Abstract

The harvesting of dragon fruit remains challenging due to uneven clamping forces, high fruit damage rates, and low redundancy in conventional end-effectors. To address these issues, we developed a novel embracing end-effector with a Variable-Span Arch (VSA) structure. The VSA design enables adaptive clamping force distribution and effective torsional fruit separation, significantly reducing static pressure damage. Theoretical modeling, mechanical testing, and field experiments were conducted to evaluate its performance. Results show that the proposed end-effector achieves a 95% harvesting success rate, with an average picking time of 15 s per fruit, and can output a maximum torque of 18 kgf·cm, which is sufficient for dragon fruit detachment. These findings demonstrate that the VSA-based embracing end-effector offers a low-damage, efficient, and robust solution for dragon fruit harvesting, providing practical guidance for robotic applications in tropical fruit production.

1. Introduction

In recent years, the large-scale development of the dragon fruit industry has highlighted the bottlenecks of manual harvesting. Conventional hand-picking practices suffer from high labor intensity, low efficiency, elevated labor costs, and a high rate of fruit damage [1,2], which severely restrict industrial benefits [3,4]. Therefore, the development of efficient and low-damage harvesting robots to replace manual labor is of great practical significance [5].

In robotic harvesting systems, the end-effector—being the component that directly interacts with the fruit—plays a decisive role in harvesting success [6]. For crops such as apples and tomatoes, researchers have developed various end-effector designs, including multi-finger flexible grippers, rigid jaw grippers, and stem gripping and shearing effectors. While these approaches have achieved certain success [7], their biomechanical adaptability is insufficient for dragon fruit.

Multi-finger flexible grippers, driven by pneumatic or motor-actuated flexible materials, enable enveloping grasping with strong shape adaptability and distributed stress, thereby reducing damage [8,9,10,11,12,13]. However, their gripping force and torsional stiffness remain limited, and durability is questionable. Rigid jaw grippers, powered by motors or cylinders, provide large gripping forces, accurate positioning, and robust structures [14,15,16,17], but their poor adaptability often leads to stress concentration and fruit bruising. Stem gripping and shearing effectors cut fruit peduncles after clamping, thus avoiding direct contact with the fruit surface and minimizing damage [18,19,20,21,22,23,24]; yet they heavily rely on precise vision, which is easily hindered by occlusion, and are not suited for torsional harvesting.

Compared to these crops, dragon fruit presents unique challenges: its thin and fragile peel is easily damaged under uneven forces; its irregular geometry requires high morphological adaptability; branch and leaf occlusions often hinder stem-cutting methods; and torsional harvesting imposes stringent requirements on gripping stability and force control [25,26,27]. Although rotary shearing and flexible three-finger grippers have been studied, they generally suffer from uneven force distribution, poor rotational stability, and fruit bruising due to slippage.

To address these limitations, this study proposes a novel embracing end-effector that integrates a Variable-Span Arch (VSA) structure with an underactuated mechanism. The key advantages are:

- (1)

- Introducing the VSA geometry for the first time to achieve linear and compliant adjustment of clamping forces, thereby alleviating stress concentration issues inherent to rigid grippers with limited contact points.

- (2)

- Employing a multi-layer redundant design that combines material and structural compliance, which significantly improves adaptability to irregular fruit geometries and reduces the risk of fruit damage.

This paper presents the design principle, mechanical modeling, optimization, and field validation of the proposed VSA-based embracing end-effector.

2. Dragon Fruit Characteristics and Fruit Detachment Principle

2.1. Morphological and Structural Characteristics of Dragon Fruit

Dragon fruit is a perennial climbing fruit tree belonging to the Cactaceae family. The fruit is a typical ellipsoidal berry with a diameter of approximately 8–12 cm and a skin thickness of about 1.5–2.5 mm. The fruit’s surface is covered with irregular scale-like protrusions [28,29], as shown in Figure 1. The peel is soft, has a high moisture content, and exhibits weak structural continuity, making it susceptible to internal damage caused by concentrated static pressure. The spatial distribution of the fruits is highly irregular; they are often scattered in multiple directions with varied stem orientations, leading to a high degree of randomness in picking postures. This poses significant challenges to the end-effector’s geometric adaptability and gripping surface redundancy.

Figure 1.

Morphological structure of the dragon fruit.

To achieve effective envelopment and flexible adaptation to the fruit body, the end-effector must possess a large gripping span and a degree of structural redundancy to ensure stable gripping of fruits of different sizes and at random postures. Furthermore, to prevent the scale-like structures from getting caught in mechanical gaps and causing structural interference, the contact matching mechanism between the gripper jaw’s surface morphology and the fruit peel’s topography must be carefully considered.

2.2. Stem Structure and Detachment Principle

In the process of dragon fruit harvesting, the characteristics of the connecting structure between the fruit stem and the fruit body have a significant influence on the design of the end-effector. At the base of the stem on a mature dragon fruit, a structurally loose abscission layer is formed, primarily composed of vascular bundles, sieve tubes, and parenchyma. While this abscission layer maintains the fruit’s transport functions, it also possesses a potential for physiological abscission, which serves as a critical structural basis for mechanical harvesting.

Among these tissues, the vascular bundles exhibit high tensile strength, making them difficult to break under axial tension, but they are sensitive to shear force. When an external force is applied tangentially or rotationally, the connection site is more easily disrupted, promoting the fracture and separation of the fruit from the stem. Therefore, manual harvesting typically employs an “envelop-and-twist” motion path. This involves clamping the fruit body and applying a rotational force around the stem’s axis, which creates an angle between the stem and the fruit. This, in turn, generates internal stress in the shear direction, causing the vascular bundles to rupture and leading to the fruit’s detachment.

A mechanical harvesting end-effector that simulates the aforementioned process must possess sufficient gripping stability and rotational output capability, enabling the fruit body to be twisted around the stem along an appropriate path. Furthermore, to prevent issues such as slipping, eccentricity, or damage due to insufficient contact area or improper twisting posture, the end-effector must also establish a relatively uniform contact support during the gripping phase to ensure the fruit’s structural stability under rotational loading.

