Abstract

The Purdue hog cooling pad has previously been demonstrated to mitigate heat stress in lactating sows by conductively transferring heat from a sow to cool water running through an integral heat exchanger. Coolant effectiveness, which describes how much heat is removed per volume of water flushed through the cooling pad, is used to compare the operation under varying conditions. Past studies have indicated that the intermittent flow of cooling water achieves a greater coolant effectiveness than continuous flow operational schemes. An electronic control system was implemented with the current cooling pad design to allow for the automated control of a solenoid valve to create the intermittent flow conditions. All testing was performed using 18 ± 1 °C inlet water. Potential control schemes were categorized into two groups, temporal and temperature threshold. The temporal schemes opened the solenoid for 30 s, enough time to flush the entire contents of the cooling coils, before closing for 3, 6, or 9 min. The temperature threshold control schemes utilized feedback from thermal probes embedded beneath the surface of the cooling pad to open the solenoid for 30 s, when a maximum surface temperature was detected. Trigger temperatures of 28.0, 29.5, or 31.0 °C were used. The temperature threshold control schemes achieved greater heat transfer rates (348, 383, 268 W) compared to the temporal control schemes (324, 128, 84 W). The cooling effectiveness for all control schemes ranged from 46.6 to 64.7 kJ/L. The tested intermittent flow control schemes in this study achieved greater cooling effectiveness than continuous flow systems from previous studies (time: 51 kJ/L; temperature: 61 kJ/L; steady: 5.8 kJ/L), although the temporal control schemes exhibited lower heat transfer rates (time: 180 W; temperature: 330 W; steady: 305 W).

1. Introduction

Lactating sows have been determined to be a vulnerable lifecycle stage in commercial swine production that is highly susceptible to heat stress [1,2]. Heat stress in lactating sows has been shown to reduce feed intake, milk production, and subsequent fertility. It can ultimately cause death in extreme situations [3,4]. This problem exists due to the disparity between the thermal neutral zone of lactating sows and that of piglets, particularly when they are first born [2,4,5]. Over the past few decades, sows have been genetically selected to produce larger litters and have greater milk production [3,6,7,8]. As a result, present-day sows produce significantly more heat than the average sows in the past [7,9]. Additionally, the mean piglet birth weight has decreased due to larger litter sizes, which has also increased piglet susceptibility to hypothermia at temperatures below their thermoneutral zone [10]. This has further increased the disparity between the sow’s comfort zone and that of her piglets, and most farm managers opt to keep their barns warmer, aiding piglets’ survivability with temperatures above the sow’s comfort zone. Heat stress is also a contributing factor to the seasonal decrease in fertility during the hot summer months [3,9]. On a global scale, more than fifty percent of 2018 pork production and nearly fifty percent of 2019 pork production is in tropical or subtropical environments [11]. This means a significant number of hogs are produced in tropical and subtropical climates, where the detrimental effects of heat stress are apparent for more than a few months each year.

Heat stress causes both short-term and long-term negative effects in sows, including in extreme cases, death [3,4]. The short-term effects of heat stress include increased skin temperature, increased internal temperature, and an increased respiration rate [12]. Sows experiencing heat stress will reduce their feed intake in order to reduce their internal heat production [4,9,12,13,14]. Heat stress reduces milk production [9,14], which affects piglet growth and ultimately causes lighter litter weights at weaning [14,15]. At high ambient temperatures, lactating sows have been shown to spend more time sitting and standing, less time nursing, and making more frequent trips to the feeder and waterer without using them [16,17,18,19]. The long-term effects of heat stress can cause sows to have increased wean-to-estrus intervals and reduced future litter sizes [1,14]. This ultimately makes the sow less productive for the remainder of her life, resulting in economic losses for the producer.

Various efforts have been made to selectively cool sows without affecting the piglets, and to mitigate their heat stress without decreasing the ambient temperature of the farrowing barn [18,20,21,22]. Floor cooling methods have great potential to successfully mitigate heat stress in sows [23]. One such effort was the development of a cooling pad at Purdue University [24]. Initial development occurred as part of a senior capstone project [25]. The cooling pad design has moved through multiple rounds of manufacturing, testing, and modification [26,27,28,29,30,31,32,33,34,35], with the aim to create a commercially viable product, that has well-characterized heat transfer properties and effectively and efficiently removes excess heat from crated, lactating sows in farrowing houses, without causing any adverse effects on the sow or piglets.

The second prototype cooling pad design increased the number of cooling pipes inside the pad from six to eight. The inlet and outlet pipes were moved to the front of the cooling pad from the left side, as well. This made the flow of water symmetrical, with the coolest water from the inlet starting in the center and working its way to the left and right sides before exiting the pad. The eight-pipe design was shown to have a smoother and more uniform temperature distribution across the top of the cooling pad than the six-pipe design. The cooling pipe design in the eight-pipe unit was more optimized than the six-pipe unit. Instead of passing across the entire surface, from one side to the other, the eight-pipe unit split the coolant in the center and pushed the flow toward the outside through two different pathways. At a continuous flowrate of , the eight-pipe design had a 16.7% increased heat rejection rate and a 16.1% increased cooling effectiveness compared to the six-pipe [26]. Table 1 summarizes the heat rejection rate and cooling effectiveness for various coolant cycles on both pad designs from that study. The effective flowrate, a value averaged over the whole coolant cycle, has been included for comparison.

Table 1.

Heat transfer properties comparison of 6- and 8-pipe design hog cooling pads (Cabezon, Field, Winslow, Schinckel, and Stwalley, 2021) [26].

Cabezon et al. (2022) concluded that the eight-pipe design was the superior design and identified the improved capabilities of the new design in reducing heat stress in lactating sows [36]. Multiple studies have been conducted with continuous flowrates using live animals. For flowrates of , , and , and an ambient temperature of , the eight-pipe cooling pad design was shown to significantly reduce sow respiration rates and rectal temperatures after of cooling at medium and high flowrates [35], along with exhibiting lower sow respiration rates, rectal temperatures, and vaginal temperatures across all flowrates [33,34]. For the same ambient temperature, cooled sows had significantly reduced heart rates and spent more time laying down when compared to uncooled sows [31]. For flowrates of and , increased ambient temperatures were shown to increase heat transfer into the cooling pad [30]. Above and 40–45% relative humidity, the higher flowrate was shown to be necessary to have a positive effect on the animals [28]. Respiration rates and rectal temperatures were significantly reduced for these cooled sows when compared to uncooled sows.

Intermittent flowrates with longer “off” periods were initially studied by Cabezon et al. (2022) [36]. The flowrate was retained from the previous intermittent flow study [26], but the examined cycle times were modified to a 30 s pulse once every 2, 3, 6, or 9 min, at ambient temperatures of , , and . Table 2 provides the heat rejection rate and cooling effectiveness values for each flowrate and ambient temperature from Cabezon et al. (2022) [36]. The cooling effectiveness was calculated by determining the energy rejected across one cooling cycle and the volume of one flush, which was 1.3 L. This study intends to provide a detailed statistical evaluation of the trends suggested by Cabezon et al. (2022), utilizing the same eight-pipe cooling pads and controllers [36].

Table 2.

Heat rejection rates and cooling effectiveness for intermittent flowrates on the Purdue hog cooling pad, ‘X’ indicating no data (Cabezon, Field, Johnson, Schinckel, and Stwalley, 2022) [36].

