The Emerging Hemp Industry: A Review of Industrial Hemp Materials and Product Manufacturing

Abstract

1. Introduction

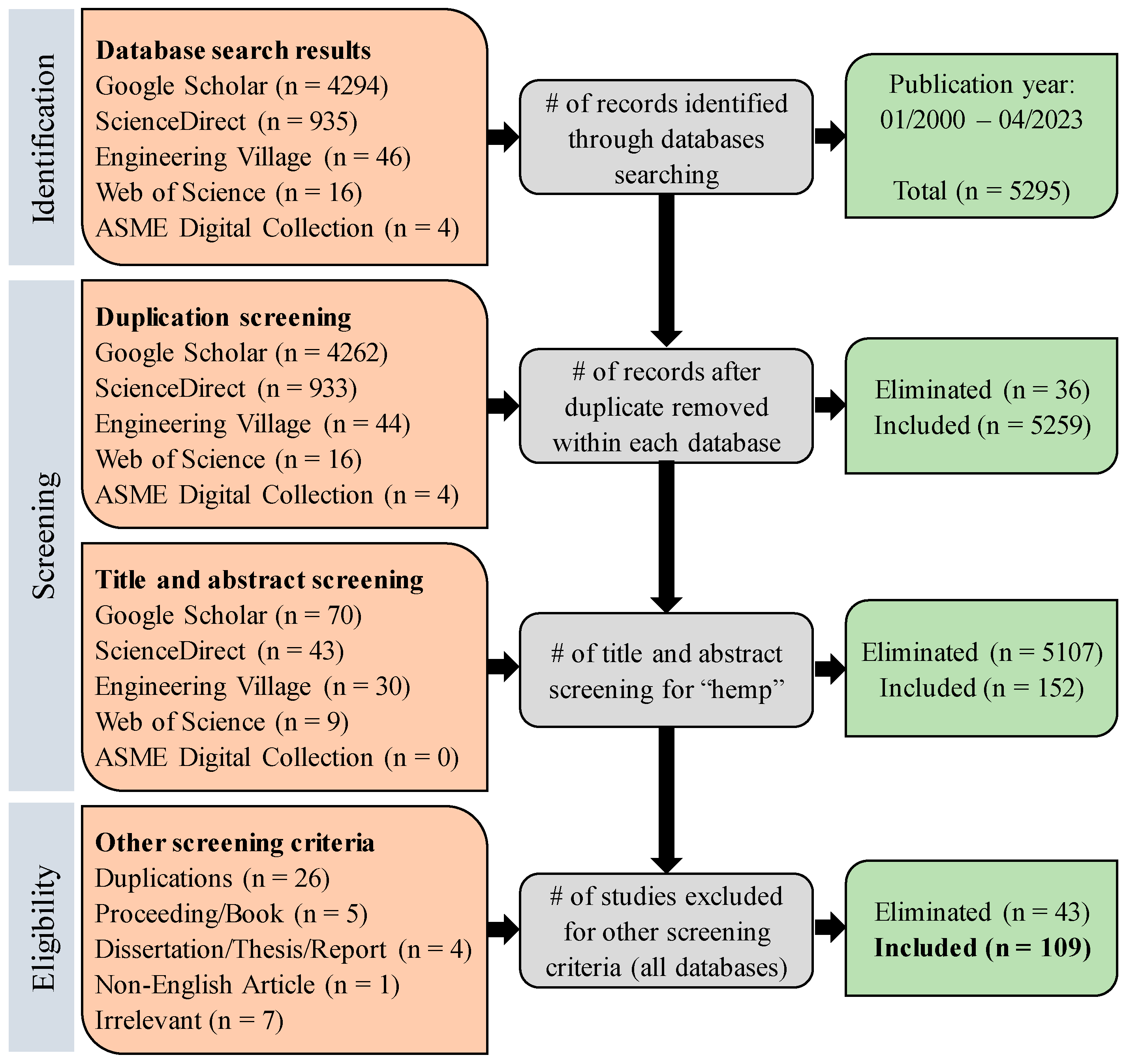

2. Methodology

2.1. Systematic Literature Review

- R1: What hemp materials and products have been studied?

- R2: What manufacturing processes or technologies have been considered for the various hemp materials and products?

- R3: What are the emerging or newly developed hemp materials or products?

- R4: What is the state of the art in assessing hemp product sustainability performance?

- R5: What future opportunities exist for the research and development of hemp materials, products, and process technologies?

