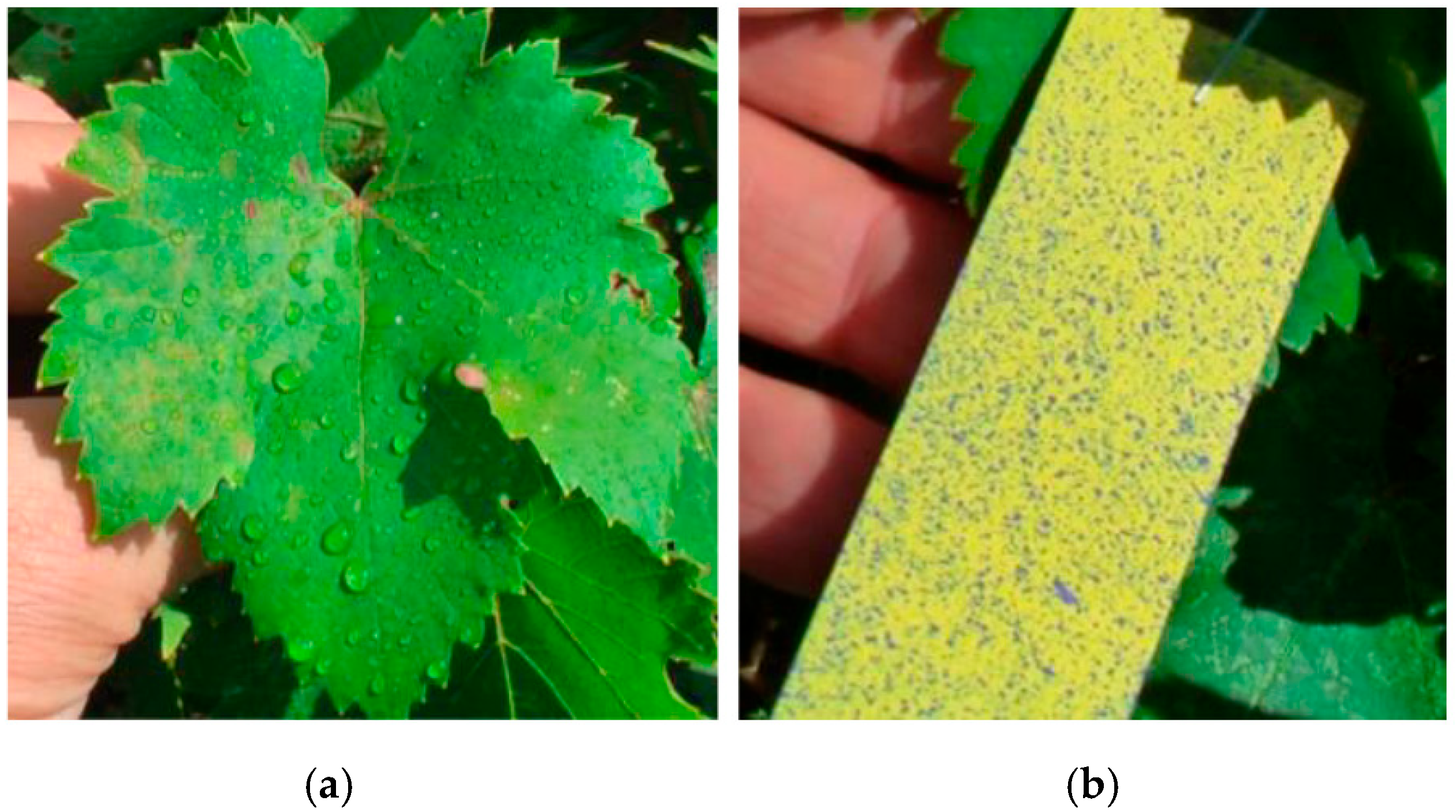

2.2. Field Testing

3. Results

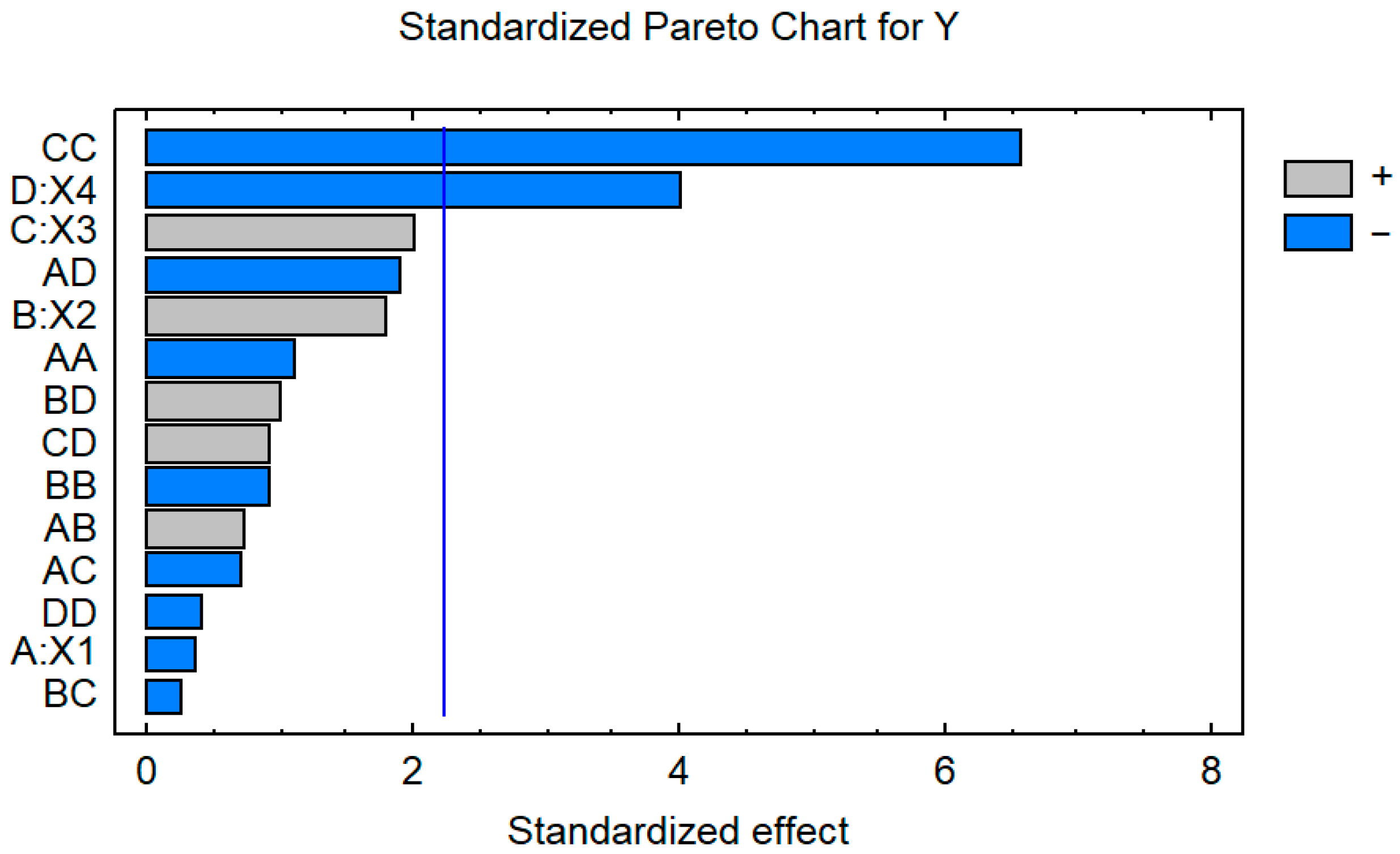

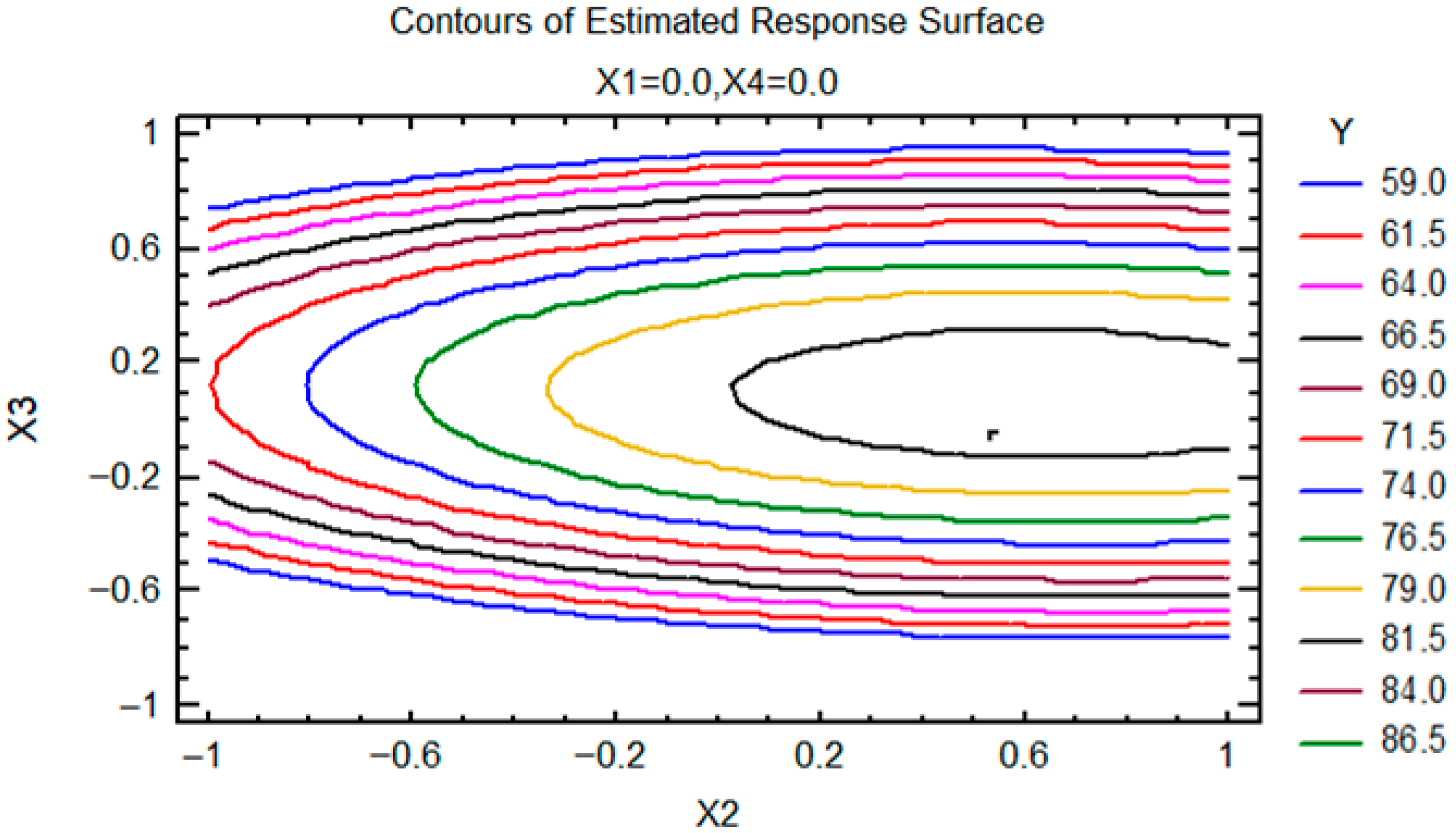

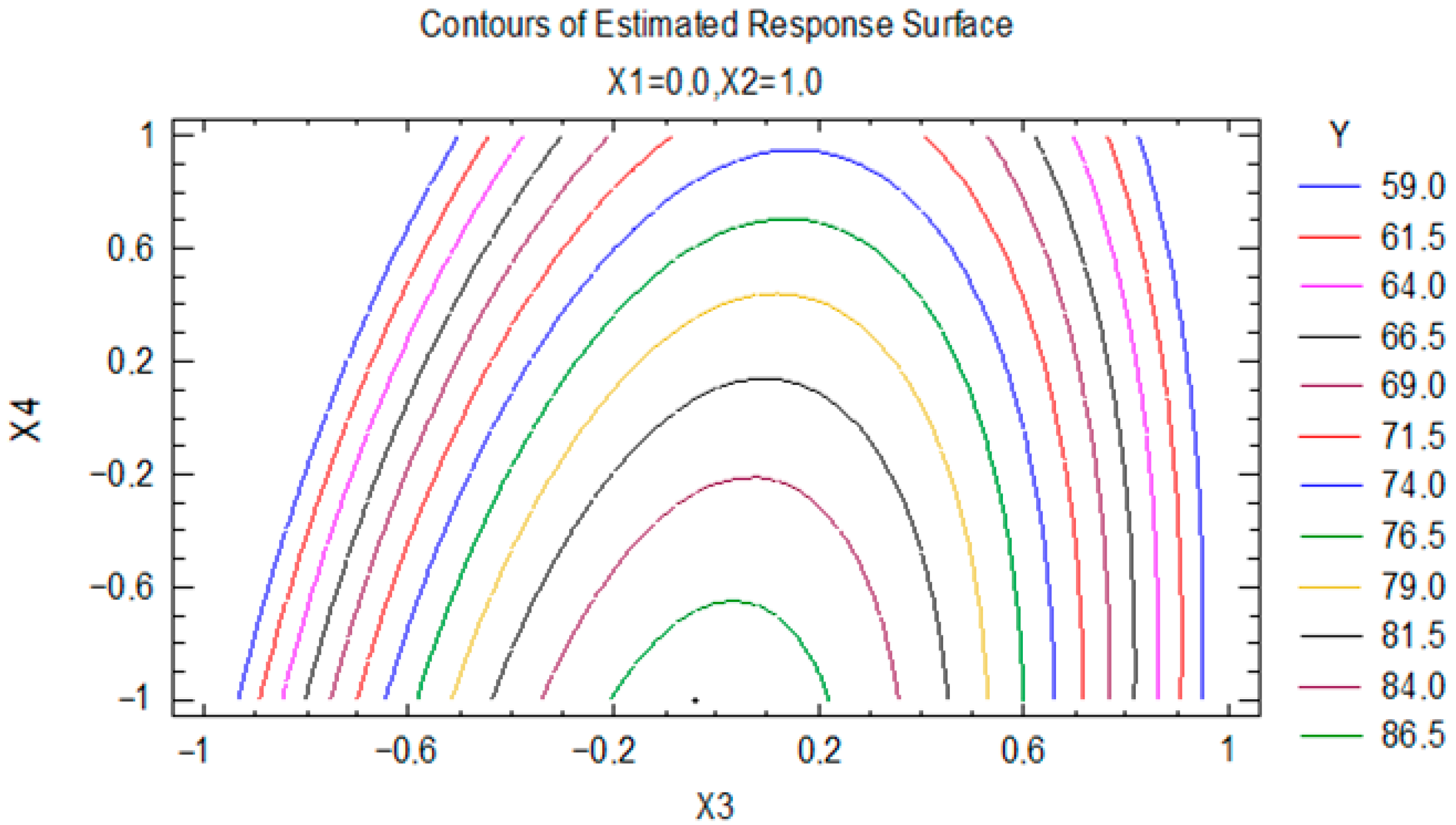

- Two effects (factors) are statistically significant (p < 0.05): X4 (p = 0.0026) and X32 (p = 0.0001).

- Since the p-value is greater than 5.0%, there is no indication of serial autocorrelation in the residuals at the 5.0% significance level.

- The obtained mathematical model (3) explains 89.25% of the variability in the response variable Y (coefficient of determination R2).

