Simulation Analysis of Energy Inputs Required by Agricultural Machines to Perform Field Operations

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Tests

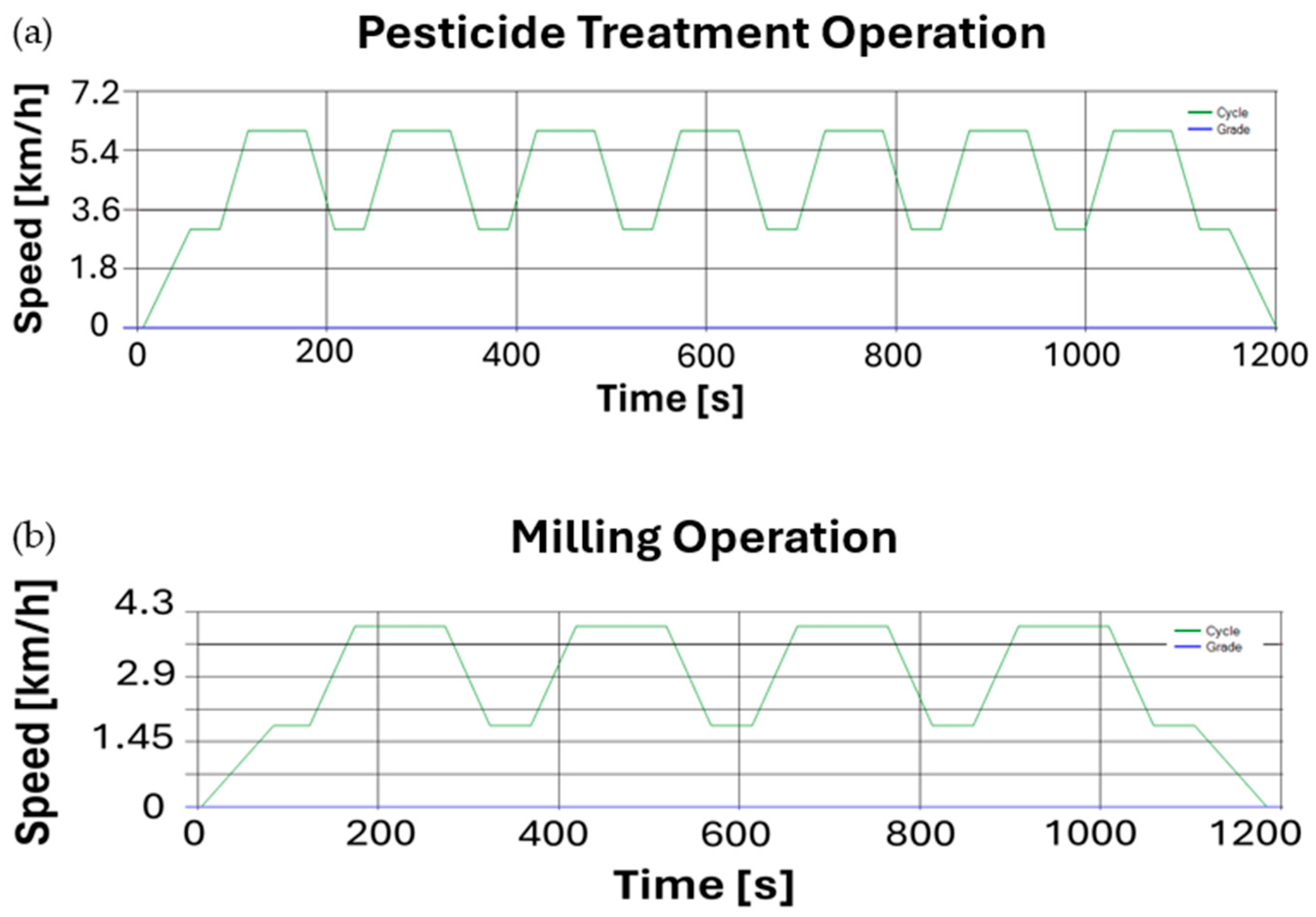

2.1.1. Pesticide Treatment

2.1.2. Milling Operation

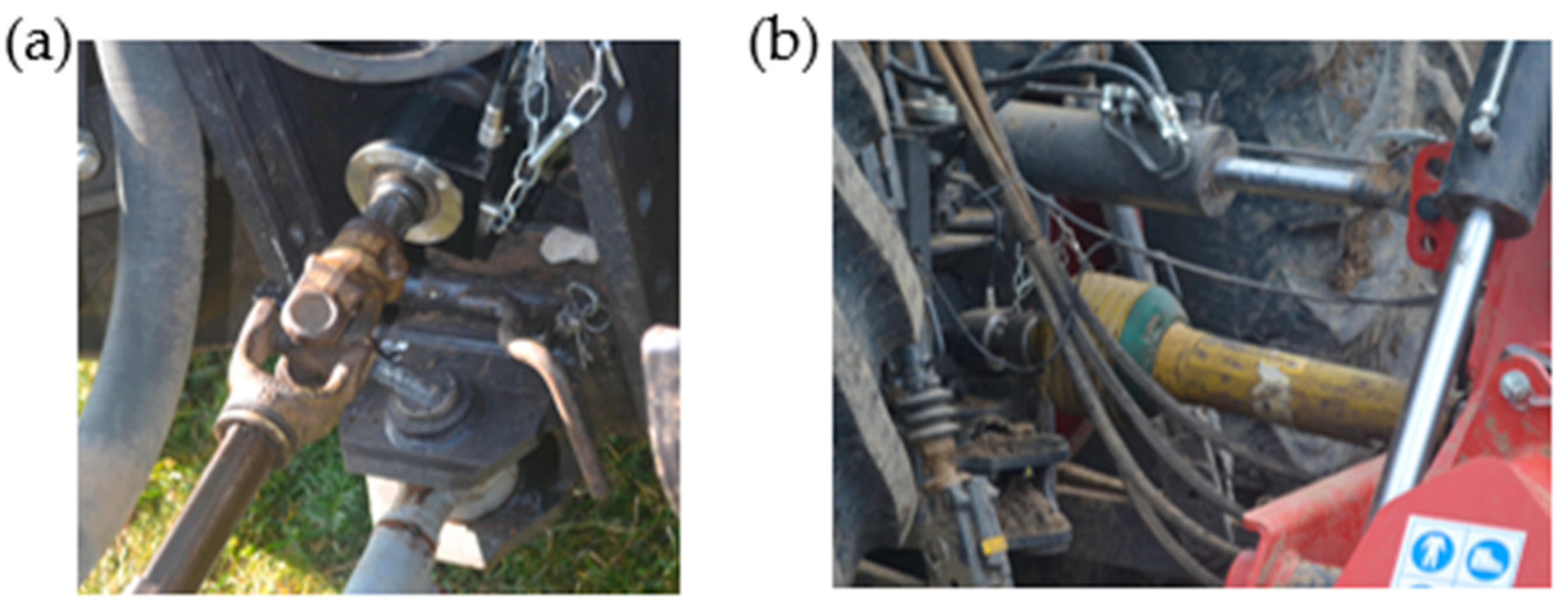

2.2. Shaft Torque and Power Monitoring System Transducer

2.3. Modeling and Simulation Software

3. Results

3.1. Shaft Torque and Power Monitoring System Transducer Measurements