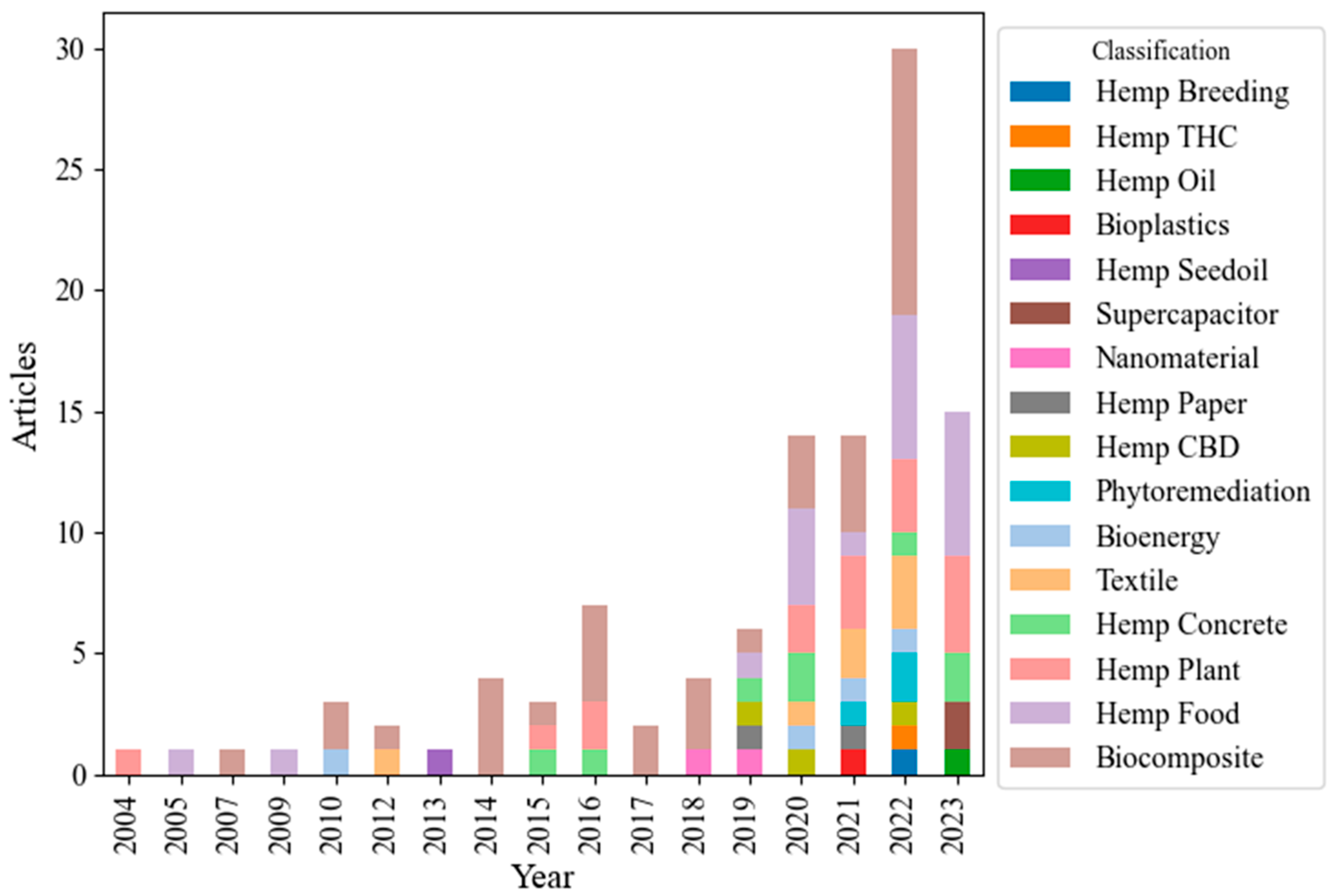

2.2. Review Publication Statistics

3. Overview of Hemp Cultivation, Processing, and Applications

4. Hemp Fiber and Hurd

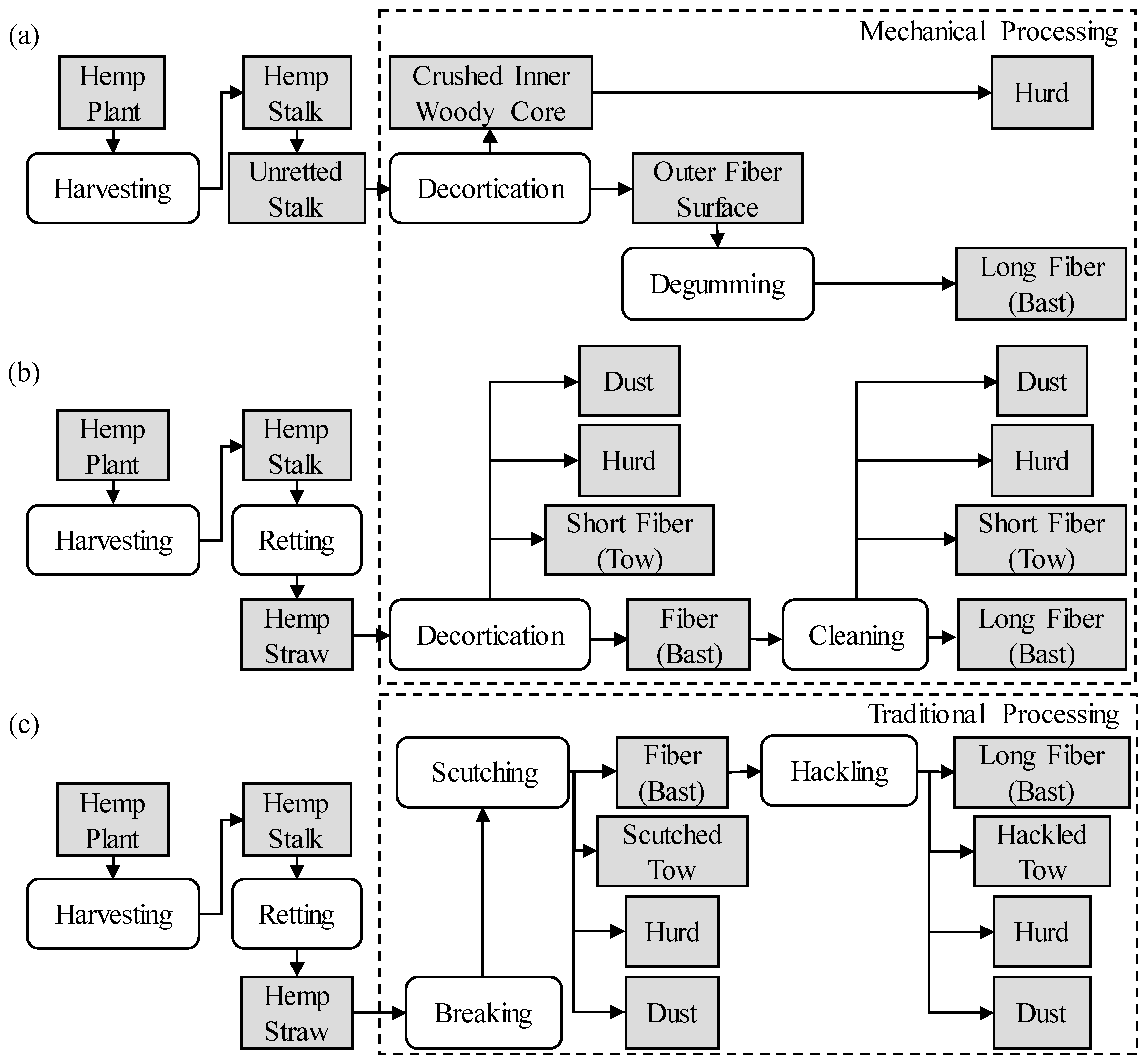

4.1. Hemp Stalk Harvesting, Pre-Treatment, and Fiber Extraction

4.1.1. Hemp Stalk Harvesting and Pre-Treatment

4.1.2. Hemp Fiber Extraction

| Processing Technique | Description |

|---|---|

| Breaking | Fluted and smooth rollers, arranged either horizontally or vertically, crush and break the straw open along its length, forming long, thin strands [28]. The output quality of bast fiber from the breaking stage depends on the degree of retting. |

| Scutching | Bast fiber passes through rotating turbine blades to open the fiber further [28]. Most of the hurd is removed by scutching except those closely adhering to the bast fiber. Hurd, dust, and scutched tow are co-products and can be used for textiles, yarns, or ropes. |

| Fiber opening | Dust and hurd are removed from the tow or bast fiber by feed rollers covered in pins of different pitches, producing finer fiber strands [28]. Drawing, slivering, doubling, and winding are other processes used based on the quality and intended use of the fiber. |

| Carding | An alternative to fiber opening, though more expensive, where the bast fiber passes through single or multiple opening cycles, carding efficiently extracts fiber from the tow [28]. Carding is used for thicker yarns like upholstery or woven, nonwoven, and technical products [44]. Optimization has improved anisotropy and hemp fiber content [13]. |

| Degumming | Further processing of bast fiber into workable, fine, and soft (cottonized) forms, in which the viscous non-cellulosic (lignin) content is significantly reduced from 8–10% to as little as 0.2%, suitable for weaving, spinning, and blending [45,47]. |

| Fiber cleaning | Bast fiber is cleaned using various combinations and sequences of cleaners (comb shaker table, step cleaner, or tambour turbine), depending on the degree of cleaning required [28]. Cleaning is similar to hackling; however, the literature has ascribed hackling to manual or traditional fiber extraction. Tow at this stage is referred to as hackled tow. |

| Hemp fiber spinning | Fibers are spun into different yarn types depending on the uniformity of fineness, quality, length, and cleanliness [28]. Generally, longer fibers are spun into finer yarns and tow into coarse yarns. Hemp spinning can be wet or dry; wet spinning produces finer yarns [48]. |

| Blending | Hemp fiber is combined with cotton or artificial fibers in fabrics to reduce the environmental impacts of textile production [11,28,45], appealing to environmentally conscious consumers. |

