Abstract

Over the years, agricultural management practices are being improved as they integrate Information and Communication Technologies (ICT) and Precision Agriculture tools. Regarding sugarcane crop production, this integration aims to reduce production cost, enhance input applications, and allow communication among different hardware and datasets, improving system sustainability. Sugarcane mechanization has some particularities that mandate the development of custom solutions based on digital tools, which are being applied globally in different crops. Digital mechanization can be conceived as the application of digital tools on mechanical operation. This review paper addresses different digital solutions that have contributed towards the mechanization of sugarcane crop production. The process of digitalization and transformation in agriculture and its related operations to sugarcane are presented, highlighting important ICT applications such as real-time mechanical operations monitoring and integration among operations, demonstrating their contributions and limitations regarding management efficiency. In addition, this article presents the major challenges to overcome and possible guidance on research to address these issues, i.e., poor communication technologies available, need for more focus on field and crop data, and lack of data interoperability among mechanized systems.

1. Introduction

To facilitate the understanding of the evolution of sugarcane mechanization and its relation with digital solutions, this review is divided into the following sections: (1) Introduction—vegetative and economical information; (2) Overview of digital work in sugarcane; (3) Digitalization and transformation in agriculture—concept and how it can be applied to sugarcane mechanization; (4) Operations related to sugarcane crop production—highlighting the most important mechanical process; (5) Digital solutions in sugarcane mechanization—examples; (6) Technological implementation—up to the date problems; (7) Final considerations—overview and opportunities.

Sugarcane (Saccharum spp.) is a perennial grass, cultivated as semi-perennial, with a growth cycle of about 12 or 18 months [1] in relation to the planting date. Crop cultivation in large areas relies on soil preparation and intensive mechanization where the productive cycle starts in the first year [2], followed by ratoon cycles that can last from five to seven harvests in tropical regions, e.g., Brazil [3], and from two to four harvests in subtropical regions, e.g., United States of America [4].

Sugarcane has worldwide importance, as it provides food security and sustainable energy [5]. It is cultivated in tropical and subtropical regions, with Brazil, India, China, Thailand and Pakistan being the largest sugarcane producers [5]. The Brazilian sugarcane production for the 2023/2024 season is projected to be 677.6 million tons. Brazil is the world’s largest producer, contributing approximately 50% of the global tradable volume of sugar [6].

Considering the timeline from 1965 to 2019, sugarcane production increased about four-fold [7] and from 1961 to 2018, the cultivated area increased from about 9 to 26 million hectares worldwide [8]. The Organisation for Economic Co-operation and Development (OECD) and the Food and Agriculture Organization of the United Nations (FAO) estimate a production increment of 1.1% per year until 2029 led by Brazil, India and Thailand [9]. As sugarcane production grows, the complexity of decisions regarding its management increases, requiring more studies to support its sustainable development [2].

This review paper focuses on the sugarcane crop production in Brazil, since it contributes half of the tradable sugar in the world. Sugarcane cultivation in Brazil started about 500 years ago [10] and spread across large areas, especially over the last 60 years, and is concentrated in the southern region, where most of the sugarcane mills are located.

Historically, sugarcane fields were burned to facilitate manual harvesting since it eliminated the leaves [11]. The removal of leaves is a critical step to improve storage and shipment and reducing impurities during sugar extraction. The process of burning sugarcane fields was one of the main sources of local air pollution that generated carcinogenic substances and high levels of polycyclic aromatic hydrocarbons, which are hazardous to humans [12]. As a result, laws have been implemented to gradually eradicate burning operations, boosting mechanized harvesting [13].

In addition, the development and availability of technological tools have been increasing in the sugarcane sector. Although the adoption rate of using at least one digital tool is considered high [14,15], cautious analyses must be carried out because the tools used must be properly evaluated by specific scenarios; otherwise, they can misguide efforts towards the development and/or implementation of digital tools in broader scenarios, thereby becoming exclusive and rather than inclusive.

For example, a survey of sugarcane farmers in Brazil, a developing country, found that owners of larger farms who have higher educational degrees and more technical support have higher adoption rates of technological tools since they have more economical returns. On the other hand, owners of smaller farms, even those with higher educational degrees, but lacking technical support, tend not to adopt these tools mainly because of high initial investments costs and skepticism about their use and benefits [16].

Moreover, these results are not exclusive to sugarcane producers; they are representative for other crops and regions as discussed in reference [15], a report about the recent adoption of precision agriculture tools in the digital era in the USA, a developed country.

Therefore, the awareness of farmers, stakeholders and policy makers about what digital technology is and how it can be conceived is of utmost importance to guide not only sugarcane crop production towards sustainability [17], but also other agricultural crops.

2. Overview of Digital Work in Sugarcane

We compiled studies carried out with digital solutions in sugarcane crop production, by conducting a search of the Scopus repository considering the timeline from 1995 to 2024 using the following parameters: (a) search within “article title, abstract, keywords”—“digital” AND “sugarcane”; (b) restrict selection to: (i) “area”—Agricultural and Biological Sciences”, “Computer Science” and “Engineering”; (ii) “Keywords”—“sugarcane”, “sugar cane”, “crops”, “remote sensing”, “image processing”, “mapping”, “ Saccharum”, “precision agriculture” AND “digital agriculture”. In this research, the terms “mechanized” and “mechanical” were not used because fewer than eight studies were retrieved from that search.

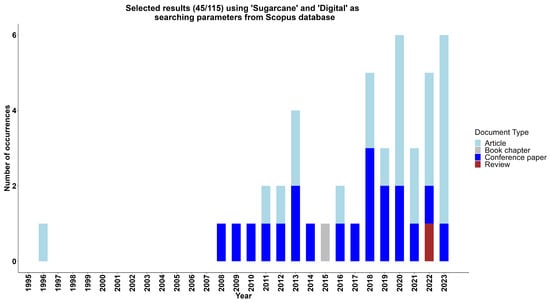

As a result, we found 115 documents, of which only 45 were within the scope of sugarcane crop production (Figure 1) which may have been caused by the misunderstanding of the meaning of the digital terminology. In addition, only one review paper was retrieved, highlighting the need for providing awareness about how “digital” can be conceived and applied in the sugarcane crop production.

Figure 1.

Results from the Scopus database considering the search terms “sugarcane” and “digital” within the range of 1995 and 2024.

A document gap was found between 1996 and 2008 related to the use of “digital” solutions for sugarcane crop production (Figure 1), presumably because technology was in development. Evaluating the documents, it was noted that the majority of them were not related to the digital aspects of mechanical crop production, but rather to the use of remote sensing for crop and soil parameter estimations. Therefore, it was necessary to retrieve documents without the explicit use of the term “digital” and to verify their suitability to be classified as being digital-related, as per the terminology explained in Section 3: Digitalization and Transformation in Agriculture.

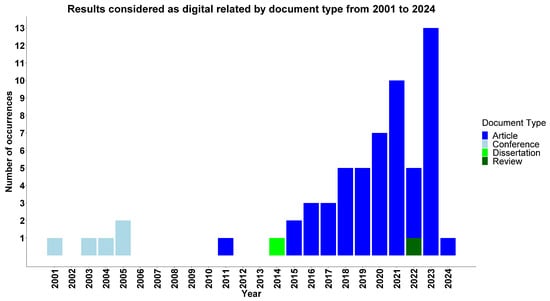

Figure 2 reveals periods (2006–2010) without documents within the papers selected. This is probably because digital tools for agricultural were under development beginning in the 2000s, a period that was marked by the disclosure of the selective availability interruption, an intentional degradation of Global Positioning Systems (GPS) to civil and commercial users worldwide, by the United States government [18]. Thus, it is reasonable to find this gap period without digital solutions in sugarcane crop production, given that time is needed to properly assess their technological usefulness. After 2015, more published works are found, which corroborates the findings of [19].

Figure 2.

Results considered to be digitally related to sugarcane crop production by document type from 2001 to 2024.

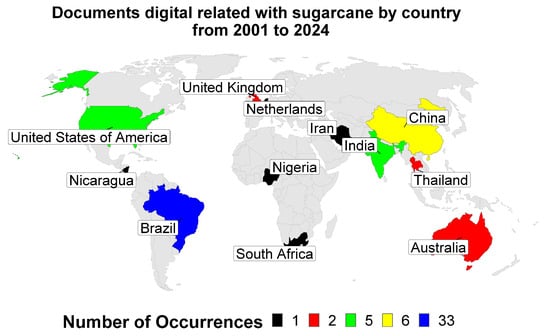

Most of the studies found were conducted in Brazil, China and India, which is expected since they are considered the largest sugarcane producers in the world [5]. Nonetheless, other countries (e.g., Australia, Iran, United Kingdom and Thailand) also have published studies with digital solutions for sugarcane crop production (Figure 3).

Figure 3.

Occurrence of documents considered to be digitally related to sugarcane crop production by country from 2001 to 2024.

3. Digitalization and Transformation in Agriculture

Modern agriculture demands evolution and development of methods to supply food production and address environmental issues. In the last years, traditional agricultural practices have been integrated with Information and Communication Technologies (ICT) and Precision Agriculture (PA) tools, contributing to the advancement of technology development and management in agriculture [20]. Regarding sugarcane, such integration and management aim to reduce production costs, optimize input applications, allow communication among different hardware and datasets, and enhance the sustainability of production systems and yield [21,22].