A two-temperature threshold flush was also tested by Cabezon et al. (2022) [36], where the water would begin to flow when the upper threshold was reached and then continued, until the temperature was brought below the lower threshold. This temperature threshold flushing potentially provided compensation for the variation in heat production between sows, preventing both over- and under-cooling. It was concluded that a more functional control system was needed so that in-depth testing of intermittent flows could be achieved. The addition of an electronic control system allowed for automated control of intermittent flow, providing a more extensive range of flow control schemes and moving the system towards a commercially viable design. The two-temperature control protocol could allow the amount of cooling to be varied for each sow, accounting for some variation in heat production between sows, as recommended [6]. Going further, with a large enough animal response database, it might be possible to eventually account for the variation in water inlet temperature, the individual sow’s activity level, and the effect of feeding and sleeping by varying the temperature control set point.

The objectives of this experimental work were to establish a live animal sow cooling exercise with varying intermittent flowrate protocols tested against control animals. The objectives are as follows:

- Collect sufficient data to determine top plate temperature average, heat rejection, and coolant effectiveness for the cooling pad under various live animal test conditions;

- Measure thermal and coolant flow for the eight-pipe cooling pad at 2.6 L/min for time-controlled protocols with a 0.5 min on/2.5 min off (3 min total), 0.5 min on/5.5 min off (6 min total), and 0.5 min on/8.5 min off (9 min total) intermittent coolant flows at ambient barn temperatures of 27 °C and 32 °C;

- Measure thermal and coolant flow for the eight-pipe cooling pad at 2.6 L/min for temperature-controlled protocols of 31.0 °C on/29.0 °C off and 29.5 °C on/27.5 °C off intermittent coolant flows at ambient barn temperatures of 27 °C and 32 °C;

- Allow an initial statistical comparison of the measured physiological heat stress indicators of rectal temperature (RT), skin temperature (ST), and respiration rate (RR) between the treatment (c-cooled) sow and the control (u-uncooled) sow using various flow-controlled protocols with the following test propositions:

- Rectal Temperature: H0: RTu ≤ RTc, H1: RTu > RTc

- Skin Temperature: H0: STu ≤ STc, H1: STu > STc

- Respiration Rate: H0: RRu ≤ RRc, H1: RRu > RRc

2. Materials and Methods

This section will introduce the physical cooling pad and the control system. The digital sensors, their calibration, and subsequent verification checks are described. Finally, the experimental design for determining whether there is a subsequent effect in the sows’ physiological indicators under the different intermittent flow control schemes.

2.1. System Design

The floor cooling system used for mitigating heat stress in the test animals consisted of two main parts, the cooling pad that had been used in previous hog cooling pad experiments [8,26,27,28,30,31,33,34,35,36] and the electronic control system that was designed and retrofitted onto the cooling pads to allow for intermittent flow control schemes to be implemented [37,38,39].

2.1.1. Cooling Pad Design

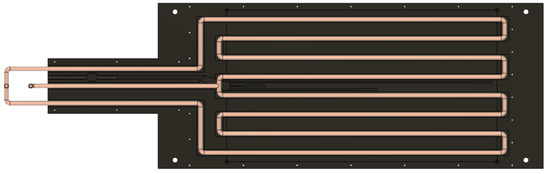

The cooling pad consisted of a high-density polyethylene (HDPE) base, a copper pipe network, an aluminum extrusion, and an aluminum diamond tread plate. The high-density polyethylene base was built from two pieces, each 61 cm wide and 2.5 cm thick. The main section was 120 cm long, and the head section was 60 cm long. The slots for the copper pipes and temperature sensors were milled using a computer numerical controlled (CNC) gantry sheet router. A specialized aluminum extrusion, ThinFin C® by Radiant Design & Supply (Bozeman, MT, USA), was used to enhance the internal heat transfer within the device. The mating area for the ThinFin C® was also recessed, so its top surface could be flush with the HDPE. The design of the pipe network is shown in Figure 1.

Figure 1.

Cooling pad pipe layout for second prototype 8-pipe design.

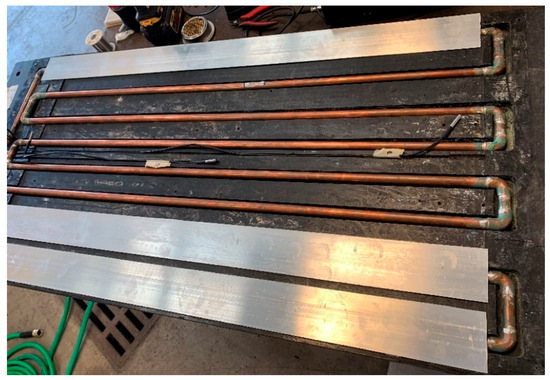

Water flowed into the center pipe and then worked its way towards the outside edges of the cooling pad. This counter-flow design allowed the coolest water to flow through the center first, which is where the sow usually has the greatest contact with the cooling pad. All current experiments used the second prototype 8-pipe cooling pad design. The ThinFin C® aluminum extrusion was clipped tightly to the copper pipe and aided in heat transfer from the upper surface of the cooling pad. The ThinFin C® can be seen partially installed in the disassembled pad in Figure 2. The temperature sensors within the cooling pad can also be seen in Figure 2. As Seidel et al. (2020) demonstrated, the placement and orientation of these sensors was critical to the accuracy of the thermal measurement system and significant care was taken in their placement [40].

Figure 2.

ThinFin C® attached to copper pipes in the 8-pipe design cooling pad.

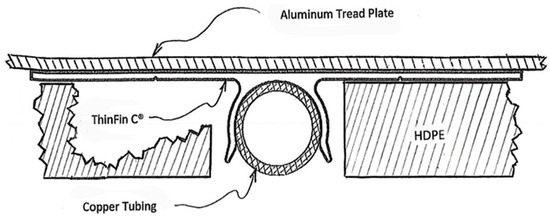

Except for the inlet and outlet connections, the pipes and ThinFin C® are covered with a piece of 3.2 mm thick aluminum diamond tread plate. This plate protected the sensors and pipes inside the cooling pad and also provided a textured surface to help prevent the sow from slipping if the cooling pad became wet. The space between the diamond plate and the inlet and outlet pipes was filled with an expanding foam window and door sealer to prevent debris from entering through these gaps and affecting the heat transfer capabilities of the cooling pad. A cross-section of the cooling pad, where the copper pipe and ThinFin C® can be seen, is shown in Figure 3. All cooling pads within the barn were connected to a single high-pressure coolant supply plenum with individual pressure reducing valves between the plenum and each pad. This ensured that the flowrate through an individual cooling pad would not be affected by the overall number of pads operating at any given time.

Figure 3.

Cross-section of hog cooling pad (Cabezon et al., 2017) [32].

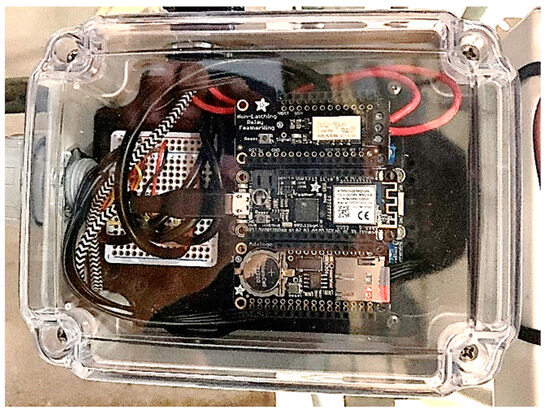

2.1.2. Control System Design

The control system for the hog cooling pad was microcontroller-based and mounted on vertical structural extensions from the cooling pad supporting inlet and outlet pipes. Due to the corrosive nature of the air in the farrowing house, all sensitive electronics were sealed inside an ingress protection (IP68) airtight enclosure. External connections were made through watertight pass-through connectors. A PVC pipe was installed between the inlet pipe and one of the outlet pipes on the cooling pad to protect the temperature sensor wires from piglets. A 12 V, IP67-rated power supply was attached above the control box to provide power for the coolant flow solenoid. The control system inside the enclosure is shown in Figure 4.

