Comparison of Mango (Mangifera indica) Dehydration Technologies: A Systematic Review

Abstract

1. Introduction

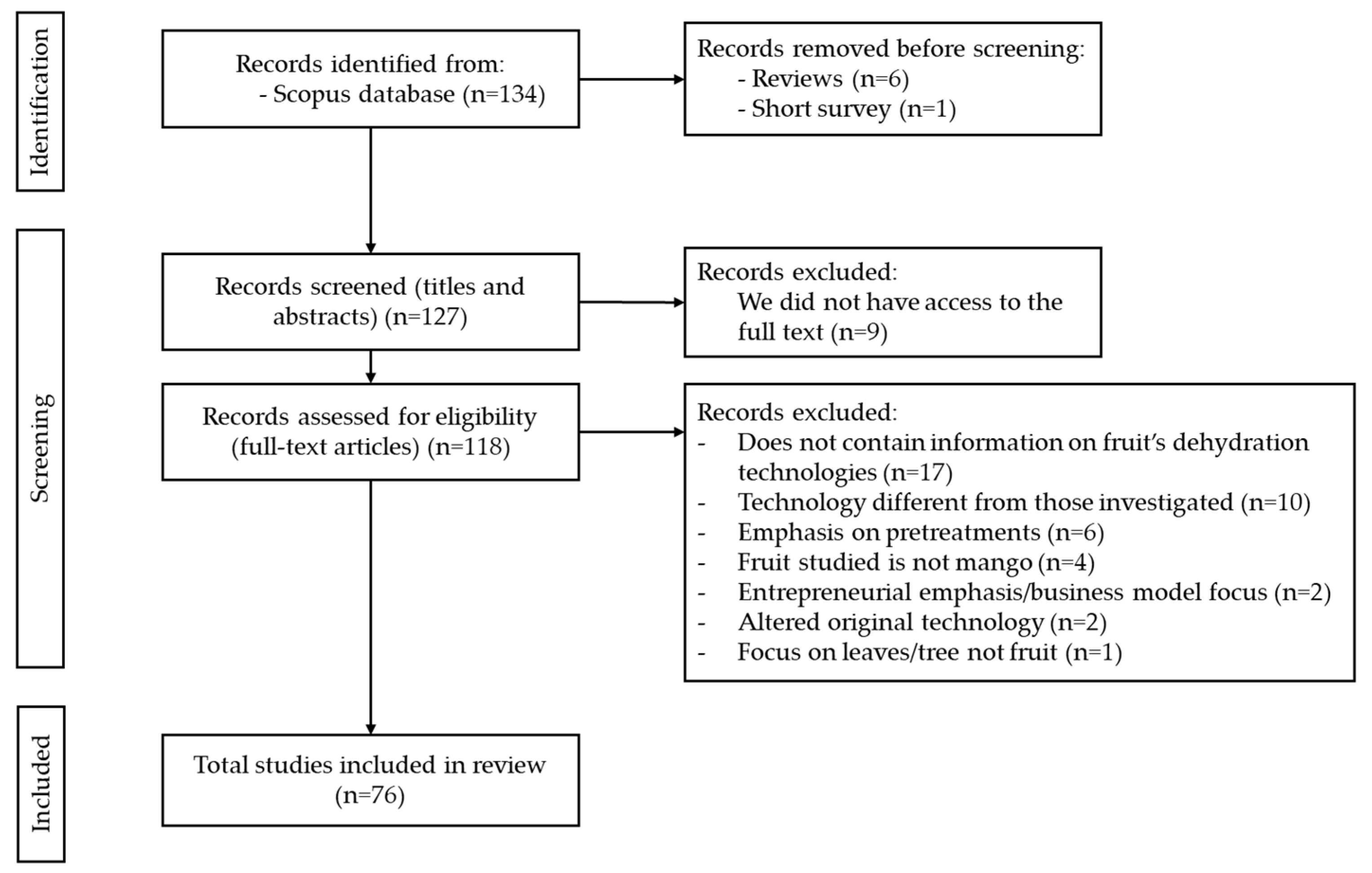

2. Materials and Methods

2.1. Planning the Review

2.2. Inclusion and Exclusion Criteria for Studies

- Does not contain information on fruit dehydration technologies

- Technology different from those investigated

- Emphasis on pretreatments

- Fruit studied is not mango

- Entrepreneurial emphasis/business model focus

- Altered original technology

- Focus on leaves/tree, not fruit

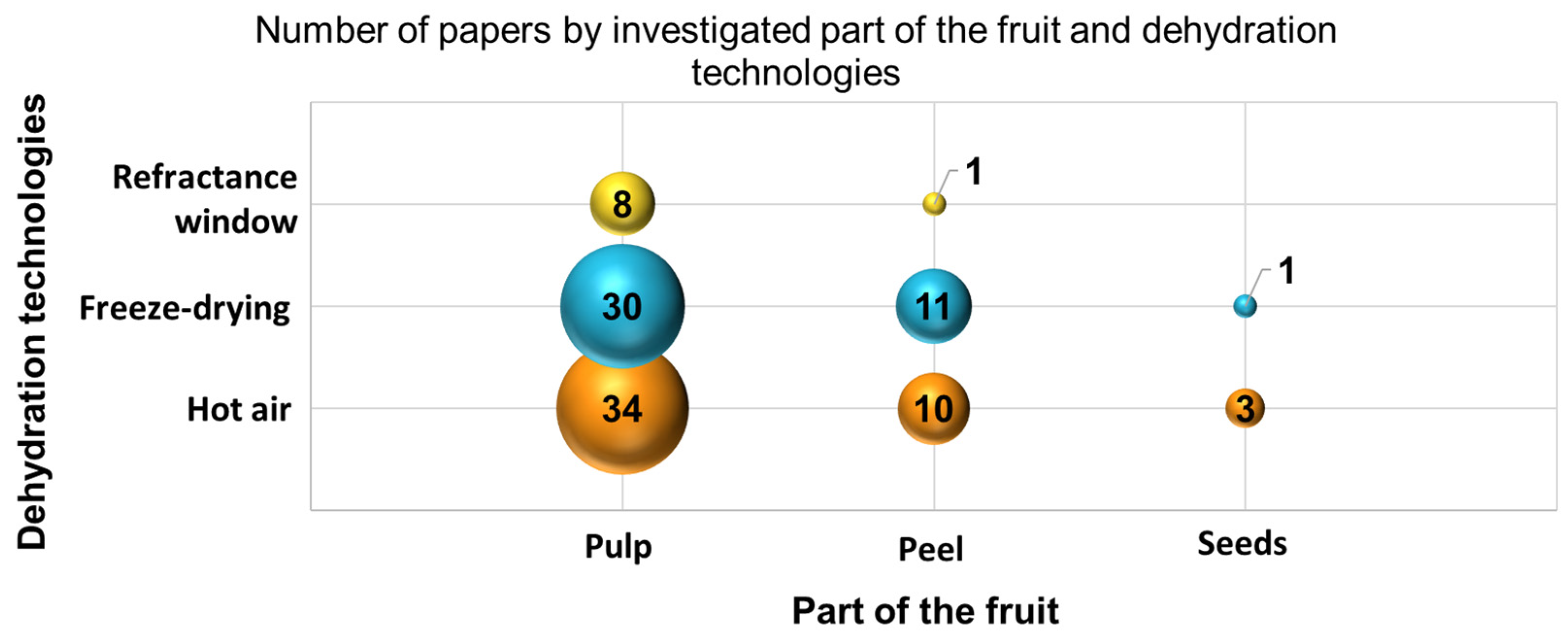

- After the screening process, 76 papers were selected for inclusion in the bibliographic and theoretical analyses.

