Changes in Soil Physical Quality, Root Growth, and Sugarcane Crop Yield During Different Successive Mechanized Harvest Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Treatments, Installation, and Experiment Procedures

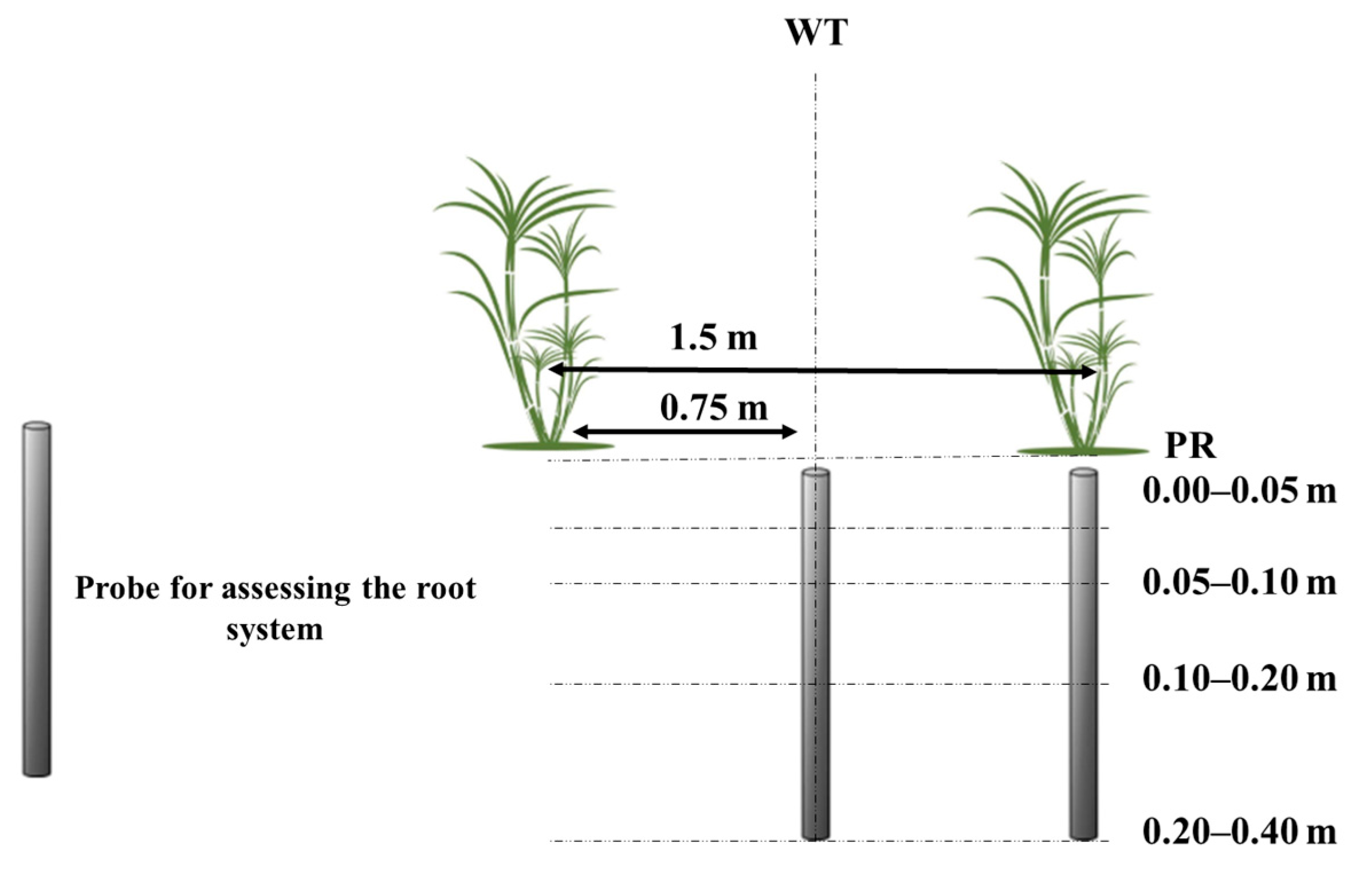

2.3. Soil Sampling

2.4. Soil Physical Properties

2.4.1. Soil Bulk Density, Particle Density, and Porosity

2.4.2. Soil Penetration Resistance (SPR)

2.4.3. Saturated Hydraulic Conductivity (Ks)

2.5. Root System Assessment

2.6. Sugarcane Productivity and Biometric Assessment

2.7. Statistical Analyses

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CONAB—COMPANHIA NACIONAL DE ABASTECIMENTO. Acompanhamento da Safra Brasileira de Cana-de-Açúcar; v.10, n.3; CONAB: Brasília, Brazil, 2023. [Google Scholar]