Figure 4.

Cooling pad control box and electronics.

The digital thermal sensors (±0.5 °C) used in the cooling pad assemblies were from Digi-Key DS18B20 (Thief River Falls, MN, USA), and they were used for the pad thermal data collection. Water flow calibration was accurate to ±0.01 L/min. Heat transfer levels were therefore measurable within ±5 W. The data from the microprocessor system was cleaned prior to use, and the calculations in the analysis codes were spot-checked with actual data at each step. The results from the automatic data acquisition systems built into the sow cooling pads appeared as reasonable and reliable as previous experience with these systems. Although there were individual digital thermal sensor failures, the redundancy in sensors provided continuity in data collection.

2.2. Sensor Calibration

Sensor calibration was performed on the temperature sensors for each cooling pad. This was to ensure accurate data collection and proper quantification of heat transfer between the sow and the cooling pad. The temperature sensors were calibrated using two control points, and then, any necessary correction offsets were determined. First, the cooling pads were installed in the farrowing house and allowed to equilibrate with the air in the room. The temperature output from each cooling pad was recorded for a minimum of ten minutes at an ambient steady state temperature, . The temperature of the room was confirmed using a calibrated mercury thermometer. The ambient temperature sensor for each cooling pad was submerged in a bucket of ice water for a second reading. The temperature of the ice water was recorded using an infrared thermometer for each cooling pad, . The sensor was allowed to sit for a minimum of ten minutes to ensure it had reached equilibrium with the ice water. Using these two measurements, the corrective slope and intercept for each cooling pad was determined using linear interpolation to convert the measured temperature, , to a real temperature, , using correction factors. For a perfect sensor, should equal one, and should equal zero. Thermal information from the temperature sensors utilized the following simple linear calibration shown in Equations (1)–(3):

where:

is the intercept correlation factor for the test thermometer;

is a slope correlation factor of each thermocouple;

is the temperature of the farrowing house taken with the test thermocouple;

is the temperature of the farrowing house taken with a calibrated thermocouple;

is the temperature of a bucket of ice water taken with the test thermocouple;

is the temperature of a bucket of ice water taken with a calibrated thermocouple.

Flowrate sensor calibration was performed by manually adjusting the gate valve on the outlet extension pipe and measuring the volume of water exiting the pipe in a set time. The valve would then be gently adjusted, until the approximate physical flowrate was set. The correction value in the software was modified so the flowrate sensor output matched the physical measurement.

2.3. Sensor Verification

Sensor verification was achieved for both the temperature sensors and flowrate sensors. This was to ensure that the level of sensor accuracy did not degrade during the course of the experiments. Verification was performed by examining values recorded before and after the experiments to determine if instrumentation changes had occurred. The verification for the temperature sensors before the experiments used the same data recorded for the ambient temperature calibration. Once the sensors reached equilibrium with the ambient temperature, the variance for each sensor was determined. A similar set of ambient equilibrium data was recorded after the experiments, and the variance of the sensors was once again calculated. A significant change in variance would indicate that a sensor failed during the course of the experiments. Flowrate sensor verification was performed by measuring the volume of water collected from each cooling pad both before and after the experiments. Data from the flowrate sensor was only used to verify the proper function of the solenoid. Unfortunately, the level of accuracy of the selected flowrate sensor was not sufficient to directly measure the coolant flow.

2.4. Experimental Design

The experimental design aimed to replicate heat stress conditions in a farrowing house and determine the effectiveness of the various operational cycles on the cooling pads at mitigating heat stress. Twelve sows that were expected to farrow on approximately the same day were selected for the experimentation. Half of these were first parity sows, and the other half were third parity sows.

2.4.1. Sow Measurements

In addition to the measurements taken with the cooling pad, skin temperature, rectal temperature, and respiration rate were also recorded during the experiments. Skin temperature was measured using an infrared thermometer with an accuracy of ±1.5 °C (FLIG TG-165, Wilsonville, OR, USA) aimed behind the ear, as seen in Figure 5. Rectal temperature was measured using a digital stick thermometer with an accuracy of ±0.2 °C (Cooper Atkins TM99A, Middlefield, CT, USA). Respiration rate was measured by counting the number of breaths in 30 s and multiplying by 2.

Figure 5.

Measuring sow skin temperature behind the ear with an infrared thermometer.

2.4.2. Schedule of Experimental Protocol

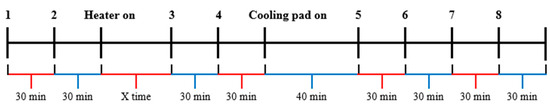

The experimental protocol for the testing of coolant control schemes is shown in Figure 6. This schedule was used for each of the individual experiments conducted. At each identified time during an experimental run, sow skin temperature, rectal temperature, and respiration rate were measured. Data points 1 and 2 were taken as baseline measurements for the sows, before any heating or cooling started, so the effects of heat stress and the cooling pad could be compared to each sow individually. The data from these two points were averaged if both were available. The room heater was then turned on and set to the desired barn ambient temperature of either 27 °C or 32 °C. Once the room reached the desired set point, two more data points were collected from each sow, approximately 30 min apart (data points 3 and 4). The cooling pads were then turned on and given 40 min to remove any transient cooling effects. Finally, four more data points were collected from each sow, again approximately 30 min apart (data points 5, 6, 7, and 8). After the eighth data point was collected for each sow, the room heating was turned off, and the sows were given time to cool-down before the protocol was repeated using different conditions. Two repetitions of each treatment combination were planned under this experimental plan.

Figure 6.

Experiment protocol for the coolant control scheme testing on the sow cooling pad.

2.4.3. Sow Treatment Assignment

Each sow was assigned to each specific treatment to remove the experimental variation from sow to sow. A total of 16 experimental runs were scheduled. This corresponded to two pad control protocols (TIME and TEMP), two ambient barn temperatures ( and ), and four coolant flowrate treatments (CONTROL, LOW, MEDIUM, and HIGH). The two control types were a temporal control scheme and a temperature threshold control scheme. The four treatments were CONTROL, LOW, MEDIUM, and HIGH and were defined differently for each control scheme.

In both coolant control schemes, the system was set so the solenoid would open for 30 s, and the operating coolant flowrate was set to 4 L/min. This allowed for a 2 L flush of cooling water. The copper pipes contained approximately 1.7 L, so 2 L was flushed to account for any intra-line mixing that might occur. For both control schemes, cooling pads on the CONTROL treatment were set to never flush, but they were operational so the temperature sensors could record data. The temporal control scheme utilized only the real-time clock module to make decisions on when to flush the water, with the frequency of flush set by the treatment. The temperature threshold control scheme utilized the three temperature sensors within the cooling pad to determine when the cooling pad should be flushed. The thermal sensors were located under the aluminum top plate of the cooling pad. The software could be set to trigger based on an average of the three temperatures or from a specific location. As a default, the middle sensor was used. The time of the last flush was also considered by the microcontroller due to the thermal diffusion delay. This prevented over-cooling and provided for a more conservative use of coolant resources. Flushing on the temperature threshold control schemes could not occur more than once every two minutes. In the temperature threshold control schemes, the threshold temperature was the parameter which initiated the coolant solenoid activation. The specific parameter for each treatment and control type can be seen in Table 3.