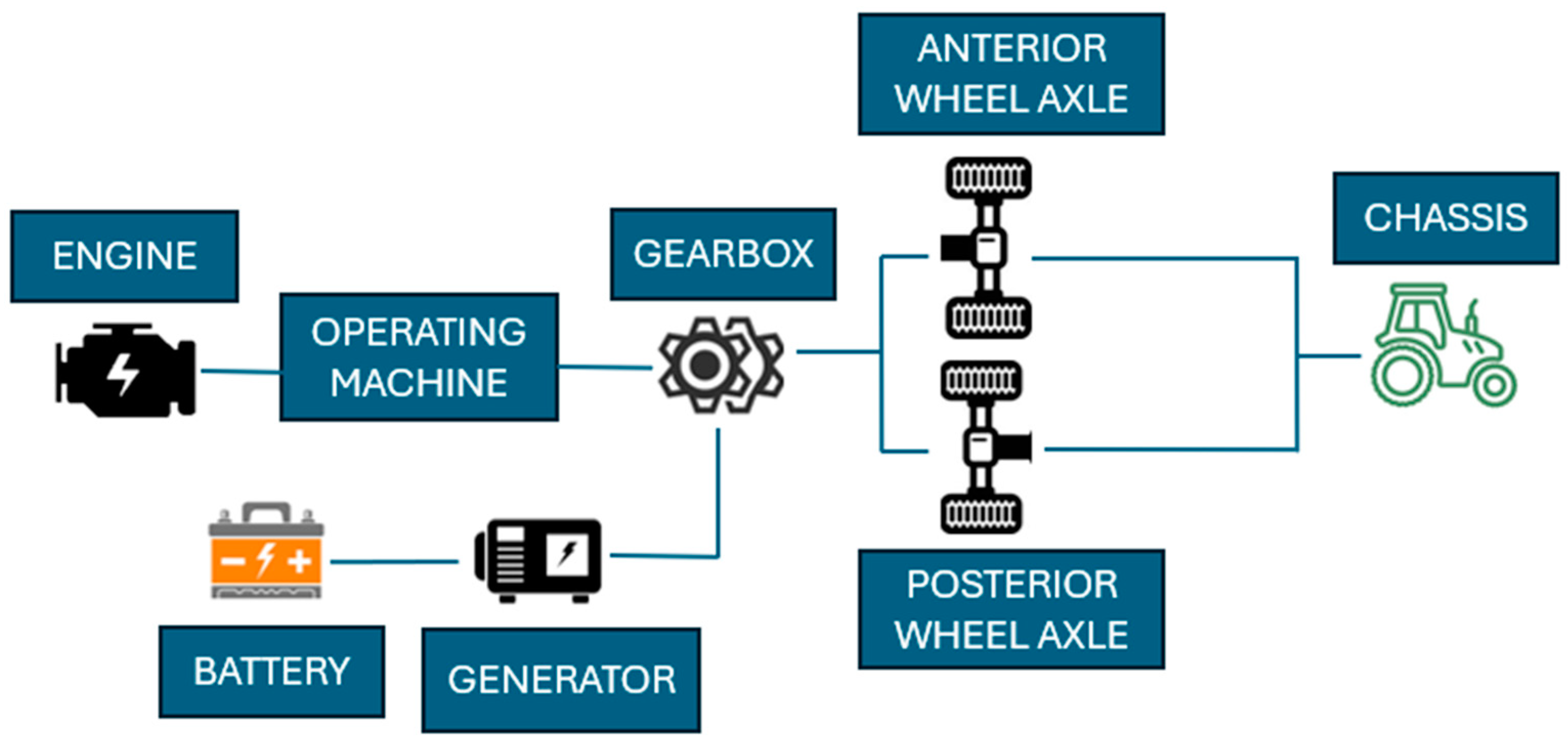

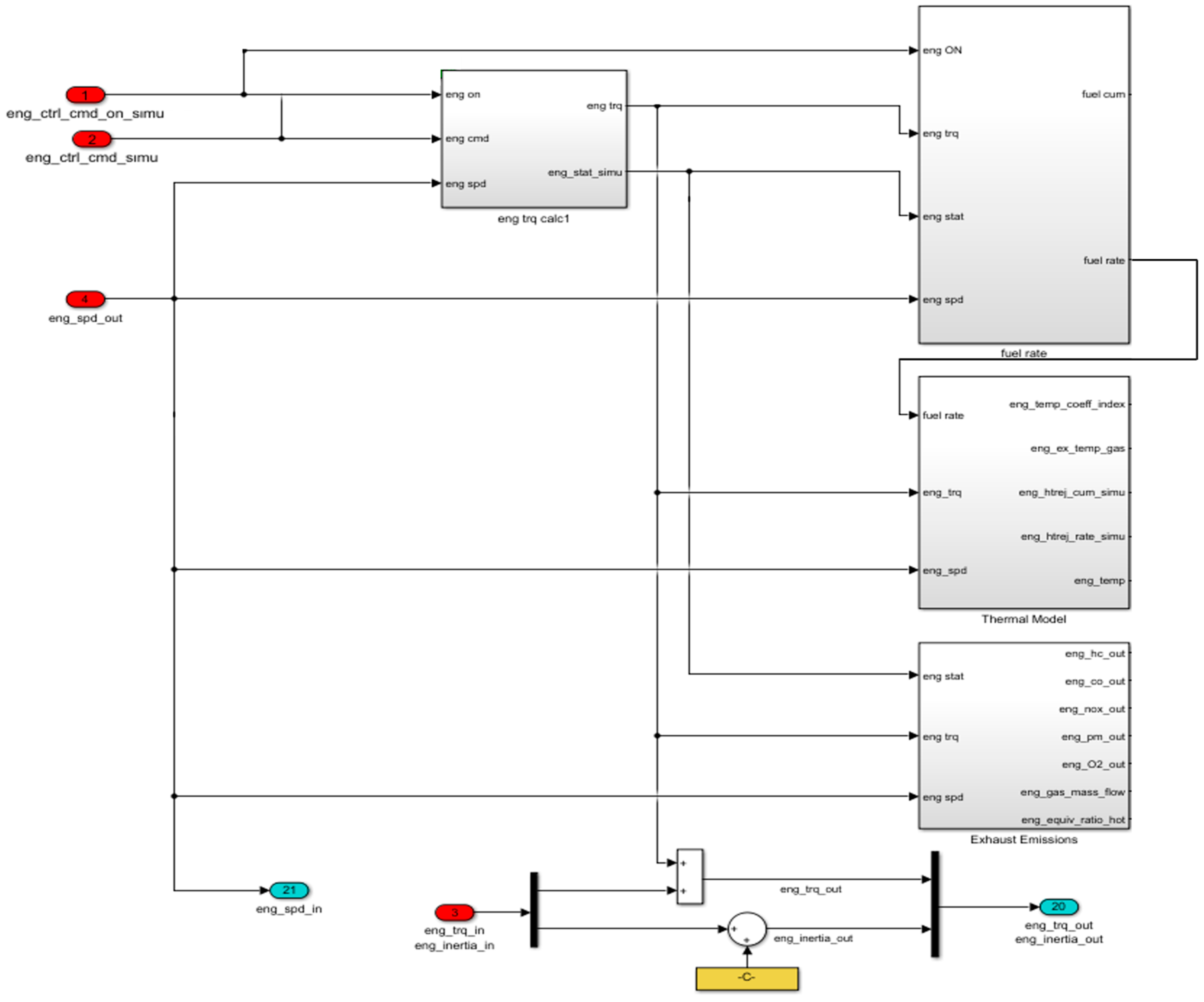

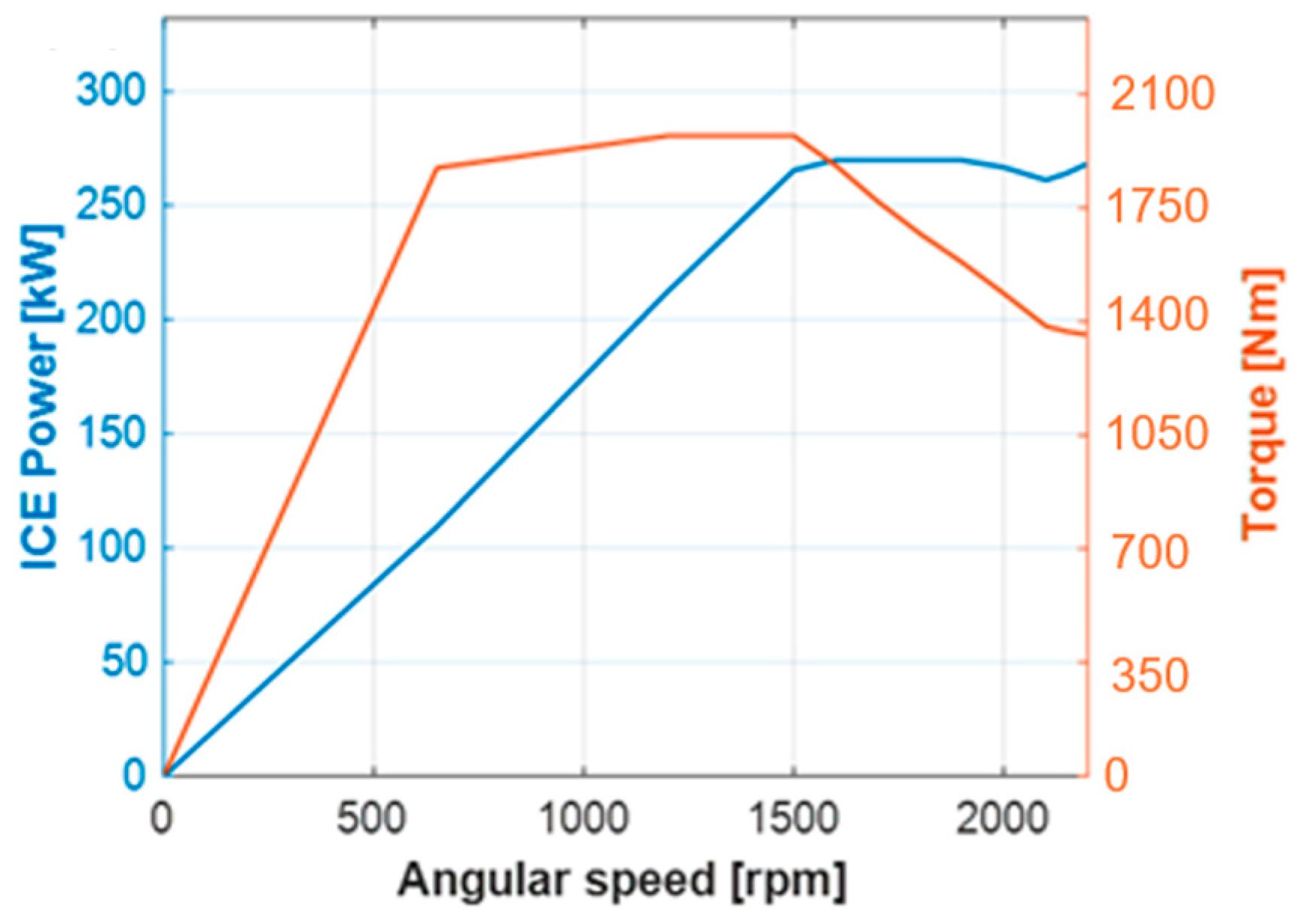

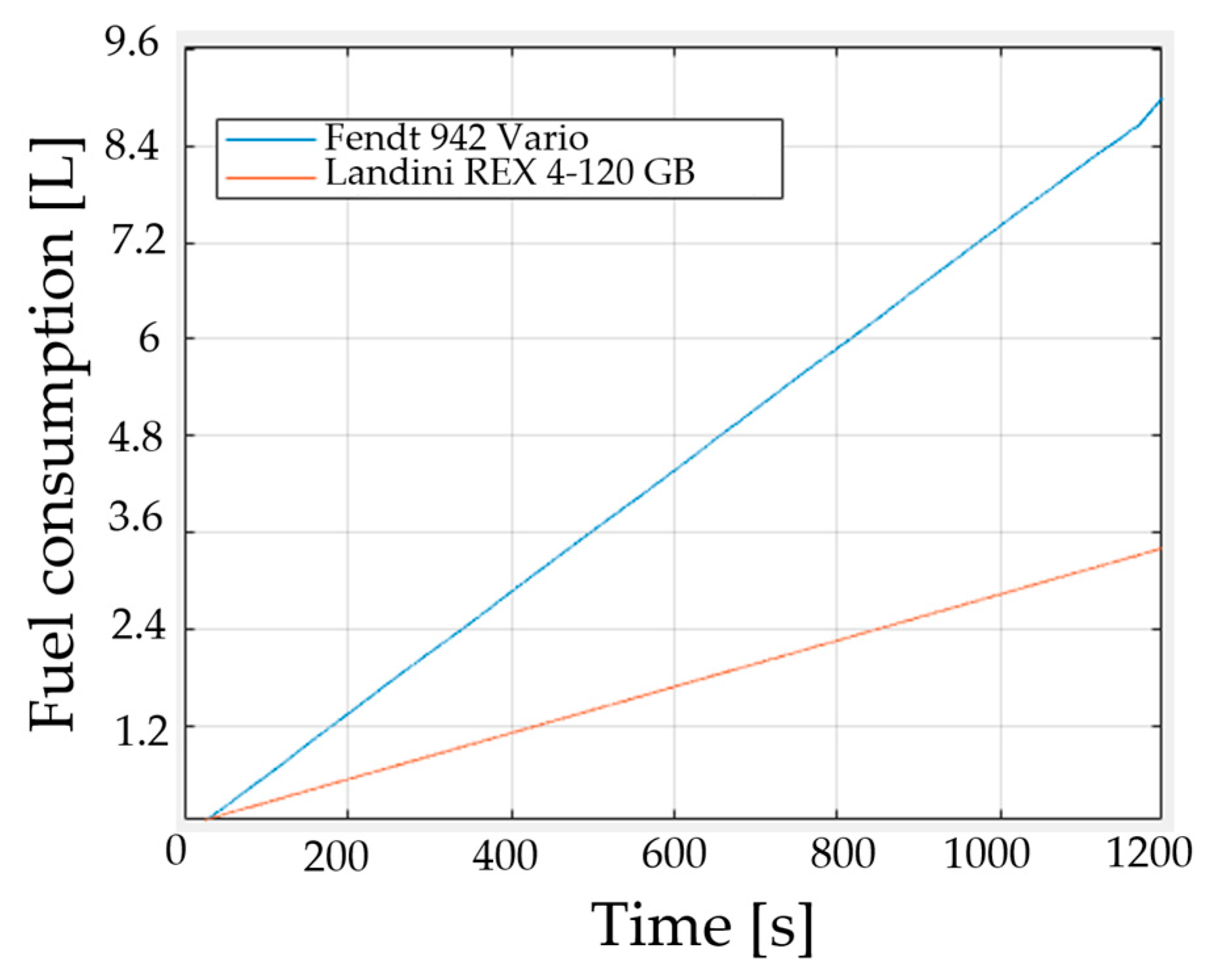

3.2. Simulation of Modeled Agricultural Tractors

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S.; Mittal, J.P. Energy in Production Agriculture; Mittal Publications: New Delhi, India, 1992. [Google Scholar]

- Martinho, V.J.P.D. Direct and indirect energy consumption in farming: Impacts