Assessment of a Deep Burial Destoning System of Agrarian Soils Alternative to the Stone Removal and On-Site Crushing

Abstract

:1. Introduction

2. State of the Art

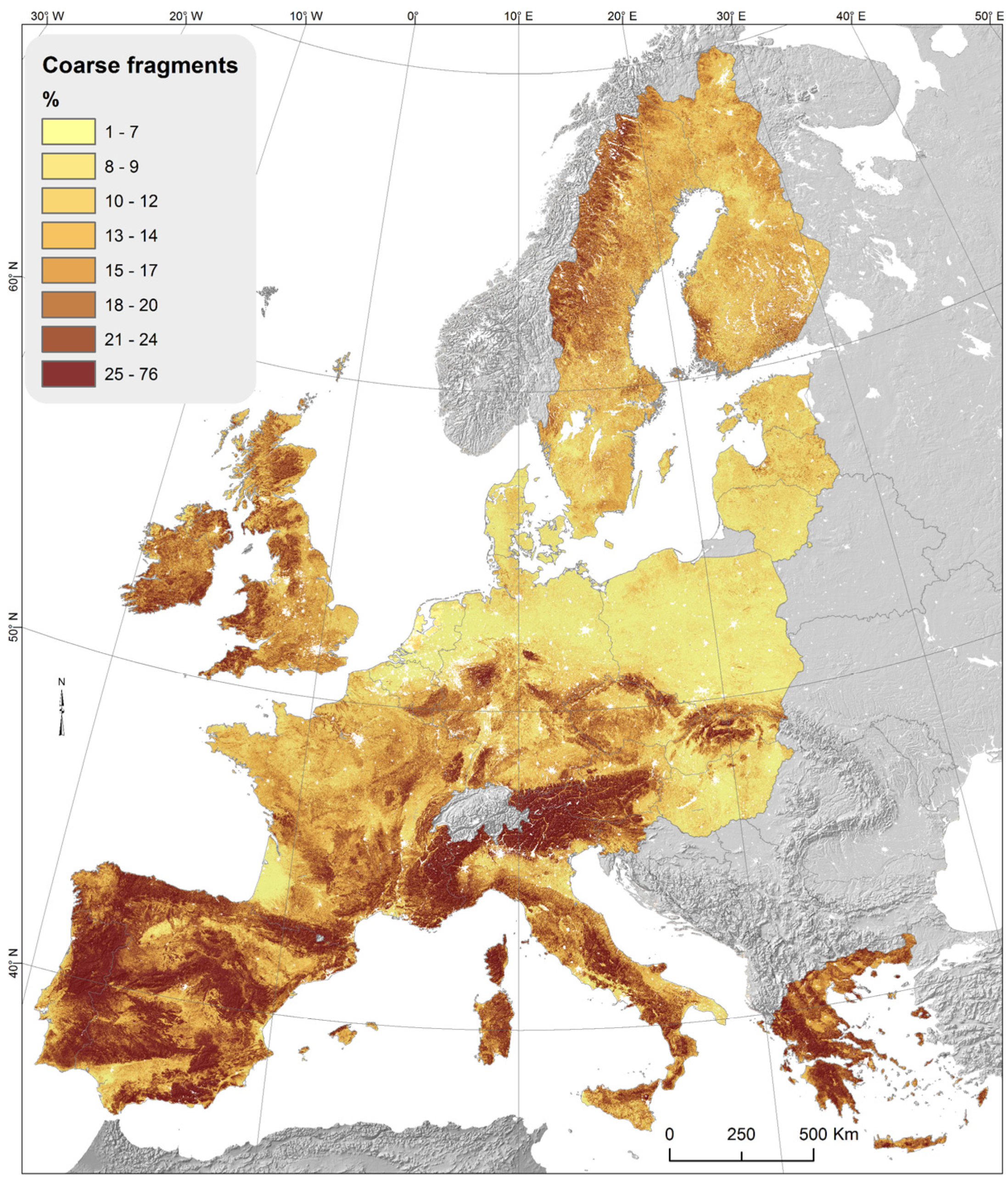

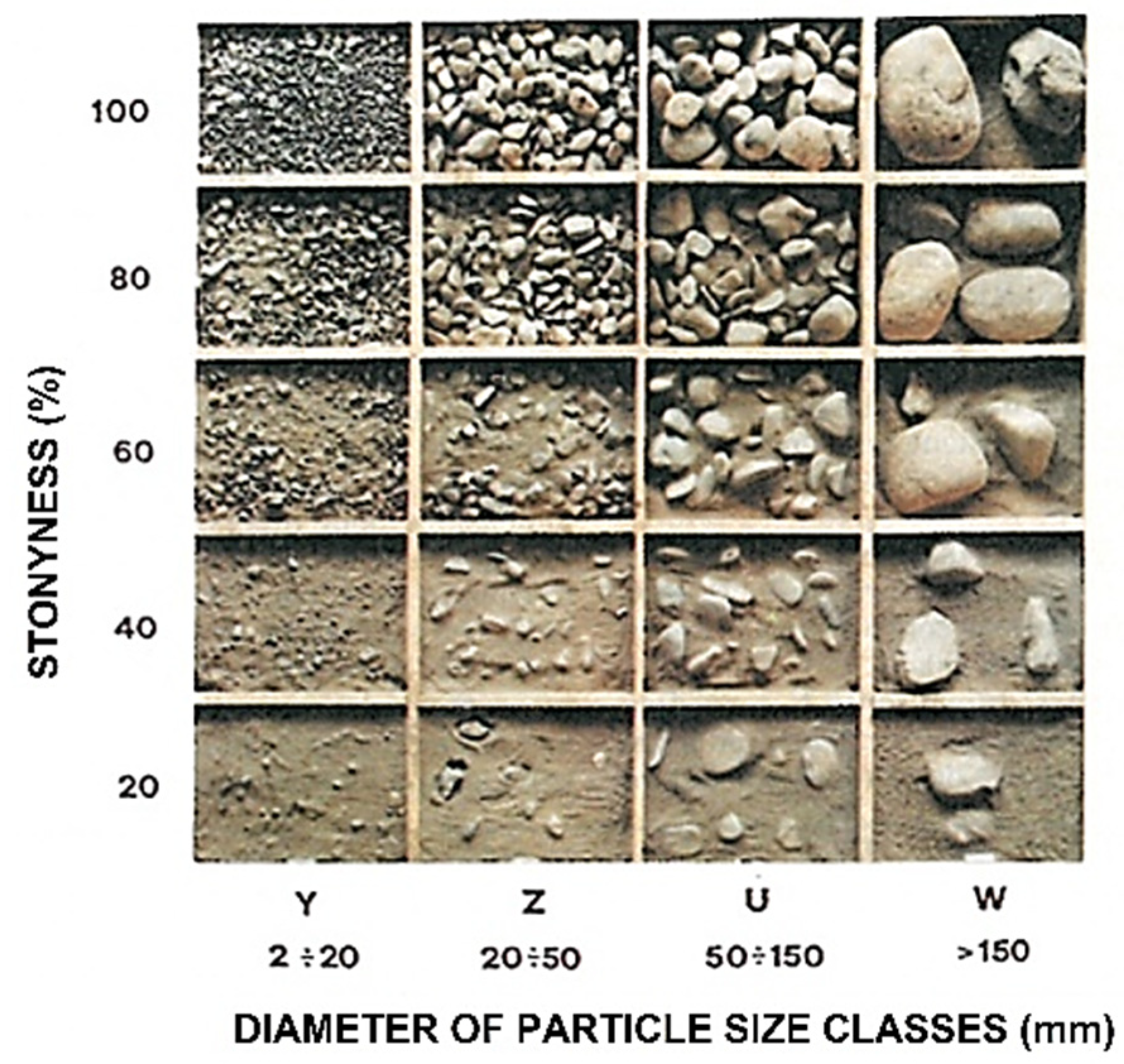

2.1. The Soil Skeleton and Stony Soils Workability Classes Concept

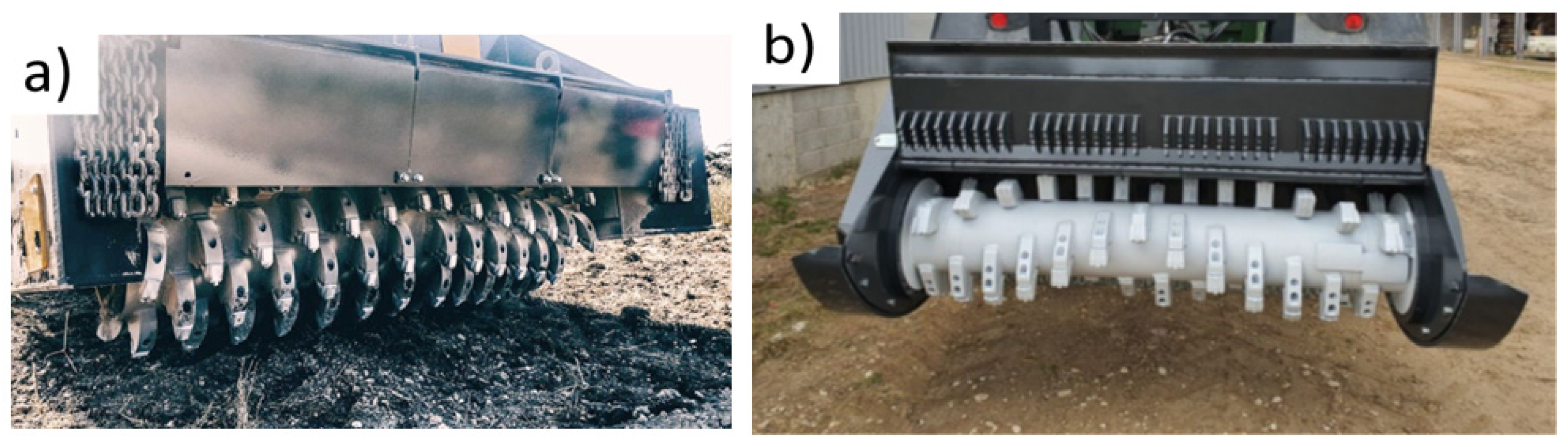

2.2. Soil Destoning Systems

2.2.1. Stone Collection and Removal

- the reduction of the topsoil volume, in proportion to the volumes of stones removed;

- the possible resurfacing of other skeletons with subsequent soil tillage, especially if effected at a depth greater than the destoned layer, which makes it necessary to repeat the destoning operations.

- additional costs for the preventive soil preparation (ripping, stones windrowing), the handling and the disposal of the removed stones.

