Abstract

Utilization of agricultural waste can be done by converting it with conventional fuels to energy. For this purpose, it is necessary to understand the properties of waste and its mixture with the fossil fuels important for its storage and conversion. The objective of the work was to examine the influence of moisture content and the composition of agricultural waste with hard coal mixtures on the mechanical and rheological properties of the waste. The materials tested were powdered biomass: dried distillers grains with solubles (DDGS), meat and bone meal (MBM), and hard coal (HC). Mechanical properties were measured to investigate flowability with the Jenike shear tester. A technique with an annular powder rheometer was applied for rheological measurements. It was shown that an increased moisture content worsened the flowability of the mixtures, while an increased biomass content reduced the influence of moisture and stabilized the mechanical properties of the mixtures in quasi-static conditions. In dynamic conditions, moisture decreased the mechanical strength of the mixtures and increased their flowability.

1. Introduction

The manufacture and processing of agricultural and food products always involve the production of waste. Agricultural waste is very challenging and lots of agricultural waste is available in the environment [1]. Among renewable energy sources, energy from bio-based sources is the largest. Biomass is one of the most widely used renewable energy sources for derived heating [2].

Current trends focus on the production of biofuels from agricultural waste as a way to utilize it [3]. To produce biofuels from agricultural wastes, different processes could be investigated. The most popular of these are thermochemical conversion [4], fermentation [5,6], gasification [7,8], liquefaction [9,10], fast pyrolysis [11,12], and processes of combustion [13,14] and co-combustion [15,16]. The co-combustion of biomass and coal is an important approach with significant industrial prospects for both carbon dioxide capture and the disposal of biomass waste produced by agriculture [16,17]. Biomass-coal co-combustion processes are relatively easy to implement in existing coal combustion systems. Research data can be found on their use in the co-firing of meat and bone meal with sewage sludge [18] and coal [19]. Another agricultural waste material used in co-firing processes with coal is dried distillers grains with solubles [20].

The benefits of mixing biomass with coal for power generation include fewer CO2 emissions and a reduced dependency on fossil fuels [21]. There is a need, however, to understand the role of biomass during direct combustion and co-firing, especially in terms of the impact of biomass use on the properties of its mixtures with coal.

However, a number of conversion processes use agricultural waste in powder form as raw material. One of the most important parameters describing the quality of powder materials is flowability [22]. Flowability is significantly influenced by the moisture content of the biomass [16,17,18]. In general, an increase in the proportion of moisture deteriorates the mechanical properties of biomass and causes problems with handling and processing [19,20,21,22].

The questionality of the biomass-coal mixture is affected by its moisture content, as well as by its proportions and physical form. Improved flowability can be achieved by adding coal to the biomass [23,24,25]. The flowability of the fuel mixture is affected by both the proportion of biomass and size distribution, as well as storage time [26,27].

Flowability can be determined by various methods, depending on many factors, including process dynamics. In static conditions under significant normal loads, the Jenike direct shear method is applicable [28]. It is the method used for the design of powder material storage devices [29,30]. In static conditions without subjecting the powder material to high normal loads, the Carr indices system is used [31,32]. Under dynamic conditions, in order to determine the properties of a powder, rheological characteristics are applied using rheometers of various designs, such as annular shear tester [33] or FT4 powder rheometers [34,35,36].

Studies on the mechanical and rheological properties of biomass-coal mixtures include both research experiments and operational studies leading to the optimization of essential parameters of processes involving biomass-coal mixtures, as well as developing crucial design guidelines. The research has allowed a better understanding of the physical processes also occurring under the influence of moisture. In addition, it had allowed effective prediction of biomass-coal mixtures properties in processes such as storage in tanks and silos, their loading and discharging, as well as transportation and conversion. For this purpose, it is necessary to understand the properties of waste and its mixture with the fossil fuels important for its storage and conversion. The objective of the work was to examine the influence of moisture content and the composition of agricultural waste with hard coal mixtures on the mechanical and rheological properties of the waste.

The manuscript is structured as follows. In the next section, the raw materials and analytical methods along with the experimental plan are described. The subsequent section presents the obtained results and their discussion and interpretation. The final chapter summarizes the results and provides some design guidelines.

2. Materials and Methods

Two types of powdered biomass were selected for testing. Corn-dried distillers grains with solubles (DDGS) from the Goświnowice Ethanol Plant, Nysa, Poland, and meat and bone meal (MBM) from SARIA Sp. Z o.o. Przewrotne, Poland. Mixtures of biomass with hard coal (HC) were prepared using hard coal from the Stalowa Wola S.A. Combined Heat and Power Plant, Poland.

Based on suggestions from representatives of the companies from which the samples for investigation came, blends with hard coal were prepared with three levels of biomass mass content of 5%, 30%, and 60%.

2.1. Sample Preparation

Biomass and coal mixtures were prepared in a V-type hopper mixer designed at Rzeszow University of Technology and manufactured by CDK Gliwice, Poland.

Mixtures were prepared with three biomass mass contents: 5%, 30%, and 60%. For this purpose, appropriate weighed amounts of biomass and hard coal were placed into the V-type hopper mixer, and the mixing process was carried out for 20 min at a mixer rotation speed of 15 rpm, with a mixer loading rate of 45% by volume with the powder material.

To prepare samples with different moisture contents, the materials were dried to a constant weight using a convection dryer and then mixed with the appropriate preweighed amount of water in a V-type hopper mixer. Samples with four weight contents of moisture: 0%, 10%, 20%, and 30% were prepared. Moisture content was calculated on a dry basis. For every 100 g of dry weight of the material, 10, 20, and 30 g of water were added, respectively, to obtain the appropriate level of moisture content. Mixing was carried out for 30 min at a rotational speed of 15 rpm and a volumetric loading rate of 45% in the mixer.