Table 3.

Treatment parameters for evaluation of coolant flow control schemes.

3. Results and Discussion

Calibration was completed without issue, but due to limited lactation time and personnel constraints, only nine of the sixteen anticipated experiments could be performed. One experiment was performed at an ambient barn temperature of 27 °C, and the remaining eight utilized 32 °C. This was determined to be the best use of limited resources, as it allowed a full comparison of control schemes at a level of moderate heat stress, leaving an analysis of the effects of ambient temperature to be completed later. The animal experimentation associated with this work was conducted over roughly one month during the summer of 2020 at the Purdue University Animal Sciences Research and Education Center (ASREC) under Purdue University Animal Care and Use Committee (PUACUC) #1804001739. The inlet water temperature from the farm’s distribution system was relatively constant at 18 ± 1 °C.

3.1. Calibration of Sensors

Sensors were calibrated after installation within the testing facility, shortly before all experiments were conducted. Sensor calibration required approximately one day to complete. The ambient temperature calibration point for each pad was measured in the morning, after being at a relative steady state during the previous night, and the ice water calibration point was measured during the afternoon. The steady state values collected for the calibration of the temperature sensors can be seen in Table 4. The calibration of the flowrate sensors was performed to achieve a flowrate of . The gate valve on each cooling pad was adjusted, until the fluid measured in a graduated cylinder was 2 L after 30 s. The measured flowrate for each cooling pad is shown in Table 5.

Table 4.

Ambient temperature sensor calibration values prior to control scheme experimentation.

Table 5.

Flowrate calibration measurements prior to control scheme experimentation.

3.2. Verification of Temperature Sensors

The initial variance of each sensor was determined using the same dataset collected for the calibration of the temperature sensors. The verification testing software was run again after all experiments were completed to determine the change in variance for each sensor. Data from sensors with significant increases in variance were removed before analyses were performed. The variance for each sensor before and after the experiments were performed can be seen in Table 6. Sensors that could not be read for the post-experiment variance are indicated with an X. The standard deviations of the pre- and post-experiment variances are identified as PRE STD and POST STD, and the post-experiment variance mean is POST MEAN. The two conditions for a sensor to be identified as a failed sensor were as follows:

Table 6.

Variance of temperature sensors prior to and after coolant control scheme experimentation, with ‘X’ representing no data collection and the strike-through representing a failed sensor.

- Having post-experiment variance greater than its pre-experiment variance;

- Having post-experiment variance at least two STD above the pre-experiment mean.

Sensors that met these failure criteria are identified with a strike-through in Table 6. Data from these sensors were not used in further analysis.

3.3. Effect of Ambient Temperature on Heat Stress

The heat transfer efficiency and cooling effectiveness at ambient temperatures of 27 °C and 32 °C were compared for the single experimental run of temperature threshold control schemes completed at 27 °C. Each sow was only compared to itself, given that not all sows were able to receive all treatments at an ambient temperature of 27 °C. The mean values for each treatment group, as well as the increase in heat transfer per degree of ambient temperature increase, can be seen in Table 7.

Table 7.

Treatment averaged cooling pad metrics for different ambient temperatures during coolant control scheme experimentation, with ’X’ representing no data collection.

A preliminary comparison for each treatment was completed by comparing each sow at 27 °C to itself at 32 °C. Heat transfer efficiency and cooling effectiveness were calculated for each sow at both ambient temperatures. The difference in each variable between the two ambient temperatures was then divided by the difference in ambient temperatures to examine the change in heat transfer efficiency and the cooling effectiveness on a per degree basis. The sample sizes were small, and the experimental sows could not be exposed to all treatments. The heat transfer efficiency and cooling effectiveness showed substantial similarity between the two remaining cooling treatments, as seen in Table 7. Heat transfer efficiency increased on average by 23.7 W/°C, and it only differed by 1.7 W/°C between the cooling treatments. The cooling effectiveness differed significantly among treatment groups, and no clear preliminary trend could be determined. This may suggest a linear relationship between heat transfer efficiency and the ambient temperature of the farrowing barn for temperature threshold control schemes. However, experimentation is needed where all sows are exposed to all treatments at both ambient temperatures, to increase the sample size of each treatment and allow each sow to act as their own control. Additionally, a more thorough study should test the temporal control schemes to examine if the linear relationship applies to both control scheme types. If the preliminary data collected are verified by larger sample sizes, then heat transfer efficiency should be expected to increase at a rate of approximately 24 W/°C.

3.4. Physiological Metrics

The skin temperature, respiration rate, and rectal temperature of each sow were recorded at each of the eight points identified in the experiment protocol. Skin temperature, respiration rate, and rectal temperature were then compared among temporal and temperature threshold schemes using the PROC MIXED procedure in the SAS® statistical analysis package (SAS, Cray, NC, USA). The potential effects considered were treatment, time, the interaction between treatment and time, sow body weight, parity, sow backfat thickness, sow loin depth, and the time measurement point of the Figure 6 protocol when data were collected. Effects in the initial model with a p-value greater than 0.20 were removed before continuing, with the same process used for the 40 min sampled cooling pad data. There was no significant interaction effect on skin temperature for either the temporal or temperature threshold schemes. In both cases, treatment was not significant, and the protocol time point was significant, with the first two time points before the heater was turned on corresponding to lower skin temperatures than the six time points after the barn was heated to its elevated experimental ambient temperature.

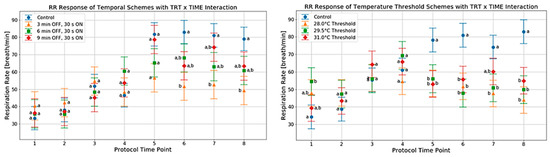

There was a significant interaction between treatment and time for respiration rate in the temperature threshold schemes (p < 0.0001), and a tendency for interaction in the temporal schemes (p = 0.0922). Removal of the interaction from the temporal model resulted in an increased Akaike Information Criterion (AIC) and residual variance, indicating a lower quality fit of the data. Therefore, the interaction between treatment and time was retained in the final regression model. The respiration rates at each protocol time point can be seen in Figure 7, with the temporal control schemes on the left and the temperature threshold control schemes on the right. Respiration rates are used as strong indications of heat stress or the lack thereof. Respiration rates under 40 breaths per minute for sows are considered unstressed. Over 90 breaths per minute is moderately stressed.

Figure 7.

Respiration rates for temporal control schemes (left) and temperature threshold control schemes (right) from coolant control scheme experimentation, where ‘a’ indicates the first repetition and ‘b’ indicates the second.

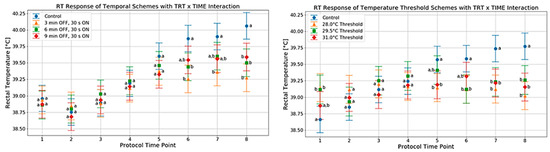

The rectal temperatures also demonstrated a significant interaction effect between treatment and time for the temporal (p = 0.0004) and temperature threshold (p < 0.0001) schemes. While none of the factors besides treatment, time, and their interaction were significant for the temporal schemes, sow body weight (p = 0.0379), parity (p = 0.0128), and sow loin depth (p = 0.0087) were all significant effects for the temperature threshold control schemes. The rectal temperatures at each protocol time point can be seen in Figure 8, with the temporal control schemes on the left and the temperature threshold control schemes on the right.

