Performance of a UHF RFID Detection System to Assess Activity Levels and Lying Behaviour in Fattening Bulls

Abstract

1. Introduction

2. Materials and Methods

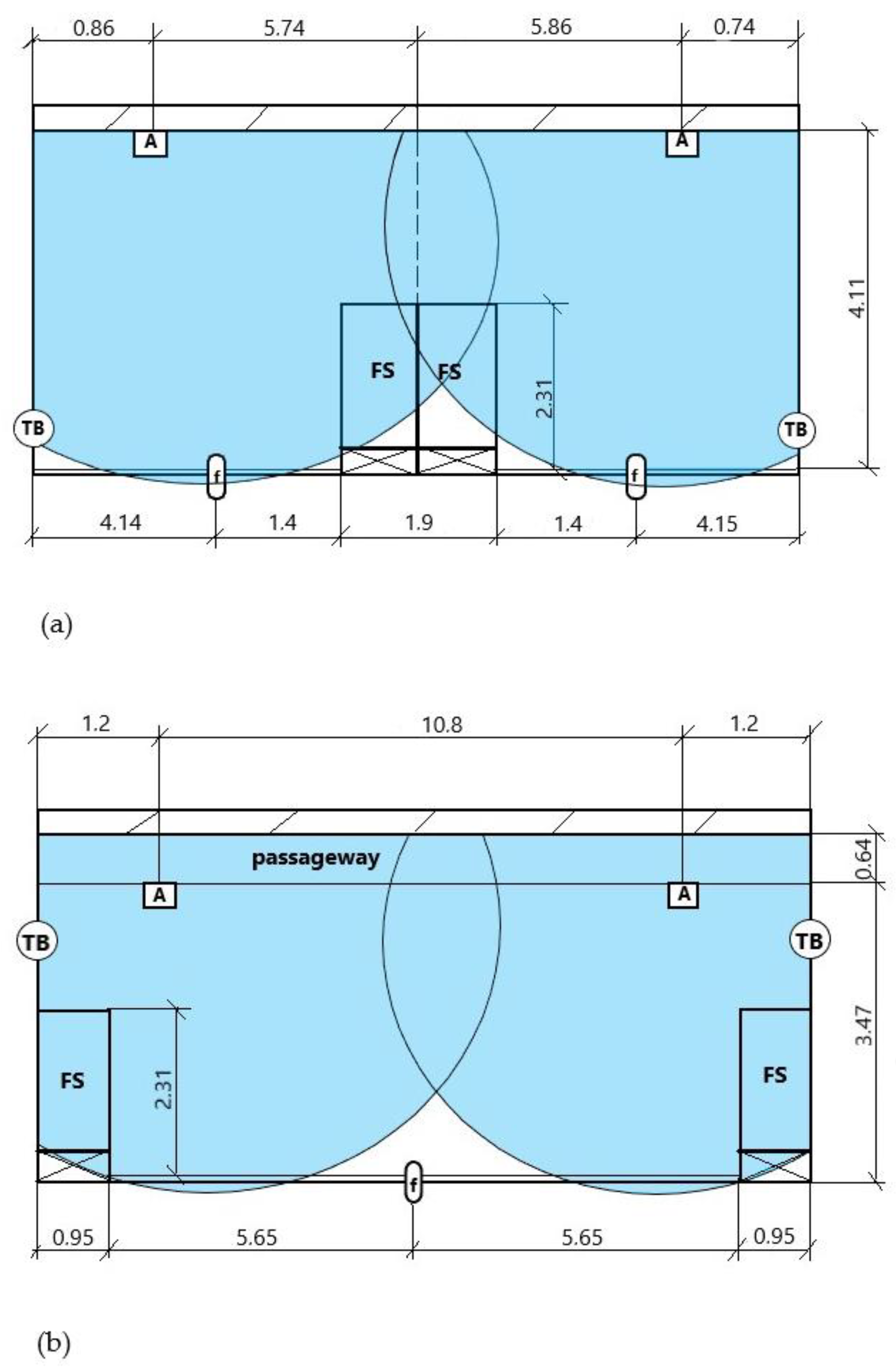

2.1. Animals and Housing

2.2. Radio-Frequency Identification (RFID)

2.3. Video Analysis

2.4. Accelerometer

2.5. Statistical Analysis

- Positives (P): events during which a bull was observed on video to move between two antenna zones.

