Design, Development, and Performance Evaluation of a Power-Operated Jute Fiber Extraction Machine

Abstract

1. Introduction

2. Materials and Methods

2.1. Development of the Aashkol

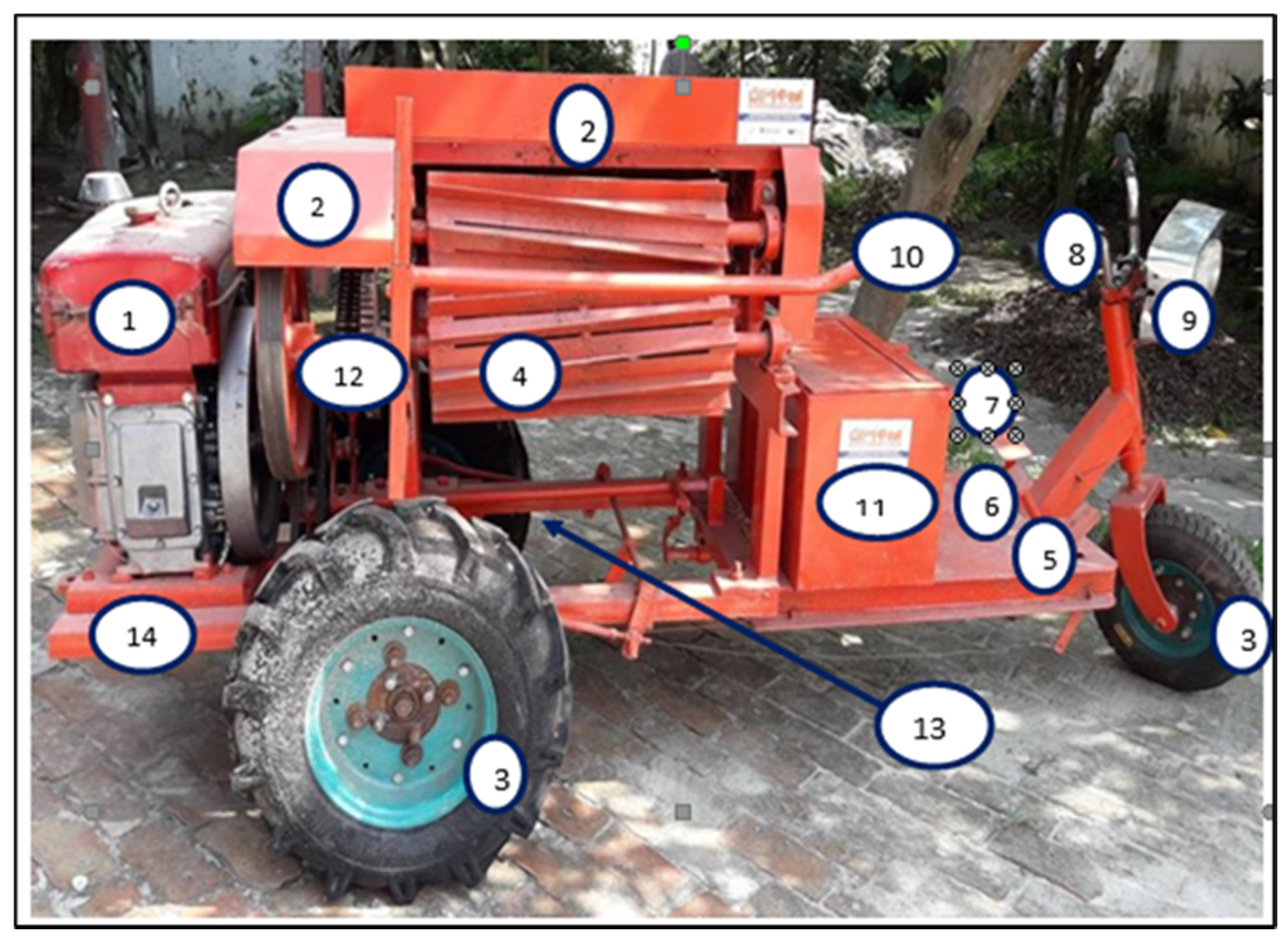

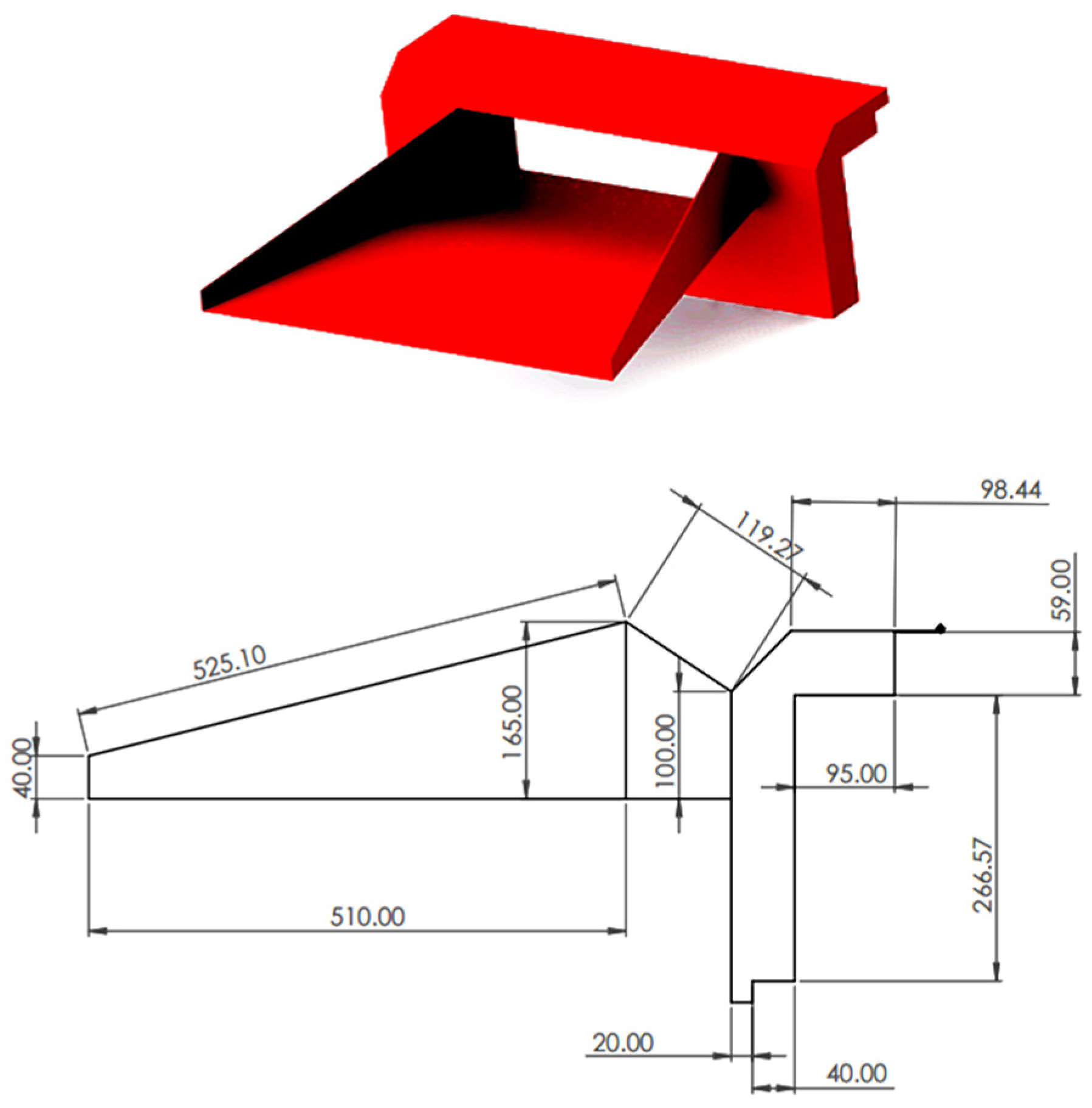