Digital agriculture can be conceived as ICT that may contain spatial analyses to aid producers in strategizing, scouting and managing their activities related to the production system. Also, digital agriculture can be associated with the term “Agriculture 4.0”, an analogy to Industry 4.0, a reference to the cutting-edge technology for food production [14]. The development of several key areas in the context of digital transformation of agriculture is required: digitalization of technological and production processes, development of digital platforms, and development of open access management systems, reliable communication channels and data availability [23].

As technological innovation and implementation in agriculture become an area of intense development, they can potentially change farming practices [24] as part of the digital transformation in agriculture. However, achieving this transformation step requires reaching the digitalization stage successfully.

“4.0 technologies” in agriculture may promote benefits such as yield increment, cost reduction, higher profits and sustainability. Despite these benefits, the adoption of technologies in agriculture is limited, mainly due to the lack of knowledge of the benefits that it can provide to the farmer and the communication gap among users and product developers [14,25]. To show how important technology has become to the agricultural sector, 26 countries in the European Union (EU) adopted a statement of cooperation, namely “A smart and sustainable digital future for European agriculture and rural areas”, highlighting the most important technologies that must be explored in agriculture: artificial intelligence, robotics, blockchain, high performance computing, internet of things and 5G [26].

To understand the expression “digital mechanization”, it is necessary to know the meaning of ‘mechanization’, which is the use of equipment to replace the manual work required in most of the steps during agricultural production. In the sugarcane production cycle, mechanization facilitates soil tillage, crop management and harvesting processes. However, it can also have negative consequences when misused, e.g., it can damage stalks and harm the soil [27,28,29,30,31].

‘Digitalization’ can be considered as the use of digital tools to automate and improve the traditional way of operating without changing the fundamental processes. Thus, digital mechanization in sugarcane can be conceived as the process of using digital tools with equipment during production, from the individual machine with digital solutions on board to the fleet operation and management.

The contribution of digital solutions to this context was initially promoted by the agricultural machinery industry for crops other than sugarcane. Nonetheless, sugarcane mechanization has some particularities that forced the implementation of customized solutions that now are being spread to the mechanization of major crops around the world.

Several technologies have been studied in the agricultural context and can be related to digital agriculture derived from the scientific knowledge and techniques already used and developed in the context of PA since the 1990s. The technologies can be divided according to their complexity of applications: (i) low (internet and connectivity, mobile applications, digital platforms and software, global positioning systems, digital maps), (ii) medium (proximal, field and remote sensors, embedded electronics, telemetry and automation) and (iii) high (deep learning and internet of things, cloud computing, big data, blockchain and cryptography, artificial intelligence) [14].

A digital farming example for sugarcane can be found in Australian studies like the Commonwealth Scientific and Industrial Research Organisation’s (CSIRO) Digiscape initiative, one of the Future Science Platforms from 2016 and 2022. This initiative fostered the benefits of the digital revolution to Australian farmers, making agriculture more profitable with lower risk and negative impacts to the environment [32,33]. To accomplish this, they relied on a multidisciplinary approach based on the traditional knowledge of farm experimentations with data analysis, engineering and software development. For example, aiming to reduce nitrogen pollution at the Great Barrier Reef from sugarcane fields [34], environmental policies and remote sensing research have been used to develop a fertilization guide [32,35].

4. Operations Related to Sugarcane Crop Production

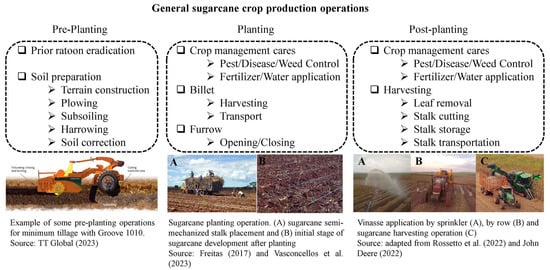

Sugarcane mechanical cultivation relies on a series of processes (Figure 4), from soil preparation to cane stalk delivery to the mill, which demands an intense use of mechanical energy when compared to other crops [36]. Some of the mechanical operations applied before planting include prior crop ratoon eradication, soil preparation (terrain construction to reduce the effects of soil erosion and runoff), plowing, subsoiling, harrowing and soil correction (lime for acidity; gypsum for aluminum toxicity).

Figure 4.

General sugarcane crop production operations: pre-planting [37], planting [38,39] and post-planting (adapted from [40,41]).

Afterwards, mechanical planting can be started, followed by crop management (pest/disease/weed control, fertilizer application) during crop development until the harvesting period. The planting operation is based on the following phases: billet harvesting, billet transport to the planting location, furrow opening, billet distribution at the bottom of the furrow, fertilizer application and furrow closing. Among these phases, the process of obtaining the billets is important because their quality, uniformity and distribution have a direct impact on yield [27].

Usually mechanical planting of sugarcane in Brazil, Australia and Cuba uses the entire stalk, which is considered inefficient [42], since planting can done with reduced sizes of stalks containing only one bud per stalk. To obtain stalks with single buds, studies have been developed applying computers [42,43] to identify improvements in mechanical planting operations that allow for carrying more material per load, thereby diminishing the reloading times required and disturbance to the crop land.

A study conducted in Brazil found that mechanized sugarcane planting was cheaper than semi-mechanized planting, with people placing the stalks in the furrows [44]. Despite this cost advantage, a restricted number of Brazilian growers use mechanical seeding since there is a high investment cost for the specific machinery required [45]. In fact, there is currently no planter on the market with a dedicated stalk meter, which is analogous to the grain seeder used for maize.

Regarding the sowing/stalk placement method, there are mainly three methods considered in relation to the furrow or plant line: transversal, vertical and horizontal. These methods are dependent on the availability of the mechanical system, since it its related to bud cutting, planting and soil-covering operations.

In some Asian countries (e.g., China and India), transversal sowing promoted higher sugarcane yield, lodging resistance and lower cane seed consumption [46,47]. However, several challenges regarding the transversal method must be overcome, especially bud cutting. In this sense, efforts in digital image analysis have been made, and promising results for its applicability are expected [48].

In Brazil, most of the sowing methods are related to horizontal planting, mainly related to the operation process. Efforts have been made towards vertical sowing; however, plant development was limiting. Sugarcane mills in Brazil conducted experiments to develop pre-sprouting seedlings that are more resistant to diseases, pest attacks, and soil salinity and acidity. However, during dry seasons, these seedlings require irrigation to survive, therefore compromising the adoption of pre-sprouting seedlings in large areas.

The use of encapsulated gems, somatic embryos or shoots encapsulated with a synthetic covering that provides a controlled environment for their development and result in seeds similar to natural ones, has been tested as an alternative to the use of pre-sprouting seedlings [49,50]; however it has not been consolidated yet. Regardless of the sowing method, it is unquestionable that mechanical planting can benefit from the application of digital solutions to improve the stalk cutting accuracy and stalk distribution, mainly relying on the computer applications. Nonetheless, the adoption of these digital and mechanical solutions is limited by the implementation costs and reluctance to change the traditional way of operations.

The sugarcane production system relies on about 30 mechanical operations from planting to harvesting [51]. Steps prior to planting aim to ensure crop longevity, as it is cultivated for more than on cycle. Thus, technological investments have mostly focused on operations related to weed detection and input applications which are commonly related to remote sensing (orbital, aerial and proximal) techniques providing site-specific weed management [52] and possible guidance for input application based on the ON/OFF system which can rely on gap detection [53].

The key factors related to sugarcane harvesting are related to the set of wagons, normally pulled by tractors, and harvesters, because they are the baseline for the design of traffic standards, fleet size, plot size and maneuver operations [36]. Mechanical harvesting has presented benefits that are not only economical, but also environmentally related; for example, in Brazil, the mechanized systems promote better working conditions, higher average income and balance of environmental impacts when compared to manual systems [54].

The harvesting operation can be responsible for up to 30% of the total crop production cost [55] because it is the operation that consumes the most energy [56]. Mechanical operations can harvest sugarcane as whole stalks or as billets. Their main difference is related of the structure complexity (billet harvesting is more complex than whole-stalk harvesting). In general, billet harvesting is more efficient than whole stalks because it can harvest more stalks considering the same machine labor; however, the billets must be used promptly, thus requiring short distances between the field and the sugar mill. Therefore, if the transportation distance of the stalks is considered a limiting factor, then whole-stalk harvesting is recommended since they can be stored for up to three days after harvesting [57].

In recent years, sugarcane harvesters with choppers have been largely adopted in Australia, the USA and Brazil and are the most used due to their low labor demand and high efficiency [56,57,58]. However, in China, only 10% of sugarcane-growing areas rely on its use, mainly because of the mountainous regions. Thus, whole-stalk harvesting is predominant in China, demanding the development of compacted harvesters [58].

During the harvesting operation, wagons accompanying the harvesters are able to cut one or two rows and harvest up to 30 tons of sugarcane stalks per hour [55], causing intense disturbance to the crop area [28]. This issue can be diminished when decision makers entirely apply the concepts of controlled traffic when designing the plot size before planting [28]. Controlled traffic is another example of digital solutions that aids the improvement of crop production, since a higher accuracy of route planning can be achieved by applying technological tools instead of a manual approach.