The samples were then conditioned for 24 h to evenly saturate the bed of powder material with moisture. Samples with different moisture content were prepared with an accuracy of ± 0.5%. The moisture content of the biomass samples was controlled using a RADWAG MA.R laboratory moisture analyzer (Radom, Poland) at 110°C. Humidity measurements were carried out until a constant mass of the sample was obtained at a given temperature.

2.2. Mechanical Properties Measurements

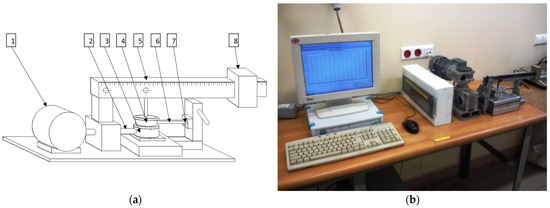

The effect of moisture content on mechanical characteristics was investigated with a direct shear apparatus (Figure 1) designed at Rzeszow University of Technology and manufactured by CDK Gliwice, Poland, on the basis of the classic Jenike’s direct shear cell [28], and in accordance with the European Eurocode 1 standard [37].

Figure 1.

(a) Schematic representation of the Jenike-type shear tester: 1—drive engine, 2—drive pin, 3—movable shear cell, 4—immovable shear cell, 5—lever, 6—arm of immovable shear cell, 7—shear stress transducer, 8—normal load; (b) Picture of Jenike-type shear tester.

The main part of the apparatus is a cylindrical chamber with diameter D = 60 mm and height H = 30 mm, divided into two parts. The lower, stationary part is permanently fixed to the base. The upper one moves at a constant speed of 2.79 mm/min during measurement. The measurement consists of placing the test material in the chamber and loading it to a normal stress σ (σ = Fn/S). The next step is to move the top of the chamber, using a thrust pin, conducted until the maximum tangential stress τ (τ = Ft/S) is reached and a steady-state flow is achieved. Fn is the normal force, Ft is the tangential force, and S is the cross-section area of the chamber. The tangential force was recorded using a C9B strain gauge force sensor from HBM (Darmstadt, Germany), with a range of up to 200 N and an accuracy of ±1 N. The determined values of shear stress τ corresponding to the set values of the normal stress σ determine the values of the coordinate points, an approximation of which is a line called the yield locus.

2.3. Rheological Properties Measurements

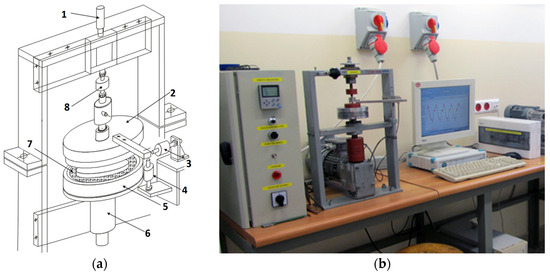

The effect of moisture content on rheological characteristics was investigated with an annular powder rheometer (Figure 2) designed at Rzeszow University of Technology and manufactured by CDK Gliwice, Poland.

Figure 2.

(a) Schematic representation of the annular powder rheometer: 1– shear plate positioner, 2—shear plate, 3—tangential load transducer, 4—displacement transducer, 5—rotating cell, 6—driving gear, 7—annular gap, 8—normal load transducer; (b) Picture of annular powder rheometer.

Jenike’s apparatus allows investigation under quasistatic conditions, i.e., at shear rates close to zero. A different method of investigation is the annular rheometer, where shear rates can take on large values. This reveals material properties that cannot be demonstrated by the Jenike method.

The biggest advantage of the rheometer is the possibility of investigation at negligible levels of external load. The characteristics of the process are not affected under such conditions by the high external load used in the Jenike apparatus. The advantage of the rheometer becomes especially apparent in investigations of plant materials, including biomass. These materials, due to their deformability under the influence of moisture, require a relatively long shear distance; in the case of the rheometer, it is unlimited.

The measuring (shear) chamber of the rheometer made for the present investigation had the shape of an annular channel cut along the circumference of the bottom plate rotated by a drive system. The inner diameter of the channel was 88 mm, the outer diameter was 102 mm, and the depth was 12 mm. The rotational speed varied from 5 to 300 rpm. A sample of the test material was distributed in the chamber in the form of a layer of uniform thickness; this was subjected to shearing with the element of the stationary top platter in the shape of a projection with dimensions exactly corresponding to those of the channel.

The normal force of the top plate to the bottom plate was set at a level of about 1 N. The device was equipped with two strain gauge sensors by HBM (Darmstadt, Germany): U9B—for measuring normal force, C9B—for measuring tangential force (both with a range of up to 200 N and an accuracy of ± 1 N), and a third, WA10—for measuring bed thickness with a measuring range of up to 10 mm and accuracy of 0.01 mm.

Placing a bulk material in a closed chamber between the moving plates of the rheometer induces two types of stresses in the material—normal σ and tangential τ. The normal stress comes from the pressure of the top plate on the material. Tangential stress comes from the frictional force of the material against the surface of the top plate caused by rotational motion—shear. Since the top plate is stationary, it is possible to measure the value of the tangential stress by measuring the stress provided by an arm attached to this plate resting on the tangential force sensor.

The results of the measured values of tangential stress τ are presented in the form of rheological characteristics, i.e., the dependence of tangential stress τ on shear rate γ.

