Using a Computer Vision System for Monitoring the Exterior Characteristics of Damaged Apples

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

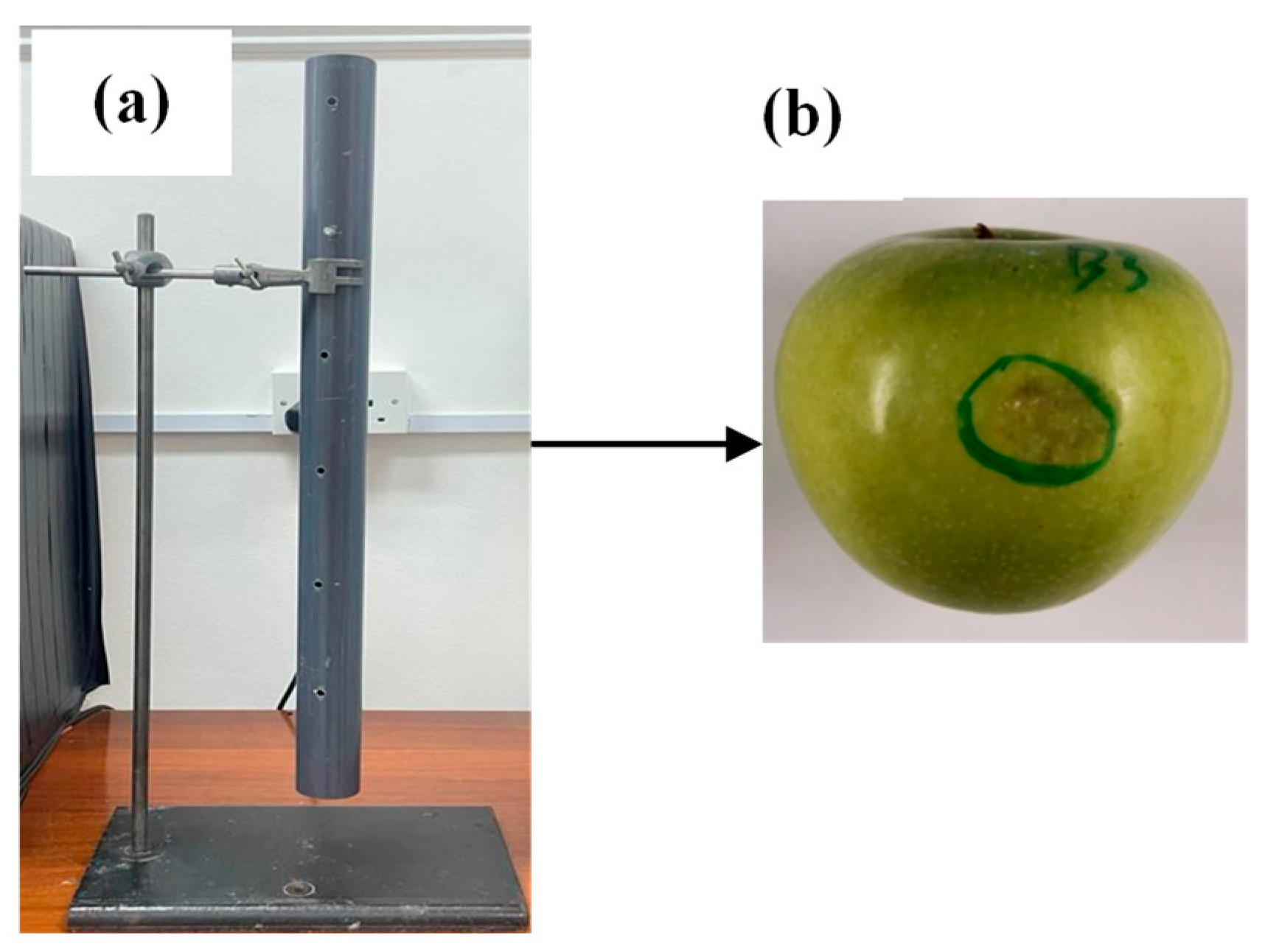

2.2. The Drop Test Method and Storage

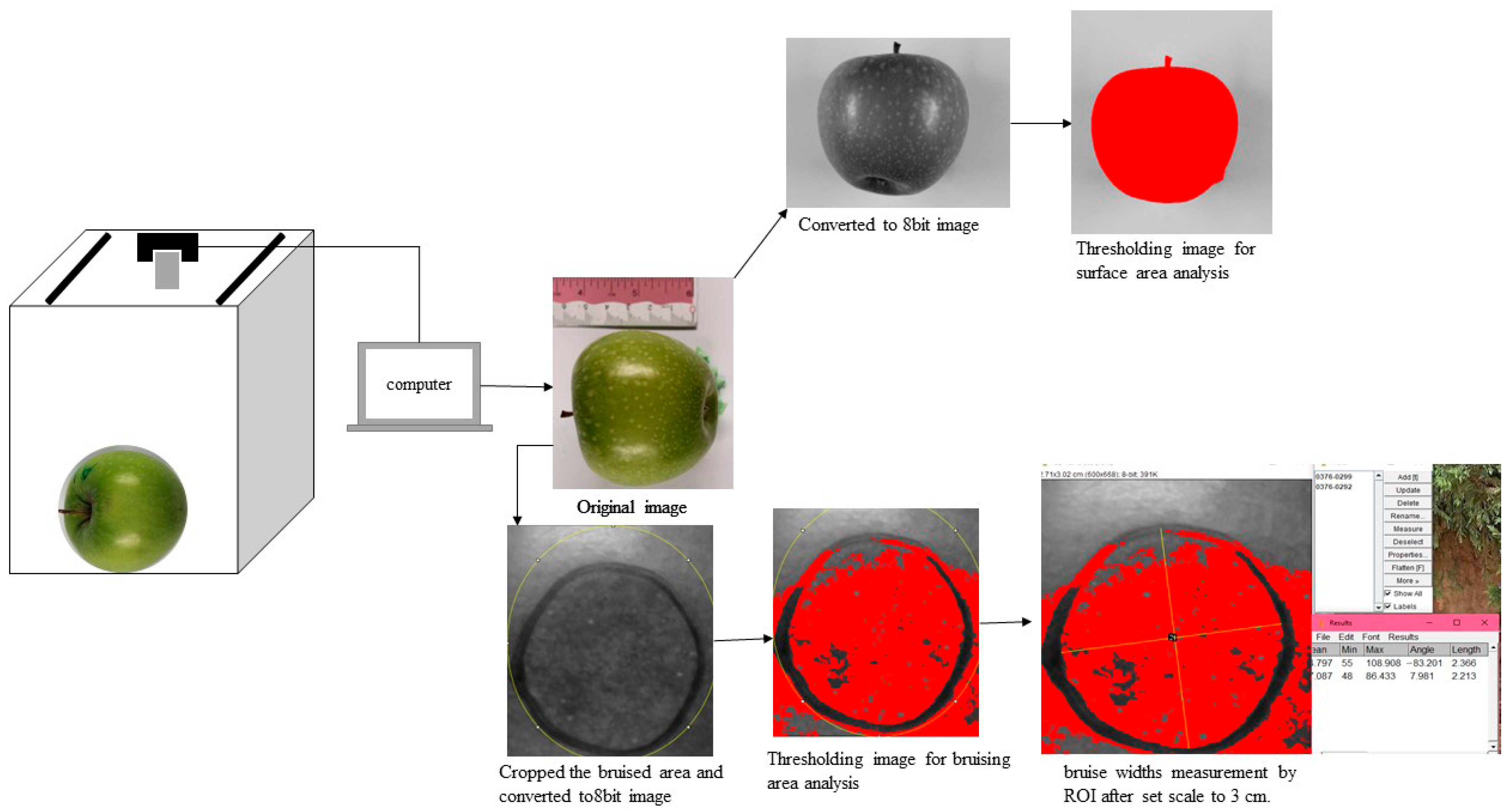

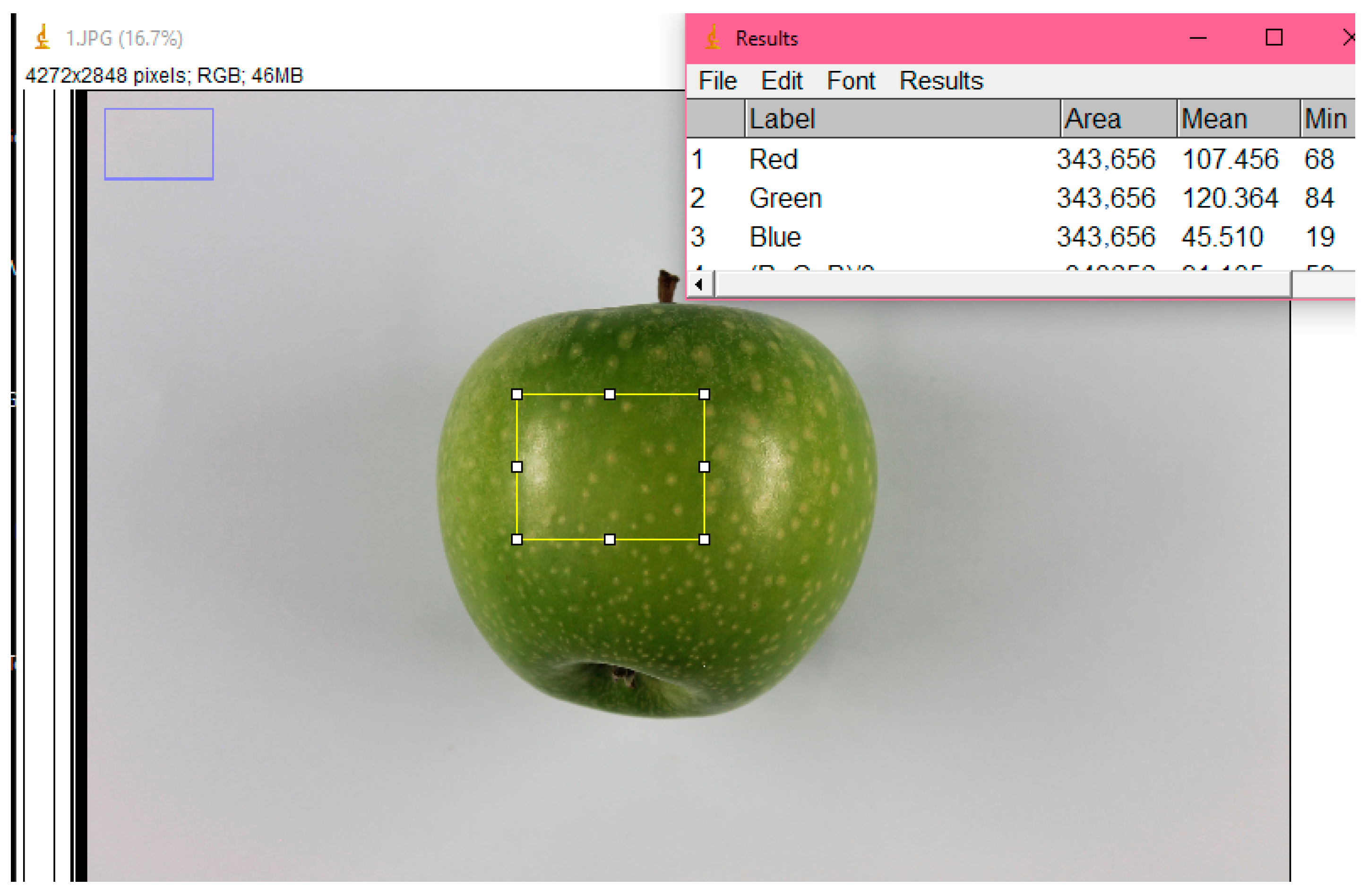

2.3. Computer Vision System (CVS)

2.4. Bruise and Physical Properties Measurement