Traffic-control farming can be conceived as a management tool used to restrict all machinery loads to the fewest areas of permanent traffic lanes to reduce the negative impact that machinery can cause to the soil and the time consumed for machinery operations. For example, ref. [59] compared the time consumed during sugarcane harvesting with and without route planning. In their study, they obtained a reduction of about 32% of he time consumed when applying route planning. Another operation that can be highly expensive is the transportation from the field to the mill, which can account for more than 30% of the total cost [55]. Therefore, traffic control, route planning and fleet size become crucial to reduce production costs that are related to the advances of ICT applied in agriculture.

5. Digital Solutions in Sugarcane Mechanization

Sugarcane yield potential depends on edaphoclimatic conditions and management practices [2] and is also related to investments in technological investigations that aim to improve the crop production management [60]. Thus, the integration among operations can improve management efficiency, reduce production costs and improve yield [61]. In sugarcane fields, integration can be used especially at the harvesting, loading and shipping stages with embedded communication technology in the equipment [62].

Sugarcane stalk preparation for planting is an expensive process during which a significant amount of stalk can be lost using conventional methods of propagation (long cane stalk or cane setts) [63]. Usually, sugarcane buds are harvested manually using a bud chipper. Despite the system, it provides an uneven cut length and is considered labor intensive. To overcome these issues and increase awareness of the potential application of image-processing techniques, studies have proposed methods to cut stalks evenly.

For example, ref. [64] proposed the development of a real-time sugarcane bud-cutting unit by applying computer vision techniques and mechatronics integration to produce standard buds, reducing labor cost and amount of cane stalk. Their work is an example of digitalization where the current methods to obtain buds are based on a human-operated machine, and their proposal is to obtain buds with high standard quality by applying new technological methods.

Among technological advancements related to the sugarcane mechanization, we highlight fleet management, the intensive use of Global Navigation Satellite Systems (GNSS) for machinery guidance and yield-monitoring systems. Agricultural operations since the 1980s established agricultural mechanization through the integration of GNSS and Geographic Information Systems (GIS) [65] followed by the advent of communication via the General Packet Radio Service (GPRS) [66], improving fleet management. Fleet management is related to telemetry, operational control, and control of how, where and when the machines are working; in addition, it generates large amounts of data that can be related to the local environment conditions encompassing soil and crops.

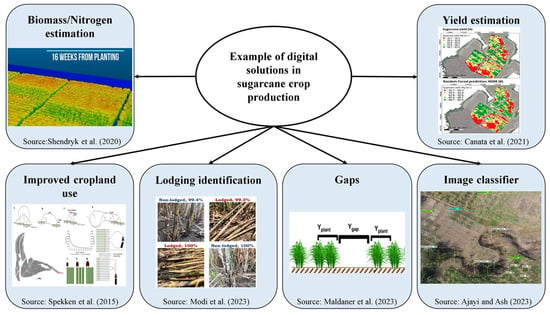

In terms of digitalization in sugarcane production and automatic intervention, several studies have been conducted (Figure 5), mostly related to sensing and predictive approaches, for example, biomass [67,68,69], gaps [1,3,53,70,71,72,73,74], lodging identification and classification [75], yield estimation [76,77,78,79,80,81,82], nitrogen application [69,83], sugarcane disease detection [84,85], weed control [52,86], improved cropland use [87], harvesting planning [88,89], and prediction of seed replenishment positions [90].

Figure 5.

Example of digital solutions in sugarcane crop production. Biomass and nitrogen estimation [68], improved cropland use [87], image classifier [52], gaps [73], lodging identification [75] and yield estimation [79].

The study of [67] is an example of the application of digitalization. The authors compared three canopy sensors to measure sugarcane biomass and found that sensors were efficient to predict biomass; this indicates that manual measurement of biomass can be replaced with technological sensing methods, fostering the development of tools to enhance management decisions related to biomass.

The use of sensor systems with GNSS in sugarcane crop production has been growing, mainly due to the benefits provided by unmanned aerial vehicles (UAVs) [70], which are powerful tools that can collect digital data at high spatial resolution. Real Time Kinematic (RTK) positioning solutions can provide higher accuracy to support decision makers to cope with field variability at a high spatial resolution, i.e., at the resolution of the sugarcane planting lines based on which sugarcane gap maps can be obtained as shown in [74].

Considering yield estimation, it is worth noting that the use of satellite imagery data has been largely applied, but the use of ground-truthed data at high density to fit predictive models during the calibration phase is not common, since data acquisition is onerous and time consuming. Thus, to illustrate yield estimation and high-density yield data, considering the use of digital solutions, we highlight studies [77,79], which rely on digital solutions to sugarcane crop production.

The generation of sugarcane yield at the resolution of individual planting rows based on yield-monitoring data from [77] indicated that to obtain more accurate results, a higher frequency of data collection should be used (2 Hz). Thus, data from UAVs or yield monitors can provide relevant and large amounts of data to be analyzed; however, they must be correctly accounted for since they can be generated with errors from different sources such as GNSS receivers, sensor system failure and others.

For sugarcane yield prediction modeling, ref. [79] applied machine learning algorithms within a dataset composed of spectral bands and vegetation indices from Sentinel-2 satellite images. They found that applying a non-linear model, random forest regression, yield was better predicted when compared to the use of multiple linear regression, a linear model. Another study applied random forest to a dataset composed of plant height, yield data and satellite imagery to assess yield estimation in Thailand [91], demonstrating the usefulness of these variables to estimate yield.

The above results [79,91] demonstrate the potential use of satellite imagery aiming to generate yield predictive models and/or crop monitoring development. However, their application is still dependent on several factors, especially reliable yield data, which can be obtained from new approaches based on direct or indirect measurements from the harvester.

Sugarcane harvesting in Brazil changed from manual to mechanical, bringing the need for the development of new technologies to address peculiar problems usually found in crop production, such as traffic control, planting and harvesting. According to the Australian Controlled Traffic Farming Association (ACTFA) [92], “controlled traffic farming is a farming system that continues to deliver unparalleled improvements in productivity and sustainability for growers of grains, cotton and sugar around the world”, and it is based on the following fundamentals: all machines present equal working and track gauge width, allowing for the establishment of permanent traffic path; all machines have the ability to stay along the permanent traffic lane; and farm, paddock and permanent traffic lanes are designed to optimize drainage and logistics.

Despite the existence of controlled traffic techniques, the set of harvesters, in some cases, tractor and wagon, do not benefit from it because of the mismatch between row spacing and equipment track width. These problems can happen because tractors, harvesters and wagons do not have standardized track widths; therefore, the traffic passes close to the crop rows and sometimes run over the crop row [27,93]. In addition, the displacement between tractor and wagon can be related to the terrain slope, which can be overcome by complementary solutions based on an automatic steering wheel [94].

The mechanical process of harvesting sugarcane can result in losses, primarily because of factors such as operator oversight, variations in terrain and soil conditions, the composition of the cane, harvester speed and cutting set [95]. Given that the cutting mechanism of the harvester plays a significant role in determining the quality of the harvest, numerous studies have been conducted on this aspect [31,93,96,97,98,99], but despite these efforts, limited studies have attempted to make real-time diagnosis on the cutting blade conditions.

Aiming to make a real-time diagnosis, ref. [95] conducted an experiment using computer vision to monitor the cutting blade quality and its effect on sugarcane ratoons and found that image processing can be used to quantify blade wear in an automated way, aiding the harvesting operation to produce reliable data. Knowing that the lifespan of cutting blades is related to the cutting height, ref. [31] proposed a fast and contactless ground radar penetration sensor to automate cutting height, which can be a digital tool to improve the harvesting process.

Depending on the sugarcane harvester model, it can cut and process double or single rows; the latter is still dominant. Real-time yield monitoring at the field level can be achieved by measuring sugarcane flow into the harvester by different methods, with emphasis on five of them: (I) chopper pressure, a proportional relation of pressure and sugarcane mass; (II) elevator power, where the power needed to move the elevator is proportional to the mass; (III) direct mass measurement, based on load cell at the elevator, which is the most studied due to the ease of obtaining the mass without the need for empirical equations; (IV) volumetric measurement by feed rollers, measured based on the distance between rollers [100]; or (V) volumetric measurement by optics, an indirect measurement obtained through the computer vision application. It is important to emphasize that complementary solutions, with more than one signal, are also relevant. Regardless of the sensing system, the cutting base, impurity extraction and stalk loading are considered the main factors related to losses during harvest [100].

As part of the harvesting operation, there is yield data information, already well-established in mechanical harvesting of grains and some other crops. It is an important layer of information for managers in terms of monitoring and acting on the spatial variability of the production fields, which allows the identification of spatial and temporal patterns in the crop, trends and areas of greater and lesser productive potential in sugarcane fields. Several studies have been conducted using different measurement principles and sensor positioning in the harvester, as shown in Table 1.

Table 1.

Sugarcane yield measurement system evolution.

Looking to accurately predict sugarcane yield in real time, efforts have been made towards the use of indirect measurements from sensors installed in the harvesters [81,111]. For example, in [111], the authors evaluated the sensor fusion installed in eight different places through the sugarcane flow process within the harvester. The harvester was instrumented with potential displacement sensors to measure the distance between feed rollers, pressure sensors to measure the hydraulic pressure at the chopper and elevator conveyor motor and tension sensors to measure the deformation at the elevator. After gathering the data from these sensors, they applied a neural network framework to predict sugarcane mass flow and were able to accurately estimate the yield at the line resolution.