− 3.93744·X1·X3 − 10.9509·X1·X4 − 4.38915·X22 − 1.31256·X2·X3 + 5.63836·X2·X4

− 32.7708·X32 +5.0·X3·X4 − 2.00297·X42

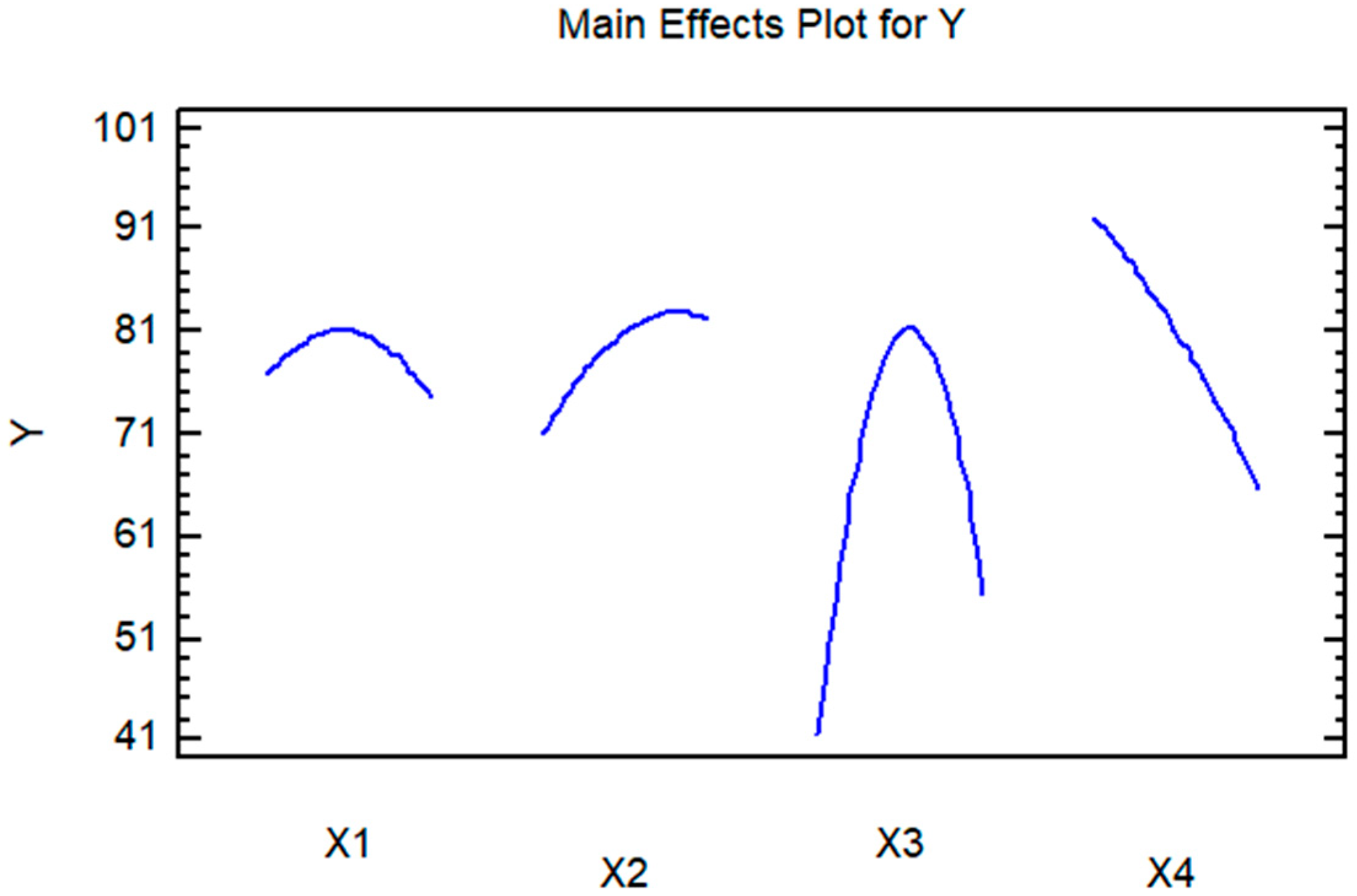

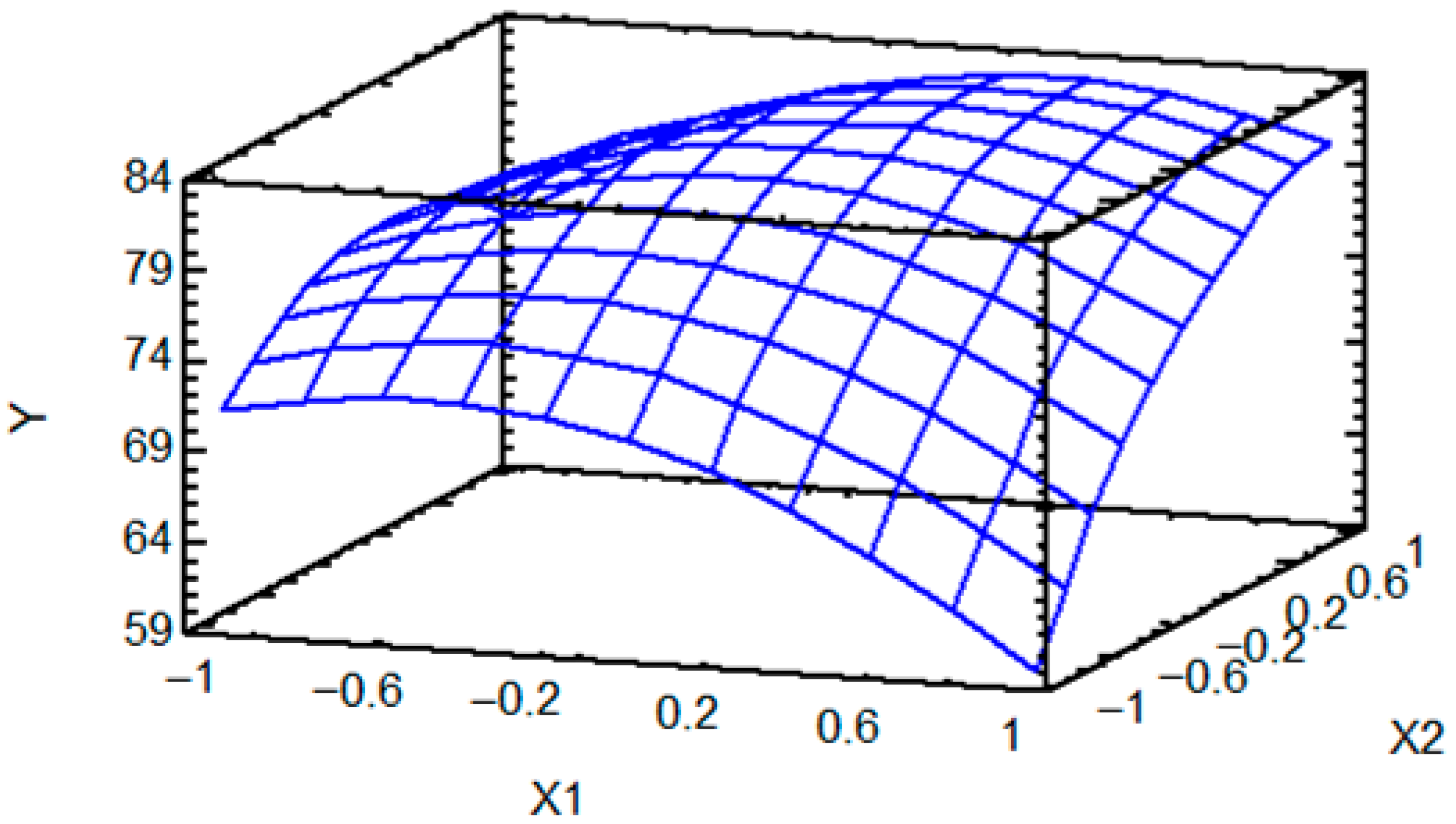

- Factor X4: The line Y = f(X4) has the steepest slope, confirming that X4 has a significant impact on Y, as also indicated by ANOVA.

- Factor X3 also significantly influences Y, but with a less steep slope than X4. The dependence Y = f(X3) is presented by a line with a pronounced curvilinear character, which coincides with the Pareto chart data (Figure 5).

- Factors X1 and X2: The lines Y = f (X1,X2) is almost horizontal, suggesting a minimal effect on Y.

- X1 = 0.999999 or, in natural value, the optimal hydraulic pressure, x1 = 25 [bar].

- X2 = 0.534786, the optimal air flow speed at the plant crown entry, x2 = 15.1 [m/s].

- X3 = −0.0435871, the optimal surface area of the diffuser’s central orifice, x3 = 1.2 [mm2].

- X4 = −1.0, plant foliage density, x4 = 0 [%].

- Distribution of the coverage density ρ over the working width: >150 drops/cm2 ρ = 0 [%]; 150 drops/cm2 ρ = 0 [%]; <150 drops/cm 2, ρ = 100 [%]. Therefore, over the entire studied surface the density ρ (number of drops per 1 cm2) did not exceed the value of 150 drops/cm2.

- Median diameter of the masked droplet fraction dm = 1560.0 [µm]; of the medium droplet fraction dm = 224.0 [µm]; of the small droplet fraction dm = 93.8 [µm].

- The weighted average diameter of the droplets was D = 970 µm.

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). The State of Food and Agriculture: Climate Change, Agriculture and Food Security; FAO: Rome, Italy, 2016; 194p, ISBN 978-92-5-109374-0. ISSN 0081-4539. Available online: http://www.fao.org/3/a-i6030e.pdf (accessed on 15 June 2025).

- Blanco, H.; Lal, R. Soil Conservation and Management, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2023; 611p, ISBN 978-3-031-30340-1/978-3-031-30341-8. [Google Scholar] [CrossRef]