2.4.1. Bruise Damage Analysis

2.4.2. Surface Area

2.4.3. Measurement of Color Change

2.4.4. Weight Losses %

2.5. Statistical Analysis

3. Results and Discussion

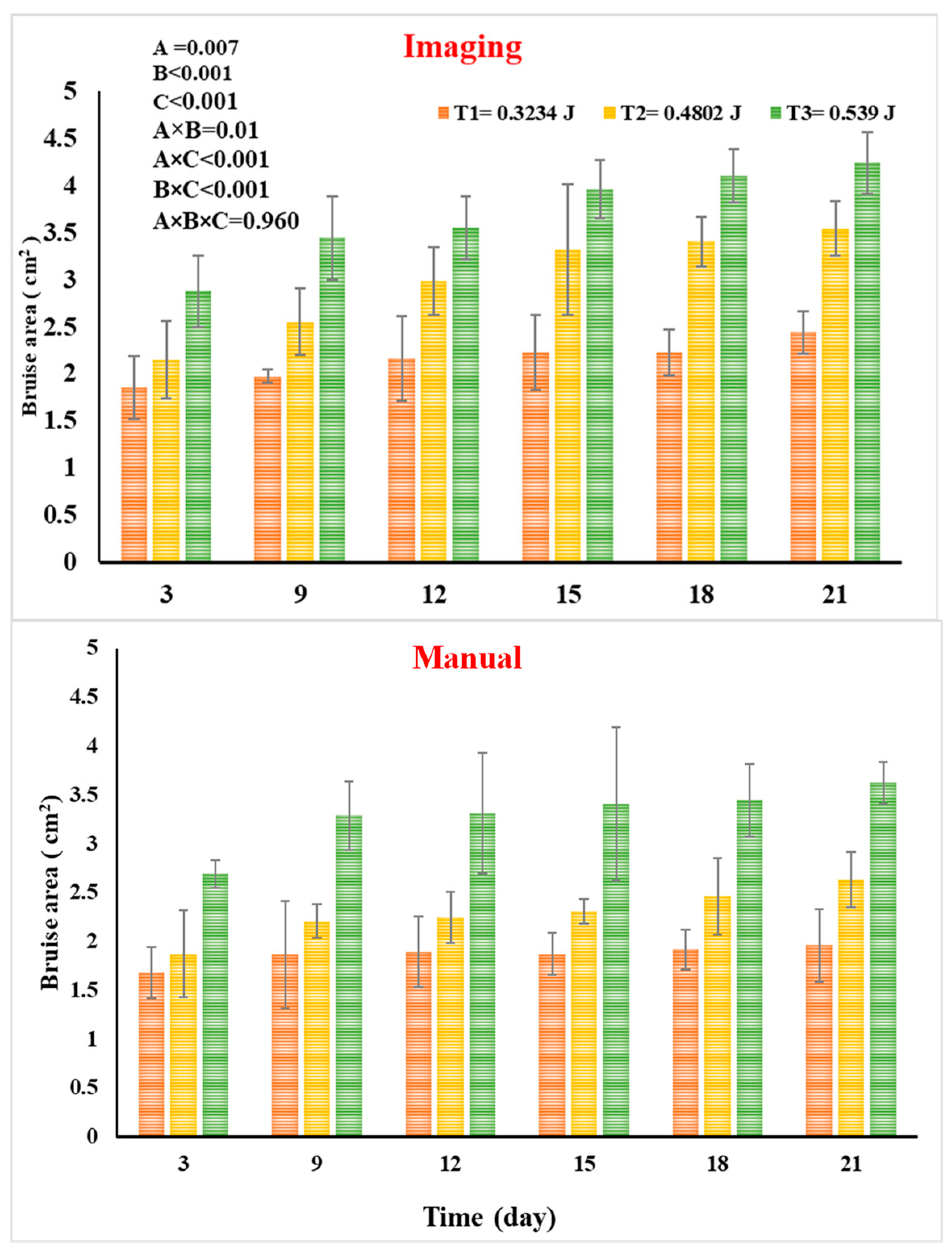

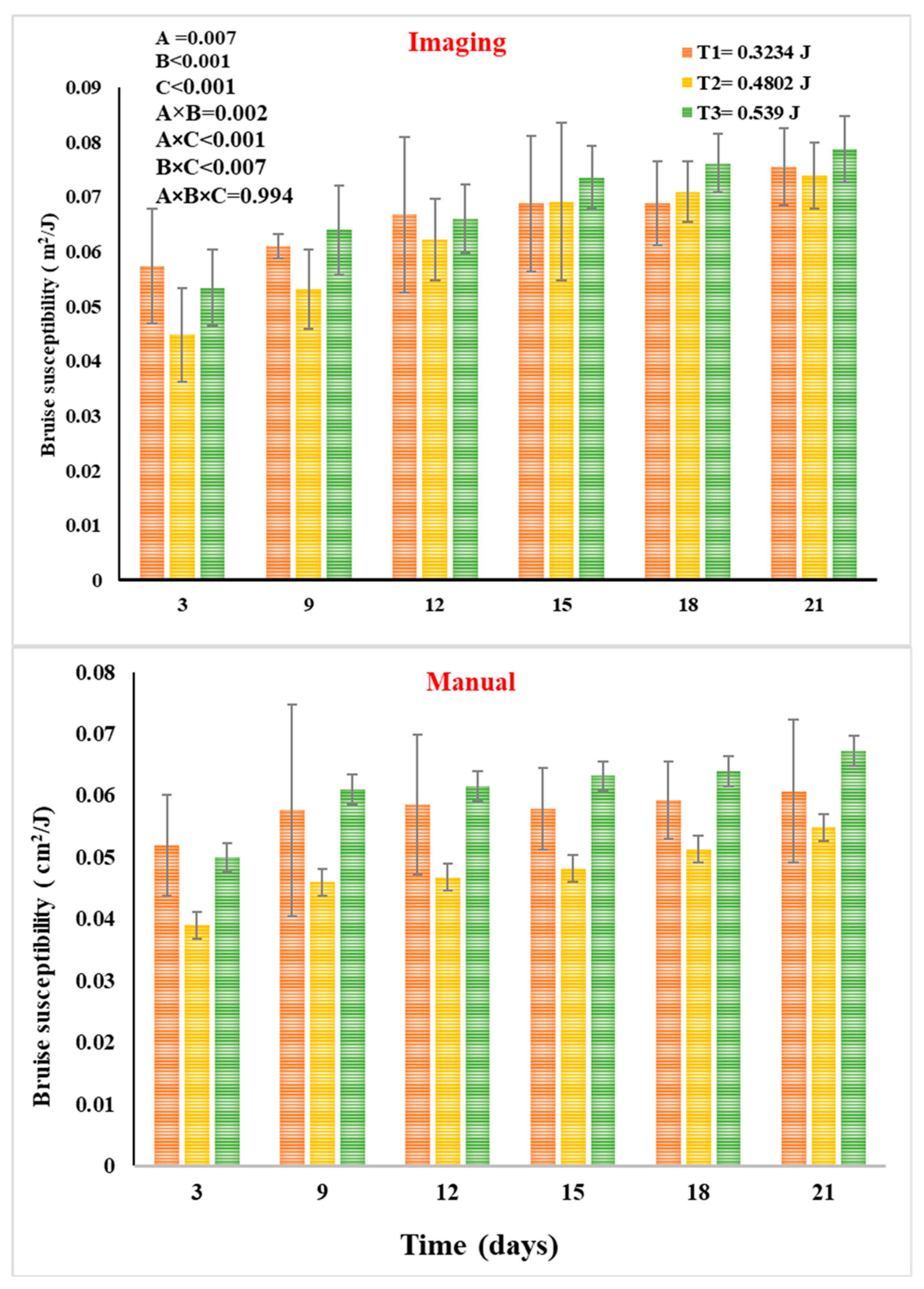

3.1. Effect of Damage on Bruise Parameters

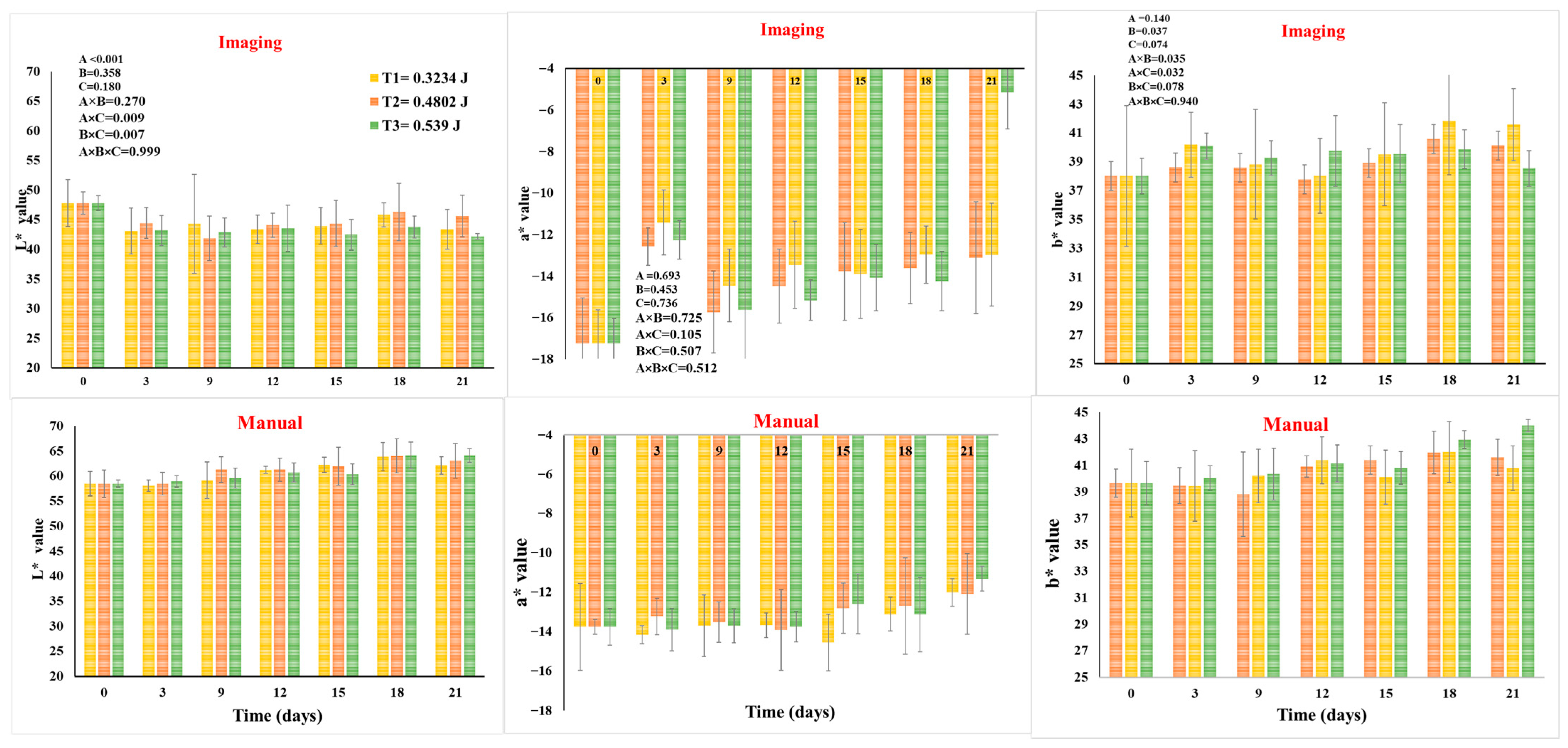

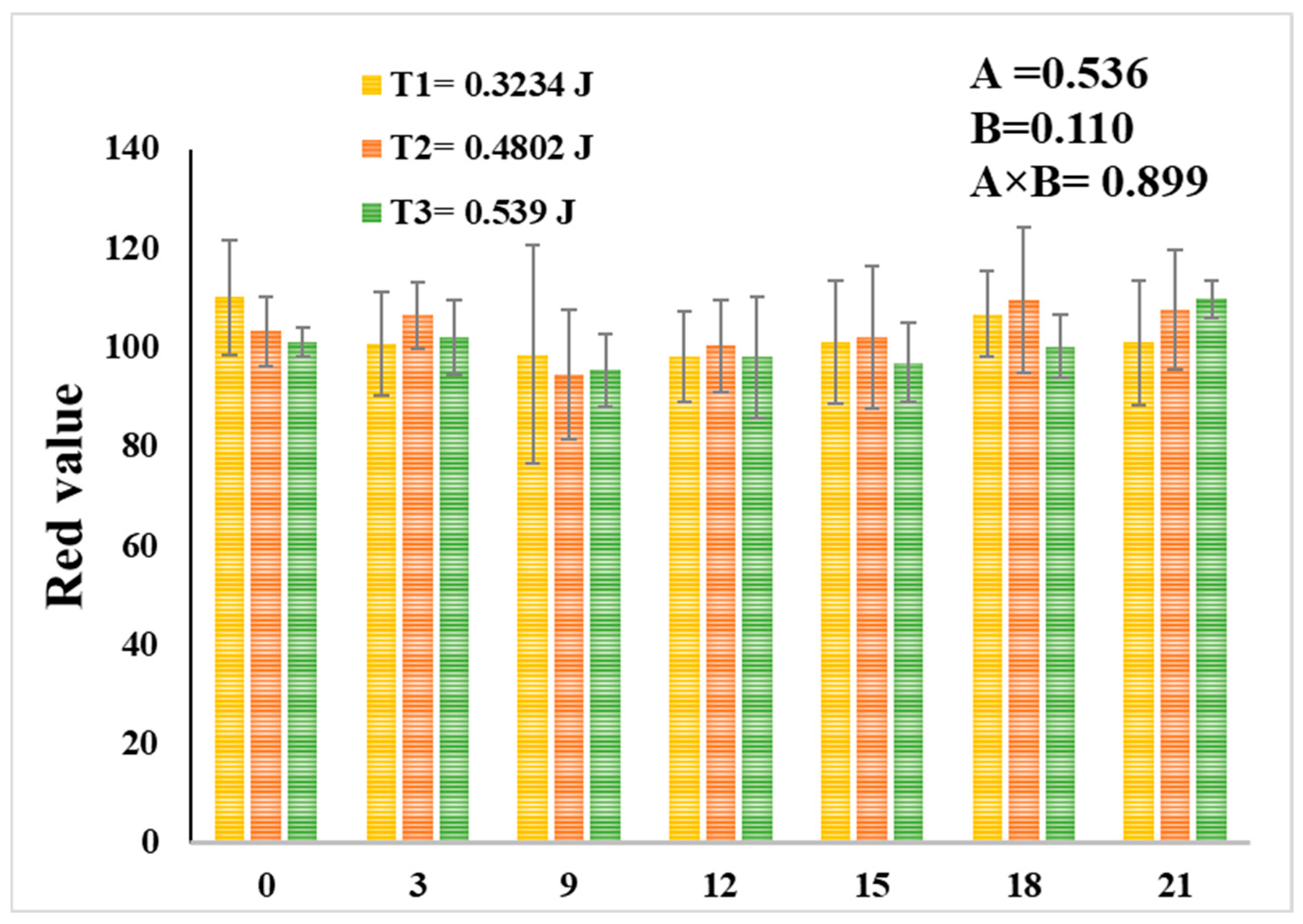

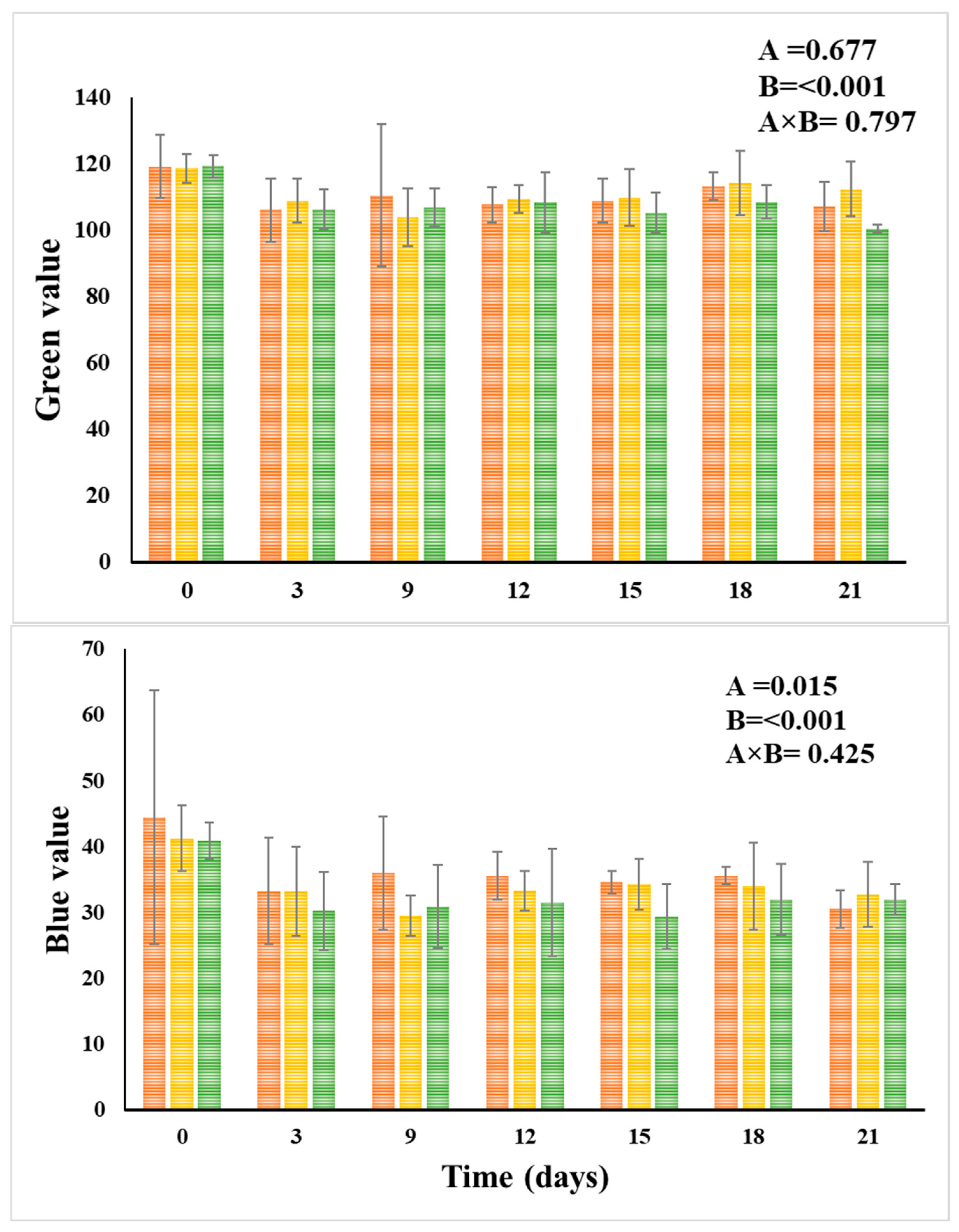