2.2.2. On-Site Stone Crushing

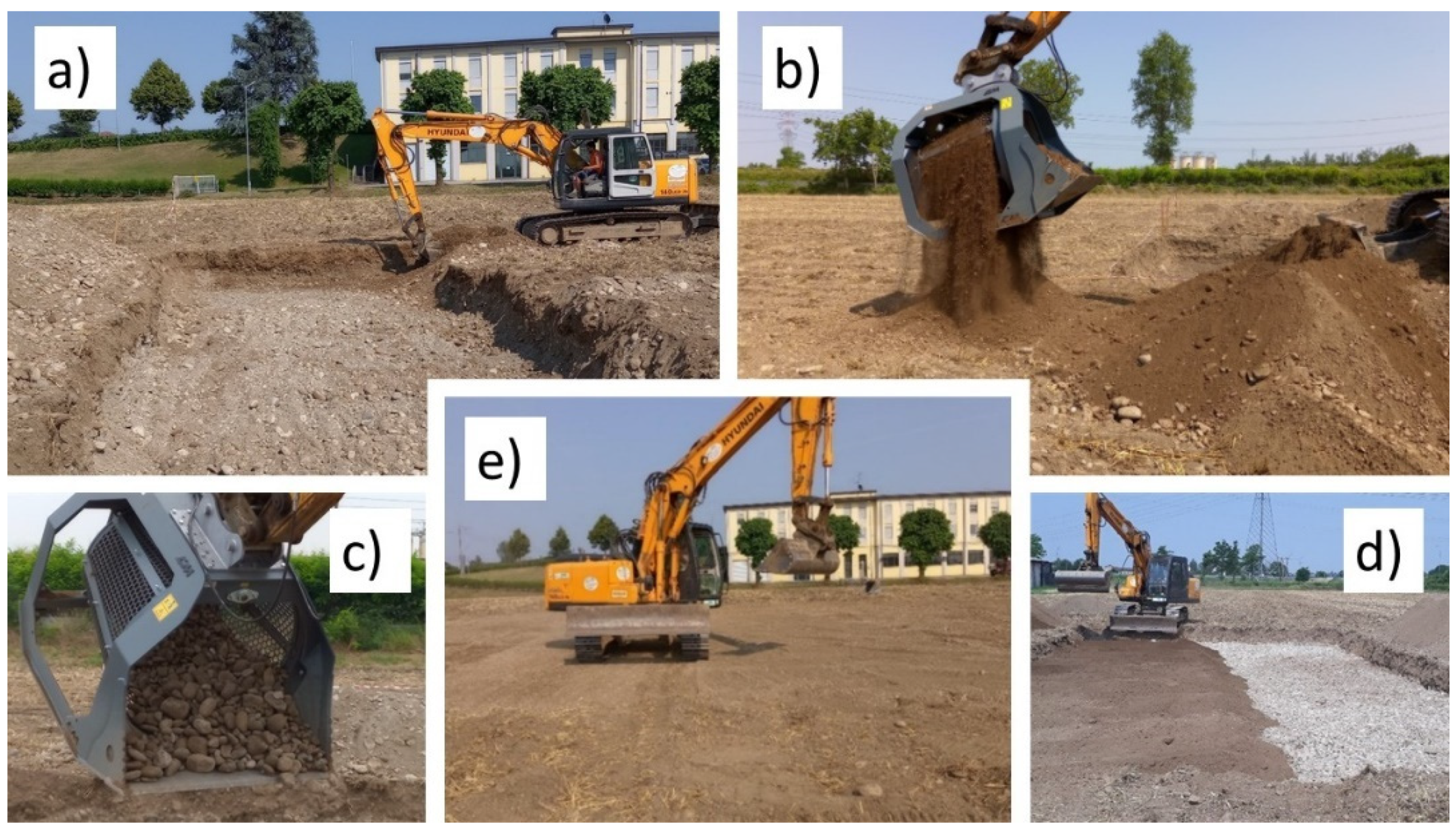

2.2.3. Stones Burial

3. Materials and Methods

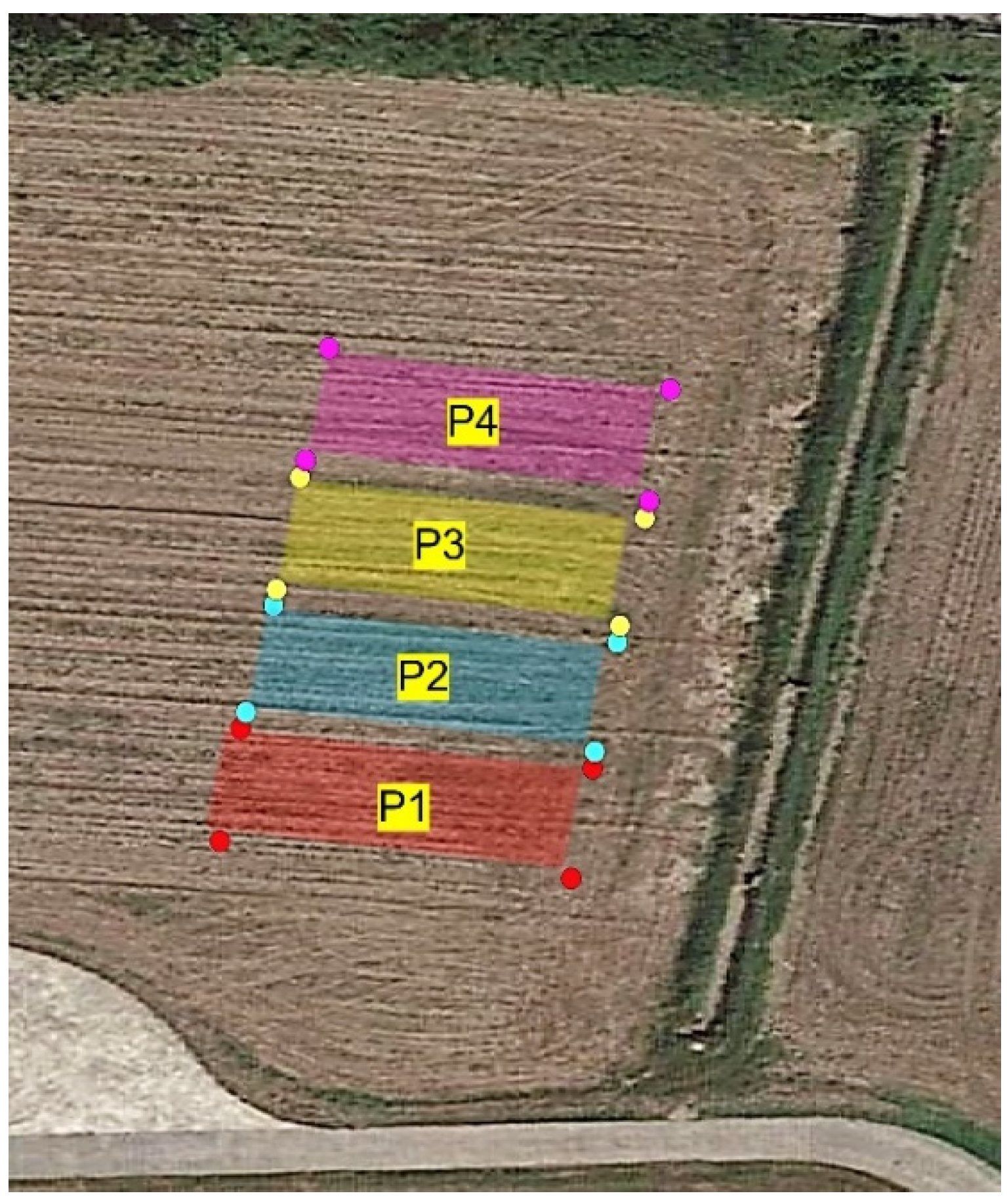

3.1. Planning of Experimental Parcels

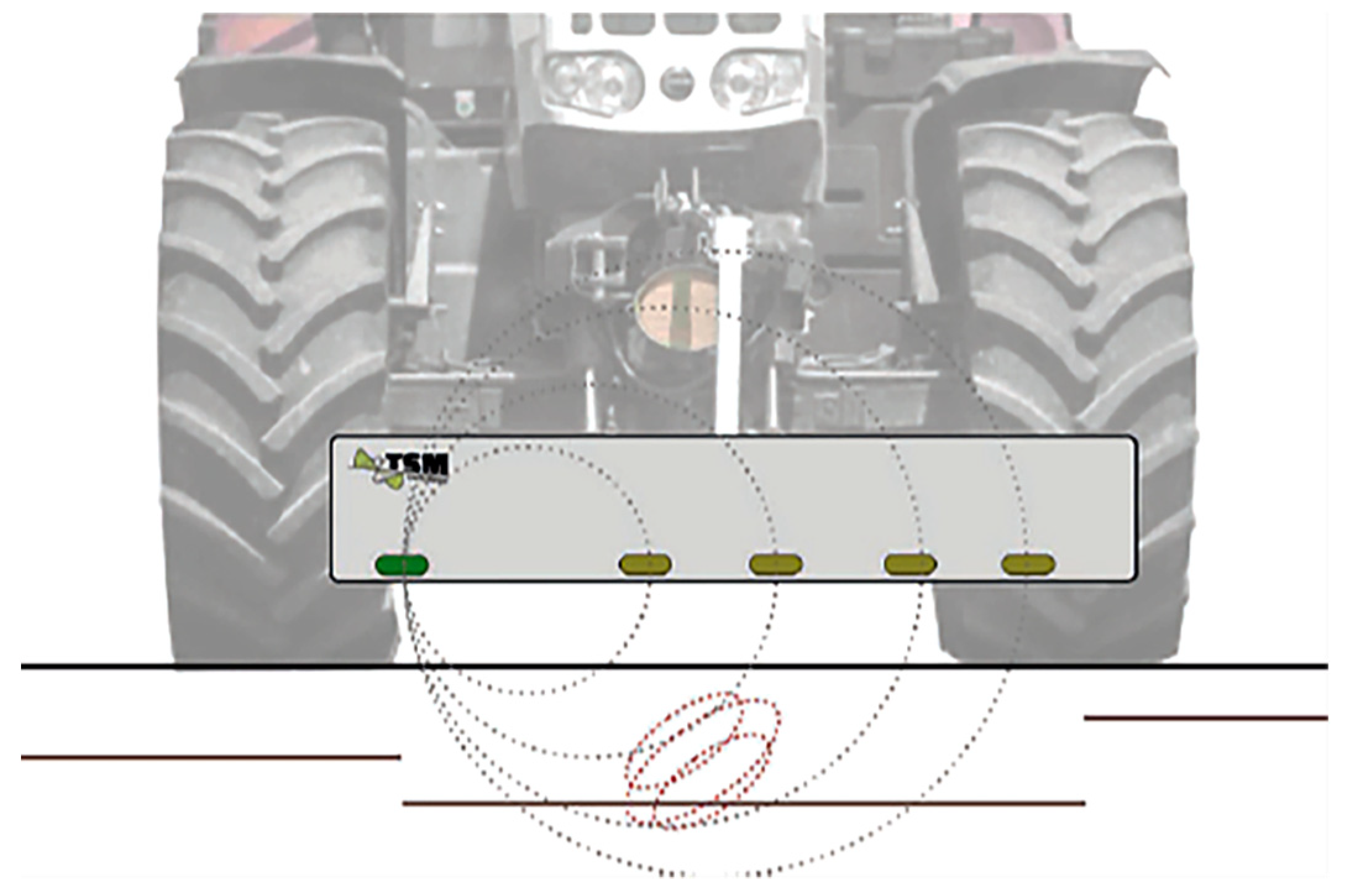

3.2. Electromagnetic Survey

4. Results and Discussion

4.1. Arable Layer Soil Quality

4.2. Electromagnetic Survey

4.3. Seeding Visual Assessment

4.4. Economic Evaluation of the Experimental Trial

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soil Survey Staff, USDA; NRCS. Soil Taxonomy: A Basic System of Soil Classification for Making and Interpreting Soil Surveys; Agriculture Handbook; 1999; Number 436. Available online: https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_051232.pdf (accessed on 15 December 2021).

- Ghezzehei, T.A. Soil structure. In Handbook of Soil Sciences: Vol. 1 Properties and Processes, 2nd ed.; Huang, P.M., Li, Y., Sumner, M.E., Eds.; CRC Press: Boca Raton, FL, USA, 2012; pp. 1–17. Available online: https://www.researchgate.net/publication/285160921_Soil_Structure (accessed on 15 September 2021).

- Schjønning, P. The soil quality concept as a tool for exposing values in science and promoting sustainability considerations. In Proceedings of the 4th International Congress of the ESSC; Kertész, A., Kovács, A., Csuták, M., Jakab, G., Madarász, B., Eds.; Hungarian Academy of Sciences, Geographical Research Institute: Budapest, Hungary, 2004; pp. 108–112. Available online: https://orgprints.org/id/eprint/3357/1/ESSC_pap_Per-Schjonning.pdf (accessed on 15 December 2021).

