High-Resolution Yield Mapping for Eucalyptus grandis—A Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Study Site

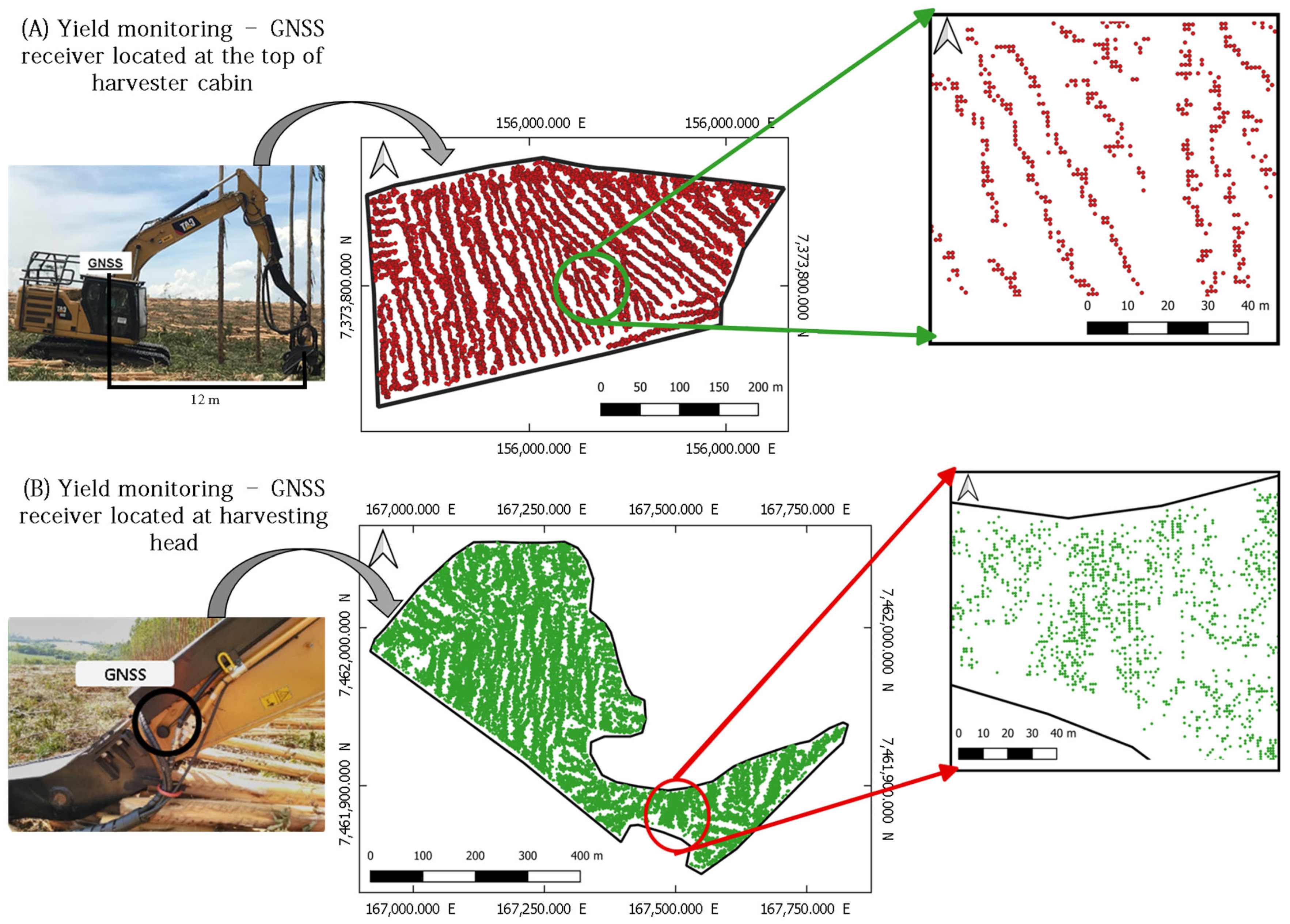

2.2. Experimental Design (GNSS Placement) and Harvesting Procedures

2.3. Sampling Procedures

2.4. Data Analysis

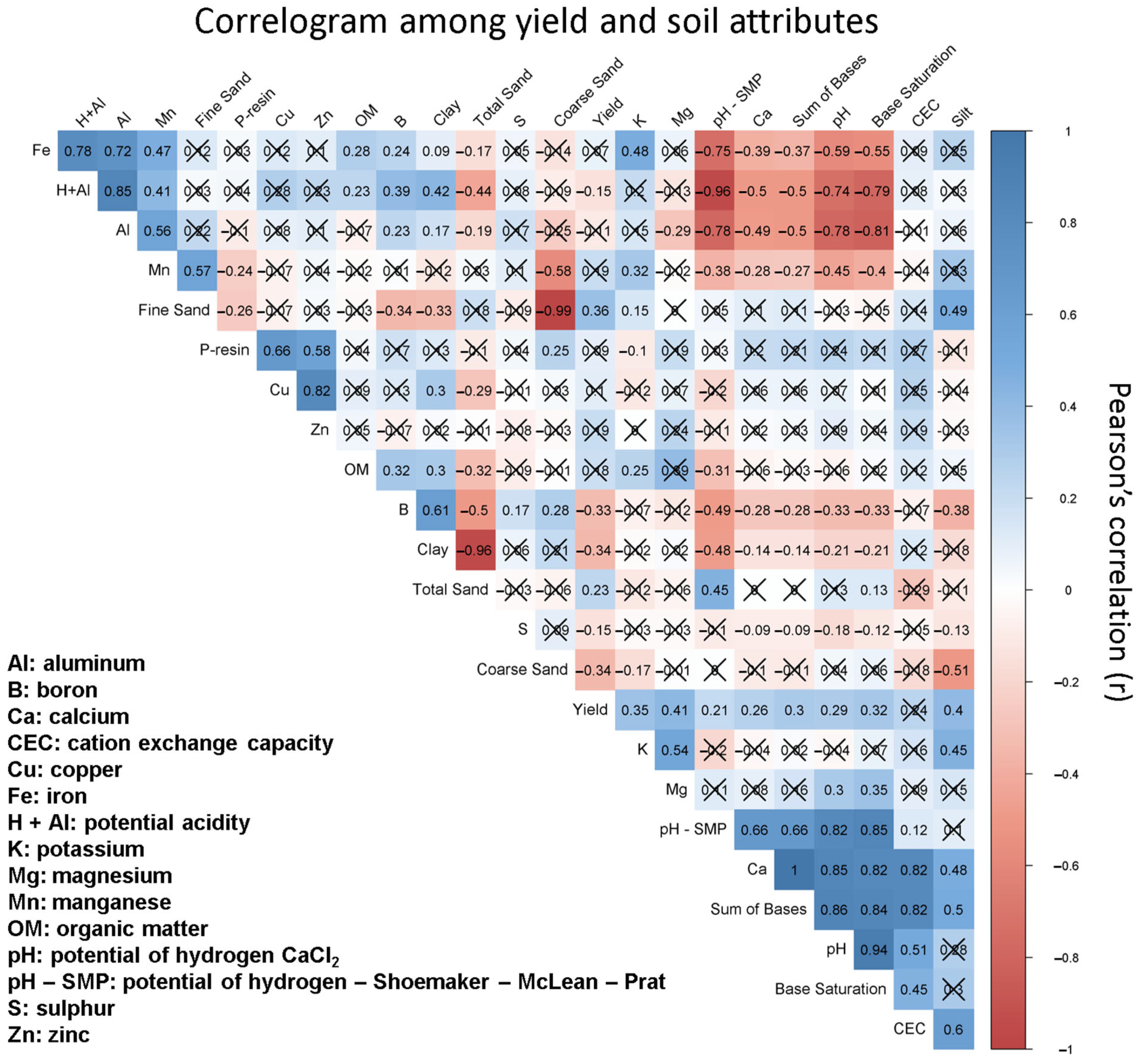

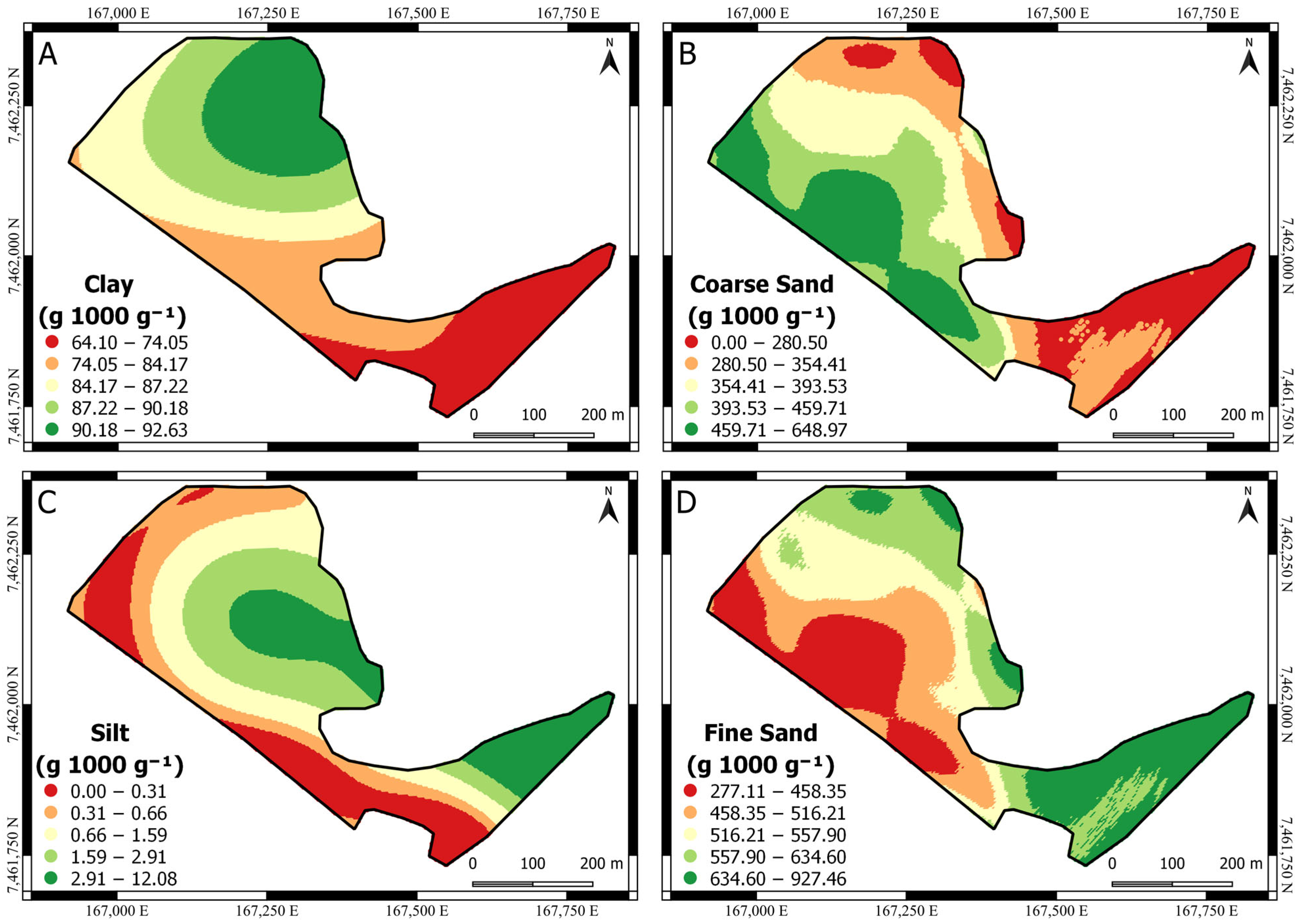

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variable | n | C0 | C1 | A1 | Variogram Model | RMSE | AIC |