- Negatives (N): events during which a bull was not observed on video to move between two antenna zones.

- True positives (TP): positives also identified in the RFID data of the same bull.

- False positives (FP): negatives also identified in the RFID data of the same bull.

- True negatives (TN): negatives not recorded in the RFID data of the same bull.

- False negatives (FN): positives not recorded in the RFID data of the same bull.

3. Results

3.1. Analysing the Activity Data Captured by the RFID System and Cameras

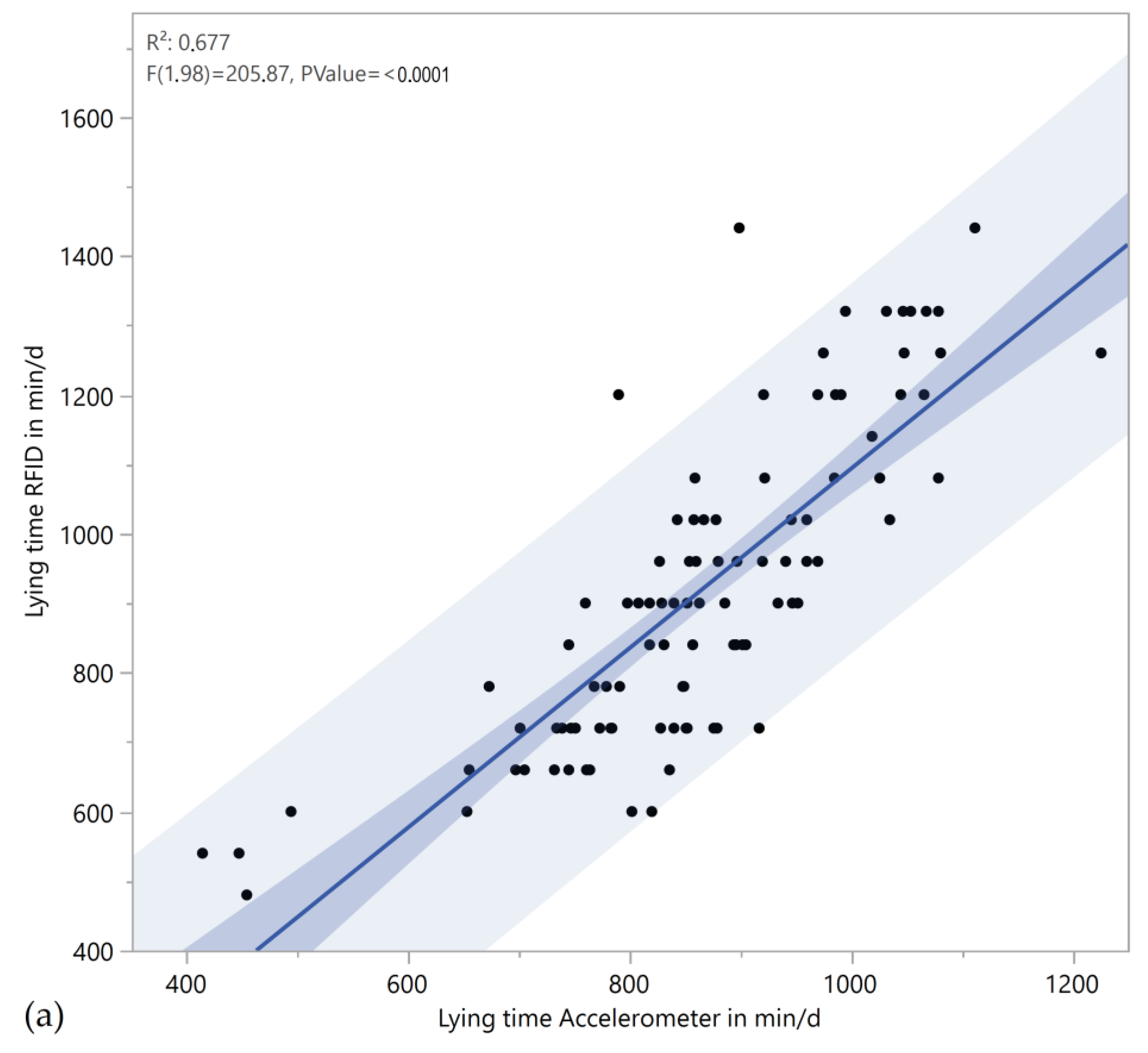

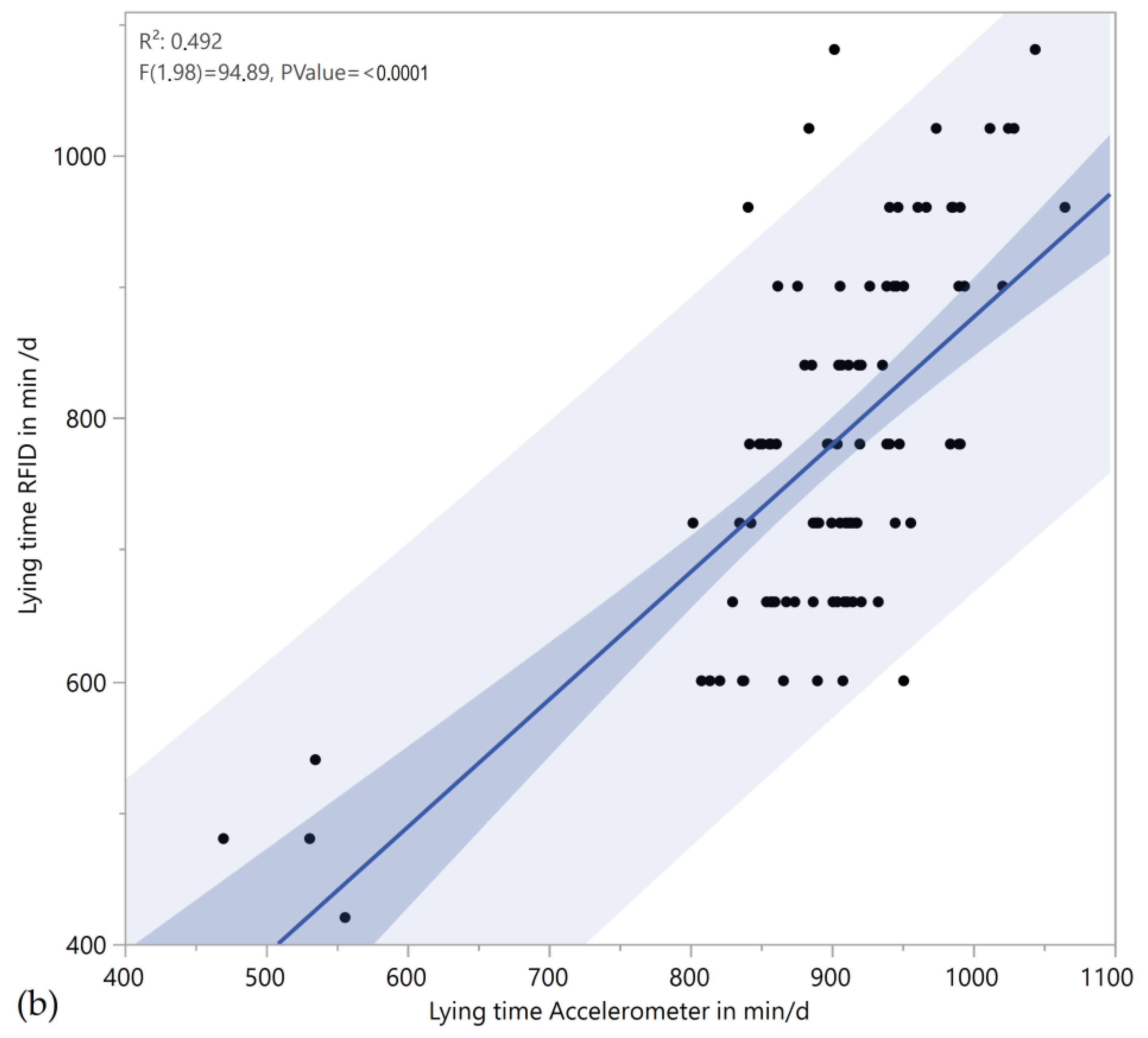

3.2. Analysing the Lying Times of Bulls from UHF RFID and Accelerometer Data

4. Discussion

4.1. Performance Test of the UHF RFID System by Comparisons with Video Observations (the Gold Standard)

4.2. Comparing the Lying Times of Bulls between UHF RFID Data and Accelerometer Data