2.3. Documentation and Analysis of Review

3. Results and Discussion

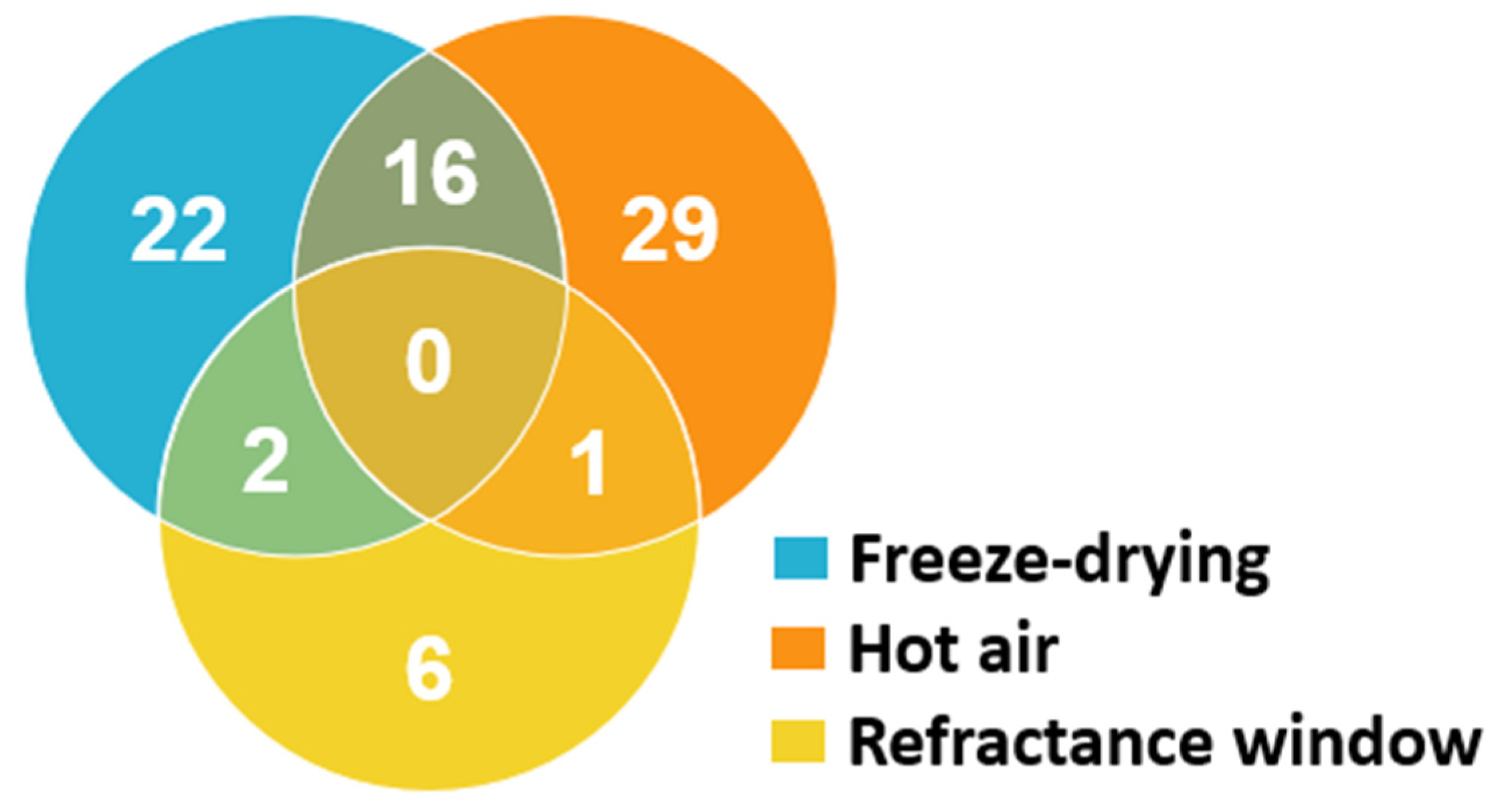

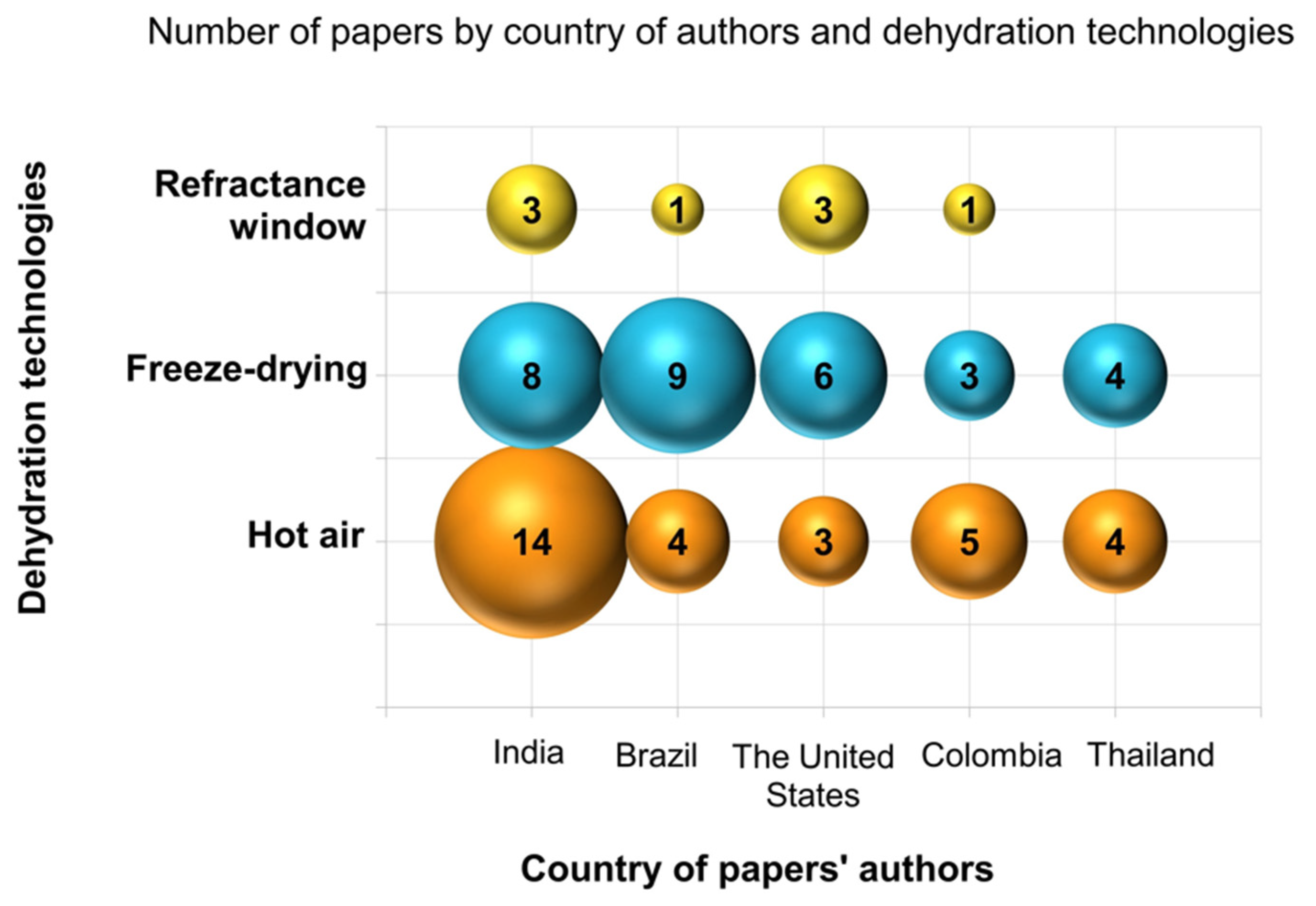

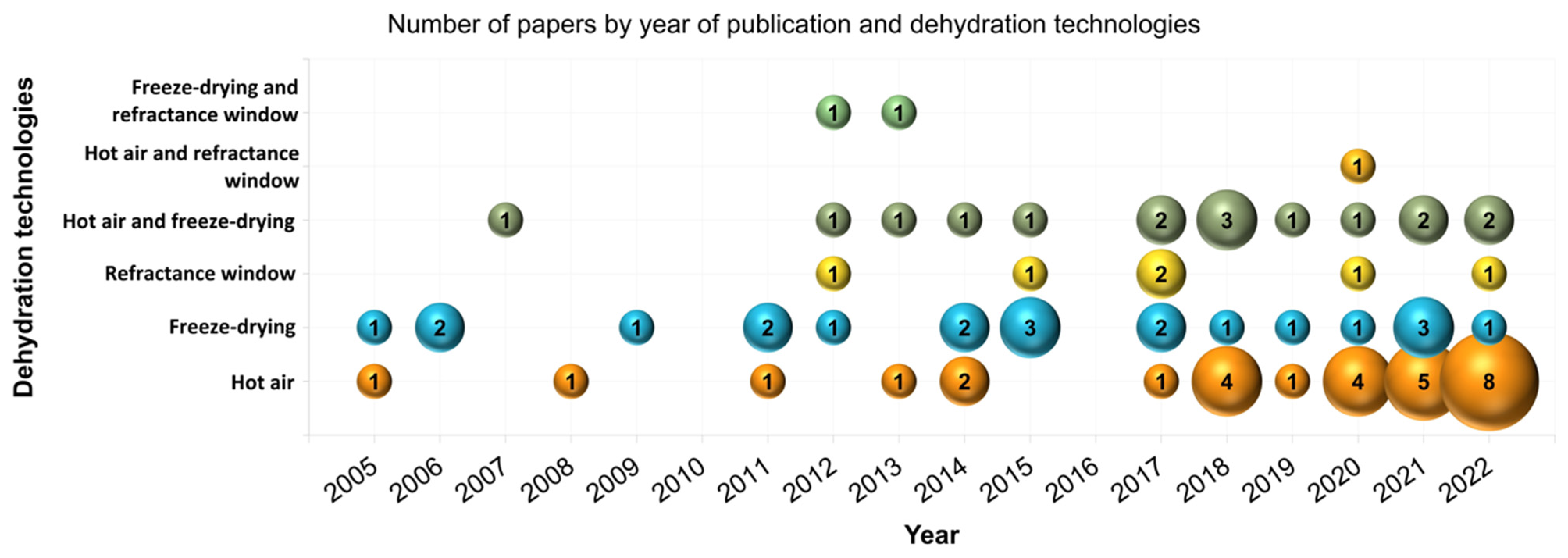

3.1. Systematic Literature Review (SLR)

3.1.1. Keywords

3.1.2. Authors

3.1.3. Year of Publication of Articles

3.1.4. Mango Varieties

3.1.5. Products and Applications

3.2. Comparison of Dehydration Technologies

3.2.1. Convective Hot-Air Drying

- Operating Conditions

- Physicochemical Properties

- Nutritional Properties

- Organoleptic Properties

3.2.2. Dehydration by Freeze-Drying

- Operating Conditions

- Physicochemical Properties

- Nutritional Properties

- Organoleptic Properties

3.2.3. Refractance Window Dehydration

- Operating Conditions

- Physicochemical Properties

- Nutritional Properties

- Organoleptic Properties

3.2.4. Parallel between Technologies

- Differences

- Similarities

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). Major Tropical Fruits: Market Review 2021; FAO: Rome, Italy, 2022. [Google Scholar]