- Silva, R.P.; Rolim, M.M.; Gomes, I.F.; Pedrosa, E.M.; Tavares, U.E.; Santos, A.N. Numerical modeling of soil compaction in a sugarcane crop using the finite element method. Soil Tillage Res. 2018, 181, 1–10. [Google Scholar] [CrossRef]

- Barbosa, L.C.; Magalhães, P.S.G.; Bordonal, R.O.; Cherubin, M.R.; Castioni, G.A.F.; Tenelli, S.; Franco, H.C.J.; Carvalho, J.L.N. Soil physical quality associated with tillage practices during sugarcane planting in south-central Brazil. Soil Tillage Res. 2019, 195, 104383. [Google Scholar] [CrossRef]

- Esteban, D.A.A.; Souza, Z.M.; Silva, R.B.; Lima, E.S.; Lovera, L.H.; Oliveira, I.N. Impact of permanent traffic lanes on the soil physical and mechanical properties in mechanized sugarcane fields with the use of automatic steering. Geoderma 2020, 362, 97–114. [Google Scholar] [CrossRef]

- Luz, F.B.; Gonzaga, L.C.; Castioni, G.A.F.; Lima, R.P.; Carvalho, J.L.N.; Cherubin, M.R. Controlled traffic farming maintains soil physical functionality in sugarcane fields. Geoderma 2023, 432, 116427. [Google Scholar] [CrossRef]

- Bordonal, R.O.; Carvalho, J.L.N.; Lal, R.; Figueiredo, E.B.; Oliveira, B.G.; La Scala Júnior, N. Sustainability of sugarcane production in Brazil. A review. Agron. Sustain. Dev. 2018, 38, 13. [Google Scholar] [CrossRef]

- Martins, M.B.; Marques Filho, A.C.; Drudi, F.S.; Bortolheiro, F.P.A.P.; Vendruscolo, E.P.; Esperancini, M.S.T. Economic efficiency of mechanized harvesting of sugarcane at different operating speeds. Sugar Tech 2021, 23, 428–432. [Google Scholar] [CrossRef]

- Guimarães Júnnyor, W.S.; Diserens, E.; De Maria, I.C.; Araujo-Junior, C.F.; Farhate, C.V.V.; Souza, Z.M. Prediction of soil stresses and compaction due to agricultural machines in sugarcane cultivation systems with and without crop rotation. Sci. Total Environ. 2019, 681, 424–434. [Google Scholar] [CrossRef]

- Jimenez, K.J.; Rolim, M.M.; Gomes, I.F.; Lima, R.P.; Berrío, L.L.A.; Ortiz, P.F.S. Numerical analysis applied to the study of soil stress and compaction due to mechanised sugarcane harvest. Soil Tillage Res. 2021, 206, 104847. [Google Scholar] [CrossRef]

- Keller, T.; Sandin, M.; Colombi, T.; Horn, R.; Or, D. Historical increase in agricultural machinery weights enhanced soil stress levels and adversely affected soil functioning. Soil Tillage Res. 2019, 194, 104293. [Google Scholar] [CrossRef]

- Castioni, G.A.F.; Lima, R.P.; Cherubin, M.R.; Bordonal, R.O.; Rolim, M.M.; Carvalho, J.L.N. Machinery traffic in sugarcane straw removal operation: Stress transmitted and soil compaction. Soil Tillage Res. 2021, 213, 105122. [Google Scholar] [CrossRef]

- Lovera, L.H.; Souza, Z.M.; Esteban, D.A.A.; Oliveira, I.N.; Farhate, C.V.; Lima, E.S.; Panosso, A.R. Sugarcane root system: Variation over three cycles under different soil tillage systems and cover crops. Soil Tillage Res. 2021, 208, 104866. [Google Scholar] [CrossRef]

- Oliveira, I.N.; Souza, Z.M.; Bolonhezi, D.; Totti, M.C.V.; Moraes, M.T.; Lovera, L.H.; Lima, E.S.; Esteban, D.A.A.; Oliveira, C.F. Tillage systems impact on soil physical attributes, sugarcane yield and root system propagated by pre-sprouted seedlings. Soil Tillage Res 2022, 223, 105460. [Google Scholar] [CrossRef]

- Stoessel, F.; Sonderegger, T.; Bayer, P.; Hellweg, S. Assessing the environmental impacts of soil compaction in Life Cycle Assessment. Sci. Total Environ. 2018, 630, 913–921. [Google Scholar] [CrossRef]

- Castioni, G.A.F.; Cherubin, M.R.; Menandro, L.M.S.; Sanches, G.M.; Bordonal, R.O.; Barbosa, L.C.; Franco, H.C.J.; Carvalho, J.L.N. Soil physical quality response to sugarcane straw removal in Brazil: A multi approach assessment. Soil Tillage Res. 2018, 184, 301–309. [Google Scholar] [CrossRef]