4.2. Applications of Hemp Fiber and Hurd

4.2.1. Application of Hemp Fiber in the Textile Industry

4.2.2. Application of Hemp Fiber in Pulp and Paper Industry

4.2.3. Application of Hemp Fiber and Hurd in the Construction Industry

4.2.4. Application of Hemp Fiber and Hurd in Biocomposites

4.2.5. Application of Hemp Fiber and Hurd in Packaging

4.2.6. Application of Hemp Fiber and Hurd as Mulch and Bedding

4.3. Emerging Applications of Hemp Fiber and Hurd

5. Hemp Seeds and Flowers

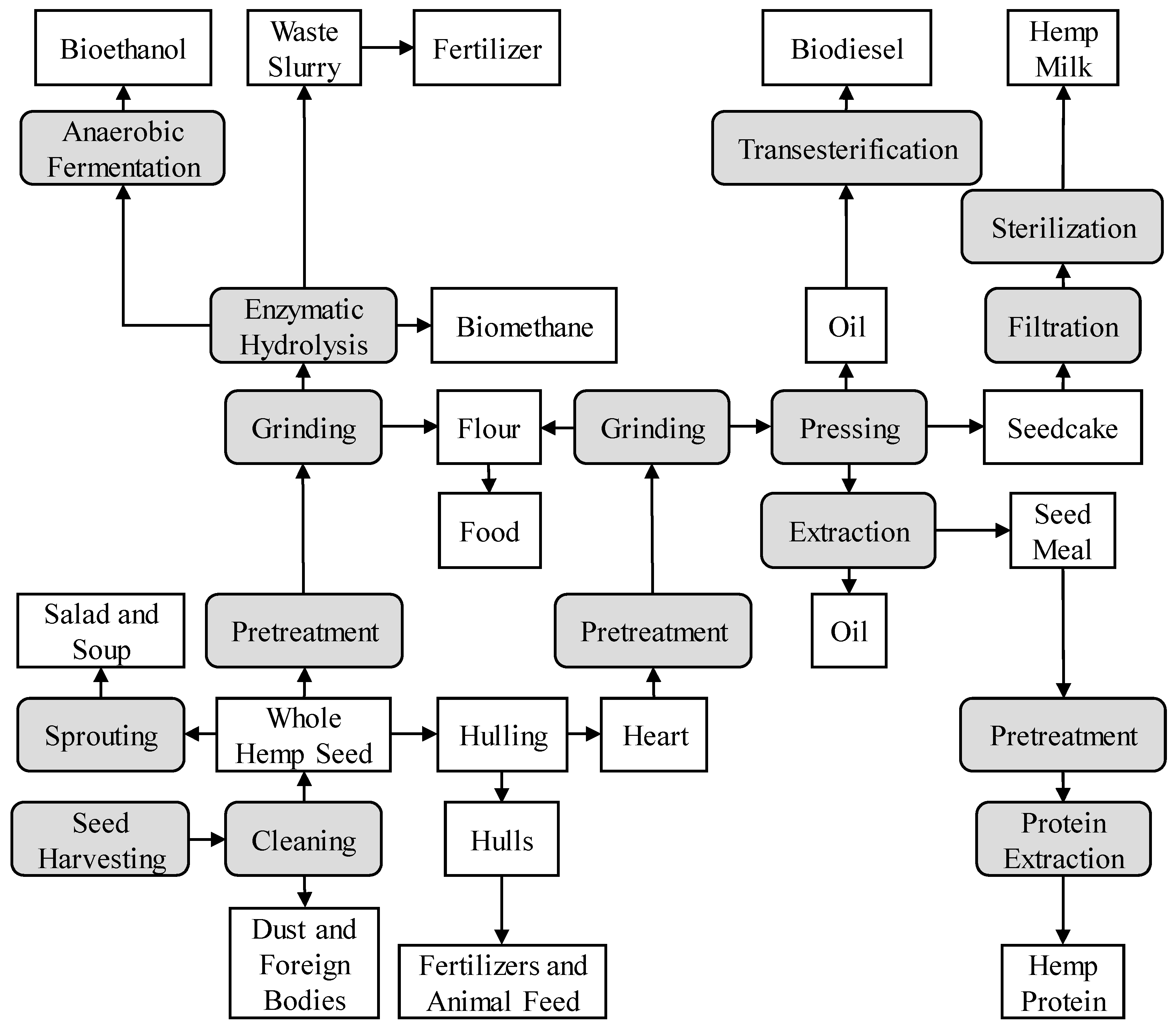

5.1. Hemp Seed Harvesting, Pre-Processing, and Extraction Processes

5.1.1. Pretreatment

5.1.2. Oil Extraction

5.1.3. Protein Extraction

5.1.4. Hemp Milk Processing

5.1.5. Hemp Seeds as Livestock Feed

5.2. Emerging Applications of Hemp Seeds for Bioenergy

5.3. Hemp Flower Oil Extraction Processes

6. Hemp Sustainability Performance

7. Future Research Opportunities

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- United Nations. The UN Global Compact: Finding Solutions to Global Challenges. Available online: https://www.un.org/en/un-chronicle/un-global-compact-finding-solutions-global-challenges (accessed on 24 May 2023).

- Kynčlová, P.; Upadhyaya, S.; Nice, T. Composite Index as a Measure on Achieving Sustainable Development Goal 9 (SDG-9) Industry-Related Targets: The SDG-9 Index. Appl. Energy 2020, 265, 114755. [Google Scholar] [CrossRef]

- Rantala, T.; Hanski, J.; Uusitalo, T.; Hemilä, J. Sustainability-Related Challenges in Customer-Supplier Relationships in the Manufacturing Industry. In Sustainable Design and Manufacturing; Scholz, S.G., Howlett, R.J., Setchi, R., Eds.; Smart Innovation, Systems and Technologies; Springer: Singapore, 2023; Volume 338, pp. 121–132. ISBN 978-981-19920-4-9. [Google Scholar]

- Yano, H.; Fu, W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods 2023, 12, 651. [Google Scholar] [CrossRef] [PubMed]

- Cameron, R.; Rana, V. Agriculture, Construction & Mining. In The Fourth Industrial Revolution; Nankervis, A., Connell, J., Montague, A., Burgess, J., Eds.; Springer: Singapore, 2021; pp. 21–38. ISBN 9789811616136. [Google Scholar]

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial Hemp Fiber: A Sustainable and Economical Alternative to Cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Tutek, K.; Masek, A. Hemp and Its Derivatives as a Universal Industrial Raw Material (with Particular Emphasis on the Polymer Industry)—A Review. Materials 2022, 15, 2565. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Fiore, V. A Systematic Literature Review on Less Common Natural Fibres and Their Biocomposites. J. Clean. Prod. 2018, 195, 240–267. [Google Scholar] [CrossRef]

- Tripathi, A.; Kumar, R. Industrial Hemp for Sustainable Agriculture: A Critical Evaluation from Global and Indian Perspectives. In Cannabis/Hemp for Sustainable Agriculture and Materials; Agrawal, D.C., Kumar, R., Dhanasekaran, M., Eds.; Springer: Singapore, 2022; pp. 29–57. ISBN 9789811687778. [Google Scholar]

- Tedeschi, A.; Cerrato, D.; Menenti, M. Is the Potential for Multi-Functional Use of Industrial Hemp Greater than Maize under Saline Conditions? Sustainability 2022, 14, 15646. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a Potential Raw Material toward a Sustainable World: A Review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Visković, J.; Zheljazkov, V.D.; Sikora, V.; Noller, J.; Latković, D.; Ocamb, C.M.; Koren, A. Industrial Hemp (Cannabis sativa L.) Agronomy and Utilization: A Review. Agronomy 2023, 13, 931. [Google Scholar] [CrossRef]

- Liao, J.; Zhang, S.; Tang, X. Sound Absorption of Hemp Fibers (Cannabis Sativa L.) Based Nonwoven Fabrics and Composites: A Review. J. Nat. Fibers 2022, 19, 1297–1309. [Google Scholar] [CrossRef]

- Ingrao, C.; Lo Giudice, A.; Bacenetti, J.; Tricase, C.; Dotelli, G.; Fiala, M.; Siracusa, V.; Mbohwa, C. Energy and Environmental Assessment of Industrial Hemp for Building Applications: A Review. Renew. Sustain. Energy Rev. 2015, 51, 29–42. [Google Scholar] [CrossRef]

- Fike, J. Industrial Hemp: Renewed Opportunities for an Ancient Crop. Crit. Rev. Plant Sci. 2016, 35, 406–424. [Google Scholar] [CrossRef]

