1. Introduction

By the mid-19th century, Gompertz [

1] proposed a sigmoid function that describes growth as being the slowest at the start and end of a given period. Because a stable population would consequently have a saturation-level point and form a numerical upper bound on the growth size, Verhulst [

2] proposed to limit this constraint and introduced the Logistic growth function. Afterward, Winsor [

3] studied the parallelism between the Gompertz curve and the Logistic one. The Gompertz and the Logistic curves have similar properties, making them useful for the empirical representation of growth phenomena. Von Bertalanffy [

4] postulated the General System Theory (GST), a logical concept applicable to all systems-related sciences, implying that specific principles have pertinence to systems. It explains the occurrence of isomorphous laws in various scientific fields. Such concepts were, after that, used to develop growth curves in living organisms and used as a basis for the genetic development of farm animals [

5,

6,

7].

Growth is a continuous function during the animal’s life, from embryonic stages to adult age. Growth models mathematically explain it with biological meaning parameters [

6]. Most functions are resultant of empirical data from specific experiments. Associating parameters with animal productivity and reproductive traits is a valuable resource for selection programs [

8]. Using the growth curve, it is possible to describe animal body changes, such as size, mass, volume, and other units of performance interest. Furthermore, relative growth rates are essential for evaluating growth performance and efficiency [

9].

Pig and broiler growth depends on feed efficiency and varies with the animal’s age or stage of production. The study of animal growth models facilitates monitoring their development, which can help establish the optimum slaughter time. Growth curves help explain body development patterns in birds and pigs [

6]. The growth curve can be analyzed in three defined stages: (1) shortly after birth or hatching when there is a moderate growth rate; (2) after a certain age, the curve settles, and the growth rate is maximum; and (3) at the end of growth, the rate is slowed down and ends in an asymptote in the mature phase [

10]. The use of non-linear models helps consolidate large volumes of information into a set of constraints that can be explained biologically [

7,

11,

12].

The growth rate is the main focus of pig farming systems, including key performance indicators such as weight gain, feed intake, and feed conversion [

7,

13,

14,

15]. Current broilers are high-yielding and growing due to excellent feed conversion [

16]. As development progresses, a more significant amount of energy is destined for the maintenance of the organism, thus reducing the mass gain and growth of the animals [

17]. Growth curves are vital to support monogastric breeding programs. The three previously described functions (Gompertz, Logistic, and von Bertalanffy) generate satisfactory results; however, they differ slightly along the curve. Mathematic models such as growth curves that result from field trials cannot necessarily be applied to all datasets, because they are developed from specific experimental conditions. A way to search for the optimal growth curve is to use the hybrid metaheuristic algorithm strategy. By optimizing the growth curve model, we can define the increase in body weight as a function of age based on the weight vs. age indicators, which is critical for the production of monogastric animals.