- Arshad, M.A.; Coen, G.M. Characterization of soil quality: Physical and chemical criteria. Am. J. Altern. Agric. 1992, 7, 25–31. [Google Scholar] [CrossRef]

- Karlen, D.L.; Andrews, S.S. The soil quality concept: A tool for evaluating sustainability. In Soil Stresses, Quality and Care, Proceedings of the NJF Seminar 310, 10–12 April 2000, Tjele, Denmark; Elmholt, S., Stenberg, B., Grønlund, A., Nuutinen, V., Eds.; Danish Institute of Agricultural Science (DIAS): Tjele, Denmark, Report No. 38; pp. 15–26.

- USDA Natural Resources Conservation Service. Soil Quality Information Sheet. Available online: https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_052207.pdf (accessed on 15 December 2021).

- Koenig, R.; Isaman, V. Topsoil quality guidelines for landscaping. Utah State University. (AG/SO-02. 2002). Available online: https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=1041&context=extension_histall (accessed on 15 December 2021).

- EEA. Land Cover and Change Statistics 2000–2018. Available online: https://www.eea.europa.eu/data-and-maps/dashboards/land-cover-and-change-statistics (accessed on 15 December 2021).

- L’AGRICOLTURA ITALIANA CONTA 2021. Available online: https://www.crea.gov.it/documents/68457/0/ITACONTA+2021_ITA_WEB.pdf/7ba21078-3d81-001e-d918-80e83cb6ff24?t=1637925904543 (accessed on 15 December 2021).

- Munafò, M. Consumo di Suolo, Dinamiche Territoriali e Servizi Ecosistemici. Ed. 2021. Report SNPA 22/21. Available online: https://www.snpambiente.it/wp-content/uploads/2021/07/Rapporto_consumo_di_suolo_2021-1.pdf (accessed on 15 September 2021).

- ISPRA, Rapporti 218/2015 ISBN 978-88-448-0703-0. Available online: https://www.isprambiente.gov.it/files/pubblicazioni/statoambiente/tematiche2011/10_Suolo_e_territorio_2011.pdf (accessed on 15 December 2021).

- Costantini, E.A.C.; Urbano, F.; Bonati, G.; Nino, P.; Fais, A. Atlante Nazionale delle aree a Rischio di Desertificazione; INEA: Rome, Italy, 2007. [Google Scholar]

- EEA. Land and Soil ch 5. 2020. Available online: https://www.eea.europa.eu/publications/soer-2020/chapter-05_soer2020-land-and-soil/view (accessed on 15 December 2021).

- Buckwell, A.; Heissenhuber, A.; Blum, W.; The Sustainable Intensification of European Agriculture. RISE Foundation, 2014, Brussels. Available online: https://risefoundation.eu/wp-content/uploads/2020/07/2014_-SI_RISE_FULL_EN.pdf (accessed on 15 December 2021).

- Magdoff, F.; Van Es, H. Building Soils for Better Crops. Ecological Management for Healthy Soils. IV Ed. 2021. Sustainable Agriculture Research and Education (SARE) Program, National Institute of Food and Agriculture, U.S. Department of Agriculture (USDA). LCCN 2021018006 | ISBN 9781888626193. Available online: https://www.sare.org/wp-content/uploads/Building-Soils-for-Better-Crops.pdf (accessed on 15 December 2021).

- Soil Mechanics, Level 1. Module 3, USDA Textural Soil Classification. Study Guide. 1987. Available online: https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/stelprdb1044818.pdf (accessed on 15 December 2021).

- Poesen, J.; Lavee, H. Rock fragments in topsoils: Significance and processes. Catena 1994, 23, 1–28. [Google Scholar] [CrossRef]

- Corti, G.; Ugolini, F.C.; Agnelli, A. Classing the Soil Skeleton (Greater than Two Millimeters): Proposed Approach and Procedure. Soil Sci. Soc. Am. J. 1998, 62, 1620–1629. [Google Scholar] [CrossRef]

- Ugolini, F.C.; Corti, G.; Agnelli, A.; Piccardi, F. Mineralogical, physical, and chemical properties of rock fragments in soil. Soil Sci. 1996, 161, 521–542. [Google Scholar] [CrossRef]

- Agnelli, A.; Trumbore, S.E.; Corti, G.; Ugolini, F.C. The dynamics of organic matter in rock fragments in soil investigated by 14C dating and measurements of 13C. Soil Sci. 2002, 53, 147–159. [Google Scholar] [CrossRef] [Green Version]

- Flint, A.L.; Childs, S. Physical Properties of Rock Fragments and Their Effect on Available Water in Skeletal Soils. In Erosion and Productivity of Soils Containing Rock Fragments; Nichols, J.D., Brown, P.L., Grant, W.J., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1984; Volume 13, Chapter 10. [Google Scholar] [CrossRef]