2.4. Particle Size Distribution Measurements

The particle size distribution (PSD) of biomass, hard coal, and biomass-hard coal mixtures was measured via laser diffraction. The measurements were performed using a Mastersizer 2000MU analyzer (Malvern Instruments, Malvern, UK). This device uses the phenomenon of dynamic light scattering by particles of powder material. Output from the analyzer is presented as an integer curve of the particle size distribution. The results are presented as volume percentages for each fraction. Additionally, the d(0.5), d(0.1), and d(0.9) diameters and Span were determined. The d(0.5) is the volume median diameter, and it is the diameter where 50% of the distribution is above and 50% is below, and d(0.x) is the volume diameter where x% of the particles is below x%. Span was calculated as follows:

2.5. Angle of Repose, Bulk Density, and Compressibility Measurements

The basic mechanical properties of the samples were determined using a Powder Tester PT-S (Hosokawa Micron B.V. Doetinchem, The Netherlands) for materials with 0% moisture content. The angle of repose, aerated bulk density, and packed bulk density were measured with a Powder Tester PT-S in accordance with ASTM D6393-14. The angle of repose refers to the angle of heap of particulate, built up by dropping according to the injection method. Powders of poor flowability show a wide angle of repose. Aerated bulk density is the bulk density of particulate containing much air, built up in a vessel by dropping according to the injection method. Packed bulk density is the bulk density of particulate of loose bulk density, built up by tapping; the standard tapping number is 180. After tapping begins, the powder is compressed, and after this process is completed, density is measured. Compressibility CC was calculated from the equation below:

where P is the packed bulk density and A the aerated bulk density, respectively.

2.6. Photographs of the Investigated Materials

Photographs of the tested materials were taken using an OPTIKA B-350 (OPTICA, Italy) optical microscope equipped with a Moticam 3 camera (Motic Asia, Hong Kong).

3. Results and Discussion

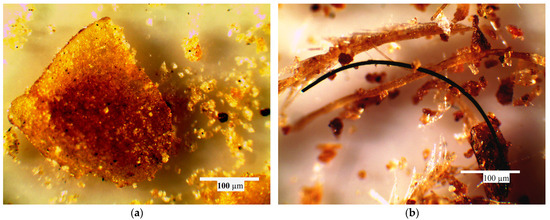

Biomass grains show significant shape anisotropy. DDGS biomass grains generally show an irregular shape (Figure 3a). MBM grains are characterized by elongated grains with a fibrous shape (Figure 3b). The shape of the powder particles was determined using a descriptive method based on ISO 3252:2019 [38], based on photographs taken.

Figure 3.

Pictures of the tested materials: (a) DDGS; (b) MBM.

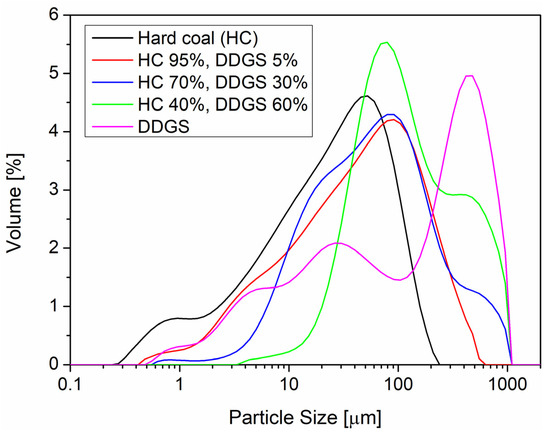

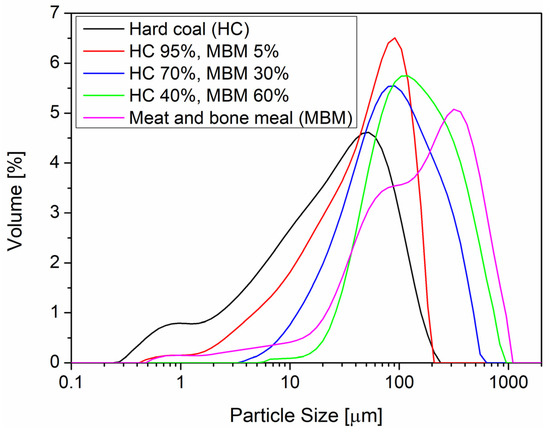

The mechanical and rheological properties of powder materials depend on their particle size distribution [39,40,41]. Summary charts revealing the particle size distributions of the analyzed biomass samples are shown in Figure 4 and Figure 5. Hard coal showed a narrow close to a normal distribution, while MBM and DDGS have a wide, bimodal, and irregular distribution. Summary charts were prepared to show the particle size distribution of biomass-coal mixtures. The material with the smallest grain size was hard coal. DDGS and MBM showed much larger grain sizes. Biomass mixtures with hard coal showed a bimodal distribution in most cases, as assumed.

Figure 4.

Particle size distribution for DDGS with hard coal mixtures.

Figure 5.

Particle size distribution for MBM with hard coal mixtures.

An increase in the proportion of biomass in the mixture moved the size distribution toward particles with larger diameters and resulted in a regular increase in the d(0.5) diameter, as well as in the other designated diameters (Table 1). The highest Span value was shown by the mixture HC 70%, DDGS 30%, and the lowest by the mixture HC 95%, MBM 5%.

Table 1.

Size properties of the tested samples.

The largest value of angle of repose was shown by MBM. As the proportion of biomass in the mixture with hard coal increased, an increase in the value of angle of repose was observed, and thus a deterioration in flowability (Table 2). The effect of the addition of biomass to the mixture with hard coal was more complex in the case of aerated bulk density and packed bulk density. The material with the highest packed bulk density was hard coal, and that with the highest aerated bulk density was DDGS. In general, the addition of biomass to the mixtures with hard coal caused a decrease in compressibility, which can cause a deterioration in flowability.