3. Case Study and Analysis of a Preliminary End-Effector Design

3.1. Structure and Limitations of an Underactuated Three-Jaw Flexible End-Effector

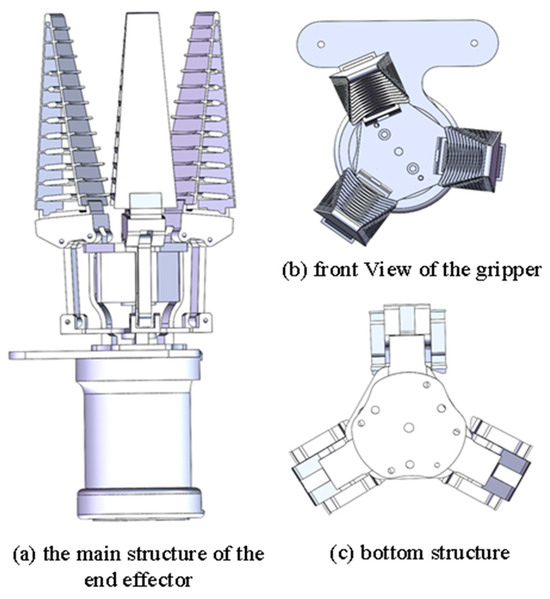

In the early exploration of dragon fruit harvesting, the research team designed an underactuated, three-jaw flexible end-effector, as shown in Figure 2. Its basic structure comprised three parts: a drive mechanism, a linkage system, and flexible jaw modules. The end-effector utilized a lead screw mechanism to raise and lower a central drive plate, which in turn actuated three symmetrically distributed linkage arms to open and close along a circular path, thereby achieving the gripping function.

Figure 2.

Structure of the three-jaw flexible end-effector.

The jaws were designed with a flexible, underactuated linkage structure. The outer frame consisted of a triangular flexible beam, while the interior was fitted with rigid connecting rods to guide the jaw body through a specific deformation during the gripping process. The main body of the jaw was 3D-printed from TPU 95A material, giving it a degree of elasticity. During gripping, the inner surface of the jaw would undergo compressive deformation upon contact with the fruit, causing the jaw body to envelop the fruit’s surface and achieve a flexible grasp. This structure possessed a certain level of morphological self-adaptability, allowing for off-center compensation and cushioned contact during the initial gripping phase.

Although this three-jaw end-effector had a simple structure, was easy to fabricate, and demonstrated good gripping performance under certain conditions, the following problems emerged during multiple rounds of laboratory and field trials:

- (1)

- Insufficient gripping force. Due to the highly elastic material of the jaws, the overall structure was prone to significant deformation when external forces were applied. This was particularly evident during the twisting motion required to detach the dragon fruit from its stem, where the jaw’s insufficient torsional stiffness prevented the effective transmission of torque, often resulting in slippage or grip failure (as shown in Figure 3a).

Figure 3. Experimental trials of the three-jaw flexible end-effector.

Figure 3. Experimental trials of the three-jaw flexible end-effector. - (2)

- Poor adaptability to off-Center Fruits. In practical operations, due to factors such as visual positioning errors and the randomness of fruit postures, the central axis of the end-effector is often difficult to align perfectly with the stem. Under such non-ideal poses, the three-jaw structure, with its linear and non-enveloping contraction, is unable to form a stable, all-encompassing contact. This leads to an uneven distribution of clamping force, causing the fruit to shift or be dropped (as shown in Figure 3b).

- (3)

- Insufficient envelopment redundancy. The contact area during the gripping pro cess of this structure is limited, relying primarily on localized force at the tips of the jaws to complete the grasp. This results in concentrated stress on the fruit’s surface, which can easily cause indentations or internal damage. Concurrently, the three-jaw structure has inherent limitations in terms of its coverage area and gripping redundancy, making it unable to effectively adapt to fruits of varying sizes and postures (as shown in Figure 3c).

To address the aforementioned problems, the research team made several localized optimizations to the three-jaw structure, such as widening the jaw’s cross-section and adding anti-slip protrusions to the inner surface to enhance friction and the envelopment effect. While these modifications improved gripping stability to some extent, the torsional gripping capability was not fundamentally improved. Especially during the stem separation process, the jaws were prone to structural distortion from excessive deformation, leading to a high failure rate for the end-effector. Furthermore, the fruit remained susceptible to damage from stress concentration, failing to meet the requirements for high-quality, non-destructive harvesting of dragon fruit.

3.2. Design and Performance Evaluation of an Underactuated Four-Jaw Gripping Structure

To meet the requirement for fruit gripping stability, the research team further designed an underactuated four-jaw end-effector, as shown in Figure 4. This structure is composed of a central servo drive unit, a linked four-jaw system, fruit-conforming gripping components, and a torque measurement interface. The jaws are connected to a central servo rod via a multi-linkage mechanism, and the restoring tension provided by elastic bands drives the four jaw bodies to close synchronously, achieving a stable envelopment of the dragon fruit. Each jaw is equipped with a rigid external support, and the jaw face, made of ABS material, integrates a multi-hole and groove design with small spikes to enhance frictional contact with the fruit peel and inhibit slippage. In the closed state, the four jaws can form a relatively symmetrical distribution of clamping force and possess good radial constraint and axial self-centering capabilities, providing the structural support necessary for subsequent torque application and rotation angle measurement.

Figure 4.

The underactuated four-jaw end-effector. The numbered components are: (1) Handheld torque meter; (2) Smooth transmission shaft; (3) Fixture handle; (4) Main frame; (5) Flange bearing; (6) Swing arm; (7) Central connecting rod; (8) Swing arm connecting rod; (9) Jaw follower rod; (10) Jaw base; (11) Fruit-conforming component; (12) Dragon fruit body and stem; (13) Central servo rod.

To accurately obtain the separation parameters of the fruit stem and fruit of the pitaya, during the experiment, an Aigoo 15BTG handheld torque meter (range: 0–15 kgf·cm, accuracy: ±3%) was used to continuously and slowly rotate at a constant speed of approximately 5°/s, and the angle and corresponding torque at the moment of stem breakage were recorded, as shown in Figure 5.