- Colzani, G.; Cammilli, A.; Pirrone, S. Stato di pietrosità dei terreni e lavorazioni agricole. L’Informatore Agrario 1989, 42, 61–64. [Google Scholar]

- He, D.; Lu, C.; Tong, Z.; Zhong, G.; Ma, X. Research Progress of Minimal Tillage Method and Machine in China. AgriEngineering 2021, 3, 633–647. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, Q.; Zhong, G.; Tong, Z.; Wang, X.; Xu, J. Brief Review of Minimum or No-Till Seeders in China. AgriEngineering 2021, 3, 605–621. [Google Scholar] [CrossRef]

- European Soil Data Center—European Commission. Stony Soils Distribution in Western Europe. Available online: https://esdac.jrc.ec.europa.eu/public_path/Cfrag.png (accessed on 15 September 2021).

- FAO. Guidelines for Soil Description, 4th ed.; FAO: Rome, Italy, 2006; ISBN 92-5-105521-1. Available online: https://www.fao.org/3/a0541e/a0541e.pdf (accessed on 15 September 2021).

- Monaci, F.; Ugolini, F.C. Nuovo approccio allo studio del suolo, valutazione analitica su base volumetrica. In Atti 10° Convegno Nazionale S.I.C.A.; Ograro, Ed.; Istituto Sperimentale per la Nutrizione delle Piante: Rome, Italy, 1992; pp. 195–197. [Google Scholar]

- Colzani, G.; Cammilli, A.; Pirrone, S. Grado di disturbo alla lavorabilità dei terreni pietrosi. L’Informatore Agrar. 1989, 44, 39–43. [Google Scholar]

- Colzani, G.; Usai, R. Le pietre nei campi: Un problema per la meccanizzazione. Agric. Ric. 1986, 72, 29–38. [Google Scholar]

- Gage, J.E. Field Clearing: Stone Removal and Disposal Practices in Agriculture & Farming. ASC Bulletin 2014, 76, 33–81. [Google Scholar]

- Wolff, P. Ödland- und Ackerbodenentsteinung—eine Möglichkeit zur Steigerung der Agrarproduktion in den Subtropen (Destoning of arable and potential arable land. A possibility to increase agricultural production in the subtropics). Der Trop.—Beiträge zur Trop. Landwirtsch. Veterinärmedizin (J. Agric. Trop. Subtrop.) 1990, 1, 85–96. Available online: https://www.jarts.info/index.php/tropenlandwirt/article/view/1008 (accessed on 15 September 2021).

- Nyssen, J.; Haile, M.; Poesen, J.; Deckers, J.; Moeyersons, J. Removal of rock fragments and its effect on soil loss and crop yield, Tigray, Ethiopia. Soil Use Manag. 2001, 17, 179–187. Available online: https://onlinelibrary.wiley.com/doi/pdf/10.1111/j.1475-2743.2001.tb00025.x (accessed on 15 September 2021). [CrossRef]

- Kamiński, J.R.; Szeptycki, A.; Weremkowicz, A. Zasady doboru maszyn w technologiach usuwania kamieni z pól uprawnych (Principles of machine selection for technologies of stone removing from cultivated fields). Probl. Inżynierii Rol. 2017, 25, 29–43. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-e201a690-72b1-479d-9e4c-aa0683a795d3 (accessed on 15 September 2021).

- Kaminski, J.; Lisowski, A.; Chlebowski, J.; Sypula, M.; Nowakowski, T. Wyciągacze kamieni z pól uprawnych (Rock diggers from farmlands). Tech. Rol. Ogrod. Leśna 2017, 3, 25–28. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.agro-73f373b9-59c4-403f-bf7e-4f747b25f65f (accessed on 15 September 2021).

- Colzani, G.; Cammilli, A.; Pirrone, S. Spietramento dei terreni agricoli: Macchine ed interventi per la frantumazione delle pietre. Terza Parte. L’Informatore Agrar. 1989, 48, 33–38. [Google Scholar]

- Colzani, G.; Cammilli, A.; Usai, R. Lo spietramento dei terreni aziendali: La frantumazione. Agric. Ric. 1987, 85, 27–42. [Google Scholar]

- Palomba, G. Lo Spietramento della Murgia: Un Disastro Ambientale Fermato dal Corpo Forestale dello Stato. Natura, Rivista di Ambiente e Territorio dell’arma dei Carabinieri, 26/10/2015. Available online: http://www.carabinieri.it/editoria/natura/la-rivista/home/tematiche/ambiente/lo-spietramento-della-murgia-un-disastro-ambientale-fermato-dal-corpo-forestale-dello-stato (accessed on 15 September 2021).

- Forigo Roteritalia srl. Interrasassi Funzionamento: Tutto ciò che c’è da Sapere. Available online: https://www.forigo.it/news/interrasassi-funzionamento-tutto-cio-che-ce-da-sapere (accessed on 15 September 2021).