from fertilizer use. Energy 2021, 236, 121504. [Google Scholar] [CrossRef]

- Lampridi, M.; Kateris, D.; Sørensen, C.G.; Bochtis, D. Energy Footprint of Mechanized Agricultural Operations. Energies 2020, 13, 769. [Google Scholar] [CrossRef]

- Rokicki, T.; Perkowska, A.; Klepacki, B.; Bórawski, P.; Bełdycka-Bórawska, A.; Michalski, K. Changes in energy consumption in agriculture in the EU countries. Energies 2021, 14, 1570. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy use in open-field agriculture in the EU: A critical review recommending energy efficiency measures and renewable energy sources adoption. Renew. Sustain. Energy Rev. 2022, 158, 112098. [Google Scholar] [CrossRef]

- Bowers, W. Agricultural field equipment. In Energy in Farm Production; Fluck, R.C., Ed.; Elsevier Science Publishers B.V.: Amsterdam, The Netherlands, 1992; pp. 117–129. [Google Scholar]

- Felten, D.; Fröba, N.; Fries, J.; Emmerling, C. Energy balances and greenhouse gas-mitigation potentials of bioenergy cropping systems (Miscanthus, rapeseed, and maize) based on farming conditions in Western Germany. Renew. Energy 2013, 55, 160–174. [Google Scholar] [CrossRef]

- Shamshirband, S.; Khoshnevisan, B.; Yousefi, M.; Bolandnazar, E.; Anuar, N.B.; Wahab, A.W.; Khan, S.U. A multiobjective evolutionary algorithm for energy management of agricultural systems—A case study in Iran. Renew. Sustain. Energy Rev. 2015, 44, 457–465. [Google Scholar] [CrossRef]

- Aguilera, E.; Guzmán Casado, G.; Infante Amate, J. Embodied energy in agricultural inputs. In Documentos de Trabajo de la Sociedad de Estudios de Historia Agraria 1507; Sociedad Española de Historia Agraria: Madrid, Spain, 2015. [Google Scholar]

- Grisso, R.D.; Perumpral, J.V.; Vaughan, D.H.; Roberson, G.T.; Pitman, R.M. Predicting tractor diesel fuel consumption. Agric. Eng. Int. CIGR J. 2010, 12, 67–74. [Google Scholar]