- Naeem, M.Y.; Corbo, F.; Crupi, P.; Clodoveo, M.L. Hemp: An Alternative Source for Various Industries and an Emerging Tool for Functional Food and Pharmaceutical Sectors. Processes 2023, 11, 718. [Google Scholar] [CrossRef]

- Malabadi, R.B.; Kolkar, K.P.; Chalannavar, R.K. Cannabis Sativa: Industrial Hemp (Fiber-Type)—An Emerging Opportunity for India. Int. J. Res. Sci. Innov. (IJRSI) 2023, 10, 1–9. [Google Scholar]

- Ely, K.; Podder, S.; Reiss, M.; Fike, J. Cannabis/Hemp: Sustainable Uses, Opportunities, and Current Limitations. In Cannabis/Hemp for Sustainable Agriculture and Materials; Agrawal, D.C., Kumar, R., Dhanasekaran, M., Eds.; Springer: Singapore, 2022; pp. 59–87. ISBN 9789811687778. [Google Scholar]

- Mark, T.; Shepherd, J.; Olson, D.; Snell, W.; Proper, S.; Thornsbury, S. Economic Viability of Industrial Hemp in the United States: A Review of State Pilot Programs; Research Serice United States Department of Agriculture: Washington, DC, USA, 2020; Volume EIB-217. [Google Scholar]

- S.2667—115th Congress (2017–2018): Hemp Farming Act; April 16, 2018. Available online: https://www.congress.gov/bill/115th-congress/senate-bill/2667/ (accessed on 24 May 2023).

- United States Departement of Agriculture (USDA). Sustainably Incorporating Hemp Biobased Economy into Western U.S. Regional Rural and Tribal Lands. Available online: https://portal.nifa.usda.gov/web/crisprojectpages/1027531-sustainably-incorporating-hemp-biobased-economy-into-western-us-regional-rural-and-tribal-lands.html (accessed on 17 January 2024).

- Renée, J. Comparing Hemp Provisions in the 2014 and 2018 Farm Bills. Available online: https://crsreports.congress.gov/product/pdf/IF/IF11984 (accessed on 25 May 2023).

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University, Software Engineering Group Department of Computer Science: Keele, UK, 2004; pp. 1–34. [Google Scholar]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 Explanation and Elaboration: Updated Guidance and Exemplars for Reporting Systematic Reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef] [PubMed]

- Enarevba, D.; Haapala, K. Publication Statistics for a Systematic Literature Review of Industrial Hemp Product Manufacturing 2024. Available online: https://figshare.com/articles/dataset/Publication_statistics_for_a_systematic_literature_review_of_industrial_hemp_product_manufacturing/25066544?file=44236898 (accessed on 25 January 2024).

- Wirawan, R.; Sapuan, S.M. Research on Cellulose-Based Polymer Composites in Southeast Asia. In Lignocellulosic Polymer Composites; Thakur, V.K., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 41–61. ISBN 978-1-118-77394-9. [Google Scholar]

- Horne, M.R.L. Bast Fibres: Hemp Cultivation and Production. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 163–196. ISBN 978-0-12-818398-4. [Google Scholar]

- Deyholos, M.K.; Potter, S. Engineering Bast Fiber Feedstocks for Use in Composite Materials. Biocatal. Agric. Biotechnol. 2014, 3, 53–57. [Google Scholar] [CrossRef]

- Smart, L.B.; Toth, J.A.; Stack, G.M.; Monserrate, L.A.; Smart, C.D. Breeding of Hemp (Cannabis Sativa). In Plant Breeding Reviews; Goldman, I., Ed.; Wiley: Hoboken, NJ, USA, 2022; pp. 239–288. ISBN 978-1-119-87412-6. [Google Scholar]

- Marin, A.; Butu, M.; Dragomir, V.; Oncioiu, I.; Dobre, I. An Overview of Hemp for Fibre Market Opportunities for Romania. Ind. Textila 2022, 73, 432–437. [Google Scholar] [CrossRef]

- Rehman, M.; Fahad, S.; Du, G.; Cheng, X.; Yang, Y.; Tang, K.; Liu, L.; Liu, F.-H.; Deng, G. Evaluation of Hemp (Cannabis sativa L.) as an Industrial Crop: A Review. Environ. Sci. Pollut. Res. 2021, 28, 52832–52843. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, B.C.; Durán-Zuazo, V.H.; García-Tejero, I.F.; Ruiz, B.G. Current and Future Applications for Hemp Essential Oils: A Review. In Current Applications, Approaches, and Potential Perspectives for Hemp; Elsevier: Amsterdam, The Netherlands, 2023; pp. 365–391. ISBN 978-0-323-89867-6. [Google Scholar]

- Żuk-Gołaszewska, K.; Gołaszewski, J. Hemp Production. In Sustainable Agriculture Reviews 42; Crini, G., Lichtfouse, E., Eds.; Sustainable Agriculture Reviews; Springer International Publishing: Cham, Switzerland, 2020; Volume 42, pp. 1–36. ISBN 978-3-030-41383-5. [Google Scholar]

- Cleophas, F.N.; Zahari, N.Z.; Murugayah, P.; Rahim, S.A.; Mohd Yatim, A.N. Phytoremediation: A Novel Approach of Bast Fiber Plants (Hemp, Kenaf, Jute and Flax) for Heavy Metals Decontamination in Soil—Review. Toxics 2022, 11, 5. [Google Scholar] [CrossRef] [PubMed]

- Cherney, J.; Small, E. Industrial Hemp in North America: Production, Politics and Potential. Agronomy 2016, 6, 58. [Google Scholar] [CrossRef]

- Khan, T.; Hameed Sultan, M.T.B.; Ariffin, A.H. The Challenges of Natural Fiber in Manufacturing, Material Selection, and Technology Application: A Review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Jami, T.; Rawtani, D.; Agrawal, Y.K. Hemp Concrete: Carbon-Negative Construction. Emerg. Mater. Res. 2016, 5, 240–247. [Google Scholar] [CrossRef]

- Tanasă, F.; Zănoagă, M.; Teacă, C.; Nechifor, M.; Shahzad, A. Modified Hemp Fibers Intended for Fiber-reinforced Polymer Composites Used in Structural Applications—A Review. I. Methods of Modification. Polym. Compos. 2020, 41, 5–31. [Google Scholar] [CrossRef]

- Manjakkal, L.; Jain, A.; Nandy, S.; Goswami, S.; Tiago Carvalho, J.; Pereira, L.; See, C.H.; Pillai, S.C.; Hogg, R.A. Sustainable Electrochemical Energy Storage Devices Using Natural Bast Fibres. Chem. Eng. J. 2023, 465, 142845. [Google Scholar] [CrossRef]

- Parvez, A.M.; Lewis, J.D.; Afzal, M.T. Potential of Industrial Hemp (Cannabis sativa L.) for Bioenergy Production in Canada: Status, Challenges and Outlook. Renew. Sustain. Energy Rev. 2021, 141, 110784. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, J.; Gratton, J.-L. Engineering Perspectives of the Hemp Plant, Harvesting and Processing: A Review. J. Ind. Hemp 2004, 9, 23–39. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Sultan, M.T.H. A Review on Processing Techniques of Bast Fibers Nanocellulose and Its Polylactic Acid (PLA) Nanocomposites. Int. J. Biol. Macromol. 2019, 121, 1314–1328. [Google Scholar] [CrossRef] [PubMed]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef]

- Subash, M.C.; Muthiah, P. Eco-Friendly Degumming of Natural Fibers for Textile Applications: A Comprehensive Review. Clean. Eng. Technol. 2021, 5, 100304. [Google Scholar] [CrossRef]