|---|---|---|---|---|---|---|---|

| Boron | 54 | 7.40 × 10−04 | 5.91 × 10−04 | 145.60 | Gaussian | 6.49 × 10−05 | −163.80 |

| Clay | 54 | 84.23 | 252.70 | 462.50 | Gaussian | 28.07 | 308.10 |

| Coarse Sand | 54 | 0.00 × 1000 | 1.00 × 10+04 | 185.00 | Gaussian | 1326.60 | 427.40 |

| Fine Sand | 54 | 0.00 × 1004 | 1.00 × 10+04 | 184.70 | Gaussian | 1154.40 | 420.70 |

| Potassium | 54 | 4.30 × 10−04 | 2.59 × 10−04 | 294.90 | Spherical | 5.69 × 10−05 | −198.80 |

| pH-SMP | 54 | 0.05 | 0.06 | 380.60 | Gaussian | 0.01 | −104.10 |

| Silt | 54 | 5.33 | 7.55 | 198.20 | Gaussian | 1.44 | 75.67 |

Appendix B

References

- Fulton, J.; Hawkins, E.; Taylor, R.; Franzen, A. Yield Monitoring and Mapping. In Precision Agriculture Basics; Shannon, D.K., Clay, D.E., Kitchen, N.R., Eds.; ASA, CSSA, SSSA: Madison, WI, USA, 2018; pp. 63–77. [Google Scholar] [CrossRef]