Figure 8.

Rectal temperatures for temporal control schemes (left) and temperature threshold control schemes (right) from coolant control scheme experimentation, where ‘a’ indicates the first repetition and ‘b’ indicates the second.

3.5. Cooling Pad Metrics

Using all twelve sows, mean values for the average surface temperature of the cooling pad and the average heat transfer efficiency were sampled from the raw data in two ways. First, the data were divided into four 40 min sections to examine major effects over the time when the cooling pads were turned on. Second, the data for each sow were sampled for each flush cycle, beginning with the 30 s flush. This provided finer resolution data that allowed a curve to be fit for each dependent variable and treatment group. The incremental heat transfer rate, , was calculated for each data point before data were resampled using Equation (4):

where:

Δ is the heat transfer rate;

is mass flowrate of water moving through the pipe;

is constant pressure specific heat capacity of the water;

is the temperature difference between the inlet and outlet pipes of the cooling pad.

By multiplying these incremental heat transfer rates by the data point sampling frequency, , the incremental energy removed during that time span was determined. These values were then aggregated to determine the total energy removed. Division by the total volume of water was used to provide the cooling effectiveness. Analysis was performed separately on temporal and temperature threshold schemes to simplify comparisons with the control treatment groups and allow for greater differentiation between the models for each control scheme.

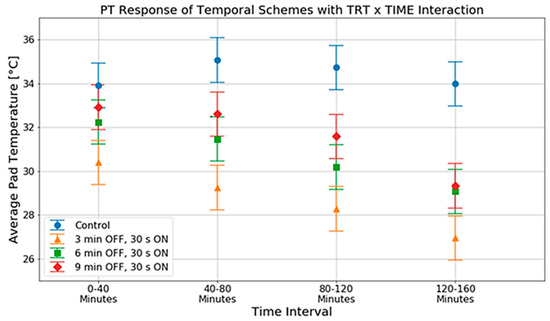

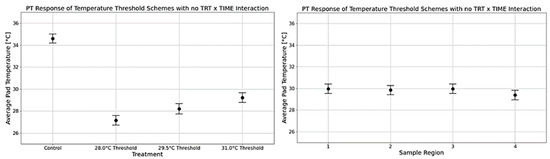

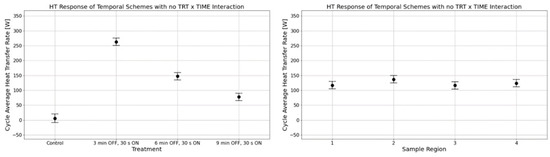

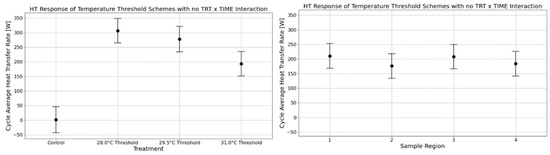

The potential effects for 40 min sampled data were treatment, time, the interaction of treatment and time, sow body weight, parity, sow backfat thickness, and sow loin depth, where time was an integer value from one to four, representing which section of the protocol the data were sampled from. Effects with p > 0.20 were removed, and the model was rerun to better elucidate the significance of the remaining effects. All analysis was performed in SAS® using the PROC MIXED procedure. The only significant interaction between treatment and time was for the average pad temperatures among the temporal schemes, as shown in Figure 9. The average pad temperatures among temperature threshold schemes with no interaction effect can be seen in Figure 10. Additionally, the average heat transfer rates with no interaction effect for temporal and temperature threshold schemes can be seen in Figure 11 and Figure 12, respectively.

Figure 9.

Average pad temperatures for temporal schemes on 40–minute averaged data from coolant control scheme experimentation.

Figure 10.

Average pad temperatures for temperature threshold schemes (left) and the sample region of the experiment (right) on 40-min averaged data from coolant control scheme experimentation.

Figure 11.

Average heat transfer rates for temporal schemes (left) and the sample region of the experimentation (right) on 40-min averaged data from coolant control scheme experimentation.

Figure 12.

Average heat transfer rates for temperature threshold schemes (left) and the sample region of the experimentation (right) on 40-min averaged data from coolant control scheme experimentation.

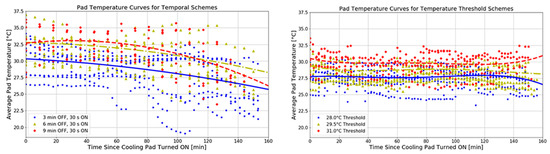

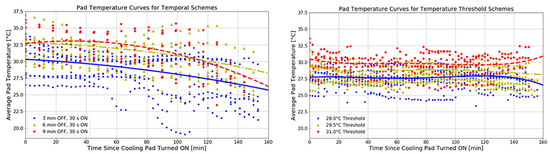

For the flush sampled data, the time parameter was the number of seconds between the cooling pad turning on and the start of the flush. The PROC MIXED procedure in SAS® was used to determine the significant effects for each dependent variable and subset of the data. Once significant effects were determined, each treatment group was run individually to calculate the coefficients of the fitted curve. The potential effects were treatment, powers of time from one to four, and the interaction of treatment with each power of time. The average pad temperatures for the temporal and temperature threshold schemes can be seen in Figure 13. The heat transfer rate for the temporal and temperature threshold schemes can similarly be seen in Figure 14. The R2 value for each of the fitted curves are provided in Table 8. The data in Figure 13 and Figure 14 show the added value of the feedback mechanism present in the temperature threshold control schemes and absent in the temporal control schemes. The temperature threshold data appear to be present within a horizontal channel of temperature, while the temporal data, with no feedback mechanism, appear to be continuing to cool the animals. This could potentially cause over-cooling.

Figure 13.

Average pad temperatures for temporal schemes (left) and temperatures for temperature threshold schemes (right) from coolant control scheme experimentation.

Figure 14.

Heat transfer rates for temporal schemes (left) and temperature threshold schemes (right) from coolant control scheme experimentation.

Table 8.

R2 values for curves fitted to flush sampled data from coolant control scheme experimentation.

The heat transfer rate curves were sampled at 6 s intervals to match the frequency that the cooling pads recorded data. This resulted in 1601 data points for each treatment group. These values were then used to determine the cooling effectiveness of each control scheme at each time point by calculating an equivalent continuous flowrate based on the total volume flushed during the experiment and the total energy transfer during that time interval. Both the heat transfer rate and cooling effectiveness for each treatment were compared in Python® using a one-way ANOVA from the SciPy 1.1.0 package (NumFocus, Austin, TX, USA). Both the heat transfer rate (F(5), 9600 = 65,789, p < 0.0001) and cooling effectiveness (F(5), 9600 = 5109, p < 0.0001) were significant at a 95% confidence level. A Tukey test was then applied to each dataset to determine which pairs of means were significantly different. All treatment pairs were significantly different for the heat transfer rate, and all treatment pairs, except the 6 MIN–9 MIN pair (p = 0.329), were significantly different for cooling effectiveness. The mean and standard error for each treatment group is shown in Table 9.

Table 9.

Mean and standard deviation of cooling pad metric results for coolant control scheme experimentation.