- Esteban, D.A.A.; Souza, Z.M.; Tormena, C.A.; Lovera, L.H.; Lima, E.S.; Oliveira, I.N.; Ribeiro, N.P. Soil compaction, root system and productivity of sugarcane under different row spacing and controlled traffic at harvest. Soil Tillage Res. 2019, 187, 60–71. [Google Scholar] [CrossRef]

- Cavalcanti, R.Q.; Rolim, M.M.; Lima, R.P.; Tavares, U.E.; Pedrosa, E.M.R.; Cherubin, M.R.; Gomes, I.F. Soil physical and mechanical attributes in response to successive harvests under sugarcane cultivation in Northeastern Brazil. Soil Tillage Res. 2019, 189, 140–147. [Google Scholar] [CrossRef]

- Carvalho, M.L.; Luz, F.B.; Lima, R.P.; Cavalieri-Polizeli, K.M.V.; Carvalho, J.L.N.; Cherubin, M.R. Assessment of soil physical quality and water flow regulation under straw removal management in sugarcane production fields. Sustainability 2022, 14, 841. [Google Scholar] [CrossRef]

- Delmond, J.G.; Guimarães Junnyor, W.S.; Brito, M.F.; Rossoni, D.F.; Araujo-Junior, C.F.; Severiano, E.C. Which operation in mechanized sugarcane harvesting is most responsible for soil compaction? Geoderma 2024, 448, 116979. [Google Scholar] [CrossRef]

- Horn, R.; Fleige, H. Risk assessment of subsoil compaction for arable soils in Northwest Germany at farm scale. Soil Tillage Res. 2009, 102, 201–208. [Google Scholar] [CrossRef]

- Khodaverdilo, H.; Cheraghabdal, H.K.; Bagarello, V.; Iovino, M.; Asgarzadeh, H.; Dashtaki, S.G. Ring diameter effects on determination of field-saturated hydraulic conductivity of different loam soils. Geoderma 2017, 303, 60–69. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, Y.; Bennett, J.M.; Wu, L.; Li, H. Effects of sodium adsorption ratio and electrolyte concentration on soil saturated hydraulic conductivity. Geoderma 2022, 414, 115772. [Google Scholar] [CrossRef]

- Hervé-Fernández, P.; Muñoz-Arriagada, R.; Glucevic-Almonacid, C.; Bahamonde-Vidal, L.; Radic-Schilling, S. Influence of rangeland land cover on infiltration rates, field-saturated hydraulic conductivity, and soil Water repellency in Southern Patagonia. Rangel Ecol. Manag. 2023, 90, 92–100. [Google Scholar] [CrossRef]

- Alagna, V.; Bagarello, V.; Di Prima, S.; Giordano, G.; Iovino, M. Testing infiltration run effects on the estimated water transmission properties of a sandy-loam soil. Geoderma 2016, 267, 24–33. [Google Scholar] [CrossRef]

- Iovino, M.; Castellini, M.; Bagarello, V.; Giordano, G. Using static and dynamic indicators to evaluate soil physical quality in a Sicilian area. Land Degrad. Dev. 2016, 27, 200–210. [Google Scholar] [CrossRef]

- Otto, R.; Silva, A.P.P.; Franco, H.C.J.; Oliveira, E.C.A.; Trivelin, P.C.O. High soil penetration resistance reduces sugarcane root system development. Soil Tillage Res. 2011, 117, 201–210. [Google Scholar] [CrossRef]

- Ortiz, P.F.S.; Rolim, M.M.; Lima, R.P.; Tormena, C.A.; Cavalcanti, R.Q.; Pedrosa, E.M.R. A Soil physical assessment over three successive burned and unburned sugarcane annual harvests. Sugar Tech 2023, 25, 518–530. [Google Scholar] [CrossRef]

- Barbosa, L.C.; Souza, Z.M.; Franco, H.C.J.; Otto, R.; Rossi Neto, J.; Garside, A.L.; Carvalho, J.L.N. Soil texture affects root penetration in Oxisols under sugarcane in Brazil. Geoderma Reg. 2018, 13, 15–25. [Google Scholar] [CrossRef]

- Colombi, T.; Keller, T. Developing strategies to recover crop productivity after soil compaction—Plant eco-physiological perspective. Soil Tillage Res. 2019, 191, 156–161. [Google Scholar] [CrossRef]

- Luz, F.B.; Carvalho, M.L.; Borba, D.A.; Schiebelbein, B.E.; Lima, R.P.; Cherubin, M.R. Linking soil water changes to soil physical quality in sugarcane expansion areas in Brazil. Water 2020, 12, 3156. [Google Scholar] [CrossRef]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; Gonçalves, J.L.M.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Santos, H.G.; Jacomine, P.K.T.; Anjo, L.H.C.; Oliveira, V.A.; Lumbrelas, J.F.; Coelho, M.R.; Almeida, J.A.; Araujo Filho, J.C.; Oliveira, J.B.; Cunha, T.J.F. Sistema Brasileiro de Classificação de Solos, 5th ed.; Revista e Ampliada; Embrapa: Brasília, Brazil, 2018. [Google Scholar]