- Cheng, S.; Han, H.; Qi, J.; Ma, Q.; Liu, J.; An, D.; Yang, Y. Design and Experiment of Real-Time Grain Yield Monitoring System for Corn Kernel Harvester. Agriculture 2023, 13, 294. [Google Scholar] [CrossRef]

- Sirikun, C.; Samseemoung, G.; Soni, P.; Langkapin, J.; Srinonchat, J. A Grain Yield Sensor for Yield Mapping with Local Rice Combine Harvester. Agriculture 2021, 11, 897. [Google Scholar] [CrossRef]

- Chandel, N.S.; Agrawal, K.N.; Tiwari, P.S.; Golhani, K. IDW Interpolation of Soybean Yield Data Acquired by Automated Yield Monitor. Int. J. Sci. Emerg. Technol. Latest Trends 2013, 3, 36–45. [Google Scholar]

- Quebrajo, L.; Pérez-Ruiz, M.; Rodriguez-Lizana, A.; Agüera, J. An Approach to Precise Nitrogen Management Using Hand-Held Crop Sensor Measurements and Winter Wheat Yield Mapping in a Mediterranean Environment. Sensors 2015, 15, 5504–5517. [Google Scholar] [CrossRef] [PubMed]

- Felipe Maldaner, L.; de Paula Corrêdo, L.; Fernanda Canata, T.; Paulo Molin, J. Predicting the Sugarcane Yield in Real-Time by Harvester Engine Parameters and Machine Learning Approaches. Comput. Electron. Agric. 2021, 181, 105945. [Google Scholar] [CrossRef]

- Fayad, I.; Baghdadi, N.; Alvares, C.A.; Stape, J.L.; Bailly, J.S.; Scolforo, H.F.; Cegatta, I.R.; Zribi, M.; Le Maire, G. Terrain Slope Effect on Forest Height and Wood Volume Estimation from Gedi Data. Remote Sens. 2021, 13, 2136. [Google Scholar] [CrossRef]

- Corte, A.P.D.; Souza, D.V.; Rex, F.E.; Sanquetta, C.R.; Mohan, M.; Silva, C.A.; Zambrano, A.M.A.; Prata, G.; Alves de Almeida, D.R.; Trautenmüller, J.W.; et al. Forest Inventory with High-Density UAV-Lidar: Machine Learning Approaches for Predicting Individual Tree Attributes. Comput. Electron. Agric. 2020, 179, 105815. [Google Scholar] [CrossRef]

- Asner, G.P.; Mascaro, J. Mapping Tropical Forest Carbon: Calibrating Plot Estimates to a Simple LiDAR Metric. Remote Sens. Environ. 2014, 140, 614–624. [Google Scholar] [CrossRef]

- Fayad, I.; Ienco, D.; Baghdadi, N.; Gaetano, R.; Alvares, C.A.; Stape, J.L.; Ferraço Scolforo, H.; Le Maire, G. A CNN-Based Approach for the Estimation of Canopy Heights and Wood Volume from GEDI Waveforms. Remote Sens. Environ. 2021, 265, 112652. [Google Scholar] [CrossRef]

- Scolforo, H.F.; McTague, J.P.; Burkhart, H.; Roise, J.; Campoe, O.; Stape, J.L. Eucalyptus Growth and Yield System: Linking Individual-Tree and Stand-Level Growth Models in Clonal Eucalypt Plantations in Brazil. For. Ecol. Manag. 2019, 432, 1–16. [Google Scholar] [CrossRef]