- Alzamora, S.M.; Guerrero, S.N.; Nieto, A.B.; Vidales, S.L. Conservación de Frutas y Hortalizas Mediante Tecnologías Combinadas: Manual de Capacitación; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2004. [Google Scholar]

- Mendoza, E.; Calvo, C. Bromatología: Composición y Propiedades de Los Alimentos; McGraw-Hill: México, Italy, 2010. [Google Scholar]

- Quintero, V.C.; Giraldo, G.G.; Lucas, J.A.; Vasco, J.L. Physicochemical characterization of the common mango (Mangifera indica L.) during ripening process. Biotecnología 2013, 11, 10–18. [Google Scholar]

- Atoche-Chauca, L.S.; García-Siu, M.W. Aprovechamiento de Residuos Agroindustriales (Cáscara de Mango) para la Formulación de Cupcakes. Bachelor’s Thesis, Universidad Nacional del Santa, Nuevo Chimbote, Peru, 2017. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). The State of Food and Agriculture 2019: Moving forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019. [Google Scholar]

- Singh, S.; Kawade, S.; Dhar, A.; Powar, S. Analysis of mango drying methods and effect of blanching process based on energy consumption, drying time using multi-criteria decision-making. Clean. Eng. Technol. 2022, 8, 100500. [Google Scholar] [CrossRef]

- Nguyen, T.V.L.; Nguyen, Q.D.; Nguyen, P.B.D. Drying kinetics and changes of total phenolic content, antioxidant activity and color parameters of mango and avocado pulp in refractance window drying. Pol. J. Food Nutr. Sci. 2022, 72, 27–38. [Google Scholar] [CrossRef]

- Basulto, J.; Moñino, M.; Farran, A.; Baladia, E.; Manera, M.; Cervera, P.; Romero-de-Ávila, M.D.; Miret, F.; Astiasarán, I.; Bonany, J.; et al. Recomendaciones de manipulación doméstica de frutas y hortalizas para preservar su valor nutritivo. Rev. Esp. Nutr. Hum. Diet. 2014, 18, 100–115. [Google Scholar] [CrossRef]

- Hernández-Ruíz, Y.N. Deshidratación de Manzanas Tipo Granny Smith en Ventana Refractiva con Pretratamiento de Deshidratación Osmótica y Campo Eléctrico Moderado. Bachelor’s Thesis, Universidad Técnica Federico Santa María, Valparaíso, Chile, 2017. [Google Scholar]

- Díaz-Urbano, C.E. Evaluación de Tecnologías de Secado en las Propiedades Fisicoquímicas del Banano (Cavendish Valery). Bachelor’s Thesis, Universidad Nacional Abierta y a Distancia (UNAD), Bogotá, Colombia, 2018. [Google Scholar]

- Chakraborty, R.; Saha, A.K.; Bhattacharya, P. Modeling and simulation of parametric sensitivity in primary freeze-drying of foodstuffs. Sep. Purif. Technol. 2006, 49, 258–263. [Google Scholar] [CrossRef]

- Nindo, C. Novel drying method for vegetables, fruits, herbs, and aquatic resources. In Proceedings of the CSBE/SCGAB Annual Conference, Vancouver, BC, Canada, 13–16 July 2008. [Google Scholar]

- Carrascosa-Morelló, A. Obtención de Aperitivos de Manzana con Efecto Probiótico Mediante Impregnación con Lactobacillus Paracasei. Bachelor’s Thesis, Universitat Politècnica de València, Valencia, Spain, 2019. [Google Scholar]

- Torres, R.; Montes, E.J.; Pérez, O.A.; Andrade, R.D. Relación del Color y del Estado de Madurez con las Propiedades Fisicoquímicas de Frutas Tropicales. Inf. Tecnol. 2013, 24, 51–56. [Google Scholar] [CrossRef]

- Rethlefsen, M.L.; Kirtley, S.; Waffenschmidt, S.; Ayala, A.P.; Moher, D.; Page, M.J.; Koffel, J.B.; Blunt, H.; Brigham, T.; Chang, S.; et al. PRISMA-S: An extension to the PRISMA Statement for Reporting Literature Searches in Systematic Reviews. Syst. Rev. 2021, 10, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Agriculture and Rural Development. Cadena del Mango: Indicadores e Instrumentos Segundo Trimestre 2021. Available online: https://sioc.minagricultura.gov.co/Mango/Documentos/2021-06-30%20Cifras%20Sectoriales.pdf (accessed on 24 February 2023).

- Food and Agriculture Organization of the United Nations (FAO). FAOSTAT. Available online: https://www.fao.org/faostat/es/#compare (accessed on 3 January 2023).

- Ministry of Commerce, Industry and Tourism. Mango Colombiano, con luz verde para ingresar a Estados Unidos 2021. Available online: https://www.mincit.gov.co/prensa/noticias/comercio/mango-colombiano-ingresa-a-estados-unidos (accessed on 24 February 2023).

- Mawilai, P.; Chaloeichitratham, N.; Pornchaloempong, P. Processing feasibility and qualities of freeze dried mango powder for SME scale. IOP Conf. Ser. Earth Environ. Sci. 2019, 301, 012059. [Google Scholar] [CrossRef]

- Guarte, R.C.; Pott, I.; Mühlbauer, W. Influence of drying parameters on β-carotene retention in mango leather. Fruits 2005, 60, 255–265. [Google Scholar] [CrossRef][Green Version]

- Sarkar, T.; Saha, S.K.; Salauddin, M.; Chakraborty, R. Drying kinetics, Fourier-transform infrared spectroscopy analysis and sensory evaluation of sun, hot-air, microwave and freeze dried mango leather. J. Microbiol. Biotechnol. Food Sci. 2021, 10, e3313. [Google Scholar] [CrossRef]

- United Nations. Trade and Development Report 2018. Available online: https://unctad.org/system/files/official-document/tdr2018_en.pdf (accessed on 24 February 2023).