3.2. Effect of Damage on Color

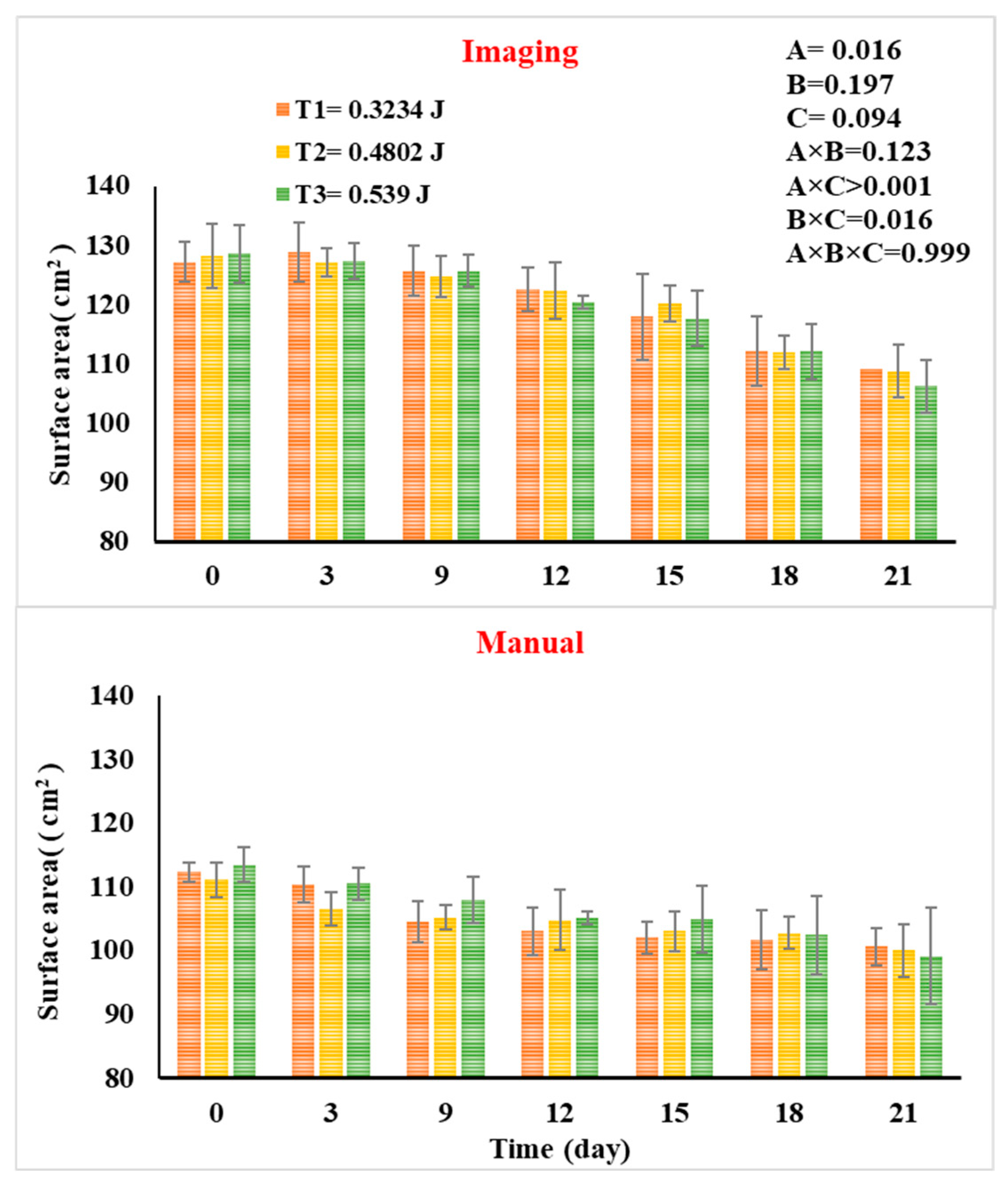

3.3. Effect of Damage on Surface Area

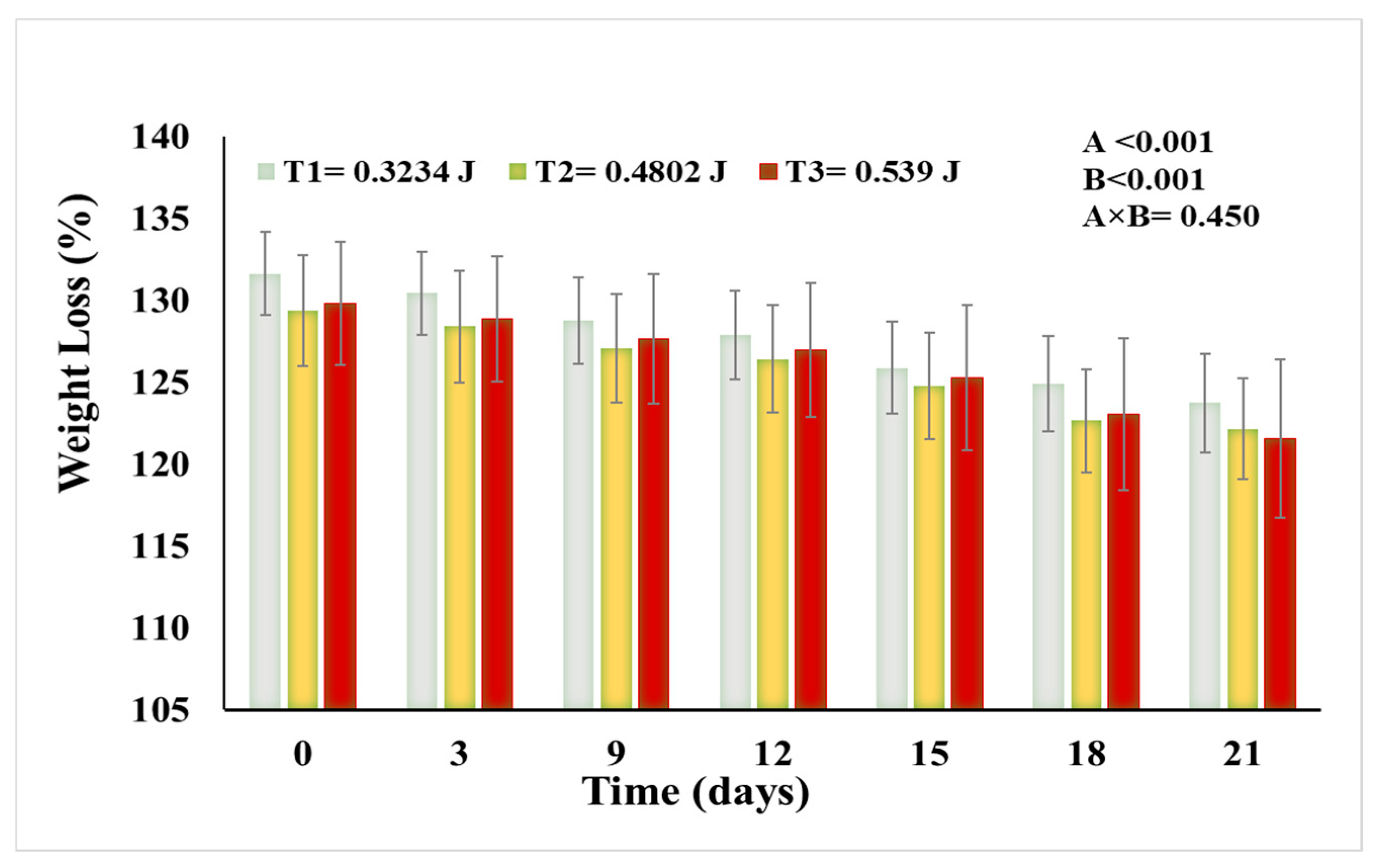

3.4. Effect of Damage on Weight Losses %

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Musacchi, S.; Serra, S. Apple fruit quality: Overview on pre-harvest factors. Sci. Hortic. 2018, 234, 409–430. [Google Scholar] [CrossRef]