- Standen Co, UK. Available online: https://standen.co.uk/products/stone-and-clod-separators/standen-uniplus-stone-and-clod-separator (accessed on 15 September 2021).

- IUSS Working Group WRB. World Soil Resources Reports 2015, No. 106; FAO: Rome, Italy, 2015. [Google Scholar]

- Colzani, G.; Cammilli, A.; Usai, R. Lo spietramento dei terreni aziendali. Agric. Ric. 1986, 73, 11–38. [Google Scholar]

- Colzani, G.; Cammilli, A.; Pirrone, S. Spietramento dei terreni agricoli: Prestazioni di cinque macchine spietratrici. L’Informatore Agrar. 1989, 50, 33–37. [Google Scholar]

- Brambilla, M.; Romano, E.; Toscano, P.; Cutini, M.; Biocca, M.; Ferré, C.; Comolli, R.; Bisaglia, C. From Conventional to Precision Fertilization: A Case Study on the Transition for a Small-Medium Farm. AgriEngineering 2021, 3, 438–446. [Google Scholar] [CrossRef]

- Tabbagh, A.; Dabas, M.; Hesse, A.; Panissod, C. Soil resistivity: A non-invasive tool to map soil structure horizonation. Geoderma 2000, 97, 393–404. [Google Scholar] [CrossRef]

- Tremsin, V.A. Real-Time Three-Dimensional Imaging of Soil Resistivity for Assessment of Moisture Distribution for Intelligent Irrigation. Hydrology 2017, 4, 54. [Google Scholar] [CrossRef] [Green Version]

- Aizebeokhai, A.P. Assessment of soil salinity using electrical resistivity imaging and induced polarization methods. Afr. J. Agric. Res. 2014, 9, 3369–3378. [Google Scholar]

- Fedotov, G.N.; Tretyakov, Y.D.; Pozdnayakov, A.I.; Zhukov, D.V. The Role of Organomineral Gel in the Origin of Soil Resistivity: Concept and Experiments. Eurasian Soil Sci. 2005, 38, 492–500. [Google Scholar]

- Piccoli, I.; Furlan, L.; Lazzaro, B.; Morari, F. Examining conservation agriculture soil profiles: Outcomes from northeastern Italian silty soils combining indirect geophysical and direct assessment methods. Eur. J. Soil Sci. 2020, 71, 1064–1075. [Google Scholar] [CrossRef]

| Surface Cover | (%) | Size Classes | mm |

|---|---|---|---|

| N: None | 0 | F: Fine gravel | 2–6 |

| V: Very few | 0–2 | M: Medium gravel | 6–20 |

| F: Few | 2–5 | C: Coarse gravel | 20–60 |

| C: Common | 5–15 | S: Stones | 60–200 |

| M: Many | 15–40 | B: Boulders | 200–600 |

| A: Abundant | 40–80 | L: Large boulders | 600–2000 |

| D: Dominant | >80 |

| Plot | T/C | ECa1 (0–250 mm) | ECa2 (0–600 mm) | ECa3 (0–950 mm) | ECa4 (0–1150 mm) |

|---|---|---|---|---|---|

| P1 | Thesis | 216.5 | 199.9 | 192.1 | 170.7 |

| P2 | Control | 214.2 | 197.5 | 189.7 | 168.3 |

| P3 | Thesis | 214.4 | 197.8 | 189.8 | 168.3 |

| P4 | Control | 213.7 | 197.0 | 189.2 | 167.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toscano, P.; Cutini, M.; Cabassi, G.; Pricca, N.; Romano, E.; Bisaglia, C. Assessment of a Deep Burial Destoning System of Agrarian Soils Alternative to the Stone Removal and On-Site Crushing. AgriEngineering 2022, 4, 156-170. https://doi.org/10.3390/agriengineering4010011

Toscano P, Cutini M, Cabassi G, Pricca N, Romano E, Bisaglia C. Assessment of a Deep Burial Destoning System of Agrarian Soils Alternative to the Stone Removal and On-Site Crushing. AgriEngineering. 2022; 4(1):156-170. https://doi.org/10.3390/agriengineering4010011

Chicago/Turabian StyleToscano, Pietro, Maurizio Cutini, Giovanni Cabassi, Nicolò Pricca, Elio Romano, and Carlo Bisaglia. 2022. "Assessment of a Deep Burial Destoning System of Agrarian Soils Alternative to the Stone Removal and On-Site Crushing" AgriEngineering 4, no. 1: 156-170. https://doi.org/10.3390/agriengineering4010011

APA StyleToscano, P., Cutini, M., Cabassi, G., Pricca, N., Romano, E., & Bisaglia, C. (2022). Assessment of a Deep Burial Destoning System of Agrarian Soils Alternative to the Stone Removal and On-Site Crushing. AgriEngineering, 4(1), 156-170. https://doi.org/10.3390/agriengineering4010011