Another example that shows the potential use of digital solutions in sugarcane crop production is [81], a study that used the wireless network ZigBee to connect front-line equipment of the harvester distributed in the field with the sugarcane mill’s Control Remote Center aiming to monitor in real time the hydraulic pressure in the chopper of each harvester during the harvesting process and predict its yield. To predict yield, they redistributed the total weight of sugarcane harvested within each field based on the chopper hydraulic pressure.

As a result, ref. [81] found that using the redistribution of total mass based on the hydraulic pressure can be used to predict yield without the need for empirical models and sensor calibration regardless of harvester. Their findings highlight the usefulness of telemetry (in this case, ZigBee technology) within the scope of sugarcane yield measurement systems and how digital mechanization is evolving in agriculture. Despite the results from these studies, there are still unanswered questions, such as the feasibility to obtain these data, reliability of the data and capacity to process these data in real time. In addition, there is the issue of data privacy policy, an uncertain point whereby the user and the developer lack communication, promoting a mismatch of interests towards the development of a transparent tradeline between them.

Advances in telemetry and growing investments in sugarcane management have used hardware device technologies and software systems such as UAVs to obtain information about the crop with high spatial resolution [70,71,112,113]; embedded sensors in sugarcane harvesters to estimate yield quantitatively and qualitatively [100,114]; Big Data and remote sensing for crop monitoring [65,91]; real-time crop monitoring for disease control [84]; controlled traffic [13,28]; Internet of Things [115]; machine learning application [60]; and others.

All of these digital advances are replacing the old manual field records to ensure reliable communication. Data centralized in telemetry centers enables automated solutions to integrate electronic sugarcane certificates and harvesting, loading and shipment to the Enterprise Resource Planning (ERP) [116].

Fleet management in agriculture has to care about not only fleet size and routine, but also regular mechanical and electrical maintenance [117] to deliver on-time farming operations as scheduled. Studies proposing different methods to predict sugarcane harvester maintenance needs have been developed, mostly based on previously collected data—post-processing methods [118,119]. Preventive maintenance is a broad topic that can be applied to different areas, not only tractors and harvesters, as it provides benefits to the users, e.g., increasing the safety during operations and the availability of machines. However, efforts must be made towards the application of real-time diagnosis during operation processes, so major damages to the user and the machine can be avoided.

Different solutions have been proposed to solve logistic problems during sugarcane harvesting, since it is a complex operation. For example, ref. [88] proposed the use of a heuristic model to solve the lot sizing and scheduling problem with parallel production lines and found that it could be applied without the need for sectorization. Studies have applied mixed-integer linear programming [120], integer linear programming [2] and others. Therefore, fleet management and agricultural operations on-farm have a straight relation with mechanical, electronics and information systems [118] that are benefiting from the advances of digital solutions in agriculture.

6. Technological Implementation

Despite the importance and benefits that technological implementation can bring to the agricultural sector, mainly to sugarcane, there are issues that must be addressed to attract users worldwide. One issue is related to connectivity in rural areas, where there are obstacles to implement the use of new technologies.

By the end of 2018, 47.7% of rural areas in the EU did not have coverage and access to communication networks [121]. In Brazil, by 2017, the scenario was even worse, as more than 71% did not have any access to communication networks [122], highlighting the lack of infrastructure in rural areas. As technology advances, there is an expectation that 5G technology can fulfill this lack of connectivity in agricultural areas [66,123]. However, the commercial implementation of 5G is currently underway, and its full capacity and functionalities are expected to be gradually achieved over the next decade [124].

Some local initiatives can be identified; for example, in 2015, the Brazilian Development Bank (BNDES) approved a project to encourage the adoption of “agriculture 4.0” establishing a partnership with a telecommunication technology organization and a sugar mill group. The aim of the project was to develop and implement an integrated communication and sensing platform for sugarcane production using Long Term Evolution (LTE) and Radio Frequency Identification (RFID) to ensure: (i) real-time decision making; (ii) harvest, shipment and loading tracking, and (iii) optimization of fleet use and supply logistics [125].

Another issue is about agricultural technological adoption of which farmers are skeptical with regard to the benefits that it can bring. Beyond this, they assume that most of the technologies are developed for big farmers due to the perception of high initial investment costs and the complexity of handling the equipment [123]. Such technological barriers were also found in a survey conducted with 240 Indian sugarcane farmers, in which only 18% of the rural population have access to the internet [126]. In addition, they highlighted the lack of time, educational access and elevated production costs [127].

Besides these barriers, there are also age-related issues, whereby most of the users who have adopted some technologies into their daily tasks are younger [128], indicating an inverse relation between age and technological adoption rate [129]. In a study by [16], interviews were conducted with 131 Brazilian sugarcane producers between September and December 2019. The results revealed that the farmers’ level of schooling is directly related to the adoption of precision farming practices, highlighting the importance of technological and managerial skills for the effective implementation of these practices.

Another survey conducted with Brazilian sugarcane farmers from May to December 2019 [130] found that the information provided by the mills could positively affect the adoption rate of some digital tools, since mills are not considered only as buyers, but also as service providers to medium and large-sized farms. However, in terms of small farming operations, the main drivers that can boost adoption rates are rural organizations (i.e., cooperatives), research institutions and public extensions; these results corroborate the findings of [131].

Therefore, comparing studies from India [126], the USA [15] and Brazil [16,130], it is shown that the lack of adoption of digital tools is not solely related to the costs, but also to the poor linkage among farmers–researchers–extensions. In addition, for example, in Kenya, even with the presence of government policies fostering the adoption of technological tools in sugarcane production, the adoption rate is jeopardized by the lack of feedback, low connectivity coverage for farmers, mediocre service delivery and scarce funding for public extensions as reported in the “Policy on Revitalization of the Sugar Industry” [132].

In Brazil, despite the low-cost rural credit policy provided by the government to small- and medium-sized farms, the adoption of digital tools especially by small farmers is not extensive [130] mainly because the benefits are not clear for them. Therefore, it is evident that technological adoption is dependent on farm size. In this sense, medium- and larger-sized farms have higher chances of boosting the adoption of digital tools supported by mills and small-sized farms, by farmer organizations and PA suppliers that can embrace the low-cost rural credit policy [130].

Despite the above issues, there is another barrier related to the technological adoption in agriculture that must be overcome, namely internet access. Thus, government political actions to promote internet and electrical access, as well as tailored crop extension aid to increase farmers’ digital trust, are needed [127].

Efforts have been made in the last three decades to develop methods for site-specific application as part of the precision agriculture technology. However, the adoption rate has to overcome industrial issues such as: (i) incompatibility of technological components from different brands and (ii) high maintenance costs [128].

Mills have to support technological implementation in field operations to foster sustainable production. In Brazil, sugarcane is mainly cultivated and harvested by the mills. According to data from [133], the sugarcane harvest in Brazil in 2015 revealed that about 66% of the areas harvested belonged to mills, while 34% were from independent suppliers. Also, there are about 350 mills and 70,000 independent producers [134]. Sugarcane production from the mills comes from areas owned or leased under the full control of these industries. A portion of the sugarcane is grown on land leased from third parties, where the mills assume all agricultural responsibilities, similar to managing their own properties, but paying for land use. In the case of independent sugarcane suppliers, they are responsible for the management themselves [133].

Therefore, the partnership among producers and mills is crucial to promote the adoption of digital technologies in sugarcane production [130]. The Brazilian sugarcane cultivated areas are managed evenly within the strategy known as “production environments”, regions within the fields that present similar soil physico-chemical properties. Besides its applicability, it is a strategy not aligned to the resolution required to describe spatial variability [60].

PA studies aiming to evaluate spatial variability were initially conducted based on the mapping of soil physico-chemical attributes towards the development/optimization of strategies to apply variable rate technology [135]. However, data representativeness is still a point to be improved, since different sampling methods and mapping strategies can be used. Thus, studies still need to be developed aiming to accurately gather data to represent the field variability and guide better management decisions. In this sense, the advances in digital mechanization can fulfill this gap by providing massive, reliable and high-resolution data fostering the development of data-driven solutions/insights that can be used as an extra decision-making layer to improve the agronomic management. Nevertheless, a careful evaluation of the results must be conducted prior any decision since it can yield false causal relationships, negatively impacting the expected outcome.

Regarding system compatibility, it is uncommon to find farmers that rely on one equipment/machinery supplier [136]; thus, to ensure that the equipment is operating properly, communication among them is necessary, which is a challenge. Data integration and standardization have been discussed for over 20 years since the formation of ISO 11783 [137], a concept introduced by [138] in the 1980s and developed by the German group of Agricultural Machinery and Tractor Association (LAV—Landmaschinen und Ackerschlepper Vereinigung) [139].

The need for brand compatibility connection between tractor and implement in agriculture is defined by the standard ISO 11783 [137], commercially known as ISOBUS [140,141]. However, interoperability between different systems (software and hardware) is broader than that and is one of the main issues that restricts the adoption of digital technology in the world. Aiming to overcome this hurdle, AgGateway proposed a solution called Agricultural Data Application Programming Toolkit (ADAPT) which can enable the interoperability among different systems [142]. Parallel to this, sugarcane harvesters, tractors and self-propelled sprayers have embedded technology, with the controller area network (CAN) allowing the communication among electronic control units (ECUs) through a standard system delivering information about the operation [79,137].