- Amaducci, S.; Scordia, D.; Liu, F.H.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S.L. Key Cultivation Techniques for Hemp in Europe and China. Ind. Crops Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Muzyczek, M. The Use of Flax and Hemp for Textile Applications. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2012; pp. 147–167. ISBN 978-0-12-818782-1. [Google Scholar]

- Promhuad, K.; Srisa, A.; San, H.; Laorenza, Y.; Wongphan, P.; Sodsai, J.; Tansin, K.; Phromphen, P.; Chartvivatpornchai, N.; Ngoenchai, P.; et al. Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review. Polymers 2022, 14, 4274. [Google Scholar] [CrossRef] [PubMed]

- Anandjiwala, R.D.; Blouw, S. Composites from Bast Fibres-Prospects and Potential in the Changing Market Environment. J. Nat. Fibers 2007, 4, 91–109. [Google Scholar] [CrossRef]

- Das, P.P.; Chaudhary, V. Moving towards the Era of Bio Fibre Based Polymer Composites. Clean. Eng. Technol. 2021, 4, 100182. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. A Review of the Factors Affecting the Properties and Performance of Hemp Aggregate Concretes. J. Build. Eng. 2020, 31, 101323. [Google Scholar] [CrossRef]

- Rohit, K.; Dixit, S. A Review—Future Aspect of Natural Fiber Reinforced Composite. Polym. Renew. Resour. 2016, 7, 43–59. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A Review of Bast Fibres and Their Composites. Part 1—Fibres as Reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Developments in Polyester Composite Materials—An in-Depth Review on Natural Fibres and Nano Fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Dutta, A. Mechanical, Thermal, and Acoustic Properties of Hemp and Biocomposite Materials: A Review. J. Compos. Sci. 2022, 6, 373. [Google Scholar] [CrossRef]

- Shuvo, I.I. Fibre Attributes and Mapping the Cultivar Influence of Different Industrial Cellulosic Crops (Cotton, Hemp, Flax, and Canola) on Textile Properties. Bioresour. Bioprocess. 2020, 7, 51. [Google Scholar] [CrossRef]

- Pandit, P.; Maity, S.; Singha, K.; Annu; Uzun, M.; Shekh, M.; Ahmed, S. Potential Biodegradable Face Mask to Counter Environmental Impact of COVID-19. Clean. Eng. Technol. 2021, 4, 100218. [Google Scholar] [CrossRef]

- Jain, P.; Gupta, C. A Sustainable Journey of Handmade Paper from Past to Present: A Review. Probl. Sustain. Dev. 2021, 16, 233–244. [Google Scholar] [CrossRef]

- Malabadi, R.B.; Kolkar, K.P.; Chalannavar, R.K. Industrial Cannabis Sativa (Hemp Fiber): Hempcrete-A Plant Based and Eco-Friendly Building Construction Material. Int. J. Res. Innov. Appl. Sci. 2023, 8, 67–78. [Google Scholar]

- Jami, T.; Karade, S.R.; Singh, L.P. A Review of the Properties of Hemp Concrete for Green Building Applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Bhusan Das, B. A Comprehensive Review on the Use of Hemp in Concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Martínez, B.; Bernat-Maso, E.; Gil, L. Applications and Properties of Hemp Stalk-Based Insulating Biomaterials for Buildings: Review. Materials 2023, 16, 3245. [Google Scholar] [CrossRef]

- Ntimugura, F.; Vinai, R.; Harper, A.; Walker, P. Mechanical, Thermal, Hygroscopic and Acoustic Properties of Bio-Aggregates—Lime and Alkali—Activated Insulating Composite Materials: A Review of Current Status and Prospects for Miscanthus as an Innovative Resource in the South West of England. Sustain. Mater. Technol. 2020, 26, e00211. [Google Scholar] [CrossRef]

- Karri, R.; Lappalainen, R.; Tomppo, L.; Yadav, R. Bond Quality of Poplar Plywood Reinforced with Hemp Fibers and Lignin-Phenolic Adhesives. Compos. Part C Open Access 2022, 9, 100299. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp Fiber and Its Composites—A Review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Tholiya, P.; Deshmukh, S.P. Property Evaluation of Hemp-Bagasse Fiber Composite—A Review. Int. J. Eng. Appl. Sci. Technol. 2021, 6, 376–382. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amuthakkannan, P. Potential of Natural Fibers in Composites for Ballistic Applications—A Review. J. Nat. Fibers 2022, 19, 1648–1658. [Google Scholar] [CrossRef]

- Jahan, F.; Soni, M.; Wakeel, S.; Ahmad, S.; Bingol, S. Selection of Automotive Brake Material Using Different MCDM Techniques and Their Comparisons. J. Eng. Sci. Technol. Rev. 2022, 15, 24–33. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted Pre-Treatment of Hemp Bast Fibres for Optimal Performance in Biocomposite Materials: A Review. Ind. Crops Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Alkbir, M.F.M.; Sapuan, S.M.; Nuraini, A.A.; Ishak, M.R. Fibre Properties and Crashworthiness Parameters of Natural Fibre-Reinforced Composite Structure: A Literature Review. Compos. Struct. 2016, 148, 59–73. [Google Scholar] [CrossRef]

- Fairuz, A.M.; Sapuan, S.M.; Zainudin, E.S.; Jaafar, C.N.A. Pultrusion Process of Natural Fibre-Reinforced Polymer Composites. In Manufacturing of Natural Fibre Reinforced Polymer Composites; Salit, M.S., Jawaid, M., Yusoff, N.B., Hoque, M.E., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 217–231. ISBN 978-3-319-07943-1. [Google Scholar]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Namvar, F.; Jawaid, M.; Tahir, P.; Mohamad, R.; Azizi, S.; Khodavandi, A.; Rahman, H.S.; Nayeri, M.D. Potential Use of Plant Fibres and Their Composites for Biomedical Applications. BioResources 2014, 9, 5688–5706. [Google Scholar]

- Khan, B.A.; Warner, P.; Wang, H. Antibacterial Properties of Hemp and Other Natural Fibre Plants: A Review. BioRes 2014, 9, 3642–3659. [Google Scholar] [CrossRef]

- Sharma, M.; Sharma, R.; Chandra Sharma, S. A Review on Fibres and Fillers on Improving the Mechanical Behaviour of Fibre Reinforced Polymer Composites. Mater. Today Proc. 2021, 46, 6482–6489. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.; Virk, A.; Hall, W. A Review of Bast Fibres and Their Composites. Part 2—Composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1336–1344. [Google Scholar] [CrossRef]

- Deshmukh, G.S. Advancement in Hemp Fibre Polymer Composites: A Comprehensive Review. J. Polym. Eng. 2022, 42, 575–598. [Google Scholar] [CrossRef]

- Parkunam, N.; Ramesh, M.; Saravanakumar, S. A Review on Thermo-Mechanical Properties of Natural Fibre Reinforced Polymer Composites Incorporated with Fire Retardants. Mater. Today Proc. 2022, 69, 641–644. [Google Scholar] [CrossRef]

- Müssig, J.; Amaducci, S.; Bourmaud, A.; Beaugrand, J.; Shah, D.U. Transdisciplinary Top-down Review of Hemp Fibre Composites: From an Advanced Product Design to Crop Variety Selection. Compos. Part C Open Access 2020, 2, 100010. [Google Scholar] [CrossRef]

- Kiruthika, A.V. A Review on Physico-Mechanical Properties of Bast Fibre Reinforced Polymer Composites. J. Build. Eng. 2017, 9, 91–99. [Google Scholar] [CrossRef]