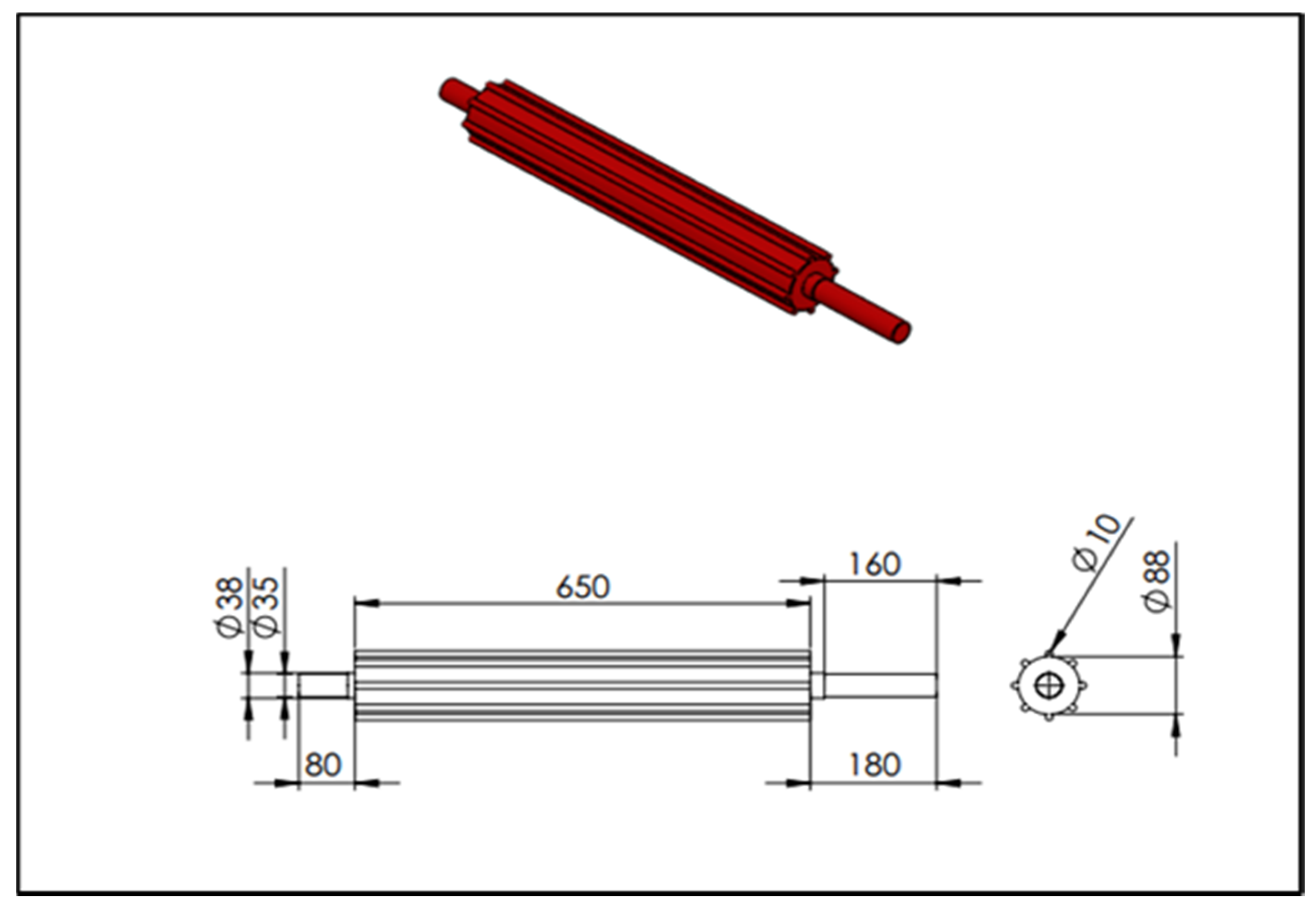

2.2. Description of Important Parts of the Aashkol

2.3. Modifications for the Aashkol Compared to the KP Model

2.4. Fiber Extraction Mechanism of the Modified Machine (Aashkol)

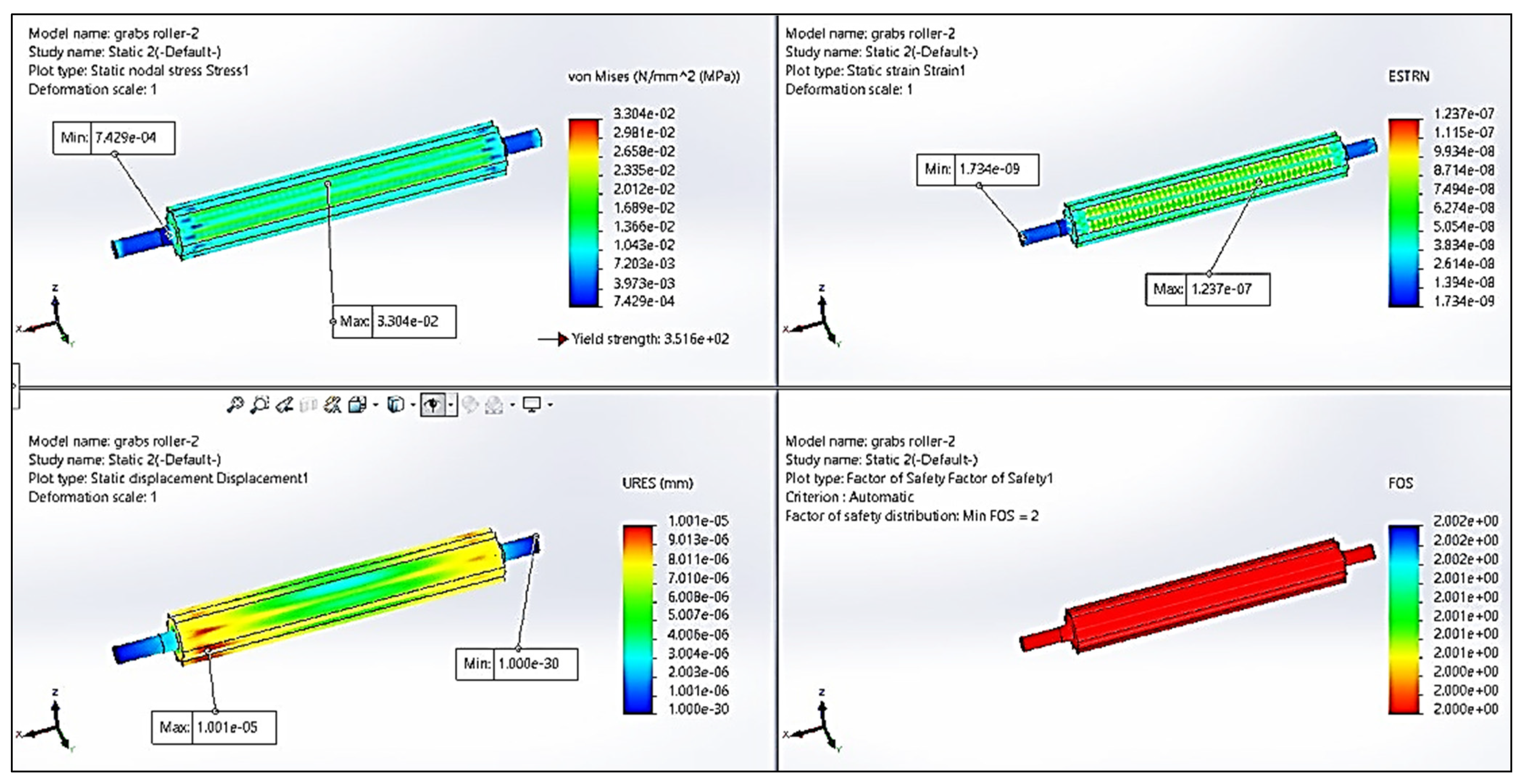

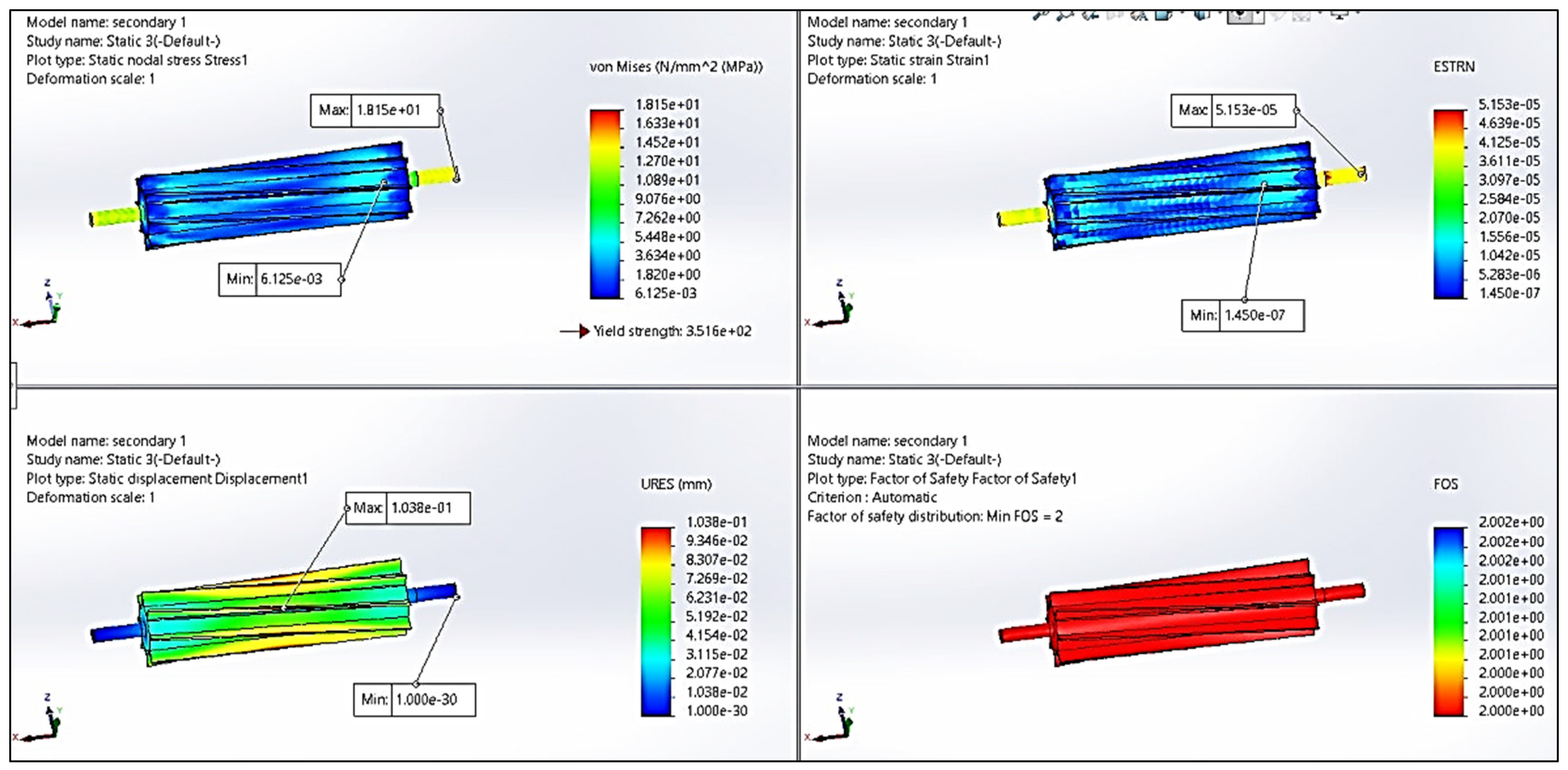