- Akter, T.; Faqeerzada, M.A.; Kim, Y.; Pahlawan, M.F.R.; Aline, U.; Kim, H.; Kim, H.; Cho, B.-K. Hyperspectral imaging with multivariate analysis for detection of exterior flaws for quality evaluation of apples and pears. Postharvest Biol. Technol. 2025, 223, 113453. [Google Scholar] [CrossRef]

- Kistechok, A.; Wrona, D.; Krupa, T. Effect of storage conditions on the storability and nutritional value of new Polish apples grown in Central Poland. Agriculture 2023, 14, 59. [Google Scholar] [CrossRef]

- Singh, B.; Bhardwaj, V.; Kaur, K.; Kukreja, S.; Goutam, U. Potato periderm is the first layer of defence against biotic and abiotic stresses: A review. Potato Res. 2021, 64, 131–146. [Google Scholar]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Bio. Technol. 2016, 118, 111–119. [Google Scholar]

- Shafie, M.; Rajabipour, A.; Mobli, H. Determination of bruise incidence of pomegranate fruit under drop case. Int. J. Fruit Sci. 2017, 17, 296–309. [Google Scholar] [CrossRef]

- Xia, M.; Zhao, X.; Wei, X.; Guan, W.; Wei, X.; Xu, C.; Mao, L. Impact of packaging materials on bruise damage in kiwifruit during free drop test. Acta Physiol. Plantarum 2020, 42, 119. [Google Scholar]