- Soil Survey Staff. Keys to Soil Taxonomy, 12th ed.; United States Department of Agriculture, Natural Resources Conservation Service: Washington, DC, USA, 2014. [Google Scholar]

- Teixeira, P.C.; Donagemma, G.K.; Fontana, A.; Teixeira, W.G. Manual de Métodos de Análise de Solos, 3rd ed.; edição Revista e Ampliada; Embrapa: Brasília, Brazil, 2017; 573p. [Google Scholar]

- UMS GmbH. Operation Manual KSAT; UMS GmbH: Munich, Germany, 2019. [Google Scholar]

- Guimarães Júnnyor, W.S.; De Maria, I.C.; Araujo-Junior, C.F.; Diserens, E.; Severiano, E.C.; Farhate, C.V.V.; Souza, Z.M. Conservation systems change soil resistance to compaction caused by mechanised harvesting. Ind. Crops Prod. 2022, 177, 114532. [Google Scholar] [CrossRef]

- Luz, F.B.; Castioni, G.A.F.; Tormena, C.A.; Freitas, R.S.; Carvalho, J.L.N.; Cherubin, M.R. Soil tillage and machinery traffic influence soil water availability and air fluxes in sugarcane fields. Soil Tillage Res. 2022, 223, 105459. [Google Scholar] [CrossRef]

- Souza, G.S.; Souza, Z.M.; Cooper, M.; Tormena, C.A. Controlled traffic and soil physical quality of an oxisol under sugarcane cultivation. Sci. Agric. 2015, 72, 270–277. [Google Scholar] [CrossRef]

- Silva, R.B.; Iori, P.; Souza, Z.M.; Pereira, D.M.G.; Vischi Filho, O.J.; Silva, F.A.M. Contact pressures and the impact of farm equipment on Latosol with the presence and absence of sugarcane straw. Cienc. Agrotec. 2016, 40, 265–278. [Google Scholar] [CrossRef]

- Cherubin, M.R.; Karlen, D.L.; Cerri, C.E.P.; Franco, A.L.C.; Tormena, C.A.; Davies, C.A.; Cerri, C.A. Soil quality indexing strategies for evaluating sugarcane expansion in Brazil. PLoS ONE 2016, 11, e0150860. [Google Scholar] [CrossRef] [PubMed]

- Awe, G.O.; Reichert, J.M.; Fontanela, E. Sugarcane production in the subtropics: Seasonal changes in soil properties and crop yield in no-tillage, inverting and minimum tillage. Soil Tillage Res. 2020, 196, 104447. [Google Scholar] [CrossRef]

- Schjønning, P.; Van Den Akker, J.J.H.; Keller, T.; Greve, M.H.; Lamandé, M.; Simojoki, A.; Stettler, M.; Arvidsson, J.; Reuning-Madsen, H. Driver- Pressure-State-Impact-Response (DPSIR) Analysis and Risk Assessment for Soil Compaction—A European Perspective. Adv. Agron. 2015, 133, 183–237. [Google Scholar]

- Lima, C.C.; De Maria, I.C.; Guimarães Júnnyor, W.S.; Figueiredo, G.C.; Dechen, S.C.F.; Bolonhezi, D. Root parameters of sugarcane and soil compaction indicators under deep strip tillage and conventional tillage. Sci. Rep. 2022, 12, 18537. [Google Scholar] [CrossRef] [PubMed]

- Cavalcanti, R.Q.; Rolim, M.M.; Lima, R.P.; Tavares, U.E.; Pedrosa, E.M.R.; Cherubin, M.R. Soil physical changes induced by sugarcane cultivation in the Atlantic Forest biome, northeastern Brazil. Geoderma 2020, 370, 114353. [Google Scholar] [CrossRef]

- Mesquita, M.G.B.F.; Moraes, S.O. A dependência entre a condutividade hidráulica saturada e atributos físicos do solo. Ci Rural 2004, 34, 963–969. [Google Scholar] [CrossRef]

- Pinheiro, E.A.R.; De Jong Van Lier, Q.; Šimůnek, J. The role of soil hydraulic properties in crop water use efficiency: A process-based analysis for some Brazilian scenarios. Agric. Syst. 2019, 173, 364–377. [Google Scholar] [CrossRef]

- Silva-Olaya, A.M.; Davies, C.A.; Cerri, C.E.P.; Allen, D.J.; Mello, F.F.C.; Cerri, C.C. Quantifying above and belowground biomass carbon inputs for sugar-cane production in Brazil. Soil Res. 2017, 55, 640–648. [Google Scholar] [CrossRef]