- Adhikary, D.; Kulkarni, M.; El-Mezawy, A.; Mobini, S.; Elhiti, M.; Gjuric, R.; Ray, A.; Polowick, P.; Slaski, J.J.; Jones, M.P.; et al. Medical Cannabis and Industrial Hemp Tissue Culture: Present Status and Future Potential. Front. Plant Sci. 2021, 12, 627240. [Google Scholar] [CrossRef] [PubMed]

- Sreenivas, H.T.; Krishnamurthy, N.; Arpitha, G.R. A Comprehensive Review on Light Weight Kenaf Fiber for Automobiles. Int. J. Lightweight Mater. Manuf. 2020, 3, 328–337. [Google Scholar] [CrossRef]

- Mohamad, M.A.; Jumahat, A.; Sapiai, N. Flexural Analysis of Hemp, Kenaf and Glass Fibre-Reinforced Polyester Resin. Phys. Sci. Rev. 2022, 9, 107–122. [Google Scholar] [CrossRef]

- Jaafar, M.A.; Abdullah, S.A.; Jumahat, A.; Muslim, M.A.; Sapiai, N.; Teng Loy, R.S. Effect of Stacking Sequence on Tensile Properties of Glass, Hemp and Kenaf Hybrid Composites. Phys. Sci. Rev. 2022, 9, 95–105. [Google Scholar] [CrossRef]

- Erchiqui, F.; Fotso Talla, A.S.; Kaddami, H. A Numerical Investigation of the Use of Novel Melt Processed PET-Hemp Fiber Composites for Thermoforming Applications. Polym. Eng. Sci. 2016, 56, 1021–1030. [Google Scholar] [CrossRef][Green Version]

- González-García, S.; Moreira, M.T.; Feijoo, G. Comparative Environmental Performance of Lignocellulosic Ethanol from Different Feedstocks. Renew. Sustain. Energy Rev. 2010, 14, 2077–2085. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, Y.; Wang, W.; Griffin, J.; Roozeboom, K.; Wang, D. Bioconversion of Industrial Hemp Biomass for Bioethanol Production: A Review. Fuel 2020, 281, 118725. [Google Scholar] [CrossRef]

- Mandal, S.; Hu, J.; Shi, S.Q. A Comprehensive Review of Hybrid Supercapacitor from Transition Metal and Industrial Crop Based Activated Carbon for Energy Storage Applications. Mater. Today Commun. 2023, 34, 105207. [Google Scholar] [CrossRef]

- Agarwal, C.; Csoka, L. Functionalization of Wood/Plant-Based Natural Cellulose Fibers with Nanomaterials: A Review. Tappi J. 2018, 17, 92–111. [Google Scholar] [CrossRef]

- Xu, J.; Bai, M.; Song, H.; Yang, L.; Zhu, D.; Liu, H. Hemp (Cannabis sativa Subsp. sativa) Chemical Composition and the Application of Hempseeds in Food Formulations. Plant Foods Hum. Nutr. 2022, 77, 504–513. [Google Scholar] [CrossRef] [PubMed]

- Montoya, Z.; Conroy, M.; Vanden Heuvel, B.D.; Pauli, C.S.; Park, S.-H. Cannabis Contaminants Limit Pharmacological Use of Cannabidiol. Front. Pharmacol. 2020, 11, 571832. [Google Scholar] [CrossRef] [PubMed]

- Kakkar, S.; Tandon, R.; Tandon, N. The Rising Status of Edible Seeds in Lifestyle Related Diseases: A Review. Food Chem. 2023, 402, 134220. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, M.; Fan, H.; Wu, J. Emerging Proteins as Precursors of Bioactive Peptides/Hydrolysates with Health Benefits. Curr. Opin. Food Sci. 2022, 48, 100914. [Google Scholar] [CrossRef]

- Woods, V.B.; Fearon, A.M. Dietary Sources of Unsaturated Fatty Acids for Animals and Their Transfer into Meat, Milk and Eggs: A Review. Livest. Sci. 2009, 126, 1–20. [Google Scholar] [CrossRef]

- Aloo, S.O.; Mwiti, G.; Ngugi, L.W.; Oh, D.-H. Uncovering the Secrets of Industrial Hemp in Food and Nutrition: The Trends, Challenges, and New-Age Perspectives. Crit. Rev. Food Sci. Nutr. 2022, 64, 5093–5112. [Google Scholar] [CrossRef] [PubMed]

- Vallath, A.; Shanmugam, A.; Rawson, A. Prospects of Future Pulse Milk Variants from Other Healthier Pulses—As an Alternative to Soy Milk. Trends Food Sci. Technol. 2022, 124, 51–62. [Google Scholar] [CrossRef]

- Steinmetz, F.P.; Nahler, G.; Wakefield, J.C. How Safe Are Hemp-Based Food Products? A Review and Risk Assessment of Analytical Data from Germany. Nutr. Food Sci. 2023, 53, 489–499. [Google Scholar] [CrossRef]

- Shen, P.; Gao, Z.; Fang, B.; Rao, J.; Chen, B. Ferreting out the Secrets of Industrial Hemp Protein as Emerging Functional Food Ingredients. Trends Food Sci. Technol. 2021, 112, 1–15. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Wang, Y.; Li, W.; He, D.; Zhang, Y.; Zhang, X.; Xing, X. Emerging Natural Hemp Seed Proteins and Their Functions for Nutraceutical Applications. Food Sci. Hum. Wellness 2023, 12, 929–941. [Google Scholar] [CrossRef]

- Finley, S.J.; Javan, G.T.; Green, R.L. Bridging Disciplines: Applications of Forensic Science and Industrial Hemp. Front. Microbiol. 2022, 13, 760374. [Google Scholar] [CrossRef] [PubMed]

- Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. [Google Scholar] [CrossRef]

- Moscariello, C.; Matassa, S.; Esposito, G.; Papirio, S. From Residue to Resource: The Multifaceted Environmental and Bioeconomy Potential of Industrial Hemp (Cannabis sativa L.). Resour. Conserv. Recycl. 2021, 175, 105864. [Google Scholar] [CrossRef]

- VanDolah, H.J.; Bauer, B.A.; Mauck, K.F. Clinicians’ Guide to Cannabidiol and Hemp Oils. Mayo Clin. Proc. 2019, 94, 1840–1851. [Google Scholar] [CrossRef] [PubMed]

- La Maida, N.; Di Giorgi, A.; Pichini, S.; Busardò, F.P.; Huestis, M.A. Recent Challenges and Trends in Forensic Analysis: Δ9-THC Isomers Pharmacology, Toxicology and Analysis. J. Pharm. Biomed. Anal. 2022, 220, 114987. [Google Scholar] [CrossRef] [PubMed]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Hempseed in Food Industry: Nutritional Value, Health Benefits, and Industrial Applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 282–308. [Google Scholar] [CrossRef] [PubMed]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef]

- Burton, R.A.; Andres, M.; Cole, M.; Cowley, J.M.; Augustin, M.A. Industrial Hemp Seed: From the Field to Value-Added Food Ingredients. J. Cannabis Res. 2022, 4, 45. [Google Scholar] [CrossRef]

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial Hemp (Cannabis sativa Subsp. sativa) as an Emerging Source for Value-Added Functional Food Ingredients and Nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Montero, L.; Ballesteros-Vivas, D.; Gonzalez-Barrios, A.F.; Sánchez-Camargo, A.D.P. Hemp Seeds: Nutritional Value, Associated Bioactivities and the Potential Food Applications in the Colombian Context. Front. Nutr. 2023, 9, 1039180. [Google Scholar] [CrossRef] [PubMed]

- Aydar, E.F.; Tutuncu, S.; Ozcelik, B. Plant-Based Milk Substitutes: Bioactive Compounds, Conventional and Novel Processes, Bioavailability Studies, and Health Effects. J. Funct. Foods 2020, 70, 103975. [Google Scholar] [CrossRef]