Figure 5.

Torque test of a dragon fruit gripped by the underactuated four-jaw fixture.

A total of 16 dragon fruits were randomly selected to measure the minimum rotation angle and maximum torque required for detachment for each fruit, with the data presented in Table 1.

Table 1.

Test Results for Dragon Fruit Detachment Angle and Maximum Torque.

The experiments showed that the fruit stem structure only undergoes complete fracture and separation when the rotation angle exceeds 720°. The maximum peak torque required during this process is approximately 14.1 kgf·cm. This value reflects the adhesion and vascular bundle shear forces that must be overcome before the natural abscission layer ruptures, and it serves as a critical structural performance metric that must be met to achieve non-destructive harvesting.

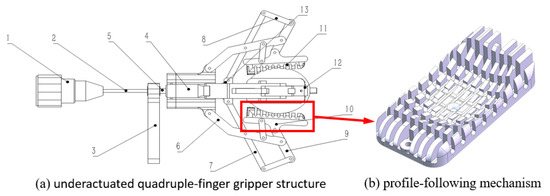

Despite demonstrating good torque transmission efficiency for parameter determination, this four-jaw structure possesses inherent limitations, including poor adaptability due to the high rigidity of the jaw material. This rigidity results in a lack of flexible, cushioning envelopment capability. During gripping, it leads to concentrated stress on the peel, which poses a risk of indentations or even minor damage. Figure 6 shows the damage caused during the fruit gripping process, with the yellow circles indicating the damaged areas.

Figure 6.

Performance of the four-jaw end-effector during trials.

Therefore, while the four-jaw underactuated fixture effectively enabled the experimental determination of the mechanical parameters for dragon fruit stem separation, and the obtained torque and angle metrics provided a clear quantitative basis for the structural selection and force control design of the subsequent enveloping, non-destructive end-effector, its own high rigidity and weak conforming ability limit its feasibility in actual harvesting tasks. This necessitates the introduction of flexible envelopment, variable force control, and a high-redundancy structure to achieve stable, non-destructive harvesting.

4. Design of the Enveloping End-Effector

4.1. Overall Structural Design

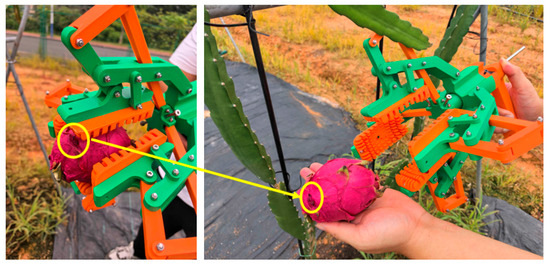

To address the characteristics of dragon fruit—namely its large diameter, fragile skin, and the need for rotational detachment when mature—a flexible, arch-based enveloping end-effector was designed, as shown in Figure 7. This end-effector adopts a modular, dual-layer structure, composed of a flexible Variable-Span Arch (VSA) mechanism and an underactuated four-bar converging mechanism, to achieve an enveloping and flexible grip on dragon fruits of various sizes.

Figure 7.

The Variable-Span Arch (VSA) end-effector.

The upper module consists of four symmetrically arranged VSA units, each 3D-printed from high-elasticity TPU (83A) material, which possesses excellent compliance and deformation recovery capabilities. The tips of the VSAs are designed with an arc-shaped contact surface to achieve a conforming envelopment in the radial direction, effectively dispersing contact stress and reducing the risk of localized pressure damage. The overall structure of a VSA is similar to a bridge arch, and the span between its “feet” can be linearly adjusted by the lower mechanism to adapt to fruits of different diameters while maintaining a stable gripping force. The structural parameters are as follows: arch thickness of 22 mm, length of 37 mm, contact tip width of 10 mm, and a center-to-center distance of 55 mm for the mounting base holes.

The lower mechanism employs an underactuated synchronous converging system composed of eight equivalent four-bar linkages. It uses a single motor to drive the synchronous expansion and contraction of the multiple VSAs. During the contraction process, the support arms drive the VSAs to converge centripetally along a circular path, thereby achieving the envelopment and gripping of the fruit. Throughout the entire gripping process, the support force can be dynamically adjusted according to the linear contraction amount of the VSAs, meeting the mechanical adaptation requirements for different axial cross-sections of various dragon fruits.

This structural design minimizes the problem of uneven gripping caused by non-uniform fruit diameters, avoiding defects common in three-jaw structures such as “localized over-pressure” and “unstable clamping.” Furthermore, the multiple VSA units can maintain a stable frictional force during the end-effector’s rotation, effectively supporting the fruit to complete the 720°+ rotational separation. Preliminary experiments indicated that the dragon fruit requires a peak torque of approximately 14.1 kgf·cm and a rotation angle of over 720° to achieve stem detachment. This data was used directly to guide the configuration of the VSA’s support force and the structural parameters of the underactuated mechanism, providing clear boundary conditions for the overall mechanical design.

4.2. Force Analysis of the Flexible Arch Structure

4.2.1. Static Compression Test and Force Response Analysis

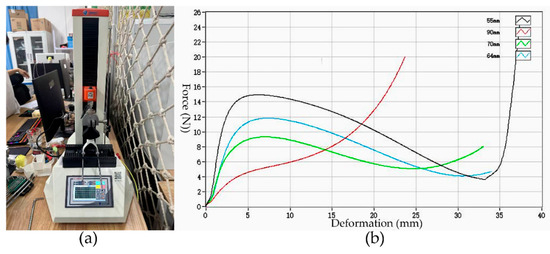

To investigate the effect of different VSA opening widths on the resulting support force, static loading tests were conducted using a ZQ-990B-01 Electric Tensile and Compression Testing Machine (accuracy: 0.01 N) (Zhiqu Precision Instruments Co., Ltd., Dongguan, China). The fixed width of the VSA’s mounting frame was varied (55 mm, 64 mm, 70 mm, and 90 mm) to simulate the contact diameters of the fruit at different axial cross-sections. Figure 8 shows the load-displacement relationship of the VSA during the gradual compression process.

Figure 8.