Table 2.

Selected properties of the tested samples.

3.1. Mechanical Characteristics

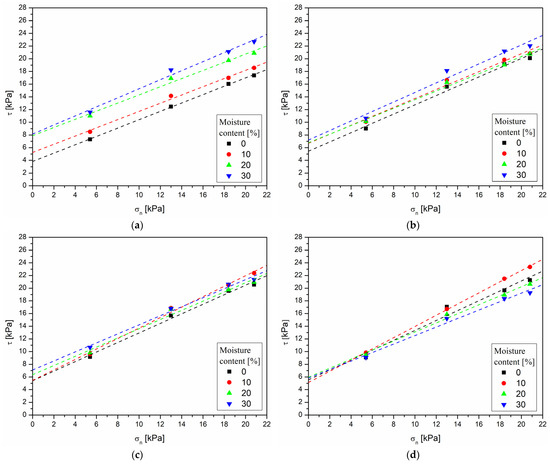

The following section presents the effect of moisture content on the course of the yield locus of the tested materials and their mixtures with coal. The higher the line of the yield locus and the higher its inclination, the greater the value of externally applied tangential stress required to cause plastic flow of the sample, i.e., the greater the cohesion of the sheared material, or the lower its flowability.

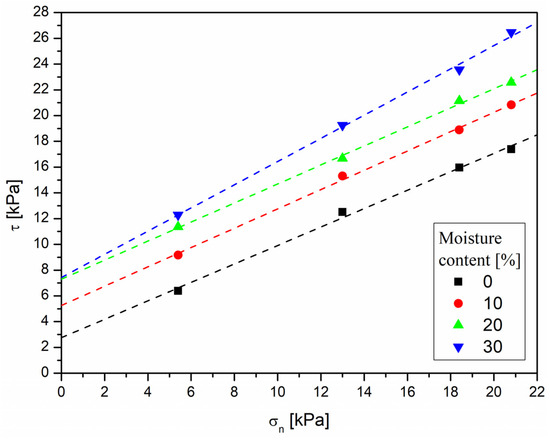

3.1.1. Hard Coal

The results obtained for hard coal—Figure 6—were taken as the basis for evaluation and comparison of the effect of moisture on the properties of the tested materials. This material showed the most regular particle shape of all the tested samples and had the smallest particle size. Hard coal showed a regular dependency, as can be seen in the plot of the yield loci. The increase in moisture content caused a systematic increase in tangential stresses corresponding to successively higher normal stresses. This meant an increase in the shear strength of the material and an increase in the cohesion of the material, which adversely affected its flowability. As a result, more force was needed to achieve the same plastic deformation.

Figure 6.

Effect of moisture content on yield loci for hard coal.

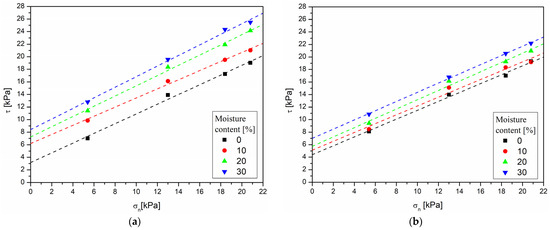

3.1.2. Mixtures of DDGS with Hard Coal

Figure 7a illustrates changes in the strength (cohesion) of the mixture (DDGS 5%, HC 95%) with increasing moisture content. Increasing moisture content significantly and systematically moved the yield loci to higher values of shear stress. This meant that the flowability of the moisturized material deteriorated, and higher loads were required to achieve the same deformation.

Figure 7.

Effect of moisture content on yield loci for: (a) mixture of HC 95%, DDGS 5%; (b) mixture of HC 70%, DDGS 30%; (c) mixture of HC 40%, DDGS 60%; (d) DDGS.

An increase in the proportion of biomass resulted in a decrease in shear stress for mixtures with higher moisture content and convergence of the lines of the individual flow conditions (Figure 7b,c), which meant a reduction in the effect of moisture on the mechanical characteristics of these materials. In the case of a mixture of coal and DDGS, with a DDGS content of 5% (Figure 7a), a significant and regular increase in shear stress was observed. By increasing the biomass content to 30%, the effect of moisture content was significantly reduced (Figure 7b). Mixtures with a DDGS content of 60% showed negligible susceptibility to moisture content (Figure 7c).

It was shown that the increase of moisture content in the biomass with hard coal mixtures changed its mechanical characteristics more, the higher the biomass content. The increase in moisture content worsened the flowability of the mixtures. The increase in biomass content reduced the influence of moisture. Biomass had a stabilizing effect on the mechanical properties of its mixtures with hard coal, especially at biomass contents above 30%.

These favorable phenomena can be explained by greater moisture absorption by the biomass, which prevented the hard coal’s properties from deteriorating with increasing moisture content.

On the other hand, the improved flowability may have resulted in the local consolidation of the material and an increase in its bulk density, which can cause local stresses that are dangerous for the construction of biomass storage and processing equipment.

As with hard coal, an increase in the shear stress caused by the presence of moisture was observed for DDGS. The largest differences were observed between samples with 0% moisture content and those with 10% moisture content. In addition, a slight decrease in stress was observed for samples with the highest moisture content, 20% and 30% (Figure 7d). This may have been due to grain deformation at higher moisture content.