- Lachenmeier, D.W.; Walch, S.G. Analysis and Toxicological Evaluation of Cannabinoids in Hemp Food Products—A Review. Electron. J. Environ. Agric. Food Chem. 2005, 4, 812–826. [Google Scholar] [CrossRef]

- Malabadi, R.B.; Kolkar, K.P.; Chalannavar, R.K. Cannabis sativa: Industrial Hemp (Fiber Type)—An Ayurvedic Traditional Herbal Medicine. Int. J. Innov. Sci. Res. Rev. 2023, 5, 4040–4046. [Google Scholar]

- Mirpoor, S.F.; Giosafatto, C.V.L.; Porta, R. Biorefining of Seed Oil Cakes as Industrial Co-Streams for Production of Innovative Bioplastics. A Review. Trends Food Sci. Technol. 2021, 109, 259–270. [Google Scholar] [CrossRef]

- King, J.W. The Relationship between Cannabis/Hemp Use in Foods and Processing Methodology. Curr. Opin. Food Sci. 2019, 28, 32–40. [Google Scholar] [CrossRef]

- El Hage, M.; Rajha, H.N.; Maache-Rezzoug, Z.; Koubaa, M.; Louka, N. Intensification of Bioethanol Production from Different Lignocellulosic Biomasses, Induced by Various Pretreatment Methods: An Updated Review. Energies 2022, 15, 6912. [Google Scholar] [CrossRef]

- Lawson, L.; Degenstein, L.M.; Bates, B.; Chute, W.; King, D.; Dolez, P.I. Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability 2022, 14, 15337. [Google Scholar] [CrossRef]

- Wu, Y.; Trejo, H.X.; Chen, G.; Li, S. Phytoremediation of Contaminants of Emerging Concern from Soil with Industrial Hemp (Cannabis sativa L.): A Review. Environ. Dev. Sustain. 2021, 23, 14405–14435. [Google Scholar] [CrossRef]

- Favero, A.; Thomas, V.M.; Luettgen, C.O. Life Cycle Analyses of Alternative Fibers for Paper. J. Adv. Manuf. Process. 2019, 1, e10023. [Google Scholar] [CrossRef]

- Enarevba, D.R.; Haapala, K.R. A Comparative Life Cycle Assessment of Expanded Polystyrene and Mycelium Packaging Box Inserts. Procedia CIRP 2023, 116, 654–659. [Google Scholar] [CrossRef]

- Zanetti, F.; Monti, A.; Berti, M.T. Challenges and Opportunities for New Industrial Oilseed Crops in EU-27: A Review. Ind. Crops Prod. 2013, 50, 580–595. [Google Scholar] [CrossRef]

- Hussain, A.; Abidi, S.H.; Syed, Q. Current Knowledge on Ethnobotany, Phytochemistry and Biological Activities of Cannabis (Hemp) from Pakistan with Emphasis on Its Legalization and Regulation. Ethnobot. Res. Appl. 2022, 23, 1–33. [Google Scholar]

- Nyland, C.R.; Moyer, D.C. Regulating for Safety: Cannabidiol Dose in Food: A Review. J. Food Prot. 2022, 85, 1355–1369. [Google Scholar] [CrossRef]

| Databases | Boolean Search |

|---|---|

| Google Scholar | (+review) AND (+hemp) AND (+product) AND (+manufacturing) |

| ASME Digital Collection, Engineering Village, ScienceDirect, and Web of Science | review AND hemp AND product AND manufacturing |

| Databases | In Title | In Abstract |

|---|---|---|

| Google Scholar | 70 | Not screened |

| ScienceDirect | 15 | 43 |

| Engineering Village | 5 | 30 |

| Web of Science | 6 | 9 |

| ASME Digital Collection | 0 | 0 |

| Field Retting | Water Retting | Chemical Retting | Enzyme Retting | |

|---|---|---|---|---|

| Degrading Agent | Naturally by microorganisms | Water and decaying microorganisms | Chemicals such as NaOH, Na2CO3, and Na2SO3 | Enzymes (bacteria) |

| Duration | 2–8 weeks | 7–14 days (4–5 days using warm water) | Hours to a few days | A few days to a few weeks |

| Advantages | Ease, low cost | Controlled process, best separation and quality, not weather-dependent | Controlled process, very good for fiber quality and yield, not weather-dependent | Same advantages as water retting without its disadvantages, eco-friendly |

| Disadvantages | Minimum control over process and land occupancy, weather-dependent | High water consumption, waste product effluent, malodor, and energy required for drying straw | Costly, not eco-friendly | Costly |

| Packaging Technologies or Processes | Hemp Feedstock and Compatible Materials |

|---|---|

| Injection molding or extruder | Hemp fiber and polypropylene, PLA, or potato starch |

| Lamination | Hemp fiber and epoxy resins, polyvinyl alcohol (PVA) solution, or PLA |

| Compression molding | Hemp fiber and wheat gluten, hemp fiber and cashew nut shell liquid matrix, hemp fiber and poly benzoxazine, hemp fiber and polyester, and hemp fiber and polyethylene |

| Solvent casting | Hemp seed oil cake, hemp fiber PLA and polybutylene succinate (PBS), hemp hurd, and PVA solution |

| Melting processing | Hemp fiber and cornstarch |

| Resin transfer molding | Hemp fiber and unsaturated polyesters |

| Hydraulic hot-press | Hemp fiber and polybenzoxazine |

| Extrusion and thermoforming | Hemp hurd powder and PLA for food packaging |

| Industry | Products | References |

|---|---|---|

| Sports | Skiing, snowboarding, and canoeing equipment, bike frames, and tennis racquets | [11,27] |

| Medical applications | Orthotic devices and wound dressings | [11,73,74] |

| Ballistic applications | Protective armor, such as bulletproof vests and helmets | [50,67] |

| Transportation (automobiles, aerospace, and railway coaches) | Brake pads, automobile interior linings, door frames, seatbacks, dashboards, trunk covers, engine covers, sun visors, air filters, spare tire covers, and roof headlining | [15,27] |

| Textile | Fabrics, preforms (woven or nonwoven), cordage, yarns, carpets, clothing, ropes, sportswear, jeans, hats, bags, pillowcases, blankets, socks, shoes, hemp jewelry, upholstery, wall decor, ornamental items, façades, curtain walls, and building skins | [12,29,61] |

| Paper and pulp | Currency notes, specialist artistic paper, specialty nonwovens, Bible sheets, grease-proof paper, handcrafted papers, cigarette paper, tea and coffee bags, office paper, and carbon tissue. | [11,12] |

| Construction and building materials | Wall insulation, roof insulation, floor slab, blocks, panels, bricks, window insulation, pavement, mortar, plaster and fillers, hemp binder-less particle boards, wall claddings, sheathing, ceilings, cabinets, composite and floor mats, storage tanks, and 3D-printed products and structures | [4,7,17,18,41,51,59,60,64] |

| Animal bedding and mulch | Animal bedding, hemp-based fleeces or mulch cloth, and weed-control mulching mats | [12,14] |