2.5. Stress, Displacement, and Strain of the Three Types of Rollers in the Aashkol

2.6. Performance Evaluation of the Machine

2.7. Determination of Capacity of the Aashkol and KP Model Machine

2.8. Evaluation of the Aashkol Extracted Jute Retting and the Traditional Jute Retting

2.9. Fiber Quality Test between Aashkol-Based Retting and the Traditional Retting

2.10. Economic Analysis

2.11. Statistical Analysis

3. Results

3.1. Strength of Aashkol Rollers

3.1.1. Strength of Grabbing Rollers

3.1.2. Strength of Primary and Secondary Extraction Rollers

3.2. Performance of the Aashkol and KP Model Jute Fiber Extraction Machine on Different Jute Types

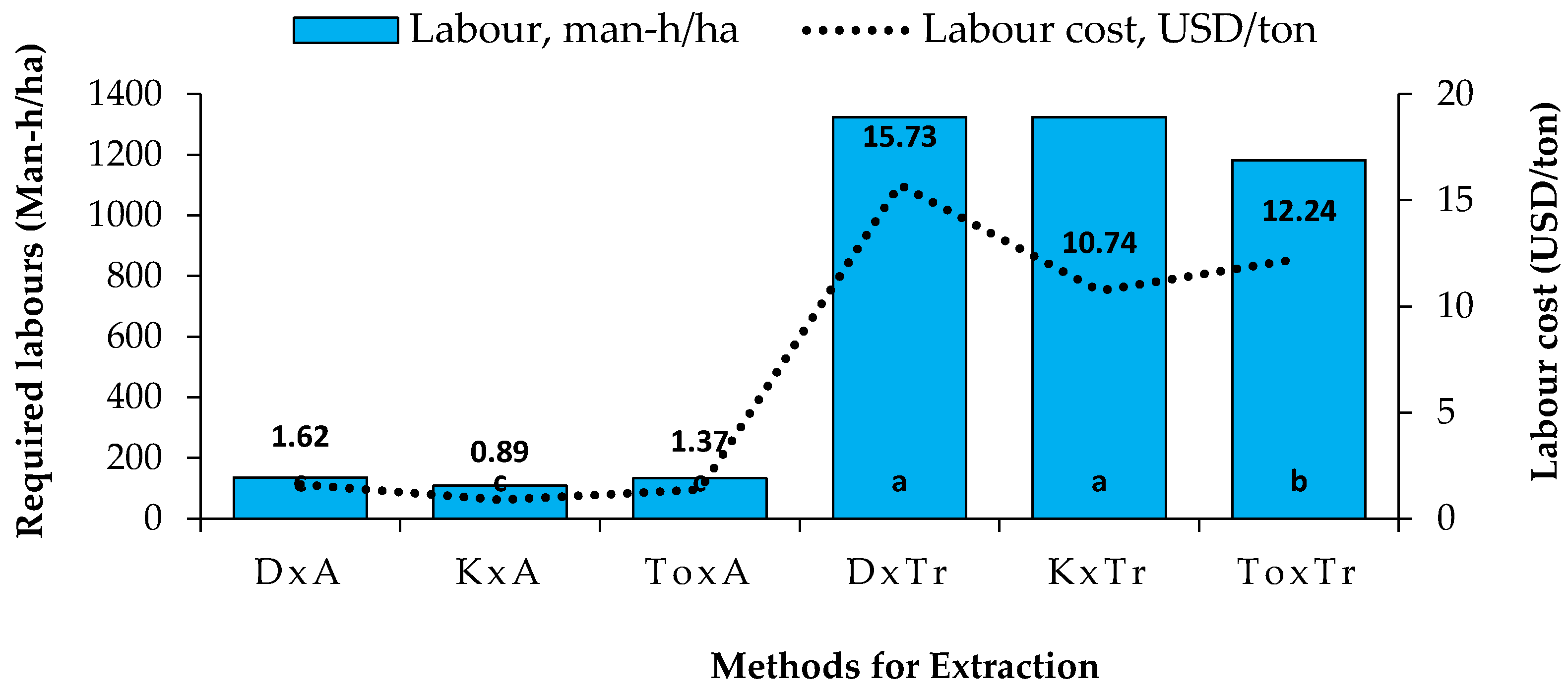

3.3. Effect of Jute Fiber Extraction Methods and Jute Types on Jute Fiber Yield, Retting Time, Labor Requirement, and Labor Cost