- Bojariu, R.; Hurmuzachi, I. Guide to Good Practices in Adapting to Climate Change and Implementing Climate Change Mitigation Measures in the Agricultural Sector; Print-Caro: Chișinău, Moldova; UCIP IFAD: Chișinău, Moldova, 2021; 120p, ISBN 978-9975-5. Available online: https://www.ucipifad.md/wp-content/uploads/2020/07/Ghid-de-bune-practici-pentru-sectorul-agricol-intru-adaptarea-la-schimbarile-climatice_pag-1-40.pdf (accessed on 13 March 2025). (In Romanian)

- Vlăduț, N.V.; Atanasov, A.; Ungureanu, N.; Ivașcu, L.V.; Cioca, L.I.; Popa, L.D.; Matei, G.; Boruz, S.; Cerempei, V.; Țîței, V.; et al. Trends in the development of conservative/ecological agriculture in the context of current climate change—A review. INMATEH-Agric. Eng. 2024, 74, 980–1032. [Google Scholar] [CrossRef]

- Visconti, F.; López, R.; Olego, M.Á. The health of vineyard soils: Towards a sustainable viticulture. Horticulturae 2024, 10, 154. [Google Scholar] [CrossRef]

- Gristina, L.; Novara, A.; Minacapilli, M. Rethinking vineyard ground management to counter soil tillage erosion. Soil Tillage Res. 2022, 217, 105275. [Google Scholar] [CrossRef]

- Cataldo, E.; Fucile, M.; Mattii, G.B. A review: Soil management, sustainable strategies and approaches to improve the quality of modern viticulture. Agronomy 2021, 11, 2359. [Google Scholar] [CrossRef]

- Molnar, I.; Keicher, R.; Schwartz, H.P. Sprayer development for vineyards. UPB. Sci. Bull. 2018, 80, 281–292. [Google Scholar]

- Chicu, B.; Lungu, G.; Vasilevschi, S.; Cerempei, V.; Cobernic, V.; Prisacari, V.; Bragari, I. Plant Protection: Technologies and Technical Means; Bons Offices: Chișinău, Moldova, 2010; 312p, ISBN 978-9975-80-418-9. (In Romanian) [Google Scholar]

- European Parliament and Council of the European Union. Directive 2009/127/EC Amending Directive 2006/42/EC with Regard to Machinery for Pesticide Application. Available online: https://eur-lex.europa.eu (accessed on 1 September 2024).