- Corte, A.P.D.; Neto, E.M.d.C.; Rex, F.E.; Souza, D.; Behling, A.; Mohan, M.; Sanquetta, M.N.I.; Silva, C.A.; Klauberg, C.; Sanquetta, C.R.; et al. High-Density UAV-LiDAR in an Integrated Crop-Livestock-Forest System: Sampling Forest Inventory or Forest Inventory Based on Individual Tree Detection (ITD). Drones 2022, 6, 48. [Google Scholar] [CrossRef]

- de Lima Neto, A.J.; Neves, J.C.L.; Martinez, H.E.P.; Sousa, J.S.; Fernandes, L.V. Establishment of Critical Nutrient Levels in Soil and Plant for Eucalyptus. Rev. Bras. Ciênc. Solo 2020, 44, e0190150. [Google Scholar] [CrossRef]

- Rocha, J.H.T.; du Toit, B.; de Moraes Gonçalves, J.L. Ca and Mg Nutrition and Its Application in Eucalyptus and Pinus Plantations. For. Ecol. Manag. 2019, 442, 63–78. [Google Scholar] [CrossRef]

- Rocha, J.H.T.; de Moraes Goncalves, J.L.; de Vicente Ferraz, A.; Poiati, D.A.; Arthur Junior, J.C.; Hubner, A. Growth Dynamics and Productivity of an Eucalyptus grandis Plantation under Omission of N, P, K Ca and Mg over Two Crop Rotation. For. Ecol. Manag. 2019, 447, 158–168. [Google Scholar] [CrossRef]

- Sandoval López, D.M.; Arturi, M.F.; Goya, J.F.; Pérez, C.A.; Frangi, J.L. Eucalyptus grandis Plantations: Effects of Management on Soil Carbon, Nutrient Contents and Yields. J. For. Res. 2020, 31, 601–611. [Google Scholar] [CrossRef]

- Reichert, J.M.; Morales, B.; Lima, E.M.; de Bastos, F.; Morales, C.A.S.; de Araújo, E.F. Soil Morphological, Physical and Chemical Properties Affecting Eucalyptus spp. Productivity on Entisols and Ultisols. Soil Tillage Res. 2023, 226, 105563. [Google Scholar] [CrossRef]

- International Society of Precision Agriculture Precision Ag Definition. Available online: https://www.ispag.org/about/definition (accessed on 4 December 2023).

- Skogforks. StandForD. Available online: https://www.skogforsk.se/english/projects/stanford/ (accessed on 3 October 2023).

- Cicciù, B.; Schramm, F.; Schramm, V.B. Multi-Criteria Decision Making/Aid Methods for Assessing Agricultural Sustainability: A Literature Review. Environ. Sci. Policy 2022, 138, 85–96. [Google Scholar] [CrossRef]

- Burkhart, H.E.; Tomé, M. Modeling Forest Trees and Stands; Springer: New York, NY, USA, 2012; Volume 1, ISBN 978-94-007-1597-4. [Google Scholar]

- Rossi, M. Mapa Pedologico Do Estado de São Paulo: Revisado e Ampliado. Available online: https://www.infraestruturameioambiente.sp.gov.br/institutoflorestal/2017/09/mapa-pedologico-do-estado-de-sao-paulo-revisado-e-ampliado/ (accessed on 6 June 2024).

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; De Moraes Gonçalves, J.L.; Sparovek, G. Köppen’s Climate Classification Map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Flores, T.B.; Alvares, C.A.; Souza, V.C.; Stape, J.L. Eucalyptus in Brazil—Climatic Zoning and Identification Guide; IPEF: Piracicaba, Brazil, 2018; ISBN 978-85-89142-10-6. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019; Available online: http://www.rstudio.com/ (accessed on 25 April 2024).

- Minasny, B.; McBratney, A.B.; Whelan, B.M. VESPER; Version 1.62; Australian Centre for Precision Agriculture, The University of Sydney: Sydney, Australia, 2006. [Google Scholar]

- QGIS Development Team. QGIS Geographic Information System; QGIS: London, UK, 2022; Available online: http://qgis.org (accessed on 25 April 2024).