The stress test. (a) Compression testing machine; (b) Pressure test curve.

The force characteristic parameters of the VSA are presented in Table 2. It can be observed that when the VSA’s frame span is less than 70 mm, the force-displacement curve exhibits clear characteristics of an elastic region; the support force increases non-linearly with the compression amount, and the maximum support force occurs at a deformation of approximately 5 mm. However, when the span is expanded to 90 mm, the structure loses its effective elastic deformation and exhibits a linear rigid response, indicating that it is beyond the effective gripping range and in an “over-travel” state.

Table 2.

Force Characteristic Parameters of the VSA.

The mechanical behavior during the gripping process is integral to the design. As the end-effector contracts, the underactuated synchronous converging mechanism drives the span of the flexible VSAs to narrow from 90 mm to 55 mm. With the fruit held relatively stationary, initial contact occurs at its widest ellipsoidal cross-section. As the mechanism continues to contract, the progressive narrowing of the VSA’s support span causes the normal force exerted on this initially contacted wide section to decrease linearly. This mechanical property, observable in the 10 mm to 30 mm displacement range shown in Figure 8, results in a compliant gripping process with a low initial clamping force, thereby reducing the risk of impact damage.

This allows the end-effector to automatically adjust its deformation during the gripping process according to the fruit’s overall size and the changing diameter of its axial cross-sections. In doing so, it achieves a compliant support force output, effectively reducing the risk of surface pressure damage to the fruit.

4.2.2. Static Modeling of Fruit Gripping

To enable effective static analysis of the gripping process, the physical model was simplified and several key assumptions were established. First, the macroscopic shape of the dragon fruit was approximated as a regular ellipsoid. This assumption is reasonable because, although the actual dragon fruit surface features local irregularities such as scales, its overall contour is relatively uniform and plump, closely resembling the geometry of an ellipsoid. Adopting an ellipsoidal model greatly simplifies the geometric relationships at the contact points and facilitates analytical mechanical calculations, thereby allowing the establishment of a tractable mathematical model for analyzing the relationship between gripping force and torque. While this approximation neglects the microstructural morphology of the peel surface, it provides sufficient accuracy for evaluating overall gripping stability and the macroscopic torque required for fruit detachment.

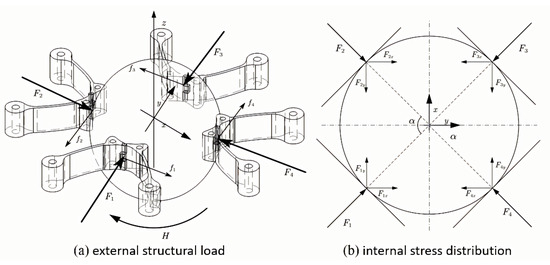

The dragon fruit is modeled as an ellipsoid, and a force model is established as shown in Figure 9. Let the contact forces generated by the circumferentially arranged VSAs be , and . The lines of action for these force vectors all pass through the gripping center, point . Therefore, the torque equation for the VSA gripping the dragon fruit:

where:

- is the clamping force exerted by the VSA on the dragon fruit (N).

- is the coefficient of friction.

- H is the frictional torque generated by the VSA on the fruit’s surface (N·cm).

Figure 9.

Static force model of the enveloping structure.

Under symmetrical operating conditions, the force vectors are concurrent at a single point, and the magnitudes of the four forces are equal. Therefore, the static equilibrium equations for the force system can be obtained as follows:

where:

- is the component of an individual force (where = 1, 2, 3, or 4) projected onto the x-axis in the coordinate plane.

- is the resultant force of and along the x-axis.

- is the component of an individual force fi projected onto the y-axis in the coordinate plane.

- is the resultant force of and along the y-axis.

- is the moment of an individual force fi about point .

- is the resultant moment of and about point .

Expanding the equation yields:

In the force analysis, as the lines of action of the forces and pass through the center point , the resultant moment about point is zero. The equilibrium equation can be obtained as follow:

where:

- is the angle between the lines of action of the VSA forces.

This result is due to the enveloping structure of the single-layer VSA, where the normal forces exerted on the fruit balance each other out, and the frictional force generated by each VSA is consistent. Therefore, a torque formula can be introduced, which models the relationship based on the normal force:

where:

- is the torque, in units of kgf·cm.

- is the support force of the VSA, in Newtons (N).

- is the coefficient of friction.

- is the radial diameter of the contact area between the fruit and the VSA, in meters (m).

4.2.3. Determination of the Coefficient of Friction Between Dragon Fruit and TPU Material

All experiments in this study were conducted using ‘Jindu No.1’ red-fleshed dragon fruits and the thermoplastic polyurethane (TPU) material used for the contact components of the end-effector. The dragon fruits were harvested from Huajie Dragon Fruit and Citrus Orchard in Nansha District, Guangzhou, Guangdong Province, China. To simulate realistic harvesting conditions, fruits with moderate ripeness and intact appearance were selected. All tests were performed within 24 h after harvesting to ensure consistency in peel freshness and physical properties. Prior to testing, the fruit surface was gently wiped with a dry cloth to remove dust, without any liquid cleaning or chemical treatment.

TPU material characteristics: The arch-shaped contact structures were fabricated using TPU 95A through fused deposition modeling (FDM) 3D printing, with a layer thickness of 0.2 mm and an infill density of 100%. The printed TPU surface was not specially treated, retaining its natural smooth texture.

To accurately determine the minimum normal force required for stable gripping, it was necessary to measure the friction coefficient between the dragon fruit peel and the TPU contact surface. This was done using the inclined plane method: a peel specimen was placed on a TPU plane, and the tilt angle of the metal plate was gradually increased until sliding occurred. The critical sliding angle θ was recorded.

The test was repeated 15 times, and the measurement results are summarized in Table 3. To evaluate repeatability, statistical analysis was conducted. The mean value of the 15 sliding critical angles θ was 20.46°, with a standard deviation (SD) of 1.23°.

Table 3.

Experimental Data from the Inclined Plane Method.