- Facchinetti, D. Atomizers with Product Recovery: An Eco-Friendly Solution (Gli Atomizzatori con Recupero del Prodotto, una Soluzione Ecologica). In MW-Machinery World. 2017. Available online: https://www.mondomacchina.it/it/gli-atomizzatori-con-recupero-del-prodotto-una-soluzione-ecologica-c1927 (accessed on 3 June 2025). (In Romanian).

- Bertoni Green Technology. Irroratrice a Tunnel Modello TR. Available online: https://www.bertonigreentechnology.com (accessed on 13 March 2025).

- Lipco GmbH. Sprühgeräte Zum Versrühen Von Pflanzenschutzmittel. Available online: https://www.lipco.com (accessed on 13 June 2025).

- Chirilă, C.; Vâlcu, V. Preliminary Tests in real working conditions of the recovery panels for spraying solution mounted on V-445 tractor. In Horticultura; University of Agricultural Sciences and Veterinary Medicine: Iași, Romania, 2006; Volume 49. [Google Scholar]

- Hăbăşescu, I.; Cerempei, V.; Chicu, B.; Vasilevschi, S.; Lungu, G.; Cobernic, V. Spraying Machine with Recovery. Short-Term Patent MD 272 Y, A 01 M 7/00, BOPI No.9/2010. Available online: https://agepi.gov.md/sites/default/files/bopi/BOPI_09_2010.pdf (accessed on 23 September 2025). (In Romanian).

- Hăbăşescu, I.; Cerempei, V.; Chicu, B.; Vasilevschi, S.; Lungu, G.; Cobernic, V.; Bragari, I. Cyclone Spraying Machine. Short-Term Patent MD 397 Y, A 01 M 7/00. Available online: https://agepi.gov.md/sites/default/files/bopi/BOPI_07_2011.pdf (accessed on 23 September 2025). (In Romanian).

- Marin, E.; Gheorghe, G.V.; Bălțatu, C.; Mateescu, M. Application of 3D printing technology for the design and manufacture of some component parts of spraying machine with solution recovery. INMATEH-Agric. Eng. 2022, 67, 147–154. [Google Scholar] [CrossRef]

- Matache, M.G.; Marin, F.B.; Gurău, C.; Gurău, G.; Marin, M.; Găgeanu, I.; Ionescu, A. Neural network testing for spot-application of phytosanitary substances in vegetable crops using a self-propelled electrical sprayer. INMATEH-Agric. Eng. 2022, 68, 471–480. [Google Scholar] [CrossRef]

- Bungescu, S.; Caba, I.; Duma Copcea, A.; Popa, D.; Salanki, R.; Giurgiu, C.; Melneciuc, C.; Valer, P. In-Depth Experimental Research regarding the verification of spraying machines in large culture farms in the Western area of Romania. In Proceedings of the International Symposium ISB INMATEH, Bucharest, Romania, 15 October 2021. [Google Scholar]

- Wimmer, A. Fachkunde: Land-Und Baumaschinentechnik; Verlag Europa-Lehrmittel: Hamburg, Germany, 2016; 575p, ISBN 978-3-8085-2007-9. Available online: www.europa-lehrmittel.de (accessed on 3 July 2025).

- Neacșu, F. Ecoprotect L3, a New Gregoire equipment for Phytosanitary Treatments in Vineyards (Ecoprotect L3, un nou Echipament Gregoire Pentru Tratamente Fitosanitare în Podgorii). Ferma, 2 July 2020. Available online: https://revista-ferma.ro/ecoprotect-l3-un-nou-echipament-gregoire-pentru-tratamente-fitosanitare-in-vii/ (accessed on 3 July 2025). (In Romanian)

- Idealitalia. Recovery Sprayers. Available online: https://www.idealitalia.it (accessed on 5 July 2025).

- Coffee. Recovery Sprayers. Available online: https://www.caffini.com (accessed on 5 July 2025).

- Ciclone SRL. Recovery Systems for Sprayers for Pesticides and Vineyards. Available online: https://www.ciclonesrl.it (accessed on 3 July 2025).

- Carraro Spray. Gli Atomizzatori Amici Dell’ambiente. Available online: https://www.carrarospray.com (accessed on 3 August 2024).

- Favaro. Drift Recovery Sprayer. Available online: https://www.favaro.eu (accessed on 2 July 2025).

- VitiBot Confined Spraying. Available online: https://vitibot.fr (accessed on 23 September 2025).

- Pergher, G.; Gubiani, R. The effect of spray application rate and air assistance on spray deposition in vineyards. Crop Prot. 1995, 14, 343–347. [Google Scholar]

- Balsari, P.; Marucco, P.; Tamagnone, M. A field study on tunnel sprayers in vineyards. Crop Prot. 2001, 20, 405–412. [Google Scholar]

- Planas, S.; Gallart, M.; Fillat, A. Evaluation of recycling tunnel sprayers in orchards. J. Agric. Eng. Res. 2002, 83, 79–88. [Google Scholar]

- Interstate Standard GOST MD 53053-2008; Plant Protection Machines. Spraying Machines. Test Methods. National Standard of The Russian Federation: Moscow, Russia, 2009. Available online: https://meganorm.ru/Data2/1/4293831/4293831096.htm (accessed on 10 July 2025). (In Russian)

- Testing of Agricultural Machinery. Sprayers, Pollinators, Entomophagous Dispersers, Machines for the Treatment and Transport of Working Fluid. Test Program and Methods. RD 10 6.1-89. Moscow. 2009. 35p. Available online: https://meganorm.ru/list2/64490-0.htm (accessed on 10 July 2025).