- Diels, E.; van Dael, M.; Keresztes, J.; Vanmaercke, S.; Verboven, P.; Nicolai, B.; Saeys, W.; Ramon, H.; Smeets, B. Assessment of bruise volumes in apples using X-ray computed tomography. Postharvest Biol. Technol. 2017, 128, 24–32. [Google Scholar] [CrossRef]

- Li, Z.; Thomas, C. Quantitative Evaluation of Mechanical Damage to Fresh Fruits. Trends Food Sci. Technol. 2014, 35, 138–150. [Google Scholar] [CrossRef]

- Li, Y.; You, S.; Wu, S.; Wang, M.; Song, J.; Lan, W.; Tu, K.; Pan, L. Exploring the limit of detection on early implicit bruised ‘Korla’fragrant pears using hyperspectral imaging features and spectral variables. Postharvest Biol. Technol. 2024, 208, 112668. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R. Measurement and analysis of vibration and mechanical damage to bananas during long-distance interstate transport by multi-trailer road trains. Postharvest Biol. Technol. 2019, 158, 110977. [Google Scholar]

- Sun, Y.; Pessane, I.; Pan, L.; Wang, X. Hyperspectral Characteristics of Bruised Tomatoes as Affected by Drop Height and Fruit Size. LWT 2021, 141, 110863. [Google Scholar] [CrossRef]

- Ergun, M. Physical, physiochemical and Electrochemical Responses of ‘Galaxy’Apples to Mild Bruising. Eur. J. Hortic. Sci. 2017, 82, 244–250. [Google Scholar]

- Celik, H.K.; Ustun, H.; Erkan, M.; Rennie, A.E.; Akinci, I. Effects of bruising of ‘Pink Lady’apple under impact loading in drop test on firmness, colour and gas exchange of fruit during long term storage. Postharvest Biol. Technol. 2021, 179, 111561. [Google Scholar]

- Fu, H.; Du, W.; Yang, J.; Wang, W.; Wu, Z.; Yang, Z. Bruise measurement of fresh market apples caused by repeated impacts using a pendulum method. Postharvest Biol. Technol. 2023, 195, 112143. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Al-Habsi, N.; Jayasuriya, H.; Al-Attabi, Z. Machine vision system combined with multiple regression for damage and quality detection of bananas during storage. Appl. Food Res. 2024, 4, 100641. [Google Scholar] [CrossRef]

- Lin, M.; Fawole, O.A.; Saeys, W.; Wu, D.; Wang, J.; Opara, U.L.; Nicolai, B.; Chen, K. Mechanical damages and packaging methods along the fresh fruit supply chain: A review. Crit. Rev. Food Sci. Nutr. 2022, 63, 10283–10302. [Google Scholar] [CrossRef]

- Ahmadi, E.; Ghassemzadeh, H.R.; Sadeghi, M.; Moghaddam, M.; Neshat, S.Z. The effect of impact and fruit properties on the bruising of peach. J. Food Eng. 2010, 97, 110–117. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.O. Effects of bruising and storage duration on physiological response and quality attributes of pomegranate fruit. Sci. Hortic. 2020, 267, 109306. [Google Scholar] [CrossRef]

- Mahanti, N.K.; Pandiselvam, R.; Kothakota, A.; Chakraborty, S.K.; Kumar, M.; Cozzolino, D. Emerging non-destructive imaging techniques for fruit damage detection: Image processing and analysis. Trends Food Sci. Technol. 2021, 20, 418–438. [Google Scholar] [CrossRef]

- Akter, T.; Bhattacharya, T.; Kim, J.-H.; Kim, M.S.; Baek, I.; Chan, D.E.; Cho, B.-K. A comprehensive review of external quality measurements of fruits and vegetables using nondestructive sensing technologies. J. Agric. Food Res. 2024, 15, 101068. [Google Scholar] [CrossRef]

- Liu, J.; Sun, J.; Wang, Y.; Liu, X.; Zhang, Y.; Fu, H. Non-Destructive Detection of Fruit Quality: Technologies, Applications and Prospects. Foods 2025, 14, 2137. [Google Scholar] [CrossRef]

- Nturambirwe, J.F.I.; Opara, U.L. Machine learning applications to non-destructive defect detection in horticultural products. Biosyst. Eng. 2020, 189, 60–83. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, Z.; Liu, H.; Wang, H.; Li, J.; Zhao, L. Detection of early bruise in apple using near-infrared camera imaging technology combined with deep learning. Infrared Phys. Technol. 2022, 127, 104442. [Google Scholar] [CrossRef]

- Al Ohali, Y. Computer vision based date fruit grading system: Design and implementation. J. King Saud. Univ. Comput. Inf. Sci. 2011, 23, 29–36. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B. Evaluation of Physio-chemical characteristics of ‘Fard’banana using computer vision system. J. Agric. Food Res. 2024, 15, 101057. [Google Scholar]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Investigating bruise susceptibility of pomegranate cultivars during postharvest handling. Afr. J. of Rural Dvlpmt. 2017, 2, 33–39. [Google Scholar]

- Du, D.; Wang, B.; Wang, J.; Yao, F.; Hong, X. Prediction of bruise susceptibility of harvested kiwifruit (Actinidia chinensis) using finite element method. Postharvest Biol. Technol. 2019, 152, 36–44. [Google Scholar] [CrossRef]

- Dagdelen, C.; Aday, M.S. The effect of simulated vibration frequency on the physico-mechanical and physicochemical properties of peach during transportation. LWT 2021, 137, 110497. [Google Scholar] [CrossRef]

- Htike, T.; Saengrayap, R.; Aunsri, N.; Tontiwattanakul, K.; Chaiwong, S. Investigation and Evaluation of Impact Bruising in Guava Using Image Processing and Response Surface Methodology. Horticulturae 2021, 7, 411. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M. Effect of mechanical damage on the quality characteristics of banana fruits during short-term storage. Discover Food 2022, 2, 4. [Google Scholar] [CrossRef]

- Hendricks, R.L.; Olsen, N.; Thornton, M.K.; Hatzenbuehler, P. Susceptibility of Potato Cultivars to Blackspot and Shatter Bruise at Three Impact Heights. Am. J. Potato Res. 2022, 99, 358–368. [Google Scholar] [CrossRef]

- Lu, F.; Ishikawa, Y.; Kitazawa, H.; Satake, T. Assessment and Prediction of Repetitive Impact Damage to Apple Fruit using Pressure-Sensitive Film Technique. J. Food Agric. Environ. 2012, 10, 156–160. [Google Scholar]

- Razavi, M.S.; Asghari, A.; Azadbakh, M.; Shamsabadi, H.-A. Analyzing the pear bruised volume after static loading by Magnetic Resonance Imaging (MRI). Sci. Hortic. 2018, 229, 33–39. [Google Scholar] [CrossRef]