- Alameda, D.; Anten, N.P.R.; Villar, R. Soil compaction effects on growth and root traits of tobacco depend on light, water regime and mechanical stress. Soil Tillage Res. 2012, 120, 121–129. [Google Scholar] [CrossRef]

- Souza, G.S.; Souza, Z.M.; Silva, R.B.; Barbosa, R.S.; Araújo, F.S. Effects of traffic control on the soil physical quality and the cultivation of sugarcane. Rev. Bras. Ci Solo 2014, 38, 135–146. [Google Scholar] [CrossRef]

- Faroni, C.E.; Trivelin, P.C.O. Quantificação de raízes metabolicamente ativas de cana-de-açúcar. Pesq. Agropec. Bras. 2006, 41, 1007–1013. [Google Scholar] [CrossRef]

- Gava, G.C.; Silva, M.A.; Silva, R.C.; Jeronimo, E.M.; Cruz, J.S.; Kölln, O.T. Produtividade de três cultivares de cana-de-açúcar sob manejos de sequeiro e irrigado por gotejamento. Rev. Bras. Eng. Agric. Ambient. 2011, 15, 250–255. [Google Scholar] [CrossRef]

- Costa, C.T.S.; Ferr, V.M.; Endres, L.; Ferreira, D.T.R.; Gonçalves, E.R. Crescimento e produtividade de quatro variedades de cana-de-açúcar no quarto ciclo de cultivo. Rev. Caatinga 2011, 24, 56–63. [Google Scholar]

- Arcoverde, S.N.S.; Souza, C.M.A.; Orlando, R.C.; Silva, M.M.; Nascimento, J.M. Níveis de compactação e sistemas de preparo sobre atributos físicos do solo e componentes de produção da soja. Rev. Eng. Agric. 2019, 27, 142–156. [Google Scholar]

- Han, L.; Yang, G.; Dai, H.; Xu, B.; Yang, H.; Feng, H.; Li, Z. Modeling maize above-ground biomass based on machine learning approaches using UAV remote- sensing data. Plant Methods 2019, 15, 10. [Google Scholar] [CrossRef]