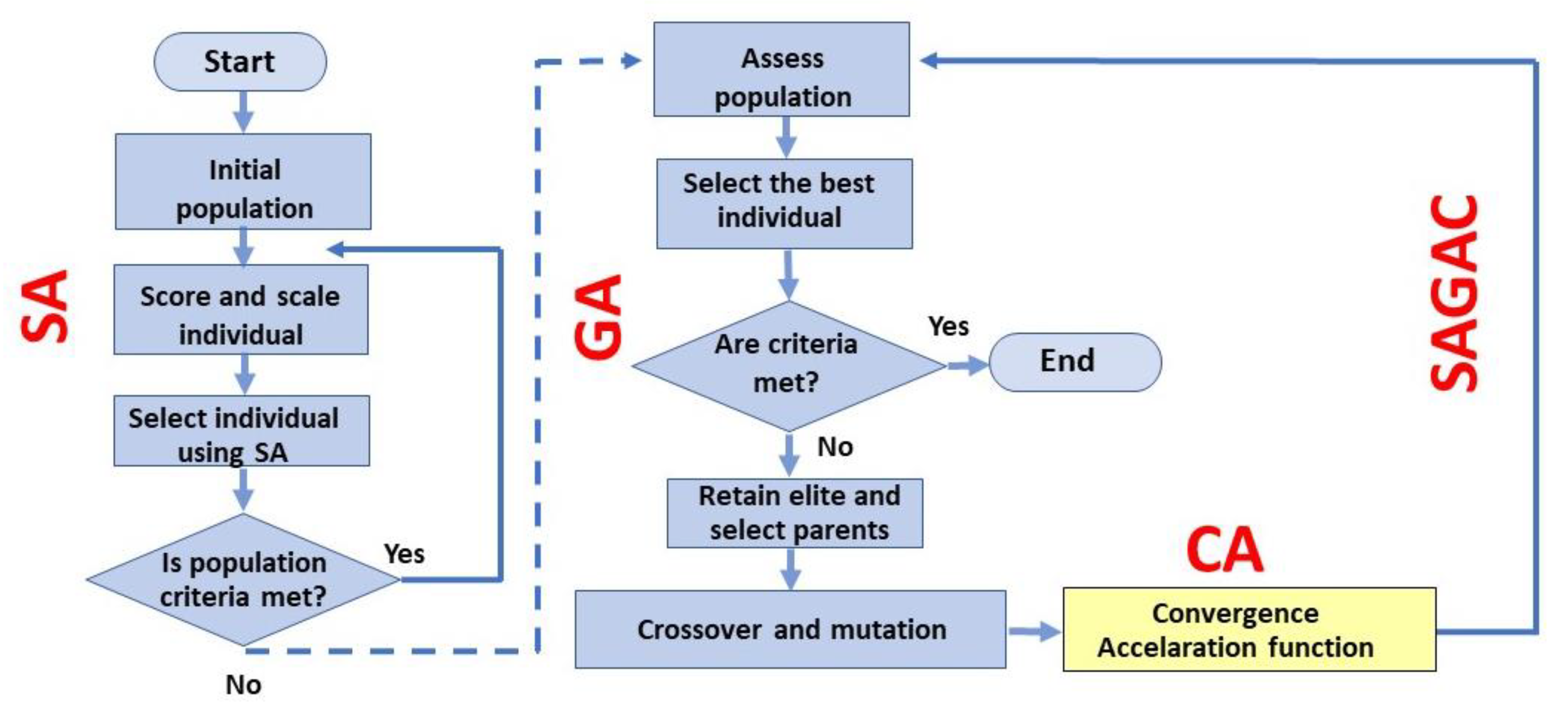

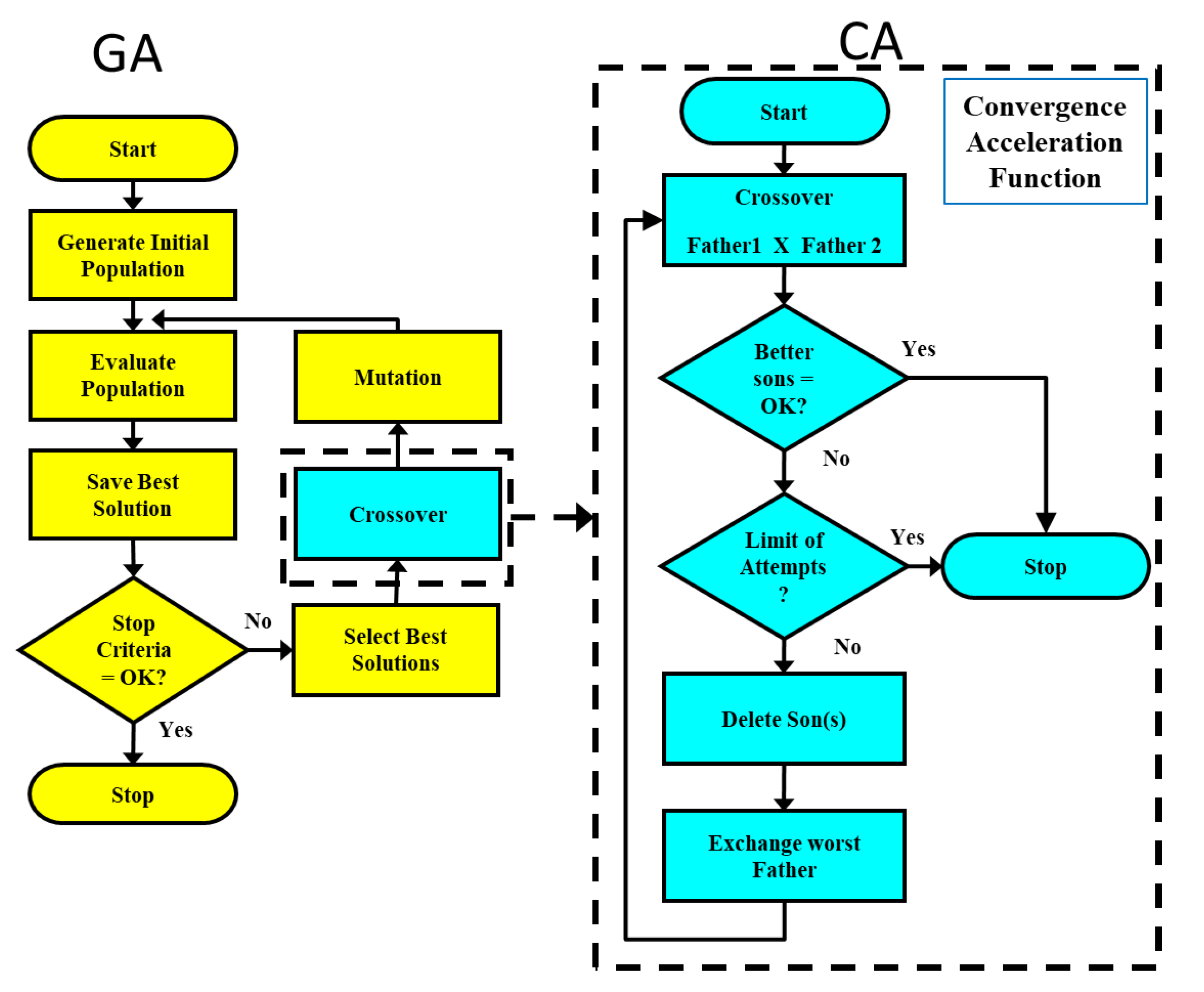

Simulated Annealing (SA) is a metaheuristic algorithm that applies a metal cooling process simulation. This method reaches a better status than the current one. If some movement generates the worst status, it may be accepted according to probability [

18]. The second algorithm is the Genetic Algorithm (GA). GA is also a metaheuristic algorithm that applies a search and optimization method based on Charles Darwin’s theory of natural selection of species, according to which it is advocated that over the generations of a population of individuals of any species, only the best or most adapted to the environment in which they live will survive. GAs are search algorithms based on the principles of natural selection and genetics, inspired by the biological evolution of living beings; therefore, surviving individuals have a chance to pass on their genetic code to subsequent generations [

19,

20].

In the current literature, there is no consensus on the best model to describe the growth curve of monogastric animals. The differences between the models may be due to many reasons, including breed or population structure, sex, feeding management, environmental conditions, sampling, and statistical methods. Metaheuristics algorithms are usually used in problems with combinatorial analysis features with many possible solutions. In this case of growth curves, the average quantity of possible solutions is nearly 1.17 × 1012 (NP-hardness in the computational complexity theory). The present study proposes optimizing the parameters of monogastric growth curves by applying a hybrid metaheuristic algorithm (SAGAC) to field data to select the best available growth curve model functions of monogastric farm animals (pigs and broilers).