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paudyal, S. Using rumination time to manage health and reproduction in dairy cattle: A review. Vet. Q. 2021, 41, 292–300. [Google Scholar] [CrossRef] [PubMed]

- Tucker, C.B.; Jensen, M.B.; de Passillé, A.M.; Hänninen, L.; Rushen, J. Invited review: Lying time and the welfare of dairy cows. J. Dairy Sci. 2020, 104, 20–46. [Google Scholar] [CrossRef] [PubMed]

- Neethirajan, S. The role of sensors, big data and machine learning in modern animal farming. Sens. Bio-Sens. Res. 2020, 29, 100367. [Google Scholar] [CrossRef]

- Sheldon, K.J.; Deboy, G.; Field, W.E.; Albright, J.L. Bull-related incidents: Their prevalence and nature. J. Agromedicine 2009, 14, 357–369. [Google Scholar] [CrossRef] [PubMed]

- Brown-Brandl, T.M.; Adrion, F.; Maselyne, J.; Kapun, A.; Hessel, E.F.; Saeys, W.; Van Nuffel, A.; Gallmann, E. A Review of Passive Radio Frequency Identification Systems for Animal Monitoring in Livestock Facilities. Appl. Eng. Agric. 2019, 35, 579–591. [Google Scholar] [CrossRef]

- Kampers, F.W.H.; Rossing, W.; Eradus, W.J. The ISO standard for radiofrequency identification of animals. Comput. Electron. Agric. 1999, 24, 27–43. [Google Scholar] [CrossRef]

- Houston, B.; Li, T.; Riley, P.; Xu, C.; Wolfendale, A.; Hurst, G.; Hammond, K.; McIntosh, A.; Yerbury, M.; Davies, L. Overcoming the Problems of Identifying and Recording Livestock under Extensive Management; Instituut voor Mechanisatie, Arbeid en Gebouwen: Wageningen, The Netherlands, 1983. [Google Scholar]

- Holm, D.; Bobbett, R.; Koelle, A.; Landt, S.; Sanders, W.; Depp, S.; Seawright, G. Passive electronic identification with temperature monitoring. In Proceedings of the Symposium on cow identification system and their applications, Wageningen, The Netherlands, 8 April 1976; pp. 125–129. [Google Scholar]

- Sowell, B.; Bowman, J.; Branine, M.; Hubbert, M. Radio frequency technology to measure feeding behavior and health of feedlot steers. Appl. Anim. Behav. Sci. 1998, 59, 277–284. [Google Scholar] [CrossRef]