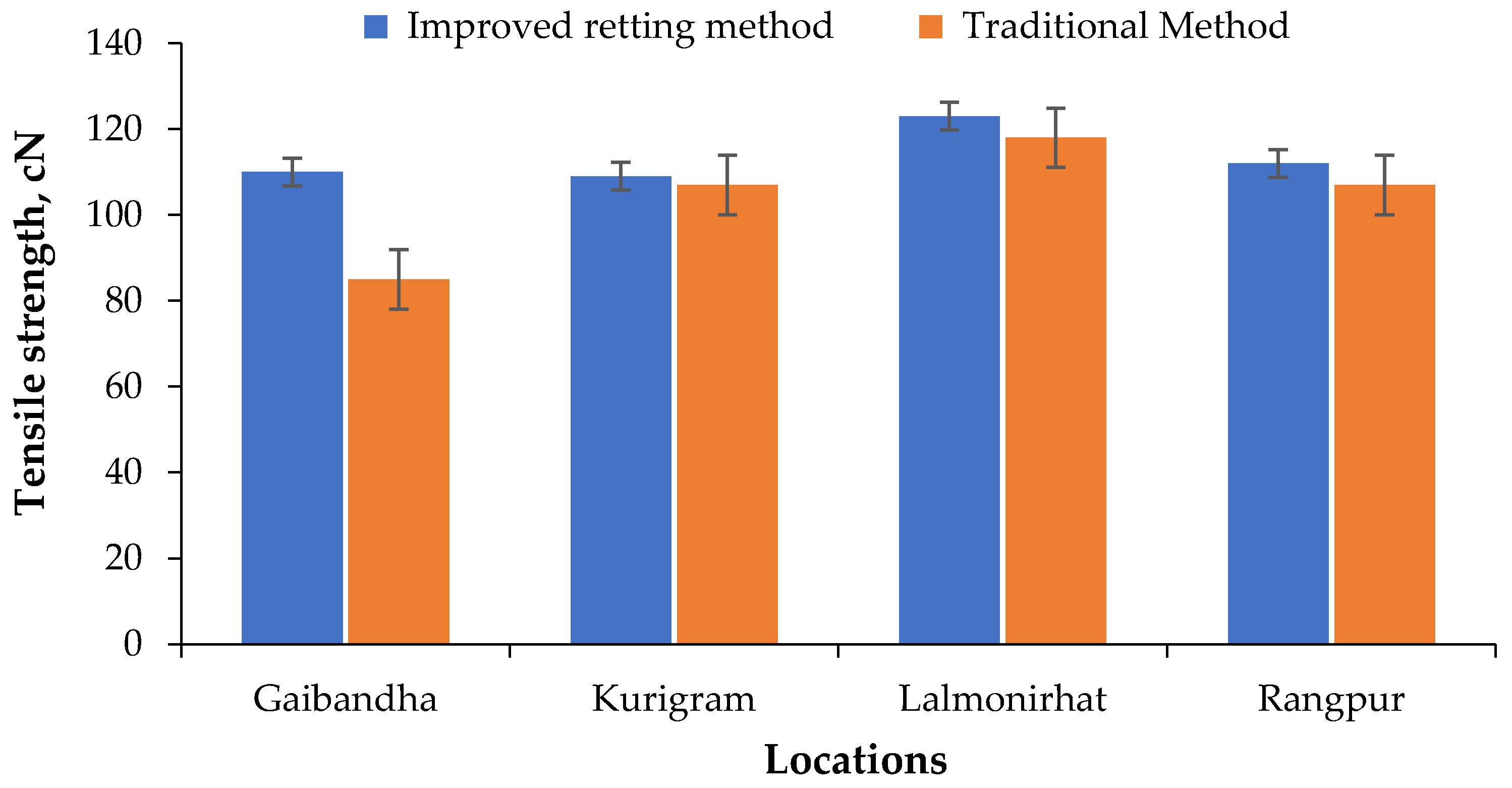

3.4. Effect of Retting Methods on the Quality of the Jute Fiber

4. Discussion

4.1. Modified Version Machine (Aashkol) vs. KP Model Machine

4.2. Traditional Retting vs. Improved Ribbon Retting

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sirohi, N. Eco-friendly fibers. Int. J. Home Sci. 2016, 2, 24–26. [Google Scholar]

- FAO. Future Fibers. The Food and Agriculture Organization of the United Nations. 2018. Available online: http://www.fao.org/economic/futurefibres/fibres/jute/en/ (accessed on 1 September 2018).

- BBS, Yearbook of Agricultural Statistics of Bangladesh; Bureau of Statistics, Statistics Division, Ministry of Planning: Dhaka, Bangladesh, 2017.