The reason for this phenomenon may be that loading a powder with increasing moisture content with a large external stress, as used in the Jenike apparatus, deformed the grains, thereby increasing the contact area between grains. Growth in the moisture content of the contacting surfaces led to elevated deformability of the grains and a decrease in the level of the surface irregularity, resulting in an increase in the contact area of the grains and an increase in the value of the coefficient of friction. The increased contact area caused an increase in friction between grains, leading to the development of stress in the material. The angle of internal friction is the angle at which equilibrium is established between the layer of material particles in motion and the stationary part of the powder material bed. It is an important parameter in the design calculations of tanks and silos [29].

The addition of hard coal to the DDGS neutralizes the negative effect of moisture by reducing the values of tangential stresses in the material, which facilitates the course of processes such as discharging and charging of tanks, as well as the transport and dosing of material.

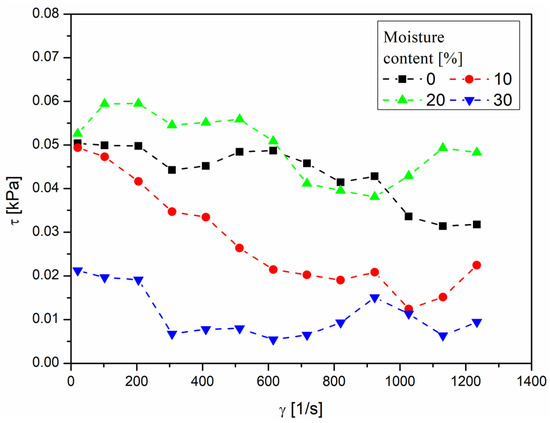

3.1.3. Mixtures of MBM with Hard Coal

In addition, in the case of mixtures of hard coal and MBM, a beneficial effect of increasing biomass content was observed (Figure 8a–c). The influence was manifested by the fact that as the proportion of MBM in the mixture increased, the influence of moisture became significantly smaller. This was particularly evident at MBM contents above 30%. A further increase in the MBM content in the mixture with hard coal (up to 60%) no longer caused significant changes in the effect of moisture on tangential stresses.

Figure 8.

Effect of moisture content on yield loci for: (a) mixture of HC 95%, MBM 5%; (b) mixture of HC 70%, MBM 30%; (c) mixture of HC 40%, MBM 60%; (d) MBM.

For MBM (Figure 8d), a lubrication phenomenon was clearly observed, consisting of the fact that in the area of higher normal stresses, biomass samples with increased moisture content manifested a greater tendency to flow, requiring lower boundary shear stresses than less moist samples. Exceeding a certain water content above the lubrication point increased the fluidity of the bed. This may have been explained by the supersaturation of the outer part of the grains with water and the formation of a moist layer that facilitated sliding. On the other hand, for low loads, moisture content had little effect on mechanical characteristics.

In the case of MBM, opposite to DDGS, at higher moisture contents (above 20%), moisture appeared on the surface of the grains, which may have been due to their low absorbency. The limited absorbency may have been due to the presence of bone particles, which do not exhibit such properties.

The lubrication phenomenon was not observed for MBM blends with hard coal, which indicated the stabilizing effect of hard coal addition on mechanical properties.

Under static conditions, biomass is a stabilizing factor for the mechanical properties of its mixture with coal. This conclusion can have important implications in terms of biomass logistics and the preparation of mixtures.

3.2. Rheological Characteristics

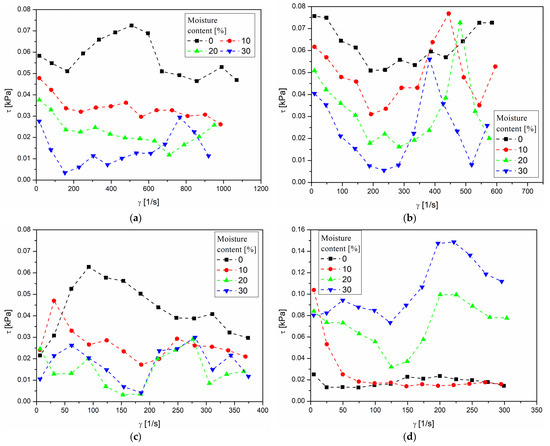

Measurements of rheological properties under dynamic conditions were made using a ring powder rheometer. The results of the tangential stress values τ were presented in the form of typical rheological characteristics, i.e., the dependence of tangential stress on shear rate γ, a measure of bed dynamics expressed in rheometer rotational speed.

3.2.1. Hard Coal

Under dynamic conditions, hard coal showed different flow characteristics compared to static conditions. The significant effect of moisture content was particularly evident for hard coal with respect to shear stresses (Figure 9). With increasing moisture content, the values of tangential stresses decreased, so the flowability of the material improved. This meant that under dynamic as opposed to static conditions, the moisture content was a factor that improved flowability. Moreover, in the case of hard coal, a decrease in shear stress values was observed, with an increase in the shear rate.

Figure 9.

The influence of moisture content and shear rate γ on shear stress τ for hard coal.

3.2.2. Mixtures of DDGS with Hard Coal

For mixtures of hard coal with DDGS, the changes in tangential stress looked different (Figure 10a–c) than for hard coal. The course of the rheological characteristics indicated the presence of characteristic flow areas of the material. In the area of low shear rate values, an increase in shear stress values was observed until a maximum is reached. Such a course of changes in rheological characteristics is referred to as a frictional state with low shear rates, otherwise known as Coulomb flow [42], which has similarities to the laminar flow of fluids between two flat walls (Couette flow), and most of the energy of the particles is dispersed by friction between them [43]. At low shear velocities, the friction of the grains against each other causes an increase in stress. At higher shear velocities, there is a slight increase in the volume of the bed, increasing the distances between grains, and the contact area and frictional force decrease, and as a result, a decrease in shear stress is observed. Data from the literature also indicates the existence of the so-called fluidized state [33] at high shear rates, in which energy is dissipated as a result of particles colliding with each other, causing an increase in shear stress. The grains of material in the fluidized state interact with each other during short-term contact. In this study, investigations did not capture this state for the rheometer speeds used, due to the maximum possible rheometer speed of 300 rpm.