Besides the communication problem among systems, the issue of data privacy is gaining prominence since major concerns have been pointed out such as (a) ownership; (b) collection, access and control; (c) choice; (d) portability; (e) disclosure, use and sale limitation; (f) data retention and availability. Therefore, to overcome these concerns, approaches based on (a) standardization; (b) trust; (c) legal frameworks and (d) blockchain can aid to cope with them, thereby improving agriculture through the application of digital technologies [143].

An example is the “Sistema Brasileiro de Agrorastreabilidade—Sibraar”, the first software registered in 2022 to the Brazilian sugarcane market to track the chain process based on a blockchain technology [144,145]. The software guarantees (i) data integrity during the production process and (ii) data traceability according to the General Personal Data Protection Law [146].

Digital solutions in sugarcane crop production are essential for farmers and sugarcane mills to meet the standard criteria of the Brazilian program—“Política Nacional de Biocombustíveis do Brasil—Renovabio” implemented in 2017 which aims to reduce greenhouse gas (GHG) emissions in accordance with the Paris Climate Conference (COP21) and fostering the production of biofuels [147].

The technological application of digital solutions can aid the development of more efficient management practices from the sugarcane crop planting (e.g., route path planting) up to the shipment process, leading direct effects such as reduced energy consumption, enhanced fertilizer use and crop longevity and indirect effects such as lower GHG emissions, reduced soil and water contamination and human health benefits. To achieve that, international collaboration is required since global efforts are being made towards the sustainable development of agriculture.

In the last decade, the sugarcane sector has been improved considering the sustainable tripod (social, economic and environmental) impact. Nonetheless, this sustainable approach has changed to fit the international needs related to the Environmental (E), Social (S) and Governance (G) dimensions, also known as ESG [148,149]. Aware of this evolution process, agricultural digitalization can be considered as one tool that benefits the application of ESG as they can standardize and monitor data [150].

7. Final Considerations

Adoption rates of new crop production technologies in the sugar-energetic sector are considered historically resistant. Recent investigations showed that digitalization processes in sugarcane crop operations have contributed on the application of technological tools related to ICT and PA mainly due to the need for reducing production costs and achieving higher yields. Technological advancement and adoption rely on the support of the government and sugarcane mills, especially in Brazil, since sugarcane mills play an important role, as they are the largest buyers and producers of the cultivated sugarcane and are able to incentivize the adoption of digital solutions and/or technological products as consumers demand products based on the ESG principles.

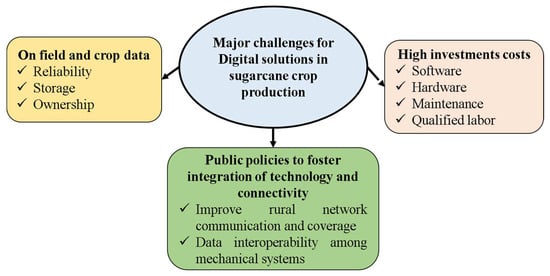

The main studies in the literature reported that mechanical, electronic and information systems have a direct relationship with agricultural operations, traffic control and fleet management. Regarding the implementation of digital solutions in sugarcane, there are major challenges (Figure 6) that must be overcome, including: high initial investments costs, need for more focus on field and crop data; regular mechanical and electrical maintenance of machines based on real-time diagnostics during the operation process; lack of coverage and access to communication networks in rural areas; limited implementation of public policies to encourage the integration of technology and connectivity in the countryside; incompatibility of technological components from different brands; difficulties in integrating technologies available on the market and high maintenance costs; absence of public initiatives to solve data interoperability in mechanized systems; and barriers to technology adoption by producers. Thus, these challenges are suggested as subjects of further research, aiming to fill research gaps and future directions of the mentioned technologies.

Figure 6.

Major challenges for digital solutions in sugarcane crop production.

To boost the adoption rate of digital tools, more case studies must be conducted internationally to demonstrate the ongoing programs and their results looking into the economic evaluation providing clearer viability for farmers. From the user feedback, solutions can be improved and/or developed to overcome the adoption barriers of the era.

This review urges to action/engagement of farmers, researchers, stakeholders and policy makers to foster the adoption and implementation of digital tools to meet the global concerns related to the environmental, social and economic aspects of sugarcane production. However, first, there is a need to raise awareness among all stakeholders about the conception of digital and its application to extract the foremost benefits it can bring.

Author Contributions

Conceptualization, J.P.M., M.C.F.W. and E.R.O.d.S.; Methodology, J.P.M., M.C.F.W. and E.R.O.d.S.; Writing—original draft, J.P.M., M.C.F.W. and E.R.O.d.S.; Writing—review & editing, J.P.M., M.C.F.W. and E.R.O.d.S.; Supervision, J.P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Data Availability Statement

No new data were created in this study. Data sharing is not applicable to this article.

Acknowledgments

We acknowledge the ‘Coordination for the Improvement of Higher Education Personnel (CAPES)’.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Souza, C.H.W.; Lamparelli, R.A.C.; Rocha, J.V.; Magalhães, P.S.G. Mapping skips in sugarcane fields using object-based analysis of unmanned aerial vehicle (UAV) images. Comput. Electron. Agric. 2017, 143, 49–56. [Google Scholar] [CrossRef]

- Florentino, H.O.; Irawan, C.; Aliano, A.F.; Jones, D.F.; Cantane, D.R.; Nervis, J.J. A multiple objective methodology for sugarcane harvest management with varying maturation periods. Ann. Oper. Res. 2018, 267, 153–177. [Google Scholar] [CrossRef]

- Rocha, B.M.; Fonseca, A.U.; Pedrini, H.; Soares, F. Automatic detection and evaluation of sugarcane planting rows in aerial images. Inf. Process. Agric. 2023, 10, 400–415. [Google Scholar] [CrossRef]

- United States of Department of Agriculture (USDA). U.S. Sugar Production. 2021. Available online: https://www.ers.usda.gov/topics/crops/sugar-sweeteners/background/ (accessed on 26 January 2022).

- Food and Agriculture Organization of the United Nations (FAO). Sugarcane. 2023. Available online: http://www.fao.org/land-water/databases-and-software/crop-information/sugarcane/en/ (accessed on 10 October 2023).

- Companhia Nacional de Abastecimento (CONAB). Safra Brasileira de Cana-de-Açúcar. 2023. Available online: https://www.conab.gov.br/info-agro/safras/cana (accessed on 20 December 2023).

- Statistica. World Sugar Cane Production from 1965 to 2019 (in Million Metric Tons). 2019. Available online: https://www.statista.com/statistics/249604/sugar-cane-production-worldwide/ (accessed on 10 October 2021).

- Babu, K.S.D.; Janakiraman, V.; Palaniswamy, H.; Kasirajan, L.; Gomathi, R.; Ramkumar, T.R. A short review on sugarcane: Its domestication, molecular manipulations and future perspectives. Genet. Resour. Crop. Evol. 2022, 69, 2623–2643. [Google Scholar] [CrossRef] [PubMed]

- Organisation for Economic Co-Operation Development (OECD); Food and Agriculture Organization of the United Nations (FAO). OECD-FAO Agricultural Outlook 2020–2029; OECD: Rome, Italy; FAO: Paris, France, 2020. [Google Scholar] [CrossRef]

- Filoso, S.; Carmo, J.B.; Mardegan, S.F.; Lins, S.R.M.; Gomes, T.F.; Martinelli, L.A. Reassessing the environmental impacts of sugarcane ethanol production in Brazil to help meet sustainability goals. Renew. Sustain. Energy Rev. 2015, 52, 1847–1856. [Google Scholar] [CrossRef]

- Fioranelli, A.; Bizzo, W.A. Generation of surplus electricity in sugarcane mills from sugarcane bagasse and straw: Challenges, failures and opportunities. Renew. Sustain. Energy Rev. 2023, 186, 113647. [Google Scholar] [CrossRef]

- Mahasuweerachai, P.; Suksawat, J. Incentives for mechanized cane harvesting in Thailand: A choice experiment. J. Asian Econ. 2022, 78, 101434. [Google Scholar] [CrossRef]

- Esteban, D.A.A.; Souza, Z.M.; Tormena, C.A.; Lovera, L.H.; Lima, E.S.; Oliveira, I.N.; Ribeiro, N.P. Soil compaction, root system and productivity of sugarcane under different row spacing and controlled traffic at harvest. Soil Tillage Res. 2019, 187, 60–71. [Google Scholar] [CrossRef]

- Bolfe, E.L.; Jorge, L.A.C.; Sanches, I.D.; Luchiari Júnior, A.; Costa, C.C.; Victoria, D.C.; Inamasu, R.Y.; Grego, C.R.; Ferreira, V.R.; Ramirez, A.R. Precision and Digital Agriculture: Adoption of Technologias and Perception of Brazilian Farmers. Agriculture 2020, 10, 653. [Google Scholar] [CrossRef]

- McFadden, J.; Njuki, E.; Griffin, T. Precision Agriculture in the Digital Era: Recent Adoption on U.S. Farms; USDA Economic Research Service: Washington, DC, USA, 2023; Volume EIB-248.

- Carrer, M.J.; Souza Filho, H.M.; Vinholis, M.M.B.; Mozambani, C.I. Precision agriculture adoption and technicla efficiency: An analysis of sugarcane farms in Brazil. Technol. Forecast. Soc. Change 2022, 177, 121510. [Google Scholar] [CrossRef]

- Cicciu, B.; Schramm, F.; Scharamm, V.B. Multi-criteria decision making/aid methods for assessing agricultural sustainability: A literature review. Environ. Sci. Policy 2022, 138, 85–96. [Google Scholar] [CrossRef]

- GPS. Selective Availability. 2021. Available online: https://www.gps.gov/systems/gps/modernization/sa/ (accessed on 21 February 2024).