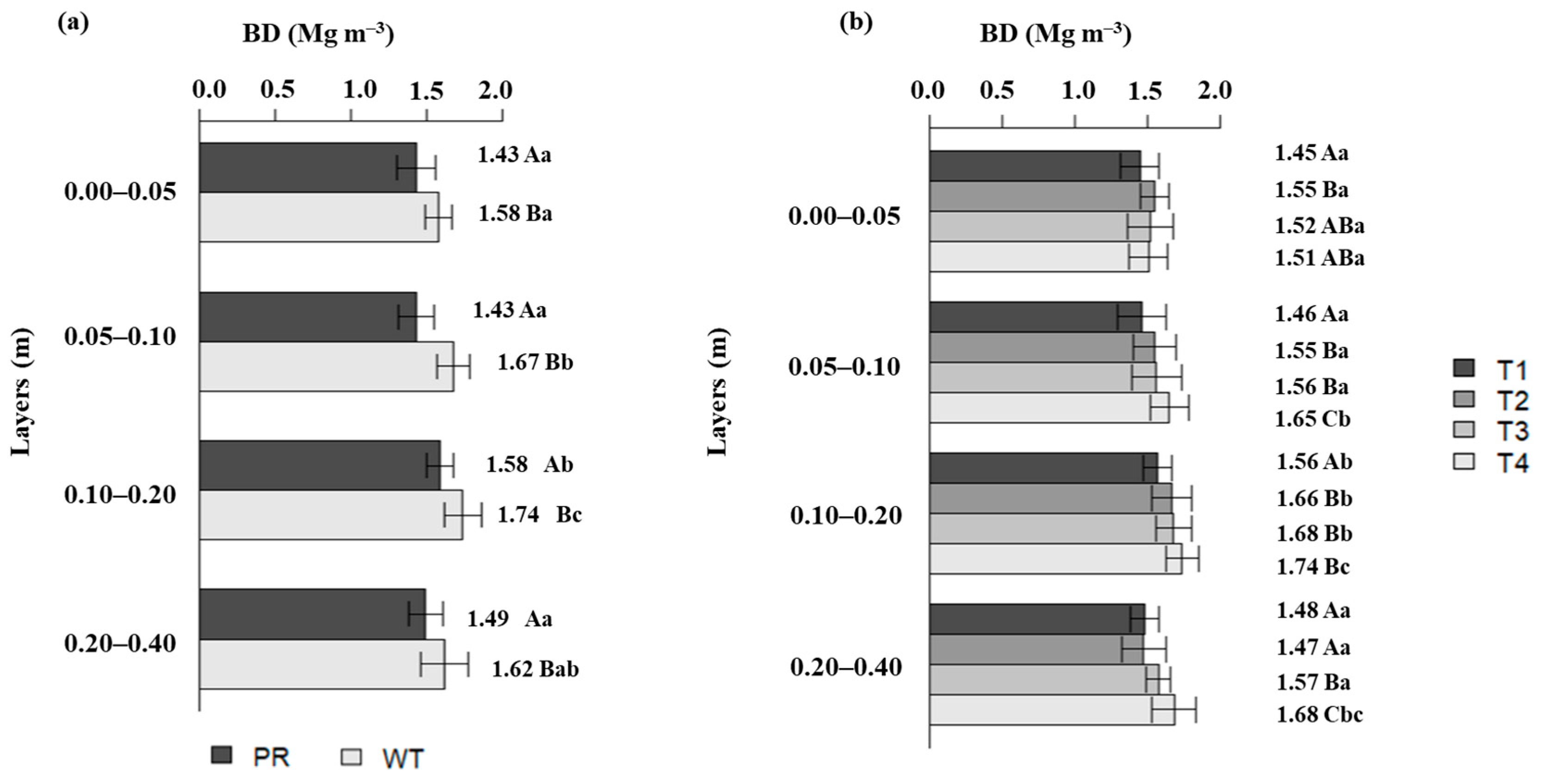

| SS | Layer | BD | TP | MiP | MaP | SPR |

|---|---|---|---|---|---|---|

| (m) | (Mg m−3) | (m3 m−3) | (MPa) | |||

| PR | 0.00–0.05 | 1.43 (0.13) | 0.44 (0.04) | 0.32 (0.03) | 0.10 (0.03) | 0.66 (0.26) |

| 0.05–0.10 | 1.44 (0.11) | 0.41 (0.04) | 0.31 (0.05) | 0.10 (0.04) | 0.84 (0.30) | |

| 0.10–0.20 | 1.59 (0.08) | 0.40 (0.05) | 0.32 (0.05) | 0.08 (0.03) | 0.91 (0.28) | |

| 0.20–0.40 | 1.49 (0.11) | 0.39 (0.05) | 0.32 (0.03) | 0.07 (0.03) | 0.93 (0.37) | |

| WT | 0.00–0.05 | 1.58 (0.11) | 0.39 (0.06) | 0.33 (0.04) | 0.04 (0.01) | 1.24 (0.31) |

| 0.05–0.10 | 1.68 (0.10) | 0.36 (0.04) | 0.30 (0.03) | 0.05 (0.02) | 1.54 (0.57) | |

| 0.10–0.20 | 1.74 (0.12) | 0.37 (0.03) | 0.31 (0.02) | 0.06 (0.02) | 1.89 (0.51) | |

| 0.20–0.40 | 1.62 (0.15) | 0.38 (0.03) | 0.32 (0.02) | 0.05 (0.02) | 1.21 (0.36) |