Figure 10.

The influence of moisture content and shear rate γ on shear stress τ for: (a) mixture of HC 95%, DDGS 5%; (b) mixture of HC 70%, DDGS 30%; (c) mixture of HC 40%, DDGS 60%; (d) DDGS.

Investigations of biomass mixtures with hard coal using the powder annular rheometer showed a different behavior when compared to the investigations with the Jenike apparatus. As in the case of hard coal, samples with higher moisture content were characterized by better flowability. Compared to static conditions, increasing the degree of moisture content of the material decreased tangential stresses, especially in the region of low shear rate values—Figure 10a–c. Furthermore, an increase in shear rate caused a decrease in stresses. This trend is favorable for the implementation of material transfer and conversion processes, as it reduces the energy requirements for the implementation of these processes.

The change in rheological characteristics with an increase in the content of DDGS in the mixtures was insignificant. The increase in the content of this type of biomass did not cause significant changes in shear stress values (Figure 10a–c).

DDGS was the only material tested for which the opposite trend was observed, i.e., an increase in shear stresses induced by the presence of moisture under dynamic conditions (Figure 10d). This material under both static and dynamic conditions was characterized by an increase in shear stresses induced by an increase in moisture content.

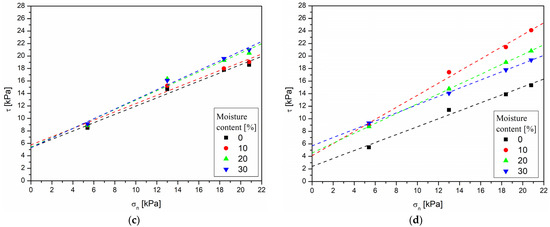

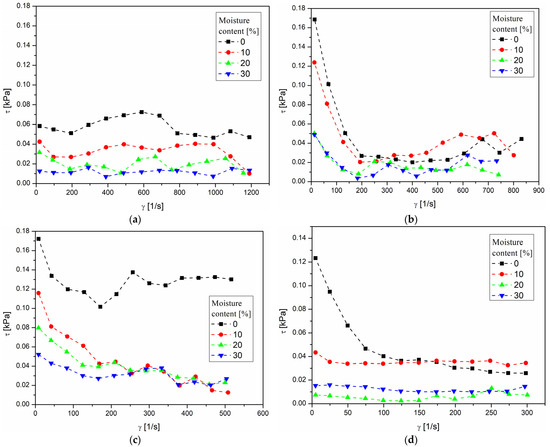

3.2.3. Mixtures of MBM with Hard Coal

Similar results were observed for mixtures of MBM and hard coal to those for hard coal. Mixtures of hard coal with MBM showed a decrease in stress due to an increase in moisture over the entire range of biomass content. This was the opposite trend to that observed during investigations of mechanical properties under static conditions. MBM mixtures with a biomass content of 5% (Figure 11a) showed the best flowability; the values of shear stresses were relatively low. Moreover, an increase in normal stresses was observed as the proportion of BMB in the mixtures grew.

Figure 11.

The influence of moisture content and shear rate γ on shear stress τ for: (a) mixture of HC 95%, MBM 5%; (b) mixture of HC 70%, MBM 30%; (c) mixture of HC 40%, MBM 60%; (d) MBM.

The effect of biomass content in the mixture on its flow characteristics was also different. From the graphs in Figure 11a–c, it is evident that an increase in the proportion of biomass increased its shear strength and worsened its flowability.

An increase in moisture content under dynamic conditions improved the flowability of mixtures, especially in the area of low shear rate values. This positive trend, evident from a moisture content of 20 ÷ 30%, can contribute to a reduction in energy requirements for implementing biomass conversion and utilization processes.

For MBM, it was observed that the stress required for the material to flow decreased as the degree of moisture content got higher (Figure 11d). Thus, less force was needed to achieve the same deformation.

The favorable trend of decreasing stresses as a consequence of decreasing cohesion of the moist bulk material was particularly pronounced for the low shear rate region, where an increase in shear rate caused a strong decrease in stresses and reduced the effect of moisture content. From this point of view, this area can be important in the design of process operations with bulk materials, including biomass, for which a certain moisture content is a natural feature resulting from its origin and storage conditions.

The different effect of moisture content under static and dynamic conditions indicates its complex influence on the properties of biomass and its mixtures with hard coal. Further investigations are required to gain a more thorough understanding of the behavior of biomass under the influence of moisture, especially under dynamic conditions.

4. Conclusions

The performed investigations showed that the effect of moisture content on the flow characteristics of biomass-coal mixtures depended significantly on both dynamic conditions and the composition of the mixtures.

Under static conditions, an increase in moisture content generally worsened the flowability of mixtures. On the other hand, increasing the proportion of biomass, which in the area of low external loads reduced the mechanical strength of the mixture and improved its flowability, had the opposite effect.

An important conclusion is that under static conditions, biomass was a stabilizing factor for the mechanical properties of its mixtures with coal.

Under dynamic conditions, an increase in moisture content improved the flowability of mixtures, especially in the area of low shear rate values and moisture content of 20 ÷ 30%.

The influence of moisture content should be considered in the context of the dynamic state of the material. The differences in the effects of moisture content on the mechanical and rheological properties may be indicative of the complexity of the humidification of agricultural materials, which may cause changes in the chemical structure and physical structure of the surface or the interior of the grains.