- Prieto-Poveda, D.O. La Tecnificación como Herramienta para Incrementar la Productividad Agropecuaria en Colombia. Bachelor’s Thesis, Fundación Universidad de América, Bogotá, Colombia, 2019. [Google Scholar]

- Oliver-Simancas, R.; Díaz-Maroto, M.C.; Pérez-Coello, M.S.; Alañón, M.E. Viability of pre-treatment drying methods on mango peel by-products to preserve flavouring active compounds for its revalorisation. J. Food Eng. 2020, 279, 109953. [Google Scholar] [CrossRef]

- Sánchez-Camargo, A.d.P.; Gutiérrez, L.F.; Vargas, S.M.; Martinez-Correa, H.A.; Parada-Alfonso, F.; Narváez-Cuenca, C.E. Valorisation of mango peel: Proximate composition, supercritical fluid extraction of carotenoids, and application as an antioxidant additive for an edible oil. J. Supercrit. Fluids 2019, 152, 104574. [Google Scholar] [CrossRef]

- Váquiro, H.A.; Mulet, A.; García-Pérez, J.V.; Clemente, G.; Bon, J. Optimization of intermittent hot air drying of mango (Mangifera indica L.). Defect Diffus. Forum 2008, 273–276, 250–255. [Google Scholar] [CrossRef]

- Vanegas-Mahecha, P.; Parra-Coronado, A. Designing, constructing and evaluating a dynamic prototype dryer for obtaining rolled dehydrated fruit pulp. Ing. Investig. 2011, 31, 163–170. [Google Scholar] [CrossRef]

- Dorta, E.; Lobo, M.G.; González, M. Using drying treatments to stabilise mango peel and seed: Effect on antioxidant activity. LWT Food Sci. Technol. 2012, 45, 261–268. [Google Scholar] [CrossRef]

- Sogi, D.S.; Siddiq, M.; Greiby, I.; Dolan, K.D. Total phenolics, antioxidant activity, and functional properties of “Tommy Atkins” mango peel and kernel as affected by drying methods. Food Chem. 2013, 141, 2649–2655. [Google Scholar] [CrossRef] [PubMed]

- Nagel, A.; Neidhart, S.; Anders, T.; Elstner, P.; Korhummel, S.; Sulzer, T.; Wulfkühler, S.; Winkler, C.; Qadri, S.; Rentschler, C.; et al. Improved processes for the conversion of mango peel into storable starting material for the recovery of functional co-products. Ind. Crops. Prod. 2014, 61, 92–105. [Google Scholar] [CrossRef]

- Sant’anna, V.; Cassini, A.S.; Marczak, L.D.F.; Tessaro, I.C. Kinetic modeling; total phenolic content and colour changes of mango peels during hot air drying. Lat. Am. Appl. Res. 2014, 44, 301–306. [Google Scholar] [CrossRef]

- Sogi, D.S.; Siddiq, M.; Dolan, K.D. Total phenolics; carotenoids and antioxidant properties of Tommy Atkin mango cubes as affected by drying techniques. LWT Food Sci. Technol. 2015, 62, 564–568. [Google Scholar] [CrossRef]

- Izli, N.; Izli, G.; Taskin, O. Influence of different drying techniques on drying parameters of mango. Ciênc. Tecnol. Aliment. 2017, 37, 604–612. [Google Scholar] [CrossRef]

- Link, J.V.; Tribuzi, G.; Laurindo, J.B. Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT Food Sci. Technol. 2017, 84, 717–725. [Google Scholar] [CrossRef]

- Link, J.V.; Tribuzi, G.; Oliveira de Moraes, J.; Laurindo, J.B. Assessment of texture and storage conditions of mangoes slices dried by a conductive multi-flash process. J. Food Eng. 2018, 239, 8–14. [Google Scholar] [CrossRef]

- De Ancos, B.; Sánchez-Moreno, C.; Zacarías, L.; Rodrigo, M.J.; Sáyago, S.; Blanca, F.J.; Domínguez, J.A.; González-Aguilar, G.A. Effects of two different drying methods (freeze-drying and hot air-drying) on the phenolic and carotenoid profile of ‘Ataulfo’ mango by-products. J. Food Meas. Charact. 2018, 12, 2145–2157. [Google Scholar] [CrossRef]

- Estrada, H.H.; Restrepo, C.E.; Saumett, H.G.; Pérez, L. Osmotic dehydration and hot air drying on mango, guava and lemon to obtain functional ingredients. Inf. Tecnol. 2018, 29, 197–204. [Google Scholar] [CrossRef]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Campanella, O.H.; Welti-Chanes, J. Influence of drying method on the composition, physicochemical properties, and prebiotic potential of dietary fibre concentrates from fruit peels. J. Food Qual. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Méndez-Calderón, E.K.; Ocampo-Castaño, J.C.; Orrego, C.E. Optimization of convective drying assisted by ultrasound for Mango Tommy (Mangifera indica L.). J. Food Process Eng. 2018, 41, e12634. [Google Scholar] [CrossRef]

- Sehrawat, R.; Nema, P.K.; Kaur, B.P. Quality evaluation and drying characteristics of mango cubes dried using low-pressure superheated steam, vacuum and hot air drying methods. LWT Food Sci. Technol. 2018, 92, 548–555. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, C.; Wang, X.; Liao, M.; Yue, J.; Jiao, S. Application of hot air-assisted radio frequency as second stage drying method for mango slices. J. Food Process Eng. 2019, 42. [Google Scholar] [CrossRef]

- Jödicke, K.; Arendt, S.; Hofacker, W.; Speckle, W. The influence of process parameters on the quality of dried agricultural products determined using the cumulated thermal load. Dry. Technol. 2020, 38, 321–332. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Shorstkii, I.; Parniakov, O.; Mykhailyk, V.; Toepfl, S.; Rybak, K.; Dadan, M.; Nowacka, M.; Wiktor, A. The effect of different methods of mango drying assisted by a pulsed electric field on chemical and physical properties. J. Food Process. Preserv. 2020, 44, e12974. [Google Scholar] [CrossRef]

- Malaikritsanachalee, P.; Choosri, W.; Choosri, T. Study on intermittent low-pressure superheated steam drying, effect on drying kinetics and quality changes in ripe mangoes. J. Food Process. Preserv. 2020, 44, e14669. [Google Scholar] [CrossRef]