- Silveira, F.; Lermen, F.H.; Amaral, F.G. An overview of agriculture 4.0 development: Systematic review of descriptions, technologies, barriers, advantages, and disadvantages. Comput. Electron. Agric. 2021, 189, 106405. [Google Scholar] [CrossRef]

- Boursianis, A.D.; Papadopoulou, M.S.; Diamantoulakis, P.; Liopa-Tsakalidi, A.; Barouchas, P.; Salahas, G.; Karagiannidis, G.; Wan, S.; Goudos, S.K. Internet of Things (IoT) and Agricultural Unmanned Aerial Vehicles (UAVs) in smart farming: A comprehensive review. Internet Things 2020, 18, 100187. [Google Scholar] [CrossRef]

- El Chami, D.; Daccache, A.; Moujabber, M.E. What are the impacts of sugarcane production on ecosystem services and human well-being? A review. Ann. Agric. Sci. 2020, 65, 188–199. [Google Scholar] [CrossRef]

- Sanches, G.M.; Bordonal, R.O.; Magalhães, P.S.G.; Otto, R.; Chagas, M.F.; Cardoso, T.F.; Luciano, A.C.S. Towards greater sustainability of sugarcane production by precision agriculture to meet ethanol demands in south-central Brazil based on a life cycle assessmen. Biosyst. Eng. 2023, 229, 57–68. [Google Scholar] [CrossRef]

- Ulezko, A.V.; Reimer, V.V.; Ulezko, O. Theoretical and methodological aspects of digitalization in agriculture. IOP Conf. Ser. Earth Environ. Sci. 2019, 274, 012062. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.J. Big data in smart farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Annosi, M.C.; Brunetta, F.; Monti, A.; Nati, F. Is the trend your friend? An analysis of technology 4.0 investment decisions in agricultural SMEs. Comput. Ind. 2019, 109, 59–71. [Google Scholar] [CrossRef]

- European Union. EU Member States Join Forces on Digitalisation for European Agriculture and Rural Areas. 2019. Available online: https://digital-strategy.ec.europa.eu/en/news/eu-member-states-join-forces-digitalisation-european-agriculture-and-rural-areas (accessed on 14 October 2021).

- Braunbeck, O.A.; Magalhães, P.S.G. Avaliação Tecnológica da Mecanização da Cana-de-açúcar. In Bioetanol de Cana-de-Açúcar. P&D Para Produtividade e Sustentabilidade; Magalhães, P.S.G., Braunbeck, O.A., Eds.; Blucher: São Paulo, Brazil, 2010; pp. 451–503. [Google Scholar]

- Esteban, D.A.A.; Souza, Z.M.; Silva, R.B.; Lima, E.S.; Lovera, L.H.; Oliveira, I.N. Impact of permanent traffic lanes on the soil physical and mechanical properties in mechanized sugarcane fields with the use of automatic steering. Geoderma 2020, 362, 114097. [Google Scholar] [CrossRef]

- Tweddle, P.B.; Lyne, P.W.L.; van Antwerpen, R.; Lagerwall, G.L. A review and synthesis of sugarcane losses attributed to infield traffic. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, UK, 2021; pp. 197–250. [Google Scholar]

- Júnnyor, W.S.G.; De Maria, I.C.; Araujo-Junior, C.F.; Diserens, E.; Severiano, E.C.; Farhate, C.V.V.; Souza, Z.M. Conservation systems change soil resistance to compaction caused by mechanised harvesting. Ind. Crops Prod. 2022, 177, 114532. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, J.; Jiao, S.; Zheng, T.; Li, J.; Zhao, T. Ground surface detection method using ground penetrating radar signal for sugarcane harvester base-cutter control. Biosyst. Eng. 2022, 219, 103–123. [Google Scholar] [CrossRef]

- Digiscape Future Science Platform. Less Fertiliser: Same Profit. Developing a Drone-Guided Fertilisation Plan. 2018. Available online: https://research.csiro.au/digiscape/less-fertiliser-same-profit-developing-a-drone-guided-fertilisation-plan/ (accessed on 27 February 2024).

- Fleming, A.; Jakku, E.; Fielke, S.; Taylor, B.M.; Lacey, J.; Terhorst, A.; Stitzlein, C. Foresighting Australian digital agricultural futures: Applying responsible innovation thinking to anticipate research and development impact under different scenarios. Agric. Syst. 2021, 190, 103120. [Google Scholar] [CrossRef]

- Waltham, N.J.; Wegscheidl, C.; Volders, A.; Smart, J.C.R.; Hasan, S.; Lédée, E.; Waterhouse, J. Land use conversion to improve water quality in high DIN risk, low-lying sugarcane areas of the Great Barrier Reef catchments. Mar. Pollut. Bull. 2021, 167, 112373. [Google Scholar] [CrossRef] [PubMed]

- Deane, F.; Wilson, C.; Rowlings, D.; Webb, J.; Mitchell, E.; Hamman, E.; Sheppard, E.; Grace, P. Sugarcane farming and the Great Barrier Reef: The role of a principled approach to change. Land Use Policy 2018, 78, 691–698. [Google Scholar] [CrossRef]

- NovaCana. Mecanização da Cana-de-Açúcar. NovaCana: Curitiba, 2021. Available online: https://www.novacana.com/cana/mecanizacao-producao-cana-de-acucar (accessed on 22 December 2021).

- TT Global. Groove 1010—Minimum Tillage for Sugar Cane. 2023. Available online: https://tt-global.net/en/groove-1010.php# (accessed on 8 January 2024).

- Freitas, P.L. Plantio de Cana-de-Açúcar Após Reforma. 2017. Available online: https://www.embrapa.br/en/busca-de-imagens/-/midia/4046004/plantio-de-cana-de-acucar-apos-reforma (accessed on 8 January 2024).

- Vasconcelos, J.C.S.; Speranza, E.A.; Antunes, J.F.G.; Barbosa, L.A.F.; Christofoletti, D.; Severino, F.J.; Almeida Cançado, G.M. Development and Validation of a Model Based on Vegetation Indices for the Prediction of Sugarcane Yield. AgriEngineering 2023, 5, 698–719. [Google Scholar] [CrossRef]

- Rossetto, R.; Ramos, N.P.; Pires, R.C.M.; Xavier, M.A.; Cantarella, H.; Landell, M.G.A. Sustainability in Sugarcane Supply Chain in Brazil: Issues and Way Forward. Sugar Tech. 2022, 24, 941–966. [Google Scholar] [CrossRef]

- John Deere. John Deere Brasil. 2022. Available online: https://www.deere.com.br/ (accessed on 8 January 2024).

- Chen, J.; Wu, J.; Qiang, H.; Zhou, B.; Xu, G.; Wang, Z. Sugarcane nodes identification algorithm based on sum of local pixel of minimum points of vertical projection function. Comput. Electron. Agric. 2021, 182, 105994. [Google Scholar] [CrossRef]

- Zhou, D.; Fan, Y.; Deng, G.; He, F.; Wang, M. A new design of sugarcane seed cutting systems based on machine vision. Comput. Electron. Agric. 2020, 175, 105611. [Google Scholar] [CrossRef]

- Zacharias, R.; Santos, F.L.; Jesus, V.A.M. Custos operacionais do plantio mecanizado e semimecanizado de cana-de-açúcar. Eng. Agric. 2011, 19, 118–124. [Google Scholar] [CrossRef]

- Amorim, F.R.; Patino, M.T.O.; Santos, D.F.L. Soil tillage and sugarcane planting: An assessment of cost and economic viability. Sci. Agric. 2022, 79, e20190317. [Google Scholar] [CrossRef]

- Li, S.P.; Huang, Z.X.; Zhang, W.; Wang, M.P.; Mo, H.N. Experiments and Design on Single-rolled Seed-sowing System of pre-seed-cutting Sugarcane Planters with Wide and Narrow Row Spacing. Trans. Chin. Soc. Agric. Mach. 2020, 51, 113–121. [Google Scholar]

- Yang, H.Q.; Guo, Z.J.; Chen, S.H.; Yan, X.Y.; Kang, N.; Yang, M.; Zhang, Y.X.; Yang, G.Q. Influence of planting method and density on economic traits of sugarcane cultivar Yunzhe 03–194. Sugar Crops China 2015, 37, 18–20. [Google Scholar]

- Xie, Z.; Li, Y.; Xiao, Y.; Diao, Y.; Liao, H.; Zhang, Y.; Chen, X.; Wu, W.; Wen, C.; Li, S. Sugarcane stem node identification algorithm based on improved YOLOv5. PLoS ONE 2024, 19, e0298247. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Sánchez, G.F.; la Cruz, H.L.; Salgado-García, S.; Córdova-Sánchez, S.; Ortiz-Laurel, H.; Castelán-Estrada, M.; la Cruz, R.G.; Castañeda-Ceja, R. Development of artificial sugarcane seed CP-54 from three cultivars (cv MEX 69-290; cv MEX 68-P-23; cv. CP 72-2086) using polymers in Tabasco, Mexico. Acta Agron. 2018, 67, 94–100. [Google Scholar] [CrossRef]