The obtained results made it possible to formulate some design guidelines for biomass-coal mixture storage, handling, and conversion. Under static conditions, the stabilizing effect of biomass addition can have important implications in terms of biomass logistics and the preparation of mixtures. The positive trend of improving flowability with increasing moisture content in dynamic conditions can contribute to a reduction in energy requirements for implementing biomass conversion and utilization processes.

Author Contributions

Conceptualization, M.P.; methodology, M.P. and R.L.-P.; software, M.C. and R.L.-P.; validation, M.P., W.Z. and I.O.; formal analysis, M.P.; investigation, M.P.; resources, R.L.-P. and I.O.; data curation, W.Z.; writing—original draft preparation, M.P.; writing—review and editing, M.P.; visualization, M.C., M.P. and R.L.-P.; supervision, W.Z.; project administration, M.P. and R.L.-P.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Swain, P.K. Utilisation of Agriculture Waste Products for Production of Bio-Fuels: A Novel Study. Mater. Today Proc. 2017, 4, 11959–11967. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics 2020; World Bioenergy Association: Stockholm, Sweden, 2020. [Google Scholar]

- Datta, A.; Hossain, A.; Roy, S. An overview on biofuels and their advantages and disadvantages. Asian J. Chem. 2019, 31, 1851–1858. [Google Scholar] [CrossRef]

- Alhazmi, H.; Loy, A.C.M. A review on environmental assessment of conversion of agriculture waste to bio-energy via different thermochemical routes: Current and future trends. Bioresour. Technol. Rep. 2021, 14, 100682. [Google Scholar] [CrossRef]

- Selim, K.A.; Easa, S.M.; El-Diwany, A.I. The xylose metabolizing yeast Spathaspora passalidarum is a promising genetic treasure for improving bioethanol production. Fermentation 2020, 6, 33. [Google Scholar] [CrossRef]

- Hao, P.F.; Qiu, C.W.; Ding, G.; Vincze, E.; Zhang, G.; Zhang, Y.; Wu, F. Agriculture organic wastes fermentation CO2 enrichment in greenhouse and the fermentation residues improve growth, yield and fruit quality in tomato. J. Clean. Prod. 2020, 275, 123885. [Google Scholar] [CrossRef]

- Chang, A.C.C.; Chang, H.F.; Lin, F.J.; Lin, K.H.; Chen, C.H. Biomass gasification for hydrogen production. Int. J. Hydrog. Energy 2011, 36, 14252–14260. [Google Scholar] [CrossRef]

- Faaij, A.; Van Doorn, J.; Curvers, T.; Waldheim, L.; Olsson, E.; Van Wijk, A.; Daey-Ouwens, C. Characteristics and availability of biomass waste and residues in the Netherlands for gasification. Biomass Bioenergy 1997, 12, 225–240. [Google Scholar] [CrossRef]

- Jiang, X.; Li, P.; Ding, Z.; Wang, A.; Bing, H.; Zhang, J. Thermochemical liquefaction of wheat straw and its effectiveness as an extender for asphalt binders: Characterization of liquefied products and potential opportunities. Constr. Build. Mater. 2021, 305, 124769. [Google Scholar] [CrossRef]

- Zhang, J.; Hori, N.; Takemura, A. Optimization of agricultural wastes liquefaction process and preparing bio-based polyurethane foams by the obtained polyols. Ind. Crops Prod. 2019, 138, 111455. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Nieto, A.; Méndez, A.; Askeland, M.P.J.; Gascó, G. Biochar from biosolids pyrolysis: A review. Int. J. Environ. Res. Public Health 2018, 15, 956. [Google Scholar] [CrossRef]

- Hawash, S.I.; Farah, J.Y.; El-Diwani, G. Pyrolysis of agriculture wastes for bio-oil and char production. J. Anal. Appl. Pyrolysis 2017, 124, 369–372. [Google Scholar] [CrossRef]

- Sagastume Gutiérrez, A.; Cabello Eras, J.J.; Hens, L.; Vandecasteele, C. The energy potential of agriculture, agroindustrial, livestock, and slaughterhouse biomass wastes through direct combustion and anaerobic digestion. The case of Colombia. J. Clean. Prod. 2020, 269, 122317. [Google Scholar] [CrossRef]

- Mlonka-Mędrala, A.; Magdziarz, A.; Dziok, T.; Sieradzka, M.; Nowak, W. Laboratory studies on the influence of biomass particle size on pyrolysis and combustion using TG GC/MS. Fuel 2019, 252, 635–645. [Google Scholar] [CrossRef]

- Werther, J.; Ogada, T. Sewage sludge combustion. Prog. Energy Combust. Sci. 1999, 25, 55–116. [Google Scholar] [CrossRef]

- Liu, Q.; Zhong, W.; Gu, J.; Yu, A. Three-dimensional simulation of the co-firing of coal and biomass in an oxy-fuel fluidized bed. Powder Technol. 2020, 373, 522–534. [Google Scholar] [CrossRef]

- Bhui, B.; Vairakannu, P. Prospects and issues of integration of co-combustion of solid fuels (coal and biomass) in chemical looping technology. J. Environ. Manag. 2019, 231, 1241–1256. [Google Scholar] [CrossRef]

- Kowalski, Z.; Banach, M.; Makara, A. Optimisation of the co-combustion of meat–bone meal and sewage sludge in terms of the quality produced ashes used as substitute of phosphorites. Environ. Sci. Pollut. Res. 2021, 28, 1241–1256. [Google Scholar] [CrossRef]