- Mukhtar, A.; Latif, S.; Mueller, J. Effect of heat exposure on activity degradation of enzymes in mango varieties Sindri, SB Chaunsa, and Tommy Atkins during drying. Molecules 2020, 25, 5396. [Google Scholar] [CrossRef] [PubMed]

- Shende, D.; Datta, A.K. Optimization study for refractance window drying process of Langra variety mango. J. Food Sci. Technol. 2020, 57, 683–692. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, C.C.; Morgano, M.A.; Germer, S.P.M. Evaluation of water sorption isotherm, glass transition temperature, vitamin C and color stability of mango peel powder during storage. SN Appl. Sci. 2021, 3, 1–12. [Google Scholar] [CrossRef]

- Mishra, M.; Kandasamy, P.; Shukla, R.N.; Kumar, A. Convective hot-air drying of green mango: Influence of hot water blanching and chemical pretreatments on drying kinetics and physicochemical properties of dried product. Int. J. Fruit Sci. 2021, 21, 732–757. [Google Scholar] [CrossRef]

- Mugodo, K.; Workneh, T.S. The kinetics of thin-layer drying and modelling for mango slices and the influence of differing hot-air drying methods on quality. Heliyon 2021, 7, e07182. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, T.; Salauddin, M.; Choudhury, T.; Um, J.S.; Pati, S.; Hazra, S.K.; Chakraborty, R. Spatial optimisation of mango leather production and colour estimation through conventional and novel digital image analysis technique. Spat. Inf. Res. 2021, 29, 439–453. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Fong-in, S.; Kawai, K. Optimum physical properties of fruit puree for freeze-drying: Effect of pulp content on freeze-concentrated glass transition temperature and yield stress of mango puree. J. Food Eng. 2021, 307, 110649. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; Durigon, A.; da Silva, V.M.; Hubinger, M.D.; Laurindo, J.B. Rehydration of mango powders produced by cast-tape drying, freeze drying, and spray drying. Dry. Technol. 2022, 40, 175–187. [Google Scholar] [CrossRef]

- Olivas-Aguirre, F.J.; González-Aguilar, G.A.; Velderrain-Rodríguez, G.R.; Torres-Moreno, H.; Robles-Zepeda, R.E.; Vázquez-Flores, A.A.; de la Rosa, L.; Wall-Medrano, A. Radical scavenging and anti-proliferative capacity of three freeze-dried tropical fruits. Int. J. Food Sci. Technol. 2017, 52, 1699–1709. [Google Scholar] [CrossRef]

- Fongin, S.; Kawai, K.; Harnkarnsujarit, N.; Hagura, Y. Effects of water and maltodextrin on the glass transition temperature of freeze-dried mango pulp and an empirical model to predict plasticizing effect of water on dried fruits. J. Food Eng. 2017, 210, 91–97. [Google Scholar] [CrossRef]

- Serna-Cock, L.; Torres-León, C.; Ayala-Aponte, A. Evaluación de polvos alimentarios obtenidos de cáscaras de mango (Mangifera indica) como fuente de ingredientes funcionales. Inf. Tecnol. 2015, 26, 41–50. [Google Scholar] [CrossRef]

- Rahman, M.M.; Das, R.; Hoque, M.M.; Zzaman, W. Effect of freeze drying on antioxidant activity and phenolic contents of Mango (Mangifera indica). Int. Food Res. J. 2015, 22, 613–617. [Google Scholar]

- Tiwari, S.; Chakkaravarthi, A.; Bhattacharya, S. Imaging and image analysis of freeze-dried cellular solids of gellan and agar gels. J. Food Eng. 2015, 165, 60–65. [Google Scholar] [CrossRef]

- De Araújo, C.R.; Botelho, P.D.S.; Da Silva, T.M.S.; Maciel, M.I.S.; Melo, E.D.A.; Ryan, S.; Smith, R.E. Phenolic compounds and metals in Tommy Atkins mango (Mangifera indica L) peels. Nat. Prod. J. 2014, 4, 2–7. [Google Scholar] [CrossRef]

- Caparino, O.A.; Sablani, S.S.; Tang, J.; Syamaladevi, R.M.; Nindo, C.I. Water sorption, glass transition, and microstructures of refractance window- and freeze-dried mango (Philippine “Carabao” var.) powder. Dry. Technol. 2013, 31, 1969–1978. [Google Scholar] [CrossRef]

- Mehrnoush, A.; Mustafa, S.; Yazid, A.M.M. Optimization of freeze drying conditions for purified pectinase from mango (Mangifera indica cv. Chokanan) peel. Int. J. Mol. Sci. 2012, 13, 2939. [Google Scholar] [CrossRef] [PubMed]

- Caparino, O.A.; Tang, J.; Nindo, C.I.; Sablani, S.S.; Powers, J.R.; Fellman, J.K. Effect of drying methods on the physical properties and microstructures of mango (Philippine “Carabao” var.) powder. J. Food Eng. 2012, 111, 135–148. [Google Scholar] [CrossRef]

- Harnkarnsujarit, N.; Charoenrein, S. Influence of collapsed structure on stability of β-carotene in freeze-dried mangoes. Food Res. Int. 2011, 44, 3188–3194. [Google Scholar] [CrossRef]

- Shofian, N.M.; Hamid, A.A.; Osman, A.; Saari, N.; Anwar, F.; Dek, M.S.P.; Hairuddin, M.R. Effect of freeze-drying on the antioxidant compounds and antioxidant activity of selected tropical fruits. Int. J. Mol. Sci. 2011, 12, 4678. [Google Scholar] [CrossRef]

- Marques, L.G.; Prado, M.M.; Freire, J.T. Rehydration characteristics of freeze-dried tropical fruits. LWT Food Sci. Technol. 2009, 42, 1232–1237. [Google Scholar] [CrossRef]

- Marques, L.G.; Silveira, A.M.; Freire, J.T. Freeze-drying characteristics of tropical fruits. Dry. Technol. 2006, 24, 457–463. [Google Scholar] [CrossRef]

- Marques, L.G.; Freire, J.T. Analysis of freeze-drying of tropical fruits. Dry. Technol. 2005, 23, 2169–2184. [Google Scholar] [CrossRef]

- Shende, D.; Kour, M.; Datta, A.K. Evaluation of sensory and physico-chemical properties of Langra variety mango leather. J. Food Meas. Charact. 2020, 14, 3227–3237. [Google Scholar] [CrossRef]