- Wackernagel, H. Multivariate Geostatistics: An Introduction with Applications, 3rd ed.; Springer: Berlin, Germany, 2003; ISBN 978-3-642-07911-5. [Google Scholar]

- Clutter, J.L.; Allison, B.J. Growth Models for Tree and Stand Simulation; Fries, J., Ed.; Royal College of Forestry: Stockholm, Sweden, 1974. [Google Scholar]

- Allen, M.G.; Coble, D.W.; Cao, Q.V.; Yeiser, J.; Hung, I.K. A Modified Stand Table Projection Growth Model for Unmanaged Loblolly and Slash Pine Plantations in East Texas. South. J. Appl. For. 2011, 35, 115–122. [Google Scholar] [CrossRef]

- Sette, C.R.; Laclau, J.P.; Tomazello Filho, M.; Moreira, R.M.; Bouillet, J.P.; Ranger, J.; Almeida, J.C.R. Source-Driven Remobilizations of Nutrients within Stem Wood in Eucalyptus grandis Plantations. Trees-Struct. Funct. 2013, 27, 827–839. [Google Scholar] [CrossRef]

- Alvares, C.A. Mapping and Edaphoclimatic Modeling of Productivity of Eucalyptus Plantations at South of São Paulo State. Ph.D. Thesis, University of São Paulo, Piracicaba, SP, Brazil, 2011. [Google Scholar]

- Gonçalves, J.L.d.M.; Alvares, C.A.; Gonçalves, T.D.; Moreira, R.M.; Mendes, J.C.T.; Gava, J.L. Soil and Productivity Mapping of Eucalyptus grandis Plantations, Using a Geographic Information System. Sci. For. Sci. 2012, 40, 187–201. [Google Scholar]

- Leite, F.P.; Silva, I.R.; Novais, R.F.; de Barros, N.F.; Neves, J.C.L. Alterations of Soil Chemical Properties by Eucalyptus Cultivation in Five Regions in the Rio Doce Valley. Rev. Bras. Ciênc. Solo 2010, 34, 821–831. [Google Scholar] [CrossRef]

- Stape, J.L.; Binkley, D.; Ryan, M.G.; Fonseca, S.; Loos, R.A.; Takahashi, E.N.; Silva, C.R.; Silva, S.R.; Hakamada, R.E.; Ferreira, J.M.d.A.; et al. The Brazil Eucalyptus Potential Productivity Project: Influence of Water, Nutrients and Stand Uniformity on Wood Production. For. Ecol. Manag. 2010, 259, 1684–1694. [Google Scholar] [CrossRef]

- McMahon, D.E.; Vergütz, L.; Valadares, S.V.; da Silva, I.R.; Jackson, R.B. Soil Nutrient Stocks Are Maintained over Multiple Rotations in Brazilian Eucalyptus Plantations. For. Ecol. Manag. 2019, 448, 364–375. [Google Scholar] [CrossRef]

- Laclau, J.P.; Ranger, J.; de Moraes Gonçalves, J.L.; Maquère, V.; Krusche, A.V.; M’Bou, A.T.; Nouvellon, Y.; Saint-André, L.; Bouillet, J.P.; de Cassia Piccolo, M.; et al. Biogeochemical Cycles of Nutrients in Tropical Eucalyptus Plantations. Main Features Shown by Intensive Monitoring in Congo and Brazil. For. Ecol. Manag. 2010, 259, 1771–1785. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, R.D.; Molin, J.P.; Wei, M.C.F.; Alvares, C.A. High-Resolution Yield Mapping for Eucalyptus grandis—A Case Study. AgriEngineering 2024, 6, 1972-1986. https://doi.org/10.3390/agriengineering6030115

Dias RD, Molin JP, Wei MCF, Alvares CA. High-Resolution Yield Mapping for Eucalyptus grandis—A Case Study. AgriEngineering. 2024; 6(3):1972-1986. https://doi.org/10.3390/agriengineering6030115

Chicago/Turabian StyleDias, Rafael Donizetti, José Paulo Molin, Marcelo Chan Fu Wei, and Clayton Alcarde Alvares. 2024. "High-Resolution Yield Mapping for Eucalyptus grandis—A Case Study" AgriEngineering 6, no. 3: 1972-1986. https://doi.org/10.3390/agriengineering6030115

APA StyleDias, R. D., Molin, J. P., Wei, M. C. F., & Alvares, C. A. (2024). High-Resolution Yield Mapping for Eucalyptus grandis—A Case Study. AgriEngineering, 6(3), 1972-1986. https://doi.org/10.3390/agriengineering6030115