4. Discussion

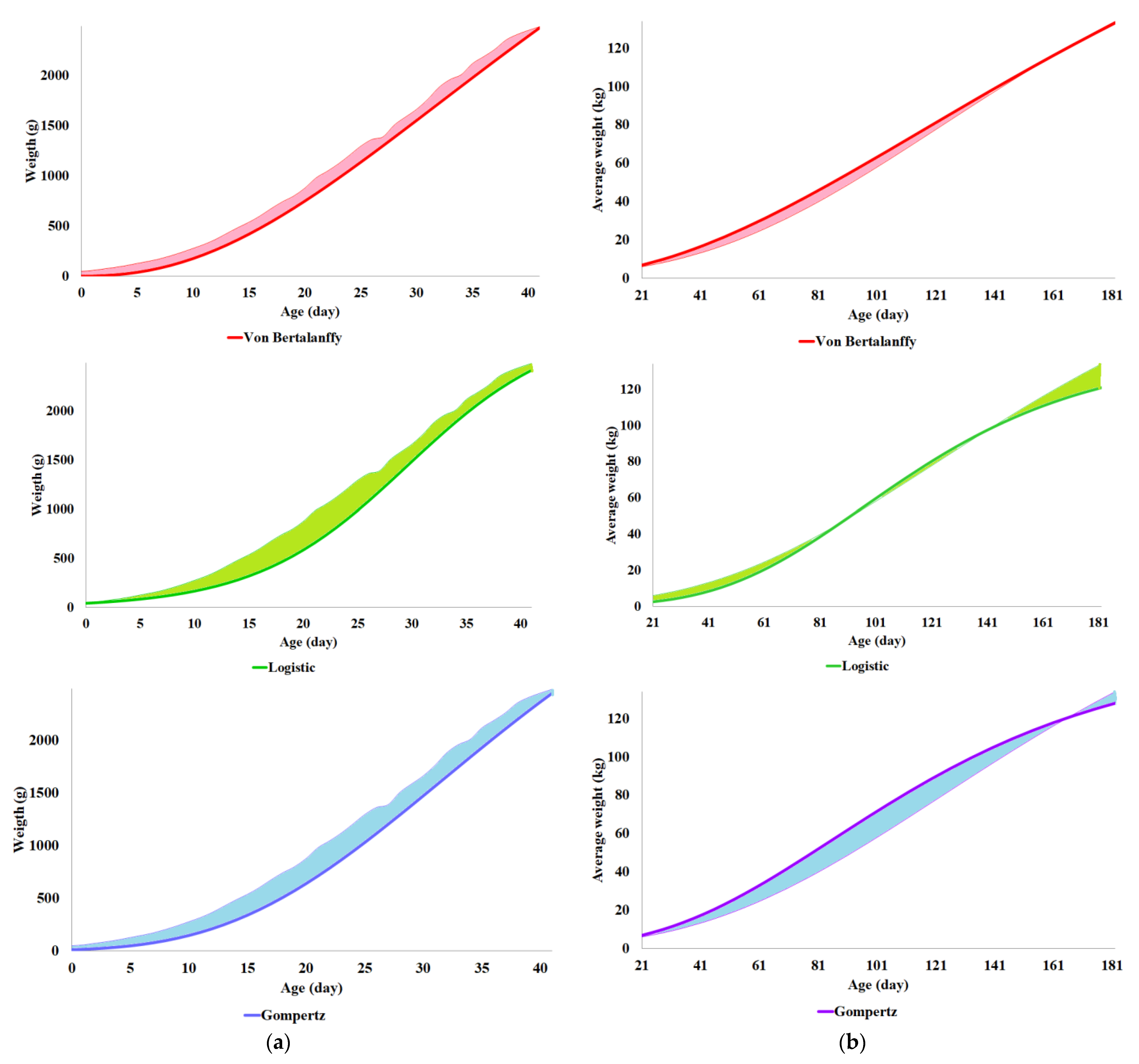

We tested the metaheuristic hybrid algorithm SAGAC to find the best fit among the possible models available for pig and broiler growth. The growth curve parameters provide an opportunity to design selection strategies by modifying either feeding practices or the genetic makeup of the growth curve shape. The quality of fit of a model of an animal species, among other factors, is dependent on the number of weight-age parameters evaluated (sex, breed, management, age of the animal) [

22]. The classical Logistic growth equation [

2] has been used as a basis for several extended models. Each is helpful to accommodate physical growth without the constraint that the maximum growth rate should occur at half of the carrying capacity in the case of population dynamics or the maximum possible dimension for the physical growth of the system being tested [

29]. Previous experimental research was carried out to directly assess the genetic variation inherent in the growth parameters of chickens using a cross-incorporating progeny of both sexes [

30]. The authors’ results indicate a moderate improvement using the genetic modifications, mainly due to biological limitations. Our results suggest enhancing the animals’ weight prediction by optimizing the growth curve parameter values. This is reached by the adherence of the simulated growth curve to the empirical ones.

Vertical management of the poultry and swine industries facilitates product segmentation and a precision approach to optimization solutions for strategic and operational decisions, such as the ’best combination of parameter values of growth models’ that would promote slaughter time planning [

31]. A comprehensive computational study might solve the integrated planning problem when considering solutions for optimizing the production chain. Hatching eggs, allocating broiler flocks on farms, and collecting broilers for slaughter were applied to accurate data. They showed that value could be added to planning, improving solutions by 15 to 24% [

32].

The metaheuristics algorithms use their strategies to search the result set for a better possible outcome in a short time of processing. The SAG successfully optimized cassava starch hydrolysis to produce biofuel [

33]. The SAGAC was previously applied to optimize the pre-processing vacuum cooling of broccoli handling [