- Kaur, G.; Saha, S.; Kumari, K.; Datta, A.K. Mango pulp drying by refractance window method. Agric. Eng. Int. CIGR J. 2017, 19, 145–151. [Google Scholar]

- Zotarelli, M.F.; Carciofi, B.A.M.; Laurindo, J.B. Effect of process variables on the drying rate of mango pulp by Refractance Window. Food Res. Int. 2015, 69, 410–417. [Google Scholar] [CrossRef]

- Ochoa-Martínez, C.I.; Quintero, P.T.; Ayala, A.A.; Ortiz, M.J. Drying characteristics of mango slices using the Refractance WindowTM technique. J. Food Eng. 2012, 109, 69–75. [Google Scholar] [CrossRef]

- Salazar, N.A.; Alvarez, C.; Orrego, C.E. Optimization of freezing parameters for freeze-drying mango (Mangifera indica L.) slices. Dry. Technol. 2018, 36, 192–204. [Google Scholar] [CrossRef]

- Prasad, N.N.; Siddalingaswamy, M.; Parameswariah, P.M.; Radhakrishna, K.; Rao, R.V.; Viswanathan, K.R.; Santhanam, K. Proximate and mineral composition of some processed traditional and popular Indian dishes. Food Chem. 2000, 68, 87–94. [Google Scholar] [CrossRef]

- Caparino, O.A.; Nindo, C.I.; Tang, J.; Sablani, S.S. Rheological measurements for characterizing sticky point temperature of selected fruit powders: An experimental investigation. J. Food Eng. 2017, 195, 61–72. [Google Scholar] [CrossRef]

- Pu, Y.Y.; Sun, D.W. Combined hot-air and microwave-vacuum drying for improving drying uniformity of mango slices based on hyperspectral imaging visualisation of moisture content distribution. Biosyst. Eng. 2017, 156, 108–119. [Google Scholar] [CrossRef]

- Dhali, K.; Datta, A.K. Experimental analyses of drying characteristics of selected food samples. Agric. Eng. Int. CIGR J. 2018, 20, 188–194. [Google Scholar]

- Suherman, S.; Trianita, A.P.; Hadiyanto, H.; Putri, W.A.M. Effect of freeze-drying pressure and operating time on mass balance and characteristics of freeze-dried mango slices. Sarhad J. Agric. 2021, 37, 90–97. [Google Scholar] [CrossRef]

- Ortiz-Jerez, M.J.; Ochoa-Martínez, C.I. Efecto de las condiciones del hidrosecado sobre el encogimiento de trozos de zapallo (Cucurbita maxima). Ing. Compet. 2018, 20, 37–44. [Google Scholar] [CrossRef]

- Fazaeli, M.; Tahmasebi, M.; Djomeh, Z.E. Characterization of food texture: Application of microscopic technology. In Current Microscopy Contributions to Advances in Science and Technology; Méndez-Vilas, A., Ed.; Formatex Research Center: Badajoz, Spain, 2012; Volume 2, pp. 855–871. [Google Scholar]

- Megías-Pérez, R.; Gamboa-Santos, J.; Soria, A.C.; Villamiel, M.; Montilla, A. Survey of quality indicators in commercial dehydrated fruits. Food Chem. 2014, 150, 41–48. [Google Scholar] [CrossRef]

- Sarkar, T.; Bharadwaj, K.K.; Salauddin, M.; Pati, S.; Chakraborty, R. Phytochemical characterization, antioxidant, anti-inflammatory, anti-diabetic properties, molecular docking, pharmacokinetic profiling, and network pharmacology analysis of the major phytoconstituents of raw and differently dried Mangifera indica (Himsagar cultivar): An in vitro and in silico investigations. Appl. Biochem. Biotechnol. 2022, 194, 950–987. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.P.; Tai, C.Y.; Chen, B.H. Effects of different drying treatments on the stability of carotenoids in Taiwanese mango (Mangifera indica L.). Food Chem. 2007, 100, 1005–1010. [Google Scholar] [CrossRef]

- Jokić, S.; Mujić, I.; Martinov, M.; Velić, D.; Lukinac, J. Influence of drying procedure on colour and rehydration characteristic of wild Asparagus. Czech J. Food Sci. 2009, 27, 171–177. [Google Scholar] [CrossRef]

- Perumal, R. Comparative Performance of Solar Cabinet, Vacuum Assisted Solar and Open Sun Drying Methods. Master’s Thesis, McGill University, Montréal, QC, Canada, 2007. [Google Scholar]

- Khuwijitjaru, P.; Somkane, S.; Nakagawa, K.; Mahayothee, B. Osmotic dehydration, drying kinetics, and quality attributes of osmotic hot air-dried mango as affected by initial frozen storage. Foods 2022, 11, 489. [Google Scholar] [CrossRef] [PubMed]

- Moon, K.M.; Kwon, E.B.; Lee, B.; Kim, C.Y. Recent trends in controlling the enzymatic browning of fruit and vegetable products. Molecules 2020, 25, 2754. [Google Scholar] [CrossRef]

- Mejía-Doria, C.M.; Gaviria-Arias, D.; Bru-Martínez, R.; Rengifo-Ramos, L.; Alegría-Soto, A.H.; Aguilar-Fernández, E. Caracterización cinética de la enzima polifenol oxidasa en seis estadios de maduración en lulo (Solanum quitoense Lam.) var. Castilla. Actual. Biol. 2014, 36, 107–117. [Google Scholar] [CrossRef]

- Manayay, D.; Ibarz, A. Modeling the kinetics nonenzymatic browning reactions and rheological behavior in the thermal process of fruit juices and pulps. Sci. Agropecu. 2010, 1, 155–168. [Google Scholar] [CrossRef][Green Version]

- Mehadi-Galib, R.; Alam, M.; Rana, R.; Ara, R. Mango (Mangifera indica L.) fiber concentrates: Processing, modification and utilization as a food ingredient. Food Hydrocoll. Health 2022, 2, 100096. [Google Scholar] [CrossRef]

- Cabrera-Gómez, A. Identificación de las Etapas de Secado Durante el Proceso de Liofilización. Bachelor’s Thesis, Universitat Politècnica de València, València, Spain, 2016. [Google Scholar]