- Mencher, É.M.; Zemșman, A.Y. Basics of Experimental Planning with Elements of Mathematical Statistics in Viticultural Research; Știința Publishing House: Chișinău, Moldova, 1986; 240p. (In Russian) [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013; 757p, ISBN 978-1-118-14692-7. Available online: https://www.slideshare.net/slideshow/douglas-c-montgomery-design-and-analysis-of-experimentswiley-2013pdf/265094162 (accessed on 8 July 2025).

- Ferreira, S.L.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandão, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; et al. Box-Behnken design: An alternative for the optimization of analytical methods. Anal. Chim. Acta 2007, 597, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Şaragov, I.; Vîrlan, L. Measurement of Local Velocities in Fluid Flows: Methodological Guide; Technical University of Moldova, Faculty of Urban Planning and Architecture: Chișinău, Moldova, 2020; 48p. (In Romanian) [Google Scholar]

- ISO 5682-2:2017; Equipment for Crop Protection—Spraying Equipment Part 2: Test Methods to Assess the Horizontal Transverse Distribution for Hydraulic Sprayers. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/60054.html (accessed on 23 September 2025).

- Stahli, W.; Bungescu, T. Devices, Equipment and Machines for Plant Protection; AgroPrint: Bucharest, Romania, 2006; 377p, ISBN (10) 973-8287-39-1/(13) 978-973-8287-39-6. (In Romanian) [Google Scholar]

- Directives 2023 for the Inspection of Existing Sprayers for Fruit, Winemaking and Outdoor Culture. Available online: https://www.agrartechnik.ch/fileadmin/user_upload/spritzentests/Richtlinien_Spr%C3%BChger%C3%A4te_2023_D.pdf (accessed on 3 July 2025).

- Lentochkin, A.M. Agronomic Research Methods: Methodological and Didactic Guide; FGBOU VO Izhevsk State Agricultural Academy: Izhevsk, Russia, 2018; 172p, Available online: http://portal.izhgsha.ru/docs/15122017_22641.pdf (accessed on 3 July 2025). (In Russian)

- EN ISO 16122-3:2024; Agricultural and Forestry Machinery—Inspection of Sprayers in Use—Part 3: Sprayers for Bush and Tree Crops. ISO: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/83370.html (accessed on 23 September 2025).

- ISO 5682-1:2017; Equipment for Crop Protection—Spraying Equipment—Part 1: Test Methods for Sprayer nozzles. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/60053.html (accessed on 23 September 2025).

- Roșu, M.; Căsăndroiu, T.; Matache, M.G.; Vlăduț, V.; Pruteanu, A. Experimental researches regarding the dispersion angle of the nozzle jet from spraying machines. UPB Sci. Bull. Ser. D Mech. Eng. 2018, 80, 207–218. [Google Scholar]

- Pergher, G.; Petris, R. The Effect of Air Flow Rate on Spray Deposition in a Guyot-trained Vineyard. Agric. Eng. Int. CIGR Ejournal 2008, X, 1–15. [Google Scholar]

- Dumitrașcu, A.; Manea, D.; Popa, R.; Popa, V.; Deak, G.; Duţă, D.; Dinu, M. Modern trends in applying phytosanitary treatments in orchards. Fruit Grow. Res. 2018, XXXIV, 83–88. [Google Scholar] [CrossRef]

| Influencing Factors Name | Natural Values | Coded Value Levels | |||||

|---|---|---|---|---|---|---|---|

| Levels | Variation Range | Lower | Basic | High | |||

| Lower | Basic | High | |||||

| X1—hydraulic pressure [bar] | 15 | 20 | 25 | 5 | –1 | 0 | +1 |

| X2—air flow speed at the nozzle exit [m/s] | 12 | 14 | 16 | 2 | −1 | 0 | +1 |

| X3—surface of the central orifice of the diffuser [mm2] | 0 | 1.25 | 2.5 | 1.25 | −1 | 0 | +1 |

| X4—plant foliage density [%] | 0 | 50 | 100 | 50 | −1 | 0 | +1 |

| Indices | Indices Value |

|---|---|

| variety | Arcadia |

| Planting scheme [m] | |

| 3.0 |

| 1.0 |

| Bush height [m] | 1.5 |

| Bush diameter [m] | |

| 2.5 |

| 0.5 |

| Vegetation phase | Active growth and berry ripening |

| Foliage coefficient | 0.37 |

| No. d/o | Coded Values | Natural Values | Specific Amount of Working Solution | Recovery Rate of the Working Solution | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Consumed | Recovered | ||||||||||

| X1 | X2 | X3 | X4 | x1 [bar] | x2 [m/s] | x3 [mm2] | x4 [%] | Y1 [L/min] | Y2 [L/min] | Y [%] | |