The key results for each of the six cooling treatments examined are shown in Table 10. Effective flowrate and cycle time were determined based on the number of flushes during the experiment duration for temperature threshold control schemes. Within the realm of this experimentation, the temperature threshold-based schemes removed more heat from the animals while using less coolant than the time-based schemes.

Table 10.

Flowrates and cooling pad metrics from coolant control scheme experimentation.

Cabezon et al. (2018) utilized the same eight-pipe design of the cooling pad but examined continuous flowrates of and at an ambient temperature of [3]. The continuous flowrate was most comparable to the flowrate of the temperature threshold scheme, which had 194% the heat transfer efficiency of the continuous flow. Additionally, the intermittent flow control scheme had about 95% more cooling effectiveness than the continuous flow. The temperature threshold scheme and 3 MIN OFF temporal scheme had the most similar flowrates to the continuous flow, with effective flowrates of and , respectively. They exhibited 92% and 79% greater heat transfer efficiency and 144% and 179% greater cooling effectiveness than the continuous flow treatment from Cabezon et al. [27]. This demonstrated that for similar effective flowrates, intermittent flow schemes not only better utilize the cooling capacity of the water by allowing it to warm up before exiting the cooling pad, but that they also have greater heat transfer rates, which allow for a better mitigation of heat stress in the sow.

Cabezon et al. performed continuous flow treatments with a continuous flowrate of at an ambient temperature of . The eight-pipe cooling pad exhibited a heat transfer rate of and had a cooling effectiveness of . This is a similar heat transfer rate to the 3 min OFF temporal scheme, but only about 12% of the cooling effectiveness. Using the preliminary temperature rate increase for heat transfer efficiency calculated previously to estimate the heat transfer for this continuous scheme at , the heat transfer rate would be approximately 424 W. This extrapolation seems to indicate that continuous flow schemes at similar actual flowrates will remove more heat than intermittent schemes. The cooling effectiveness would be expected to be greater at greater ambient temperatures, but it is improbable that there would be an eight-fold cooling effectiveness increase with a greater ambient temperature. As a result, the cooling effectiveness of the intermittent schemes will likely still significantly outperform similar continuous flow operational schemes. These results reaffirm that intermittent flow control schemes better utilize the cooling water flowing through the cooling pad than continuous flow systems. However, higher levels of heat transfer efficiency may be reached with continuous flow. Continuous flow operation is limited primarily by convective heat transfer effects, rather than the intermittent flow control schemes that are limited by both conductive and convective heat transfer mechanisms.

The most similar dataset of intermittent flow for comparison to this study was at an ambient temperature of from Cabezon et al. [26]. Due to the difference in flowrates used, two determinations could be surmised between these studies as follows:

- For a given effective flowrate, which control scheme developed the greatest heat transfer efficiency and cooling effectiveness;

- For a given cycle time, which flowrate developed the greatest heat transfer efficiency and cooling effectiveness.

For an effective flowrate of 0.22 L/min, the 6 min cycle time from Cabezon et al. [26] had approximately 86% more heat transfer efficiency and 9% more cooling effectiveness than the 9 min temporal control scheme examined in this study. This suggests that for a given effective flowrate, the control scheme with the lower overall flowrate will have better heat transfer efficiency and cooling effectiveness. This is presumably due to the exponential decay of temperature difference as the water in the pipes is warmed during the conductive heat transfer portion of the cycle with no coolant flow. Less frequent flushing allows for more time for transferring heat to the water using a higher temperature gradient.

By comparing the 3 min cycle time from Cabezon et al. [26] to the 3 min OFF temporal scheme, to , respectively, cooling effectiveness was measured at approximately greater for the 3 min OFF scheme from this study at vs. , respectively. This suggests that greater flowrates allow for increased cooling effectiveness. Less frequent flushing allows for a single volume of water to warm up more, before being replaced.

Overall, the and temperature threshold schemes tested in this study performed better than all of the temporal control schemes tested. The temporal scheme with the greatest heat transfer efficiency and cooling effectiveness was the 3 min OFF scheme. Heat transfer rate decreased with increased cycle time on temporal schemes and increased with decreased threshold temperature on temperature threshold schemes. There was a statistically significant difference () found between each pair of the six control schemes for heat transfer efficiency and each pair, except 6–9 min OFF schemes, for cooling effectiveness. The effective flowrates of the temperature threshold control schemes were bounded by the effective flowrates of the 3 min OFF and 9 min OFF temporal schemes. The greater heat transfer rate of the temperature threshold schemes may be due to the variable cycle time, which can take advantage of the exponential decay in temperature difference by flushing after crossing set thresholds. These schemes allow more frequent flushing during periods of high heat stress and provide a transient response when the cooling pad is initially turned on in a hot environment. Once below the threshold temperature, they transition to less frequent flushing to maintain the cooling pad surface.

On average, those temporal and temperature threshold schemes outperformed the no cooling and cooling with a steady flow through the pads. From Cabezon et al. [26], an eight-pipe cooling pad with a steady flow of 2.6 L/min moves heat away from the animal at 305 W, with an effectiveness of 5.8 kJ/L. The tested time-triggered flow control schemes averaged 180 W at 51 kJ/L, while the temperature control schemes yielded 330 W at 61 kJ/L. The intermittent flow control schemes clearly demonstrate a superiority in resource utilization and may actually provide a higher heat rejection rate than steady flow under certain conditions.

A deeper analysis of the processes within the sow cooling pad might reveal further subtleties, but it seems clear that the major input factors within the process, the coolant flowrate, inlet coolant temperature, ambient barn temperature, and the process cycle, have significant effects on the total heat transfer, the heat transfer efficiency, and the coolant use effectiveness. A more sophisticated experimental design will be required to optimize the field performance of the device, but certain trends are clear. A higher coolant flowrate, from longer on periods of higher flowrates, transfers larger amounts of energy from the sows to the coolant at the expense of both efficiency and effectiveness. Longer off periods improve efficiency and effectiveness. Thermal control schemes operate in a feedback manner and attempt to keep the registered temperature below the set point. These schemes can be wasteful in coolant effectiveness. Time-based control schemes are attempting to maintain an overall heat transfer rate of heat from the sow to the coolant. This scheme has no feedback, but it does try to optimize coolant use.

4. Conclusions and Future Work

Intermittent flow control schemes were tested using two different control mechanisms to increase the cooling effectiveness of the Purdue hog cooling pad system. A preliminary comparison of the control schemes at different ambient temperatures demonstrated greater heat transfer rates at greater ambient temperatures. The key conclusions from this study were the following:

- Temperature threshold control and temporal control schemes outperformed their relative control treatments with no cooling in both rectal temperature and respiration rate;

- Temperature threshold control schemes overall outperformed the temporal control schemes;

- Previous continuous flow studies exhibited greater heat transfer rates, but much lower cooling effectiveness than the intermittent control schemes examined in this study;

- Previous intermittent flow studies outperformed comparable control schemes from this study, but that can be attributed to the lower flowrates during the earlier testing;

- Optimization of the flush frequency will be necessary to assess the trade-offs between heat transfer efficiency and cooling effectiveness.

While the general results from this work seem clear, there are limitations to the current study. Due to time constraints within the experimental facility, this study could have used more testing of the temperature-based schemes. There is no means of controlling the inlet coolant water temperature at ASREC. This would require the installation of a recirculating coolant system to control. It would also be nice to enlarge the sample size and increase the replicates in each study. That will require either a new dedicated space or more funding to utilize the present facilities. The current building provided good environmental control and batch sizes, so further experimentation at the present site, following some renovation would be ideal. Improved animal testing should provide sufficient data to develop a fully generalized model of cooling pad performance with sows under varying conditions.