- Passarin, D.M.M.; Fernandes, R.Z.; Perticarrari, J.G. Method for Obtaining Plant Propagules for Sugar Cane Micropropagation, for Producing Synthetic Sugar Cane Seeds, for Storing Synthetic Seeds, for Producing Viable Sugar Cane Seedlings Propagules and Synthetic Seeds; WIPO: Geneva, Switzerland, 28 March 2013. [Google Scholar]

- Oliveira, I.N.; Souza, Z.M.; Bolonhezi, D.; Totti, M.C.V.; Moraes, M.T.; Lovera, L.H.; Lima, E.S.; Esteban, D.A.A.; Oliveira, C.F. Tillage systems impact on soil physical attributes, sugarcane yield and root system propagated by pre-sprouted seedlings. Soil Tillage Res. 2022, 223, 105460. [Google Scholar] [CrossRef]

- Ajayi, O.G.; Ashi, J. Effect of varying training epochs of a Faster Region-Based Convolutional Neural Network on the Accuracy of an Automatic Weed Classification Scheme. Smart Agric. Technol. 2023, 3, 100128. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Molin, J.P.; Martello, M.; Tavares, T.R.; Dias, F.L.F. Identification and measurement of gaps within sugarcane rows for site-specific management: Comparing different sensor-based approaches. Biosyst. Eng. 2021, 209, 64–73. [Google Scholar] [CrossRef]

- Cardoso, T.F.; Watanabe, M.D.B.; Souza, A.; Chagas, M.F.; Cavalett, O.; Morais, E.R.; Nogueira, L.A.H.; Leal, M.R.L.V.; Braunbeck, O.A.; Cortez, L.A.B.; et al. A regional approach to determine economic, environmental and social impacts of different sugarcane production systems in Brazil. Biomass Bioenergy 2019, 120, 9–20. [Google Scholar] [CrossRef]

- Aliano Filho, A.; Melo, T.; Pato, M.V. A bi-objective mathematical model for integrated planning of sugarcane harvesting and transport operations. Comput. Oper. Res. 2021, 134, 105419. [Google Scholar] [CrossRef]

- Xie, L.; Wang, J.; Cheng, S.; Zeng, B.; Yang, Z. Performance Evaluation of a Chopper System for Sugarcane Harvester. Sugar Tech. 2019, 21, 825–837. [Google Scholar] [CrossRef]

- Xie, L.; Wang, J.; Cheng, S.; Zeng, B.; Yang, Z. Optimisation and dynamic simulation of a conveying and top breaking system for whole-stalk sugarcane harvesters. Biosyst. Eng. 2020, 197, 156–169. [Google Scholar] [CrossRef]

- Wu, T.; Liang, X.L.; Liu, Q.T.; Zhang, Z.X.; Xu, H.; Huang, J.B.; Li, J.X.; Zou, X.P. Chopper Sugarcane Combine Harvester with Middle-Mounted Primary Extractor. Sugar Tech. 2020, 22, 589–595. [Google Scholar] [CrossRef]

- Santoro, E.; Soler, E.M.; Cherri, A.C. Route optimization in mechanized sugarcane harvesting. Comput. Electron. Agric. 2017, 141, 140–146. [Google Scholar] [CrossRef]

- Almeida, G.M.; Pereira, G.T.; Bahia, A.S.R.S.; Fernandes, K.; Marques Júnior, J. Machine learning in the prediction of sugarcane production environments. Comput. Electron. Agric. 2021, 190, 106452. [Google Scholar] [CrossRef]

- Neves, M.F.; Gray, A.; Valerio, F.R.; Martinez, L.F.; Rodrigues, J.M.; Kalaki, R.B.; Marques, V.N.; Cambaúva, V. Food and Agribusiness in 2030: A Roadmap; Wageningen Academic Publishers: Noordwijk, The Netherlands, 2020. [Google Scholar]

- Scheidl, H.A.; Simon, A.T. Avaliação do processo de terceirização do corte mecanizado, carregamento e transporte de cana-de-açúcar. Rev. Ciênc. Tecnol. 2012, 17, 103–118. [Google Scholar] [CrossRef]

- Naik, R.; Annamalai, S.J.K.; Nair, N.V.; Prasad, N.R. Studies on mechanisation of planting of sugarcane bud chip settlings raised in Protrays. Sugar Tech. 2013, 15, 27–35. [Google Scholar] [CrossRef]

- Nare, B.; Tewari, V.K.; Chandel, A.K.; Kumar, S.P.; Chethan, C.R. A mechatronically integrated autonomous seed material generation system for sugarcane: A crop of industrial significance. Ind. Crops Prod. 2019, 128, 1–12. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, Z.; Tao, Y.; Huang, X.; Gu, X.-F. Agricultural remote sensing big data: Management and applications. J. Integr. Agric. 2018, 17, 1915–1931. [Google Scholar] [CrossRef]

- Debauche, O.; Trani, J.P.; Mahmoudi, S.; Manneback, P.; Bindelle, J.; Mahmoudi, S.A.; Guttadauria, A.; Lebeau, F. Data management and internet of things: A methodological review in smart farming. Internet Things 2021, 14, 100378. [Google Scholar] [CrossRef]

- Amaral, L.R.; Molin, J.P.; Portz, G.; Finazzi, F.B.; Cortinove, L. Comparison of crop canopy reflectance sensors used to identify sugarcane biomass and nitrogen status. Precis. Agric. 2015, 16, 15–28. [Google Scholar] [CrossRef]

- Shendryk, Y.; Sofonia, J.; Garrard, R.; Rist, Y.; Skocaj, D.; Thorburn, P. Fine-scale prediction of biomass and leaf nitrogen content in sugarcane using UAV LiDAR and multispectral imaging. Int. J. Appl. Earth Obs. Geoinf. 2020, 92, 102177. [Google Scholar] [CrossRef]

- Portz, G.; Molin, J.P.; Canata, T.F.; Adamchuk, V.I. Integration of ultrasonic and optical sensing systems to assess sugarcane biomass and N-uptake. Precis. Agric. 2023, 25, 83–99. [Google Scholar] [CrossRef]

- Luna, I.; Lobo, A. Mapping Crop Planting Quality in Sugarcane from UAV Imagery: A Pilot Study in Nicaragua. Remote Sens. 2016, 8, 500. [Google Scholar] [CrossRef]

- Barbosa Júnior, M.R.; Tedesco, D.; Corrêa, R.G.; Moreira, B.R.A.; Silva, R.P.; Zerbato, C. Mapping Gaps in Sugarcane by UAV RGB Imagery: The Lower and Earlier the Flight, the More Accurate. Agronomy 2021, 11, 2578. [Google Scholar] [CrossRef]

- Cavalcanti, R.Q.; Rolim, M.M.; Lima, R.P.; Ortiz, P.F.S.; Pedrosa, E.M.R.; Rodrigues, J.A.M. Sugarcane Row Gaps Assessment over Successive Burned and Unburned Annual Harvests. Agronomy 2023, 13, 2545. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Molin, J.P.; Silva, E.R.O. Spatial–Temporal Analysis to Investigate the Influence of in-Row Plant Spacing on the Sugarcane Yield. Sugar Tech. 2023, 26, 194–206. [Google Scholar] [CrossRef]

- Oliveira, M.P.; Cardoso, P.H.; Oliveira, R.P.; Barbosa Júnior, M.R.; Silva, R.P. Mapping Gaps in Sugarcane Fields Using UAV-RTK Platform. Agriculture 2023, 13, 1241. [Google Scholar] [CrossRef]

- Modi, R.U.; Chandel, A.K.; Chandel, N.S.; Dubey, K.; Subeesh, A.; Singh, A.K.; Jat, D.; Kancheti, M. State-of-the-art computer vision techniques for automated sugarcane lodging classification. Field Crops Res. 2023, 291, 108797. [Google Scholar] [CrossRef]

- Som-ard, J.; Hossain, M.D.; Ninsawat, S.; Veerachitt, V. Pre-harvest sugarcane yield estimation using UAV-based RGB images and ground observation. Sugar Tech. 2018, 20, 645–657. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Molin, J.P. Data processing within rows for sugarcane yield mapping. Sci. Agric. 2020, 77, e20180391. [Google Scholar] [CrossRef]

- Yu, D.; Zha, Y.; Shi, L.; Jin, X.; Hu, S.; Yang, Q.; Huang, K.; Zeng, W. Improvement of sugarcane yield estimation by assimilating UAV-derived plant height observations. Eur. J. Agron. 2020, 121, 126159. [Google Scholar] [CrossRef]

- Canata, T.F.; Wei, M.C.F.; Maldaner, L.F.; Molin, J.P. Sugarcane yield mapping using high-resolution imagery data and machine learning technique. Remote Sens. 2021, 13, 232. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Corrêdo, L.P.; Canata, T.F.; Molin, J.P. Predicting the sugarcane yield in real-time by harvester engine parameters and machine learning approaches. Comput. Electron. Agric. 2021, 181, 105945. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Canata, T.F.; Molin, J.P. An approach to sugarcane yield estimation using sensors in the harvester and ZigBee Technology. Sugar Tech. 2022, 24, 813–821. [Google Scholar] [CrossRef]

- Das, A.; Kumar, M.; Kushwaha, A.; Dave, R.; Dakhore, K.K.; Chaudhari, K.; Bhattacharya, B.K. Machine learning model ensemble for predicting sugarcane yield through synergy of optical and SAR remote sensing. Remote Sens. Appl. Soc. Environm. 2023, 30, 100962. [Google Scholar] [CrossRef]