| 1 | 1 | 0 | 0 | 1 | 25 | 14 | 1.25 | 100 | 81.6 | 48.0 | 59 |

| 2 | 0 | −1 | 0 | 1 | 20 | 12 | 1.25 | 100 | 75.6 | 33.8 | 45 |

| 3 | −1 | 0 | 0 | −1 | 15 | 14 | 1.25 | 0 | 66.0 | 40.6 | 62 |

| 4 | 1 | 0 | 0 | −1 | 25 | 14 | 1.25 | 0 | 81.6 | 70.4 | 86 |

| 5 | 0 | 1 | 1 | 0 | 20 | 16 | 2.5 | 50 | 152.0 | 92.4 | 61 |

| 6 | −1 | 0 | 1 | 0 | 15 | 14 | 2.5 | 50 | 130.0 | 69.6 | 54 |

| 7 | −1 | 1 | 0 | 0 | 15 | 16 | 1.25 | 50 | 66.0 | 42.0 | 64 |

| 8 | 0 | −1 | 0 | −1 | 20 | 12 | 1.25 | 0 | 75.6 | 70.8 | 94 |

| 9 | 0 | 0 | 0 | 0 | 20 | 14 | 1.25 | 50 | 75.6 | 61.2 | 81 |

| 10 | 1 | 0 | 1 | 0 | 25 | 14 | 2.5 | 50 | 168.0 | 81.6 | 46 |

| 11 | 0 | −1 | −1 | 0 | 20 | 12 | 0 | 50 | 52.8 | 12.0 | 23 |

| 12 | −1 | −1 | 0 | 0 | 15 | 12 | 1.25 | 50 | 66.0 | 51.6 | 78 |

| 13 | 1 | 1 | 0 | 0 | 25 | 16 | 1.25 | 50 | 81.6 | 61.2 | 71 |

| 14 | −1 | 0 | 0 | 1 | 15 | 14 | 1.25 | 100 | 66.0 | 54.0 | 82 |

| 15 | 0 | 1 | −1 | 0 | 20 | 16 | 0 | 50 | 52.8 | 26.4 | 50 |

| 16 | 1 | 0 | −1 | 0 | 25 | 14 | 0 | 50 | 57.2 | 25.2 | 44 |

| 17 | 0 | 0 | 0 | 0 | 20 | 14 | 1.25 | 50 | 75.6 | 61.2 | 81 |

| 18 | 0 | 1 | 0 | 1 | 20 | 16 | 1.25 | 100 | 75.6 | 54.0 | 71 |

| 19 | −1 | 0 | −1 | 0 | 15 | 14 | 0 | 50 | 45.6 | 18.0 | 39 |

| 20 | 0 | 0 | −1 | −1 | 20 | 14 | 0 | 0 | 52.8 | 32.4 | 61 |

| 21 | 0 | 0 | −1 | 1 | 20 | 14 | 0 | 100 | 52.8 | 7.2 | 14 |

| 22 | 1 | −1 | 0 | 0 | 25 | 12 | 1.25 | 50 | 81.6 | 51.6 | 63 |

| 23 | 0 | 0 | 1 | −1 | 20 | 14 | 2.5 | 0 | 150.3 | 98.4 | 65 |

| 24 | 0 | 0 | 0 | 0 | 20 | 14 | 1.25 | 50 | 75.6 | 61.2 | 81 |

| 25 | 0 | −1 | 1 | 0 | 20 | 12 | 2.5 | 50 | 150.3 | 63.6 | 42 |

| 26 | 0 | 0 | 1 | 1 | 20 | 14 | 2.5 | 100 | 150.3 | 56.4 | 38 |

| 27 | 0 | 1 | 0 | −1 | 20 | 16 | 1.25 | 0 | 75.6 | 73.2 | 97 |

| Effect | Estimate | Standard Error | VIF |

|---|---|---|---|

| X1 | −2.20 | 6.43 | 1.03 |

| X2 | 11.43 | 6.43 | 1.04 |

| X3 | 13.57 | 6.75 | 1.14 |

| X4 | −26.61 | 6.67 | 1.11 |

| X12 | −10.84 | 9.92 | 1.37 |

| X32 | −65.54 | 10.00 | 1.39 |

| Source | Sum of Squares | df | Mean Squares | F-Ratio | p-Value |

|---|---|---|---|---|---|

| X1 | 14.02 | 1 | 14.02 | 0.12 | 0.7400 |

| X2 | 377.84 | 1 | 377.84 | 3.15 | 0.1100 |

| X3 | 484.47 | 1 | 484.47 | 4.04 | 0.0700 |

| X4 | 1905.83 | 1 | 1905.83 | 15.91 | 0.0030 |

| X32 | 5143.46 | 1 | 5143.46 | 42.93 | 0.0001 |

| Total error | 1198.03 | 10 | 119.80 |

| Treatment Method | Operating Hydraulic Pressure x1 [bar] | Airflow Speed x2 [m/s] | Travel Speed of the Tractor-Sprayer Assembly [km/h] | Treated Plantation Area [ha] | Working Solution Volume | Working Solution Economy | ||

|---|---|---|---|---|---|---|---|---|

| Absolutely Administered [L] | Specifically Consumed [Lha] | |||||||

| [L/ha] | [%] | |||||||

| with working solution recovery | 30 | 15.5 | 4 | 0.43 | 700 | 1627 | 431 | 38 |

| without working solution recovery | 30 | 15.5 | 4 | 0.36 | 700 | 2058 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasat, I.; Cerempei, V.; Chicu, B.; Vlăduţ, N.-V.; Ungureanu, N.; Gheorghiță, N.-E. Experimental Study on Working Solution Recovery in an Innovative Spraying Machine. AgriEngineering 2025, 7, 326. https://doi.org/10.3390/agriengineering7100326

Pasat I, Cerempei V, Chicu B, Vlăduţ N-V, Ungureanu N, Gheorghiță N-E. Experimental Study on Working Solution Recovery in an Innovative Spraying Machine. AgriEngineering. 2025; 7(10):326. https://doi.org/10.3390/agriengineering7100326

Chicago/Turabian StylePasat, Igor, Valerian Cerempei, Boris Chicu, Nicolae-Valentin Vlăduţ, Nicoleta Ungureanu, and Neluș-Evelin Gheorghiță. 2025. "Experimental Study on Working Solution Recovery in an Innovative Spraying Machine" AgriEngineering 7, no. 10: 326. https://doi.org/10.3390/agriengineering7100326

APA StylePasat, I., Cerempei, V., Chicu, B., Vlăduţ, N.-V., Ungureanu, N., & Gheorghiță, N.-E. (2025). Experimental Study on Working Solution Recovery in an Innovative Spraying Machine. AgriEngineering, 7(10), 326. https://doi.org/10.3390/agriengineering7100326