- Tirado, D.F.; Acevedo-Correa, D.; Montero-Castillo, P.M. Dried fruit breadfruit slices by Refractive Window technique. TecnoLógicas 2016, 19, 103–111. [Google Scholar]

- Richards, K.; Tran, K.; Levine, R.A.; Luo, R.; Maia, J.G.S.; Sabaa-Srur, A.A.U.; Maciel, M.I.S.; Melo, E.A.; de Moraes, M.R.; Godoy, H.T.; et al. Improved extraction of soluble solids from some Brazilian and North American fruits. Nat. Prod. J. 2014, 4, 201–210. [Google Scholar] [CrossRef]

- Figueredo-Rondon, M.C.; Gonzalez-Gutierrez, R.R. Funcionamiento del aparato de laboratorio SBAN en una Universidad Venezolana para el secado de arena. Sci. Tech. 2018, 23, 69–76. [Google Scholar]

| Parameters | Technologies | ||||||

|---|---|---|---|---|---|---|---|

| Convective Hot-Air Drying | References | Freeze-Drying | References | Refractance Window | References | ||

| Operating conditions | Operating temperature(s) | Air: 40–80 °C | [21,22,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51] | Cryogenic (between −10 and −80 °C) and low temperature (not exceeding ambient temperature) in process temperature ramps | [20,22,25,26,29,30,33,34,35,36,37,39,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67] | Water bath: 95 °C; sample surface does not exceed 75 °C with clear Mylar® film | [47,60,68,69,70,71] [60,69] |

| Operating pressure | Atmospheric | Vacuum (<0.1 up to 0.0007 mbar) | [12,22,25,26,29,30,33,34,35,36,37,39,51,53,54,55,56,59,60,62,63,65,66] | Atmospheric | [13,70,71] | ||

| Final moisture of the sample | 10–20% wet basis | [21,30,33,40,42,44,46,47] | 5–10% wet basis | [20,22,25,30,33,35,36,39,51,52,56,60,62,65,66,72,73] | 15–20% wet basis | [47,60,62,68,69,71,74] | |

| Drying air velocity | 1.70 ± 0.87 m/s | [21,27,28,30,32,35,36,39,40,43,44,45,46,48,49] | N/A | 0.7 m/s approximately (atmospheric air) | [60] | ||

| Sample thickness | 2–8 mm, values close to 3 mm and 5 mm are preferable | [21,32,35,36,42,47,50,75,76] | 7.8 ± 4.6 mm, 5 mm being frequent | [29,30,34,35,36,60,62,63,66,67,72,77] | 2.3 ± 1.4 mm; thicknesses below 1 mm recommended | [78] | |

| Relative humidity of drying air | 15–24% | [35,36] | N/A | 50–73% | [60,70,71] | ||

| Dehydration time | 11.5 ± 6.1 h | [21,22,26,28,29,30,35,36,38,39,40,41,42,45,46,47,49,50,75] | 35.7 ± 29.8 h | [20,26,29,30,35,36,37,53,54,55,57,59,61,62,64,66,72] | 0.46 ± 0.31 h (or 27.5 ± 18.9 min) | [47,62,69,71] | |

| Degrees Brix (°Brix) of fresh mango | 16.74 ± 5.06 | [21,22,25,27,28,35,36,38,39,45,46,47,48,49,50,51] | 18.66 ± 3.79 | [20,22,25,35,36,39,51,52,53,54,55,56,62,63] | 15.82 ± 2.77 | [47,62,70,71] | |

| Physicochemical properties | Microstructure (porosity) | Little porous (and dense) structure | [45,75,79] | Porous structure | [60,66] | Non-porous structure | [60] |

| Water activity (aw) | 0.468 ± 0.155 | [21,28,35,36,38,46,47,48,80] | 0.278 ± 0.082 | [20,35,36,56,62] | 0.412 ± 0.172 | [47,62,69,71] | |

| Rehydration capacity | 3.11 ± 0.72 | [41,42,49,50] | 3.62–3.79 | [65,72] | - | ||

| Nutritional properties | Ascorbic acid content in sample | 29.81 and 34.17 mg/100 g sample on a dry basis (drying at 50 and 70 °C, respectively) (Dasheri mango variety) | [49] | 333.00 to 513.00 mg/100 g sample on a dry basis (Tommy Atkins, Keitt, and Sugar varieties) | [56] | 62.66 mg/100 g sample on a dry basis (Langra, mango variety) | [47] |

| Phenol content in sample | 705.0 mg GAE/100 g sample on a dry basis (drying at 70 °C) (Himsagar mango variety) | [81] | 848.0 mg GAE/100 g sample on a dry basis (Himsagar mango variety), 987.0 mg GAE/100 g sample on a dry basis | [54,81] | - | ||

| Organoleptic properties | Flavor | Panelists highlight sweetness | [22] | - | Weighted as good and excellent by panelists | [68] | |

| Aftertaste | - | Highlighted by panelists | [22] | - | |||

| Chewiness | Chewable | [47] | - | Chewable | [68] | ||

| Sample color | Dark orange–brown | [22,68,75,82] | Light yellow–orange | [22,72,82] | Yellow. Highlighted as good and excellent by panelists | [62,68] | |

| Texture | Rough; irregular surface | [22,75] | Regular surface | [35] | Smooth | [60] | |

| Smell | - | - | Weighted as “medium” by panelists | [68] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López, L.C.; Hincapié-Llanos, G.A. Comparison of Mango (Mangifera indica) Dehydration Technologies: A Systematic Review. AgriEngineering 2024, 6, 2694-2717. https://doi.org/10.3390/agriengineering6030157

López LC, Hincapié-Llanos GA. Comparison of Mango (Mangifera indica) Dehydration Technologies: A Systematic Review. AgriEngineering. 2024; 6(3):2694-2717. https://doi.org/10.3390/agriengineering6030157

Chicago/Turabian StyleLópez, Luna C., and Gustavo Adolfo Hincapié-Llanos. 2024. "Comparison of Mango (Mangifera indica) Dehydration Technologies: A Systematic Review" AgriEngineering 6, no. 3: 2694-2717. https://doi.org/10.3390/agriengineering6030157

APA StyleLópez, L. C., & Hincapié-Llanos, G. A. (2024). Comparison of Mango (Mangifera indica) Dehydration Technologies: A Systematic Review. AgriEngineering, 6(3), 2694-2717. https://doi.org/10.3390/agriengineering6030157