- Molina-Corral, F.J.; Espino-Diaz, M.; Jacobo, J.L.; Mattinson, S.D.; Fellman, J.K.; Sepulveda, D.R.; Gonzalez-Aguilar, G.A.; Salas-Salazar, N.A.; Olivas, G.I. Quality attributes during maturation of ‘Golden Delicious’ and ‘Red Delicious’ apples grown in two geographical regions with different environmental conditions. Not. Bot. Horti Agrobot. Cluj-Napoca 2021, 49, 12241. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Dobrzanski, B.; Rybezynski, R. Colour change of apple as a result of storage, shelf-life, and bruising. Int. Agrophysics 2002, 16, 261–268. [Google Scholar]

- Pathare, P.B.; Al-Dairi, M. Bruise damage and quality changes in impact-bruised, stored tomatoes. Horticulturae 2021, 7, 113. [Google Scholar] [CrossRef]

- Htike, T.; Saengrayap, R.; Kitazawa, H.; Chaiwong, S. Fractal image analysis and bruise damage evaluation of impact damage in guava. Inf. Process. Agric. 2024, 11, 217–227. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Jayasuriya, H.; Al-Attabi, Z. Evaluation of chemical quality attributes in bruised bananas during storage. LWT 2024, 197, 115904. [Google Scholar] [CrossRef]

- Pérez-López, A.; Chávez-Franco, S.; Villaseñor-Perea, C.; Espinosa-Solares, T.; Hernández-Gómez, L.; Lobato-Calleros, C. Respiration rate and mechanical properties of peach fruit during storage at three maturity stages. J. Food Eng. 2014, 142, 111–117. [Google Scholar] [CrossRef]

- Huang, H. Molecular Regulation Mechanisms of Ripening, Senescence and Stress Resistance in Fruits and Vegetables. Agronomy 2024, 14, 1703. [Google Scholar] [CrossRef]

- Adi, D.D.; Oduro, I.N.; Tortoe, C. Physicochemical changes in plantain during normal storage ripening. Sci. Afr. 2019, 6, e00164. [Google Scholar] [CrossRef]

- Wei, X.; Xie, D.; Mao, L.; Xu, C.; Luo, Z.; Xia, M.; Zhao, X.; Han, X.; Lu, W. Excess water loss induced by simulated transport vibration in postharvest kiwifruit. Sci. Hort. 2019, 250, 113–120. [Google Scholar] [CrossRef]

| Treatment | Ball Mass (g) | Impact Energy (J) | Level of Damage |

|---|---|---|---|

| 1 | 66 | 0.3234 | Low |

| 2 | 98 | 0.4802 | Medium |

| 3 | 110 | 0.539 | High |

| Chrome | Hue° | |||||

|---|---|---|---|---|---|---|

| Manual Measurements | ||||||

| Time | T1 | T2 | T3 | T1 | T2 | T3 |

| 0 | 40.76 ± 2.60 | 40.76 ± 2.60 | 40.76 ± 2.60 | 109.15°± 0.44 | 105.15° ± 0.44 | 105.15° ± 0.44 |

| 3 | 41.92 ± 1.45 | 41.6 ± 2.83 | 42.39 ± 1.42 | 109.74° ± 1.24 | 108.55° ± 1.24 | −109.15° ± 0.71 |

| 9 | 41.16 ± 3.54 | 42.41 ± 2.26 | 42.61 ± 2.13 | 109.46° ± 1.11 | 108.59° ± 1.10 | 108.78° ± 1.16 |

| 11 | 43.13 ± 1.03 | 43.66 ± 2.72 | 43.38 ± 1.60 | 108.50° ± 0.91 | 108.60° ± 0.72 | 108.50° ± 1.08 |

| 15 | 43.87 ± 1.78 | 42.1 ± 2.41 | 42.69 ± 1.96 | 109.38° ± 0.64 | 107.71° ± 1.01 | 107.17° ± 0.68 |

| 18 | 43.98 ± 1.82 | 43.88 ± 3.36 | 44.9 ± 2.01 | 107.36° ± 1.08 | 106.82° ± 0.76 | 107.00° ± 0.35 |

| 21 | 43.3 ± 1.53 | 42.54 ± 2.67 | 43.51 ± 0.78 | 106.11° ± 1.10 | 106.51° ± 0.69 | 104.43° ± 0.64 |

| Computer vision system | ||||||

| Time | T1 | T2 | T3 | T1 | T2 | T3 |

| 0 | 39.38 ± 1.07 | 39.38 ± 1.07 | 39.38 ± 1.07 | 114.41° ± 1.09 | 114.41° ± 1.09 | 114.41° ± 1.09 |

| 3 | 40.61± 1.50 | 41.77± 2.43 | 41.92 ± 2.43 | 108.04° ± 0.70 | 105.86° ± 0.80 | 107.01° ± 0.78 |

| 9 | 41.66 ± 2.10 | 41.43 ± 1.13 | 42.26 ± 2.63 | 112.18° ± 0.38 | 110.43° ± 0.34 | 111.69° ± 0.82 |

| 11 | 40.46 ± 1.44 | 40.33 ± 2.14 | 42.54 ± 1.33 | 110.98° ± 0.60 | 109.49° ± 0.62 | 110.88° ± 0.72 |

| 15 | 41.28 ± 1.82 | 41.89 ± 1.40 | 41.97 ± 1.95 | 109.50° ± 0.26 | 109.37° ± 0.42 | 109.58° ± 0.67 |

| 18 | 42.80 ± 2.47 | 43.79 ± 1.78 | 42.34 ± 1.38 | 108.55° ± 0.28 | 107.22° ± 0.59 | 109.66° ± 0.81 |

| 21 | 42.20 ± 1.97 | 43.56 ± 2.55 | 38.88 ± 2.52 | 108.12° ± 0.36 | 107.33° ± 0.54 | 97.60° ± 1.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Riyami, Z.; Al-Dairi, M.; Pathare, P.B.; Kramchote, S. Using a Computer Vision System for Monitoring the Exterior Characteristics of Damaged Apples. AgriEngineering 2025, 7, 318. https://doi.org/10.3390/agriengineering7100318

Al-Riyami Z, Al-Dairi M, Pathare PB, Kramchote S. Using a Computer Vision System for Monitoring the Exterior Characteristics of Damaged Apples. AgriEngineering. 2025; 7(10):318. https://doi.org/10.3390/agriengineering7100318

Chicago/Turabian StyleAl-Riyami, Zamzam, Mai Al-Dairi, Pankaj B. Pathare, and Somsak Kramchote. 2025. "Using a Computer Vision System for Monitoring the Exterior Characteristics of Damaged Apples" AgriEngineering 7, no. 10: 318. https://doi.org/10.3390/agriengineering7100318

APA StyleAl-Riyami, Z., Al-Dairi, M., Pathare, P. B., & Kramchote, S. (2025). Using a Computer Vision System for Monitoring the Exterior Characteristics of Damaged Apples. AgriEngineering, 7(10), 318. https://doi.org/10.3390/agriengineering7100318