The experimental data from the table are then substituted into the equation:

The experimental results are presented in Table 3. For each trial, the tangent of the recorded angle of slide was used to calculate the corresponding static coefficient of friction. An analysis of this data indicates that the standard deviation of the angle measurements is small and the data distribution is relatively concentrated, which demonstrates the good repeatability of the experimental method. Subsequently, the average value was obtained using Equation (6) to mitigate the impact of experimental error. The final calculation yields a representative static coefficient of friction between the dragon fruit skin and the TPU material of μ = 0.372.

This static coefficient of friction is an important parameter for defining the critical point of transition from a static to a dynamic state. The value is essential for the subsequent calculation of the minimum theoretical clamping force required by the gripper jaws to prevent the fruit from slipping. However, in actual dynamic gripping and rotational operations, the frictional force at the contact interface is not a constant value. Once an object begins to slide, its frictional force (i.e., the kinetic friction) is typically less than the maximum static friction and may vary with the relative velocity, which constitutes the non-linear characteristics of friction [30].

Thus, the static coefficient of friction measured in this study provides a foundational experimental basis for subsequent static and quasi-static mechanical analyses. If high-fidelity dynamic simulations of the harvesting process are to be conducted in the future, the introduction of a non-linear friction model describing the relationship between frictional force and velocity should be considered, as this represents a direction for more in-depth research.

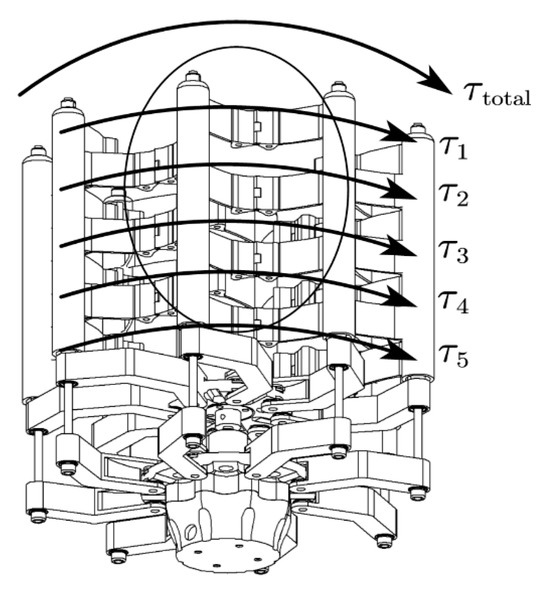

4.2.4. Calculation of Total Torque for the Multi-Layer Gripping Structure

To evaluate the torsional resistance performance of the flexible arches during the gripping of a dragon fruit, a total axial torque model for the multi-layer gripping structure was established based on the previously measured force-deformation results. The dragon fruit is approximated as a tri-axial ellipsoid with a major axis length of 100 mm and a maximum diameter of 80 mm. Considering the 22 mm axial width of each VSA layer, the fruit can be discretized into five axial layers for modeling purposes, as shown in Figure 10.

Figure 10.

Schematic diagram of the radial frictional force.

From Equation (7), the maximum radial frictional force of the dragon fruit within the end-effector can be obtained:

Based on the cross-sectional geometry and deformation dimensions of the equally spaced layers, the support force provided by a single VSA at each layer is obtained from the graph in Figure 8 and presented in Table 4.

Table 4.

Support Force Test Results.

By substituting these support forces into Equations (5) and (7), the maximum torque is calculated to be 24.73 kgf·cm. This value is significantly higher than the maximum separation torque required for the fruit stem to break (experimentally measured as 14.1 kgf·cm). This indicates that the end-effector possesses sufficient gripping stability to complete the rotational harvesting task, and the dragon fruit will not experience relative slippage or instability during the rotation process.

Furthermore, to achieve a more effective grip with less clamping force, the frictional force can be further enhanced by increasing the surface roughness or by designing micro-textures on the VSA surface.

4.3. Motor Selection and Parameter Rationale

To ensure the end-effector possesses sufficient driving capability while considering structural compactness and system energy efficiency, a planetary geared motor with a rated torque of 10 Nm was selected as the drive source. This selection requires careful justification, as it must be reconciled with a significantly higher theoretical maximum torque calculated for the mechanism.

The theoretical total torque of 29.04 Nm was calculated by summing the maximum support force from each VSA layer, as detailed in the previous section. This value, however, represents a theoretical upper bound derived from an idealized worst-case scenario: the assumption that the end-effector grips a perfectly sized object causing all arches to reach maximum deformation simultaneously. In practice, this condition is not physically realized when harvesting ellipsoidal dragon fruits due to their non-uniform curvature. Therefore, this theoretical value is not representative of the peak operating torque encountered during actual tasks.

Applying a conventional safety factor (e.g., S.F. = 1.2–1.5) to this unattainable theoretical value would lead to significant over-engineering, contradicting the design principles of lightweighting and energy efficiency. The more appropriate engineering approach is to size the motor based on the actual peak operating torque. To validate this approach and determine the practical load requirements, an extreme-case envelopment experiment was conducted using the largest ‘Jindu No. 1’ fruit sample (approx. 100 mm in axial length and 80 mm in diameter). The experiment demonstrated that the 10 Nm motor could successfully drive the end-effector to achieve full closure and complete the rotational separation task without any signs of jamming or failure.

This result provides strong empirical evidence that the actual peak operating torque is well within the 10 Nm capacity of the selected motor. It thus experimentally validates the acceptability of the design’s safety margin, confirming that the motor selection is appropriate and strikes a rational balance between performance and efficiency.

5. Field Gripping and Harvesting Trials and Analysis

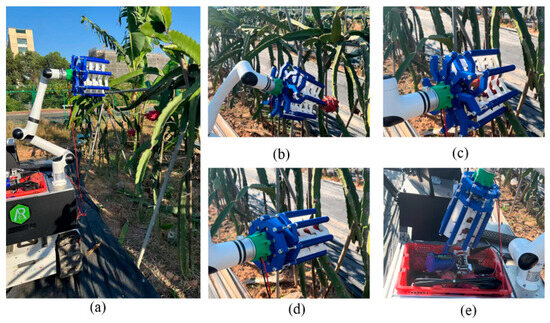

To comprehensively evaluate the harvesting performance, adaptability, and stability of the enveloping end-effector designed in this study within a real agricultural environment, systematic field trials were conducted in October 2024 at the standardized orchard of the Baiyun Campus, Zhongkai University of Agriculture and Engineering.