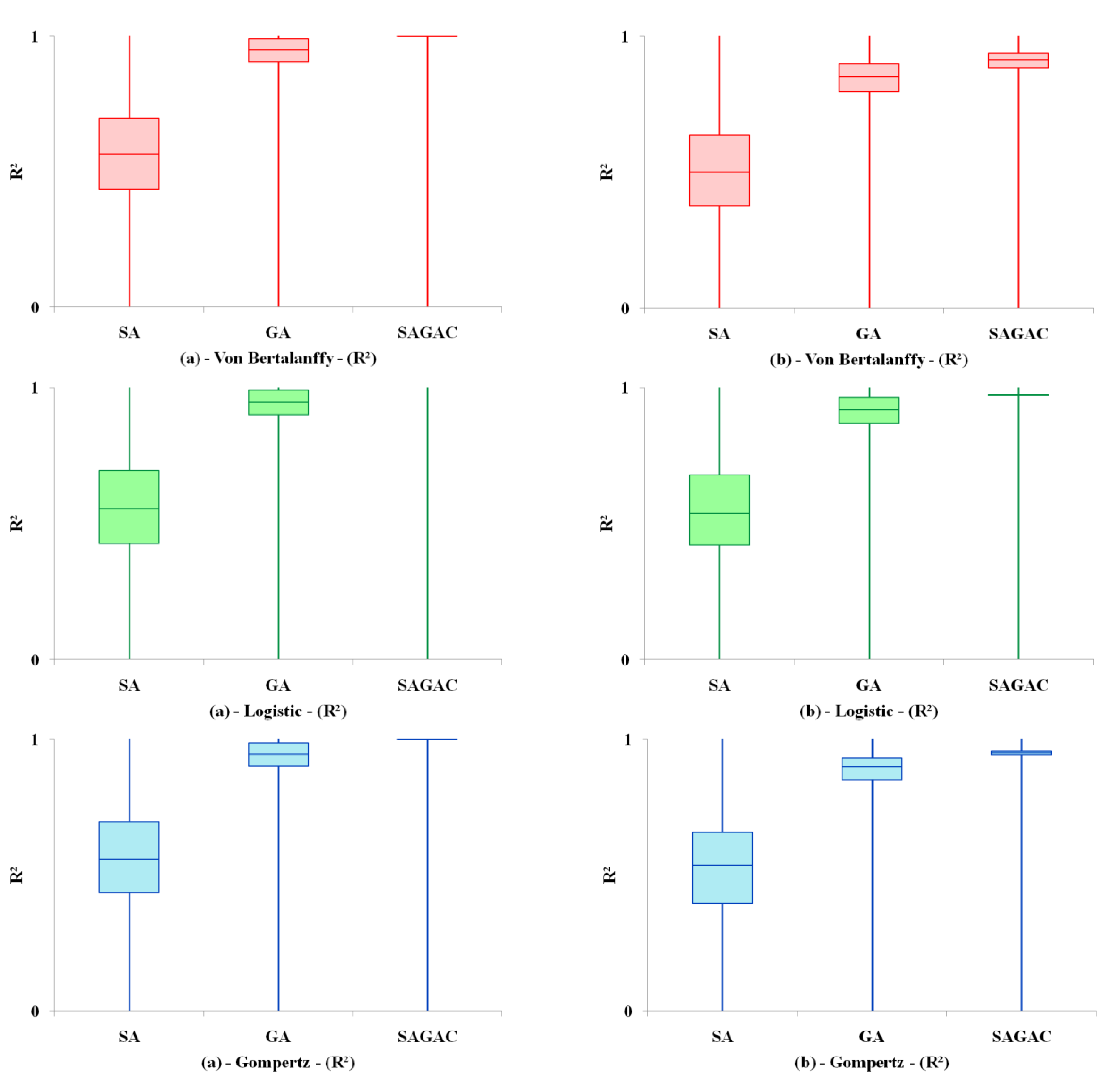

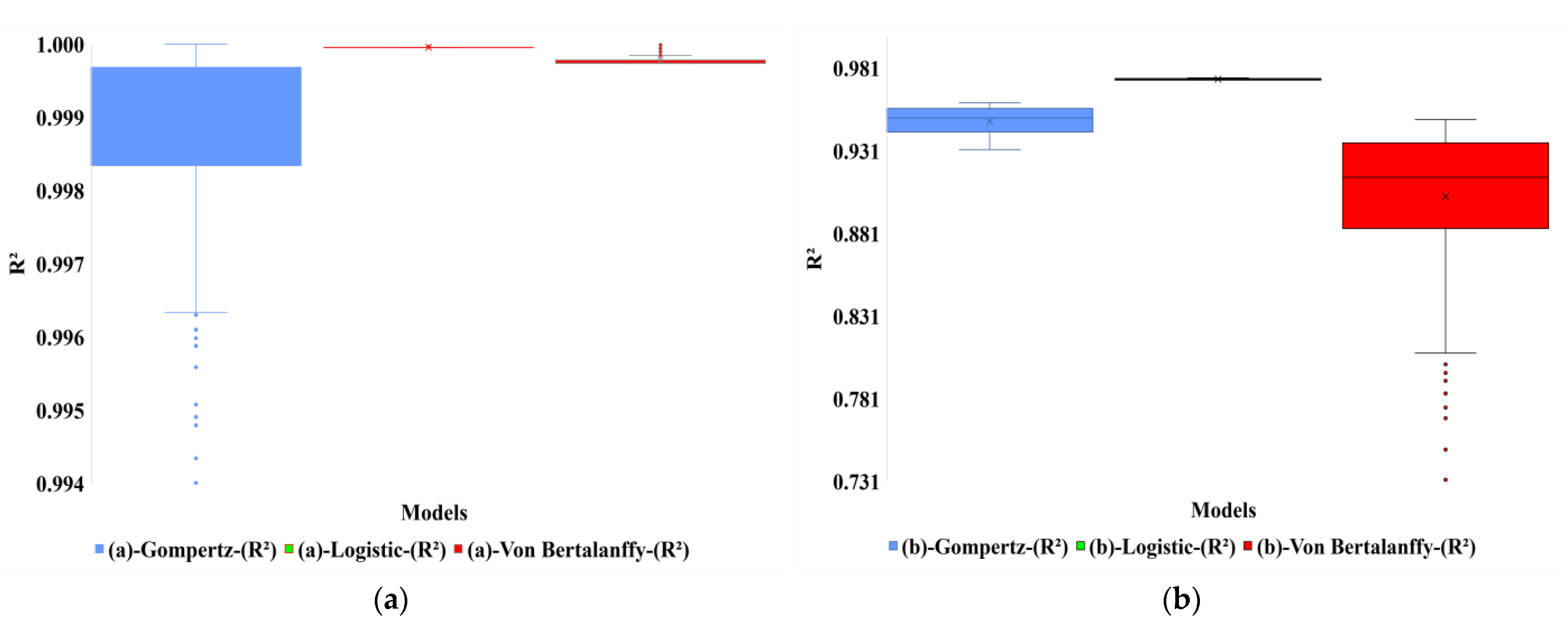

34]. The refined combination of SA and GA (SAG) and adding the convergence acceleration function (AC) improved the performance of the hybrid algorithm (SAGAC) in the optimization process. One characteristic of SAGAC that could be considered a limitation is that the algorithm does not have the optimal result for each problem; however, it finds a satisfactory result due to the complexity of the problem. The computational cost (due to the NP-hardness of the functions) is often unfeasible if an exact algorithm is used for these problems. Our findings show that the Logistic model fits live weight data very well for studying the growth of pigs (R

2 = 0.9738). The best-fitted model for the broiler is the Gompertz model (R

2 = 0.999998). This result agrees with [

6], who found that the Gompertz model was the best model for male and female broilers.

The biological interpretations rationalized for parameters from growth functions and their specific cases have been a primary reason for their popularity [

35]. The von Bertalanffy equation was directly argued from metabolic laws [

8]. Biological understandings have evolved after choosing a mathematical model on empirical grounds, so it is not unexpected that the functions do not always hold for all models and datasets [

36,

37,

38,

39]. Therefore, the curve growth functions vary depending on the species and environmental conditions of housing. In our study, there is a slight difference in the results; however, using the SAGAC algorithm decreases that disparity.

There is a constant search for tools and methods to improve production and meat quality [

40]. The forecasting of pig growth to devise the market is optimizing production planning and management. In the present research, a hybrid metaheuristic algorithm (SAGAC) was tested to better estimate the model’s parameters for predicting pig and broiler growth curves, thus promoting greater reliability in the predictive data of the meat supply chain.

5. Conclusions

The current models for predicting growth curves for monogastric farm animals are developed using experimental data (curve fitting), and these models cannot generalize these curves to other datasets. All tuning of the growth curves using the proposed SAGAC method for broilers presented an R2 value above 99%, and the SAGAC for pigs presented an R2 value above 94% for the growth curve. Our study showed that within the three tested models for each monogastric animal (pig and broiler), there is a prevalence of the Logistic model for pig production and the Gompertz model for broiler production.

This study proposes applying SAGAC to optimize the growth parameter models for pigs and broilers, effectively reducing the NP-hardness of the studied functions. Our results improve prediction reliability and enhance production planning quality, minimizing production costs.