- Kanke, Y.; Tubaña, B.; Dalen, M.; Lofton, J.; Viator, H. Relation between early season–measured agronomic variables and sugar yield responses to nitrogen. Agron. J. 2016, 108, 794–804. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, S.; Khanna, P.; Pragya. Precision Sugarcane Monitoring Using SVM Classifier. Procedia Comput. Sci. 2017, 122, 881–887. [Google Scholar] [CrossRef]

- Ong, P.; Jian, J.; Li, X.; Zou, C.; Yin, J.; Ma, G. New approach for sugarcane disease recognition through visible and near-infrared spectroscopy and a modified wavelength selection method using machine learning models. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 302, 123037. [Google Scholar] [CrossRef] [PubMed]

- Yano, I.H.; Alves, J.R.; Santiago, W.E.; Mederos, B.J.T. Identification of weeds in sugarcane fields through images taken by UAV and Random Forest classifier. IFAC-PapersOnLine 2016, 49, 415–420. [Google Scholar] [CrossRef]

- Spekken, M.; Molin, J.P.; Romanelli, T.L. Cost of boundary manoeuvres in sugarcane production. Biosyst. Eng. 2015, 129, 112–126. [Google Scholar] [CrossRef]

- Junqueira, R.A.R.; Morabito, R. Modeling and solving a sugarcane harvest front scheduling problem. Int. J. Prod. Econ. 2019, 213, 150–160. [Google Scholar] [CrossRef]

- Chavez, M.M.M.; Sarache, W.; Costa, Y.; Soto, J. Multiobjective stochastic scheduling of upstream operations in a sustainable sugarcane supply chain. J. Clean. Prod. 2020, 276, 123305. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, O.; Wu, J.; Liu, Q.; Su, J.; Li, H. An improved YOLOv5s model for effectively predict sugarcane seed replenishment positions verified by a field re-seeding robot. Comput. Electron. Agric. 2023, 214, 108280. [Google Scholar] [CrossRef]

- Som-ard, J.; Immitzer, M.; Vuolo, F.; Atzberger, C. Sugarcane yield estimation in Thailand at multiple scales using the integration of UAV and Sentinel-2 imagery. Precis. Agric. 2024. [Google Scholar] [CrossRef]

- Australian Controlled Traffic Farming Association (ACTFA). What Is Controlled Traffic Farming? 2021. Available online: https://www.actfa.net/controlled-traffic-farming/ (accessed on 14 October 2021).

- Gírio, L.A.S.; Silva, R.P.; Menezes, P.C.; Carneiro, F.M.; Zerbato, C.; Ormond, A.T.S. Quality of multi-row harvesting in sugarcane plantations established from pre-sprouted seedlings and billets. Ind. Crops Prod. 2019, 142, 111831. [Google Scholar] [CrossRef]

- Passalaqua, B.P.; Molin, J.P. Path errors in sugarcane transshipment trailers. Eng. Agríc. 2020, 40, 223–231. [Google Scholar] [CrossRef]

- Araújo, G.M.; Santos, F.F.L.; Almeida, S.L.H.; Martins, R.N.; Voltarelli, M.A.; Paixão, C.S.S.; Pinto, F.A.C. Sugarcane harvesting quality by digital image processing. Sugar Tech. 2021, 23, 209–218. [Google Scholar] [CrossRef]

- Momin, M.A.; Wempe, P.A.; Grift, T.E.; Hansen, A.C. Effects of four base cutter blade designs on sugarcane stem cut quality. Trans. ASABE 2017, 60, 1551–1560. [Google Scholar] [CrossRef]

- Qiu, M.; Meng, Y.; Li, Y.; Shen, X. Sugarcane stem cut quality investigated by finite element simulation and experiment. Biosyst. Eng. 2021, 206, 135–149. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, Y.; Tang, Y.; Luo, W.; Ye, Z. Analysis of blockage and wrapping by leaves in the cutting mechanism of a sugarcane leaf shredder. Biosyst. Eng. 2021, 211, 152–166. [Google Scholar] [CrossRef]

- Yang, W.; Zhao, W.; Liu, Y.; Chen, Y.; Yang, J. Simulation of forces acting on the cutter blade surfaces and root system of sugarcane using FEM and SPH coupled method. Comput. Electron. Agric. 2021, 180, 105893. [Google Scholar] [CrossRef]

- Corrêdo, L.P.; Canata, T.F.; Maldaner, L.F.; Lima, J.J.A.; Molin, J.P. Sugarcane Harvester for In-field Data Collection: State of the Art, Its Applicability and Future Perspectives. Sugar Tech 2021, 23, 1–14. [Google Scholar] [CrossRef]

- Cox, G.J.; Harris, H.D.; Cox, D.R. Application of Precision Agriculture to Sugarcane. In Proceeding of the Fourth International Conference on Precision Agriculture, Saint Paul, Italy, 19–22 July 1998; Robert, P.C., Rust, R.H., Larson, W.E., Eds.; ASA/CSSA/SSSA: Minneapolis, MN, USA, 1998; pp. 753–765. [Google Scholar]

- Benjamin, C.E.; Price, R.R.; Mailander, M.P. Sugar Cane Monitoring System; ASAE: St. Joseph, MI, USA, 2001. [Google Scholar]

- Molin, J.P.; Meneggati, L.A.A. Field-testing of a sugarcane yield monitor in Brazil. In Proceedings of the ASAE/CSAE Annual International Meeting, ASAE, Las Vegas, NV, USA, 1–4 August 2004. [Google Scholar]

- Hernandez, B.; Fernandez, F.; Ponce, E.; Quintana, L.; Esquivel, M.; Rodriguez, J. Sugarcane yield mapping from the harvester biomass input flux. In Proceedings of the 4th European Conference on Precision Agriculture, Berlin, Germany, 16–19 June 2003. [Google Scholar]

- Hernandez, B.; Fernandez, F.; Ponce, E.; Esquivel, M.; Rodriguez, J.; Quintana, L.; Interian, S.; Alvarez, R. Application of precision farming technologies for sugarcane crop. In Proceedings of the 5th European Conference on Precision Agriculture, Uppsala, Sweden, 9–12 June 2005; Stafford, J.V., Ed.; Wageningen Academic Publishers: Noordwijk, The Netherlands, 2023. [Google Scholar]

- Cerri, D.G.P.; Magalhães, P.S.G. Sugar Cane Yield Monitor. In Proceedings of the ASAE Annual Meeting, ASAE, St. Joseph, MI, USA, 17–20 July 2005. [Google Scholar]

- Price, R.R.; Johnson, R.M.; Viator, R.P.; Larsen, J.; Peters, A. Fiber Optic yield monitor for a sugarcane harvester. Trans. ASABE 2011, 54, 31–39. [Google Scholar] [CrossRef]

- Just, J. A Non-Contact Volumetric Based Approach Using a Stereo Camera for Measuring Yield on Sugarcane Harverters. Master’s Dissertation, Iowa State University, Ames, IA, USA, 2014. [Google Scholar]

- Darr, M.J.; Corbett, D.J.; Herman, H.; Vallespi-Gonzalez, C.; Dugas, B.E.; Badino, H. Yield Measurement and Base Cutter Height Control Systems for a Harvester. US20150124054A1, 6 August 2019. [Google Scholar]

- Momin, M.A.; Grift, T.E.; Valente, D.S.; Hansen, A.C. Sugarcane yield mapping based on vehicle tracking. Precis. Agric. 2019, 20, 896–910. [Google Scholar] [CrossRef]

- Lima, J.J.A.; Maldaner, L.F.; Molin, J.P. Sensor Fusion with NARX Neural Network to Predict the Mass Flow in a Sugarcane Harvester. Sensors 2021, 21, 4530. [Google Scholar] [CrossRef]

- Sanches, G.M.; Duft, D.G.; Kölln, O.T.; Luciano, A.C.S.; Castro, S.G.Q.; Okuno, F.M.; Franco, H.C.J. The potential for RGB images obtained using unmanned aerial vehicle to assess and predict yield in sugarcane fields. Int. J. Remote Sens. 2018, 39, 5402–5414. [Google Scholar] [CrossRef]

- Ferreira, A.S.; Marcato Junior, J.; Pistori, H.; Melgani, F.; Gonçalves, W.N. Unsupervised domain adaptation using transformers for sugarcane rows and gaps detection. Comput. Electron. Agric. 2022, 203, 107480. [Google Scholar] [CrossRef]

- Corrêdo, L.P.; Molin, J.P.; Canal Filho, R. Is It Possible to Measure the Quality of Sugarcane in Real-Time during Harvesting Using Onboard NIR Spectroscopy? AgriEngineering 2024, 6, 64–80. [Google Scholar] [CrossRef]

- Wang, E.; Attard, S.; Linton, A.; McGlinchey, M.; Xiang, W.; Philippa, B.; Everingham, Y. Development of a closed-loop irrigation system for sugarcane farms using the Internet of Things. Comput. Electron. Agric. 2020, 172, 105376. [Google Scholar] [CrossRef]

- Garcia, A.P.; Umezu, C.K.; Polania, E.C.M.; Dias Neto, A.F.; Rossetto, R.; Albiero, D. Sensor-Based Technologies in Sugarcane Agriculture. Sugar Tech. 2022, 24, 679–698. [Google Scholar] [CrossRef]