- Uddin, M.; Hossain, J.J.; Hoque, M.A. Present conditions of jute sector in Bangladesh. Banglavis. Res. J. 2014, 14, 68–79. [Google Scholar]

- BBS, Yearbook of Agricultural Statistics of Bangladesh; Bureau of Statistics, Statistics Division, Ministry of Planning Bangladesh: Dhaka, Bangladesh, 2018.

- Ghimire, T.B.; Thakur, N.S. Constraint and opportunity of raw jute production: A case study of eastern Terai. Nepal. Agron. J. 2013, 3, 117–122. [Google Scholar] [CrossRef]

- Sheheli, S.; Roy, B. Constraints and opportunities of raw jute production: A household level analysis in Bangladesh. Progress. Agric. 2014, 25, 38–46. [Google Scholar] [CrossRef]

- IJSG. Low-Cost Retting of Jute/Kenaf/Mesta for Qualityup-Gradation. Jute Corporation of India Ltd. (JCI) and Bangladesh Jute Research Institute (BJRI), The Common Fund for Commodities (CFC). 2009. Available online: https://nanopdf.com/download/low-cost-retting-of-jute-kenaf-mesta-for-quality-up_pdf (accessed on 30 April 2018).

- Ali, M.R.; Kozan, O.; Rahma, A.; Islam, K.T.; Hossain, M.I. Jute retting process: Present practice and problems in Bangladesh. Agric. Eng. Int. CIGR J. 2015, 17, 43–247. [Google Scholar]

- BJRI. Bulletin, June 2017. Bangladesh Jute Research Institute (BJRI). 2017. Available online: https://travel.state.gov/content/travel/en/legal/visa-law0/visa-bulletin/2017/visa-bulletin-for-june-2017.html (accessed on 9 June 2017).

- Shambhu, V.B.; Thakur, A.K.; Nayak, L.; Das, B. NIRJAFT Power Ribboner for improved retting of Jute and Mesta Plants. In Proceedings of the National Seminar on Market Driven Innovations in Natural Fibers, ICAR-National Institute of Research on Jute and Allied Fiber Technology, Kolkata, India, 29 August 2018. [Google Scholar]

- Das, P.K.; Nag, D.; Debnath, S.; Nayak, L.K. Machinery for extraction and traditional spinning of plant fibers. Indian J. Tradition. Knowle. 2010, 9, 386–393. [Google Scholar]

- Makanjuola, G.A. The Design and development of a small scale kenaf decorticator for decortication kenaf and similar fiber plants. Nigeria Agric. J. 1976, 10, 106–113. [Google Scholar]

- Makanjuola, G.A.; Ayorinde, T.A.; Aluko, O.B.; Owolarafe, O.K.; Sanni, L.A. Performance evaluation of a Kenaf decorticator. Agric. Eng. Int. CIGR J. 2019, 21, 192–202. [Google Scholar]

- Anonymous. Jute fiber extracting machine revives cultivation. Independent 2016.

- Dudda, W. Strength Analysis of a Boom Sprayer with the Use of CAD/CAE Systems. Mechanik 2018, 91, 549–551. [Google Scholar] [CrossRef]

- Ukatua, A. CA Modified Threshing Unit for Soyabeans; Department of Agricultural Engineering, University of Agriculture: Abeokuta, Nigeria, 2006. [Google Scholar]

- Anonymous. Compatible Disk of Video Documentary (Jute_Video_Final_PRISM): Jute Fiber Extraction and Improved Retting Process Prescribed to Practical Action (PA); Rangpur Regional Station, Bangladesh Jute Research Institute (BJRI): Dhaka, Bangladesh, 23 August 2017. [Google Scholar]

- Islam, M.M.; Rahman, M.M. Advances in jute and allied fibers post-harvest processing technologies in Bangladesh: Adoption constraints, prospect and future thrust. Res. Web Pub. 2013, 1, 20–30. [Google Scholar]

- Majumdar, B.; Suparna, D.; Saha, A.R.; Chowdhury, H.; Kundu, D.K.; Mahapatra, B.S. Improved Retting of Jute and Mesta with Microbial Formulation; Bulletin No. 04 /2013; Central Research Institute for Jute and Allied Fibers (ICAR): Kolkata, India, 2013; p. 32.

- Sow, S.; Ranjan, S.; Sarita, A.K.; Kumar, M. Improved retting methods of jute to enhance fibre quality and retting waste management. J. Pharmacogn. Phytochem. 2021, 10, 2614–2618. [Google Scholar] [CrossRef]

- Banik, S.; Basak, M.K.; Paul, D.; Nayak, P.; Sardar, D.; Sil, S.C.; Sanpui, B.C.; Ghosh, A. Ribbon retting of jute—A prospective and eco-friendly method for improvement of fiber quality. Ind. Crops Prod. 2003, 17, 183–190. [Google Scholar] [CrossRef]