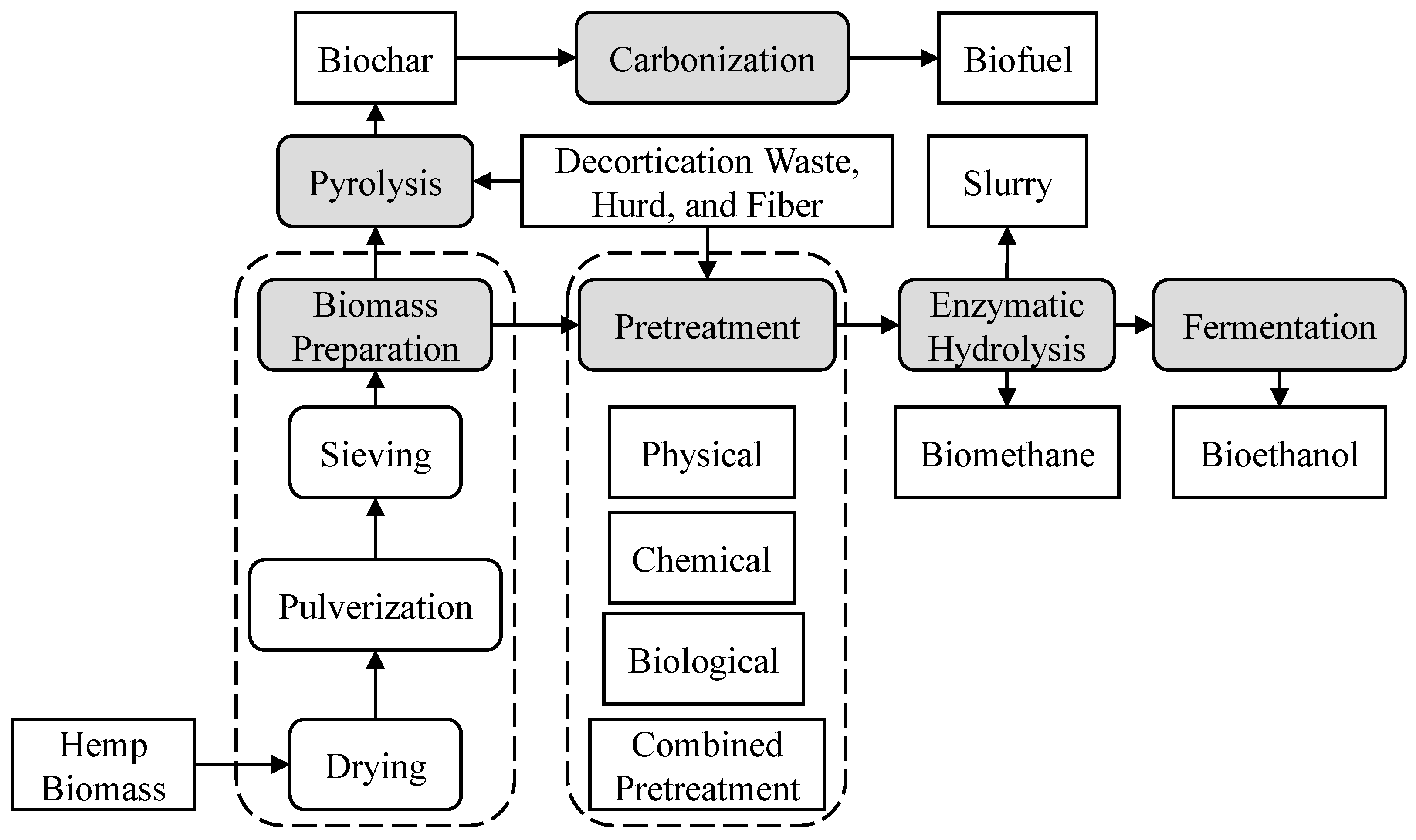

| Bioenergy | Biogas, biofuel, biohydrogen, bioethanol, and biomethane | [41,86,87] |

| Packaging | Package trays for food (salads, meats, and ready-made food products), drinks (wine), electronic products, and barrier coatings/films | [4,18,74] |

| Others | Luggage boxes, carpets, bathtubs, toilet seats, wing box geotextiles, insulation mats, furniture, 3D printing filament, nano carbon sheets, supercapacitors, and hybrid supercapacitor batteries for portable and wearable applications | [9,16,17,40,41,51,52] |

| Plant Part | Primary Products (Extraction Methods) | Derived Products/Use | References |

|---|---|---|---|

| Hemp Seeds | Hemp oil cake, also called seed cake or hemp meal (cold pressing [101] and enzyme-assisted low-temperature pressing [95]) | Pasta, tortilla chips, salad dressings, snack products (crackers, cookies, and gluten-free biscuits), frozen desserts, hemp milk, fertilizer, animal feed, and supplements | [14,35] [90,95] |

| Hemp seed oil (enzyme hydrolysis and freeze-drying [95]) | Butter, margarine, oil paint, inks, polishes, sealers, cleaning agents coating, lubricating oil, sealant, varnishes, lamp oil, biofuel (ethanol), cosmetics, industrial fuel oil, pralines, chocolates, enriched bread, enriched potato chips, smoothies additive, hemp-based bioplastics, lip balms, hand creams, massage oil, and face and body cream | [14,16] [41,108] [95,111] [7,35] [12,33,112] | |

| Hemp powder (grinding and milling) | Hemp flour, beverages (beer, lemonade, drink mixes, probiotic drinks), sweetened yogurt, enriched bread, enriched pasta, enriched gnocchi, extruded rice, pork loaf, Indian flat bread (Indian Chapatti), hemp-based meat analogs, and hemp sauce | [16,95] [90,106] [92,111] [7,35,107] | |

| Hemp protein isolates and concentrates | Extruded energy bars, cookies, pork loaf, edible and biodegradable plastics | [90,106] [92,107,113] | |

| Dehulled hemp seed or heart (dehulling) | Hemp tofu (HempFu), pork loaf, and animal feed | [90,106] [92,101,106] | |

| Hemp hull | Fertilizer and animal feed | [11] | |

| Hemp Flowers | Hemp oil (microwave heating, vacuum-microwave drying [95]) | Essential oils, skin moisturizers, shampoos, soaps, bathing gels, cosmetic and pharmaceutical products, topical oils, sparkling water, lotions and balms, enriched bread, wine, hemp sauce, confectionery, biopesticide (insect repellant), food additives (flavoring agent), tinctures, and soft gels | [18,101] [90,95] [35,111] [7,33,114] |

| Hemp Leaves | Hemp leaf powder | Hemp leaf tea | [111] |

| Process/Material | Pretreatment Methods (Types) |

|---|---|

| Hemp Stalk | Field retting, water retting, chemical retting, and enzymatic retting |

| Fiber Treatment | Physical treatment (stretching, steam explosion, clantering, cold plasma treatment, corona treatment, and osmotic degumming) Chemical retting (alkalization, propionylation, acetylation, and coupling agents such as maleated polypropylene treatments) Physico-chemical and hybridization treatments |

| Hemp Biomass (Bioenergy) | Biological, chemical, or physical treatment or a combination of two or more treatments |

| Hemp Seed | Ultrasound, microwave, or degumming |

| Hemp Protein | Degreasing or defatting |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enarevba, D.R.; Haapala, K.R. The Emerging Hemp Industry: A Review of Industrial Hemp Materials and Product Manufacturing. AgriEngineering 2024, 6, 2891-2925. https://doi.org/10.3390/agriengineering6030167

Enarevba DR, Haapala KR. The Emerging Hemp Industry: A Review of Industrial Hemp Materials and Product Manufacturing. AgriEngineering. 2024; 6(3):2891-2925. https://doi.org/10.3390/agriengineering6030167

Chicago/Turabian StyleEnarevba, Dolor R., and Karl R. Haapala. 2024. "The Emerging Hemp Industry: A Review of Industrial Hemp Materials and Product Manufacturing" AgriEngineering 6, no. 3: 2891-2925. https://doi.org/10.3390/agriengineering6030167

APA StyleEnarevba, D. R., & Haapala, K. R. (2024). The Emerging Hemp Industry: A Review of Industrial Hemp Materials and Product Manufacturing. AgriEngineering, 6(3), 2891-2925. https://doi.org/10.3390/agriengineering6030167