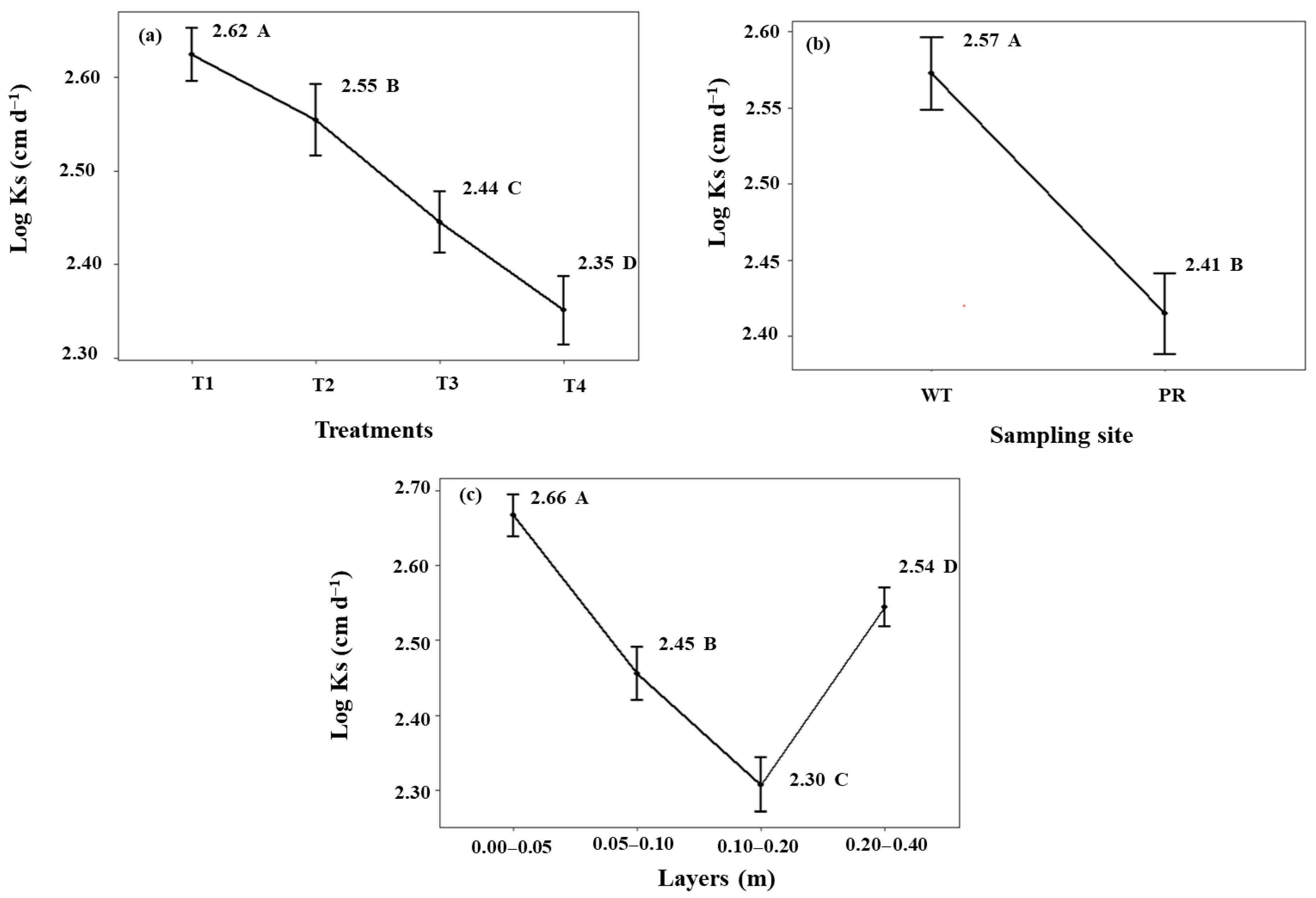

| Macroporosity (m3 m−3) | ||||

| Treatment | T1 | T2 | T3 | T4 |

| WT | 0.29 Aa | 0.29 Aa | 0.33 Ba | 0.39 Ca |

| PR | 0.29 Aa | 0.30 Aa | 0.33 Ba | 0.34 Bb |

| Layer (m) | 0.00–0.05 | 0.05–0.10 | 0.10–0.20 | 0.20–0.40 |

| WT | 0.35 Aa | 0.32 Ba | 0.32 Ba | 0.32 Ba |

| PR | 0.31 Ab | 0.32 Aa | 0.30 Aa | 0.32 Aa |

| Macroporosity (m3 m−3) | ||||

| Treatment | T1 | T2 | T3 | T4 |

| WT | 0.061 Ab | 0.056 Ab | 0.059 Ab | 0.046 Ab |

| PR | 0.11 Aa | 0.098 Aba | 0.089 Ba | 0.062 Cb |

| Layer (m) | 0.00–0.05 | 0.05–0.10 | 0.10–0.20 | 0.20–0.40 |

| WT | 0.047 Aa | 0.057 Aa | 0.060 Aa | 0.058 Aa |

| PR | 0.10 Ab | 0.10 Ab | 0.080 ABb | 0.073 Ba |

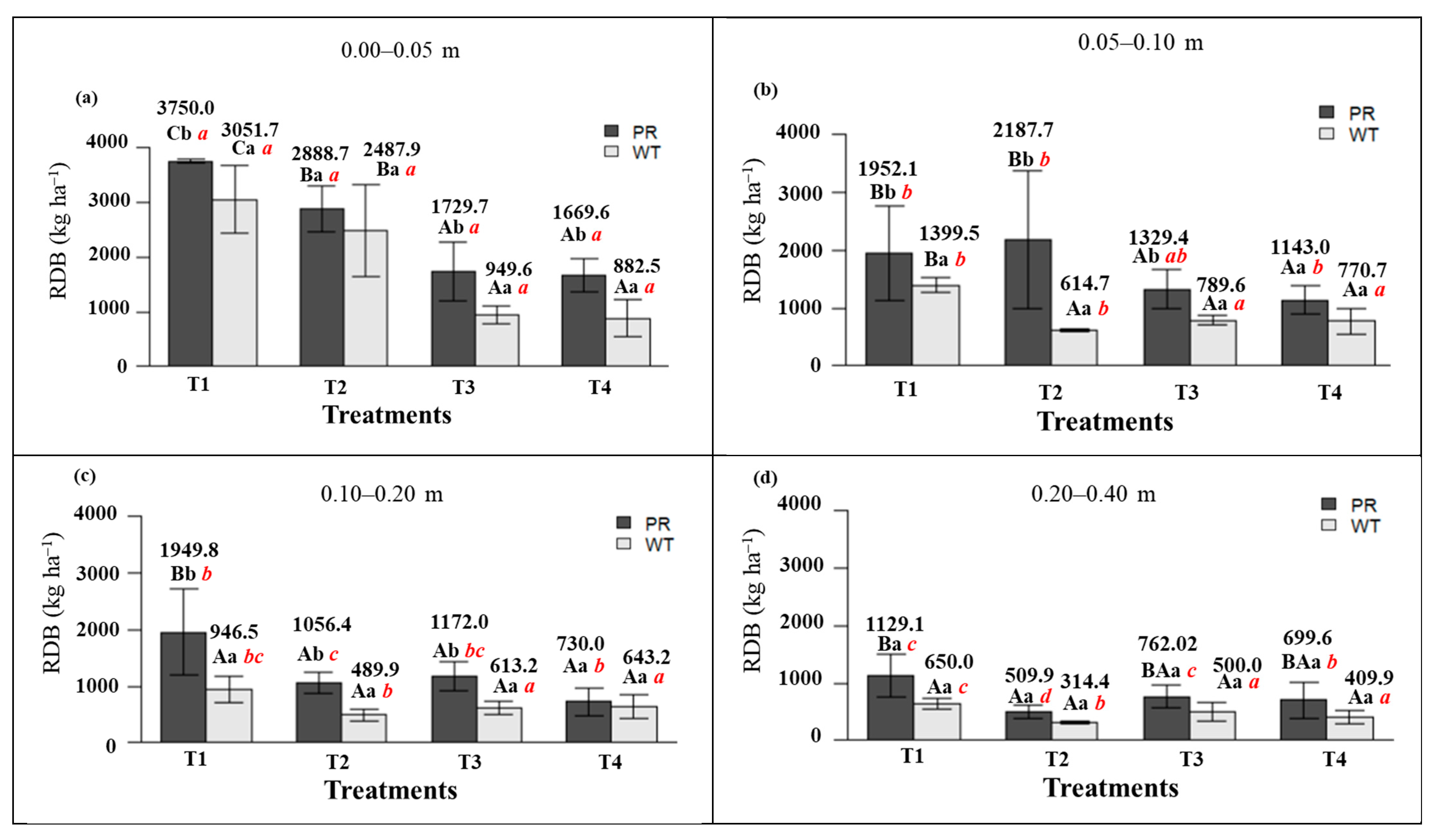

| Treatment | Productivity (Mg ha−1) | Diameter (cm) | Height (m) | NP/ha−1 |

|---|---|---|---|---|

| T1 | 95.96 a | 3.03 a | 3.35 a | 57.33 a |

| T2 | 74.34 b | 2.95 a | 2.65 b | 55.67 a |

| T3 | 60.43 c | 2.92 a | 2.51 bc | 48.93 b |

| T4 | 40.04 d | 2.68 b | 2.26 c | 45.73 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valente, I.Q.M.; de Souza, Z.M.; Cassama, G.S.; da Silva Bitter, V.; Parra, J.A.S.; Guimarães, E.M.; da Silva, R.B.; Tavares, R.L.M. Changes in Soil Physical Quality, Root Growth, and Sugarcane Crop Yield During Different Successive Mechanized Harvest Cycles. AgriEngineering 2025, 7, 325. https://doi.org/10.3390/agriengineering7100325