Future work on this project is aimed at optimizing both the design of the cooling pad and the control scheme used to dictate when flushing should occur. A computational heat transfer model has been developed for the cooling pad, with inputs for the material of each subcomponent, pipe geometry, flow rate, and control scheme. Once further refinement of the model is completed and it is verified with the data collected from this and past studies, it will allow future potential design changes to be evaluated without the need to build and test each modification. This will include reevaluating the control schemes examined in this study at lower flowrates for better comparison with previous studies.

The cooling pad system is also being implemented into a larger Internet of Things system within the Purdue ASREC farrowing barn. The current cooling pad data retrieval system requires the manual collection of each microSD card, which are then individually read and copied to a computer. This exposes sensitive electronics to the corrosive air of the farrowing environment, shortening the life of the control systems. This new IoT system will wirelessly collect data from each cooling pad, as well as other sensors, store the data in a single, central location, and provide notifications to farm personnel when certain warning criteria are met. This will not only increase the lifespan of the electronics by minimizing exposure to the air within the farrowing barn, but will also simplify data collection for future studies with larger sample sizes. The promise of utilizing an IoT system is within the level of analysis that can be performed near the first point of data collection. Data collection rates needed for accuracy within machine systems can be reduced to trends and warning levels for human review. Thermal and environmental data fed into a barn-based computer wirelessly could eventually allow a more sophisticated control program in anticipation of a significant warming trend or to vary the cooling for individual sows. Data from IoT systems in swine facilities could allow a more proactive response to ongoing environmental conditions and the treatment of animals as individuals rather than as members of a herd, significantly improving animal welfare for domestic sows.

Author Contributions

Conceptualization: T.C.F., A.P.S. and R.M.S.III; Methodology: T.C.F., A.P.S. and R.M.S.III; Software: T.C.F.; Validation: T.C.F.; Formal Analysis: T.C.F.; Investigation: T.C.F.; Resources: A.P.S. and R.M.S.III; Data Curation: T.C.F.; Writing—Original Draft Preparation: T.C.F.; Writing—Review and Editing: T.C.F., A.P.S. and R.M.S.III; Visualization: R.M.S.III; Supervision: R.M.S.III; Project Administration: R.M.S.III; Funding Acquisition: R.M.S.III. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any specific grant funding from agencies in the public, commercial, or government sectors. However, the Pork Board, the Purdue AgSEED fund, the Purdue Trask fund, and the Wabash Heartland Innovation Network (WHIN) have previously helped develop this technology. The assistance of the Purdue University Agricultural & Biological Engineering and Animal Sciences departments are gratefully acknowledged for their support over the years with graduate teaching assistance positions and faculty salaries.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, R.M.S.III, upon reasonable request.

Acknowledgments

We would like to thank the swine farm staff of the Animal Science department at Purdue University for animal care and transport assistance. Additionally, thanks are due to the employees of the Agricultural & Biological Engineering department at Purdue University for their support with the hardware systems necessary to run the current experiment. All animal testing performed in conjunction with the work reported in this paper was performed in accordance with the Purdue University Animal Care and Use Committee (PUACUC) approved animal subject protocols. Robert M. Stwalley IV is graciously thanked for his technical illustration support. The mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by Purdue University. The findings and conclusions in this publication are those of the authors, and they should not be construed to represent any official USDA, U.S. Government, or Purdue University determination or policy. Purdue University is an equal opportunity/equal access organization.

Conflicts of Interest

The researchers do not have any financial interests in any entity or organization that would stand to benefit from the publication of this work. Allan P. Schinckel and Robert M. Stwalley III are the inventors of USPTO 11,219,192. However, all rights to the patent have been assigned to Purdue University, and the authors have nothing to gain from this publication.

References

- Pang, Z.Z.; Li, B.M.; Zheng, W.C.; Lin, B.Z.; Liu, Z.H. Effects of water-cooled cover on physiological and production parameters of farrowing sows under hot and humid climates. Int. J. Agric. Biol. Eng. 2016, 9, 178–184. [Google Scholar] [CrossRef]

- Black, J.L.; Mullan, B.P.; Lorschy, M.L.; Giles, L.R. Lactation in sow during heat stress. Livest. Prod. Sci. 1993, 35, 153–170. [Google Scholar] [CrossRef]

- Ross, J.W.; Hale, B.J.; Gabler, N.K.; Rhoads, R.P.; Keating, A.F.; Baumgard, L.H. Physiological consequences of heat stress in pigs. Anim. Prod. Sci. 2015, 55, 1381–1390. [Google Scholar] [CrossRef]

- Baumgard, L.H.; Rhoads, R.P. Effects of heat stress on postabsorptive metabolism and energetics. Annu. Rev. Anim. Biosci. 2013, 1, 311–337. [Google Scholar] [CrossRef]

- Pedersen, L.J.; Malmkvist, J.; Kammersgaard, T.; Jorgensen, E. Avoiding hypothemia in neonatal pigs: Effect of duration of floor heating at different room temperatures. J. Anim. Sci. 2013, 91, 425–432. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Richert, B.T.; Peralta, W.A.; Gandarillas, M. Development and application of a model of heat production for lactating sows. J. Anim. Sci. 2017, 95, 30. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Richert, B.T.; Peralta, W.A.; Gandarillas, M. Application of models to estimate daily heat production of lactating sows. Prof. Anim. Sci. 2017, 33, 357–362. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Stewart, K.R.; Richert, B.T.; Gandarillas, M.; Marchant-Forde, J.N.; Johnson, J.S.; Peralta, W.A.; Stwalley, R.M., III. 243 Young Scholar Presentation: Heat stress alleviation in lactating sows by dietary betaine Supplementation and cooling pads. J. Anim. Sci. 2017, 95, 116–117. [Google Scholar] [CrossRef]

- Renaudeau, D.; Collin, A.; Yahav, S.; de Basilio, V.; Gourdine, J.L.; Collier, R.J. Adaptation to hot climate and strategies to alleviate heat stress in livestock production. Animal 2012, 6, 707–728. [Google Scholar] [CrossRef]

- Quinion, N.; Dagorn, J.; Gaudre, D. Variation of piglets’ birth weight and consequences on subsequent performance. Livest. Prod. Sci. 2002, 78, 63–70. [Google Scholar] [CrossRef]

- USDA: Foreign Agricultural Service. Livestock and Poultry: World Markets and Trade; United States Government: Washington, DC, USA, 2019; Available online: https://downloads.usda.librarycornell.edu/usda-esmis/files/73666448x/g445ct12h/ff365k146/Livestock_poultry.pdf (accessed on 24 January 2023).