5.1. Experimental Method

5.1.1. Experimental Platform, Samples, and Environment

The experimental platform consisted of a six-degree-of-freedom (6-DOF) collaborative robotic arm integrated with the enveloping flexible end-effector designed in this study. The test site was a cultivation area of ‘Jindu No. 1’ red-fleshed dragon fruit using a standard straight-row planting system, with a row spacing of 2.5 m, which provided excellent accessible space for the robotic arm’s operation.

To ensure the universality of the conclusions, a total of 12 mature dragon fruits, consistent in ripeness and free from external damage, were selected as harvesting samples for this experiment. Detailed dimensional parameters of the sample fruits are statistically presented in Table 5.

Table 5.

Fruit Size Data Statistics.

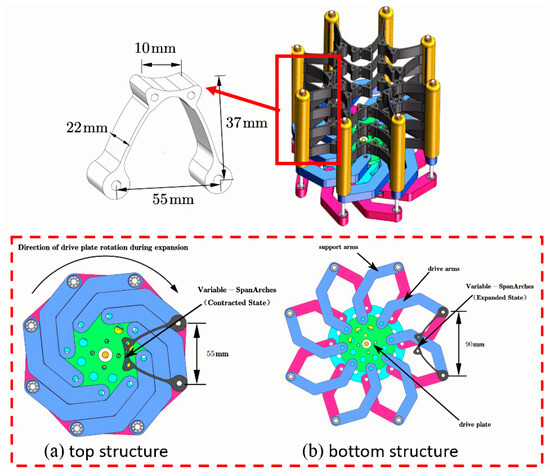

5.1.2. Operational Workflow and Damage Assessment

For the experiment, a row of dragon fruit plants in the orchard with a high density of mature fruits was selected. Harvesting trials were conducted by moving the robotic arm along both the left and right sides of the row to test the harvesting performance of the enveloping end-effector at different envelopment depths. The operational workflow consisted of several sequential steps: first, visual localization of the dragon fruit (Figure 11a); followed by the end-effector performing gripping and envelopment (Figure 11b,c); then, torsional detachment of the fruit from its stem (Figure 11d); and finally, placement of the harvested fruit into a collection bin (Figure 11e).

Figure 11.

Field trials of the dragon fruit harvesting end-effector. (a) The dragon fruit harvesting robot and the end-effector; (b) The robotic arm navigating the end-effector to the ideal docking point on the fruit; (c) The end-effector enveloping the fruit and rotating the sixth axis of the robotic arm to detach the fruit from its stem; (d) Completely encase the dragon fruit; (e) Completion of the harvest, with the fruit being placed into a collection device.

To rigorously assess fruit damage, the following objective damage rating scale (0–3 levels) was established [31], and 12 post-harvest samples were evaluated:

- Level 0 (No Damage): Fruit skin intact, stem detachment point smooth, no pulp bruising.

- Level 1 (Slight Damage): Slight indentations on the fruit skin but no breakage.

- Level 2 (Moderate Damage): Fruit skin broken or obvious tearing at the stem.

- Level 3 (Severe Damage): Severe damage to the pulp tissue.

All samples were evaluated 24 h after harvesting according to this standard.

6. Results

6.1. Harvesting Success Rate and Efficiency

For the field trials, a row of fruit trees with a high density of mature fruits was selected for continuous operation. The end-effector performed sequential harvesting along both the left and right sides of the row, and its operational performance at different envelopment depths was recorded. When the end-effector enveloped the fruit along 85% or more of its axial length, the harvesting success rate reached 95%. However, when the envelopment ratio decreased to 60% and 50%, the success rates correspondingly dropped to 75% and 70%, respectively. This indicates that a greater envelopment area leads to a more stable and reliable harvesting process.

The average harvesting time per fruit was approximately 15 s, representing a reduction of about 32.7% in operational time compared to traditional three-jaw structures [32], thus demonstrating a significant improvement in overall efficiency.

The experiments further revealed that a larger envelopment area correlates with enhanced control capability of the end-effector over the fruit and a more uniform distribution of gripping forces. The designed structure maintained good adaptability and stability across fruits of varying sizes, with no significant fruit slippage or detachment observed during the gripping process.

6.2. Assessment of Static Pressure Bruising and Torsional Harvesting Damage

To further evaluate the impact of the end-effector on fruit quality, 12 mature dragon fruits were selected for static pressure bruising and stem separation damage tests, as shown in Figure 12. After harvesting, the fruits were rested for 24 h and then cut open for observation. Among the 12 samples evaluated for damage, 8 were rated as Level 0, and 4 were rated as Level 1, with no samples exhibiting moderate damage (Level 2) or higher. This indicates that the designed end-effector, during the application of torque, can effectively avoid damage caused by improper clamping force or excessive torque.

Figure 12.

Front view of the dragon fruit stem.

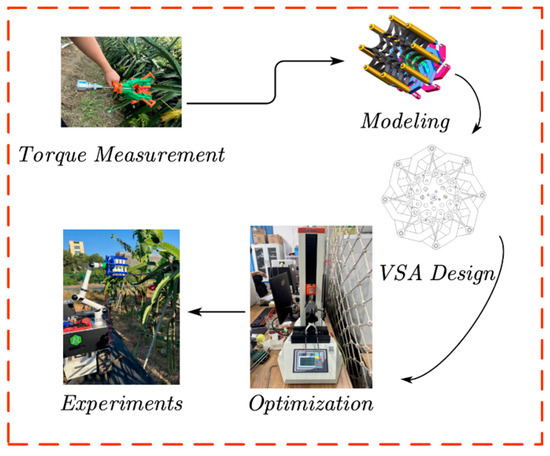

The trials demonstrated that the enveloping end-effector exhibited good gripping stability and flexible adaptability in the field tests, possessing a high harvesting success rate and a low fruit damage rate. Its structural characteristics can significantly enhance the efficiency of non-destructive harvesting for dragon fruit, providing an efficient and reliable structural design concept for the flexible mechanical harvesting of tropical fruit trees, as systematically outlined in the overall design workflow (Figure 13).