Valente IQM, de Souza ZM, Cassama GS, da Silva Bitter V, Parra JAS, Guimarães EM, da Silva RB, Tavares RLM. Changes in Soil Physical Quality, Root Growth, and Sugarcane Crop Yield During Different Successive Mechanized Harvest Cycles. AgriEngineering. 2025; 7(10):325. https://doi.org/10.3390/agriengineering7100325

Chicago/Turabian StyleValente, Igor Queiroz Moraes, Zigomar Menezes de Souza, Gamal Soares Cassama, Vanessa da Silva Bitter, Jeison Andrey Sanchez Parra, Euriana Maria Guimarães, Reginaldo Barboza da Silva, and Rose Luiza Moraes Tavares. 2025. "Changes in Soil Physical Quality, Root Growth, and Sugarcane Crop Yield During Different Successive Mechanized Harvest Cycles" AgriEngineering 7, no. 10: 325. https://doi.org/10.3390/agriengineering7100325

APA StyleValente, I. Q. M., de Souza, Z. M., Cassama, G. S., da Silva Bitter, V., Parra, J. A. S., Guimarães, E. M., da Silva, R. B., & Tavares, R. L. M. (2025). Changes in Soil Physical Quality, Root Growth, and Sugarcane Crop Yield During Different Successive Mechanized Harvest Cycles. AgriEngineering, 7(10), 325. https://doi.org/10.3390/agriengineering7100325