- Lee, D.H.; Choi, C.H.; Chung, S.O.; Kim, Y.J.; Inoue, E.; Okayasu, T. Evaluation of tractor fuel efficiency using dynamometer and baler operation cycle. J. Fac. Agric. 2016, 61, 173–182. [Google Scholar] [CrossRef]

- Alcock, R. Tractor-Implement Systems; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Wal, T.V.d.; Soto, I.; Gómez-Barbero, M.; Barnes, A.; Eory, V. Precision Agriculture Technologies Positively Contributing to GHG Emissions Mitigation, Farm Productivity and Economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Renius, K.T. Fundamentals of Tractor Design; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Mantoam, E.J.; Romanelli, T.L.; Gimenez, L.M. Energy demand and greenhouse gases emissions in the life cycle of tractors. Biosyst. Eng. 2016, 151, 158–170. [Google Scholar] [CrossRef]

- Zamagni, A.; Masoni, P.; Buttol, P.; Raggi, A.; Buonamici, R. Finding life cycle assessment research direction with the aid of meta-analysis. J. Ind. Ecol. 2012, 16, S39–S52. [Google Scholar] [CrossRef]

- Lovarelli, D.; Fiala, M.; Larsson, G. Fuel consumption and exhaust emissions during on-field tractor activity: A possible improving strategy for the environmental load of agricultural mechanisation. Comput. Electron. Agric. 2018, 151, 238–248. [Google Scholar] [CrossRef]

- Paciolla, F.; Patimisco, P.; Farella, A.; Quartarella, T.; Pascuzzi, S. Performance evaluation of hybrid-electric architectures for agricultural tractors. In Proceedings of the International Symposium on Farm Machinery and Processes Management in Sustainable Agriculture, Cham, Switzerland, 12–14 June 2024; Springer Nature: Cham, Switzerland, 2024; pp. 346–356. [Google Scholar]

- Pascuzzi, S. The effects of the forward speed and air volume of an air-assisted sprayer on spray deposition in tendone trained vineyards. J. Agric. Eng. 2013, 44, e18. [Google Scholar] [CrossRef]

- Crolla, D.A. Torsional Vibration Analysis of tractor and machine PTO drivelines. J. Agric. Eng. Res. 1978, 23, 259–272. [Google Scholar] [CrossRef]

- Karbowski, D.; Pagerit, S. Autonomie 2023, a plug-and-play software architecture. In Proceedings of the Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–3. [Google Scholar]

- Kim, Y.-S.; Kim, W.-S.; Siddique, M.A.A.; Baek, S.-Y.; Baek, S.-M.; Cheon, S.-H.; Lee, S.-D.; Lee, K.-H.; Hong, D.-H.; Park, S.-U.; et al. Power Transmission Efficiency Analysis of 42 kW Power Agricultural Tractor According to Tillage Depth during Moldboard Plowing. Agronomy 2020, 10, 1263. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability Evaluation of Hybrid Agriculture-Tractor Powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Koniuszy, A.; KostencKi, P.; Berger, A.; Golimowski, W. Power performance of farm tractor in field operations. Eksploat. Niezawodn. 2017, 19, 43–47. [Google Scholar] [CrossRef]

- Adewoyin, A.O.; Ajav, E.A. Fuel consumption of some tractor models for ploughing operations in the sandy-loam soil of Nigeria at various speeds and ploughing depths. Agric. Eng. Int. CIGR J. 2013, 15, 67–74. [Google Scholar]

- Cech, R.; Leisch, F.; Zaller, J.G. Pesticide Use and Associated Greenhouse Gas Emissions in Sugar Beet, Apples, and Viticulture in Austria from 2000 to 2019. Agriculture 2022, 12, 879. [Google Scholar] [CrossRef]

- Fathollahzadeh, H.; Mobli, H.; Tabatabaie, S. Effect of ploughing depth on average and instantaneous tractor fuel consumption with three-share disc plough. Int. Agrophys. 2009, 23, 399–402. [Google Scholar]