Figure 13.

Overall Design Workflow.

7. Discussion

7.1. Challenges and Design Limitations in Field Trials

Despite the overall superior performance, some practical challenges and design limitations were identified during the trials. The primary challenge encountered was the physical size of the end-effector. In confined spaces, particularly where fruits were densely clustered or located close to the main branch, its bulk sometimes obstructed the achievement of optimal gripping postures, which was the main reason for a few failure cases. Furthermore, the performance of the current design is, to some extent, dependent on the orientation of the fruit, making gripping more difficult for fruits with highly oblique postures. The long-term durability of the TPU material (e.g., performance degradation under continuous UV exposure and physical abrasion) also warrants further investigation.

7.2. Future Outlook

Based on the observations and analysis from this field trial, future improvement efforts will focus on the following key areas:

- Structural Optimization and Miniaturization: Addressing the accessibility challenges identified, a primary task for future work will be to optimize and miniaturize the end-effector’s structure. This aims to reduce its overall size and weight without compromising its enveloping performance.

- Enhanced Perception and Adaptability: Integrating flexible tactile sensors to achieve closed-loop adaptive control of gripping force. Concurrently, visual algorithms will be improved to enhance robustness in complex environments.

- Expanded Application Scope: Extending the design concept to the harvesting of other irregularly shaped, high-value fruits, such as mangoes and avocados. Furthermore, its scalability and application in large-scale industrial harvesting robots will be explored.

8. Conclusions

This study successfully developed and validated an enveloping end-effector based on the Variable-Span Arch (VSA) structure, which demonstrated significant performance advantages and application potential in practical applications. The main conclusions are as follows:

- (1)

- Significantly Improved Gripping Reliability and Reduced Fruit Damage Rate: Benefiting from the VSA structure’s linear force control and multi-point flexible envelopment features, the end-effector effectively overcomes the damage and slippage issues caused by stress concentration and off-center gripping, which are common in traditional rigid jaws. Field trials showed that its optimal harvesting success rate reached 95%, with the pulp of harvested samples remaining completely undamaged, achieving genuinely low-damage harvesting.

- (2)

- Achieved More Efficient Harvesting Operations: The average harvesting time per fruit is approximately 15 s, which is a significant improvement in operational efficiency compared to traditional harvesting structures reported in the literature. The successful application of the 10 Nm motor, while ensuring the completion of harvesting tasks for the largest fruit samples, also validates the rational matching of the structure in terms of energy efficiency and lightweight design, ensuring stability during continuous operation.

- (3)

- Demonstrated Broad Application Potential: The principles of adaptive gripping and force control based on the VSA, as proposed in this study, are not limited to dragon fruit. This design concept can provide an important technical reference and an efficient, reliable solution for the automated harvesting of other high-value fruits with irregular shapes and fragile skins (such as mangoes, avocados, etc.).

Author Contributions

Conceptualization, L.Z. and G.F.; methodology, T.C. and Y.C.; software, Y.C. and S.Z.; validation, T.C.; formal analysis, X.F. and S.K.; investigation, L.Z. and G.F.; resources, L.Z.; data curation, T.C. and Y.C.; writing—original draft preparation, T.C. and Y.C.; writing—review and editing, Q.L.; supervision, T.C. and G.F.; project administration, G.F. and T.C.; funding acquisition, G.F. All authors have read and agreed to the published version of the manuscript.

Funding

The paper is supported by the Department of Agriculture and Rural Affairs of Guangdong Province’s Special Fund for Rural Vitalization Strategy—“Development and Demonstration of Small-scale Applicable Intelligent Harvesting Equipment for Dragon Fruit” (Yue Nong Nong Ji [2024] No. 51), the Key Area Research and Development Program in Guangdong Province of China under Grant 2019B020223003, and the “14th Five-Year Plan”, Guangdong Agricultural Science and Technology Innovation Project 2022SDZG03.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Acknowledgments

The authors acknowledge the editors and reviewers for their constructive comments and all the support in this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, G.; Ji, C.; Zhai, L. Research progress and analysis of end-effector for fruits and vegetables picking robot. J. Chin. Agric. Mech. 2014, 35, 231–236, 240. [Google Scholar] [CrossRef]

- Wu, J.; Fan, S.; Gong, L.; Yuan, J.; Zhou, Q.; Liu, C. Research Status and Development Direction of Design and Control Technology of Fruit and Vegetable Picking Robot System. Smart Agric. 2020, 2, 17–40. [Google Scholar] [CrossRef]

- Li, W.; Liao, L. An Analysis of the Current Situation and Strategies for the Development of the Dragon Fruit Industry in Guangxi. South China Agric. 2024, 18, 202–205. [Google Scholar] [CrossRef]

- Yang, H.; Xing, Y.; Chen, C.; Xie, F.; Zhang, Z.; Zhoa, J.; Hu, G.; Qin, Y.; Zhang, Z. Analysis and Evaluation of Fruit Quality of Different Batches of Dragon Fruit. South China Fruits 2023, 52, 36–46. [Google Scholar] [CrossRef]

- Vrochidou, E.; Tsakalidou, V.N.; Kalathas, I.; Gkrimpizis, T.; Pachidis, T.; Kaburlasos, V.G. An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture 2022, 12, 1240. [Google Scholar] [CrossRef]

- Qiu, L.; Yu, J.; Zhang, X.; Zhao, J. Automatic Picking and Harvesting Machine for Pitaya Fruit. South Agric. Mach. 2022, 53, 4–6+19. [Google Scholar] [CrossRef]

- Chen, Q.; Xiao, C.; Luo, D.; Gao, J.; Ouyang, C.; Zeng, C.; Li, W.; Zhou, X. Design of Shear End Effector for Dragon Fruit Picking Based on Oval Claw. J. Agric. Sci. Technol. 2025, 27, 113–121. [Google Scholar] [CrossRef]