- Anonymous. Jute fiber extraction machines to ease retting, improve quality. Daily Star. 2018. [Google Scholar]

| Feeding System | Direct Feeding |

|---|---|

| Dimension | 1.5 × 1.4 × 1.05 m |

| Weight | 255 kg |

| Motor | 5.5 kW electric motor; 10 hp diesel engine |

| Capacity | 2–3 t h−1 for fresh jute fiber extraction |

| Sl. No. | Parameters | KP Model | Aashkol |

|---|---|---|---|

| 01 | Engine power | 10 hp | 16 hp |

| 02 | Power transmission systems | One way | Differential |

| 03 | Accelerator | None | Pedal operated |

| 04 | Main clutch | None | Incorporated |

| 05 | Head light | None | Incorporated |

| 06 | Operator’s seat cum toolbox | None | Incorporated |

| 07 | Front wheel | None | Incorporated |

| 08 | Primary and secondary extraction rollers | 3 mm thick angle; 6 mm bush pipe | >4 mm thick angle; 6 mm bush pipe |

| 09 | Grabbing roller | Made with MS rod | Made with MS shaft |

| 10 | Fiber collection stand | Fixed | Adjustable |

| 11 | Feeding tray | Length of 300 mm | Length of 762 mm |

| 12 | Rear wheels | Tire size of 4-00-8 | Tire size of 6-00-12 |

| Parameters | Jute Stem Input Capacity (t h−1) | Ribbon Output Capacity (t h−1) |

|---|---|---|

| Jute fiber extraction machine (FEM) | ||

| Aashkol | 4.99 a | 1.43 a |

| KP model | 3.38 b | 0.96 b |

| Jute types | ||

| Deshi (D) | 3.29 c | 0.93 c |

| Kenaf (K) | 5.22 a | 1.45 a |

| Tossa (To) | 4.05 b | 1.20 b |

| Analysis of Variance | ||

| FEM | 0.001 | 0.001 |

| Jute types | 0.001 | 0.001 |

| FEM × Jute types | NS | NS |

| Parameters | Retting Time (Days) | Dry Fiber Yield (t h−1) | Labor Requirement for Extraction and Retting (h ha−1) | Labor Cost for Extraction and Retting, (USD t−1) | Price of Jute Fiber (USD t−1) | Price of Jute Stick (USD t−1) |

|---|---|---|---|---|---|---|

| Jute extraction methods (EM) | ||||||

| Aashkol (A) | 14.7 b | 3.18 a | 126 b | 1.30 b | 537.96 a | 5.90 b |

| Traditional (Tr) | 27.2 a | 2.91 b | 1276 a | 12.93 a | 498.92 b | 26.15 a |

| Jute types | ||||||

| Deshi (D) | 21.8 a | 2.36 c | 729 a | 8.68 a | 478.26 b | 16.68 a |

| Kenaf (K) | 20.2 b | 3.70 a | 716 ab | 5.81 c | 582.99 a | 15 b |

| Tossa (To) | 21.1 ab | 3.06 b | 657 b | 6.8 b | 490.86 b | 16.39 a |

| Analysis of Variance | ||||||

| EM | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Jute types | 0.02 | 0.001 | 0.03 | 0.001 | 0.001 | 0.001 |

| EM × Jute types | NS | 0.01 | 0.01 | 0.001 | 0.03 | 0.001 |

| CV, % | 8.30 | 4.19 | 12.77 | 16.11 | 6.97 | 2.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karim, M.R.; Hoque, M.A.; Chawdhury, A.; Faruk-Ul-Islam; Ahmed, S.; EL Sabagh, A.; Hossain, A. Design, Development, and Performance Evaluation of a Power-Operated Jute Fiber Extraction Machine. AgriEngineering 2021, 3, 403-422. https://doi.org/10.3390/agriengineering3020027

Karim MR, Hoque MA, Chawdhury A, Faruk-Ul-Islam, Ahmed S, EL Sabagh A, Hossain A. Design, Development, and Performance Evaluation of a Power-Operated Jute Fiber Extraction Machine. AgriEngineering. 2021; 3(2):403-422. https://doi.org/10.3390/agriengineering3020027

Chicago/Turabian StyleKarim, Md. Rejaul, Muhammad Arshadul Hoque, Alamgir Chawdhury, Faruk-Ul-Islam, Sharif Ahmed, Ayman EL Sabagh, and Akbar Hossain. 2021. "Design, Development, and Performance Evaluation of a Power-Operated Jute Fiber Extraction Machine" AgriEngineering 3, no. 2: 403-422. https://doi.org/10.3390/agriengineering3020027

APA StyleKarim, M. R., Hoque, M. A., Chawdhury, A., Faruk-Ul-Islam, Ahmed, S., EL Sabagh, A., & Hossain, A. (2021). Design, Development, and Performance Evaluation of a Power-Operated Jute Fiber Extraction Machine. AgriEngineering, 3(2), 403-422. https://doi.org/10.3390/agriengineering3020027