- Moitzi, G.; Haas, M.; Wagentristl, H.; Boxberger, J.; Gronauer, A. Energy consumption in cultivating and ploughing with traction improvement system and consideration of the rear furrow wheel-load in ploughing. Soil Tillage Res. 2013, 134, 56–60. [Google Scholar] [CrossRef]

- Gupta, H.N. Fundamentals of Internal Combustion Engines; PHI Learning Pvt. Ltd.: New Delhi, India, 2012. [Google Scholar]

- Mollenhauer, K.; Tschöke, H. (Eds.) Handbook of Diesel Engines; Springer: Berlin, Germany, 2010; Volume 1. [Google Scholar]

- Ortiz-Cañavate, J.; Gil-Sierra, J.; Casanova-Kindelán, J.; Gil-Quirós, V. Classification of agricultural tractors according to the energy efficiencies of the engine and the transmission based on OECD tests. Appl. Eng. Agric. 2009, 25, 475–480. [Google Scholar] [CrossRef]

- Al-Sager, S.M.; Almady, S.S.; Marey, S.A.; Al-Hamed, S.A.; Aboukarima, A.M. Prediction of specific fuel consumption of a tractor during the tillage process using an artificial neural network method. Agronomy 2024, 14, 492. [Google Scholar] [CrossRef]

| Parameter | Landini REX 4-120 GB | Fendt 942 Vario |

|---|---|---|

| ICE Maximum Power @ 2200 rpm [kW] | 77 | 261 |

| Maximum Torque @ 1600 rpm [Nm] | 420 | 1970 |

| Mass of the tractor [kg] | 2800 | 11,700 |

| Anterior wheel radius [mm] | 506 | 872 |

| Posterior wheel radius [mm] | 600 | 1084 |

| Parameter | Min | Max | Average | Standard Deviation |

|---|---|---|---|---|

| AGRI IONICA model AGR/P | ||||

| Angular Speed (rad/s) | 56.1 | 56.5 | 56.4 | 0.1 |

| Torque (Nm) | 258.2 | 365.9 | 307.1 | 21.2 |

| Power (kW) | 14.5 | 20.7 | 17.3 | 1.2 |

| Series DG45—400 milling machine | ||||

| Angular Speed (rad/s) | 99.8 | 102.2 | 101.1 | 0.5 |

| Torque (Nm) | 919.9 | 1808 | 1429.6 | 166.8 |

| Power (kW) | 91.8 | 184.8 | 144.5 | 16.6 |

| Parameter | AGRI IONICA Model AGR/P | Series DG45-400 Milling Machine |

|---|---|---|

| Mass [kg] | 1350 | 3600 |

| Mean Power required at PTO [kW] | 17.3 | 144.5 |

| Parameter | Landini REX 4-120 GB | Reference | Fendt 942 Vario | Reference | Fendt 942 Vario On-Board Instrumentation |

|---|---|---|---|---|---|

| Fuel Consumption [L∙ha−1] | 7.8 | 7.0 [26] | 23.2 | 24.0 [27] | 25.2 |

| CO2 emissions [kg∙ha−1] | 26.5 | * | 68.4 | * | * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paciolla, F.; Łyp-Wrońska, K.; Quartarella, T.; Pascuzzi, S. Simulation Analysis of Energy Inputs Required by Agricultural Machines to Perform Field Operations. AgriEngineering 2025, 7, 7. https://doi.org/10.3390/agriengineering7010007

Paciolla F, Łyp-Wrońska K, Quartarella T, Pascuzzi S. Simulation Analysis of Energy Inputs Required by Agricultural Machines to Perform Field Operations. AgriEngineering. 2025; 7(1):7. https://doi.org/10.3390/agriengineering7010007

Chicago/Turabian StylePaciolla, Francesco, Katarzyna Łyp-Wrońska, Tommaso Quartarella, and Simone Pascuzzi. 2025. "Simulation Analysis of Energy Inputs Required by Agricultural Machines to Perform Field Operations" AgriEngineering 7, no. 1: 7. https://doi.org/10.3390/agriengineering7010007

APA StylePaciolla, F., Łyp-Wrońska, K., Quartarella, T., & Pascuzzi, S. (2025). Simulation Analysis of Energy Inputs Required by Agricultural Machines to Perform Field Operations. AgriEngineering, 7(1), 7. https://doi.org/10.3390/agriengineering7010007