- Park, H.; Kang, H.; Hwang, B.; Joe, S.; Kim, B. A Fruit Harvesting Mechanism Capable of Multidimensional Movements: A Preliminary Study on the Integrated Mechanism with a Hexacopter. Aerospace 2024, 11, 203. [Google Scholar] [CrossRef]

- Deng, L.; Liu, T.; Jiang, P.; Qi, A.; He, Y.; Li, Y.; Yang, M.; Deng, X. Design and Testing of Bionic-Feature-Based 3D-Printed Flexible End-Effectors for Picking Horn Peppers. Agronomy 2023, 13, 2231. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Armada, M.; Gonzalez-De-Santos, P. Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting. Agronomy 2021, 11, 1727. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, W.; Xu, B.; Yu, X. Optimizing Contact Force on an Apple Picking Robot End-Effector. Agriculture 2024, 14, 996. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.; Wang, Y.; Bao, R.; Chen, X.; Fu, S.; Tian, M.; Zhang, Y. Research on Flexible End-Effectors with Humanoid Grasp Function for Small Spherical Fruit Picking. Agriculture 2023, 13, 123. [Google Scholar] [CrossRef]

- Zhao, Y.; Geng, D.; Liu, X.; Sun, G. Kinematics Analysis and Experiment on Pneumatic Flexible Fruit and Vegetable Picking Manipulator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 31–42. [Google Scholar] [CrossRef]

- Liu, J.; Li, P.; Li, Z. A Multi-Sensory End-Effector for Spherical Fruit Harvesting Robot. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; IEEE: New York, NY, USA, 2007; pp. 258–262. [Google Scholar]

- Xu, Y.; Lv, M.; Xu, Q.; Xu, R. Design and Analysis of a Robotic Gripper Mechanism for Fruit Picking. Actuators 2024, 13, 338. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, X.; Yang, Z. Design, simulation, and experiment for the end effector of a spherical fruit picking robot. Int. J. Adv. Robot. Syst. 2023, 20, 17298806231213442. [Google Scholar] [CrossRef]

- Jin, S.; Xu, G.; Wang, M. Research and Design of the Robotic Harvesting Manipulator for Pitaya. Mold Manuf. 2025, 25, 204–206. [Google Scholar] [CrossRef]

- Ye, M.; Zou, X.; Cai, P.; Zou, H. Design of a General Gripping Mechanism for Fruit-Picking Robots. Trans. Chin. Soc. Agric. Mach. 2011, 42, 177–180. [Google Scholar]

- Chen, Y.; Jiang, z.; Li, W.; Wang, J.; Liu, W.; Zou, X. Design and Testing of Litchi Picking End-effector Integrated Clamping and Cutting Performance. Trans. Chin. Soc. Agric. Mach. 2018, 49, 35–41. [Google Scholar] [CrossRef]

- Masood, M.U.; Haghshenas-Jaryani, M. A Study on the Feasibility of Robotic Harvesting for Chile Pepper. Robotics 2021, 10, 94. [Google Scholar] [CrossRef]

- Yu, Y.; Xie, H.; Zhang, K.; Wang, Y.; Li, Y.; Zhou, J.; Xu, L. Design, Development, Integration, and Field Evaluation of a Ridge-Planting Strawberry Harvesting Robot. Agriculture 2024, 14, 2126. [Google Scholar] [CrossRef]

- Yi, W.; Shun, F.; Zhe, Z.; Ma, T.; Xu, H. Design and Experimentation on End-effector of Citrus Picking Robot. J. Agric. Sci. Technol. 2018, 20, 69–77. [Google Scholar] [CrossRef]

- Xu, L.; Liu, X.; Zhang, K.; Xing, J.; Yuan, Q.; Chen, J.; Duan, Z.; Zhuang, M.S.; Yu, C.C. Design and Testing of the End-Effector for a Navel Orange Harvesting Robot. Trans. Chin. Soc. Agric. Eng. 2018, 34, 53–61. [Google Scholar]

- Lou, K.; Wang, Z.; Zhang, B.; Xu, Q.; Fu, W.; Gu, Y.; Liu, J. Analysis and Experimentation on the Motion Characteristics of a Dragon Fruit Picking Robot Manipulator. Agriculture 2024, 14, 2095. [Google Scholar] [CrossRef]

- Zhang, Y.; Tian, J.; Wang, W.; Zhou, J.; Hu, H. Design and experiments of end-effector for dragon fruit picking robot. J. For. Eng. 2023, 8, 144–150. [Google Scholar] [CrossRef]

- Zhu, L.; Deng, W.; Lai, Y.; Guo, X.; Zhang, S. Research on Improved Road Visual Navigation Recognition Method Based on DeepLabV3+ in Pitaya Orchard. Agronomy 2024, 14, 1119. [Google Scholar] [CrossRef]

- Huang, Y.; Brennan, M.A.; Kasapis, S.; Richardson, S.J.; Brennan, C.S. Maturation Process, Nutritional Profile, Bioactivities and Utilisation in Food Products of Red Pitaya Fruits: A Review. Foods 2021, 10, 2862. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Xu, J.; He, Y.; Shi, M.; Han, X.; Li, W.; Zhang, X.; Wen, X. Metabolic Profiling of Pitaya (Hylocereus polyrhizus) during Fruit Development and Maturation. Molecules 2019, 24, 1114. [Google Scholar] [CrossRef]

- Fotuhi, M.J.; Hazem, Z.B.; Bingül, Z. Comparison of joint friction estimation models for laboratory 2 DOF double dual twin rotor aero-dynamical system. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 2231–2236. [Google Scholar]

- Huang, M.; Zhao, J. Recent advances in postharvest storage and preservation technology of pitaya (dragon fruit). J. Hortic. Sci. Biotechnol. 2024, 99, 115–129. [Google Scholar]

- Zhu, L.; Lai, Y.; Zhang, S.; Wu, R.; Deng, W.; Guo, X. Image Segmentation and Pose Estimation Method for Pitaya Picking Robot Based on Enhanced U-Net. Trans. Chin. Soc. Agric. Mach. 2023, 54, 180–188. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).