- Achour, B.; Belkadi, M.; Saddaoui, R.; Filali, I.; Aoudjit, R.; Laghrouche, M. High-accuracy and energy-efficient wearable device for dairy cows’ localization and activity detection using low-cost IMU/RFID sensors. Microsyst. Technol. 2022, 28, 1241–1251. [Google Scholar] [CrossRef]

- Saint-Dizier, M.; Chastant-Maillard, S. Towards an Automated Detection of Oestrus in Dairy Cattle. Reprod. Domest. Anim. 2012, 47, 1056–1061. [Google Scholar] [CrossRef]

- Adrion, F.; Keller, M.; Bozzolini, G.; Umstatter, C. Setup, Test and Validation of a UHF RFID System for Monitoring Feeding Behaviour of Dairy Cows. Sensors 2020, 20, 7035. [Google Scholar] [CrossRef]

- McGowan, J.E.; Burke, C.; Jago, J.G. Validation of a technology for objectively measuring behaviour in dairy cows and its application for oestrous detection. In Proceedings of the New Zealand Society of Animal Production, Wanaka, New Zealand, 20–22 June 2007; Volume 67, pp. 136–142. [Google Scholar]

- Robért, B.D.; White, B.J.; Renter, D.G.; Larson, R.L. Determination of lying behavior patterns in healthy beef cattle by use of wireless accelerometers. Am. J. Vet. Res. 2011, 72, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Trénel, P.; Jensen, M.B.; Decker, E.L.; Skjøth, F. Technical note: Quantifying and characterizing behavior in dairy calves using the IceTag automatic recording device. J. Dairy Sci. 2009, 92, 3397–3401. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, L.R.; Pedersen, A.R.; Herskin, M.S.; Munksgaard, L. Quantifying walking and standing behaviour of dairy cows using a moving average based on output from an accelerometer. Appl. Anim. Behav. Sci. 2010, 127, 12–19. [Google Scholar] [CrossRef]

- Rutten, C.J.; Velthuis, A.G.J.; Steeneveld, W.; Hogeveen, H. Invited review: Sensors to support health management on dairy farms. J. Dairy Sci. 2013, 96, 1928–1952. [Google Scholar] [CrossRef] [PubMed]

- Richeson, J.T.; Lawrence, T.E.; White, B.J. Using advanced technologies to quantify beef cattle behavior. Transl. Anim. Sci. 2018, 2, 223–229. [Google Scholar] [CrossRef] [PubMed]

- Belaid, M.A.; Rodriguez-Prado, M.; Chevaux, E.; Calsamiglia, S. The Use of an Activity Monitoring System for the Early Detection of Health Disorders in Young Bulls. Animals 2019, 9, 924. [Google Scholar] [CrossRef] [PubMed]

- Munksgaard, L.; Simonsen, H.B. Behavioral and pituitary adrenal-axis responses of dairy cows to social isolation and deprivation of lying down. J. Anim. Sci. 1996, 74, 769–778. [Google Scholar] [CrossRef] [PubMed]

- Westin, R.; Vaughan, A.; de Passillé, A.M.; DeVries, T.J.; Pajor, E.A.; Pellerin, D.; Siegford, J.M.; Vasseur, E.; Rushen, J. Lying times of lactating cows on dairy farms with automatic milking systems and the relation to lameness, leg lesions, and body condition score. J. Dairy Sci. 2016, 99, 551–561. [Google Scholar] [CrossRef] [PubMed]

- Jensen, M.B.; Pedersen, L.J.; Munksgaard, L. The effect of reward duration on demand functions for rest in dairy heifers and lying requirements as measured by demand functions. Appl. Anim. Behav. Sci. 2005, 90, 207–217. [Google Scholar] [CrossRef]

- Keane, M.P.; McGee, M.; O’riordan, E.G.; Kelly, A.K.; Earley, B. Effect of floor type on performance, lying time and dirt scores of finishing beef cattle: A meta-analysis. Lifestock Sci. 2018, 212, 57–60. [Google Scholar] [CrossRef]