- Mayorga, E.J.; Renaudeau, D.; Ramirez, B.C.; Ross, J.W.; Baumgard, L.H. Heat stress adaptations in pigs. Anim. Front. 2019, 9, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Renaudeau, D.; Quiniou, N.; Noblet, J. Effects of exposure to high ambient temperature and dietary protein level on performance of multiparous lactating sows. J. Anim. Sci. 2001, 79, 1240–1249. [Google Scholar] [CrossRef] [PubMed]

- Noblet, J.; Quiniou, N. Influence of high ambient temperatures on performance of multiparous lactating sows. J. Anim. Sci. 1999, 77, 2124–2134. [Google Scholar] [CrossRef]

- Johnson, J.S.; Jansen, T.L.; Galvin, M.; Field, T.C.; Graham, J.R.; Stwalley, R.M., III; Schinckel, A.P. Electronically controlled cooling pads can improve litter growth performance and indirect measures of milk production in heat-stressed lactating sows. J. Anim. Sci. 2022, 100, skab371. [Google Scholar] [CrossRef]

- de Oliveira, G.M., Jr.; Ferreira, A.S.; Oliveira, R.F.; Silva, B.A.; de Figueiredo, E.M.; Santos, M. Behaviour and performance of lactating sows housed in different types of farrowing rooms during summer. Livest. Sci. 2011, 141, 194–201. [Google Scholar] [CrossRef]

- Silva, B.A.N.; Oliveira, R.F.M.; Donzele, J.L.; Fernandes, H.C.; Lima, A.L.; Renaudeau, D.; Noblet, J. Effect of floor cooling and dietary amino acids content on performance and behavior of lactating primiparous sows during summer. Livest. Sci. 2009, 120, 20–34. [Google Scholar] [CrossRef]

- Silva, B.A.N.; Olivera, R.F.M.; Donzele, J.L.; Feranandes, H.C.; Abreu, M.L.T.; Noblet, J.; Nunes, C.G.V. Effect of floor cooling on performance of lactating sows during summer. Livest. Sci. 2006, 105, 176–184. [Google Scholar] [CrossRef]

- Murphy, J.P.; Nichols, D.A.; Robbins, F.V. Drip cooling of lactating sows. Appl. Eng. Agric. 1987, 3, 200–202. [Google Scholar] [CrossRef]

- Perin, J.; Gaggini, T.S.; Manica, S.; Magnabosco, D.; Bernardi, M.L.; Wentz, I.; Bortolozzo, F.P. Evaporative snout cooling system on the the performance of lactating sows and their litters in a subtropical region. Cienc. Rural. 2016, 46, 342–347. [Google Scholar] [CrossRef]

- Pang, Z.Z.; Li, B.M.; Xin, H.W.; Yuan, X.Y.; Wang, C.Y. Characterization of an experimental water-cooled cover for sows. Biosyst. Eng. 2010, 105, 439–447. [Google Scholar] [CrossRef]

- van Wagenberg, A.V.; van der Peet-Schwering, C.M.; Binnendijk, G.P.; Claessen, P.P. Effect of floor cooling on farrowing sow and litter performance: Field experiment under Dutch conditions. Trans. ASABE 2006, 49, 1521–1527. [Google Scholar] [CrossRef]

- Bjerg, B.; Brandt, P.; Sorensen, K.; Pedersen, P.; Zhang, G. Review of methods to mitigate heat stress among sows. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. [Google Scholar] [CrossRef]

- Schinckel, A.P.; Stwalley, R.M., III. Systems and Methods for Cooling an Animal. U.S. Patent 11,219,192, Purdue University Office of Technology Commercialization, 11 January 2022. [Google Scholar]

- Geis, E.; Zumwalt, D.; Carter, J. Sow Cooling Pad; Lafayette, W., Ed.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2015; Available online: https://engineering.purdue.edu/ABE/academics/seniorprojects/2015 (accessed on 24 January 2023).

- Cabezon, F.A.; Field, T.C.; Winslow, E.; Schinckel, A.P.; Stwalley, R.M., III. Computerized data acquisition to demonstrate the influence of coil density on hog cooling pad heat transfer and long-term operational sustainability. Int. J. Agric. Sci. 2021, 11, 1–17. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Stwalley, C.S.; Stwalley, R.M., III. Heat transfer properties of hog cooling pad. Trans. ASABE 2018, 61, 1693–1703. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Maskal, J.; Schinckel, A.P.; Marchant-Forde, J.N.; Johnson, J.S.; Stwalley, R.M., III. 14 Evaluation of floor cooling on lactating sows under mild and moderate heat stress. J. Anim. Sci. 2018, 96, 7–8. [Google Scholar] [CrossRef]

- Maskal, J.; Cabezon, F.A.; Schinckel, A.P.; Marchant-Forde, J.N.; Johnson, J.S.; Stwalley, R.M., III. 480 Evaluation of floor cooling on lactating sows under moderate heat stress within a day and relationships of measures of heat stress to estimated heat removal rates. J. Anim. Sci. 2018, 96, 257. [Google Scholar] [CrossRef]

- Maskal, J.; Cabezon, F.A.; Schinckel, A.P.; Smith, A.J.; Marchant-Forde, J.N.; Johnson, J.S.; Stwalley, R.M., III. Evaluation of floor cooling on lactating sows under mild and moderate heat stress. Prof. Anim. Sci. 2018, 34, 84–94. [Google Scholar] [CrossRef]

- Parois, S.P.; Cabezon, F.A.; Schinckel, A.P.; Johnson, J.S.; Stwalley, R.M., III; Marchant-Forde, J.N. Effect of floor cooling on behavior and heart rate of late lactation sows under acute heat stress. Front. Vet. Sci. 2018, 5, 223. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Stwalley, R.M., III. Thermal capacity of hog-cooling pad. Appl. Eng. Agric. 2017, 33, 891–899. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Smith, A.J.; Marchant-Forde, J.N.; Johnson, J.S.; Stwalley, R.M., III. Effect of floor cooling on late lactation sows under acute heat stress. Livest. Sci. 2017, 206, 113–120. [Google Scholar] [CrossRef]

- Cabezon, F.A.; Schinckel, A.P.; Smith, A.J.; Marchant-Forde, J.N.; Johnson, J.S.; Stwalley, R.M., III. Technical Note: Initial evaluation of floor cooling on lactating sows under acute heat stress. Prof. Anim. Sci. 2017, 33, 254–260. [Google Scholar] [CrossRef]

- Smith, A.J.; Cabezon, F.A.; Schinckel, A.P.; Marchant-Forde, J.N.; Johnson, J.S.; Stwalley, R.M., III. 379 Initial evaluation of floor cooling on lactating sows under acute heat stress. J. Anim. Sci. 2017, 95, 183–184. [Google Scholar] [CrossRef][Green Version]

- Cabezon, F.A.; Field, T.C.; Johnson, J.S.; Schinckel, A.P.; Stwalley, R.M., III. Initial evaluation of sow cooling pad coolant protocols on performance and physiological conditions measured by precision animal data system. Appl. Eng. Agric. 2022, 38, 179–191. [Google Scholar] [CrossRef]

- Field, T.C.; Schinckel, A.P.; Stwalley, R.M., III. Impact of variation in electronic control scheme parameters for hog cooling pads. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, Omaha, NE, USA, 13–15 July 2020. [Google Scholar] [CrossRef]

- Field, T.C.; Burgett, M.I.; Schinckel, A.P.; Stwalley, R.M., III. Electronic control for hog cooling pads. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. [Google Scholar] [CrossRef]

- Field, T.C.; Schinckel, A.P.; Stwalley, R.M., III. Development of a hog-cooling panel. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018. [Google Scholar] [CrossRef]

- Seidel, D.S.; Field, T.C.; Schinckel, A.P.; Stwalley, C.S.; Stwalley, R.M., III. Effects of temperature probe orientation on the Purdue hog cooling pad data acquisition. Comput. Electron. Agric. 2020, 175, 105609. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).