- Fryda, L.; Panopoulos, K.; Vourliotis, P.; Pavlidou, E.; Kakaras, E. Experimental investigation of fluidised bed co-combustion of meat and bone meal with coals and olive bagasse. Fuel 2006, 85, 1685–1699. [Google Scholar] [CrossRef]

- Pang, C.H.; Lester, E.; Wu, T. Influence of lignocellulose and plant cell walls on biomass char morphology and combustion reactivity. Biomass Bioenergy 2018, 119, 480–491. [Google Scholar] [CrossRef]

- Pang, C.H.; Hewakandamby, B.; Wu, T.; Lester, E. An automated ash fusion test for characterisation of the behaviour of ashes from biomass and coal at elevated temperatures. Fuel 2013, 103, 454–466. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Gancarz, M.; Wiącek, J.; Parafiniuk, P.; Lisowski, A. Characterization of shear behaviour in consolidated granular biomass. Powder Technol. 2018, 327, 120–127. [Google Scholar] [CrossRef]

- Zulfiqar, M.; Moghtaderi, B.; Wall, T.F. Flow properties of biomass and coal blends. Fuel Process. Technol. 2006, 87, 281–288. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, X.; Xu, Y.; Liu, H. Study of flow characteristics of biomass and biomass-coal blends. Fuel 2015, 141, 207–213. [Google Scholar] [CrossRef]

- Chen, P.; Yuan, Z.; Shen, X.; Zhang, Y. Flow properties of three fuel powders. Particuology 2012, 10, 438–443. [Google Scholar] [CrossRef]

- Guo, Q.; Liu, H.; Chen, X.; Li, S.; Guo, X.; Gong, X. Research on the flow properties of the blended particles of rice straw and coal. Fuel 2012, 102, 438–443. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, X.; Liu, H.; Lu, H.; Guo, X.; Gong, X. Effect of storage time on the flowability of biomass-coal granular system. Fuel Process. Technol. 2014, 125, 59–66. [Google Scholar] [CrossRef]

- Jenike, A. Storage and Flow of Solids, Bulletin No. 123; Utah Engineering Experiment Station: Salt Lake City, UT, USA, 1964; Volume 53. [Google Scholar]

- Carson, J.W.; Wilms, H. Development of an international standard for shear testing. Powder Technol. 2006, 167, 1–9. [Google Scholar] [CrossRef]

- Cheng, Z.; Leal, J.H.; Hartford, C.E.; Carson, J.W.; Donohoe, B.S.; Craig, D.A.; Xia, Y.; Daniel, R.C.; Ajayi, O.O.; Semelsberger, T.A. Flow behavior characterization of biomass Feedstocks. Powder Technol. 2021, 387, 156–180. [Google Scholar] [CrossRef]

- Kaleem, M.A.; Alam, M.Z.; Khan, M.; Jaffery, S.H.I.; Rashid, B. An experimental investigation on accuracy of Hausner Ratio and Carr Index of powders in additive manufacturing processes. Met. Powder Rep. 2021, 76, S50–S54. [Google Scholar] [CrossRef]

- Hao, T. Understanding empirical powder flowability criteria scaled by Hausner ratio or Carr index with the analogous viscosity concept. RSC Adv. 2015, 5, 57212–57215. [Google Scholar] [CrossRef]

- Klausner, J.F.; Chen, D.; Mei, R. Experimental investigation of cohesive powder rheology. Powder Technol. 2000, 112, 94–101. [Google Scholar] [CrossRef]

- Leaper, M.C.; Fisk, E.; Browne, R. Feasibility study to investigate caking in washing powder formulations using a Freeman FT4 powder rheometer. Part. Sci. Technol. 2019, 37, 1009–1014. [Google Scholar] [CrossRef]

- Valentyn, M.; Styliari, I.D.; Dmytryi, N.; Reiss, P.; Rajeev, D. Assessment of the effect of Cellets’ particle size on the flow in a Wurster fluid-bed coater via powder rheology. J. Drug Deliv. Sci. Technol. 2019, 54, 101320. [Google Scholar] [CrossRef]

- Khala, M.J.; Hare, C.; Wu, C.Y.; Venugopal, N.; Murtagh, M.J.; Freeman, T. Density and size-induced mixing and segregation in the FT4 powder rheometer: An experimental and numerical investigation. Powder Technol. 2021, 390, 126–142. [Google Scholar] [CrossRef]

- CEN (European Commitee for Standardization). Eurocode 1—Actions on Structures—Part 4: Silos and Tanks. Eurocode 1; European Commitee for Standardization: Brussels, Belgium, 2006; Volume 4. [Google Scholar]

- ISO. 3252:2019; Powder Metallurgy—Vocabulary. Int. Organ. Stand. ISO: Geneva, Switzerland, 2019.

- Kudo, Y.; Yasuda, M.; Matsusaka, S. Effect of particle size distribution on flowability of granulated lactose. Adv. Powder Technol. 2020, 31, 121–127. [Google Scholar] [CrossRef]

- Stavrou, A.G.; Hare, C.; Hassanpour, A.; Wu, C.Y. Investigation of powder flowability at low stresses: Influence of particle size and size distribution. Powder Technol. 2020, 364, 98–114. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, X.; Liu, H. Experimental research on shape and size distribution of biomass particle. Fuel 2012, 94, 551–555. [Google Scholar] [CrossRef]

- Tardos, G.I. A fluid mechanistic approach to slow, frictional flow of powders. Powder Technol. 1997, 92, 61–74. [Google Scholar] [CrossRef]

- Tardos, G.I.; Irfan Khan, M.; Schaeffer, D.G. Forces on a slowly rotating, rough cylinder in a Couette device containing a dry, frictional powder. Phys. Fluids 1998, 10, 335–341. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).