- Gygax, L.; Mayer, C.; Westerath, H.S.; Friedli, K.; Wechsler, B. On-farm assessment of the lying behaviour of finishing bulls kept in housing systems with different floor qualities. Anim. Welf. J. 2007, 16, 205–208. [Google Scholar] [CrossRef]

- Rouha-Muelleder, C.; Absmanner, E.; Kahrer, E.; Zeiner, H.; Scharl, T.; Leisch, F.; Troxler, J. Alternative housing systems for fattening bulls under Austrian conditions with special respect to rubberised slatted floors. Anim. Welf. 2012, 21, 113–126. [Google Scholar] [CrossRef]

- Hickey, M.; Earley, B.; Fisher, A. The effect of floor type and space allowance on welfare indicators of finishing steers. Ir. J. Agric. Food Res. 2003, 42, 89–100. [Google Scholar]

- Robert, B.; White, B.J.; Renter, D.G.; Larson, R.L. Evaluation of three-dimensional accelerometers to monitor and classify behavior patterns in cattle. Comput. Electron. Agric. 2009, 67, 80–84. [Google Scholar] [CrossRef]

| Total | Positives | Negatives | True Positives | False Positives | True Negatives | False Negatives | |

|---|---|---|---|---|---|---|---|

| Group 1 | 903 | 611 | 292 | 590 | 12 | 280 | 21 |

| Group 2 | 840 | 473 | 367 | 462 | 15 | 352 | 11 |

| Both Groups | 1743 | 1084 | 659 | 1052 | 27 | 632 | 32 |

| Sensitivity (%) | Specificity (%) | Accuracy (%) | Precision (%) | False-Positive Rate (%) | False-Negative Rate (%) | |

|---|---|---|---|---|---|---|

| Group 1 | 96.56 | 95.89 | 98.89 | 98.01 | 4.11 | 3.44 |

| Group 2 | 97.67 | 95.91 | 98.21 | 96.86 | 4.09 | 2.33 |

| Both Groups | 97.05 | 95.9 | 98.45 | 97.5 | 4.09 | 2.96 |

| Mean Lying Time Accelerometer in min/d | Mean Lying Time UHF RFID in min/d | SE | p-Value | |

|---|---|---|---|---|

| Group 1 | 856.62 | 908.4 | 13.91 | 0.0003 |

| Group 2 | 892.83 | 772.2 | 10.39 | 0.0001 |

| Both Groups | 874.73 | 840.3 | 10.6 | 0.0014 |

| Difference Group 1/Group 2 | −36.21 | 136.2 | 18.73 | 0.0005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fromm, K.; Heinicke, J.; Ammon, C.; Amon, T.; Hoffmann, G. Performance of a UHF RFID Detection System to Assess Activity Levels and Lying Behaviour in Fattening Bulls. AgriEngineering 2024, 6, 1886-1897. https://doi.org/10.3390/agriengineering6020110

Fromm K, Heinicke J, Ammon C, Amon T, Hoffmann G. Performance of a UHF RFID Detection System to Assess Activity Levels and Lying Behaviour in Fattening Bulls. AgriEngineering. 2024; 6(2):1886-1897. https://doi.org/10.3390/agriengineering6020110

Chicago/Turabian StyleFromm, Kay, Julia Heinicke, Christian Ammon, Thomas Amon, and Gundula Hoffmann. 2024. "Performance of a UHF RFID Detection System to Assess Activity Levels and Lying Behaviour in Fattening Bulls" AgriEngineering 6, no. 2: 1886-1897. https://doi.org/10.3390/agriengineering6020110

APA StyleFromm, K., Heinicke, J., Ammon, C., Amon, T., & Hoffmann, G. (2024). Performance of a UHF RFID Detection System to Assess Activity Levels and Lying Behaviour in Fattening Bulls. AgriEngineering, 6(2), 1886-1897. https://doi.org/10.3390/agriengineering6020110